Page 1

Directions for Use

and

Service Manual

for compact units of Types from WPB 120 to WPB 8300,

and of Types from WVB 120 to WVB 8300,

and

Base units of Types from WPB 120 to WPB 8300

BE 853 2.5.2004

Gardner Denver Schopfheim GmbH

Postfach 1260 • 79642 SCHOPFHEIM / GERMANY

Phone 07622/392-0 • Fax 07622/392300

er.de@gardnerdenver.com

www.gd-elmorietschle.com

Page 2

TABLE OF CONTENTS

1. Introduction

1.1. Basic information

1.2. Symbols used in the manual

2. Transport, Handling and Storage

2.1. Transport and transport data

2.2. Handling

2.3. Storage conditions

3. Installation and Assembly

3.1. Assembly conditions

3.2. Space necessary for installation and operation

3.3. Requirements for anchoring the blower set or blower

3.4. Requirements for connecting the pipeline

3.5. Instruction for connecting the blower set to the power supply

3.6. Belt installation

3.7. Precautionary measures

3.8. Machine hall ventilation

4. Machine

4.1. Blower description

4.2. Blower set description

4.3. PVO combined safety and starting valves

4.3.1. Starting valve function

4.3.2. Safety valve function

4.4. Noise-damping hood

4.5. Use

4.5.1. Work media

4.5.2. Suction and discharge temperatures

4.5.3. Suction and discharge pressures

4.5.4. Lubricant specification

4.5.5. Maximum temperatures of the lubricating system

4.5.6. Maximum speeds

4.5.6.1. Pulley revolutions

4.5.6.2. Work medium speed

4.5.7. Necessary safety equipment

4.5.8.

Warning against use in explosion-hazard environments

4.5.9. Recommendations for operation at a temperature of 0

4.5.10. Application fields for blowers and blower sets

4.5.11. Electrical equipment data

4.5.12. Certificate of conformity

5. Operating the Machine

5.1. Inspection prior to first turning on the compact unit or base unit

5.2. First turning on of the compact unit or base unit

5.3. Trial Operation

5.3.1. Check intervals for trial operation

5.4. Emergency stopping controllers

5.5. Setting and adjustment instructions

5.5.1. Filling and changing the oil

5.5.2. Replacing the filter inserts of the suction filter

5.5.3. pulleys and belt tension

5.6. Running without operators

5.7. Plates and labels used on compact unit or base unit

5.8. Instructions for tracing simple failures

5.9. Routine maintenance and checks

5.10. Service checks executed by the manufacturer

5.11. Information on improper use

5.12. Information on residual risks

5.13. Places of excessively hot surfaces

5.14. Equipment for protecting operators against residual risks

5.15. Spare parts

6. Taking the machine out of operation and waste disposal

7. Noise level

8. Training operators

Rietschle Thomas GmbH + Co. KG page 2 / 23

o

C and lower

9. Pressure Device

10. Non-standard blower drive

Appendices

1. Identification of Characteristic Values, Standard compact unit Diagram, and

pressure ratios of standard blower set

2. PVO Combined Safety and Starting Valve - Assembly

3.1 Forced and natural ventilation

3.2 Forced and natural ventilation

4. Connection diagram of the acoustic enclosure fan (3 x 400V)

5. Connection diagram of the acoustic enclosure Fan (240 V)

6. Report on measurement of blower set oscillation power

Catalogue sheet (dimensional drawing) of the compact unit

Catalogue sheet (dimensional drawing) of the compact unit in the acoustic

enclosure

Quality certificate

Connection diagram of the electric motor (not included in this Manual,

submitted on request)

Page 3

1. INTRODUCTION

1.1 BASIC

INFORMATION

1.2 SYMBOLS

USED IN THE

MANUAL

The Directions for use and service manual for the

SHARK compact unit and base units (hereinafter

referred to as the Manual) contain important directions to

be observed throughout the machine’s operating life,

starting on receipt of the machine. The manual has been

compiled for complete SHARK series. It also applies to

separately delivered base units. Before installing and/or

putting the machine into operation, you must familiarize

yourself with this manual in order to ensure trouble-free

and safe operation of the machine and a long operating

life. The manual mentions and quotes safety regulations to

be considered particularly during machine operation. It is

necessary that the personnel responsible for the machine

operation and maintenance have this manual at their

disposal so that operation and maintenance is done in

accordance with the instructions stated in this manual. We

recommend entrusting repairs and redesigns only to

Rietschle Thomas (RT) specialists. If under guarantee, the

machine shall be disassembled only by RT specialists or

persons authorized by RT.

The manual contains only instructions for use of standard

blowers and blower sets designed for air transport. The

instructions for use of non-standard blowers and blower

sets for transport of other gases must be consulted with the

manufacturer.

The instructions stated in the manual apply to the blower

set, the quality certificate of which is enclosed with this

manual. If any failure occurs, immediately contact the

Section for Business-technical Services (hereinafter

referred to as the RT service department). When

contacting RT about any problem, state the data from the

type plate: the type and serial number of the blower set or

blower.

Caution: Read the directions for use!

Warning: Overlooking these instructions

might cause damage to the machine

and/or slight injuries.

Warning: Danger of injury

Warning: High temperature risk

Caution: Wear ear protectors!

Oil filling

Forbidden: Do not turn on the machine!

Forbidden: Do not use a hammer!

Suspension

2. TRANSPORT, HANDLING AND STORAGE

2.1 TRANSPORT

AND TRANSPORT

DATA

2.2

H

ANDLING

Delivery

Delivered blower sets are assembled as complete units.

Delivered belts are not installed on the machine. The

pendulous motor frame is secured by bolts in the bottom

position. Delivered compensators and non-return valves of

larger SHARK types (supplied with noise-damping hoods)

are not installed on the machine. Blowers are delivered

without oil fillings. The delivery contains the accessories

specified in the purchase contract. The dimensions and

weight are stated in the dimensional drawing of the

appropriate blower set, which is enclosed with the Manual.

Transport

Compact units must be transported in protected freight

space.

Blower sets must be transported with belts removed! Otherwise, the shaft or bearings could be

damaged. During transport, the pendulous motor

frame must be secured by appropriate bolts in the

bottom position!

Receipt

On receipt, the delivery must be checked with the delivery

notes for completeness. Any potential damage caused

during transport must be recorded in the presence of the

carrier. The record signed by the carrier must be

immediately submitted to the supplier.

To handle the machine, use a forklift truck and/or crane as

described below.

Base unit

The picture shows the handling of a base unit. To handle

the blower, use soft binding ropes. Steel wire ropes can be

used provided they are padded in order to prevent damage

to the paint.

WARNING

On no account should the blower be lifted with

the ropes attached to the flanges!

