Page 1

Instruction Manual

Form 5864

September 2008

Type 112 Restrictor

Type 112

Introduction

Scope of Manual

This instruction manual provides technical

specications, installation, startup, adjustment, and

parts ordering information for the Type 112 restrictor.

Product Description

The 112 Restrictors are mainly used in natural gas,

air, or other non-corrosive gas applications. Their

installation is foreseen together with a Type 161 pilot

for Pressure Regulators Type EZR.

Specications

The Specication section lists pressure limitations and

other specications for Type 112 Restrictor.

Principle of Operation

The Type 112 restrictor controls the regulator’s

proportional band (droop) and speed of response.

The restrictor can be used to ne tune the regulator

for maximum performance by decreasing the restrictor

setting for tighter control (increased opening speed,

decreased closing speed); or increasing the restrictor

setting for maximum stability (decreased opening

speed, increased closing speed). A lower setting

also provides a narrower proportional band for better

accuracy. The “8” position has the largest ow, is

most stable, and easiest for startup, however, using

the “8” position is not necessary. The “0” setting has

the smallest (minimum) ow passage; at no point

of rotation will the Type 112 restrictor be completely

shutoff. After initial adjustment, the restrictor does not

need to be adjusted for maintenance or startup.

Startup and Adjustment

Startup for Both Single-Regulator and

Monitoring Installations

1. Make sure all block and vent valves are closed.

2. Back out the pilot adjusting screw(s).

3. For easy initial startup, set the restrictor to the “8”

position. For future startups, the restrictor can be

left in the desired run position.

4. SLOWLY OPEN the valves in the following order:

a. Pilot supply and control line valve(s), if used

b. Inlet block valve

c. Outlet block valve

5. For a 161 Series pilot with Type 112 restrictor,

turn the restrictor(s) to position “2” or to desired

run position. Set then the pilot to the desired

outlet (control) pressure according to the pilot

adjustment procedure. Refer to Tables 2 and 3 for

recommended settings.

Maintenance

Type 112 Restrictor

Perform this procedure only if O-rings are leaking.

Key numbers are referenced in Figure 2.

1. Unscrew the groove valve (key 22) and retainer

(key 23) just enough to loosen them, but do not

completely separate.

2. Push on the retainer (key 23) to push the groove

valve (key 22) out of the body (key 21), then

complete disassembly.

3. Replace the groove valve O-rings (key 24) if

necessary, being sure to lightly apply lubricant to

the replacement O-rings before installing them in

the groove valve (key 22) and retainer (key 23).

www.emersonprocess.com/regulators

D103237X012

Page 2

Type 112

Specications

Maximum Inlet Pressure and Pressure Drops

Restrictor: 1500 psig (103 bar)

Flow Coefcients

Restrictor: See Table 1

(1)

Construction Materials

Body: CB7Cu-2 Stainless steel

Groove Valve: 416 Stainless steel

Retainer: 416 Stainless steel

Pipe Plug: 316 Stainless steel

O-rings: Fluorocarbon (FKM)

