Page 1

Instruction and service manual

Screw vacuum pumps

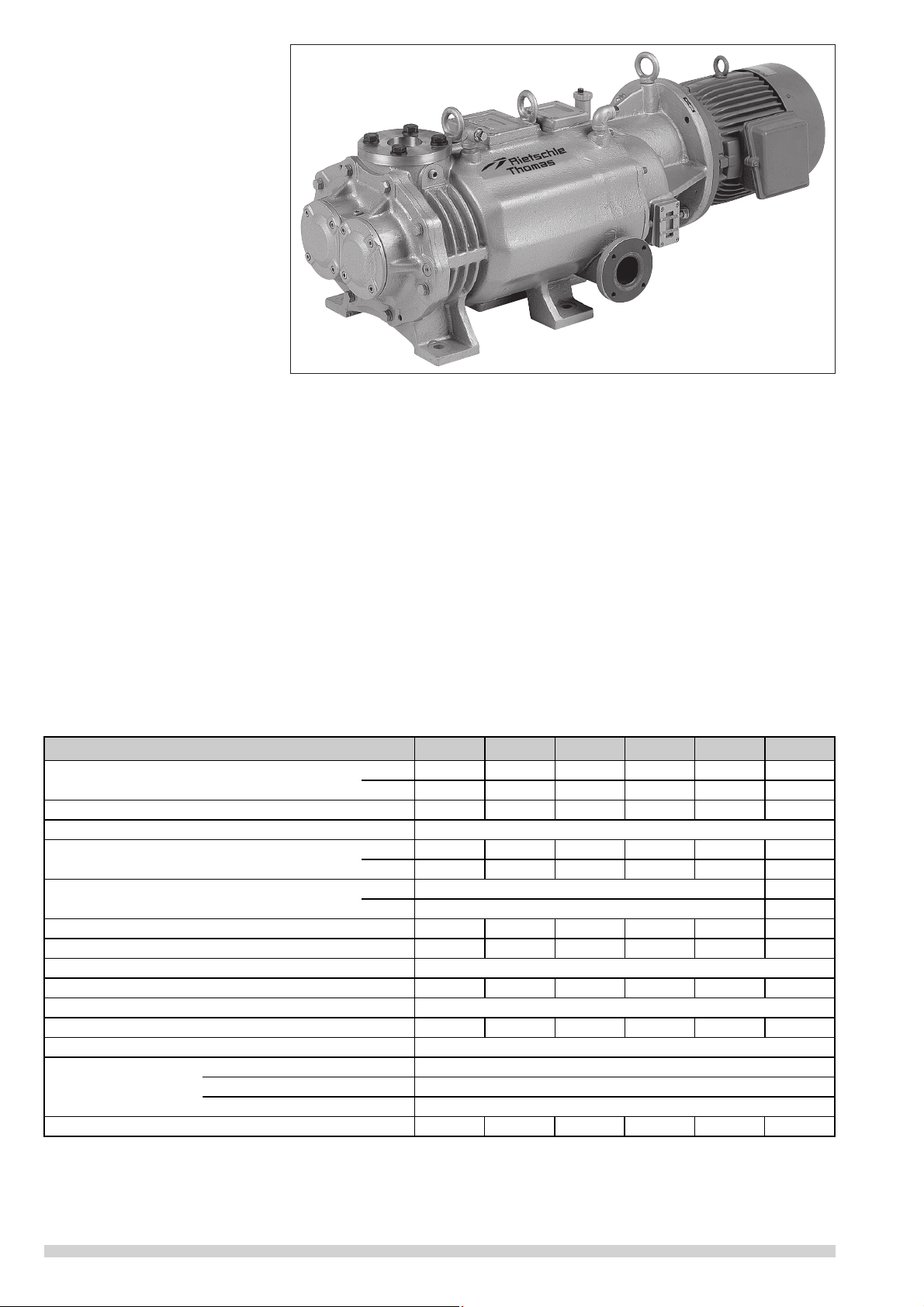

S-VSB

S-VSB 120

S-VSB 200

S-VSB 320

S-VSB 430

S-VSB 800

S-VSB 2700

BE 831

2.1.2002

Gardner Denver

Schopfheim GmbH

Postfach 1260

79642 SCHOPFHEIM

GERMANY

Fon +49 7622 / 392-0

Fax +49 7622 / 392-300

e-mail: er.de@

gardnerdenver.com

www.gd-elmorietschle.com

Page 2

Screw vacuum pumps

Table of contents: Page:

1. Introduction 3

2. Application 3

3. General Construction 4

3.1 General 4

3.2 Construction 4

3.3 Technical specifications 4

3.4 Cooling system 5

3.4.1 Fresh water cooling 5

3.4.2 Circulation Cooling 5

3.4.3 Cooling gas 5

3.5 Gases 5

3.5.1 Sealing gas 5

3.5.2 Cleaning gas 5

3.6 Bleeding valve 5

4. Handling procedure 6

4.1 Assembly of piping 6

4.1.1 Location 6

4.1.2 Foundation 6

4.1.3 Installation 6

4.2 Piping work 6

4.2.1 Main piping 6

4.2.2 Cooling water piping 6

4.3 Coupling drive 6

4.4 Preparation for operation 6

4.5 Operation 6

4.6 Stopping 6

4.7 Lubrication 6

5. Maintenance and inspection 7

5.1 General 7

5.2 Periodical inspection 7

5.3 Disassembly 8

5.3.1 Cautions in disassembly 8

5.3.2 Disassembling procedure 8

5.4 Re-assembly 8

5.4.1 Cautions in re-assembly 8

5.4.2 Re-assembling procedure 9

6. Trouble shooting 10

Data sheets:

D831/1 ➝ VSB (30), (20)

Spare parts list:

E831/1 ➝ VSB (01)

- 2 -

Page 3

1. Introduction

To prevent contamination from possible dangerous substances contained in the process, the exhaust outlet must always be

connected to an appropriate emission control system.

All units being returned to our works for maintenance or any other reason must be free of harmful and dangerous

material. A Health and Safety certificate should always be provided.

The customer has the responsibility for providing and checking explosion proof safety requirements for the total site in which

vacuum pumps are used.

An appropriate agreement should be obtained from the local licensing authorities.

2. Application

The TWISTER vacuum pumps are particularly suitable for the handling of extremely humid gases. These pumps have a high water

vapour tolerance.

The ambient temperatures may be between 5 and 40°C. The suction temperatures should not exceed 60°C. For

temperatures out of this range please contact your supplier.

Liquid slugs and solids cannot be handled by TWISTER.

Handling of explosive gases or vapours only on request with our company.

For installations that are higher than 1000 m sea level there will be a loss in capacity. For further advice please

contact your supplier.

The standard versions may not be used in hazardous areas. Special versions with Ex-proof motors can be supplied.

All applications where an unplanned shut down of the pump could possibly cause harm to persons or installations, then the corresponding safety backup systems must be installed.