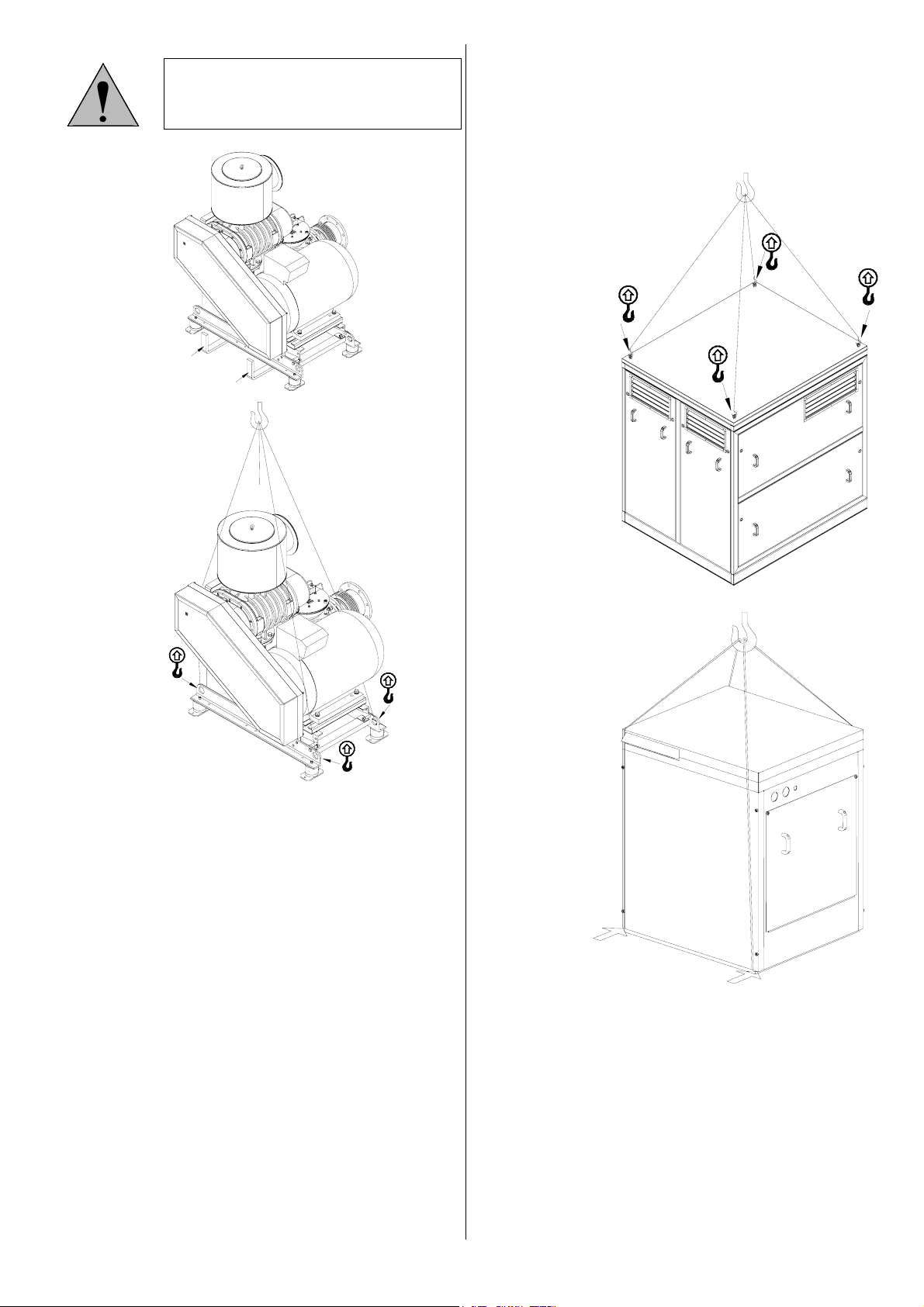

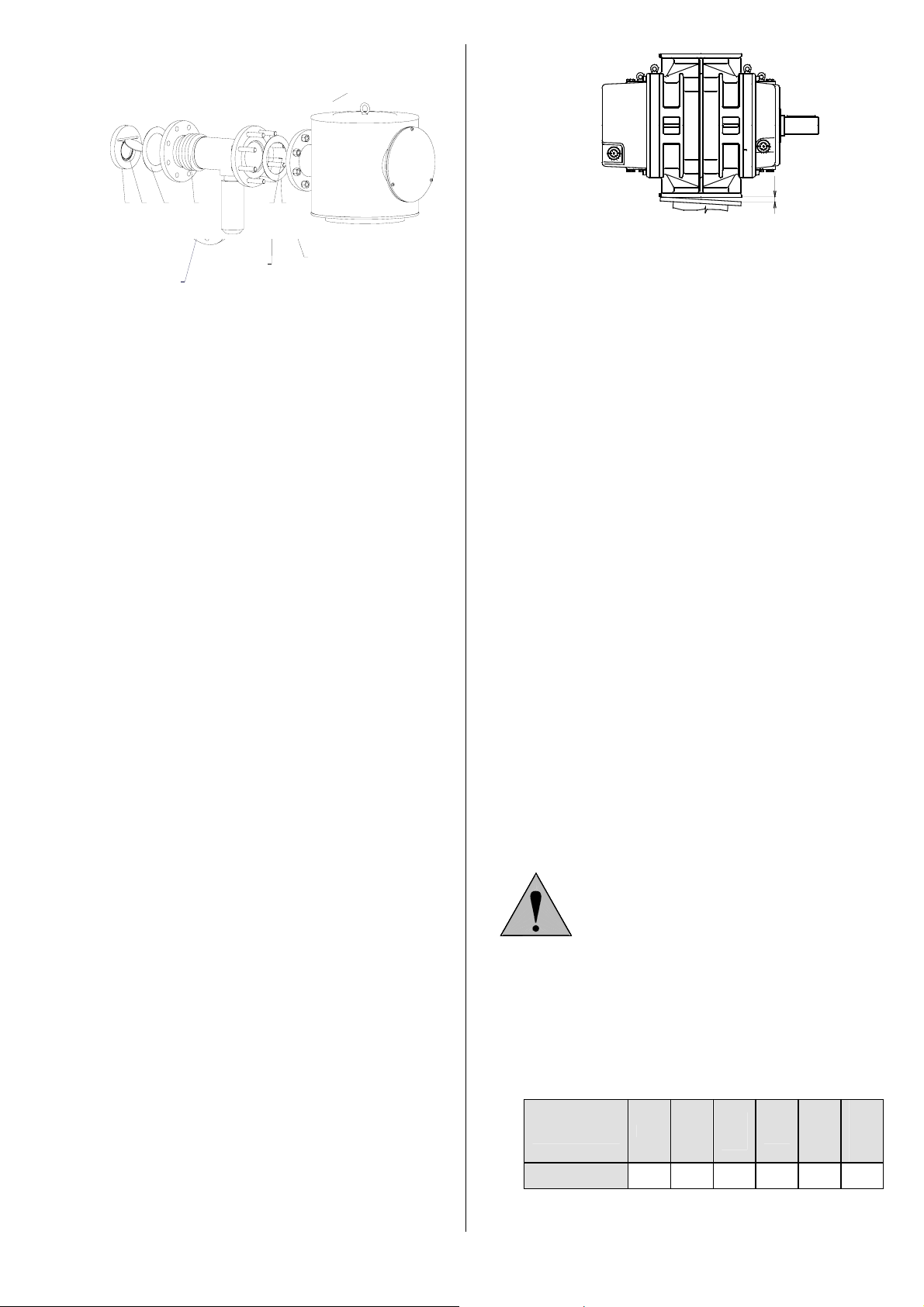

Compact unit

To handle the compact unit, use a forklift truck and/or

crane. The following pictures show the ideal handling of

blower sets. To handle the compact unit with a crane, use

soft binding ropes. Steel wire ropes can be used provided

they are padded in order to prevent damage to the paint.

Further, you must avoid using too short binding ropes in

order to prevent deformation of the suction filter during

transport.

Rietschle Thomas GmbH + Co. KG page 3 / 23

Page 4

t

t

WARNING

On no account should the compact unit be lifted

with the ropes attached to the set bases, blower

flanges, suction silencer, and/or motor!

Without a compact uni

Acoustic enclosure

Smaller types of acoustic enclosures, in which compact

units are placed, can be handled by a crane or a forklift

truck. Ropes must be placed under the bottom base as

displayed in the picture - in the direction shown by the

arrows. The forks of the forklift truck must also be placed

in the direction shown by the arrows.

Larger types of acoustic enclosures are equipped with

lifting-eye nuts. If crane handling of the hoods is

impossible, they can be handled with a forklift truck. When

handling the enclosure with a forklift truck, you must put

baulks on the truck forks (where the enclosure is placed) in

order to prevent damage to the enclosure. The enclosure

can also be disassembled into individual parts and then

reassembled at the place of installation. The following

pictures show the handling of acoustic enclosures.

With a compact uni

Motors

The handling of motors is described in the motor manual.

For handling, motors are usually equipped with eye screws.

Rietschle Thomas GmbH + Co. KG page 4 / 23

Page 5

2.3 STORAGE

R

R

R

CONDITIONS

3. INSTALLATION AND ASSEMBLY

3.1 ASSEMBLY

CONDITIONS

3.2 SPACE

NECESSARY FO

INSTALLATION

AND OPERATION

3.3 REQUIREMENTS

FOR ANCHORING THE

BLOWER SET O

BLOWE

1) 2) 3)

The blower set must be stored in its original packaging in a

dry place and must be protected against dust. Compact

units in the acoustic enclosure intended for outside use can

be stored in the open air. If the blower set has been stored

for more than six months, you should (re)preserve it. For

this purpose, you can use standard preservative agents.

Storage conditions:

Temperature: -30 °C up to 40 °C

Relative humidity: up to 80%

Assembly in the Open Air

To install the blower set (the set including the enclosure) in

the open air, you must consider the local conditions (snow,

possibility of flooding, etc.)

Service passages and the space necessary for the set

assembly in the machine hall are shown in Appendix 3.

Acoustic enclosures designed for outside use also serve as

weather protection.

Assembly in the machine hall

The minimum dimensions of the machine hall are based on

the maximum dimensions of the compact unit (acoustic

enclosure) and the necessary 1-metre (better 1.2-metre)

operation space at the sides of the blowers (enclosures) and

between the blowers (enclosures). They are further based

on the 1.2-metre space between the wall of the discharge

section at the acoustic enclosure and the wall. The machine

hall height depends on the method chosen for handling the

machine(s).

When designing the machine hall, you must remember the

openings for the blower sets (the delivered sets are

normally assembled). The acoustic enclosure are

demountable. You should consider equipping the machine

hall with an overhead track for a crane crab or leaving

enough space for a forklift truck in order to handle those

blower sets to be maintained or repaired (necessity to

dismantle the blower and/or motor if a failure has

occurred).

The space necessary for installation of individual types of

SHARK blower sets can be derived from the dimensions

stated in the dimensional drawings.

The floor designed for installation must be flat and

dimensioned for the machine weight and anchor length.

With respect to the loading capacity, no special

requirements are stipulated for the floor design since both

the blowers and motors are dynamically balanced. The

mechanical oscillation power of the blowers and motors are

stated in Tables 3 and 4. The weight of the blower set is

distributed between its individual bases. The weight of the

delivered blower set is stated in its appropriate dimensional

drawing.

The blower set must be positioned horizontally by placing

plates under the machine bases. The permitted deviation is

1 mm for 1 metre.

WARNING

After being set in its position, the blower set must

be anchored to the floor. Otherwise, it could move

spontaneously and thus be damaged.

