Page 1

Instruction Sheet 1066

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

1066 L

iquid

Analytic

al Transm

itt

er

ESSENTIAL INSTRUCTIONS

Read this page before proceeding!

Emerson designs, manufactures, and tests its Rosemount

Analytical products to meet many national and international

standards. Because these instruments are sophisticated

technical products, you must properly install, use, and maintain them to ensure they continue to operate within their

normal specifications. The following instructions must be

adhered to and integrated into your safety program when

installing, using, and maintaining Rosemount Analytical

products. Failure to follow the proper instructions may cause

any one of the following situations to occur: Loss of life; personal injury; property damage; damage to this instrument;

and warranty invalidation.

• Read all instructions prior to installing, operating, and

servicing the product. If this Instruction Manual is not

the correct manual, telephone 1-800-854-8257 and the

requested manual will be provided. Save this Instruction

Manual for future reference.

• If you do not understand any of the instructions, contact your Emerson representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the product.

• Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the appropriate Instruction Manual and per

applicable local and national codes. Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement parts specified by Rosemount.

Unauthorized parts and procedures can affect the product’s performance and place the safe operation of your

process at risk. Look alike substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being

performed by qualified persons, to prevent electrical shock and personal injury.

WARNING: EXPLOSION HAZARD

DO NOT OPEN WHILE CIRCUIT IS LIVE. ONLY CLEAN WITH DAMP CLOTH.

NOTICE

If a Model 475 Universal HART®Communicator is used with these transmitters, the software within the Model 475 may

require modification. If a software modification is required, please contact your local Emerson Process Management Service

Group or National Response Center at 1-800-654-7768.

Page 2

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

QUICK START GUIDE – 1066 Liquid Analytical Transmitter

1. For mechanical installation instructions, see page 8 for panel mounting and page 9 for pipe or wall mounting.

2. Wire the sensor to the main circuit board. See page 10 for wiring instructions. Refer to the sensor instruction

sheet for additional details. Make loop power connections.

3. Once connections are secured and verified, apply DC loop power to the transmitter.

4. When the transmitter is powered up for the first time, Quick Start screens appear. Quick Start operating tips are

as follows:

a. A highlighted field shows the position of the cursor.

b. To move the cursor left or right, use the keys to the left or right of the ENTER key. To scroll up or down or to

increase or decrease the value of a digit use the keys above and below the ENTER key. Use the left or right keys

to move the decimal point.

c. Press ENTER to store a setting. Press EXIT to leave without storing changes. Pressing EXIT during Quick Start

returns the display to the initial start-up screen (select language).

5. Choose the desired language and press ENTER.

6. Choose measurement and press ENTER.

a. For pH or ORP, choose preamplifier location. Select Analyzer to use the integral preamplifier in the transmitter;

select Sensor/J-Box if your sensor is SMART or has an integral preamplifier or if you are using a remote preamplifier located in a junction box.

5. If applicable, choose units of measurement.

6. For contacting and toroidal conductivity, choose the sensors type and enter the numeric cell constant using the keys.

7. Choose temperature units: °C or °F.

8. After the last step, the main display appears. The outputs are assigned to default values.

9. To change output settings, to scale the 4-20mA current outputs, to change measurement-related settings from

the default values, and to enable pH diagnostics, press MENU. Select Program and follow the prompts. Refer to

the appropriate menu.

10. To return the transmitter to the factory default settings, choose Program under the main menu, and then scroll to

Reset.

11. Please call the Rosemount Analytical Customer Support Center at 1-800-854-8257 if you need further support.

2

Page 3

Instruction Sheet 1066

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

Specifications

GENERAL SPECIFICATIONS

Case: Polycarbonate. IP66 (CSA, FM), NEMA 4X (CSA)

Dimensions: Overall 155 x 155 x 131mm (6.10 x 6.10 x 5.15 in.). Cutout: 1/2 DIN 139mm x 139mm (5.45 x 5.45 in.)

