Page 1

Edition: 12.2009 · 610.444430.40.000 Original Operating Instructions · English

Operating Instructions L-BV3

2BV3151

L-Serie

L-Series

Flüssigkeitsring

Liquid Ring

Page 2

Contents

Contents

1 Safety ..................................................................................................................................................3

1.1 Definitions .................................................................................................................................3

1.1.1 Safety alert symbol.......................................................................................................3

1.1.2 Signal words.................................................................................................................3

1.2 General safety precautions .......................................................................................................4

1.3 Residual risks............................................................................................................................5

2 Intended Use .......................................................................................................................................6

3 Technical Data ....................................................................................................................................7

3.1 Mechanical data ........................................................................................................................7

3.2 Electrical data............................................................................................................................7

3.3 Operating conditions .................................................................................................................7

4 Operating modes.................................................................................................................................9

4.1 Self-priming operation...............................................................................................................9

4.2 Operation with operating-liquid feed .........................................................................................9

5 Transport and Handling.....................................................................................................................10

6 Installation .........................................................................................................................................11

6.1 Installation ...............................................................................................................................11

6.2 Electrical connection (motor) ..................................................................................................12

6.3 Connecting pipes/hoses (vacuum pump/compressor)............................................................14

6.3.1 Inlet connection and discharge connection................................................................15

6.3.2 Operating-liquid port...................................................................................................15

6.3.3 Notes ..........................................................................................................................15

7 Commissioning..................................................................................................................................16

7.1 Preparation and start-up .........................................................................................................16

7.2 Self-priming operation.............................................................................................................17

7.3 Operation with operating-liquid feed .......................................................................................18

8 Operation...........................................................................................................................................20

8.1 Self-priming operation.............................................................................................................20

8.2 Operation with operating-liquid feed .......................................................................................20

9 Shut-Down and Longer Standstills....................................................................................................22

9.1 Draining...................................................................................................................................22

9.2 Preparing for longer standstill .................................................................................................22

9.3 Storage conditions ..................................................................................................................23

10 Servicing............................................................................................................................................24

10.1 Maintenance............................................................................................................................24

10.2 Repairs/troubleshooting ..........................................................................................................26

10.3 Service/After-sales service......................................................................................................29

10.4 Decontamination and Declaration of Clearance .....................................................................29

11 Disposal.............................................................................................................................................29

EC Declaration of Conformity .................................................................................................................30

Form for statement on safety .................................................................................................................31

© 2009 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Germany

Replication, distribution and / or editing of this document and the use and distribution of its content is

prohibited unless explicitly permitted. Violation obligates compensation for damages.

All rights reserved in case of the issue of a patent, utility patent or design patent.

Page 3

1 Safety

Safety

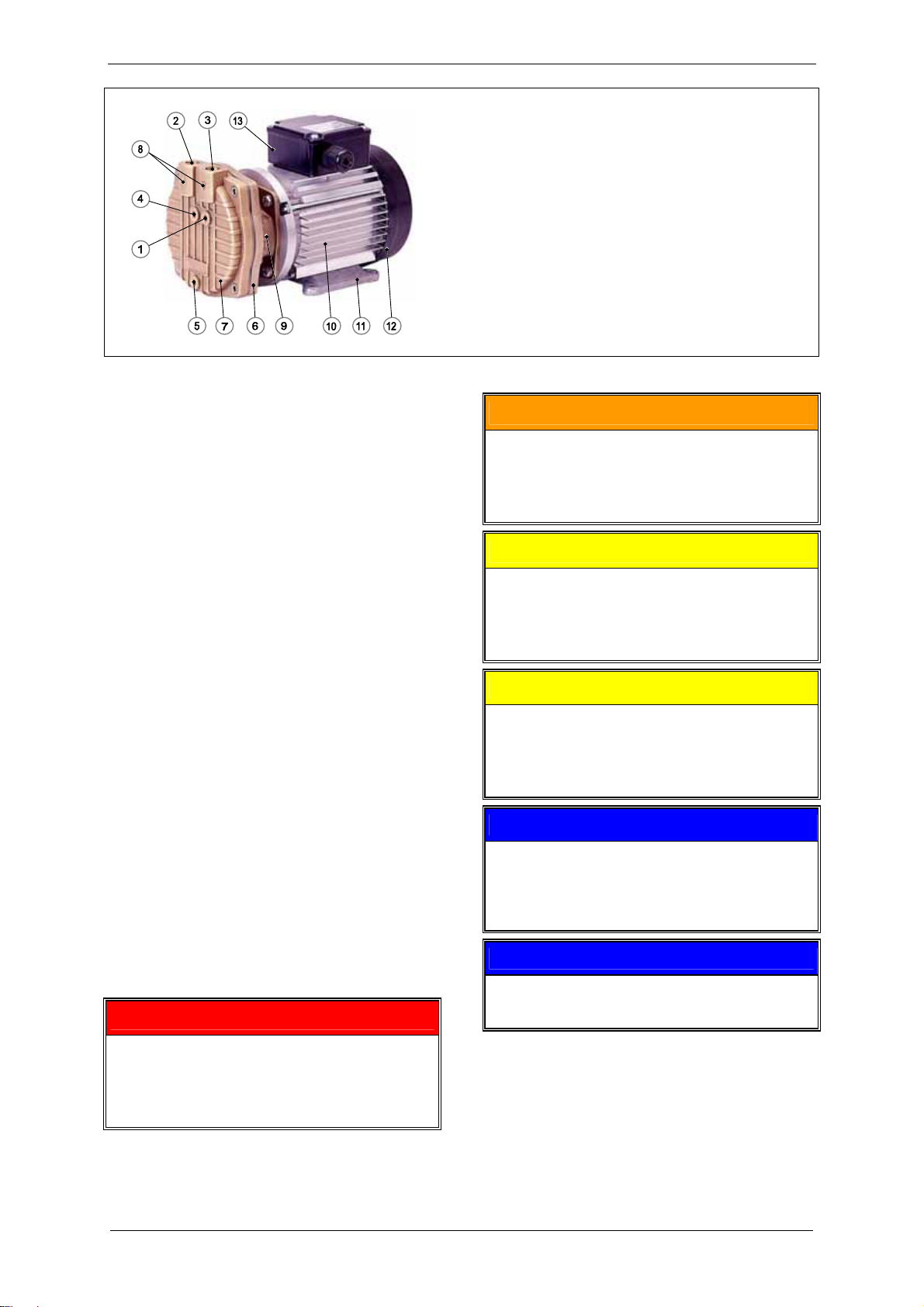

Fig. 1: Design of liquid-ring vacuum

pump/compressor

1 Operating-liquid port

2 Discharge connection

3 Inlet connection

4 Connection for cavitation protection

5 Drain hole

6 Vacuum pump/compressor housing

7 Vacuum pump/compressor cover

8 Flow direction arrows

9 Rotating direction arrow

10 Drive motor

11 Base

12 Fan guard (over external fan)

13 Terminal box

WARNING

1.1 Definitions

To point out dangers and important

information, the following signal words and

symbols are used in these operating

instructions:

1.1.1 Safety alert symbol

The safety alert symbol

is located in the

safety precautions in the highlighted heading

field on the left next to the signal word

(DANGER, WARNING, CAUTION).