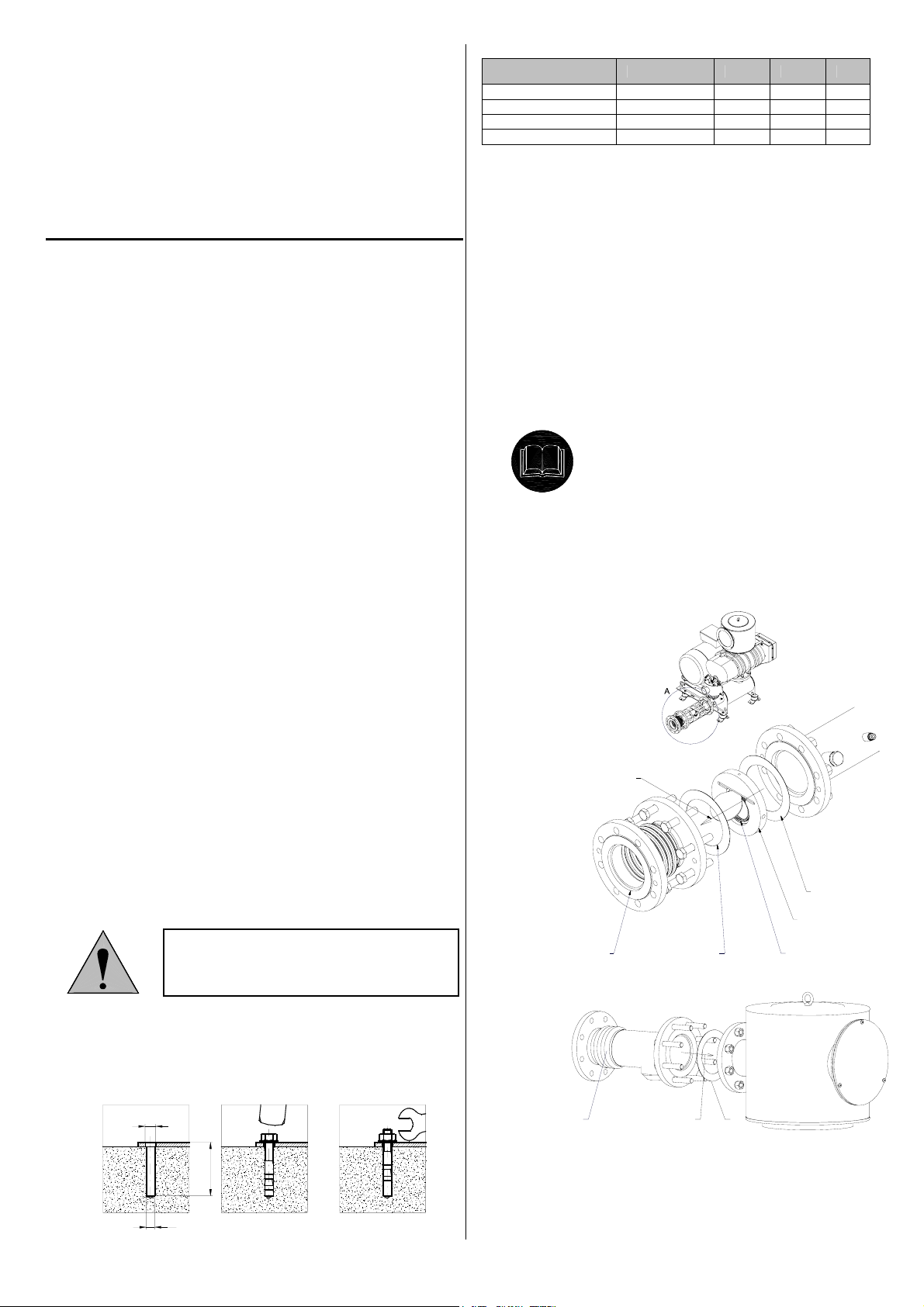

Working procedure for anchoring compact units and

acoustic enclosures.

1. Drill a hole and clean it;

2. Stick the anchor into the hole; and

3. Tighten the nut.

OD

L

OD1

Compact unit –

acoustic enclosure

Anchor OD [mm] OD1 [mm] L [mm]

WPB/WVB 120 – 430 Upat EXA M 8K 9 8 40

WPB/WVB 550 – 8300 Upat EXA 12/15 13 12 90

K 42 - K 202 Upat EXA M 8K 9 8 40

K 302 - K 802 Upat MC 12/70 13 12 65

The space and diameters of the base holes are stated in the

enclosed dimensional drawing of the compact unit. The

procedure for anchoring acoustic enclosures is the same.

You should, however, pay attention to the tightness of the

gap between the hood and the floor. After setting the hoods

in their positions, you must also level any floor unevenness

in order to prevent the sidewalls from being tight. In order

to seal the gap between the hood and the floor, you can

apply polyurethane foam, for example. The electric cable

must be laid in the floor.

If you intend to put a blower set in the hood on a half grid,

you must order a non-standard enclosure because the

bottoms of the acoustic enclosures are not soundproof.

Connecting the pipeline to the SHARK compact unit

3.4

EQUIREMENTS

R

FOR CONNECTING

THE PIPELINE

Since the entire aggregate is placed on rubber dampers, the

pipeline must be connected through flexible elements.

Otherwise, the running blower could shake the pipeline,

thus increasing the noise level. Standard compact units are

delivered with compensators for connection of the

discharge section. If a SHARK blower for vacuum is been

required or intended to be connected to the central suction,

a compensator for connection of suction is also supplied.

Delivered compensators and valves of larger blower sets

supplied with acoustic enclosures (from the K 302 type) are

not installed. These parts must be installed behind the

outlet flange of the discharge silencer or also in front of the

inlet flange of the suction silencer according to the

following pictures:

Overpressure WPB:

F

3

TOP

TOP

4

1

4

2

Overpressure WPB - central suction:

3

4

F

F Air flow

1. Non-return valve

2. O-ring

3. Compensator

4. Sealing

Rietschle Thomas GmbH + Co. KG page 5 / 23

Page 6

Vacuum version WVB:

3

3

F Air flow

1. Non-return valve

2. O-ring

3. Compensator

4. Sealing

41 2 4

F

F

4

While overpressure blower sets contain discharge pressure

gauges, vacuum blower sets contain suction pressure

gauges. If either a non-standard blower set or a separate

blower is delivered, a pressure gauge must be installed on

the pipeline as near the discharge flange of an overpressure

blower set/blower or the suction flange of a vacuum blower

set/blower as possible.

Due to gas pulsation, it is necessary

to use pressure gauges resistant to cyclical fluctuations in

the pipeline pressure, for example glycerine-charge

pressure gauges. If you use an ordinary pressure gauge, an

absorber must be installed between the pipeline and the

pressure gauge. After setting the blower set in its position,

you must open the plugs of the glycerine-charge pressure

gauges in order to de-aerate them. Otherwise, they will

indicate incorrect values! If a blower set with a acoustic

enclosure is delivered, once it has been set up it is

necessary to interconnect the pressure gauges installed on

the enclosure and the measurement points on the blower set

with the supplied tubes.

For overpressure blower sets: the point on the blower’s

suction flange located below the suction filter must be

interconnected with the button connected to the pressure

gauge that is designed for measurement of filter insert

clogging. Further, the point on the discharge silencer must

be interconnected with the glycerine-charge pressure

gauge.

For vacuum blower sets: the point in front of the suction

filter must be interconnected with the pressure gauge

installed on the hood.

Connecting the Pipeline to the SHARK compact blower

You must ensure that the intake medium is free of

impurities.

Blowers could suck in outside air. Equipping the blower

with a suction filter produced by RT will suffice in order to

ensure purity of the intake air.

If a pipeline is to be used for transport of air to the suction

part, it is suitable to equip the blower with a RT suction

filter (used for vacuum blower sets) in order to connect the

pipeline. It is also necessary to install a compensator

between the suction filter and the pipeline.

If the intake air is filtered centrally for more blowers, you

must carefully clean the suction pipeline of foreign

particles. A compensator must be installed between the

blower and the suction pipeline. It is suitable to use a

suction sieve installed as near to the blower’s suction

flange as possible for the first 500 operating hours. Suitable

sieve densities can be derived from the following table,

which provides permissible sizes of impurities for

individual blower types:

It is not permissible to load the blower sockets with the

pipeline. Before being bolted together, the flanges of the

pipeline and the blower must fit closely. The maximum gap

in the gasket circumference can be 0.05 mm, as shown in

the picture.

3.5 INSTRUCTIONS

FOR CONNECTING

THE BLOWER SET TO

THE POWER SUPPLY

Blower WPB /

WVB

Permissible

impurity size [mm]

0,05

After the flanged connections have been tightened, the

blower must spin smoothly!

Rules for connecting the pipeline:

• The pipeline must be installed in the compensator axis.

• The pipeline must be placed on both fixed and sliding

points. It is not permissible to load the compensator with

the pipeline weight. The first fixed point of the pipeline

must be as near to the compensator as possible.

• The pipeline diameters should not be smaller than the

nominal inside diameters of the blower flanges.

• The recommended flow speed in the pipeline should be

below 22 m.s

-1

.

• If possible, large radii of pipe bends should be used (in

order to reduce loss).

