Page 1

Edition: 03.2010 · 610.44440.40.000 Original operating instructions · English

Operating instructions L-BV2, L-BV5

2BV2 06.

2BV2 07.

2BV5 11.

2BV5 121

2BV5 131

2BV5 161

2BV5 41.

2BV5 421

2BV5 47.

L-Serie

L-Series

Flüssigkeitsring

Liquid Ring

Page 2

Contents

Contents

Layout of the units .............................................................................................................................. 3

1 Safety ..................................................................................................................................................4

1.1 Definitions .................................................................................................................................4

1.1.1 Warning symbol............................................................................................................4

1.1.2 Key word ......................................................................................................................4

1.2 General safety instructions .......................................................................................................4

1.3 Other risks.................................................................................................................................6

2 Correct use of the equipment ..............................................................................................................6

3 Technical data .....................................................................................................................................8

3.1 Mechanical data ........................................................................................................................8

3.2 Electrical data..........................................................................................................................10

3.3 Operating conditions normal operation ...................................................................................10

4 Transport ...........................................................................................................................................13

5 Installation .........................................................................................................................................14

5.1 Installing the unit .....................................................................................................................14

5.2 Mechanical connection of the unit...........................................................................................15

5.2.1 Connecting the suction and discharge connections...................................................16

5.2.2 Making the operating-liquid connection......................................................................16

5.2.3 Connecting up system components ...........................................................................17

5.2.4 Ancillaries ...................................................................................................................17

5.3 Connecting the electric motor .................................................................................................18

5.3.1 Connection to the motor terminal box ........................................................................18

5.3.2 Operation with a frequency converter ........................................................................19

6 Commissioning..................................................................................................................................19

6.1 Preparation of the unit.............................................................................................................19

6.2 Start-up of unit with operating-liquid supply............................................................................20

6.3 Start-up of unit with self-suction of operating-liquid ................................................................20

6.4 Checking the direction of rotation ...........................................................................................20

7 Operation...........................................................................................................................................21

7.1 Operation with supply of the operating-liquid, automatically controlled operation..................21

7.2 Operation with supply of the operating-liquid, non-automatic control of operation.................21

7.3 Operation with self-suction of the operating-liquid..................................................................22

7.4 Checking and correcting the operating-liquid flow-rate...........................................................22

8 Decommissioning the machine and shutting it down for a longer period of time..............................23

8.1 Draining down .........................................................................................................................23

8.2 Preparations for long-term shutdown......................................................................................24

8.3 Storage conditions ..................................................................................................................24

8.4 Commissioning after a long shutdown period .........................................................................24

9 Maintenance......................................................................................................................................25

9.1 Maintenance............................................................................................................................26

9.2 Repairs / Troubleshooting .......................................................................................................27

9.3 Service / Customer service .....................................................................................................29

9.4 Decontamination and declaration of Clearance......................................................................29

10 Disposal.............................................................................................................................................29

11 Explosion-protected design ...............................................................................................................29

EU declaration of conformity ............................................................................................................ 30

Form for statement on safety ........................................................................................................... 31

© 2009 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Germany

Replication, distribution and / or editing of this document and the use and distribution of its content is

prohibited unless explicitly permitted. Violation obligates compensation for damages.

All rights reserved in case of the issue of a patent, utility patent or design patent.

Page 3

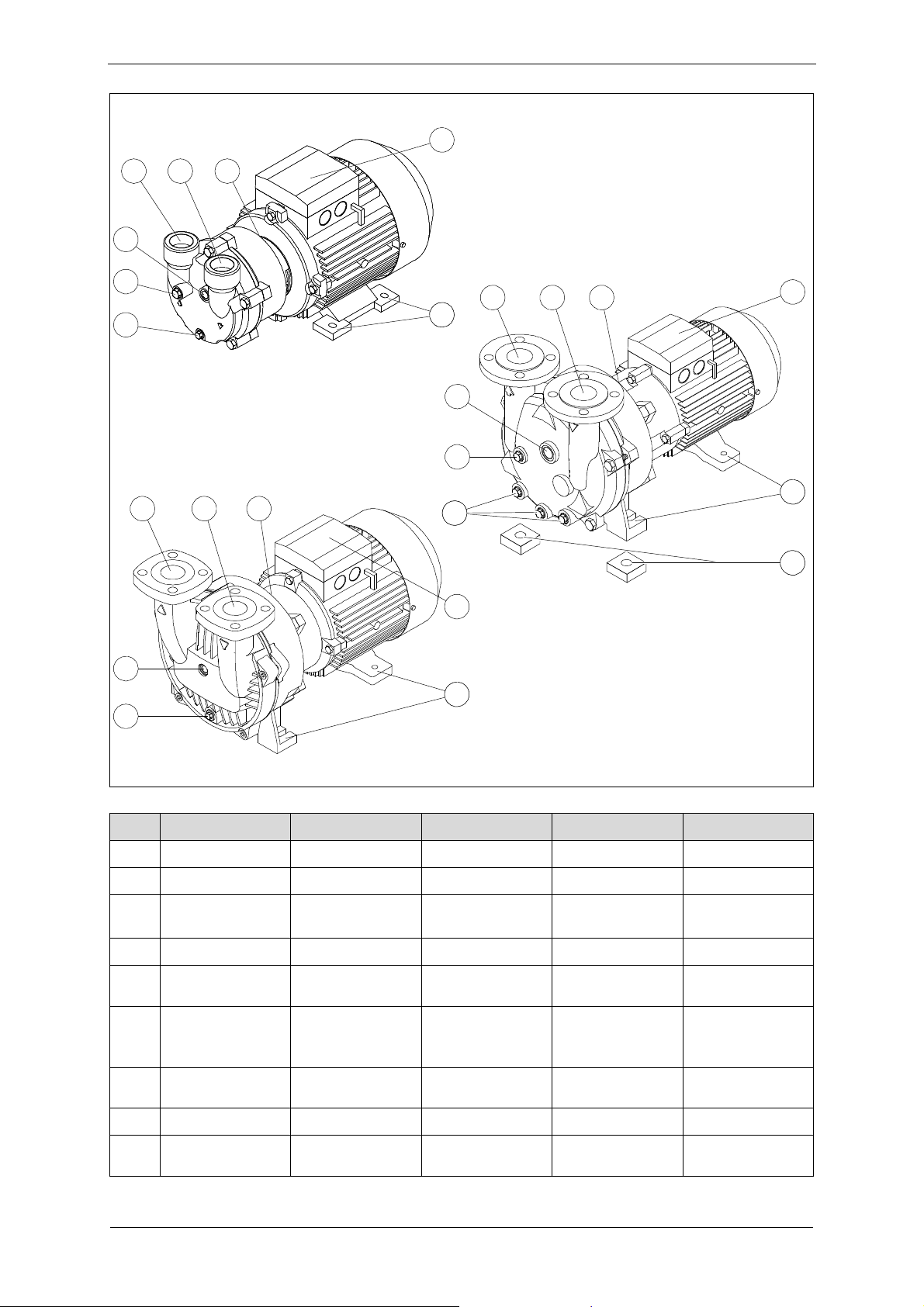

Layout of the units

Layout of the units

2BV2 0..

1

87

6

9

2BV5 1..

5

7

4

22

6

5

98

1

2BV5 4..

2

2

87

9

444

33

1

6

22

4

610.44440.99.B01…B03

Fig. 1: Layout of the units

Designation

Item

Terminal box

1

Mounting feet

2

Intermediate plates —

3

Drain tapping(s)

4

Anti-cavitation

5

connection

Operating-liquid

6

connection

Discharge connec-

7

tion

Inlet connection

8

Direction of rota-

9

tion arrow

2BV2 … 2BV5 1.. 2BV5 4..-.F 2BV5 4..-1G

2BV5 110-….2-.S

2BV5 121-….2-.S

3

G

/4 ODER

3

/8 G

3

/8 — —

G 1/4 G

G 3/8 G

G 3/8

Flange (stainless

— —

3

/8 G

3

/8 G

G

3

/8

3

/8

steel)

Threaded Flanged Flanged Threaded

Threaded Flanged Flanged Threaded

© Gardner Denver Deutschland GmbH 3 / 32 610.44440.40.000

Page 4

Safety

1 Safety

1.1 Definitions

The following key words and symbols are used to

impart warnings, important information and notes

in these operating instructions:

1.1.1 Warning symbol

The warning symbol is depicted in the safety

instructions in the related title frame on the left

next to the key word (DANGER, WARNING,

CAUTION).

Safety instructions and warning symbols indicate

danger of personal injury.

Please follow these safety instructions to protect

yourself against injury or death!

Safety instructions without warning symbols indicate danger of material damage.

1.1.2 Key word

DANGER

WARNING

CAUTION

ATTENTION

NOTE

Danger of personal injury.

Indication of an immediately threatened danger

which could lead to death or serious injury if the

appropriate precautions are not observed.

Danger of personal injury.

Indication of an immediately threatened danger

which could lead to death or serious injury if the

appropriate precautions are not observed.

Danger of personal injury.

Indication of a possible danger which could lead

to medium or light injury if the appropriate precautions are not observed.

The key words are in the title frame

in the safety instructions.

They follow a defined hierarchy and

they indicate (in connection with

the warning symbol, see chapter 1.1.1) the importance of the

danger or the nature of the instruction.

Refer to the following clarifications:

DANGER

WARNING

CAUTION

CAUTION

Danger of material damage.

Indication of a possible danger which could lead

to material damage if the appropriate precautions are not observed.

CAUTION

Indication of a possible disadvantage, i.e. undesired circumstances may arise if the appropriate

precautions are not observed.

