Page 1

Edition: 12.2009 · 610.44440.40.200 Original operating instructions · English

Supplementary instructions L-BV2, L-BV5

Supplement to instruction manual 610.44440.40.000

Devices of group II, category 2G

2BV2 060

2BV2 061

2BV2 070

2BV2 071

2BV5 110

2BV5 111

2BV5 121

2BV5 131

2BV5 161

L-Serie

L-Series

Flüssigkeitsring

Liquid Ring

Page 2

Concerning 1 Safety

Content

Concerning 1 Safety

Concerning 1

Safety.........................................2

Concerning 1.2 General safety instructions.2

Concerning 2 Correct use of the equipment ....3

Concerning 3 Technical Data ........................... 5

Concerning 3.3 Operating conditions,

normal operation............... .............................5

Concerning 5 Installation..................................5

Concerning 5.1 Installing the unit ................5

Concerning 5.2 Connecting the unit

mechanically................................................... 5

Concerning 5.2.1 Connecting the suction

and discharge branches............................5

Concerning 5.2.3 Connecting up system

components...............................................5

Concerning 5.2.4 Ancillaries ...................8

Concerning 5.3 Connecting the motor

electrically.......................................................8

Concerning 5.3.2 Operating with a

frequency converter...................................8

Concerning 7 Operation ...................................8

Concerning 9 Maintenance ..............................8

Concerning 9.1 Servicing.............................8

EU Declaration of conformity...............................9

Form for statement on safety ............................10

Concerning 1.2 General safety instructions

WARNING

The respective national accident prevention

regulations must be complied with!

WARNING

Improper handling of the system can result

in serious or even fatal injuries!

Operating manual 610.44440.40.000 as well as

this supplementary operating manual:

must be read and understood before

commencing any work on or with the unit,

must be strictly adhered to.

must be available where the unit is used.

WARNING

Improper handling of the system can result

in serious or even fatal injuries!

All work on and with the system (transport,

installation, commissioning, decommissioning,

maintenance, disposal) may only be carried out

by trained and reliable skilled staff!

© 2009 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Germany

Disclosure, replication, distribution and / or editing of this document and the use and distribution of its

content are prohibited if not explicitly permitted. Violation obligates compensation. All rights reserved

in case of the issue of a patent, utility patent or design patent.

Page 3

Concerning 2 Correct use of the equipment

Concerning 2 Correct use of the

equipment

Point 2 “Intended Use” from 610.44440.40.000 is

replaced by:

This operating manual

is applicable to L-Series Liquid ring vacuum

pumps / compressors (units) types:

2BV2 060 2BV2 061 2BV2 070 2BV2 071

2BV5 110 2BV5 111 2BV5 121 2BV5 131

2BV5 161

Additional instructions Concerning explosion

protection according to Guideline 94/9/EG

contains instructions for the unit’s

transportation, installation, start-up, operation,

shut-down, storage, maintenance and

disposal,

must have been read and properly understood

by operating and maintenance staff before

beginning any work with or on the unit.

must be complied with and

must be at hand where the unit is installed.

G-BH1 units

create a vacuum or overpressure.

are used to extract, deliver and compress the

following gases / vapours:

− all dry and damp gases which are not

explosive, combustible, aggressive or

poisonous,

− air or air-vapour mixtures.

− in the case of aggressive or poisonous

gases / vapours, please consult the

manufacturer.

− the gases / vapours must be free of solid

matter.

Small quantities of light suspended matter

or liquids can be conveyed along too.

are suitable for a deep vacuum range.

are equipped with RL 94/9/EG three-phase

drive motors. For more detailed information

please consult the motor manufacturer’s

accompanying operating instructions.

are available in two constructions:

− Construction for normal requirements

− Construction for higher corrosion-resistance

and hygiene requirements (only 2BV2 070.

2BV2 071 and 2BV5 ..)

Operating and maintenance personnel

Operating and maintenance personnel for G-BH1

units must be trained and authorised for the work

to be carried out.

Work on electrical installations may only be

carried out by an electrics specialist.

An electrics specialist is someone who can

evaluate and identify potential risks for the

assigned task as a result of their technical

training, knowledge and experience as well as

knowledge about relevant regulations.

are designed for industrial plants.

are designed for continuous operation.