• The closing fittings must be installed near the branches

in order to prevent impurities from accumulating in the

blind pipeline branches.

• Hot (discharge) pipelines should be insulated.

• The wall openings should be flexible and the pipeline in

them should be soundproofed (do not cement the

pipeline in the openings).

• Compensators should be installed on long and branched

pipelines.

• You should avoid the pipeline running perpendicularly

into the registers. You should check the lengths of those

registers where standing waves could occur for the

excitation frequencies of sextuple blower revolutions

(the frequency of the air pulsations).

When designing pneumatic transport, cement clarification,

and similar applications where contaminated transported air

(the volume between the non-return valve and the

technological device) could expand after the blower has

been turned off, you must consider such applications or

ensure that the pollutants are separated when the air is

flowing back (the mechanical non-return valves do not

close immediately). Contact RT in these cases.

Warning: Only authorized persons with appropriate

electrical qualifications are allowed to connect electrical

devices.

Blowers, compact units, acoustic enclosures and electric

motors are equipped with earth lugs. The protection of the

standard blower set is determined by the electric motor

protection (IP 55).

The wiring must meet the requirements for machinery in

accordance with the 98/37/ES Directive and primarily the

requirements stipulated in the EN 60204-1 Standard. Such

requirements must be ensured by the electric part supplier.

The standard deliveries of the RT blower sets contain only

the electric motor terminals. If the delivery also includes

the control system, only the power cable (if not included in

the delivery) must be installed and connected. More

detailed instructions are given in the separate manual for

the control unit.

The supply cable must not restrict the movement of the

motor and its pendulous frame!

Electric motors should be connected in accordance with

300

400

780

120

430

550

750

0.01 0.05 0.07 0.09 0.1 0.2

1000

1300

1600

2000

3000

4000

5000

6500

7000

8300

recommendations from their Manufacturers. The

connection diagram is attached to the inside of the cover of

the electric motor’s terminal block. We recommend starting

Rietschle Thomas GmbH + Co. KG page 6 / 23

Page 7

3.6 BELT

INSTALLATION

the electric motors in the star-delta connection (soft-start,

etc.) even when the user could connect high-power electric

motors directly (in the delta connection). The “soft” start

saves the blower.

Electric motors with power of over 11 kW must

not be started directly (in the delta connection)

without approval from the blower’s

manufacturer.

The electric motors of the compact units with

acoustic enclosure must be connected so that they

cannot be turned on if the electric motor fans in

the acoustic enclosure are not running – the fans

must exhaust air from the enclosures. Appendices

9 and 10 show the connection diagrams.

Due to transport of blower sets, the delivered belts are not

installed and the pendulous frame with the motor is secured

by bolts in the bottom position. Belts can be put on only

when the blower set has been set in its position. You must

first remove the bolts securing the pendulous motor frame

in the transport position. In order to lift the frame, you must

use a jack with the appropriate lifting capacity. An arrow

shows the point to place the jack. For smaller blower sets

(up to the size 2000), it is sufficient to use a screw jack

with a lifting capacity of 700 kg (the type used for lifting

private cars). For larger blower sets [from the size 3300

with motors from the 280 type (axial height in

millimetres)], you must use a jack with a lifting capacity of

2,000 kg, preferably a hydraulic one. The jack must be

placed on a solid base. If the jack is placed on a smooth

surface, such as a pavement or painted surface, you must

secure it with a rubber pad, for example, in order to prevent

it from slipping. Before starting any operation, you must

prevent the lifted pendulous motor frame from falling by

using suitable supports.

On the inside of the frame sidewall below the pendulous

motor frame, you must then install a stop checking the

lower limit of the pendulous motor frame misalignment.

Before putting on the belts, you must screw the stop bolt

into its bottom position.

When putting on the belts, be very careful you do

not injure yourself by a suddenly falling

pendulous motor frame that might come loose.

You must hold the belt only at the place that will

not be in contact with the pulley when the

pendulous motor frame has been lowered. It is

also forbidden to touch the blower set at the

places between the edges of the sub frame and the

pendulous motor frame, where a cutting effect

will occur when the pendulous motor frame is

moving.

WARNING

WARNING

P

RECAUTIONARY

MEASURES

3.8 MACHINE HALL

VENTILATION

Before putting on the belts, you must remove the supports

securing the pendulous motor frame in the lifted position.

When gradually lowering the pendulous motor frame, you

must ensure that the belts remain in the pulley grooves.

Since the pendulous motor frame is secured in its working

position only by tightened belts, you must therefore prevent

it from sudden loosening (with a jack, for example) before

adjusting the stop. The stop bolt must be adjusted to a

sufficient height so that the pendulous motor frame does

not hit it when the motor is starting. When new belts are

being installed, it is better to leave a larger gap between the

stop bolt and the pendulous motor frame as the frame will

lower after the belts have been set in their positions.

3.7

• The machine owner is obligated to observe the

provisions of this manual.

• The machine owner is obligated to maintain the

minimum spaces stipulated in this manual.

• The machine owner is obligated to see to good

readability of safety labels and markings.

• The machine owner is obligated to provide operators

with the protective equipment stipulated in this manual.

Machine hall ventilation

The machine hall is warmed by the heat radiated from the

motors, blowers, discharge silencer and discharge pipeline.

In order to reduce the machine hall temperature, the heat

must be suitably dissipated (machine hall ventilation). If

the output temperature is high, it is necessary to insulate the

outlet pipeline. In most cases when blower sets suck air

directly from the machine hall, you must ensure forced

ventilation of the machine hall.

It is not permissible to direct flow of cool air

towards any part of the blower casing. Local

cooling causes thermal deformation – the blower

could thus be damaged.

Appendix 8 shows the ventilation diagram. When

designing the machine hall, you must remember sufficient

openings for both cooling air intake and warmed air

exhaust. It is assumed that the fans will be located in the

exhaust section. Cooling air intake for the blower suction

from the machine hall must be designed so that sufficient

volumes of both cooling air and air sucked by the blower

set are ensured. If the intake air is transported from outside

by a pipeline, it will suffice to dimension the inlet opening

only for the cooling air volume and fit the exhaust section

with fans of the required capacity. The air speed in the

openings should range between 5 m.s

suction and exhaust openings must be designed so that no

noise will escape from the machine hall.

WARNING

-1

and 10 m.s-1. The

Rietschle Thomas GmbH + Co. KG page 7 / 23

Page 8

4.1 BLOWE

R

R

N

DESCRIPTION

4.2 BLOWE

SET

DESCRIPTION

4. MACHINE

The RT SHARK-compact units sets are fitted with RT base

units of the Roots type with three-tooth rotors.

The Rietschle Thomas Roots blowers work on the principle

of oil-free gas transport. These blowers are the most

widespread type of two-rotor blowers. The axes of the rotor

rotation are parallel. A synchronizing gear, both of whose

wheels have the same number of teeth, moves the rotors.

The synchronizing gear ensures contact-less movement of

the rotors. The rotors turn against each other. Both the

suction and discharge sockets run between the rotor axes.

The blower transports gas without increasing the pressure.

Gas is compressed in the discharge socket by the gas that

has already been transported (blowers with external

compression).

The rotor seals of the standard blower types are not subject

to wear. Since the seals do not ensure absolute tightness of

the blower, the oil levels in the covers must not exceed the

stipulated limits. Otherwise, oil could leak into the

blower’s working space or outer space. In order to

prevent oil from leaking during transport and/or

handling of the blower, you must fill oil before putting

the machine into operation.

Blower Drive

Blowers are mostly driven by electric motors. A belt drive

normally transfers the torque from the motor shaft to the

blower shaft. The blower shaft is a part of one rotor.

Blower sets are shown in the dimensional drawings of the

individual types that are enclosed with this Manual.

The main parts of the blower sets are:

• A suction filter - a resonance silencer with a filter insert.

• A discharge silencer - a welded construction of the base

frame and the vessel. It serves as a supporting element

for the blower and is also designed to suspend and

secure the pendulous motor frame.

• A pendulous motor frame - it is suspended by pins in

the silencer frame. It enables the belts to be tightened by

tipping the motor.

• A non-return valve – an inter-flanged type. The non-

return valve of the overpressure machine type is

installed at the discharge section while that of the

vacuum machine type is installed at the suction section.

• A safety valve - it serves as overload protection of the

blower.

a) Overpressure version: if the valves are opened, air

(gas) is released into the atmosphere. Directly

controlled, HEROSE spring valves are used in smaller

blower sets. Their opening pressure is set by spring bias.

Larger types of blower sets are protected indirectly by

controlled combined safety and starting valves (see the

PVO valve description for more detail information).

b) Vacuum version: if the vacuum set by the spring has

been exceeded, the seat will lift and air will be sucked

from the atmosphere into the suction pipeline. The used

valves are directly controlled and spring-operated. Their

opening pressure is set by spring bias.

• A compensator - metal bellows.

• An electric motor - a bottom, fixed-speed or two-speed

electric motor.

• A belt drive with V-shaped or toothed belts.

• A belt guard - it is made from common constructional

steel.

The standard blower sets in acoustic enclosures are

not equipped with a belt drive guard because the

enclosure itself protects the drive.

• Bases with rubber dampers - they minimize transfer of

vibrations to the bases.