Conduit openings: Six. Accepts PG13.5 or 1/2 in. conduit fittings

Display: Monochromatic graphic liquid crystal display. No backlight. 128 x 96 pixel display resolution. Active display

area: 58 x 78mm (2.3 x 3.0 in.). All fields of the main instrument display can be customized to meet user requirements.

Ambient temperature and humidity: -20 to 65°C (-4 to 149°F), RH 5 to 95% (non-condensing).

Storage Temperature: -20 to 70°C (-4 to 158°F)

®

HART

RFI/EMI: EN-61326

Complies with the following Standards:

CSA: C22.2 No 0 – 10; C22.2 No 0.4 – 04; C22.2 No. 25-M1966: , C22.2 No. 94-M91: , C22.2 No.142-M1987: , C22.2

No. 157-M1992: , C22.2 No. 213-M1987: , C22.2 No. 60529:05. UL: 50; 508; 913; 1203. ANSI/ISA: 12.12.02-2011.

ATEX: IEC 60079-0:2011, 60079-11:2011

IECEx: IEC 60079-0: 2011 Edition: 6.0, I EC 60079-11 : 2011-06 Edition: 6.0

FM: 3600: 2011, 3610: 2010, 3611: 2004, 3810: 2005, IEC 60529:2004, ANSI/ISA 60079-0: 2009, ANSI/ISA 60079-11: 2009

Communications: PV, SV, TV, and 4V assignable to measurement, temperature and all live HART diagnostics.

Hazardous Location Approvals

Intrinsic Safety (with appropriate safety barrier):

Class I, II, III, Div. 1

Groups A-G

T4 Tamb = -20°C to 65°C

ATEX

Non-Incendive:

1180 II 1 G

Baseefa04ATEX0195X

EEx ia IIC

T4 Tamb = -20°C to 65°C

Class I, Div. 2, Groups A-D

Dust Ignition Proof

Class II & III, Div. 1, Groups E-G

NEMA 4/4X, IP66 Enclosure

T4 Tamb = -20°C to 65°C

IECEx BAS 11.90098X

EEx ia IIC

T4 Tamb = -20°C to 65°C

Class I, II & III, Division 1, Groups A-G T4

Tamb = -20°C to 40°C for -FI option

Tamb = -20°C to 65°C for -HT and -FF options

Class I, Zone 0, AEx ia IIC T4

Tamb = -20°C to 40°C for -FI option

Tamb = -20°C to 65°C for -HT and -FF options

Class I, Division 2 Groups A-D

Dust Ignition proof

Class II & III, Division 1, Groups E-G

IP66 enclosure

Tamb = -20°C to 40°C for -FI option

Tamb = -20°C to 65°C for -HT and –FF options

3

Page 4

1066 Instruction Sheet

1500

1250

1000

750

500

250

0

Load, ohms

with HART

communication

without HART

communication

12 18 24 30 36 42

545

ohms

1364

ohms

Power supply voltage, Vdc

HART option

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

Input: One isolated sensor input. Measurement choices of

pH/ORP, resistivity/conductivity/TDS, % concentration,

otal and free chlorine, monochloramine, dissolved oxy-

t

gen, dissolved ozone, and temperature. For contacting

conductivity measurements, temperature element can be

a PT1000 RTD or a PT100 RTD. Other measurements

(except ORP) and use PT100 or PT1000 RTDs or a 22k NTC

(D.O. only).