Safety precautions with a safety alert symbol

indicate a danger of injuries.

Be sure to follow these safety precautions to

protect against injuries or death!

Safety precautions without a safety alert

symbol indicate a danger of damage.

1.1.2 Signal words

DANGER

WARNING

CAUTION

NOTICE

NOTE

The signal words are located in

the safety precautions in the

highlighted heading field.

They follow a certain hierarchy

and indicate

(in conjunction with the safety

alert symbol, see Chapter 1.1.1)

the seriousness of the danger

and the type of warning.

See the following explanations:

DANGER

Danger of injuries.

Indicates an imminently hazardous situation,

that will result in death or serious injury if the

corresponding measures are not taken.

Danger of injuries.

Indicates a potentially hazardous situation, that

could result in death or serious injury if the

corresponding measures are not taken.

CAUTION

Danger of injuries.

Indicates a potentially hazardous situation, that

may result in minor or moderate injury if the

corresponding measures are not taken.

CAUTION

Danger of damage.

Indicates a potentially hazardous situation that

may result in property damage if the

corresponding measures are not taken.

NOTICE

Indicates a possible disadvantage, i.e.

undesirable conditions or consequences can

occur if the corresponding measures are not

taken.

NOTE

Indicates a possible advantage if the

corresponding measures are taken; tip.

© Gardner Denver Deutschland GmbH 3 / 32 610.444430.40.000

Page 4

Safety

1.2 General safety precautions

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

These operating instructions

must have been read completely and

understood before beginning any work with

or at the pump-motor unit,

must be strictly observed,

must be available at the operating location

of the pump-motor unit.

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Only operate the pump-motor unit

for the purposes indicated under "Intended

Use"!

with the fluids indicated under 'Intended

Use'!

with the values indicated under 'Technical

Data'!

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

All work on and with the pump-motor unit

(transport, installation, operation, shut-down,

maintenance, disposal) may only be carried

out by trained, reliable expert personnel!

WARNING

When working on the unit, there is a danger

of injury, e.g. in the form of cuts/cutting off,

crushing and burns!

During all work on and with the pump-motor

unit (transport, installation, operation, shut-

down, maintenance, disposal) wear personal

safety equipment (safety helmet, protective

gloves, safety shoes)!

WARNING

Hair and clothing can be pulled into the unit

or caught and wound up moving parts!

Do not wear long, loose hair or wide, loose

clothes! Use a hair net!

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

DANGER

Electrical danger!

Work on electrical installations may be carried

out by trained and authorized electricians only!

DANGER

Electrical danger!

Replace loose connections, singed or burned

cables immediately!

DANGER

Electrical danger!

Do not open the motor terminal box unless

absence of electricity has been ensured!

DANGER

Electrical danger!

Depending on the charging state of the

capacitors, a residual voltage may be present

on the terminals in the terminal box.

After opening the terminal box cover, it must

be ensured that the capacitors are completely

deenergized:

Measure the voltage at the corresponding

jumpers (see the circuit diagram in the

terminal box).

Dissipate the residual voltage with suitable

means if necessary.

The capacitors must be completely

deenergized.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the unit or system:

Interrupt supply of operating liquid.

Bleed lines and vacuum pump/compressor

(depressurize).

610.444430.40.000 4 / 32 © Gardner Denver Deutschland GmbH

Page 5

Safety

WARNING

Danger from rotating external fan of unit!

Only operate the unit with the fan guard

mounted!

It is prohibited to remove the fan guard!

WARNING

Danger from rotating impeller of unit!

Only operate the unit with the vacuum

pump/compressor cover and housing mounted!

It is prohibited to remove the vacuum

pump/compressor cover and the housing!

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Danger from rotating impeller of unit!

Only operate the unit with the pipes/hoses

connected to the intake and discharge

connection, as well as to the operating-liquid

port!

WARNING

Danger in the form of cuts or cutting off

extremities on the impeller of the pumpmotor unit!

Do not reach into the unit through open

connections!

Do not insert objects into the unit through the

openings!

WARNING

Danger due to gauge pressure and vacuum!

Check the lines and containers used for

sufficient strength!

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Check the connections of the pipe/hose

connections for leaks!

WARNING

Danger of burns and scalding from hot

surfaces of the pump-motor unit and from

hot fluids!

Do not touch during operation!

Allow to cool after shut-down!

CAUTION

Danger of crushing from unit tipping over!

Secure the pump-motor unit on the installation

surface before putting into operation!

1.3 Residual risks

WARNING

Danger zone:

Fan guard

Hazard:

Long, loose hair can be drawn into external fan

through fan guard grate, even with fan guard

mounted!

Protective measures:

Wear hair net!

WARNING

Danger zone:

Hot surface.

Hazard:

Burns/scalding possible.

Protective measures:

Do not touch! Wear protective gloves!

© Gardner Denver Deutschland GmbH 5 / 32 610.444430.40.000

Page 6

Intended Use

2 Intended Use

These operating instructions

applies to liquid-ring vacuum

pumps/compressors of the series L-BV3,

model 2BV3151,

contain instructions bearing on transport

and handling, installation, commissioning,

operation, shut-down, storage, servicing

and disposal of the L-BV3,

must be completely read and understood by

all operating and servicing personnel before

beginning to work with or on the L-BV3,

must be strictly observed,

must be available at the site of operation of

the L-BV3.

About the operating and servicing personnel of

the L-BV3:

These persons must be trained and

authorized for the work to be carried out.

Work on electrical installations may be

carried out by trained and authorized

electricians only.

The L-BV3

are pump-motor units for generating

vacuum or gauge pressure.

are used to extract, transport and compress

the following pumped gases/vapors:

– all dry and humid gases,

which are not explosive, aggressive or

toxic,

– preferably air or air/vapor mixtures.

– The gases/vapors to be fed must be free

of solid material.

However, small quantities of light

suspended materials or liquids can also

be transported.

are designed for operation with the

following operating liquids:

– Water

with a pH of 6.5 to 9.5,

free of solid materials (such as sand).

– If the pH values or operating liquids

differ, it is necessary to contact the

Service Department.

have the rough vacuum range as the

intended operating range.

are intended for industrial applications.

are designed for continuous operation.

When operating the L-BV3, the limits listed in

Chapter 3, "Technical Data", Pg. 7 ff. must

always be complied with.

If the L-BV3 is used to extract hot fluids, the

necessary safety measures must be taken by

the user.

Foreseeable Misuse

It is prohibited

to use the L-BV3 in applications other than

industrial applications

unless the necessary protection is provided

on the system,

e.g. guards suitable for children's fingers,

to use the L-BV3 in rooms in which

explosive gases can occur,

the sucking up, feeding and compression of

explosive, flammable, aggressive or toxic

fluids,

to operate the L-BV3 with values other than

those specified in Chapter 3, "Technical

Data", Pg. 7 ff.