NOTE

Indicates a possible advantage, if the appropriate precautions are observed; tip.

1.2 General safety instructions

WARNING

Improper handling of the unit

can result in serious or even fatal injuries!

This operating manual

must be read and understood before com-

mencing any work on or with the unit, and

must be complied with and

must be available at the unit's location

WARNING

Improper handling of the unit

can result in serious or even fatal injuries!

Operate the unit

for the purposes specified under "Correct use

of the equipment", page 6!

using the media specified under "Correct use

of the equipment", page 6!

using the values specified under "Technical

data", page 8!

WARNING

Improper handling of the unit

can result in serious or even fatal injuries!

Only trained and responsible specialist

personnel may work on or with the unit

(transport, installation, commissioning,

shutdown, maintenance, disposal)!

610.44440.40.000 4 / 32 © Gardner Denver Deutschland GmbH

Page 5

Safety

WARNING

Working on the unit involves a risk of injury,

e.g. through cutting / shearing, squashing

and burning!

First get personal protection gear (helmet,

gloves, safety shoes)

and only then work on the system!

WARNING

Hair and clothing can be drawn into the unit

or caught or wound in by moving parts!

Do not wear any large or loose items of cloth-

ing!

If you have long, loose hair, wear a hair net!

DANGER

Electrical hazard!

Before starting work on the unit or system, the

following precautions are to be taken:

De-energize it.

Protect it from being switched on again.

Make sure that it is de-energized.

Earth it and bypass it.

Cover or block off adjoining parts which are

still live.

DANGER

Electrical hazard!

Work on electrical equipment must be performed by specialist electricians!

DANGER

Electrical hazard!

First check that it is de-energized.

Then open the motor terminal box!

WARNING

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Before starting work on the unit or on the system:

Shut off the operating-liquid supply.

Vent the piping and the unit (de-pressurize).

WARNING

Hazard presented by rotation of the unit's

external fan!

Operate the unit only if the fan guard is fitted!

WARNING

Hazard presented by rotation of the unit's

impeller!

Operate the unit only if the cover is fitted!

Removal of the cover is forbidden!

WARNING

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Hazard presented by rotation of the unit's

impeller!

Operate the unit only with the piping / hoses

connected up to the suction and discharge connections and to the operating-liquid connection!

WARNING

Hazard of cutting or severing of limbs by the

unit's impeller!

Do not reach inside the unit through open

connections!

Do not put objects into any of the openings in

the unit!

WARNING

Hazard in case of overpressure and negative

pressure!

Pressure-test the piping and vessels installed

in the system!

WARNING

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Check the piping / hose connections for leak-

age!

WARNING

Danger of burns or scalding from hot surfaces on the unit and from hot media!

Do not touch when in operation!

After shutdown, allow system to cool down!

CAUTION

Danger of crushing if the unit should tip

over!

Secure the unit to it's foundation before start-

up!

© Gardner Denver Deutschland GmbH 5 / 32 610.44440.40.000

Page 6

Correct use of the equipment

1.3 Other risks

WARNING

It is possible for long, loose hair to be drawn

into the external fan through the grille in the

fan guard!

Wear a hair net!

WARNING

Long, loose hair can be caught and wound in

by the rotation of the shaft between the motor end-shield and the pump casing.

Wear a hair net!

WARNING

Injury can be caused by friction (abrasion,

burning, etc.) against the rotating shaft between the motor end-shield and the pump

casing.

Do not reach into the openings between the

motor end-shield and the pump casing!

Do not insert any objects into the openings

between the motor end-shield and the pump

casing.

WARNING

Hot surfaces can cause burning / scalding!

Do not touch!

Wear protective gloves!

2 Correct use of the equipment

This operating instructions

is applicable for Liquid ring vacuum pumps/

compressors (units) types:

2BV2 06. 2BV2 07. 2BV5 11. 2BV5 121

2BV5 131 2BV5 161 2BV5 41. 2BV5 421

2BV5 47.

in standard design,

contains instructions for the unit’s transporta-

tion, installation, start-up, operation, shutdown, storage, maintenance and disposal,

Must have been read and properly understood

by operating and maintenance staff before

beginning any work with or on the unit.

must be complied with and

Must be at hand where the unit is installed.

Operating and maintenance personnel

Operating and maintenance personnel units

must be trained and authorised for the work to be

carried out.

Work on electrical installations may only be carried out by a specialist electrician.

A specialist electrician is someone who can

evaluate and identify potential risks for the assigned task as a result of their technical training,

knowledge and experience as well as knowledge

about relevant regulations.

610.44440.40.000 6 / 32 © Gardner Denver Deutschland GmbH

Page 7

Correct use of the equipment

The units

create a vacuum or overpressure.

are used to extract, deliver and compress the

following gases / vapours:

- all dry and humid gases,

which are not explosive, flammable, aggressive

or poisonous,

- Air or air-vapour mixtures.

- In the case of explosive, flammable, ag-

gressive or poisonous gases / vapours,

please consult the manufacturer.

- The gases / vapours must be free of solid

matter.

Small quantities of light suspended matter

or liquids can be conveyed along too.

are designed for operation with the following

operating-liquids:

- Water

of pH-value between 6 and 9,

that are free of solid matter (e.g. sand).

- in the case of pH-values or operating-liquids

deviating from the above, please contact

the manufacturer.

are suitable for a deep vacuum range.

are fitted with one of the following types of

drive motor:

- standard design,

- explosion-protected design.

These operating instructions are only applicable for units in the standard design.

For the explosion-protected design

(RL 94/9/EG) - see supplementary special

operating instructions.

are available in two constructions:

- cast iron construction for normal require-

ments,

- stainless steel construction for higher corro-

sion-resistance and hygiene requirements

(only 2BV2 070, 2BV2 071, 2BV5 1..).

are designed for industrial plants.

Are designed for continuous operation.

For operation of the units, please refer to chapter 3, "Technical data", page 8 hereunder for the

specified tolerance limits which must be adhered

to.

Foreseeable misuse

The following are forbidden:

to use the unit in non-industrial systems,

to operate the system if it does not include the

necessary precautions and protective devices,

e.g. protection against touching by small fingers,

to operate the unit in spaces in which explo-

sive gases may be present, insofar as the unit

is not specifically designed for such conditions;

extraction, conveyance and compression

of explosives, combustible, aggressive or poisonous media,

insofar as the unit is not specifically designed

for such conditions,

operation of the unit at any values other than

those specified in chapter 3, "Technical data",

page 8 hereunder.

Modifications to the units are forbidden for safety

reasons.

The operator is allowed to carry out maintenance

and repair work only to the extent described in

these operating instructions.

Maintenance and repair work which goes beyond

this may only be carried out by companies which

have been authorised by the manufacturer (ask

the service department for details).

© Gardner Denver Deutschland GmbH 7 / 32 610.44440.40.000

Page 8

Technical data

3 Technical data

3.1 Mechanical data

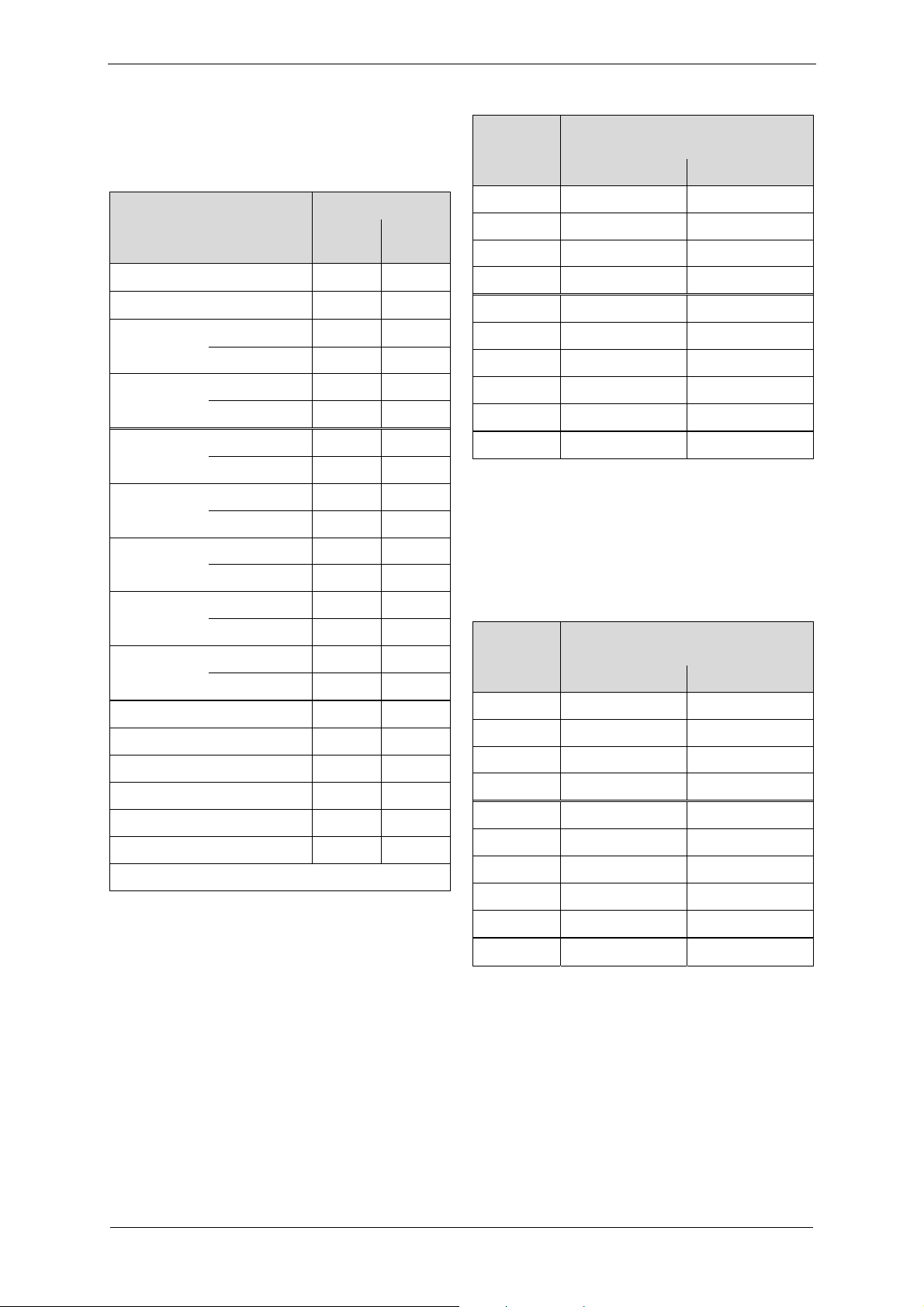

Mass / Weight

Weight* Type

approx.