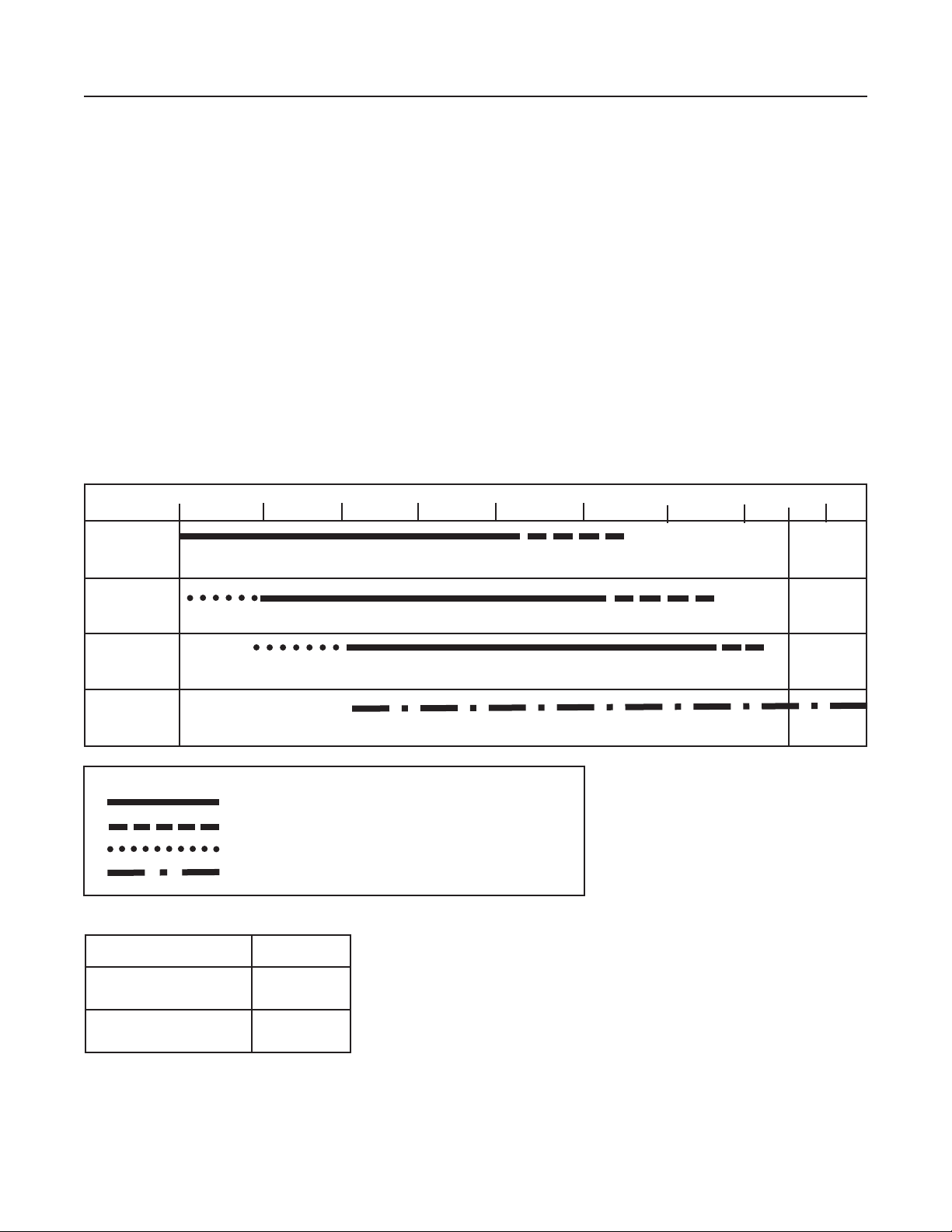

Power & Load Requirements: Supply voltage at the

transmitter terminals should be at least 12.7Vdc. Power

supply voltage should cover the voltage drop on the cable

plus the external load resistor required for HART communications (250 Ω minimum). Minimum power supply voltage is 12.7Vdc. Maximum power supply voltage is 42.4

Vdc (30 Vdc for intrinsically safe operation). The graph

shows the supply voltage required to maintain 12 Vdc

upper line) and 30 Vdc (lower line) at the transmitter ter-

(

minals when the current is 22 mA.

Analog Outputs: Two-wire loop powered (Output 1

only). Two 4-20 mA electrically isolated current outputs

(Output 2 must be externally powered). Superimposed

HART digital signal on Output 1. Fully scalable over the

operating range of the sensor.