Any unauthorized modifications of the L-BV3

are prohibited for safety reasons.

Maintenance and repair work by the operator

are only permitted in the scope described in

these operating instructions.

Any maintenance and repair work going

beyond this may only be conducted by

companies authorized by the manufacturer

(inquiry with the Service Department

necessary).

610.444430.40.000 6 / 32 © Gardner Denver Deutschland GmbH

Page 7

3 Technical Data

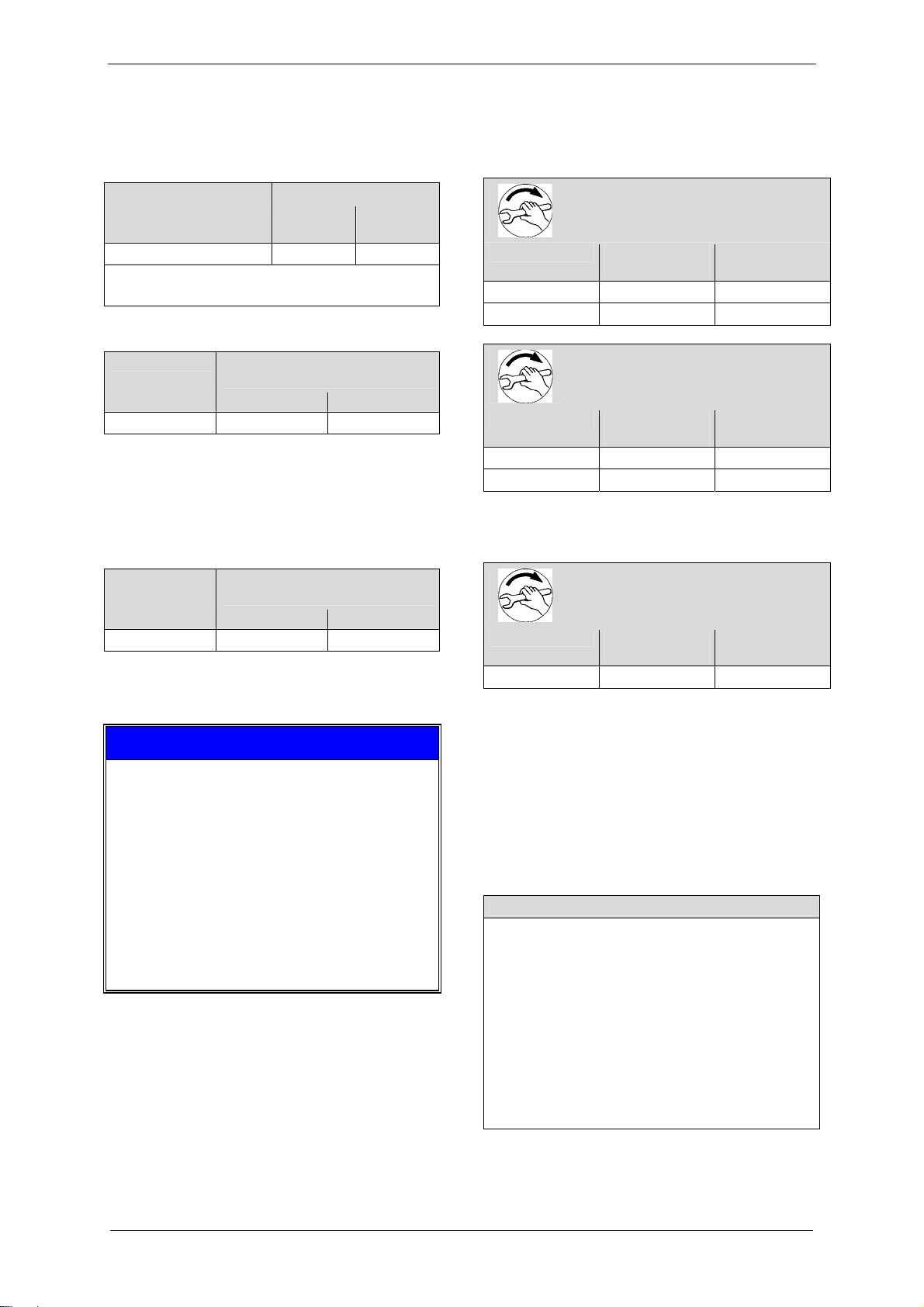

3.1 Mechanical data

Weight

Technical Data

Tightening torques

The values specified here for tightening

torques apply unless other values are

indicated.

Type Weight

approx.

[kg]

2BV3151 9 19.8

approx.

[lbs]

Thread [Nm]

Higher weights are possible with special

models.

Minimum distances for heat dissipation

Type Minimum distance from

fan guard to adjacent surface

[mm] [inches]

2BV3151 20 0.787

G⅛ 4.5 3.32

G⅜ 16 11.8

Thread [Nm]

Noise level

Measuring-surface sound-pressure level

according to EN ISO 3744 measured at a

distance of 1 m [3.28 ft] with moderate

throtteling (8 kPa abs. [1.16 psia]) and lines

connected.

Type 1-m measuring-surface sound

pressure level L [dB (A)

at 50 Hz: at 60 Hz:

2BV3151 70 70

M4 1.0 0.738

M5 2.2 1.62

These values for electrical connections applies

to all terminal board connections with the

exception of modular terminal blocks.)

Thread [Nm]

Operating speed

See rating plate.

NOTICE

Exceeding of the operating speed will

negatively affect the operating behavior of the

pump-motor unit:

higher noise emissions

stronger vibrations

shorter grease consumption time

M3 0.6 0.443

(These values for electrical connections apply

to all modular terminal blocks.)

3.2 Electrical data

See drive motor rating plate.

3.3 Operating conditions

Temperatures

reduced bearing change interval

To prevent damage due to excessively high

speeds, it may be necessary to request the

limit speed (inquire with the Service

Department).

Temperature of pumped gases/vapors:

max. +110 °C max. +230 °F

At higher fluid temperatures, measures must

be taken on the system to prevent burns, e.g.

mount separating safety device (cover).

In addition, we also recommend one of the

following measures at temperatures > 80 °C

[> 176 °F]:

Increasing the operating-liquid flow rate by

up to twice the rated liquid flow rate (cooling

circuit)

Use of a series capacitor

Tightening torques

for screw connections

(pipe-connections)

± 10 %

Tightening torques

for electrical connections

(terminal board-connections)

± 10 %

Tightening torques

for electrical connections

(modular terminal blocks)

± 10 %

[ft lbs]

± 10 %

[ft lbs]

± 10 %

[ft lbs]

± 10 %

© Gardner Denver Deutschland GmbH 7 / 32 610.444430.40.000

Page 8

Technical Data

Operating-liquid temperature:

max. +40 °C max. +104 °F

min. +5 °C min. +41 °F

Nominal value:

+15 °C +59 °F

Ambient temperature:

max. +40 °C +104 °F

min. +5 °C +41 °F

Pressures

Min. inlet pressure p

1 min

:

Depending on the type and temperature of the

operating liquid.