When operating the units, the limiting values

listed in chapter 3 operating manual

610.44440.40.000 "Technical Data" are to be

complied with.

Scope of application for units according to

Guideline 94/9/EG

Inside area of explosion prevention design

G-BH1 units are suitable for conveying

gases/vapours where a potentially explosive

atmosphere is occasionally expected to be

present.

This specification includes category 2G for the

internal space of the units.

If the specified maximum temperatures are

complied with, the units are suitable for

temperature class T4.

Surrounding area

When rating the device category, both the place

where it is installed and its internal space must

be taken into consideration.

Installing G-BH1 units for category 2G is allowed

for areas where potentially explosive gases /

vapours are expected to occur occasionally.

© Gardner Denver Deutschland GmbH 3 / 12 610.44440.40.200

Page 4

Concerning 2 Correct use of the equipment

If the specified maximum temperatures are

Foreseeable misuse

complied with, the units are suitable for

temperature class T3.

G-BH1 unit operating liquid

WARNING

The ignition temperature of the operating fluid

must be above 150°C [150.00°F].

The chosen operating liquid must comply with

the requirements / properties stated below.

It must not corrode or destroy the pump

components used.

WARNING

Monitoring of the operating liquid status before

starting up as well as monitoring of trouble-free

feeding of the operating liquid while in operation

should be built into the system.

The system must shut down if there is a failure

in the operating fluid feed.

Operating without operating fluid must be

avoided under all circumstances.

NOTE

When using operating fluids with a heat capacity

of < 3 kJ/kg K, or a boiling point which does not

lie 20 K above the input temperature, consult

the manufacturer.

The following are forbidden:

Use of the unit2BV2 060 2BV2 061 2BV2

070 2BV2 071 2BV5 110 2BV5 111

2BV5 121 2BV5 131 2BV5 161 in nonindustrial plants, unless the necessary

precautions and protective measures have

been taken at the plant, e.g. protection

against contact by children's' fingers.

Setting up and use of units in zones 0, 20, 21

and 22.

The extraction, transport and condensing

of aggressive or poisonous media unless the

units are specifically designed for such media.

to evacuate, convey and compress explosive,

inflammable, or aggressive mediums, which

could damage the slide ring seal.

To evacuate, convey and compress gases or

gas mixtures which are explosive when air is

not present, or may change the unit’s safetyrelevant material properties.

Operation with a frequency converter.

Operation of the unit at any values other than

those specified in chapter 3 “Technical data”

in the 610.44440.40.000 operating manual.

Modifications to the units are forbidden for safety

reasons.

The operator is not allowed to carry out

maintenance, servicing and repair work which

requires the machine to be dismantled.

Operating liquid type:

Normally use water with a pH-value between 6

and 9, or any other liquid compatible with the

process.

It must be free of:

− Foreign matter and objects:

− Crystalline precipitate substances

− Substances which tend to stick or jam

No precipitate substances may be produced from

the operating fluid during the sealing process.

Likewise, no substances may be used which tend

to polymerise of their own accord or when in

contact with propellant gas.

Compatibility must be checked with regards to

chemical reactions between the operating liquid

and the slide ring seal, the operating fluid and

other pump parts as well as the operating fluid

and the propellant gas.

610.44440.40.200 4 / 12 © Gardner Denver Deutschland GmbH

Page 5

Concerning 3 Technical Data

Concerning 3 Technical Data

Concerning 5.2 Connecting the unit

mechanically...............

Concerning 3.3 Operating conditions,

normal operation...............

Temperatures

Concerning 5.2.1 Connecting the suction and

discharge branches

In order to prevent overloading from throttle on

the discharge side, pressure monitoring (G2,

Temperature of the operating liquid

[°C] [°F]

max. +65 max. +149

Nominal value:

min. +5 min. +41

+15 +59

Fig. 1, page 6) must be installed on the other side

of the unit’s gas output flange. If the maximum

outlet pressure p

specified in the

2 max

610.44440.40.000 operating manual section 3.3,

“Operating conditions, normal operation” is

exceeded, the equipment must switch off.

If operating with cavitation protection, the line

must have sufficient electrical conductivity

(bleeder resistance < 10

6

Ω).

Foreign bodies must be prevented from getting

Pressures

into the pump.

If there is danger of foreign bodies getting in

Minimum suction pressure of the gas

while the pump is operating or switched off,

suitable filters must be attached.