Weight/Shipping Weight: 2 lbs/3 lbs (1 kg/1.5 kg)

FIGURE 1. Load/Power Supply Requirements

4

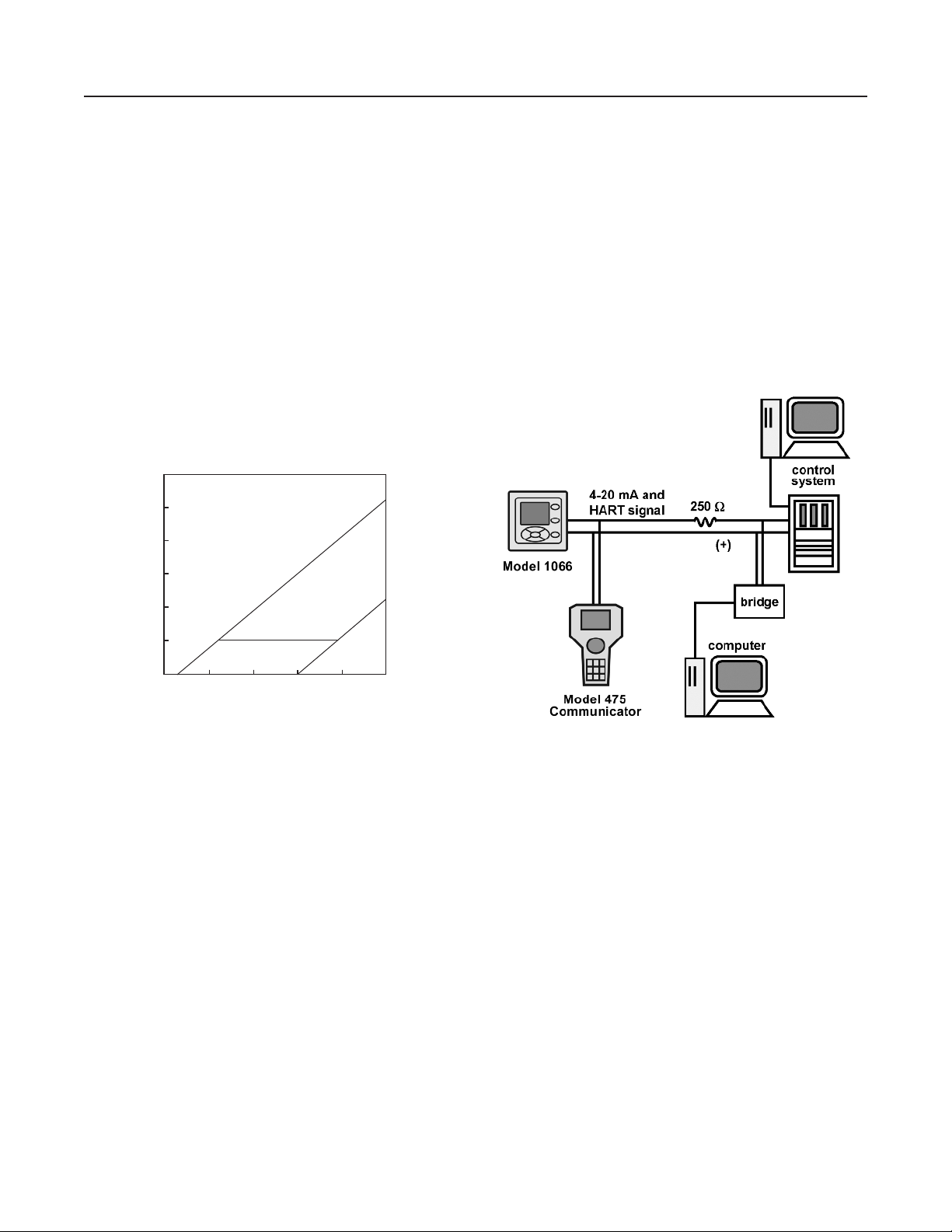

FIGURE 2. Power Supply-Current Loop Wiring

Page 5

Instruction Sheet 1066

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

Specifications CONTINUED

CONTACTING CONDUCTIVITY

Performance Specifications

Measurement Range: see table below

Input filter: time constant 1 - 999 sec, default 2 sec.