During vacuum operation without cavitation

protection (cavitation protection hole closed):

5 kPa 0.725 psi

It may not be dropped below to prevent

damage due to cavitation!

Damage due to cavitation are purposely

disregarded if the minimum inlet pressure is

3.3 kPa [0.479 psi].

The specified values apply to the following

conditions:

Operating liquid:

Water at +15 °C [+59 °F]

pumped gases/vapors:

dry air at +20 °C [68 °F]

They are higher the higher the temperature

and the higher the vapor pressure of the

operating liquid used.

During vacuum operation with cavitation

protection (cavitation protection hole open):

max. achievable vacuum, i.e. complete

throttling

The following generally applies: The higher the

temperature, the lower the intake capacity, i.e.

the higher the minimum achievable inlet

pressure.

Max. discharge pressure p

2 max

during

vacuum operation:

110 kPa abs. 16.0 psia

This value applies, provided the rated

operating-liquid flow rate is adhered to.

Max. discharge pressure (differential

pressure) p

during compressor

2 max

operation (at inlet pressure p1 = 101.3

bar abs. [14.7 psia]):

60 kPa 8.70 psi

This value applies, provided the rated operatingliquid flow rate is adhered to.

Max. permissible pressure in the pumpmotor unit p

during compressor

int max

operation:

300 kPa abs. 43.5 psia

If higher pressures can occur in the system, then

corresponding protective devices must be provided.

Max. pre-pressure of the operating liquid

300 kPa abs. 43.5 psia

When the permissible operating liquid pressure is

exceeded, too much liquid enters the vacuum

pump/compressor. Damage can occur.

Liquid quantities

Nominal operating-liquid flow rate

(with dry air extraction and with water at 15 °C

[59 °F] as operating liquid)

0.65 l/min 0.172 gal (US)/min 0.143 gal (UK)/min

(0.039 m³/h) (1.38 ft³/h)

Max. filling quantity for operating liquid at a

standstill

0.200 l 0.053 gal (US) 0.044 gal (UK)

Repeated switching on of the pump-motor unit

in the flooded state can result in damage.

Maximum permissible quantity of water

entrained via the inlet connection

3.9 l/min 1.03 gal (US)/min 0.858 gal (UK)/min

If larger quantities can occur, a separator must be

installed upstream on the inlet side.

610.444430.40.000 8 / 32 © Gardner Denver Deutschland GmbH

Page 9

Operating modes

4 Operating modes

The pump-motor unit can function in several

different operating modes.

These differ in how the pump-motor unit is

supplied with operating liquid:

Self-priming operation

Operation with operating-liquid feed:

– Non-automatic operation

– Automatic operation

4.1 Self-priming operation

In this operating mode the pump-motor unit

automatically sucks in the operating liquid.

The operating-liquid flow rate is automatically

adjusted.

See Fig. 4, Pg. 17.

4.2 Operation with operating-liquid feed

In this operating mode the pump-motor unit

DOES NOT automatically suck in the operating

liquid.

A certain volume flow ("nominal operatingliquid flow rate") or pre-pressure must be set

for the operating liquid.

Here the following additional distinctions are

made:

Non-automatic operation

In this case the operating liquid feed is

switched on and off manually with a stop valve.

See Fig. 6, Pg. 19.

Automatic operation

In this case the operating liquid feed is

switched on and off by a solenoid valve. The

solenoid valve is dependent on the motor

operating mode:

Motor/pump-motor unit switched on:

Valve open.

Motor/pump-motor unit switched off:

Valve closed.

See Fig. 7, Pg. 19.

NOTICE

The following is dependent on the operating

mode:

when and how the pump-motor unit must

be filled with operating liquid the first time,

how the pump-motor unit is put into

operation.

The specifications for this are contained in

Chapter 6, "Installation", Pg. 11ff., and

Chapter 7, "Commissioning", Pg. 16ff.

© Gardner Denver Deutschland GmbH 9 / 32 610.444430.40.000

Page 10

Transport and Handling

5 Transport and Handling

WARNING

Improper use of the machine can result in

serious or even fatal injuries!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 3 f.?

Otherwise you may not carry out any work with

or on the machine!

WARNING

Danger from tipping or falling loads!

Prior to transport and handling make sure that

all components are securely assembled and

secure or remove all components the fasteners

of which have been loosened!

CAUTION

Tipping or falling can lead to crushing,

broken bones etc.!

Sharp edges can cause cuts!

Wear personal safety equipment (protective

helmet, protective gloves, safety shoes) during

transport!

Packing:

In case of a separate delivery, the pump-motor

unit is packed in a carton.

In the case of a group delivery, the pumpmotor units are packed in cardboard boxes or

screen boxes on pallets.

Manual handling:

WARNING

Danger from lifting heavy loads!

Manual handling of the unit is only permitted

within the following limits:

max. 30 kg [max. 66 lbs] for men

max. 10 kg [max. 22 lbs] for women

max. 5 kg [max. 11 lbs] for pregnant women

For the weight of the pump-motor unit, see

Chapter 3.1, "Mechanical data",

Section "Weight", Pg. 7.

For weights above the given values use

suitable lifting appliances and handling

equipment!

WARNING

Danger from tipping or falling loads!

Do not hold the pump-motor unit on the

capacitors or cable glands on the terminal box!

Handling by means of lifting equipment:

WARNING

Danger from tipping or falling loads!

When transporting with lifting equipment,

observe the following basic rules:

The lifting capacity of lifting equipment and

lifting gear must be at least equal to the

unit's weight.

For the weight of the pump-motor unit, see

Chapter 3.1, "Mechanical data",

Section "Weight", Pg. 7.

The pump-motor unit must be secured so

that it cannot tip or fall.

Do not hook the pump-motor unit onto the

capacitors or cable glands on the terminal

box!

Do not stand or walk under suspended

loads!

Use two lifting belts, of which one is routed

under the interface between the motor housing

and the vacuum pumps/compressor housing,

and the other under the interface between the

motor housing and the fan guard.

When transporting the pump-motor unit, make

sure that attached fittings are not damaged.

WARNING

Danger from tipping loads!

Be sure to observe the routing of the strap

belts under the pump-motor unit, even if the

motor is provided with attachment points such

as transport eyes or eye bolts.

These are solely designed for the separate

transport of the motor, however not for the

different weight distribution that results for the

mounted vacuum pump/mounted compressor,

so that the unit could tip!

610.444430.40.000 10 / 32 © Gardner Denver Deutschland GmbH

Page 11

Installation

6 Installation

WARNING

Improper use of the machine can result in

serious or even fatal injuries!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 3 f.?

Otherwise you may not carry out any work with

or on the machine!

6.1 Installation

CAUTION

Danger of crushing from pump-motor unit

tipping over!

In the unmounted state, the unit can easily tip

due to its weight distribution!