• A visual indicator of suction filter clogging. For

blower sets in acoustic enclosures, a pressure gauge is

used instead of the indicator.

• A discharge overpressure gauge or a suction vacuum

gauge.

4.3 PVO

COMBINED SAFETY

AND STARTING

VALVES

4.3.1

S

TARTING

VALVE

FUNCTION

4.3.2 SAFETY

VALVE

FUNCTION

4.4

OISE-

DAMPING

HOOD

• Optional accessories:

a) A suction pressure gauge, or an electric indicator of

filter clogging instead of the visual indicator.

b) An electric motor. You can choose a fixed-speed or

two-speed motor or a type of motor where a frequency

converter changes the motor revolutions.

• Special accessories:

a) A acoustic enclosure for inside or outside installation.

b) Pressure and temperature sensors.

c) An auxiliary discharge silencer of the vacuum blower

set. It (usually with a acoustic enclosure) serves to

reduce noise made by air being released into the blower

set’s surroundings.

Functions

The PVO combined valve has two functions. When the

blower is starting, the valve gradually increases the air

pressure, thus increasing the torque – starting valve

function. When the blower is in operation, the valve

protects it against overload (against pressure increase over

the permissible limit) – safety valve function.

Valve description

The numbers of the main parts correspond to the numbers

of the positions shown in Appendix 4 (PVO combined

valve assembly): control valve (1), mobile base (2), bottom

base (3), top base (4), bellows flange (5), hose (6), guide

rod (7), bellows (14), and springs (15).

If there is no pressure, the main valve is open – the springs

(15) lift the bottom base (3). When the blower is starting,

pressure is generated in the gap between the seat and the

disc. The control valve will feed the pressure into the

bellows. As the bellows area is larger and the bellows

power is higher than those of the seat, the bellows will

close within several seconds due to gradually increasing

pressure, thus enabling the blower to start with the load

increasing fluently. The bellows must simultaneously press

the springs (those ensuring that the unloaded valve will

open). If the unloaded valve were closed, it would not serve

as a starting valve. By removing the springs, you could

disengage the starting valve function.

By installing a solenoid valve (a special design), you could

control the blower’s start-up time electrically. When the

electromagnet of this valve is turned on, the inner space of

the bellows is interconnected with the atmosphere and the

main valve is open.

During normal operation, i.e., after the blower has started,

the main valve disc is closed. The control valve

interconnects the spaces of the outlet pipeline and the

bellows. If pressure exceeds the adjusted limit, the control

valve will release it into the atmosphere. This will result in

reducing the pressure in the bellows and opening the main

valve disc. After the pressure has dropped, the control

valve will stop releasing the pressure into the atmosphere,

thus increasing the pressure in the bellows and closing the

main valve disc.

Acoustic enclosures serve to reduce the blower set noise.

Acoustic enclosures are steel with absorption damping

material. The enclosures are equipped with fans ensuring

forced ventilation. The intake and exhaust openings for

cooling air are fitted with silencers. During forced

ventilation, the fan exhausts air out of the enclosure. The

enclosures enable the machine to be installed both outside

and in the machine hall. The types of outside enclosures up

to K 552 differ from the inside enclosures only in their

finish. The K 802 outside enclosures also have small roofs.

You can find the dimensions of the appropriate enclosure

types in their dimensional drawings.

CAUTION

Forced acoustic enclosure ventilation does not

replace machine hall ventilation.

Rietschle Thomas GmbH + Co. KG page 8 / 23

Page 9

4.5 USE

K

S

S

R

R

R

4.5.1 WOR

4.5.2 SUCTION

AND DISCHARGE

TEMPERATURES

4.5.3 SUCTION

AND DISCHARGE

PRESSURES

4.5.4 LUBRICANT

SPECIFICATION

Oil charge volumes

Type WPB / WVB

120

300, 400

430, 550, 750

780, 1000, 1300

1600, 2000

3300

4000, 5000

6500, 7000, 8300

4.5.5 MAXIMUM

TEMPERATURES OF

THE LUBRICATING

4.5.6 MAXIMUM

4.5.6.1 PULLEY

REVOLUTIONS

4.5.6

MEDIUM SPEED

4.5.7 NECESSARY

4.5.8 WARNING

AGAINST USE IN

THE EXPLOSION-

ENVIRONMENTS

MEDIA

SYSTEM

PEED

.2 WORK

SAFETY

EQUIPMENT

HAZARD

Blowers are used to transport and compress gases. Since

the rotors neither touch each other nor are in contact with

the casing, blowers are suitable for oil-free transport and

gas compression. During transport, media are not

contaminated with either abrasion particles or oil.

Standard blowers are designed to compress or exhaust air

or non-aggressive and non-explosive gases. If you may

need further assistance in using the blower with special

gases, please contact Rietschle Thomas.

Suction and discharge temperatures depend on the

compression degree. Both temperatures are stated in the

calculation of the blower set parameters. Such calculations

are included in the offers of the blower sets. In standard

blowers, the maximum temperature of the discharged

medium is 140 °C. In order to prevent the temperature from

exceeding the limit value in the discharge section (even

during the highest medium compression), the intake

medium temperature must be below 40 °C.

The suction and discharge pressures are stated on the type

plates of the blower sets and in the calculations of the

blower set parameters. The maximum permissible

differential pressure is stated on the blower type plates. The

pressure at the blower’s discharge flange is referred to as

, the pressure at the blower’s suction flange is referred to

p

v

, and the pressure at the flange that connects the

as p

s

blower set with the pipeline system is referred to as p

.

3

The following table provides oil charge volumes for

blowers:

Oil charge

Drive side

[l]

0.07 0.1 0.17

0.1 0.15 0.25

0.2 0.45 0.65

0.55 0.7 1.25

0.75 1.4 2.15

1.5 2.75 4.25

1.4 2.6 4

5 6 11

Gear side

[l]

Total

[l]

The prescribed oil is fully synthetic motor (automotive)

oil, Rietschle Thomas GEAR LUBE 150:

Use of different oils (e.g., for applications in the foodprocessing industry) must be consulted with Rietschle

Thomas.

Electric motor lubrication is described in the enclosed

electric motor manual. There are no other lubrication places

in the blower sets.

The maximum temperature of the oil charges must not

exceed 120 °C (standard stabilization of the blower

bearings).

The maximum revolutions of the pulleys correspond to

those of blowers.

The used designs of the pulley guards or the acoustic

enclosures are tough enough to withstand any damage

(break-off and/or tear) caused by broken belts.

- The speed in the openings for intake and exhaust of air

from the machine hall: between 5 m/s and 10 m/s;

- The recommended speed in the pipeline: 22 m/s;

- The maximum speed in the discharge pipeline: 35 m/s;

and

- The maximum speed in the suction pipeline: 30 m/s.

If the delivery contains no blower discharge pressure

gauge, you must install it on the discharge pipeline. The

used pressure gauge must be glycerine or with an absorber

in order to ensure reliable functioning.

WARNING!

Blowers of standard types are not designed for

use in explosion-hazard environments!

ECOMMENDATIONS

R

FOR OPERATION AT A

TEMPERATURE OF 0

AND LOWE

°C

4.5.10 APPLICATION

4.5.9

FIELDS FOR BLOWERS

AND BLOWER SETS

4.5.11 ELECTRIC

EQUIPMENT DATA

4.5.12

C

ERTIFICATE OF

CONFORMITY

5. OPERATING THE MACHINE

5.1 INSPECTION

PRIOR TO FIRST

TURNING ON THE

BLOWER SET O

BLOWE

The minimum ambient temperature when the blower set

operation is still stable is -20 °C. Nonetheless, blower sets

can be operated for a short time at a temperature as low as

-30 °C. Such restrictions apply particularly to the belts,

standard types of electric motors, and PVO valves. The

blower set contains no water cooling. The minimum

volume of condensate that builds up in the discharge

pipeline cannot affect the blower set operation.

Wastewater Treatment Plants

- Increasing the volume of oxygen in water and keeping

bacteria above the surface; and

- Ventilating activated

sludge and detritus tanks in

wastewater treatment plants.

Pneumatic Transport

- Transporting all kinds of loose materials, granules, and

variously-grained materials.

Other Applications

- Backward rinsing of filters in water treatment plants;

- Release of material from silos (storage tanks);

- Clarification of loose materials and mixtures;

- Vacuum transport;

- Exhaust of air from various equipment systems at an

absolute pressure of up to 500 mbar; and

- Supply of process air at a pressure of up to 1000 mbar.

The standard deliveries of blower sets contain no wiring or

control units. The basic data about the installed electric and

electronic devices are stated on their type plates and in their

accompanying documentation (manuals, connection

diagrams, etc.). The electric part supplier must ensure

conformity with the requirements of the appropriate

standards. The requirements for of equipment with electric

motors, the nominal current of which is below 16 A, were

not verified because the emission of such equipment

depends on the installation and properties of the equipment

complex where the equipment is used. If the delivery

contains a switchboard with a control unit, the unit’s basic

data are stated in separate operating instructions.

A Declaration of Conformity in accordance with the Czech

Republic’s Act No. 22/97 Coll. and the European Union

Council’s Directive No. 98/37/ES is enclosed with this

Manual.

For at least the guarantee period, you must keep

an operating diary where you record operating

dates, maintenance, inspections, and repairs.