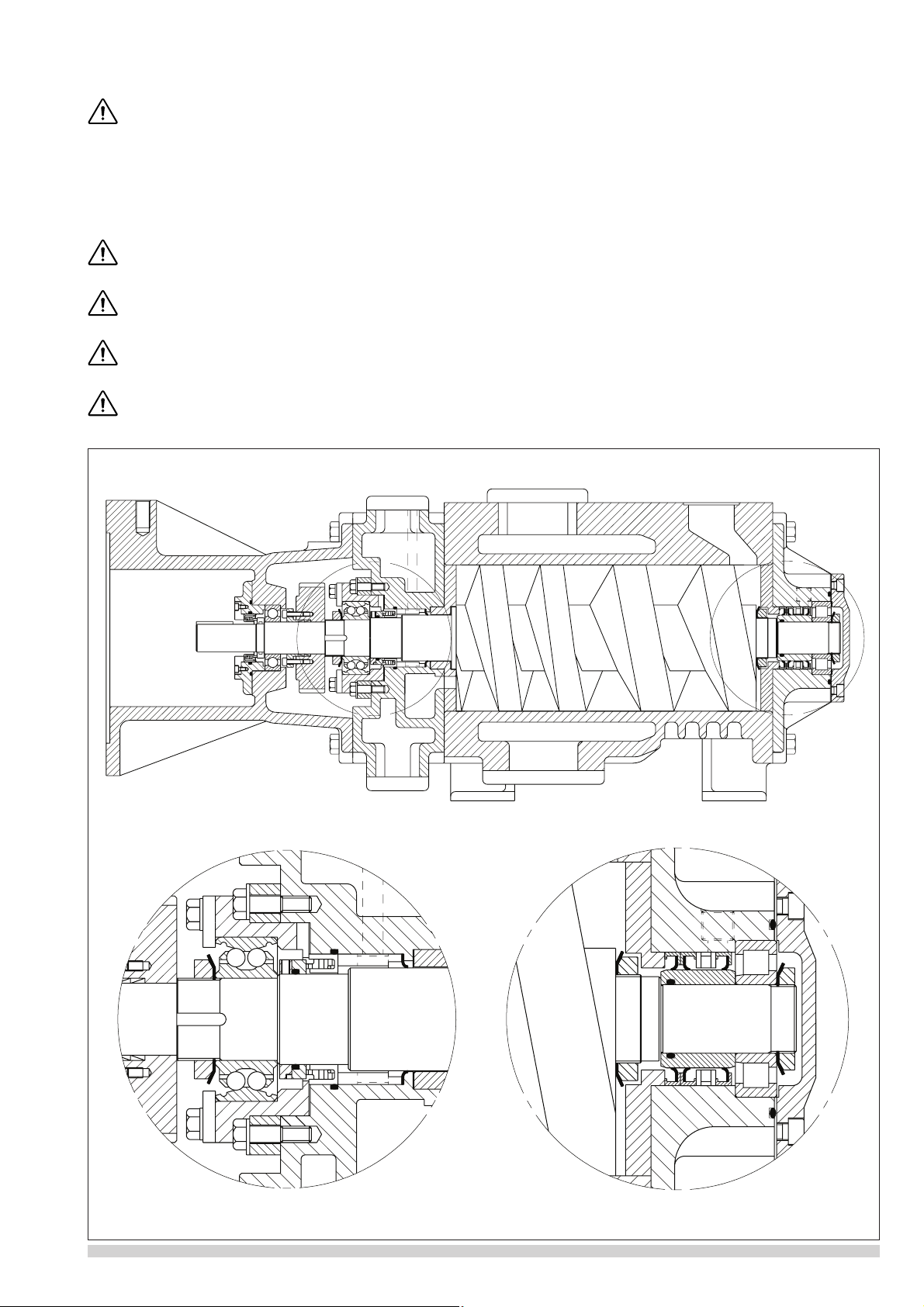

Cut view TWISTER VSB

- 3 -

Page 4

3. General Construction

3.1 General

The Rietschle TWISTER pumps gases

and vapours by use of two screw rotors, having a profile comprising a plurality of curves, i.e. Archimedean curve,

Quimby curve and arc, which rotate

smoothly with a certain clearance maintained between each other and inside

wall of the casing.

The gases and vapours being pumped

are smoothly pressurised up to the

pressure on the discharge side. The

pump is so constructed as to prevent

oil from entering the pumping chamber.

The power of the motor is transmitted

to the gear by a coupling.

3.2 Construction

• Rotor shaft: The rotor shaft is

made of high grade spheroidal

graphite cast steel, and precision machined through numerical control by a special machine. It is perfectly dynamically

balanced after the rotor is machined.

• Timing Gear: The timing gears are the most important part of the screw vacuum pump, and they are required to maintain

the precision clearance between the rotors. The tooth surface is heat cured, and then polished with a special high precision

tooth polishing machine for noise reduction.

• Bearing: The bearings on the fixed end are angular contact ball bearings and on the floating end are roller bearings of

heavy load capacity. These bearings have been selected for high speed and heavy load service and to assure the accurate

maintenance of clearances between gears and between rotors.

• Shaft sealing suction side: The shaft sealing consists of two double lipped shaft seals.

Shaft sealing pressure side: A mechanical spring plate assures sealing between the chamber and the gear box. An

additional single lipped shaft seal in combination with sealing gas prevents foreign particles from entering the sealing system.

Shaft sealing gear box: A single lipped shaft seal seperates the gear box from the atmospheric pressure.

• Oil Level Gauge: The Oil Level Gauge is located in the Front End Cover. Oil should be supplied to the top level of Red mark.

If the oil level is too low, Gear, Bearing and Mechanical Seal will be damaged as a result of improper lubrication. The timing

gears, bearings and mechanical seals are splash lubricated. Check oil level and look for contamination when the pump is

stopped.

3.3 Technical specifications

VSB 120 (30) 200 (30) 320 (30) 430 (30) 800 (30) 2700 (20)

Nominal (theoretical) Displacement

Ultimate vacuum

Discharge pressure

Motor rating

Speed

Port size (Suction / Discharge)

Gear oil

Max. internal pressure

Cooling water

Cooling water pressure

Cooling gas

Sealing gas

m³/h

50 Hz 80 120 220 330 560 1700

60 Hz 100 150 260 400 700 2100

mbar (abs.) 0,3 0,3 0,3 0,3 0,05 0,05

bar (abs.) max. 1,3

50 Hz 3,0 4,0 5,5 7,5 15 55

kW

60 Hz 3,6 4,8 6,5 9,0 18 65

50 Hz 2850 1450

-1

min

60 Hz 3450 1740

DN 40 50 / 40 50 / 40 80 / 50 100 / 80 150 / 100

l 0,45 1,0 1,6 1,8 2,0 9,0

bar (abs.) 10

l/h 120 240 480 660 1200 2160

bar (abs.) max. 6

3

Nm

/h - - - 25 30 30

cm³/min max. 3

Front end plate Bellows type mechanical seal

Seal type Rear end plate Lip seals

Front end cover (drive shaft Oil seal

Weight

kg 120 240 480 660 1200 2160

Note:

(1) The quantity of oil listed is only for reference, and surplus should be available. It should be noted that fluorine and mineral

based oils can be used. For shipping, we supply pure gear oil.

(2) The Cooling Water flow quoted is based on water temperature of 20° C. The amount of water will vary when using an After

Cooler. Please check with Vendor’s approved drawing.

- 4 -

Page 5

3.4 Cooling system

TWISTER pumps are water cooled. They are distinguished in:

3.4.1 Fresh water cooling

The fresh water cooling system is characterised by a continuous flow of the cooling water through a hollow space between

the inner and outer wall of the chamber. For safety reasons the

cooling system is equipped with a temperature switch and a

flow switch.

Cooling water outletCooling water inlet

Flushing gas

Cooling gas

Flushing gas

Cooling gas

3.4.2 Circulation Cooling

The circulation cooling system is equipped with a radiator. Two

different types of radiators can be used: Air-water radiator: A

bypass piping and a 3-way valve with integrated temperature

controller bypass the cooling water around the air-water. During

operation of the pump a temperature switch monitors the water

temperature and a flow switch supervises the water flow rate.