Wear gloves and safety shoes! Handle the unit

with the appropriate care!

CAUTION

Danger of tripping and falling!

Make sure the unit does not present a danger

of tripping!

WARNING

Electrical danger!

The pump-motor unit must be installed so that

the electrical device cannot be damaged by

external influences!

In particular, the feed pipes must be securely

routed, e.g. in cable ducts or in the floor.

CAUTION

Danger of injuries from flying parts!

Select installation so that parts that are thrown

out through the grate if the external fan breaks

cannot hit persons!

CAUTION

Danger of damage to the pump-motor unit

due to overheating!

When installing the unit, make sure that heat

dissipation and cooling are not obstructed. The

minimum distances specified in Chapter 3.1,

"Mechanical data", Section "Minimum

distances for heat dissipation", Pg. 7 must be

complied with.

Discharge air of other units may not be directly

sucked in again!

Minimum distances:

To ensure sufficient cooling of the pump-motor

unit, it is absolutely necessary that the required

minimum distances to the fan guard and to the

face of the vacuum pump/compressor

cover be maintained.

For minimum clearances for heat dissipation

and cooling, see Chapter 3.1, "Mechanical

data", Section "Minimum distances for heat

dissipation", Pg. 7.

Installation conditions:

The pump-motor unit must be installed as

follows:

on flat, level surfaces,

on stationary (fixed) surfaces or structures,

at a maximum height of 1000 m [3280 ft]

above sea level.

For installation under different conditions, the

Service Department must be consulted.

Observe the following when installing the

pump-motor unit:

The load-bearing capacity of the

installation surface must at least be

designed for the weight of the pump-motor

unit.

The vibration behavior at the operating

location must be taken into account.

The total vibrations of the unit are

dependent on the following factors:

– the characteristic vibrations of the unit,

– the alignment and installation,

– the condition (vibration behavior) of the

load-bearing surface,

– the influences by vibrations of other

parts and system components (external

vibrations).

The maximum permissible value for

vibrations is v

= 4.5 mm/s [0.177"/s].

eff

To ensure proper operation and a long

© Gardner Denver Deutschland GmbH 11 / 32 610.444430.40.000

Page 12

Installation

service life of the pump-motor unit, this

value may not be exceeded.

Generally, this value can be adhered to

without a special foundation or a special

base plate.

The points on the unit for measuring the

vibration speed are shown in Fig. 2, Pg. 12.

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

DANGER

Electrical danger!

Replace loose connections, singed or burned

cables immediately!

DANGER

Fig. 2: Points for measuring the vibration speed

Securing:

Screw the feet of the pump-motor unit to the

surface with suitable mounting elements.

Proceed as follows:

The feet of the pump-motor unit are

provided with mounting holes.

Select the suitable screw type.

Screw the feet of the pump-motor unit to

the surface with the screws.

When doing so, be sure to provide all

mounting holes with screws!

6.2 Electrical connection (motor)

DANGER

Electrical danger!

Malpractice can result in severe injuries and

material damage!

DANGER

Electrical danger!

Depending on the charging state of the

capacitors, a residual voltage may be present

on the terminals in the terminal box.

After opening the terminal box cover, it must

be ensured that the capacitors are completely

deenergized:

Measure the voltage at the corresponding

jumpers (see the circuit diagram in the

terminal box).

Dissipate the residual voltage with suitable

means if necessary.

The capacitors must be completely

deenergized.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the unit or system:

Interrupt supply of operating liquid.

Bleed lines and vacuum pump/compressor

(depressurize).

CAUTION

Incorrect connection of the motor can lead to

serious damage to the unit!

Electrical danger!

The electrical connection may be carried out

by trained and authorized electricians only!

610.444430.40.000 12 / 32 © Gardner Denver Deutschland GmbH

Page 13

Regulations:

The electrical connection must be carried out

as follows:

according to the applicable national and

local laws and regulations,

according to the applicable system-

dependent prescriptions and requirements,

Installation

All conductors under outer angled

grounding brackets must be bent into a "U"

shape.

This also applies to:

the protective conductor,

the outer ground conductor.

according to the applicable regulations of

the utility company.

Electrical power supply:

Observe the rating plate.

It is imperative that the operating conditions

correspond to the data given on the rating

plate!

Deviations permissible without reduction in

performance:

±5 % voltage deviation

±2 % frequency deviation

Connection to drive-motor terminal box:

Carry out the connection and the arrangement

of the jumpers in accordance with the circuit

diagram in the terminal box.

Connect the protective conductor to the

terminal with the following symbol:

The electrical connection must be carried out

as follows:

The electrical connection must be

permanently safe.

There may be no protruding wire ends.

Clearance between bare live parts and

between bare live parts and ground: ≥ 5.5

mm [0.217"] (at a nominal voltage of

UN ≤ 690 V).

Tightening torques for terminal plate

connections:

see Chapter 3.1, "Mechanical data",

Section "Tightening torques", Pg. 7.

Use suitable cable lugs.

For terminals with clamping straps, the

conductors must be inserted so that

approximately the same clamping height

results on both sides of the bar.

Individual conductors must therefore be

bent into a U-shape or connected with a

cable lug.

Both conductors can be recognized from their

color (green/yellow).

WARNING

Electrical danger!

Clearance between bare live parts and

between bare live parts and ground:

at least 5.5 mm [0.217"] (at a nominal voltage

of V

≤ 690V)

n

Make sure there are no

protruding pieces of wire!

WARNING

Electrical danger!

The terminal box must be free from

foreign bodies,

dirt,

humidity.

Terminal box cover and cable entries must be

tightly closed so as to make them dustproof

and waterproof.

Check for tightness at regular intervals.

For motor overload protection:

Use motor circuit breakers.

Set the motor circuit breakers to the

nominal current specified on the rating

plate.

© Gardner Denver Deutschland GmbH 13 / 32 610.444430.40.000

Page 14

Installation

6.3 Connecting pipes/hoses (vacuum

pump/compressor)

CAUTION

To prevent foreign bodies from entering the

unit, all connections are sealed off when

delivered.

Do not remove the sealing plugs until

immediately before connecting the

pipes/hoses.

For the arrangement of the pipe/hose

connections, see Fig. 3, Pg. 14.

The pumped gases/vapors are sucked in via

the inlet connection

and discharged via the

discharge connection (see Chapter 6.3.1,

Pg. 15).

For operation the unit must be continuously

supplied with operating liquid.

This is fed in via the operating-liquid port

(see

Chapter 6.3.2, Pg. 15) and discharged

together with the pumped gases/vapors

through the discharge connection

.

If the unit is run dry, the mechanical seal will

be destroyed in a matter of seconds!

DO NOT switch on as long as the unit is not

filled with operating liquid!

Fill with operating liquid:

When and how the pump-motor unit must be

filled with operating liquid the first time is

dependent on the operating mode:

For self-priming operation:

During installation.

For operation with operating-liquid feed:

After completing installation.