Keeping the operating diary during the guarantee

period is a precondition for accepting guarantee

claims. This applies particularly to the checks

stated in Tables 5 and 6.

Since acoustic enclosures have the same function

as belt drive guards during machine operation,

standard blower sets placed in acoustic enclosures

are not equipped with these guards. Only

authorized persons whose familiarization with the

risk of touching rotating parts can be proved are

allowed to execute operations that are directly

related to putting the blower set into operation,

and those operations that must be performed

when the acoustic enclosure during blower set

operation.

Installation Inspection

- Check the installation of the machine and attachment of

the anchoring bolts;

- Check proper installation of all parts that could be left

unattached during installation. Check especially those parts

that could endanger the operators if they were not attached

and/or installed; and

Rietschle Thomas GmbH + Co. KG page 9 / 23

Page 10

CHANGING

K

R

R

5.2 FIRST

TURNING ON THE

BLOWER SET O

BLOWE

- Check all valves in the discharge pipeline whether they

are open.

Connecting elements

- Check whether all connecting elements are installed and

tight.

Filling with oil

Blowers are transported without oil. The approximate

volumes of oil charges and the recommend types of oil are

stated in Table 1 and Table 2 respectively (Chapter 4.5.4).

On no account should oils be mixed! See Chapter 5.5.1 for

more information.

Movement inspection

Check whether the blower moves smoothly (turn the pulley

slowly with your hand).

WARNING!

You might be hurt when turning the pulley. You

must hold the pulley at the places of contact with

the belt **).

Dmychadlo

*

*

Motor

Be careful you do not crush your fingers!

Pipeline Inspection

Check whether the suction and discharge sides are clear.

Inspection of the direction of rotation

Turn the blower on for no more than 1 second. If it were

turned on for a longer time and the direction of rotation

were incorrect, the blower could be damaged. The blower

drive must turn in the direction indicated by the arrows.

FORBIDDEN!

Backward running will damage the blower.

FORBIDDEN!

Do not turn the blower on again when it is still

running down. Otherwise, it could be seriously

damaged (the blower must be turned on only

when at a standstill).

Take care the following steps:

• Open the acoustic enclosures (if installed).

• Turn on the electric motor. Check the position of the

stop bolt (the pendulous motor frame must not hit the

bolt).

• Check the functioning and adjustment of the safety

valve when the machine is in operation.

• After approximately 1 minute, check the operating

pressure. When the specified pressure is reached, turn

off the drive unit.

• Observe the blower running down. The blower must

run down smoothly, without impacts and/or sudden

stop.

• Check whether the direction of fan rotation is correct -

air must flow from the opening above the top wall of

the noise-damping hood.

Safety valve functioning inspection

You should check the functioning of the safety valve and

the mobility of the sealing cone during operation, at a

pressure of 80% (or higher) of the opening pressure. If

HEROSE valves are used in smaller blower sets, it is

necessary to check the cone mobility. You must unload the

cone by loosening the knurled nut in the valve body cover.

You must turn the nut until it moves with difficulty, then

turn the nut a further approximately 180°. The cone will be

unloaded and the safety valve will start releasing air. Then

you must tighten the nut again. Larger blower sets are

equipped with safety valves with control valves. After one

end of the hose has been disconnected from the control

valve, the “bellows” space will open into the atmosphere

and the valve will open automatically. After re-connecting

the hose, you must check the joint for tightness (for

example, with soapy water).

5.3 TRIAL

OPERATION

• Check, monitor and document the operating pressure

and temperature;

• Monitor the noise level and vibrations when the blower

set is in operation;

• Check the temperature on the blower surface for local

overheating; and

• Check the state and volume of oil in the oil level gauges.

Table 3 – Maximum oscillation power of blowers

Blower revolutions [1.min-1]

WPB/WVB

Oscillation

power

[mm.s-1]

Note: The power of blower mechanical oscillation is in accordance with the ČSN ISO 3945 Standard.

*

*

120 300 400

5000 6000 5600 5500 5250 5250 4600 3000 3500 3000 2600 2200 1850

< 2 < 3 < 3 < 4 < 4 < 5 < 5 < 6 < 7 < 7 < 8 < 8 < 9

430

550

750

Type

780

1300 1600 2000 3300

1000

4000

5500

Table 4 – Maximum oscillation power of electric motors

ELECTRIC MOTOR

Type 56 - 132 160 - 225 250 - 280 315 - 355

Category N R N R N, R N R

No. of poles 2,4,6,8 4,6,8 2 2,4,6,8 4,6,8 2 4,6,8 2 2,4,6,8 2,4,6,8

Oscillation

power

[mm.s-1]

Note: The power of electric motors’ mechanical oscillation is in accordance with the ČSN ISO 35 0000

< 1.8 < 0.71 < 1.12 < 2.8 < 1.12 < 1.8 < 4.5 < 4.5 < 4.5 < 1.8

Standard, Part 14 (IEC 34-14), Category N – normal, Category R – reduced.

If the values stated in Tables 3 and 4 are exceeded, you must contact the RT service department!!!

5.3.1 CHEC

INTERVALS FOR THE

TRIAL OPERATION

- During the first two operating hours, a permanent

operator records values in a report every 15 minutes.

- During the next two operating hours, the permanent

operators record values in the operating diary every 30

minutes.

- During another eight operating hours, the permanent

operators hourly record values in the operating diary.

5.4

E

MERGENCY

STOPPING

CONTROLLERS

No emergency stopping controllers are normally delivered

with the RT compact units. The electric part supplier is

required to ensure their installation.

5.5 SETTING

ADJUSTMENT

INSTRUCTIONS

5.5.1 FILLING AND

THE OIL

AND

The blower has two separate oil charges.

Oil is filled through the filling holes in the tops of both

covers. After removing their caps, you can pour in oil. You

should use a funnel so that oil will not leak uncontrollably

into the surroundings, stain the belt drive, etc.

Oil is discharged through the drain holes in the cover

bottoms. Used oil must be drained into sufficiently large

tanks. After removing the drain hole cap, you must also

remove the filling hole cap so that oil can drain freely into

the tank and a vacuum cannot build up when oil is being

discharged. You must visually check the used oil whether it

does not contain metal particles or metal dust. The presence

of such substances might indicate the initial stage of

malfunction of either the bearings or the gear. In such

cases, you must contact the RT service department.

The blower can be refilled with oil only when all the

remaining oil has drained away and the drain hole cap is

closed.

6500

7000

8300

Rietschle Thomas GmbH + Co. KG page 10 / 23

Page 11

5.5.2 REPLACING

THE

FILTER INSERTS OF

THE SUCTION FILTER

5.5.3 PULLEYS AND

BELT TENSION

While the maximum oil level is in the middle of the oil

level gauge, the minimum level is 3 mm lower. The oil

level measured when the machine is turned off must be

maintained within these limits. When the oil level has

reached the minimum, you must immediately top up with

oil. Top up with oil carefully so that its level will not be

above the middle of the oil level gauge. Otherwise, oil

could leak through the release openings or into the blower

when the machine is in operation.

Depending on the operating conditions, the blower oil

temperature could exceed 100 °C. Thus, you must

drain and top it up with oil when it is cool!

Otherwise, you could burn yourself.

Greases (motor):

The bearings of the smaller standard electric motors are

lubricated by a permanent grease charge. The bearings of

the larger electric motors must be greased. The greasing

procedure is described in the directions for motor use.

Increased underpressure in the blower’s suction part

indicates suction filter clogging (indicated by a red strip in

the filter clogging sensor). If a pressure gauge is used

instead of the filter clogging sensor, the working section

and the state of increased underpressure are marked in

green and red respectively. If the filter is clogged, you must

replace its filter insert. You can order filter inserts; their

part numbers are stated on their flanges or in the Certificate

of Completeness and Quality.

After replacing the filter insert, you must release (by

pressing) the mechanical catch of the filter clogging sensor

so that the red strip indicating increased underpressure will

disappear.

Pulleys

The standard blower sets are equipped with V-belt drives.

Taper Lock bushings transfer the torque from the pulleys to

the shafts.

Taper lock clamp bushings –

Disassembly and assembly

Disassembly procedure

Loosen and remove all bolts. Screw bolts onto the releasing

threads. Tighten the bolts evenly (gradually tighten the

bolts opposite one another) until the clamp bushing is

released from the pulley.

Releasing thread

1/2 thread

Releasing threads

1/2 thread

V-belt Maintenance

Belts are tensioned depending on the transferred output.

During operation, the optimum belt tension is ensured

automatically by tilting of the pendulous motor frame. The

tilt of the pendulous motor frame is limited by the stop bolt

(see Chapter 3.6). After the belts have been lengthened,

you must readjust the bolt so that the pendulous motor

frame will not hit it when the motor is starting.

The belt drive parameters (the sizes and types of pulleys

and the number and sizes of belts) have been designed and

optimized for the required gear ratio and transferred output

so that the V-belts will be maximally employed. If any

functional drive belt is missing, you must always put on

the belt drive a new set of belts of the same type and

size. You must always use belts with a guaranteed

peripheral speed of 50 m.s

-1

! You can find the type and

length of belts in the Certificate of Completeness and

Quality.