[kg]

2BV2 060

2BV2 061

2BV2 070

Stainless steel

2BV2 071 Cast iron

Stainless steel

2BV5 110 Cast iron

Stainless steel

2BV5 111 Cast iron

Stainless steel

2BV5 121 Cast iron

Stainless steel

2BV5 131 Cast iron

Stainless steel

2BV5 161 Cast iron

Stainless steel

2BV5 470 Cast iron

2BV5 471 Cast iron

2BV5 410-.F Bronze

2BV5 410-1G Cast iron

2BV5 411 Cast iron

2BV5 421 Cast iron

Cast iron

Cast iron

Cast iron

25 55.5

26 57.5

35 77.5

42 93.0

61 135

67 148

95 201

98 216

110 243

113 249

170 375

182 401

181 399

196 432

252 556

264 582

68 150

77 170

95 210

87 192

137 302

153 337

* Specified is the weight for the largest motor size.

approx.

[lbs]

Minimum clearances for heat dissipation

Type Minimum clearance

Fan guard - adjacent surfaces

[mm] [inches]

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

2BV5 410

34 1.34

34 1.34

53 2.09

53 2.09

53 2.09

53 2.09

53 2.09

53 2.09

80 3.15

83 3.27

Noise level

Measured area sound pressure in accordance

with EN ISO 3744, measured at 1 m [3.28 ft]

distance at medium throttle (100 mbar abs.

[1.45 psia]) and with piping connected, tolerance

±3 dB(A)

Type Sound pressure level measured at

1 m distance, L [dB(A)]

50 Hz: 60 Hz:

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

70 70

70 70

70 71

72 76

70 70

70 74

70 75

73 77

74 75

2BV5 410

70 70

Operating speed

See nameplate.

The operating speed is specified for a 50/60 Hz

power supply.

For other speeds please contact the manufacturer.

610.44440.40.000 8 / 32 © Gardner Denver Deutschland GmbH

Page 9

Technical data

ATTENTION

If the permissible operating speed is exceeded

this has a detrimental effect on the unit's operating characteristics:

higher noise levels

heavy vibrations

reduced grease useful lifetime

reduced time between changing bearings

The maximum speed should not be exceeded,

as damage can result from higher operating

speeds.

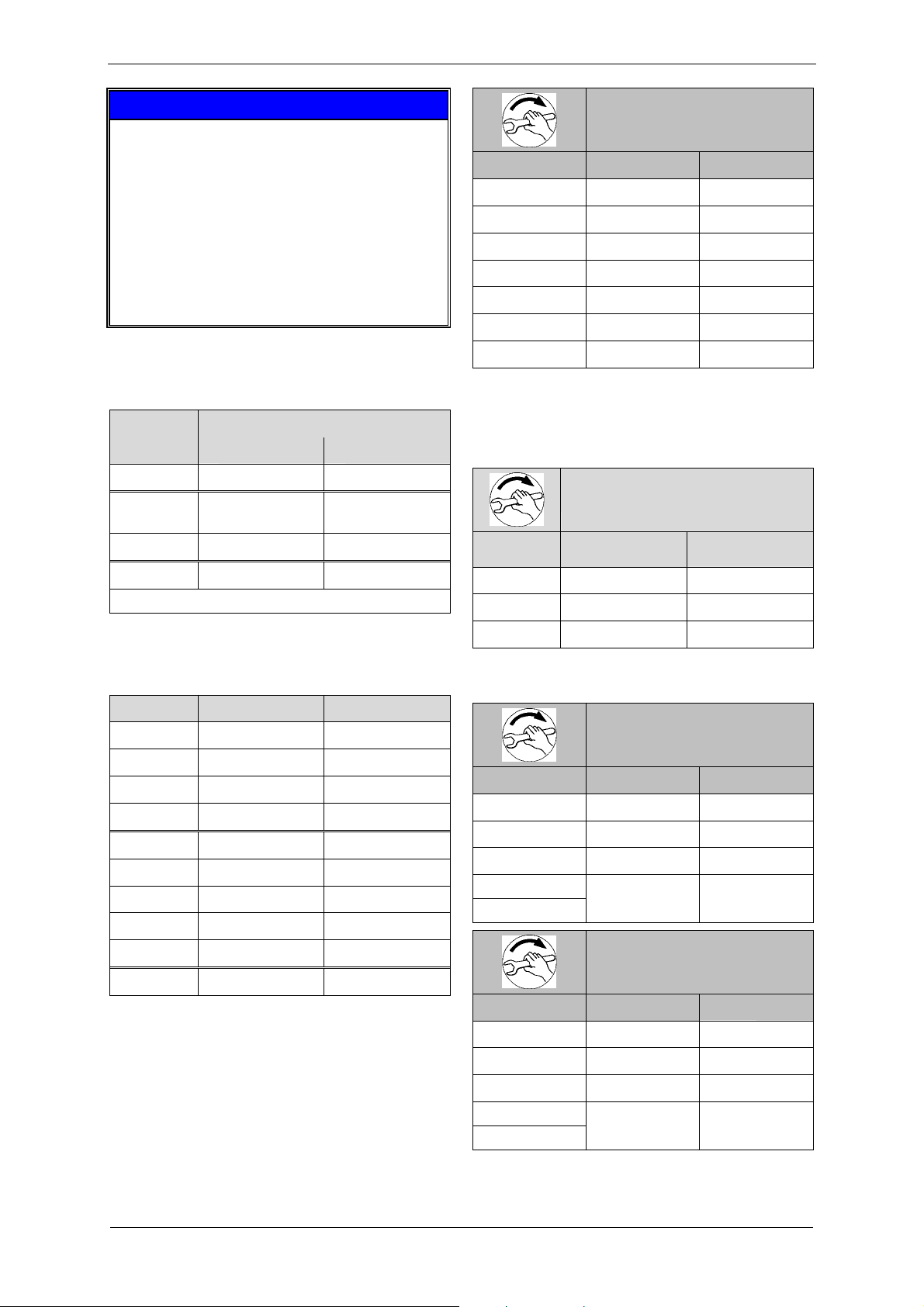

Operating speeds standard operation at

50/60 Hz

n [min-1]* Type

50 Hz 60 Hz:

2BV2 …

2BV5 110 2BV5 131

2BV5 161

3000 3600

1500 1800

1000 1200

Tightening torques for

non-electrical connections

Thread [Nm] [ft lbs]

M4

M5

M6

M8

M10

M12

M16

2.7 - 3.3 1.99 - 4.44

3.6 - 4.4 2.65 - 3.25

7.2 - 8.8 5.31 - 6.5

21.6 - 26.4 15.9 - 19.5

37.8 - 46.2 27.9 - 34.1

63.0 - 77.0 46.5 - 56.8

90 - 110 66.42 – 81.18

The following specifications for electrical connections apply to all terminal board connections with

the exception of terminal strips.

Tightening torques

for electrical connections

Thread [Nm] [ft lbs]

2BV5 410

*

No account is taken of motor slip

1500 1800

Maximum speeds for operation with electronic frequency converter

Type n

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

2BV5 410

[min-1] n

min

[min-1]

max

2636 4612

2636 4612

2123 3715

2123 3715

1402 2454

1402 2454

1290 2258

1180 2066

913 1597

1402 2454

Tightening torques

The following values shall apply insofar as no

other specifications are available.

The basis for non-electrical connections is tightness classes 8.8 and 8 or higher in accordance

with EN ISO 898-1.

M4 0.8 - 1.2 0.59 - 0.89

M5 1.8 - 2.5 1.33 - 1.84

M6 2.7 - 4 1.99 - 2.95

The following values apply specially for metallic

and plastic cable and pipe unions:

Tightening torques for metal

threaded glands/unions

Thread [Nm] [ft lbs]

M12x1,5

M16x1,5

M25x1,5

4 - 6 2.95 - 4.43

5 - 7.5 3.69 - 5.53

6 - 9 4.43 - 6.64

M32x1,5

M40x1,5

8 - 12 5.9 - 8.85

Tightening torques for plastic

threaded glands/unions

Thread [Nm] [ft lbs]

M12x1,5

M16x1,5

M25x1,5

2 - 3.5 1.48 - 2.58

3 - 4 2.21 - 2.95

4 - 5 2.95 - 3.69

M32x1,5

M40x1,5

5 - 7 3.69 - 5.16

© Gardner Denver Deutschland GmbH 9 / 32 610.44440.40.000

Page 10

Technical data

1

1

3.2 Electrical data

See motor rating plate.