The radiator is equipped with an integrated fan. The cooling circuit is furthermore equipped with a tap through which it is filled,

an expansion tank, a relief valve and a manometer.

Flushing

gas

Cooling gas

Water-water radiator: The external cooling circuit is connected

to the factory’s main water supply. It is equipped with a dust

trap and a temperature controlled valve. This valve remains

closed during the start run of the pump.

The internal cooling circuit is equipped with a temperature switch

that monitors the cooling water temperature and a flow switch

that regulates the water flow rate. The circuit includes furthermore a tap through which it is filled, an expansion tank, a relief

valve and a manometer.

3.4.3 Cooling gas

This purge is intended to cool the rotors and internals which

are heated by gas compression.. Since this compression heat

can reach above 200° C in the discharge side, a cooling purge

is needed to cool the gases. In most cases, an atmospheric air

cooling purge is used, this is the standard purge.

An air filter is provided near the discharge side of the casing for

this purge.

Cooling gas capacity see table page 4.

Remark: The TWISTER VSB 120 does not require any cooling

gas!

(1) Purge gas flow

This purge gas flow can vary according to operating vacuum

level

(2) Type of Cooling Purge

1. Standard: Atmosphere purge through air filter

2. Using Heat Exchanger, Recycle process gases after

cooling through the heat exchanger.

3. As an alternative other gases may be used.

3.5 Gases

3.5.1 Sealing gas (see picture )

The sealing gas is located on the pressure side between the

mechanical spring plate and the single lipped shaft seal. It prevents process gases and liquids from entering the gear box

and the bearings.

The maximum gas pressure allowed is 1,5 bar (abs). The mechanical seals guarantee a sealing up to 4 bar (abs.).

3.5.2 Cleaning gas

This purge is used to clean the inside the pump before stopping. Before stopping the pump, purge with N

gas, steam or

2

cleaning agent for 20 to 30 minutes after closing the main suction valve to clean sticky process materials or process gases.

This purge is especially important when pumping corrosive/

toxic or sticky materials like resin etc.

3.6 Bleeding valve

The suction side of the pump is equipped with a bleeding valve

which implies two functions

On start run:

In an hazardous environment the pump in neutralized with an

inert gas.

While bringing the pump to operating temperature it is flooded

with inert gas.

Shutting the pump down:

After the process the pump is neutralized with an inert gas.

- 5 -

Page 6

4. Handling procedure

4.1 Assembly of piping

4.1.1 Location

• Mount the Pump on a clean, flat & level surface of suffi-

cient rigidity. If it is to be installed outdoors, check motor,

V-belt and other parts are for outdoor service.

• There should be enough space for maintenance, disas-

sembly, reassembly and periodical inspection, etc.

4.1.2 Foundation

• The pump can be mounted on a suitable concrete plinth or

steel framework.

4.1.3 Installation

• Mount the pump horizontally and centre it in accordance

with the instruction manual. The pump should be level to

within 0.5 mm per metre.

4.2 Piping Work

4.2.1 Main Piping

• Clean the inside of suction and discharge pipework to en-

sure it is free from rust, dust and foreign matter, place a

strainer of 40 mesh on or over suction port.

• It is advisable to install an expansion joint on the suction

and discharge side of the pumps. Provide supports for piping so that no excessive load to be imposed on the pump.

• If silencer is to be fitted on the discharge side, install it as

near the discharge port as possible.

• Be sure to install a Non-return Valve adjacent to the suc-

tion port so that the pump will not turn in reverse when

switched off. If installation of the Non-return Valve is a problem for the duty of the pump, install a shut off valve, and

ensure it is closed prior to stopping the pump.

• In the event of condensate being collected at the pump

discharge, a collection tank may be installed under the

pump, and then the condensate and water will be collected

during operation and be discharged by the opening of a

drain valve.

• A drain receiver should be installed under the drain valve

to collect discharge.

4.2.2 Cooling water piping

Cooling water required to cool front end plate and casing.

The piping should be assembled with reference to the piping diagram and the outline drawing supplied.

* If Water Jacket type Silencer is installed, this Silencer also

requires cooling water.

4.3 Coupling drive

Align coupling by using Dial Gauge. The concentricity should

be as follows:

Motor Pump Motor Pump

side side side side

Feeler gauge

Class of motor On side of coupling

M180 less than 0.05

M200M and above less than 0.08

Class of motor At end of coupling

M132M and under less than 0.1

M160M and above less than 0.18

4.4 Preparation for operation

• Remove dust from Vacuum Pump and piping. Clean the

pipework thoroughly, ensuring welding slag and debris etc.

are removed.

• Check all suction and discharge connections are properly

tightened and all the piping is properly supported. Also

check cooling water piping.

• Supply oil up to the red mark of the oil gauge. If oil level is

low, gear and bearings can seize, and if oil level is too

high, the temperature will rise excessively, and can be the

cause of gear noise or some effect on other parts.