For self-priming operation you now pour

operating liquid into the working space of the

pump-motor unit before you connect the

pipes/hoses to the unit.

Proceed as follows:

Pour operating liquid into the open inlet

connection or discharge connection. For

proper filling quantities, see Chapter 3.3,

"Operating conditions", Section "Max. filling

quantity for operating liquid at a standstill",

Pg. 8.

Fig. 3: Pipe/hose connection of vacuum

pump/compressor

1 Operating liquid connection

G⅛", 10 mm [0.394"] deep

2 Discharge connection

G⅜", 12 mm [0.472"] deep

3 Inlet connection

G⅜", 12 mm [0.472"] deep

4 Connection for cavitation protection

G⅛", 10 mm [0.394"] deep

5 Drain hole

G⅛", 10 mm [0.394"] deep

OR

Remove the sealing plug with the seal from

the cavitation protection hole.

Pour operating liquid into the open inlet

connection or discharge connection until

the operating liquid exits from the cavitation

protection hole.

Close the cavitation protection hole with the

sealing plug and seal.

Then attach the pipes/hoses to the unit as

described in the following.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

During operation, connected pipes and vessels

are pressurized or vacuumized!

Make sure that all connections are sufficiently

tight! Use only pipes and vessels of sufficient

strength!

610.444430.40.000 14 / 32 © Gardner Denver Deutschland GmbH

Page 15

NOTICE

Installation

6.3.3 Notes

Attach pipes/hoses free of mechanical

tensions.

Support the weight of the pipes/hoses.

6.3.1 Inlet connection and discharge

connection

The inlet connection (Fig. 3, Item 3) is

marked with an arrow pointing downward (↓).

Connect the inlet pipe here. The pumped

gases/vapors are sucked in via this.

The discharge connection (Fig. 3, Item 2) is

marked with an arrow pointing upward (↑).

Connect the discharge pipe here. Both the

pumped gases/vapors and the operating liquid

are discharged via this pipe.

CAUTION

When connecting the pump-motor unit to a

vacuum accumulator:

In this case, a check valve must be installed.

Without a check valve, operating liquid can be

sucked into the system from the pump-motor

unit. Damage to the system can occur!

CAUTION

The tightening torque for pipe connections on

intake and discharge connections (G⅜") may

not exceed 16 Nm ± 10 % [11.8 ft lbs ± 10 %]!

6.3.2 Operating-liquid port

NOTICE

For operating liquid with impurities:

Install a filter, screen or separator in the

supply line if necessary.

NOTICE

In case of operating liquid with a high lime

content:

Soften operating liquid

OR

Decalcify pump-motor unit regularly (see

Chapter 10.1, "Maintenance", Pg. 24).

NOTICE

To prevent installation residues (e.g. welding

spatter) from entering the unit,

a start-up screen should be installed in the inlet

pipe for the first 100 operating hours.

The operating liquid connection (Fig. 3, Item 1)

is located on the face of the vacuum

pump/compressor housing below the inlet

connection.

Connect the feed pipe for the operating liquid

here.

© Gardner Denver Deutschland GmbH 15 / 32 610.444430.40.000

Page 16

Commissioning

7 Commissioning

WARNING

Improper use of the machine can result in

serious or even fatal injuries!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 3 f.?

Otherwise you may not carry out any work with

or on the machine!

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Danger due to rotating parts!

The pump-motor unit may only be put into

operation when the following conditions are

met:

Fan guard and vacuum pump/compressor

cover and housing are mounted.

The lines to the discharge connection, inlet

connection and operating-liquid port are

attached.

The lines and connections have been

tested for strength and leaks.

CAUTION

If the unit is run dry, the mechanical seal will

be destroyed in a matter of seconds!

DO NOT switch on as long as the unit is not

filled with operating liquid!

7.1 Preparation and start-up

CAUTION

If the pumped gases/vapors discharged on the

pressure side are passed on,

then it must be ensured that the maximum

discharge pressure of 110 kPa abs. [16.0 psia]

is not exceeded!

NOTICE

Fill with operating liquid:

For operation with self-priming of the

operating liquid during installation (see

Chapter 6.3, "Connecting pipes/hoses

(vacuum pump/compressor)", Pg. 14).

For operation with operating-liquid feed,

you now fill the working area of the unit with

operating liquid.

Proceed as follows:

Remove the sealing plug with the seal from

the cavitation protection hole.

Open the respective shut-off valve until the

operating liquid exits from the cavitation

protection hole:

– For non-automatic operation:

Stop valve (Fig. 6, Pg. 19, Item 4).

– For automatic operation:

Stop valve in the bypass pipe (Fig. 7,

Pg. 19, Item 4a).

Close the shut-off valve again.

Close the cavitation protection hole with the

sealing plug and seal.

Then proceed with commissioning as

described in the following.

Check connections of the pipes/hoses for

leaks.

Check direction of rotation:

The direction of flow of the pumped

gases/vapors is marked with arrows on the

intake and discharge connection.

The intended shaft rotating direction is

marked with an arrow on the vacuum

pump/compressor housing.

The pump-motor unit may not be allowed to

run dry!

Have you filled it with operating liquid

beforehand (during or after installation)?

See sections "Fill with operating liquid",

Pg. 14 and Pg. 16.

Briefly switch on pump-motor unit.

Maximum permissible quantity of water

entrained via the inlet connection:

See Fig. 9, Pg. 19.

Compare the actual rotating direction of the

external fan with the intended shaft rotating

direction as it is indicated with the arrow on

the vacuum pump/compressor housing of

the pump-motor unit (Fig. 1, Pg. 3, Item 9).

If a shut-off device is installed in the discharge

pipe:

Make sure that the unit CANNOT be operated

with the shut-off device closed.

610.444430.40.000 16 / 32 © Gardner Denver Deutschland GmbH

Switch off pump-motor unit again.

If necessary, reverse the direction of

rotation of the motor.

Page 17

DANGER

Electrical danger!

The electrical connection may be carried out

by trained and authorized electricians only!

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

DANGER

Electrical danger!

Depending on the charging state of the

capacitors, a residual voltage may be present

on the terminals in the terminal box.

After opening the terminal box cover, it must

be ensured that the capacitors are completely

deenergized:

Measure the voltage at the corresponding

jumpers (see the circuit diagram in the

terminal box).

Dissipate the residual voltage with suitable

means if necessary.

The capacitors must be completely

deenergized.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the unit or system:

Interrupt supply of operating liquid.

Bleed lines and vacuum pump/compressor

(depressurize).

The further procedure is again dependent

on the unit operating mode:

Commissioning

7.2 Self-priming operation

CAUTION

The liquid level in the feed pipe or in the

reservoir may not exceed the height of the

shaft center of the pump-motor unit!

If this height is exceeded, too much liquid gets

into the pump-motor unit. Damage can occur!

See Fig. 4, Pg. 17.

Here the following must be watched:

The pump-motor unit must be pre-throttled

on the inlet side. This means a vacuum of

at least 80 kPa abs. [11.6 psia] must be

present in the inlet pipe (Item B) at switchon.