Response time: 3 seconds to 95% of final reading using

the default input filter

Recommended Sensors for Conductivity

All Rosemount Analytical ENDURANCE Model 400 series

conductivity sensors (Pt 1000 RTD) and Model 410VP 4electrode sensor.

PERFORMANCE SPECIFICATIONS

Recommended Range – Contacting Conductivity

Cell 0.01S/cm 0.1mS/cm 1.0mS/cm 10mS/cm 100mS/cm 1000mS/cm 10mS/cm 100mS/cm 1000mS/cm

Constant

0.01

0.1

1.0

4-electrode

Temperature specifications:

Temperature range 0 to 200°C

Temperature Accuracy,

Pt-1000, 0-50°C

0.01mS/cm to 200mS/cm

Linearity for Standard Cable ≤50 ft (15 m)

±0.6% of reading in recommended range

±2% of reading outside high recommended range

±5% of reading outside low recommended range

±4% of reading in recommended range

± 0.1°C

0.1mS/cm to 2000mS/cm

1 mS/cm to 20mS/cm

200mS/cm to 2000mS/cm

2000mS/cm to 20mS/cm

20mS/cm to 200mS/cm

2mS/cm to 1400mS/cm

Temperature Accuracy,

Pt-1000, Temp. > 50°C

± 0.5°C

5

Page 6

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

Specifications CONTINUED

TOROIDAL CONDUCTIVITY

Performance Specifications

Measurement Range: see table below

Input filter: time constant 1 - 999 sec, default 2 sec.

Response time: 3 seconds to 95% of final reading

Recommended Sensors for Conductivity

All Rosemount Analytical submersion/immersion and

flow-through toroidal sensors.