• Cooling water flow to be as specified in chart 1.3.

4.5 First Operation

Warning –> Start-up with pipework

At start-up, severe damage may occur if there is debris in

the pipework.

We therefore recommend a vacuum tight inlet filter of 5

micron rating is installed for start-up.

• With suction valve closed, run the motor briefly to check

direction of rotation, correct if required.

• Run the pump under no load condition for 20-30 minutes

to check for any abnormal vibration or heat. In case of any

abnormality, stop the pump and search for the cause. In

most cases, the cause is improper installation or coupling

centring. Check for correct lubricant level.

• Run the pump for 2 - 3 hours under normal load condition

and check the temperature and vibration of each parts.

• During operation, pay attention to indication of motor am-

pere Meter. If any abnormality is found, stop the pump immediately and check the cause. Often, the cause is interference between rotors or between the periphery of rotor

and the inner surface of casing. All pumps are factory run

before despatch, however, full care will be still necessary

after the pump installed on site.

* Caution during Operation:

• Check temperature of bearing & lubricant and indication of

Ampere meter & cooling water.

• Keep operation within designated specifications.

4.6 Stopping

• Shut suction valve.

• If any corrosive gas, solvent or water vapour has been

pumped, introduce atmospheric air ( or N

) from suction

2

side for 20-30 minutes before stopping to clean the pump

internals. If a solvent or steam cleaning purge is used, run

the pump for 10 minutes on air or N2 purge only after steam/

solvent has been turned off.

• Stop the pump by turning off the motor.

• Shut off cooling water. If freezing is anticipated, discharge

water by opening of drain valves.

4.7 Lubrication

Lubricants to be used must be good and high grade petroleum products containing oxidation inhibitor, rust preventive, extreme-pressure additive, etc. (Do not use any lubricant which contains any element of water , sulphate resin

or tar.).

Turbine oil (ISO VG 68) readily obtainable in the market

will generally satisfy these requirements.

The following brands are recommended for use as lubricants for gear and bearing.

•

Lubricant: BP Energol THHT 68, BP Energol THB 68,

Regal R & O 68, Shell Turbo 68, Mobil Gear 626 or equivalent oils.

• Grease: Aeroshell grease 150, Shell Dorium Grease R, G

40 M, JFE 552 (NOK-Kluber) or equivalent grease.

- 6 -

Page 7

5. Maintenance and Inspection

5.1 General

• During operation, the temperature will rise corresponding to the compression ratio due to compression heat. However, if

localised temperature hot spots occur or the paintwork is scorched, this is abnormal. It may be because of the interference

of rotor with casing, or the pump has sucked in some foreign material. Therefore, stop the pump immediately to check the

condition. In some case, the rotors and the casings might have corroded after a long service life, which will make the

clearance between these parts larger and result in high rates of pumped gas re-cycling, with the result that the temperature

rise becomes higher than it was initially. In such cases, the pumping speed will be reduced. Stop the pump and take measurements of the clearances for consideration of corrective action.

• Abnormalities can be noted by making routine checks on bearing temperature, vibration or noise. Therefore, daily inspection

is advised.

• Interference between rotors or between rotor and casing can be noted by listening to sound through a stethoscope applied

against the casing.

• In winter, in cold regions, whenever the pump is stopped, cooling water should be drained. Freezing of water could damage

the jacket.

5.2 Periodical Inspection

a.) Daily

• Oil-Level Gauge: Excess or lack of lubricant can damage gears and bearings.

• Check that the amount of cooling water is adequate.

• Check the temperatures of Grease cover and Front end Cover. Use of a suitable thermometer or a surface thermometer may

be convenient.

• Check the suction and discharge pressures. To check these pressures, make sure that the operation of the pump is within

planned specifications.

• Check the load on the motor. Note that an increase in the motor load indicates some kind of abnormality.

b.) Monthly

• Check tension of V-belt.

• Check lubricant colour (If, Oil colour is discoloured, replace lubricant).

• Check oil level. If oil consumption is high with no apparent leaks, check mech. seal.

c.) Every 6 month

• Check pipe connections.

• Check oil & grease and change them when need.

d.) Yearly

• Check mech. seals, lip seals & oil seal.

• Check inner surface of rotors and casings. Disassemble the piping on suction side to check the inner surface of rotors and

casings.

• Check the gear. - Remove the front end cover to check the gear.

• Replace lubricant in the front end cover.

Screw vacuum pump maintenance and check list

No. Item Check point a.) b.) c.) d.)