During switch-on, the liquid level in the feed

pipe (Item A) and in the reservoir (Item C)

respectively must be at the same level as

the center of the unit shaft (Item 1).

During operation the liquid level in the

reservoir (Item C) may not drop below

approx. 1 m [3.28 ft] below the center of

the unit shaft (Item 1).

80 kPa abs

11,6 psia

6104443001005

Fig. 4: Self-priming operation

A Feed pipe for operating liquid

B Inlet pipe

C Reservoir for operating liquid

1 Required liquid level when switching on

2 Min. liquid level during operation

Starting the pump-motor unit:

B

A

1

1 m

2

3,28 ft

C

Switch on the unit.

The operating liquid is sucked in.

© Gardner Denver Deutschland GmbH 17 / 32 610.444430.40.000

Page 18

Commissioning

7.3 Operation with operating-liquid feed

For automatic operation (Fig. 7, Pg. 19):

See Fig. 5, Pg. 18, and Fig. 8, Pg. 19, as well

as Fig. 6, Pg. 19, and Fig. 7, Pg. 19.

Proceed as follows here:

Method A:

1) Set pre-pressure of operating liquid (Fig. 5,

Pg. 18):

Set a pre-pressure p

in the feed pipe for

A

the operating liquid (Item A) around

approx. 100 kPa [14.5 psi] above the inlet

pressure p

in the inlet pipe (Item B).

B

B

PA=PB+100 kPa

P

A=PB

6104443001006

A

+14,5 psi

Fig. 5: Setting the operating-liquid flow rate:

Setting pre-pressure

A Feed pipe for operating liquid

B Inlet pipe

2) Start up the unit:

For non-automatic operation (Fig. 6, Pg. 19):

Open the stop valve (Item 4) manually.

The operating liquid is fed in.

Switch on the unit.

Switch on the unit.

The solenoid valve (Item 4) opens

and the operating liquid is fed in.

Method B:

1) Start up the unit:

For non-automatic operation (Fig. 6, Pg. 19):

Open the stop valve (Item 4) manually.

The operating liquid is fed in.

Switch on the unit.

For automatic operation (Fig. 7, Pg. 19):

Switch on the unit.

The solenoid valve (Item 4) opens

and the operating liquid is fed in.

2) Check the operating-liquid flow rate:

with the flow meter (Fig. 6, Pg. 19, and

Fig. 7, Pg. 19, Item 2)

OR

by measuring the volume of operating liquid

per unit of time that exits at the discharge

connection with a graduated vessel (Fig. 8,

Pg. 19)

3) Set/correct the operating-liquid flow rate:

via the control valve (Fig. 6, Pg. 19, and

Fig. 7, Pg. 19, Item 3)

Nominal operating-liquid flow rate:

For nominal values, see Chapter 3.3,

"Operating conditions", Section "Nominal

operating-liquid flow rate", Pg. 8.

610.444430.40.000 18 / 32 © Gardner Denver Deutschland GmbH

Page 19

Commissioning

23

1

6104443001008

45

6

23

1

6104443001009

45

4a

6

Fig. 6: Operation with operating-liquid feed:

Non-automatic operation

Fig. 7: Operation with operating-liquid feed:

Automatic operation

1 Pump-motor unit

2 Flow meter

3 Control valve

4 Stop valve

5 Dirt trap

6 Feed pipe for operating liquid

1 Pump-motor unit

2 Flow meter

3 Control valve

4 Solenoid valve, connected to motor

4a Bypass with stop valve (for priming)

5 Dirt trap

6 Feed pipe for operating liquid

B

A

3x4x

1x

6104443001007

6104443001010

Fig. 8: Setting the operating-liquid flow rate:

Measuring the volume with a graduated vessel

A Feed pipe for operating liquid

B Drain pipe for operating liquid

Fig. 9: Maximum permissible quantity of water

entrained via the inlet connection

3x quantity of operating-liquid flow rate

© Gardner Denver Deutschland GmbH 19 / 32 610.444430.40.000

Page 20

Operation

8 Operation

WARNING

Improper use of the machine can result in

serious or even fatal injuries!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 3 f.?

Otherwise you may not carry out any work with

or on the machine!

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Danger due to rotating parts!

The pump-motor unit may only be put into

operation when the following conditions are

met:

Fan guard and vacuum pump/compressor

cover and housing are mounted.

The lines to the discharge connection, inlet

connection and operating-liquid port are

attached.

The lines and connections have been

tested for strength and leaks.

CAUTION

If the unit is run dry, the mechanical seal will

be destroyed in a matter of seconds!

DO NOT switch on as long as the unit is not

filled with operating liquid!

WARNING

Danger of burns and scalding from hot

surfaces of the pump-motor unit and from

hot fluids!

Do not touch during operation!

Allow to cool after shut-down!

NOTICE

Maximum permissible quantity of water

entrained via the inlet connection:

See Fig. 9, Pg. 19.

CAUTION

The feeding in of overheated steam at the inlet

connection of the pump-motor unit while it is

not rotating has the following effect:

Operating liquid is pressed out of the pump-

motor unit.

Considerable thermal loading of the pump-

motor unit.

The pump-motor unit may be damaged!

Before feeding in overheated steam at the inlet

connection, switch on the pump-motor unit for

approx. 10 s to ensure sufficient supply with

operating liquid. The operating liquid cools the

pump-motor unit.

8.1 Self-priming operation

Follow the instructions contained in

Chapter 7.2, "Self-priming operation", Pg. 17

for this operating mode.

8.2 Operation with operating-liquid feed

Start-up

For non-automatic operation (Fig. 6, Pg. 19):

Open the stop valve (Item 4) manually.

The operating liquid is fed in.

Switch on the unit.

For automatic operation (Fig. 7, Pg. 19):

Switch on the unit.

The solenoid valve (Item 4) opens

and the operating liquid is fed in.

Shut down:

For non-automatic operation (Fig. 6, Pg. 19):

Switch off the pump-motor unit.

Close the stop valve (Item 4) manually.

Feeding of the operating liquid is cut off.

The following applies for the control valve

(Item 3) for setting the operating-liquid flow

rate:

In case of an interruption in operation, the

valve setting (i.e. the valve position or the

open valve cross-section) is not changed.

© Gardner Denver Deutschland GmbH 20 / 32 610.444430.40.000

Page 21

For automatic operation (Fig. 7, Pg. 19):

Switch off the pump-motor unit.

The solenoid valve (Item 4) closes,

and feeding of the operating liquid is cut off.

The following applies for the control valve

(Item 3) for setting the operating-liquid flow

rate:

In case of an interruption in operation, the

valve setting (i.e. the valve position or the

open valve cross-section) is not changed.

Operation

© Gardner Denver Deutschland GmbH 21 / 32 610.444430.40.000

Page 22

Shut-Down and Longer Standstills

9 Shut-Down and Longer

Standstills

Disconnect the hose connections on the

inlet connection, discharge connection and

operating liquid opening.