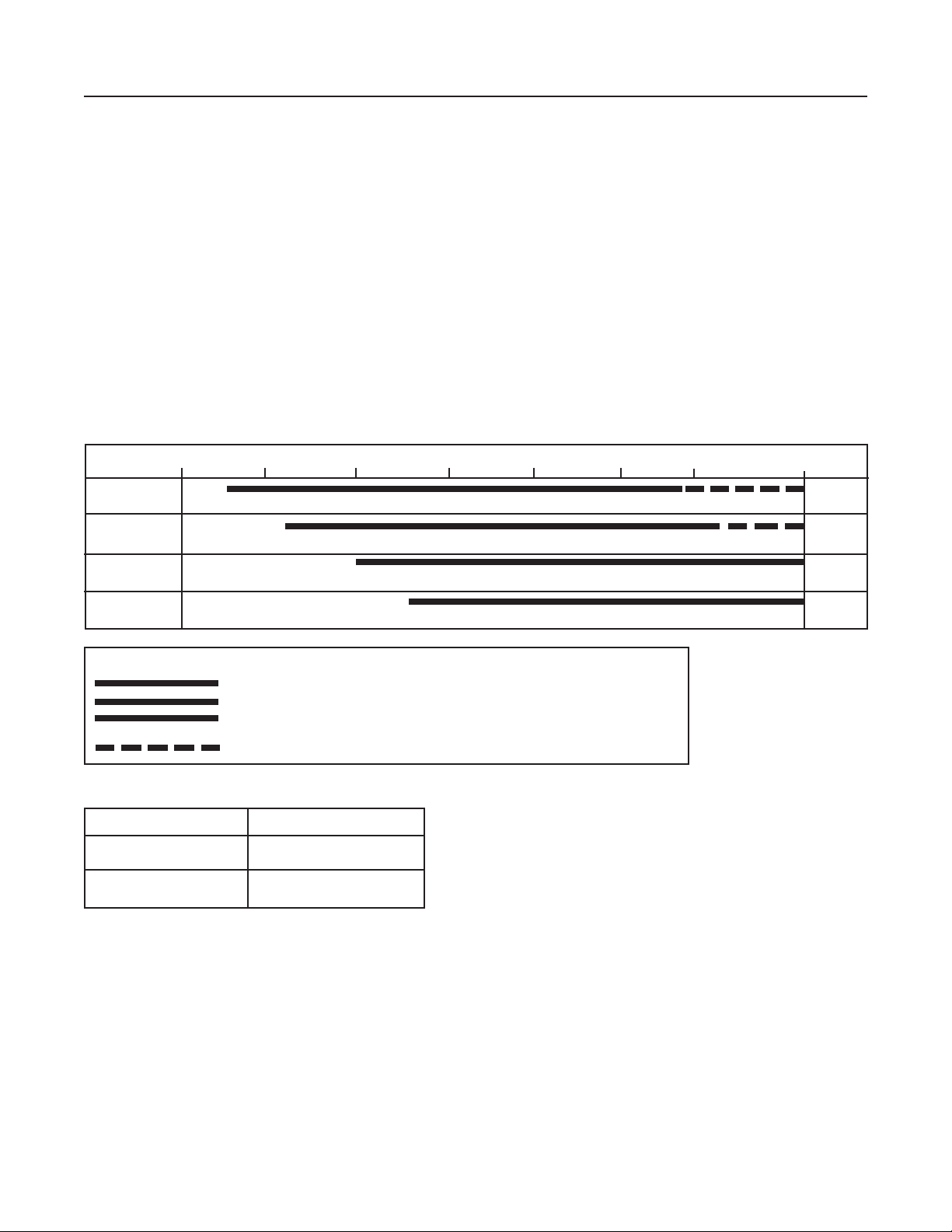

PERFORMANCE SPECIFICATIONS

Recommended Range - Toroidal Conductivity

Model 1mS/cm 10mS/cm 100mS/cm 1000mS/cm 10mS/cm 100mS/cm 1000mS/cm 2000mS/cm

226

225 & 228

242

222

(1in & 2in)

LOOP PERFORMANCE (Following Calibration)

Temperature specifications:

Temperature range -25 to 210°C (-13 to 410ºF)

Temperature Accuracy,

Pt-100, -25 to 50 °C

Temperature Accuracy,

Pt-100,. 50 to 210°C

5mS/cm to 500mS/cm

15mS/cm to 1500mS/cm

100mS/cm to 2000mS/cm

Model 226: ±1% of reading ±5mS/cm in recommended range

Models 225 & 228: ±1% of reading ±15

Models 222, 242: ±4% of reading ±5mS/cm in recommended range

Models 225, 226 & 228: ±5% of reading outside high recommended range

± 0.5°C

± 1°C

500mS/cm to 2000mS/cm

1500mS/cm to 2000mS/cm

500mS/cm to 2000mS/cm

mS/cm in recommended range

6

Page 7

Instruction Sheet 1066

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

Installation

UNPACKING AND INSPECTION

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions. Save the box. If there

is no apparent damage, unpack the container. Be sure all items shown on the packing list are present. If items are missing, notify Rosemount Analytical immediately.

INSTALLATION

General Information

1. Although the transmitter is suitable for outdoor use, installation is direct sunlight or in areas of extreme temperatures is not recommended unless a sunshield is used.

2. Install the transmitter in an area where vibration and electromagnetic and radio frequency interference are minimized or absent.

3. Keep the transmitter and sensor wiring at least one foot from high voltage conductors. Be sure there is easy access

to the transmitter.

4. The transmitter is suitable for panel, pipe, or surface mounting.

5. The transmitter case has six 1/2-inch (PG13.5) conduit openings. Use separate conduit openings for the power/output cable, the sensor cable, and the other the sensor cable as needed (pH input for free chlorine with continuous pH

correction).

6. Use weathertight cable glands to keep moisture out to the transmitter. If conduit is used, plug and seal the connections at the transmitter housing to prevent moisture from getting inside the instrument.

PREPARING CONDUIT OPENINGS

There are six conduit openings in all configurations of Model 1066. (Note: four enclosure opening plugs will be provided upon shipment.)

Conduit openings accept 1/2-inch conduit fittings or PG13.5 cable glands. To keep the case watertight, block unused

openings with NEMA 4X or IP66 conduit plugs.

NOTE: Use watertight fittings and hubs that comply with your requirements. Connect the conduit hub to the

conduit before attaching the fitting to the transmitter.