1 Ampere of motor Any change? Ampere as specified? •

2 Rotation Is rotation smooth and correct •

3 Suction and discharge pressure Are those pressure as specified •

4 Noise and Vibration Any abnormal sound or vibration •

5 Temperature Any excessive oil temperature rise on bearing and other parts •

6 Oil amount of front end cover Is oil at proper level? •

7 Water contamination of front end cover Clean or not? •

8 Oil leak Oil not leaked? •

9 Lubricant replacement All oil & grease in front end cover & grease cover to be replaced •

Amount and pressure of cooling water

10

for pump casing & silencer (separator)

Is the amount as specified? •

11 Suction and discharge pipe Is there any scale? •

12 Cleaning and dry run at stop

Close the main V/V on suction side, and run for 20 ~ 30 min.

while purging N

or air

2

13 Check inside of casing and rotor Any rust or flaw found? •

Mech. seal, lip seal, bearing, o-ring,

14

packing V-belt / coupling

Replace when need •

- 7 -

Page 8

5.3 Disassembly (see spare parts list E 831/1)

5.3.1 Cautions in disassembly

(1) Put alignment marks on all connections and covers etc.

(2) Take measurements of all gasket thickness when they are disassembled.

(3) Keep disassembled parts away from dust, especially for bearings.

5.3.2 Disassembling procedure

(1) Remove all accessories from the pump unit.

(2) By opening drain valves, discharge cooling water from casing.

(3) Remove oil drain plug from front end cover 4 and drain oil.

(4) Remove socket bolts from seal adapter housing 25 and separate seal adapter housing from front end cover.

(5) Separate oil seal 21, speedy sleeve 20 and ball bearing 24 from seal adapter housing.

(6) Remove hex. bolt (M16) from front end cover 4 and front end plate 2, then separate front end cover.

(7) Remove power lock 15 from timing gear (A) 27 & (B) 28, by loosing socket bolt with wrench.

(8) Separate timing gear (A), (B).

(9) Remove bearing stopper (A) 13 & (B) 14 by loosing socket bolt with Hexagon wrench.

(10) Separate lock nut 16 with lock nut wrench and remove lock washer 17

(11) Separate bearing holder (A) 10 & (B) 11 from front end plate by securing hex bolt (M8) in tapping in bearing holder (A) 10

& (B) 11.

(12) Push out ball bearing 23 from bearing holder (A) 10 & (B) 11 with puller.

(13) Remove spacer (A) 36 from drive & driven shaft (A) 6, (B) 7.

(14) Remove mech. seal from drive & driven shaft (A) 6, (B) 7.

(15) Remove hex. bolt (M16) from casing 1 and front end plate 2. Secure hex. bolt (M16) in tapping in front end plate and

separate it from casing.

(16) Remove plate guide (A) 8, (B) 9 from front end plate by loosing socket bolts.

(17) Separate grease cover 5 from bearing holder (C) 12 by loosing socket bolts.

(18) Remove lock nut 16 with lock nut wrench, and pull out lock washer 17 & bearing push sleeve 36.

(19) Separate bearing holder (C) 12 from rear end plate by securing hex bolt (M12) in tapping in bearing holder.

(20) Pull out roller bearing 22 from bearing holder (C) 12 and remove lip seals 19 and speedy sleeve 20.

(21) Remove slip sleeve 39 from drive & driven shaft (A) 6, (B) 7.

(22) Remove lip seals (19) from slip sleeve 39.

(23) Remove spacer (B) 28 from drive shaft (A) 6, (B) 7.

(24) Remove hex bolt (M16) from rear end plate 3. Then, separate rear end plate 3 from casing 1 by securing hex bolt (M16)

on tap.

(25) Separate plate guide (B) 9 from rear end plate by loosing socket bolt (M8).

(26) Gently push out drive & driven shaft (A), (B) from casing and sling them with nylon string. Separate drive & driven shaft

(A), (B) from casing.

(27) Separate blind plates for water jacket from casing, covers, plates.

Clean all parts with good grade of clean solvent and replace any worn or damaged parts with factory approved parts. New

bearings, seals, gasket and o-rings should be installed at each assembly.

5.4 Re-assembly (see spare parts list E 830)

5.4.1 Cautions in re-assembly

(1) Check all parts for wear or damage during the disassembly. Damage at gasket faces or component locating faces will

greatly influence assembly. Therefore, utmost care is required for inspection of gasket faces and component locating

faces. If damage or wear is found, replace or repair.

(2) Clean bearings with light oil. Then apply lubrication on them. When handling bearings, always clean tools and hands.

(3) Use soft tissue and cleaning agent to clean dust from locating faces, and apply oil. For tight fits, use of Molybdenum

Disulphide is recommended since these fits will become hard to disassembleif corroded. Reassembly is more difficult

than disassembling. (For tapered sections of gear, clean the surface throughly with soft tissue and cleaning agent before

fitting).

(4) New gaskets should be the same thickness as those removed.

- 8 -

Page 9

5.4.2 Re-assembly procedure

(1) Insert plate guide (A) 8 & (B) 9 on front end plate 2 and secure with socket bolt (M8).

(2) Insert plate guide (B) 9 on rear end plate 3 and secure with socket bolt. (M8).

(3) Insert drive shaft (A) 6 & driven shaft (B) 7 on front & rear end plate.

(4) The reassembly should be done from gear side (=discharge side) first. Insert mechanical seals on drive & driven shaft.

(5) Inset spacer (A) 36 on drive & driven shaft.

(6) Insert bearing holder (A) 10 & (B) 11 on front end plate.