If an explosive gas mixture should arise due to

ambient air entering the unit, the use of process

gas must be ensured for the cavitation protection.

If the unit suction pressure (p

) doesn’t stand

1 min

at a minimum of 50 mbar above the vapour

pressure (p

(=> p

1 min

≤ p

) of the operating fluid

Vapour

+ 50 mbar) or when there are

Vapour

changes in the operating conditions (media,

temperatures), consult the manufacturer.

Concerning 5 Installation

Concerning 5.2.3 Connecting up system

components...............

The built-in monitoring systems must be fully

functional independently from one another. The

systems must also remain independent if

computer-programmed controls are used.

Monitoring of continual operating liquid feed

Concerning 5.1 Installing the unit

Monitoring of continual operating liquid feed is

compulsory. Monitoring can be ensured by the

Conditions for setting up the system:

The type of protection on the drive motor must

correspond to the ambient atmosphere

requirements in accordance with guideline

94/9/EG.

The equipment and components added to the

unit must also correspond to the requirements for

device group II category in guideline 94/9/EG.

The equipment and components added to the

unit must also correspond to the requirements for

device group II category in guideline 94/9/EG,

unless they have their own ignition source. The

bleeder resistance for each installed accessory or

attached part as well as for the unit must have

6

< 10

Ohm to ground when assembled!

following alternative systems:

a) Measuring the operating liquid volume flow

(F1, Fig. 1, page 6) with suitable sensor and

analysis device. Switching commands must

operate directly on the switches.

When using a volume flow device which can

block, an additional redundant monitoring

system must be provided.

Specifications regarding failure safety as well

as calibration and servicing intervals should

be taken from the monitoring device operating

manual.

Disconnection condition:

Volume flow ≤ 50 % of the design operating

fluid flow

(see 610.44440.40.000 operating manual

section 3.3, “Operating conditions, normal

operation”)