3.3 Operating conditions normal operation

Temperatures

Temperatures of the gases / vapours

[°C] [°F]

max. +80 max. +176

For higher media temperatures provisions have to

be made in the system to protect against burning,

e.g. fitting of guards.

In this case one of the following provisions can be

made:

increase of the operating-liquid flow-rate to 2.5

times (2BV2 …) or to 2 times (2BV5 …) the design operating-liquid flow-rate (cooling circulation)

installation of a pre-condenser

Temperature of the operating-liquid

[°C] [°F]

max. +80 max. +176

min. +5 min. +41

Nominal value:

+15 +59

Ambient temperature

[°C] [°F]

max. +40 +104

min. +5 +41

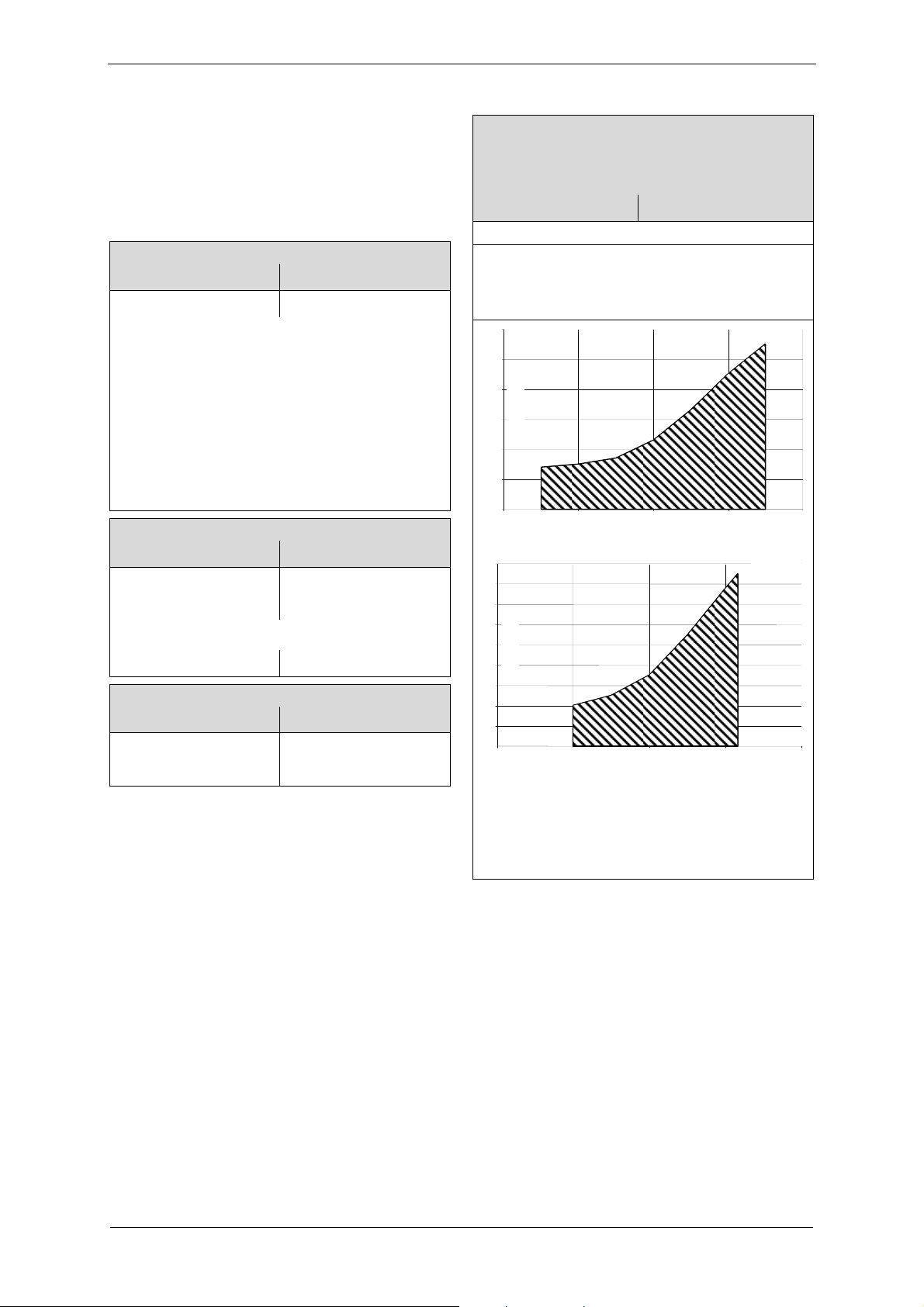

Pressures

Min. suction pressure p

for operation

1 min

with cavitation-protection

Cavitation-protection tapping open (2BV2 0.. and

2BV5 1.. only)

[mbar abs.] [psia]

max. achievable under-pressure (full throttling)

As a general rule:

The higher the temperature, the lower the suction

capacity, i.e. the higher the minimum achievable

suction pressure.

300

250

200

150

[mbar abs.]

p

100

50

4,5

3,5

2,5

1,5

0,5

0

4

3

2

1

0

-

[psia]

p

fl

20 40 60

[°C]

fl

50 100 150 200

[°F]

fl

610.44440.99.B04

[°C, °F] = temperature of the operating-

liquid

- p

[mbar abs., psia] = absolute suction pres-

1

sure

Fig. 2: Pressure characteristics at varying

operating conditions

80

610.44440.40.000 10 / 32 © Gardner Denver Deutschland GmbH

Page 11

Technical data

Min. suction pressure p

for operation

1 min

without cavitation-protection*

Cavitation-protection tapping closed

[mbar abs.] [psia]

80 1.16

As a general rule:

The min. suction pressure will be the higher in dependence of the height of the temperature and the

height of the vapour pressure of the operatingliquid used.

The min. suction pressure must at least be maintained otherwise damage may be caused by the

resulting cavitation.

When operating without cavitation-protection the

minimum suction pressure is to be set above the

level of the hatched range (Fig. 2, page 10).

*

Dependent on the type and temperature of the

operating-liquid. The values apply for standard

conditions:

operating-liquid: water at +15 °C [+59 °F]

gases / vapours: dry air at +20 °C [68 °F]

design operating-liquid flow

Max. discharge pressure p

for vacuum op-

2 max

eration*

Type [bar abs.] [psia]

2BV2 ...

2BV5 ...

*

when the design operating-liquid flow is main-

1.1 16.0

1.3 18.9

tained.

Max. discharge pressure, p

for compressor

2 max

operation

(at suction pressure, p1 = 1 bar abs. [14.5 psia])

Type [bar abs.] [psia]

At

50 Hz:

2BV2 060–....2–..

2BV2 061–....3–..

2BV2 070–....3–..

2BV2 071–....5–..

2.5 2.2 36.3 31.9

2.4 1.9 34.8 27.6

3.6 2.9 52.2 42.1

3.5 2.6 52.2 37.7

at

60 Hz:

at

50 Hz:

at

60 Hz:

Max. permissible pressure within unit, p

int max

Type [bar abs.] [psia]

2BV2 …

2BV5 1..

2BV5 4..

8 116

8 116

6 87.0

If higher pressures can occur elsewhere in the

system, then appropriate protection devices are to

be installed

Liquid quantities

For extraction of dry air and using water at 15°C

[59 °F] as the operating-liquid, the following design operating-liquid flows apply:

Design operating-liquid flow [m³/h]

Type Flow rate,

Vacuum operation

in the pressure range

[mbar]

33-200 200-500 >500

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

2BV5 410

*

Value for 50 Hz operation / value for 60 Hz op-

0.20 0.20 0.20 0.20

0.23 0.23 0.23 0.25

0.28 /

0.34*

0.54

0.14 /

0.17*

0.23

0.28*

0.14 /

0.17*

0.23

0.28*

0.80 0.35 0.30 0.90

1.20 0.40 0.35 1.20

1.20 /

1.50*

0.40 0.35 1.50

1.80 0.45 0.40 1.80

2.40 0.70 0.50 2.40

0.80 0.80 0.55 0.80

Flow

rate,

com-

pressor

opera-

tion

0.50

0.70

eration

All other values for 50 Hz and 60 Hz operation.

2BV5 110–....1–..

2BV5 111–....3–..

2BV5 121–....3–..

2BV5 131–....1–..

2BV5 161–....2–..

2BV5 410

1.85 1.6 26.8 23.2

1.9 1.5 27.6 22.5

1.85 1.4 26.8 20.3

1.7 1.4 24.6 21.8

1.8 1.5 27.6 23.9

2.0 2.0 29.0 29.0

© Gardner Denver Deutschland GmbH 11 / 32 610.44440.40.000

Page 12

Technical data

Design operating-liquid flow [ft³/h]

Type Flow rate

Vacuum operation

in the pressure range [psi]

0.479-

2.90

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

2BV5 410

*

Value for 50 Hz operation / value for 60 Hz op-

7.06 7.06 7.06 7.06

8.12 8.12 8.12 8.83

9.89 /

12.0*

15.89

28.25 12.36 10.59 31.78

42.38 14.13 12.36 42.38

42.38 /

52.97*

63.57 15.89 14.13 63.57

84.76 24.72 17.66 84.76

28.25 28.25 19.42 28.25

2.90-

>7.25

7.25

4.94 /

6.0*

8.12

9.89*

4.94 /

6.0*

8.12

9.89*

14.13 12.36 52.97

Flow

rate,

com-

pressor

opera-

tion

17.66

24.72

eration

All other values for 50 Hz and 60 Hz operation.