(7) Push insert ball bearing 23 on bearing holder (A) & (B).

(8) Secure ball bearing on drive & driven shaft with lock washer 17´& lock nut 16 and bend one edge of lock washer to fix it.

(9) Put bearing stopper (A) 13 & (B) 14 on bearing holder (A) & (B) and secure them together to front end plate with socket

bolt (M10).

(10) Separate rear end plate from drive & driven shaft to assemble casing 1.

(11) Apply sealant on mating faces of casing and front end plate. Insert O-ring on cooling water line of front end plate. Insert

shaft to casing and fix front end plate of casing with bolt.

(12) Apply sealant on mating face of casting and rear end plate. Insert O-ring on cooling water line of casing. Secure rear end

plate and casing with bolt (M10).

(13) Install spacer (B) 38 on drive & driven shaft.

(14) Insert lip seals (2ea for each bearing holder) inside the bearing holder

(C) 12.

(15) Insert bearing holder (C) 12 on rear end plate.

(16) Install slip sleeve 20 on drive & driven shaft for the lip seals to sit on slip

sleeve.

Feeler gauge

(17) Push insert roller bearing 22 on bearing holder (C). Secure bearing

holder (C) 12 with socket bolt (M8).

(18) Fix expansion side roller bearing on drive & driven shaft with push sleeve

37, lock washer 17 and lock nut 16. Now, go to front end cover side.

(19) Insert timing gear (A) on drive shaft and timing gear (B) on driven shaft. Install power lock 15 on timing fear (B) and secure

it with wrench. Set clearance to be 0.1 mm with thickness gauge through suction port as shown above. Tighten fix timing

gear (A) with power lock.

(20) Put O-ring on Groove of cooling water line of front end cover 4 and insert oil paper packing 58 between front end plate 3

and front end cover 4. Secure them with bolt temporary.

(21) Insert ball bearing 24 on drive shaft (A). Tightly secure front end cover to front end plate.

(22) Insert O-ring on seal adapter housing 25 and fix them to front end cover with socket bolt.

(23) Insert speedy sleeve 20 & oil seal on seal adapter housing 25.

(24) Fill lubrication oil through oil inlet on the top of front end plate. The oil level should be on the top of red mark in oil level

gauge. (Oil amount for each model is listed on specification 1.3)

(25) Assemble blind plates & covers on casing & plate side.

(26) Install all accessories. Now, go to rear end plate side.

(27) Tightly secure lock nut 16 and bend one edge of lock washer 17 to fix expansion side roller bearings.

(28) Apply vacuum grease (approx. 1/2 of the space) into the space of bearing holder (C).

(29) Apply sealant between grease cover 5 and rear end plate 3. Secure them with bolt. Now, the assembly is completed.

For reference, clearance table for assembling of the units are listed as follows:

Discharge (fixed) side

P

Suction (expansion) side

V

Screw clearances table in mm

mm

VSB 120 0,07 - 0,12 0,12 - 0,17 0,07 - 0,12 0,12 - 0,17 0,10 - 0,11 0,15 - 0,16 0,10 - 0,12 0,04 - 0,06

VSB 200 0,08 - 0,13 0,15 - 0,20 0,08 - 0,13 0,15 - 0,20 0,13 - 0,14 0,18 - 0,19 0,10 - 0,12 0,05 - 0,07

VSB 320 0,13 - 0,18 0,23 - 0,28 0,13 - 0,18 0,23 - 0,28 0,11 - 0,12 0,26 - 0,27 0,10 - 0,15 0,07 - 0,09

VSB 430 0,16 - 0,21 0,28 - 0,33 0,16 - 0,21 0,28 - 0,33 0,18 - 0,19 0,33 - 0,34 0,12 - 0,15 0,09 - 0,11

VSB 800 0,21 - 0,26 0,42 - 0,46 0,21 - 0,26 0,34 - 0,39 0,23 - 0,24 0,38 - 0,39 0,12 - 0,15 0,12 - 0,15

VSB 2700 0,33 - 0,38 0,73 - 0,78 0,33 - 0,38 0,73 - 0,78 0,31 - 0,32 0,72 - 0,73 0,55 - 0,65 0,18 - 0,22

V A P V B P V C P

DE

- 9 -

Page 10

6. Troubleshooting

Problem Cause Solution

Insufficient air

quantity

Overload on

electric motor

• Filter is clogged

• Too much clearance

• Filter is clogged

• Foreign matter are caught in

• Pressure loss in piping is increased (increase in

suction pressure)

• Interference between rotors

• Interference between rotor and casing

• Clean or change filter

• Check clearance

• Clean or change filter

• Adjust or replace the rotor and casing

• Check the pressure difference between inlet and

outlet

• Adjust improper rotor clearance. Adjust timing gear

• Make the side clearance larger

Make the clearance between rotor and casing

lager

Overheat

• Excessive lubricant in front end cover

• Vacuum pump inlet temperature high

• Too much compression ratio

• Interference between rotor and casing

• Interrelated position between timing gear and rotor

• Check oil level

• Check suction & discharge pressure

• Search for the cause of interference

• Reposition

is incorrect

Knocking

• Improper assembly

• Abnormal rise in pressure

• Damage on gear due to overload or improper

• Reassemble

• Search for the cause

• Replace timing gear

lubricant

Bearing or

gear damaged

/ shaft broken

• Improper lubricant

• Lubricant runs short

• Overload

• Change lubricant

• Refill lubricant

• Replace the shaft

* If the troubles are not resolved by the above mentioned actions, the cause may possibly be located in pump operation condi-

tion. In such case, please contact us with the following information.