© Gardner Denver Deutschland GmbH 5 / 12 610.44440.40.200

Page 6

Concerning 5 Installation

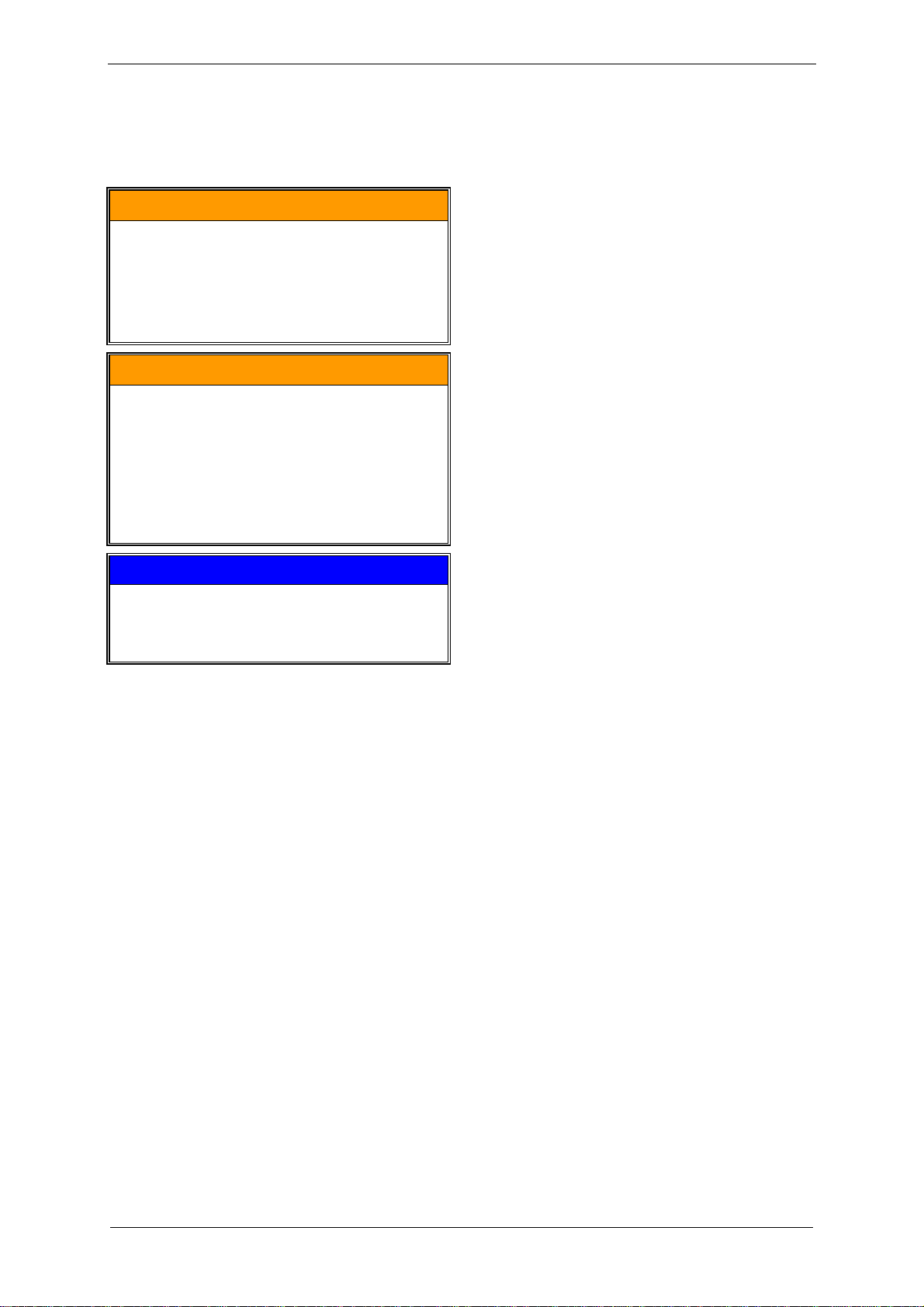

b) Operating fluid temperature measurement in

the drain tapping (F2, Fig. 1, page 6), or on

the unit housing (F5, Fig. 1, page 6) with

suitable temperature sensor.

Disconnection condition:

Temperature ≥ 60 °C (140 °F)

2BV2 0.. 2BV5 1..

G1

F3

G2

F5

F4

F2

The measurement and control device must be

suitable or certified to take reliable

measurements for disconnection conditions and

shut down the equipment if necessary.

The device must be certified with regard to its

point of installation in accordance with its

category.

It is recommendable to implement the monitoring

systems in accordance with EN ISO 13849.

The volume flow measurement sensor must be

suitable for the area prevailing in the measuring

point internal space.

F3

F5

F1

F4

F2

G1G2

F1

A

F1 Flow measurement in the operating fluid feed. G1 Pressure measurement in propellant gas on

suction side, to monitor suction pressure

≤ p

p

1

F2 Temperature measurement in the operating

fluid.

F3 Liquid level for operating liquid, maximum. A Drain tapping

F4 Liquid level for operating liquid, minimum. B,C Drain tapping (only 2BV5 1..)

F5 Temperature measurement on housing

Fig. 1: Position of measuring points

G2 Pressure measurement in propellant gas on

suction side as overload protection.

+ 50 mbar

vapour

B C A

Monitoring liquid level before starting up

Monitoring the liquid level before starting up is

compulsory.

Monitoring can be ensured, for instance, by

inductive proximity switches, solenoid-operated

sensors, or pressure-dependent sensors, each

combined with an analysis device.

The liquid level switches (F3, F4, Fig. 1, page 6)

should be installed in the liquid level monitoring

device (position Fig. 1 page 6).

The monitoring device sensors must be noncorrosive and certified for category 2 if there is

direct contact with the internal space.

The measurement and control device must be

suitable or certified to take reliable

measurements for disconnection conditions and

shut down the equipment if necessary.

The device must be certified with regard to its

point of installation in accordance with its

category.

It is recommendable to implement the monitoring

systems in accordance with EN ISO 13849.

The liquid level monitoring sensor must be

suitable for the area prevailing in the measuring

point internal space.

It must only be possible to turn on the unit if the

given fluid level stands between h

f min

and h

(Fig. 2, page 7).

f max

610.44440.40.200 6 / 12 © Gardner Denver Deutschland GmbH

Page 7

Concerning 5 Installation

NOTE

The liquid level monitoring device (Fig. 1,

page 6) is equipped with a shut-off valve which

opens after the unit is switched off and closes

again before starting up after the filling level has

been regulated.