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

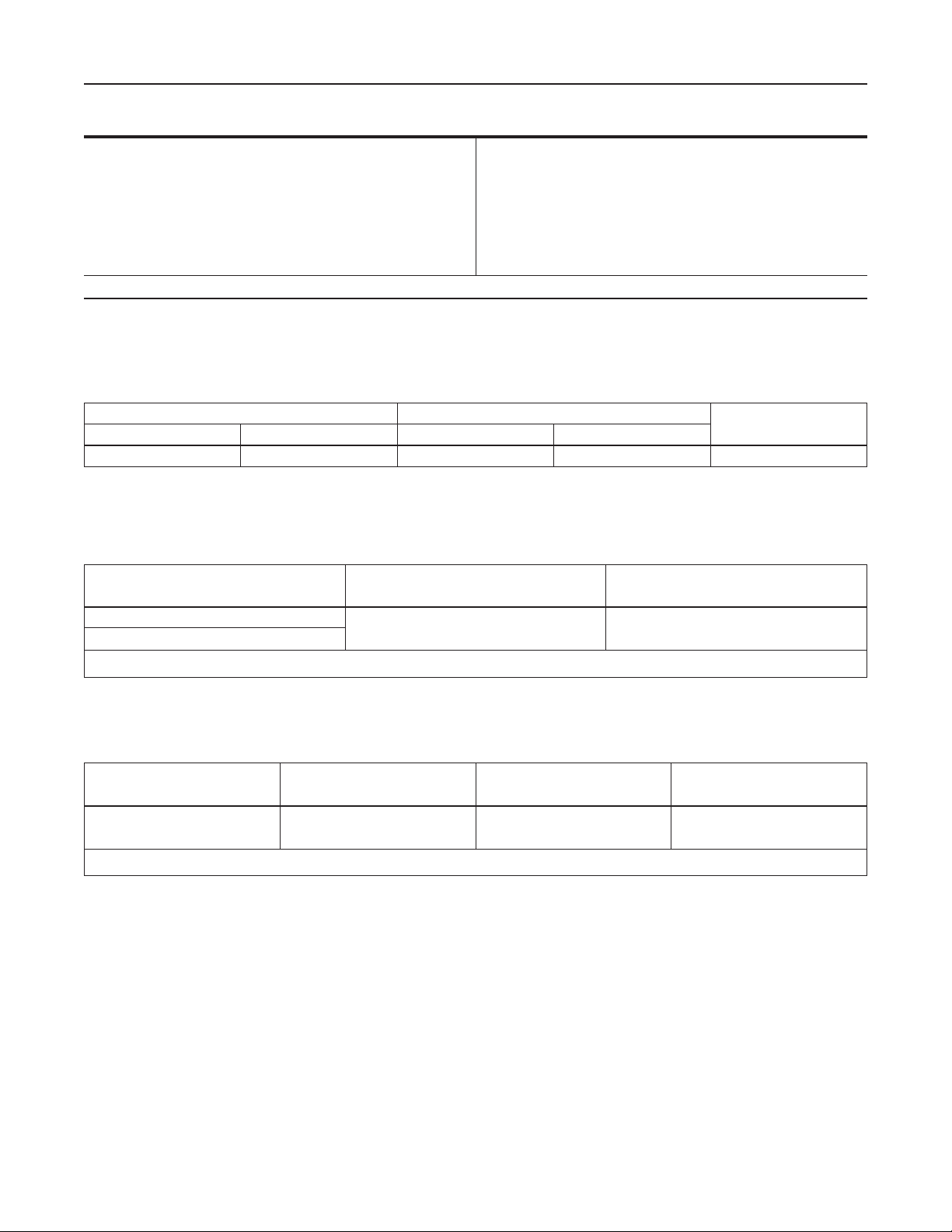

Table 1. Restrictor Flow Coefcients

SET ON START SET ON RUN

C

g

6 0.17 1 0.03 35

C

V

C

g

C

V

Table 2. Adjustment Recommendations with 161 and 161EB Series Pilot

SERIES

161 / 161H Pilots

161EB Pilots

Note: Higher Type 112 restrictor setting will increase proportional band. Adjustment of the Type 112 restrictor will also cause a shift in setpoint. Setpoint should be checked and

adjusted following restrictor setting adjustment.

RECOMMENDED TYPE 112

RESTRICTOR SETTINGS FOR LOW

FLOW OPERATION

Restrictor Setting of “5” or Greater

TYPE 112 RESTRICTOR SETTINGS

TO AVOID LOW FLOW OPERATION

Restrictor Setting of “2” or less if continuous

ows are expected to be less than 5% of

maximum capacity

C

1

Table 3. Adjustment Recommendations with 161AY / 161AYM Series Pilot

SERIES

161AY Pilots Restrictor Setting of “5” or greater

Note: Higher Type 112 restrictor setting will increase proportional band. Adjustment of the Type 112 restrictor will also cause a shift in setpoint. Setpoint should be checked and

adjusted following restrictor setting adjustment.

2

RECOMMENDED TYPE 112

RESTRICTOR SETTINGS FOR LOW

FLOW OPERATION

RECOMMENDED ORIFICE SIZE(S)

FOR LOW FLOW OPERATION

3/32 or 1/8-inch (2,38 or 3,18 mm)

(3/32-inch (2,38 mm) is standard)

TYPE 112 RESTRICTOR SETTINGS

AND ORIFICE SIZES TO AVOID

LOW FLOW OPERATION

Restrictor Setting of “2” or less if

continuous ows are expected to be

less than 5% of maximum capacity

Page 3

Type 112

STAMPED INDICATOR

MARK AND “B” TO BE

ORIENTED WITH HEX

AND V-GROOVE AS SHOWN

PILOT SUPPLY CONNECTION

1/4-INCH NPT PIPE TO UPSTREAM

PILOT SUPPLY TAP

V-GROOVE

20B4403

LOADING CONNECTION 1/4-INCH NPT

PIPE TO TYPE EZR DIAPHRAGM

LOADING PORT

HI CAP GROOVE VALVE

OUTLET CONNECTION 1/4-INCH NPT

PIPE TO PILOT INLET CONNECTION

11B5004

Figure 1. Type 112 Restrictor Port Function and Connection Sizes

4. Install the groove valve (key 22) into the same

side of the body where the scale appears. Install

the retainer (key 23) into the opposite side of the

body, and tighten until both are secure.

5. When all maintenance is complete, refer to

the Startup and Adjustment section to put the

regulator back into operation.

OPTIONAL LOADING

CONNECTION

1/4-INCH NPT NORMALLY

PLUGGED

Parts Ordering

When corresponding with your local Sales Ofce about

this equipment, always reference the equipment serial

number or FS number found on a nameplate attached

to the bonnet. When ordering replacement parts,

reference the complete 11-character part number of

each needed part as found in the following parts list.

3

Page 4

Type 112

2114

20B4393-D

APPLY LUBRICANT

Figure 2. Type 112 Restrictor Assembly

Parts List

Type 112 Restrictor (Figure 2)

Key Description Part Number

14 Pipe Plug, 316 Stainless steel 1A767535072

21 Body, CB7Cu-2 Stainless steel 20B4429X012

22 Groove Valve, 416 Stainless steel 20B4403X012

22

24

23

Key Description Part Number

23 Retainer, 416 Stainless steel 10B4402X012

24* Groove Valve O-ring (2 required),

Fluorocarbon (FKM) 1C8538X0052

* Recommended spare part

Industrial Regulators

Regulator Division

Emerson Process Management

USA - Headquarters

McKinney, Texas 75070 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Regulator Division

Emerson Process Management

USA - Headquarters

McKinney, Texas 75070

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Regulator Division

Emerson Process Management

USA - Headquarters

Elk River, Minnesota 55330 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Fisher Controls International, Inc., 2008; All Rights Reserved

Loading...

Loading...