Quantity of operating-liquid for first fill

Type [l] [gal (US)] [gal (UK)]

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

2BV5 410

0.5 0.132 0.110

0.5 0.132 0.110

1.0 0.264 0.220

1.0 0.264 0.220

3.0 0.793 0.660

3.0 0.793 0.660

3.0 0.793 0.660

3.0 0.793 0.660

8.0 2.113 1.760

3.0 0.793 0.660

Maximum permissible quantity of water carried

along through the inlet connection

1x

1x

+ D

1x

+ K

Type Continuous op-

eration [D]*

2BV2 …

2BV5 1..

2BV5 4..

2.5x 7x

2.5x 5x

7x 7x

max. 2 sec

D

K

610.44440.99.B05

[K]*

* 1x = design operating-liquid flow

610.44440.40.000 12 / 32 © Gardner Denver Deutschland GmbH

Page 13

Transport

4 Transport

WARNING

Improper handling of the equipment can result in serious or even fatal injuries!

Have you read the safety notes in chapter 1,

"Safety", page 4 above?

If not then you are not allowed to carry out any

work on or with the equipment!

WARNING

Hazard presented by tilting or falling loads!

Before transport, make sure that all the components are securely assembled and that all the

components for which the fixings have been

loosened are either properly secured or removed!

CAUTION

Tilting or falling over can result in crushing

or breaking of bones, etc.!

Sharp edges can cause cuts!

Wear personal protective gear (helmet, gloves,

and safety shoes) during transportation!

Transportation by hand:

WARNING

Transport with lifting gear:

WARNING

Hazard presented by tilting or falling loads!

The following basic rules should be observed

when transporting with the aid of lifting gear:

The load-bearing capacity of the lifting gear

and load-handling devices must correspond

to the weight of the unit.

Weight of the unit, see table ""Mass /

Weight", page 8.

Secure the system so that it cannot tilt over

or fall off.

Do not stand under suspended loads!

Transportation is expected to be carried out by

crane using lifting straps/chains.

Transport of type 2BV2 …:

Transport using crane and lifting straps.

Run the lifting straps under the pump casing

and under the fan guard (Fig. 3, page 13).

The lifting straps should locate securely in the

undercuts so that the unit cannot slip out from

them.

The lifting straps must be long enough

(spreading angle less than 90°).

Take care that the fittings are not damaged.

Danger when lifting heavy loads!

Lifting by hand is permitted only within the following weight limits:

max. 30 kg [max. 66 lbs] for men

max. 10 kg [max. 22 lbs] for women

max. 5 kg [max. 11 lbs] for pregnant women

Weight of the unit, see table "Mass / Weight",

page 8.

Above these limits suitable lifting gear or transport must be used!

Fig. 3: Lifting points, 2BV2 …

© Gardner Denver Deutschland GmbH 13 / 32 610.44440.40.000

Page 14

Installation

Transport of type 2BV5 …:

Transport using crane and chains.

the lifting points are the lifting eyes on the

motor and one drilling in the discharge connection or the suction connection (Fig. 4 - Fig.

6, page 14).

secure the chains to these lifting points.

take care that the fittings are not damaged.

Fig. 4: Lifting points, 2BV5 1..

5 Installation

WARNING

Improper handling of the equipment can result in serious or even fatal injuries!

Have you read the safety notes in chapter 1,

"Safety", page 4 above?

If not then you are not allowed to carry out any

work on or with the equipment!

5.1 Installing the unit

CAUTION

Danger of crushing if the unit tilts over when

installation is not yet completed!

Wear gloves and safety shoes!

Handle the unit cautiously!

CAUTION

Danger of tripping and falling over the unit!

avoid the places where tripping may occur!

WARNING

Electrical hazard!

The system is to be installed in such a way that

external effects cannot lead to damage of the

electrical equipment.

Lay out the connecting cables safely, e.g. in

cable ducts or in the ground.

CAUTION

Danger of injury due to parts flying off of a

broken external fan!

Set the unit up such that if parts of a broken

external fan should fly through the grille, no

personnel can be hit!

CAUTION

Fig. 5: Lifting points, 2BV5 41./2BV5 421

Risk of damaging the unit by overheating

due to blocking the path of dissipated heat

and cooling air supply!

Observe the requirements stated in

"Minimum clearances for heat dissipation",

page 8.

Make sure that the exhaust air from other

equipment is not drawn in!

Fig. 6: Lifting points, 2BV5 47.

610.44440.40.000 14 / 32 © Gardner Denver Deutschland GmbH

Page 15

Installation

Conditions for setting up the system:

The unit should be set up:

on a level surface with a load-bearing capabil-

ity suitable for the weight of the unit,

with the shaft in a horizontal position,

on stationary (fixed) surfaces or structures,

with a clearance from adjacent surfaces in

accordance with the table, "Minimum clearances for heat dissipation", page 8

at a maximum height of 1000 m [3280 ft]

above sea level.

If the conditions for setting up the unit deviate

from the above please contact the service department.

When setting up, take due account of vibration

characteristics at the location. The unit's overall

vibration will depend on:

- the unit's own vibration,

- the alignment and positioning,

- the condition (vibration characteristics) of

the supporting surface,

- The effects resulting from oscillations in o-

ther components and parts of the plant (external oscillations).

The maximum permissible value for oscillations is v

= 4.5 mm/s [0.177"/s].

eff

The measuring points for determining the oscillating speed are shown in Fig. 7, page 15.

2BV2 … 2BV5 …

5.2 Mechanical connection of the unit

The unit is supplied with all connection openings

sealed off to prevent the ingress of foreign matter.

Only remove the seals immediately before

connecting up the piping / hoses.

The gases /vapours are drawn in through the

inlet connection (item 8, page 3) and expelled

through the discharge connection (item 7,

page 3).

The unit has to be continuously supplied with

operating-liquid during operation.

This supply is introduced via the operating-liquid

connection (item 6, page 3) and is expelled together with the gases / vapours via the discharge

connection.

Filling up with operating-liquid:

The initial charge of operating-liquid is dependent

on the type of operating-liquid supply:

When operating with self-suction of the oper-

ating-liquid:

before installation, see description below.

When operating with supply of the operating-

liquid:

after completion of installation, see "Filling up

with operating-liquid", page 20.

For operation with self-suction of the operatingliquid, fill the unit's operating chamber with operating-liquid before the piping / hoses are installed

on the unit.

Fill up with operating-liquid through the open

inlet connection or discharge connection in

610.44440.99.B08

Fig. 7: Measuring points for oscillating speed

Securing the unit:

the unit's mounting feet (item 2, page 3) are to

be bolted to the base using suitable fixings.

Fit bolts in all fixing holes!

The types 2BV5 110-….2-.S and

2BV5 121-….2-.S are supplied with intermediate

plates for height adjustment.

The intermediate plates (item 3, page 3) are

to be inserted under the mounting feet on the

pump casing before securing.

The unit's mounting feet (item 2,, page 3) are

to be bolted to the base using suitable fixings.

Fit bolts in all fixing holes!

accordance with the table, "Quantity of operating-liquid for first fill, page 12.

© Gardner Denver Deutschland GmbH 15 / 32 610.44440.40.000

Page 16

Installation

5.2.1 Connecting the suction and discharge

connections

CAUTION

If the unit is connected to a vacuum tunnel

the operating-liquid can be drawn out of the

unit into the system risking damage to the

system.

Fit a check valve in the suction line.

CAUTION

The tightening torque for piping connections to

the suction and discharge connections may not

exceed 100 Nm [73.8 ft lbs]!

CAUTION

When attaching pipelines / hoses, make sure

that these are free from mechanical stresses.

CAUTION

In the case of gases / vapours containing

impurities:

if necessary a filter, strainer or separator

should be installed in the suction line.

CAUTION

In order to prevent residues left over from installation work (e.g. welding beads) entering the

unit, an intake strainer should be fitted in the

suction line for the first 100 operating hours.

Connection sizes, suction / discharge connections

Type Connection

2BV2 06. Threaded end G1

2BV2 07. Threaded end G11/2

2BV5 11. Flange 50 ND10-DIN 2501 or

ANSI-B16,5-2-150

Gasket DN50 PN40 DIN EN 1514-1

form FF

2BV5 12.

2BV5 13.

2BV5 16. Flange 80 ND10-DIN 2501 or

2BV5 410 Flange 50 ND10-DIN 2501 or

Flange 65 ND10-DIN 2501 or

ANSI-B16,5-2 1/2-150

Gasket DN65 PN6 DIN EN 1514-1

form FF

ANSI-B16,5-3-150

Gasket DN80 PN6 DIN EN 1514-1

form FF

ANSI-B16,5-2-150

Gasket DN50 PN40 DIN EN 1514-1

form FF

The inlet connection (item 8, page 3) is marked

with an arrow pointing downward. The gases /

vapours are drawn inward in this direction.

Connect the system suction line.

The discharge connection (item 7, page 3) is

marked with an arrow pointing upward. The

gases / vapours as well as the operating-liquid

are expelled in this direction.

Connect the system discharge line.

5.2.2 Making the operating-liquid connection

CAUTION

In the case of operating-liquid with impurities:

if necessary a filter, strainer or separator

should be installed in the supply line.

ATTENTION

If the operating-liquid is highly calciferous:

soften the operating-liquid

OR

decalcify the unit regularly (chapter 9.1,

"Maintenance", page 26).

Connection sizes, operating-liquid inlet

Type Connection

2BV2 0 Threaded tapping G3/8, 12 mm deep

2BV5 1

Cast iron

2BV5 1

Stainless

steel

2BV5 410 Threaded tapping G3/4, 24 mm deep

Connect the operating-liquid supply line to the

operating-liquid inlet (item 6, page 3).