If a connection between the device and the

ambient atmosphere is not possible, or

undesirable, due to the type of media used, the

line should be routed back into the equipment

behind the shut-off valve on the suction side in a

suitable way (Fig. 1. page 6).

2BV2 0.. 2BV5 1..

h

f max

h

f min

h

f max

h

f min

0

0

Type Minimum h

[mm]

f min

Maximum h

[mm]

f max

Minimum h

[inches]

f min

Maximum h

2BV2 060

75 95 2.95 3.74

2BV2 061

2BV2 070

95 120 3.74 4.72

2BV2 071

2BV5 110

116 156 4.57 6.14

2BV5 111

2BV5 121 130 170 5.12 6.69

2BV5 131 140 185 5.51 7.28

2BV5 161 175 235 6.89 9.25

Fig. 2 Operating liquid level

[inches]

f max

© Gardner Denver Deutschland GmbH 7 / 12 610.44440.40.200

Page 8

Concerning 7 Operation

Concerning 5.2.4 Ancillaries

Operating fluid separator

The 2BX1 102, 2BX2 103 und 2BX1 107

stainless steel separators do not come under

guideline 94/9/EG as they don’t have their own

ignition sources. The propellant gas and the

operating fluid must not react chemically to the

separator. The separator bleeder resistance must

have < 10

6

Ohm to ground when attached or

installed!

When a suction-side separator is used, only a

pressure-resistant construction is permitted in

accordance with guideline 97/23/EG. The

standard separator as in the catalogue must not

be used.

Check valve

The 2BY6 9-type metal check valves do not

come under guideline 94/9/EG as they don’t have

their own ignition sources. The propellant gas

and the operating fluid must not react chemically

to the check valve. The check valve bleeder

resistance must have < 10

6

Ohm to ground when

attached or installed!

Gas ejector

The 2BP5-type metal gas ejectors do not come

under guideline 94/9/EG as they don’t have their

own ignition sources. The propellant gas and the

operating fluid must not react chemically to the

gas ejector. The gas ejector bleeder resistance

must have < 10

6

Ohm to ground when attached

or installed! The gas propellant must be free of

statically rechargeable particles.

Concerning 9 Maintenance

Concerning 5.3 Connecting the motor

electrically...............

The accompanying drive motor operating manual

must be strictly adhered to:

Concerning 5.3.2 Operating with a frequency

converter

WARNING

Operating the unit with a converter is not

permitted.

Concerning 7 Operation

DANGER

If the system is shut down by a monitoring

system during operation, its cause must be

identified and the problem must be rectified

before restarting.

Do not go below the safety level required by the

device category!

Concerning 9.1 Servicing

The operator is not allowed to carry out any kind of maintenance, servicing and repair work which

requires the machine to be dismantled.

Interval Maintenance procedure

weekly Remove dust deposits from unit.

2 years or

18,000 operating hours

Ball bearings to be replaced or re-greased by service technician.

610.44440.40.200 8 / 12 © Gardner Denver Deutschland GmbH

Page 9

EU Declaration of conformity

EU Declaration of conformity

EU declaration of conformity

Manufacturer: Gardner Denver Deutschland GmbH

P.O. Box 1510

D-97605 Bad Neustadt / Saale

Responsible for documentation: Holger Krause

P.O. Box 1510

D-97605 Bad Neustadt / Saale

Designation:

L Series Liquid ring vacuum pump/ compressor

L-BV2, L-BV5

Types 2BV2 060-..D..-Z

2BV2 061-..D..-Z

2BV2 070-..D..-Z

2BV2 071-..D..-Z

2BV5 110-..D..-Z

2BV5 111-..D..-Z

2BV5 121-..D..-Z

2BV2 060-..G..-Z

2BV2 070-..G..-Z

2BV2 071-..G..-Z

2BV5 110-..G..-Z

2BV5 121-..G..-Z

2BV5 131-..D..-Z

2BV5 161-..D..-Z

The liquid ring vacuum pump/compressor described above with motor fitted as per the EC declaration of conformity

issued by Siemens complies with the following applicable Community harmonisation legislation:

94/9/EC Directive 94/9/EC of the European Parliament and the Council of 23 March 1994 on the approximation of

the laws of the Member States concerning equipment and protective systems intended for use in

potentially explosive atmospheres

II 2G b c T3

2006/42/EC Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and

amending Directive 95/16/EC

The protection targets of the directive 2006/95/EC have been met

Harmonised standards applied:

EN 1012-1:1996 Compressors and vacuum pumps — Safety requirements — Part 1: Compressors

EN 1012-2:1996 Compressors and vacuum pumps — Safety requirements — Part 2: Vacuum pumps

EN 1127-1:2007 atmospheres — Explosion prevention and protection —

Part 1: Basic concepts and methodology

EN 13463-1:2001 Non-electrical equipment for potentially explosive atmospheres —

Part 1: Basic method and requirements

EN 13463-5:2003 Non-electrical equipment intended for use in potentially explosive atmospheres —

Part 5: Protection by constructional safety "c"

EN 13463-6:2005 Non-electrical equipment for use in potentially explosive atmospheres —

Part 6: Protection by control of ignition source "b"

The technical documentation is stored at the notified body DEKRA EXAM GmbH, no. 0158 under certification number

BVS 03 ATEX H/B 072/ BVS 03 ATEX H/B 073.

Bad Neustadt/Saale, 29.12.2009

(Place and date of issue)

ppa. Fred Bornschlegl

(Name and function) (Signature)

664.44440.40.200

© Gardner Denver Deutschland GmbH 9 / 12 610.44440.40.200

Page 10

Form for statement on safety

Form for statement on safety

For the safety of our employees and to comply with statutory requirements on handling substances harmful to the health and

the environment, this statement must be enclosed, fully completed, with each unit/system sent.

Without the fully completed statement, repair/disposal is not possible and delays are unavoidable!

The statement is to be completed and signed by suitably qualified, authorised personnel at the operating organisation.

In the case of shipment to Germany, the statement is to be completed in German or English.

The statement is to be attached to the outside of the packing on shipment.

If necessary, the carrier is to be informed.

1. Product designation (type):

2. Serial number (no. BN):

3. Reason for sending:

4. The unit/system

has not come into contact with hazardous substances. There will be no hazards for personnel or the environment during

repair/disposal. Continue with "6. Legally binding statement“

has come into contact with hazardous substances. Continue with "5. Information on the contamination“

5. Information on the conta mina tio n

The unit/system was used in the following application:

and has come into contact with the following classifiable substances or substances presenting a hazard to health/environment:

Trade name: Chemical designation:

Statement on health safety and on the protection of the environment

(if necessary provide more information on an additional sheet)

Hazardous

substance class:

Properties (e.g. toxic, inflammable,

caustic, radioactive):

The unit/system has been emptied in accordance with the operating instructions, flushed and cleaned externally.

Safety data sheets in accordance with the applicable regulations are enclosed ( sheet).

The following safety precautions are necessary for handling (e.g. personal protective equipment):

6. Legally binding statemen t

I herewith guarantee that the details specified are true and complete and that I, as signatory, am in a position to judge that this is

so.

We are aware that we are liable to the contractor for any damages arising from incomplete or incorrect specifications. We are

obliged to indemnify the contractor against claims for damages by third parties arising from incomplete or incorrect specifications.

We are aware that, irrespective of this statement, we are directly liable to third parties - in particular including the contractor's

employees tasked with repair/disposal.

Company/institute:

Name, position: Phone:

Street: Fax:

Post code, city:

Country: Stamp:

Date, signature:

© Gardner Denver Deutschland GmbH 610.00250.40.905

P.O. box 1510 Phone: +49 7622 392 0 E-mail: er.de@gardnerdenver.com 10.2009

97605 Bad Neustadt Fax: +49 7622 392 300 Internet: www.gd-elmorietschle.com English

610.44440.40.200 10 / 12 © Gardner Denver Deutschland GmbH

Page 11

© Gardner Denver Deutschland GmbH 11 / 12 610.44440.40.200

Page 12

Elmo Rietschle is a brand of

Gardner Denver‘s Industrial Products

Group and part of Blower Operations.

www.gd-elmorietschle.de

er.de@gardnerdenver.com

Gardner Denver

Schopfheim GmbH

Roggenbachstraße 58

79650 Schopfheim · Deutschland

Tel. +49 7622 392-0

Fax +49 7622 392-300

Gardner Denver

Deutschland GmbH

Industriestraße 26

97616 Bad Neustadt · Deutschland

Tel. +49 9771 6888-0

Fax +49 9771 6888-4000

Loading...

Loading...