Long operating life of the designed belt drive is assured if

all conditions for regular maintenance are observed and the

replaced belts are the same as those originally designed by

Rietschle Thomas.

The parallelism of the shafts of both the blower and the

motor and the alignment of the pulley grooves are ensured

when the machine is being produced. When reassembling

the pulley, you must put it on the shaft so that the faces of

both pulleys are levelled. The maximum permissible

deviation is 0.4% (the maximum gap between the rule and

the pulley is 4 mm per one metre). When reassembling the

motor, you must ensure that the shafts are parallel and the

pulleys are levelled according to the picture:

5.6 RUNNING

WITHOUT

OPERATORS

Securing threads

1/2 thread 1/2 thread

Securing threads

Assembly procedure

Degrease the shaft journals, clamp bushing and pulley

hole. Put the clamp bushing in the pulley. Position the half

threaded hole so that the holes of the bushing and the

pulley fit. Oil the bolts slightly and screw them into the

securing holes. Do not tighten them yet! Put the clamp

bushing together with the pulley on the shaft. Now you can

evenly tighten the bolts with a torque wrench. Tighten them

gradually up to the stated torque (M

). Check the bolts for

s

correct tightening (according to the torque) after the clamp

bushings have been in operation for a short time. Put grease

into the empty threaded holes to prevent dirt from

collecting.

Table 5 – Torques according to the clamp bushing types

Type 1008 1108 1210 1215 1310 1610 1615 2012

M

[Nm]

s

Type 2517 3020 3030 3535 4040 4545 5050

M

[Nm]

s

5.6 5.6 20 20 20 20 20 31

48 90 90 112 170 192 271

Rietschle Thomas GmbH + Co. KG page 11 / 23

Since blowers normally work without operators being

present, they must be protected against overload and/or

sudden failures.

The electrical part supplier is responsible for current

overload protection.

The machine owner must ensure that the machine will not

be overloaded by the safety valve’s being permanently

relieved. This applies mainly to simultaneous operation of

several blower sets (e.g., in wastewater treatment plants)

when one discharge branch is closed but the volume of

supplied air is not reduced to the necessary volume (by

reducing the revolutions or turning off one of the blower

sets). Blower set operation during which the safety valve

releases air for a long time causes pressure fluctuations that

significantly shorten the operating life of both the bearings

and the non-return valve. They might also damage the

blower.

In order to ensure thermal overload protection, it is suitable

to arrange electrical control of the permissible temperatures

of both the discharged air and the surroundings (a thermal

sensor connected to a signalling device or machine

stopping).

Page 12

5.7 PLATES

AND LABELS

USED ON BASE

UNITS AND

COMPACT UNITS

Plates and labels on base units and compact units:

Base unit, compact unit and sound enclosure plate

The following cardboard label is hung on the suction

sensor, pressure gauge or blower itself (if delivered

separately):

TRANSPORTED

WITHOUT OIL

The correct direction of rotation is indicated by the

following arrow placed on the blower cover (near the shaft)

and the belt guard:

In accordance with the EN 1012 Standard, the following

labels are placed on the blower and blower sets (according

to their types):

- C1 Order: Read the Directions for Use

- C2 Required activity: Order to wear ear protectors

- C7 Warning: High temperature risk

- C19 Oil filling

5.8

NSTRUCTIONS

I

FOR TRACING

SIMPLE FAILURES

- C 21 Suspension point

- Plate - warning

- “ATTENTION“ red plate.

On the suction silencer or the acoustic enclosure.

- “ATTENTION: CUTTING EDGE“ plate.

On the sub frame of the blower set, below the pendulous

motor frame.

Blower operation failures can be divided into two main

categories:

- Mechanical failures (bearings, toothed wheels, rotors,

etc.); and

- Electrical failures (faulty drive, wiring, contactors, fuses,

etc.).

If any electric failure occurs, you must notify the specialists

authorized to repair such failures.

If you are unsure about the correctness of your procedure,

call the Rietschle Thomas service department.

Rietschle Thomas GmbH + Co. KG page 12 / 23

Page 13

LIST OF POSSIBLE FAILURES AND METHODS FOR REMOVING THEM

FAILURE POSSIBLE CAUSE REMOVAL

The machine will not start Electrical part failure

Oil leaks through the ventilation openings High oil level (measured when the

Elevated noise level, the blower makes a

“metallic” sound

High current consumption

pulley

Slipping belt Greasy belt Clean both the belt and the pulleys and degrease them with petrol.

The blower is loaded immediately after

start-up (applies only to blower sets with

PVO valves)

opposite direction when being turned off

The safety valve releases air when the

blower is in operation

The safety valve sucks air when the blower

is in operation

The safety valve will not open when the full

blower load is exceeded

An overheated blower

Low supplied volume

Vibration

*) The cause might lie in a project error, for example. At a specific flow, the pipeline resistance is higher than the overpressure (required when the blower parameters

were being specified). This is usually detected when the blower is first turned on and/or when the projected machines are being put into operation. Another cause

blower is turned off)

Blower rotor knocking, bearing failure or

incorrect setting of the limit clearances

Bearing failure or seizing of the rotors in

their working space

High overpressure in the outlet pipeline Measure the overpressure and remove the cause.

High vacuum Replace the filter inserts.

No oil in the blower High temperature of the cover at the blower

Bearing failure

No oil in the blower High temperature of the cover at the gear

Failure of the bearing or gear

Disengaged starting valve function Set the combined safety and starting valve so that it will be open when

Malfunctioning non-return valve

High overpressure in the outlet pipeline Measure the overpressure in the outlet pipeline and remove the cause *)

Failure of the combined safety and

starting valve

High vacuum in the inlet pipeline Measure the vacuum in the inlet pipeline and remove the cause *)

The safety valve is clogged with dirt

(applies to the Herose valves)

Dirty filter insert Replace the filter insert.

Overload Maintain the load - data.

Large piston clearances Repair by Rietschle Thomas

Incorrectly installed non-return valve Repair the installation. No transport

Slipped or broken belt Belt failure and/or incorrectly set pulleys

Incorrectly dimensioned blower Compare the values with the efficiency table.

Leaky safety valve Check the valve setting and operating pressure.

Slipping belt Check visually the operation of the belt whether it runs without

The rotors touch each other Check the bearings and gear setting.

Damaged bearings Replace the bearings and change oil

Incorrectly aligned pulley and/or

coupling

Loosened bolts securing the motor and/or

blower

Rotor imbalance due to dirt Clean the transport space and rotors.

Check the wiring, contactors, fuses, thermal or other protection, and

cable connection state. Check the state and functioning of the electric

motor.

Drain excessive oil.

Repair by the Rietschle Thomas servicemen

Repair by the Rietschle Thomas servicemen

Repair by the Rietschle Thomas servicemen

Repair by the Rietschle Thomas servicemen

the machine is turned off.

Check the non-return valve and replace if necessary. The blower turns spontaneously in the

Disassemble the pipeline and replace the sealing ring.

The safety valve is set for maximum + 10% of the outlet overpressure.

Remove leakage and dirt from the control valve, and/or replace the

rubber bellows.

The safety valve is set for maximum + 10% of the vacuum.

Disassemble and clean the valve.

Blower failure

vibrations. Check the motor power. Recheck the belt state. Set the lower

possible limit of the pendulous motor frame position lower by adjusting

the stop bolt.

Adjust it/them and tension the belt of the belt drive.

Tighten and adjust them.

Rietschle Thomas GmbH + Co. KG page 13 / 23

Page 14

might be a change in the resistance after the machine has been operated for some time. This is caused by pipeline clogging, clogging of the tanks’ aeration openings

R

in wastewater treatment plants, etc., or by operators’ unfamiliarity (see Chapter 5.6).

5.9 ROUTINE

MAINTENANCE

AND CHECKS

Table 5 – Blower checks

Operating time Check Lubrication

After 400 hours

Blower operation check.

In a dry continental climate, preserve the rotors and cylinders after a

six-week standstill. In a humid climate, preserve them sooner (see

Chapter 2.3).

Check of the oil bath levels.

First change of oil since the machine was

put into operation.

Check of the lubrication discs functioning

After 4,000 2) hours

After 20,000

After 40,000

Notes:

1) Executed by the

2) The oil change interval depends on the operating temperature of the oil bath (it also depends indirectly on both the input and output temperatures of the

transported air). If the oil temperature does not exceed 50 °C, you can change oil annually (after 8,000 hours). If the temperature is higher than 100 °C, you must

change oil four times a year (after 2,000 hours). If the temperature is 120 °C, you must change it monthly. You can detect the oil state by comparing an oil sample

with new oil. Dark and/or thick oil indicates contamination or the initial stage of carbonization; i.e., you must change it. Analyzing an oil sample is more reliable.

1)

hours Oscillation power measurement (bearings)

1)

hours

Bearings check by oscillation power measurement. Expected

replacement of the bearings.

Rietschle Thomas servicemen.

(the level moves slightly).

Oil change

Oil change

Table 6 – Blower set checks

Operating time Check Lubrication

Visual checks, checks of the blower set operation, bolted connections,

operating pressure, discharge temperature, noise level, and noise-

After 400 hours

damping hood fan.

Check of the safety valve functioning (check smooth operation of the

PVO valve’s closing piston).