Threaded tapping G3/4, 24 mm deep

Threaded tapping G3/4, 24 mm deep

OR

flange in accordance with

EN 1092-PN40-DN15 and

ANSI-B16.5-1/2-150

610.44440.40.000 16 / 32 © Gardner Denver Deutschland GmbH

Page 17

Installation

5.2.3 Connecting up system components

Connect up the components in accordance

with the flow diagram shown below:

Operation with supply of the operating-liquid,

automatically controlled operation

1 2 3 4 5 6 7

610.44440.99.B09

1 Unit

2 Flow meter

3 Throttle valve

4 Solenoid valve coupled to the motor

5 Bypass line with shut-off valve (for initial filling)

6 Strainer

7 Operating-liquid supply line

Fig. 8: Operation with supply of the operating-

liquid: automatically controlled operation

Operation with supply of the operating-liquid,

non-automatic control of operation

1 2 3 4 6 7

610.44440.99.B10

1 Unit

2 Flow meter

3 Throttle valve

4 Shut-off valve

6 Strainer

7 Operating-liquid supply line

Fig. 9: Operation with supply of the operating-

liquid: non-automatic control of operation

Operation with self-suction of the operatingliquid

7

≤ 1 m

≤ 3.28 ft

1

9

a

b

4

1 Unit

4 Shut-off valve

7 Operating-liquid supply line

8 Suction line

9 Operating-liquid storage vessel

a Liquid level necessary on start-up

b Min. liquid level during operation

Fig. 10: Operation with self-suction of the operat-

ing-liquid

900 mbar abs

13.1 psia

8

610.44440.99.B11

5.2.4 Ancillaries

The following ancillaries can be supplied from our

catalogue:

liquid separator including return line and cavi-

tation-protection line

cavitation-protection valve

check valve

connection and contra-flanges

gas ejector

flow limiter.

© Gardner Denver Deutschland GmbH 17 / 32 610.44440.40.000

Page 18

Installation

5.3 Connecting the electric motor

DANGER

Electrical hazard!

Incorrect actions can lead to severe harm to

persons and material damage!

DANGER

Electrical hazard!

Electrical connection may only be carried out by

specialist electricians!

DANGER

Electrical hazard!

Before starting work on the unit or system, the

following precautions are to be taken:

de-energize it.

protect it from being switched on again.

make sure that it is de-energized.

earth it and bypass it.

cover or block off adjoining parts which are

still live.

CAUTION

Incorrect connection of the motor can result in

severe damage to the unit!

Regulations:

The electrical connection is to be set up as follows:

in accordance with the currently valid national,

local and system-specific regulations and requirements,

in accordance with the current regulations of

the power supply company which apply to the

place of erection.

Supply of electrical power:

The conditions at the place of use must agree

with the details on the data plate.

5.3.1 Connection to the motor terminal box

WARNING

Electrical hazard!

The air-gaps between non-insulated, energized

components in relation to each other and to

earth must be at least 5.5 mm [0.217"] (at a design voltage of U

≤ 690V).

N

No exposed wires are permissible.

The electrical connections must be permanently

secured.

WARNING

Electrical hazard!

Terminal boxes must be free of

foreign objects,

dirt and

moisture.

Close and seal the cover to the terminal box and

also seal the cable entry openings against the

entry of dust and water.

Check regularly to make sure they are sealed

tight.

Any scale / blind plugs are to be properly re-

moved (Fig. 11, page 19).

Fit the entry union (item A , Fig. 12, page 19)

Screw in the reducer for the PTC resistor

connection (item B, Fig. 12, page 19).

Connect the protective conductor to the termi-

nal.

connect up the connection frame in accor-

dance with the wiring diagram inside the

terminal box (item 1, page 3).

- For tightening torques for terminal boards

see the table "Tightening torques", page 9.

- For cable terminals with retaining clips, set

up the cable so that both sides of the bridge

are at about the same clamping height.

- Bend the individual conductors into a U-

form or connect up using a suitable terminal

end.

- The protective conductor and the outermost

earth conductor must be bent into a U-form.

Permissible deviations which do not lead to loss

of performance:

±5% variation in voltage

±2% deviation in frequency

610.44440.40.000 18 / 32 © Gardner Denver Deutschland GmbH

Page 19

610.44440.99.B12

Fig. 11: Knocking out the openings in the terminal

A Standard entry union

B Entry union with reducer

C Installation position of backing nut

Fig. 12: Entry unions with backing nut

box

A

C

B

610.44440.99.B13

To protect the motor against overloading:

Use a power limiting switch.

These have to be adjusted to the design current specified on the rating plate.

5.3.2 Operation with a frequency converter

High-frequency current and voltage harmonics

in the motor supply line can create electromagnetic interference. This is dependent on

the converter design (type, manufacturer, interference suppression measures).

Observe the EMC instructions provided by the

manufacturer of the converter.

Use screened supply cables.

For optimum screening a large area of the

screen should be connected to the motor's

metallic terminal box using a metallic, conductive union.

Depending on the type of converter used,

when using motors having integral sensors

(e.g. PTC resistors) interference can be created in the sensor cables.

For the maximum speed of rotation see the

table, "Maximum speeds", page 9.

In the USA, units having UL approbation may

not be operated on frequency converters

Commissioning

without testing by an appropriate inspection

authority.

6 Commissioning

WARNING

Improper handling of the equipment can result in serious or even fatal injuries!

Have you read the safety notes in chapter 1,

"Safety", page 4 above?

If not then you are not allowed to carry out any

work on or with the equipment!

WARNING

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Hazard presented by moving parts!

The unit may only be started up if:

the fan guard and cover are fitted.

the piping is connected to the suction and

discharge connections and the operatingliquid inlet.

the piping and connections have been pres-

sure and leak tested.

CAUTION

If the unit runs dry the rotary seals will be destroyed within a matter of seconds.

DO NOT switch on until the system has been

filled with operating-liquid!

6.1 Preparation of the unit

CAUTION

If the gases / vapours expelled on the discharge

side are to be transferred onward, then care

must be taken that the maximum outlet pressure

is not exceeded!

See the section, "Pressures", page 10 above.

ATTENTION

Maximal permissible quantity of water carried

along through the inlet connection:

see the table, Maximum permissible quantity of

water carried along", page 12.

If a shut-off device is installed in the discharge

line:

© Gardner Denver Deutschland GmbH 19 / 32 610.44440.40.000

Page 20

Commissioning

Take measures to ensure that the unit

CANNOT be operated with the shut-off device

6.3 Start-up of unit with self-suction of op-

erating-liquid

closed.

Measure the motor insulation resistance.

At values ≤ 1kΩ / Volt of measurement potential, dry the windings.

Check the piping / hose connections for leaks.

6.2 Start-up of unit with operating-liquid

supply

Fill up with operating-liquid

Units with self-suction of operating-liquid are filled

with operating-liquid before completion of the

installation (Filling up with operating-liquid,

page 15.

Further steps at start-up are identical to the procedures during operation.

6.4 Checking the direction of rotation

Filling up with operating-liquid

Check the piping / hose connections on the

For operation with supply of the operating-liquid,

now fill the unit's operating chamber with operating-liquid.

suction and discharge connections.

The unit may not run dry!

See the section, "Filling up with operatingliquid", page 15 and page 20.

For automatically controlled operation:

the shut-off valve in the bypass line (item 5,

Fig. 8, page 17) is to be opened for approx.

20 s.

For non-automatic control of operation:

the shut-off valve (item 5, Fig. 9, page 17) is

to be opened for approx. 20 s.

Briefly switch the unit on then off again.

The intended direction of shaft rotation is

marked by an arrow (item 9 page 3) on the

pump casing.

Before shutting the unit down compare the

actual direction of rotation of the external fan

with the intended direction of rotation of the

shaft.

If necessary, reverse the direction of rotation

Setting the initial pressure of the operatingliquid

The initial pressure, p

in operating-liquid

A

supply line (item B, Fig. 11, page20) is to be

set at approx. 1 bar [14.5 psi] above the suction pressure, p

in the suction line (item A,

B

Fig. 11, page20).

B

A

of the motor.

pB = pA + 1 bar

pB = pA + 14.5 psi

610.44440.99.B14

A Suction line

B Operating-liquid supply line

Fig. 13: Adjusting the operating-liquid flow-rate:

setting the initial pressure

Further steps at start-up are identical to the procedures during operation.

610.44440.40.000 20 / 32 © Gardner Denver Deutschland GmbH

Page 21

Operation

7 Operation

WARNING

Improper handling of the equipment can result in serious or even fatal injuries!

Have you read the safety notes in chapter 1,

"Safety", page 4 above?

If not then you are not allowed to carry out any

work on or with the equipment!

WARNING

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Hazard presented by moving parts!

The unit may only be started up if:

the fan guard and cover are fitted.

the piping is connected to the suction and

discharge connections.

the piping and connections have been pres-

sure and leak tested.

CAUTION

If the unit runs dry the rotary seals will be destroyed within a matter of seconds.

DO NOT switch on until the system has been

filled with operating-liquid!

WARNING

Danger of burns or scalding from hot surfaces on the unit and from hot media!

Do not touch when in operation!

After shutdown, allow system to cool down!

ATTENTION

Maximum permissible quantity of water carried

along through the inlet connection:

see the table, "Maximum permissible quantity of

water carried along", page 12.

7.1 Operation with supply of the operatingliquid, automatically controlled operation

Starting the unit up

Switch on the power supply.