1. Pump type & model number, serial number, application, etc.

2. Information of piping (suction pressure, strainer, mesh, number of bends, etc.)

Vacuum system check list

Check point

Open cooling water supply valve. Is it flow properly ?

Before Operation

Close vacuum suction. Open discharge line.

Check lubricant colour and level. Is it acceptable ?

Run vacuum pump for few minute before open the suction line.

Check vacuum level in full vacuum. Is it normal ?

Check electric condition (voltage & amperage) in full vacuum. Is it acceptable ?

During Operation

Any abnormal noise ?

Check operation temperature. Is it normal ?

Check lubricant colour and level. Is it acceptable?

Run vacuum pump for few minute after closing suction line.

Stopping

If foreign material is introduced inside of vacuum pump, clean it with cleaning agent.

Discharge cooling water from vacuum pump if the pump is stopped for a long time.

Make sure that suction & discharge line is closed. Make sure power supply is cut off.

- 10 -

2.10

/ PM7

Page 11

Hereby the manufacturer

confirms:

EC - declaration of conformity 2006/42/EC

Gardner Denver Schopfheim GmbH

Postfach 1260

D-79642 Schopfheim

that the machine:

of the:

Screw vacuum pump TWISTER

Series: S-VSB

Type: S-VSB 120, S-VSB 200,

S-VSB 320, S-VSB 430,

S-VSB 800

is conform to the regulations of the guideline indicated above.

The following harmonized and national standards and specifications are applied:

EN 1012-1:1996 Compressors and vacuum pumps — Safety requirements — Part 1: Compressors

EN 1012-2:1996 Compressors and vacuum pumps — Safety requirements — Part 2: Vacuum

pumps

These declarations of conformity are invalid when the machine has been modified without prior approval by us and the approval has been documented in writing.

Name and address of the EC person in

charge for documentation

Wolfgang Darsch

Postfach 1260

D-79642 Schopfheim

Gardner Denver Schopfheim GmbH

Schopfheim, 27.11.2009

Dr. Friedrich Justen, Director Engineering

C_0046_EN

Page 12

Safety declaration form

s

.

s

/

A

.

3

S

for vacuum pumps and component

7.7025.003.17

Page 1 of 1

Gardner Denver Schopfheim GmbH

Roggenbachstr. 58, 79650 Schopfheim Phone: +49/(0)7622/392-0 Fax: +49/(0)7622/392-300

Repairs and/or maintenance of vacuum pumps and components will only be carried out if a declaration has been

filled in correctly and completely

.

If not, the repair work cannot be started and delays will result.

This declaration must only be filled in and signed by authorised qualified staff

2. Reason for the submission1. Type of vacuum pumps/ components

Type description:

Machine number

Order number:

Delivery date:

3. Condition of vacuum pumps/ component

4. Contamination of the vacuum pumps

Was this being operated? YES NO components when in use

Which lubrication was used? Toxic YES NO

Corrosive YES NO

Was the pump/ component emptied? Microbiological*) YES NO

(Product/Consumables) YES NO Explosive*) YES NO

Has the pump/ component been cleaned and decontaminaRadioactive*) YES NO

other YES NO

YES

Cleaning agent:

Cleaning method:

*) Microbiological, explosive or radioactively contaminated vacuum pumps/ components will only be accepted

with proof that they have been cleaned properly.

Type of toxic substance or process-related, dangerous reaction products with which the vacuum pumps/

components came into contact:

Trade name, manufacturer's Chemical Hazard

product name name class substances are released accidents

1

2

3

4

Personal protection measures:

ction to be taken if toxic First aid in the event of

Hazardous decomposition products when subjected to thermal load

YES NO

Which?

5. Legally binding declaration

We swear that the information in this declaration is accurate and complete and that I, the undersigned, am in a

position to judge this. We are aware that we are liable to the contractor for damage caused by incomplete and

inaccurate information. We undertake to release the contractor from any damage claims from third parties arising

from incomplete or incorrect information. We are aware that, regardless of this declaration, we are directly liable

to third parties including in particular the contractor's staff entrusted with handling or repairing the product

Company:

Street: Post code/ Town:

Phone: Fax:

Name (in capitals) Position:

Date:

Legally binding signature:

TOS no. / Index: 7.7025.003.17 / 0

Office responsible: G

Company stamp:

File management: ..\7702500317.xl

Gardner Denver Schopfheim GmbH Postfach 1260 D-79642 Schopfheim

Loading...

Loading...