2)

Checks of the suction filter and the suction vacuum.

After 800 hours Checks of the driving elements, motor operation, and belt tension.

Addition of lubricants to the bearings

According to the electric

motors

After 20,000

After 30,000

Notes:

1) Executed by the

2) The control PVO valve maintenance – the valve need not be maintained during routine operation. Apart from the valve functioning check (see Chapter 5.2), you

must ensure that all joints are tight, particularly after reassembling or handling the valve. With respect to the PVO 200 valve, you must also check the tightness of

the cap in the top base if the lifting eye was used for valve handling (check the tightness with soapy water, for example). If any leakage occurs, the pressure in the

rubber bellows will drop and the valve will open. The same effect is caused by a clogged sieve or a blocked nozzle of the control valve (you must clean the sieve or

blow through the nozzle).

1)

hours Expected minimal operating life of the bearings of the two-pole motors

1)

hours

Rietschle Thomas servicemen.

Expected minimal operating life of the bearings of the four-, six-, and

eight-pole motors

according to the recommendations of the

motor Manufacturers; see the instructions

for motor operation and maintenance.

WARNING! During any service operation, the

Contact addresses:

blower must be turned off and secured against being

turned on. If technical conditions, cautions, and/or

warnings are violated, Rietschle Thomas cannot

provide a guarantee.

If your operation demands are unusual, please

contact Rietschle Thomas.

When contacting Rietschle Thomas, please state the

following:

• The serial number and type of the blower;

• The serial number and type of the blower set;

• The serial number and type of the motor;

• The failure(s); and

• The measures you have taken to remove the failure(s).

If the blower must be dispatched to the production plant,

please drain oil. You should also lubricate the unpainted

parts with preservative oil and put covers on the blower’s

suction and discharge sections. Motors to be dispatched

for repair must be without pulleys and/or couplings.

For an additional charge, the Rietschle Thomas

servicemen can execute the checks of blowers and blower

sets mentioned in Chapter 5.9, Table 5, including

diagnostic measurements of the bearing state and

oscillation power of the blowers and electric motors.

These precautionary activities could prevent serious

failures.

I

NFORMATION

ON IMPROPE

I

NFORMATION ON

RESIDUAL RISKS

www.rtpumps.com

• Standard blowers must not be operated if the direction

5.11

of rotation is opposite.

• Standard blowers must not be pressure-overloaded; the

maximum permissible compression ratio is 2.

• Standard blowers must not be thermally overloaded.

• Standard blowers must not be operated in explosion-

hazard environments.

• The sizes of intake medium impurities must not exceed

the values stated in Chapter 3.4.

5.12

Health and Safety Protection at Work

Rietschle Thomas blowers meet European Standards for

health protection; nonetheless, they might endanger health.

In order to prevent injuries, authorized workers must

observe the following rules:

• The operators must be trained and instructed.

• All operations must be executed according to this

manual.

• No solid, liquid, and/or powdery material must be

present in the suction space.

• If you are unsure or uncertain, contact Rietschle

Thomas.

• Blowers must not be handled when the machine is in

operation.

Rietschle Thomas GmbH + Co. KG page 14 / 23

Page 15

5.13 PLACES OF

EXCESSIVELY HOT

SURFACES

5.14 EQUIPMENT

FOR PROTECTING

THE OPERATORS

AGAINST THE

RESIDUAL RISKS

5.15 SPARE

PARTS

6. TAKING THE MACHINE OUT OF

• Blowers must not be operated when the suction part

is open because the rotors are accessible. There is a

risk of touching them.

• Do not operate the machine if any of its guards is

damaged (belt guards, fan guards, etc.).

• Use protective gloves – the machine temperature is high

when it is in operation or before it cools down.

• Use ear protectors when the acoustic enclosure is open

or the machine is operated without such a hood.

• If the blower set is equipped with a acoustic enclosure,

such a enclosure also serves as a solid guard cover.

Separate pulley guards are not installed, which results

in a residual risk – possible injury. It is thus forbidden

to operate the aggregates if the enclosures are open.

• Since the pendulous motor frame is secured in its

working position only by a belt(s), be very careful when

standing in its working space. The position of this

frame could change suddenly if a belt broke.

• Before maintaining and/or repairing the machine, you

must disconnect it from the power supply and secure it

against being turned on again.

• When detergents are being used, there is a risk of

cauterizing or poisoning by fumes inhalation. Observe

the directions and instructions of the detergent

Manufacturers!

Excessively hot surfaces:

• The blower;

• The discharge silencer;

• The discharge pipeline; and

• The safety and starting valve.

• Ear protectors; and

• Working gloves.

Consumable spare parts (filter inserts, belts, non-return

valves, and/or oil) are delivered on customer request. They

are not included in the standard delivery. The production

plant repairs its own blowers. We can deliver sets of spare

parts for individual blower types to external service

organizations. Fixtures are necessary for both smooth

assembly and disassembly. Bearing replacement is usually

the main reason for repair. If any specific problem arises,

contact the Rietschle Thomas service department.

Parts and material necessary for routine service and

simple repairs of the blower set:

a) Filter inserts;

b) V-belts – the belt specification is stated in the

Certificate of Quality and Completeness; and

c) Non-return valves.

OPERATION – WASTE DISPOSAL

Packaging

All packaging material is environmentally friendly and

recyclable. The cardboard parts were made from waste

paper. The wooden parts were not treated. The pallets can

be sold to the nearest organization dealing in pallet

purchase. The plastics are marked as follows:

>PE< polyethylene, e.g., the plastic film.

Base unit and compact unit

• Spare parts and/or the blower must be disassembled and

cleaned of petroleum products. Dispatch the parts

sorted according to the used materials for professional

disposal.

• If the blower is still functional, you can offer it to the

production plant for redemption by mutual agreement.

Operating oils

The recommended oils contain no polychlorinated

biphenyls (PCB); for more information, see the safety data

sheets of the oil.

7. NOISE LEVEL

7.1 General

The equivalent levels of the sound pressure A (measured

at the workplace of operators by using the A weight filter

in accordance with the EN ISO 11200, ISO 7574, and ISO

3740 Standards) are stated in the value tables in the

Catalogue of Rietschle Thomas blower aggregates. The

stated values express the actual values of noise levels of

blower sets with or without acoustic enclosures.

7.2 Vacuum blower sets

With respect to blowers working at vacuum, you must take

into account the fact that the catalogue values of the

equivalent levels of the sound pressure A apply only when

air is diverted by the discharge pipeline from the area

where the blower set operates or when an additional

discharge silencer is installed behind the outlet flange. If

air is discharged into the surroundings behind the

discharge flange of the blower set, the values of the

equivalent levels of the sound pressure A are

approximately 15-20 dB higher than the values stated in

the Catalogue.

7.3 Pipeline noise levels

Noise emitting from the surfaces of either the suction or

discharge pipelines is not included in the values of the

equivalent levels of the sound pressure A. You must pay

due attention when designing pipelines so that the

excitation frequency of the blower will not cause them to

resonate. It is necessary to select optimum diameters, wall

thickness, and material of the pipelines, and the anchoring

method, including the distances of the supports for both

the discharge and suction pipelines. The excitation

frequency of RT three-tooth blowers ranges between 100

and 500 Hz. The excitation frequency depends directly on

the blower revolutions (the blower revolutions range

between 1,000 and 5,000 1/min).

On customer request, we can supply an additional pipeline

silencer for specific parameters of the blower. This

silencer can prevent problems with noise emitted from the

pipeline near, e.g., housing, etc.

7.4 Machine hall

You must also pay due attention to the pipelines in the

machine hall. It is necessary to select flexible wall

openings for the pipeline in order to prevent pipeline

pulsation from being transferred to the walls of the

machine hall. You must also pay attention to the wall

material because it should absorb the emitted noise. If

possible, avoid using smooth concrete walls or steel

structures.

8. TRAINING OPERATORS

After the machine has been put into operation and

transferred to the customer, it is necessary to train its

operators.

Training Schedule:

1. Checking the volumes and states of the oil charges,

topping them up, and changing them.

These operations are executed only when the blower set is

turned off. The oil volume depends on the blower type.

When oil is being topped up, its level must not exceed the

middle of the oil level gauge.

The operators are notified of the necessity to use the

recommended oils. The procedure for changing oil and the

frequency of oil changes are explained to them.

2. Checking the state of the belt drive or the coupling

3. Checking and replacing the filter inserts

Rietschle Thomas GmbH + Co. KG page 15 / 23

Page 16

The necessity of such replacements is explained. The

frequency of replacements depends on the ambient

dustiness and the method of the blower set use.

4. Acquainting the operators with the correct

procedure for starting

The operators are warned about the potential risks.

5. Acquainting the operators with the contents and

importance of the accompanying documents -

Operating Instructions and Certificate of Quality and

Completeness.

6. Servicing the machine

The identification of failures and possible methods for

removing them. The procedure for ordering servicing.

7. Transfer certificate

Both sides complete and sign the transfer certificate form:

- The copy is intended for LUTOS; and

- The original is for the customer.

9. PRESSURE DEVICE

According to the European Parliament and Council’s

Directive 97/23/ES, which stipulate the technical

requirements for pressure devices, the discharge silencer

of the blower set is classified as a pipeline part.