The unit will start to draw in the gases / va-

pours to be handled.

The solenoid valve (item 4, Fig. 8, page 17)

opens and the operating-liquid is supplied.

Switching the unit off:

Switch off the power supply.

The unit interrupts suction of the gases / va-

pours.

The solenoid valve (item 4, Fig. 8, page 17)

closes and supply of the operating-liquid ceases.

The throttle valve (item 3, Fig. 8, page 17) is

used for setting the operating-liquid flow rate:

during operational shutdown the valve-setting

(i.e. the position of the valve or the crosssectional area of the valve that is open) is not

to be changed.

7.2 Operation with supply of the operatingliquid, non-automatic control of operation

Starting the unit up

The shut-off valve (item 4, Fig. 9, page 17) is

to be opened manually.

the operating-liquid is supplied.

switch on the power supply.

The unit will start to draw in the gases / va-

pours to be handled.

Switching the unit off:

Switch off the power supply.

The unit interrupts suction of the gases / va-

pours.

The shut-off valve (item 4, Fig. 9, page 17) is

to be closed manually.

supply of operating-liquid ceases.

The throttle valve (item 3, Fig. 9, page 17) is

used for setting the operating-liquid flow rate:

during operational shutdown the valve-setting

(i.e. the position of the valve or the crosssectional area of the valve that is open) is not

to be changed.

© Gardner Denver Deutschland GmbH 21 / 32 610.44440.40.000

Page 22

Operation

7.3 Operation with self-suction of the operating-liquid

When switching the unit on there should be a

vacuum in the suction line (item 8, Fig. 10,

page 17) of min. 900 mbar abs. [13.1 psia].

When switching on the liquid level in the sup-

ply line (item 7, Fig. 10, page 17) or in the

storage vessel (item 9, Fig. 10, page 17) must

be at the same level as the operating-liquid

connection on the unit (item a, Fig. 10,

page 17).

During operation the liquid level in the storage

vessel (item 9, Fig. 10, page 17) may not sink

below approx. 1 m [3.28 ft] under the level of

the operating-liquid connection (item b, Fig.

10, page 17).

Starting the unit up

Switch on the power supply.

The unit begins to draw in the operating-liquid

and the gases / vapours to be handled.

Switching the unit off:

Switch off the power supply.

The unit ceases drawing in the operating-

liquid and the gases / vapours.

7.4 Checking and correcting the operatingliquid flow-rate

using the flow meter (item 2Fig. 8, page 17, or

item 2, Fig. 9, page 17)

OR

by measuring the quantity of operating-liquid

per unit of time flowing from the discharge

connection using a measuring cup (Fig. 14,

page 22)

C

B Operating-liquid supply line

C Discharge line

Fig. 14: Adjusting the operating-liquid flow-rate:

Measuring the flow-rate using a measuring

cup

B

610.44440.99.B15

Correcting the operating-liquid flow-rate for

unit with operating-liquid supplied

Correct the operating-liquid flow-rate by

means of the throttle valve (item 3, Fig. 8,

page 17, or item 3, Fig. 9, page 17).

see the table, "Design operating-liquid flow",

page 11.

For self-suction of operating-liquid the operating-liquid flow-rate varies as follows:

The higher the suction pressure, the lower the

operating-liquid flow-rate.

The lower the suction pressure, the lower the

operating-liquid flow-rate.

610.44440.40.000 22 / 32 © Gardner Denver Deutschland GmbH

Page 23

Decommissioning the machine and shutting it down for a longer period of time

8 Decommissioning the machine

and shutting it down for a longer

period of time

WARNING

Improper handling of the equipment can result in serious or even fatal injuries!

Have you read the safety notes chapter 1,

"Safety", page 4 above?

If not then you are not allowed to carry out any

work on or with the equipment!

8.1 Draining down

DANGER

Electrical hazard!

Before starting work on the unit or system, the

following precautions are to be taken:

de-energize it.

protect it from being switched on again.

make sure that it is de-energized.

earth it and bypass it.

cover or block off adjoining parts which are

still live.

WARNING

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Before starting work on the unit or system:

shut off the operating-liquid supply.

vent the piping and the unit (de-pressurize).

WARNING

Switch off the power supply.

Take the abovementioned precautionary

measures for safety when working on the unit

or system.

Place suitable drain-off containers underneath

the cover.

Open the screwed plugs in all drain tappings

(item 4, page 3).

Allow the liquid to drain off.

Whilst doing so turn the shaft in its normal

direction from time to time (Fig. 15, page 23).

For 2BV2 …:

- screw in an M8 bolt of sufficient length into

the shaft end on the external fan side.

- use a wrench to turn the shaft manually.

For 2BV5 …:

- remove the fan guard.

- turn the external fan by hand.

if necessary remove the fixings from the

mounting feet and tip the unit over by 45° toward the cover side.

continue these measures until no further liquid

comes out.

close the screwed plugs in all drain tappings

(item 4, page 3).

Tightening torques: 2 3 Nm

[1.48 ... 2.21 ft lbs].

for 2BV2 … remove the bolt from the shaft

end on the fan side.

For 2BV5 … refit the fan guard.

reinstall the fixings in the mounting feet.

2BV2 ... 2BV5 ...

Danger of burns or scalding from hot surfaces on the unit and from hot media!

Do not touch when in operation!

After shutdown, allow system to cool down!

WARNING

Hazard presented by combustible, caustic or

poisonous substances!

In order to protect persons and the environment:

Units that have come into contact with hazard-

ous substances must be flushed out whilst running, before opening the unit up.

Fig. 15: Turning the shaft

610.44440.99.B16

© Gardner Denver Deutschland GmbH 23 / 32 610.44440.40.000

Page 24

Decommissioning the machine and shutting it down for a longer period of time

8.2 Preparations for long-term shutdown

For longer shutdown periods (from approx.

4 weeks) or in the event of frost hazard proceed

as follows:

Cast iron construction:

Drain down the unit as described in chap-

ter 8.1, "Draining down", page 23.

Remove the piping / hoses from the suction

and discharge connections.

Pour a preserving agent (anti-rust oil, e.g.

Mobilarma 247 supplied by the Mobil Oil Co.)

into the open suction and discharge connections.

Charge required:

for 2BV2 …:

½ l [0.132 gal (US); 0.110 gal (UK)]

For 2BV5 …:

1 l [0.264 gal (US); 0.220 gal (UK)]

Seal off the suction and discharge connec-

tions as well as the operating-liquid connection or alternatively reinstall the piping / hoses.

Start and stop the unit briefly to distribute the

preserving agent.

There are two alternatives for storage:

- the unit remains connected up to the sys-

tem,

- or the unit is removed and stored sepa-

rately.

Stainless steel and bronze constructions:

Drain down the unit as described in chap-

ter 8.1, "Draining down", page 23.

There are two alternatives for storage:

- the unit remains connected up to the sys-

tem,

OR

- or the unit is removed and stored sepa-

rately.

8.3 Storage conditions

This chapter applies to:

new units,

units that have been prepared for long-term

shutdown as described in chapter 8.2,

"Preparations for long-term shutdown",

page 24.

In order to avoid damage during shutdown and

storage periods, the ambient conditions should

be as follows:

dry,

free of dust,

low vibration (effective value for the speed of

oscillation veff ≤ 2.8 mm/s [0.11"/sec]).

ambient temperature:

max. +40 °C [+104 °F].

CAUTION

Risk of material damage due to high temperatures!

Storage at ambient temperatures in excess of

40 °C [104 °F] can result in damage to the windings and reduced re-greasing intervals.

8.4 Commissioning after a long shutdown

period

CAUTION

Risk of material damage due to insufficient

lubrication of roller bearings after long term

storage!

If the unit is stored for a period of more than

2 years then the roller bearings will require

new greasing (see Re-grease or renew roller

bearings, page 27).

Drain off the preserving agent (chapter 8.1,

"Draining down", page 23).

No further cleaning of the unit is necessary.

Dispose of the preserving agent in accor-

dance with the manufacturer's recommendations.

In the event that the impeller does not rotate

freely:

Decalcifying the unitt or To free it, rotate the

shaft (chapter 9.1, "Maintenance", page 26).

For new units proceed as described in chap-

ter 5, "Installation", page 14.

For units having been shut down for long pe-

riods proceed as described in chapter 6

"Commissioning", page 14.

610.44440.40.000 24 / 32 © Gardner Denver Deutschland GmbH

Page 25

Maintenance

A

9 Maintenance

WARNING

Improper handling of the equipment can result in serious or even fatal injuries!

Have you read the safety notes in chapter 1,

"Safety", page 4 above?

If not then you are not allowed to carry out any

work on or with the equipment!

WARNING

Improper handling of the unit

can result in serious or even fatal injuries!

ll maintenance and service work on the system

must be carried out by the service department!

The operator may only carry out maintenance

work on the unit if they are in possession of the

relevant maintenance instructions!

Please consult our service department!

DANGER

Electrical hazard!

Before starting work on the unit or system, the

following precautions are to be taken:

de-energize it.

protect it from being switched on again.

make sure that it is de-energized.

earth it and bypass it.

cover or block off adjoining parts which are

still live.

WARNING

WARNING

Danger of burns or scalding from hot surfaces on the unit and from hot media!

After shutdown, allow system to cool down!

WARNING

Hazard presented by rotation of the unit's

impeller!

Removal of the cover is forbidden!

WARNING

Danger of injury if components tip over or

fall off!

If fixings have come loose then some components may only be held by their centring, their

seating or even not at all and so they could fall

off.

take appropriate precautions when disman-

tling and reinstalling components.

WARNING

Hazard presented by combustible, caustic or

poisonous substances!