WARNING: RISK OF ELECTRICAL SHOCK

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-70) and/or any other applicable

national or local codes.

ELECTROSTATIC IGNITION HAZARD

Special condition for safe use (when installed in hazardous area)

1. The plastic enclosure, excepting the front panel, must only be cleaned with a damp cloth. The surface resistivity of

the non-metallic enclosure materials is greater than one gigaohm. Care must be taken to avoid electrostatic charge

build-up. The Model 1066 Transmitter must not be rubbed or cleaned with solvents or a dry cloth.

2. The panel mount gasket has not been tested for type of protection IP66 or Class II and III. Type of protection IP66

and Class II, III refer the enclosure only.

3. The surface resistivity of the non-metallic enclosure materials is greater than one gigaohm. Care must be taken to

avoid electrostatic charge build-up. The Model 1066 Transmitter must not be rubbed or cleaned with solvents or a

dry cloth.

4. Special Condition of Use of 1066-C-FF/FI-67 and 1066-T-FF/FI-67. For use with simple apparatus model series 140,

141, 142, 150, 400, 401, 402, 402VP, 403, 403VP, 404, and 410VP contacting conductivity sensors and model

series 222, 225, 226, 228 toroidal sensors.

7

Page 8

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

FIGURE 3. Panel Mounting Dimensions

8

Page 9

Instruction Sheet 1066

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

FIGURE 4. Pipe and wall mounting dimensions (Mounting bracket PN: 23820-00)

9

Page 10

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

FIGURE 5. Contacting and Toroidal Conductivity sensor wiring to 1066 circuit board (1066-C and 1066-T)

10

Page 11

Instruction Sheet 1066

SCHEMATIC, INSTALLATION

MODEL 1066 XMTR, (CSA)

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

FIGURE 6. CSA Installation

11

Page 12

SCHEMATIC, INSTALLATION

MODEL 1066 XMTR, (CSA)

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

FIGURE 7. CSA Installation

12

Page 13

Instruction Sheet 1066

SCHEMATIC, INSTALLATION

MODEL 1066 XMTR, (CSA)

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

FIGURE 8. CSA Installation

13

Page 14

LABEL, INFO, 1066

CSA

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

FIGURE 9. CSA Label Information

14

Page 15

Instruction Sheet 1066

LABEL, INFO, 1066

ATEX

9241717-00

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

FIGURE 10. ATEX, IECEx Label Information

15

Page 16

SCHEMATIC, INSTALLATION

MODEL 1066 XMTR, (FM)

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

FIGURE 11. FM installation

16

Page 17

Instruction Sheet 1066

SCHEMATIC, INSTALLATION

MODEL 1066 XMTR, (FM)

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

FIGURE 12. FM Installation

17

Page 18

SCHEMATIC, INSTALLATION

MODEL 1066 XMTR, (FM)

1066 Instruction Sheet

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

FIGURE 13. FM installation

18

Page 19

Instruction Sheet 1066

LABEL, INFO, 1066

FM

LIQ_MAN_ABR_1066-CT-HT-FF-FI July 2013

FIGURE 14. FM label information

19

Page 20

1066 Instruction Sheet

8

July 2013 LIQ_MAN_ABR_1066-CT-HT-FF-FI

facebook.com/EmersonRosemountAnalytical

AnalyticExpert.com

twitter.com/RAIhome

youtube.com/user/RosemountAnalytical

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

rosemountanalytical.com

© Rosemount Analytical Inc. 2013

Rev. A

Credit Cards for U.S. Purchases Only.

©2013 Rosemount Analytical, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark

of one of the Emerson Process Management family of companies. All other marks are the property

of their respective owners.

The contents of this publication are presented for information purposes only, and while effort has

been made to ensure their accuracy, they are not to be construed as warranties or guarantees,

express or implied, regarding the products or services described herein or their use or applicability.

All sales are governed by our terms and conditions, which are available on request. We reserve the

right to modify or improve the designs or specifications of our products at any time without notice.

Loading...

Loading...