Units that have come into contact with haz-

ardous substances must be flushed out whilst

running, before opening the unit up.

Hazard in case of overpressure and negative

pressure!

Hazard presented by leaking media!

Before starting work on the unit or system:

shut off the operating-liquid supply.

vent the piping and the unit (de-pressurize).

© Gardner Denver Deutschland GmbH 25 / 32 610.44440.40.000

Page 26

Maintenance

9.1 Maintenance

Interval Maintenance procedure

monthly

check the piping and screwed joints for leakage and secure fixing then reseal

and retighten them as necessary.

monthly

check the terminal box cover and cable entry openings for proper sealing and

reseal if necessary.

dependent on the

concentration of

contaminant particles

in the ambient air

Check the fan guard, the external fan and the cooling vanes on the motor for

contamination and clean if necessary

Take protective measures appropriate for the use of compressed air:

get personal protection gear (gloves and protective safety glasses).

secure the surrounding area. Remove any objects lying around in the area.

Clean the fan guard, external fan and motor cooling vanes using compressed

air.

dependent on the

concentration of contaminant particles in

the operating-liquid

separator, filter or strainer to be installed in the supply line.

Flushing the pump casing

Shut down the unit.

Dismantle the piping / hoses.

Place suitable drain-off containers underneath the cover.

Open the screwed plugs in all drain tappings (item 4, page 3).

Connect a hose to the discharge connection and run it to the drain-off container.

Connect a flushing liquid hose to the operating-liquid connection.

use a clean, non-hazardous medium (e.g. water) for flushing.

Start the unit up and keep the flushing liquid supply flowing continuously.

- contaminants will be flushed out of the pump casing along with the flushing

liquid.

- continue the procedure until the flushing liquid emerges free of contamina-

tion.

Shut down the unit.

Remove the hoses from the discharge connection and from the operating-liquid

connection and reconnect the system piping to the unit.

Close the screwed plugs in all drain tappings (item 4, page 3). Tightening

torques: 2 ... 3 Nm [1.48 ... 2.21 ft lbs].

depending on the

hardness of the operating-liquid

(hardness > 15°dH)

Operating-liquid to be softened.

Decalcifying the unit (3-monthly intervals)

Get personal protection gear (gloves and protective safety glasses).

Shut down the unit.

Drain the unit down (see chapter 8.1, "Draining down", page 23).

Dismantle the piping / hoses.

Fill the unit with decalcifying agent through one of the connection openings. use

a 10% acetic acid concentrate or another commercially available decalcifying

agent.

Leave the decalcifying liquid in the unit for at least 30 min.

Whilst doing so turn the shaft in its normal direction from time to time (Fig. 15,

page 23).

2BV2 …:

Screw in an M8 bolt of sufficient length into

the shaft end on the external fan side.

Use a wrench to turn the shaft manually.

Remove the bolt.

2BV5 …:

Remove the fan guard.

Turn the external fan by

hand.

Refit the fan guard.

610.44440.40.000 26 / 32 © Gardner Denver Deutschland GmbH

Page 27

Interval Maintenance procedure

Drain off the decalcifying liquid from the unit (see chapter 8.1, "Draining down",

page 23).

Flushing the pump casing(see page 26).

Reconnect the piping / hoses.

Start up the unit again (see chapter 6, "Commissioning", page 19).

Dispose of the decalcifying agent in accordance with the applicable directives.

2.5 years or

20,000 operating

hours

Re-grease or renew roller bearings

Open roller bearings and adjacent grease cups are to be cleaned of old grease

and contamination.

Fill approx. 50% of the free space in the roller bearings and approx. 65% of the

volume in the adjacent areas with grease.

Grease type: UNIREX N3 (ESSO Co.)

Alternative grease acc. DIN 51825-K3N

Sealed roller bearings are to be renewed and the adjacent areas do not require

greasing.

It is recommended that the rotary seal, the V-ring and the valve head are

checked for wear and replaced if necessary.

The specified intervals apply only when using UNIREX N3 grease. Avoid mixing

different types of grease.

Maintenance

9.2 Repairs / Troubleshooting

Fault Cause Correction Remedy

Motor does

not start

Electrical power supply failure

Impeller does not rotate freely

Check fuses, terminals and cables for continuity. Re-

pair any break in continuity.

To free it, rotate the shaft:

2BV2 …:

Screw in an M8 bolt of suf-

ficient length into the shaft

end on the external fan

side.

Use a wrench to turn the

2BV5 …:

Remove the fan guard.

Turn the external fan

by hand.

Refit the fan guard.

Electrician

Operator

shaft manually.

Remove the bolt.

See "Decalcifying the unit", page 26. Operator

See "Flushing the pump casing", page 26. Operator

Check the clearance adjustment on the impeller and

Service

readjust if necessary.

Foreign matter in the

unit

Defective impeller

Defective motor bear-

Remove the foreign matter.

Check that the unit functions correctly.

Replace the impeller.

Replace the motor bearing.

Service

Service

Service

ing

breaker trips

out again

after it has

been

switched on

Short-circuit in the

winding

Motor

overloaded

Check the winding.

When operating with supply of the operating-liquid:

Check the operating-liquid flow-rate and if necessary

reduce it (see chapter 7.4, "Checking and correcting

ElectricianCircuit

Operator

the operating-liquid flow-rate", page 22).

© Gardner Denver Deutschland GmbH 27 / 32 610.44440.40.000

Page 28

Maintenance

Fault Cause Correction Remedy

Excessive backpres-

Reduce the backpressure.

Operator

sure in the discharge

connection

Proportion of liquid

Reduce the proportion of liquid.

Operator

entrained in the main

flow is too high

Impeller does not ro-

See "Impeller does not rotate freely", page 27

tate freely

See "Decalcifying the unit", page 26. Operator Power con-

See "Flushing the pump casing", page 26. Operator

When operating with supply of the operating-liquid:

Operator

Check and correct the operating-liquid flow-rate. (see

chapter 7.4, "Checking and correcting the operating-

sumption

too high

Unit does

not generate

a vacuum

Build up of lime-scale

or

contamination

No operating-liquid

supply

liquid flow-rate, page 22).

When operating with self-suction of the operating-liquid:

See 7.3, "Operation with self-suction of the operating-

liquid", page 22.

Clean out the operating-liquid supply hose.

Increase the diameter of the operating-liquid supply

hose.

Large-scale leak in the

Seal off leaks in the system.

Operator

system.

System

generates

too little

vacuum

Incorrect direction of

rotation

Insufficient operatingliquid

Operating-liquid too

warm

Change the direction of rotation by switching polarity

between two of the electrical power supply phases.

See "No operating-liquid supply", page 28. Operator

cool the operating-liquid or increase the flow-rate (see

chapter 7.4, "Checking and correcting the operating-

Electrician

Operator

liquid flow-rate", page 22).

(nominal temperature: 15°C [59 °F]).

Erosion / Corrosion

Inspection of the casing, the impeller and the control

Service

disk.

Renew the affected components.

Leakage in the system

Rotary seal leaking

Motor connection in-

Repair leakage in the system.

Replace rotary seal.

Check and repair motor connection.

Operator

Service

Electrician

correct

Electrical power sup-

Check and repair electrical power supply.

Electrician

ply incorrect

Squealing

noises

Unit is too small

Cavitation in the unit

Install a larger unit.

2BV2 … and 2BV5 1..

Connect separator

cavitation-protection

hose (ancillary) or

2BV5 4..

Check that the pressure set-

ting is in accordance with the

permitted operating pressure.

Operator

Operator

clean out cavitationprotection system.

Operating-liquid flowrate too high

Check the operating-liquid flow-rate and if necessary

reduce it (see chapter 7.4, "Checking and correcting

Operator

the operating-liquid flow-rate", page 22).

Leakage in

Defective seals

Check the seals.

Service

the unit

610.44440.40.000 28 / 32 © Gardner Denver Deutschland GmbH

Page 29

Disposal

9.3 Service / Customer service

Our service department (ref. cover sheet of these

operating instructions) is always available for

work that is not described in these operating

instructions (fitting of replacement parts and

maintenance and repair work).

When returning units to us:

before dispatch:

- Drain down the unit completely as de-

scribed in chapter 8.1, "Draining down",

page 23.

- Clean the unit internally and externally,

as described under "Flushing the pump casing", page 26.

The unit must be delivered complete, i.e. not

disassembled.

A suitable individual packaging is necessary

on dispatch to prevent transport damage.

A declaration of conformity must accompany

the delivery as described in chapter 9.4,

"Decontamination and declaration of Clearance", page 29.

The unit's original data plate must be correctly

in place, intact and readable.

All claims against guarantee lapse where they

apply to systems which are delivered for an

estimate of damage to be made, and where

the system is without the original data plate or

where the original data plate has been destroyed.

In the event of any guarantee claim the manu-

facturer must be notified of the operating conditions and duration of operation as well as

any other details on request.

9.4 Decontamination and declaration of

Clearance

WARNING

Hazard presented by combustible, caustic or

poisonous substances!

Units which have come into contact with haz-

ardous substances must be decontaminated

before being sent to a workshop!

Every unit that is sent to a workshop for inspection, maintenance or repair must be accompanied

by what is known as a declaration of Clearance.

The declaration of Clearance,

which is included in the chapter, Form for

statement on safety", page 31in a form that

can be photocopied

and is legally binding,

must be completed and signed by authorized

technical personnel,

must be completed separately for each unit

dispatched (i.e. one declaration for each unit),

must be affixed to the outside of the unit's

packaging

and a copy should be sent (e.g. by fax) to the