WARNING

Improper use of the machine can result in

serious or even fatal injuries!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 3 f.?

Otherwise you may not carry out any work with

or on the machine!

9.1 Draining

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the unit or system:

Interrupt supply of operating liquid.

Bleed lines and vacuum pump/compressor

(depressurize).

Switch off the pump-motor unit.

Remov ethe mounting screws on the feet of

the pump-motor unit.

Place the pump-motor unit on the vacuum

pump/compressor cover and tilt it several

times over the connection.

Remount the mounting screws on the feet.

Reattach the hoses.

9.2 Preparing for longer standstill

Before a longer standstill (from approx.

4 weeks) or when there is danger of frost,

proceed as follows:

Drain pump-motor unit as described in

Chapter 9.1, "Draining", Pg. 22.

Remove the pipe/hose from the intake or

discharge connection.

Pour ¼ l [0.066 gal (US); 0.055 gal (UK)] of

preservative (rust protection oil, e.g.

Mobilarma 247 form Mobil Oil)

into the open intake or discharge

connection.

Close the intake and discharge connection,

as well as the operating-liquid port and

remount the disconnected pipes/hoses.

Guide a screwdriver through the central

opening in the fan guard up to the shaft end

on the external fan side (see Fig. 10,

Pg. 23).

Turn the shaft by hand using the

screwdriver.

The above safety precautions apply when

working on the unit or system.

Provide suitable catch containers below the

vacuum pump/compressor cover.

Open the sealing plug of the drain hole

(Fig. 3, Pg. 14, Item 5).

Remove the screwdriver again.

You have two options for the standstill:

Either the pump-motor unit remains

connected in the system,

or the unit is removed for storage.

Allow the liquid to drain out.

Colse the sealing plug again,

tightening torque for G⅛" = 4.5 Nm ± 10 %

[3.32 ft lbs ± 10 %].

OR

Switch off the pump-motor unit.

The above safety precautions apply when

working on the unit or system.

Have a suitable catch container ready.

610.444430.40.000 22 / 32 © Gardner Denver Deutschland GmbH

Page 23

Shut-Down and Longer Standstills

described in Chapter 7, "Commissioning",

Pg. 16.

For pump-motor unit that are already

installed in a system:

Commission the pump-motor unit as

described in Chapter 7, "Commissioning",

Pg. 16.

DANGER

Electrical danger!

Work on electrical installations may be carried

out by trained and authorized electricians only!

6104443001004

Fig. 10: Pour in preservative and turn shaft

9.3 Storage conditions

This chapter applies in the following cases:

new pump-motor units,

pump-motor unit that are already installed

in a system and were prepared for a longer

standstill, as described in Chapter 9.2,

"Preparing for longer standstill", Pg. 22.

To prevent standstill damage during storage,

the environment must provide the following

conditions:

dry,

dust-free,

low-vibration (effective value of vibration

speed v

≤ 0.2 mm/s [0.008"/sec]).

eff

Take the following measures for

commissioning following a longer

standstill:

Measure the insulation resistance of the

motor.

In case of values ≤ 1kΩ per volt of nominal

voltage, dry winding.

Drain off preservative, as described in

Chapter 9.1, "Draining", Pg. 22.

Subsequent cleaning of the pump-motor

unit is not required.

Dispose of preservative in accordance with

the manufacturer's specifications.

For new pump-motor units:

Install pump-motor unit as described in

Chapter 6, "Installation", Pg. 11.

Commission the pump-motor unit as

© Gardner Denver Deutschland GmbH 23 / 32 610.444430.40.000

Page 24

Servicing

10 Servicing

WARNING

Improper use of the machine can result in

serious or even fatal injuries!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 3 f.?

Otherwise you may not carry out any work with

or on the machine!

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

All maintenance work on the pump-motor unit

must always be performed by the Service

Department!

Inquire with the Service Department!

DANGER

Electrical danger!

Before beginning work on the unit or system,

the following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

DANGER

Electrical danger!

Replace loose connections, singed or burned

cables immediately!

DANGER

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the unit or system:

Interrupt supply of operating liquid.

Bleed lines and vacuum pump/compressor

(depressurize).

WARNING

Danger from rotating external fan of unit!

It is prohibited to remove the fan guard!

WARNING

Danger from rotating impeller of unit!

It is prohibited to remove the vacuum

pump/compressor cover and the housing!

WARNING

Danger of burns and scalding from hot

surfaces of the pump-motor unit and from

hot fluids!

Do not touch during operation!

Allow to cool after shut-down!

10.1 Maintenance

The pump-motor unit is largely maintenancefree.

If water containing lime is used as the

operating liquid, the operating liquid must be

softened or the pump-motor unit must be

decalcified at regular intervals.

Refer to the following table:

Electrical danger!

Depending on the charging state of the

capacitors, a residual voltage may be present

on the terminals in the terminal box.

After opening the terminal box cover, it must

be ensured that the capacitors are completely

deenergized:

Measure the voltage at the corresponding

jumpers (see the circuit diagram in the

terminal box).

Dissipate the residual voltage with suitable

means if necessary.

The capacitors must be completely

deenergized.

610.444430.40.000 24 / 32 © Gardner Denver Deutschland GmbH

Page 25

Contamination/Problem Remedy

Servicing

Dirt collects in the motor

cooling fins.

Fine-grain dirt (e.g. sand) get

into the vacuum

pump/compressor with the

Clean the motor cooling fins at regular intervals.

Install a liquid separator, filter or screen in the feed pipe.

It is prohibited to remov ethe vacuum pump/compressor housing!

operating liquid or pumped

gases/vapors.

Impeller is jammed. Free shaft by turning.

To do so, proceed as follows:

Shut unit down.

Guide a screwdriver through the central opening in the fan guard up to the

shaft end on the external fan side (see Fig. 10, Pg. 23).

Turn the shaft by hand using the screwdriver.

Remove the screwdriver again.

Extremely hard water used

as operating liquid

Lime content > 15°dH).

Soften operating liquid.

OR

Decalcify the pump-motor unit at intervals of 3 months.

To do this, proceed as follows (also see Fig. 11, Pg. 26):

Wear personal protective equipment (protective gloves and safety

goggles),

Shut unit down.

Drain pump-motor unit as described in Chapter 9.1, "Draining", Pg. 22.

Remove pipes/hoses.

Fill the unit with decalcifying liquid through one of the connection

openings. Use 10% solution of acetic acid or another commercially

available decalcifying agent.

Allow the decalcifying liquid to soak for at least 30 minutes.

Turn the shaft occasionally during this time. To do this, guide a

screwdriver through the central opening in the fan guard up to the shaft

end on the external fan side (see Fig. 11, Pg. 26).

Turn the shaft using the screwdriver.

Remove the screwdriver again.

Drain the decalcifying liquid out of the unit. To do this, proceed as

described in Chapter 9.1, "Draining", Pg. 22.

Mount pipes/hoses.

When commissioning the pump-motor unit, proceed as described in

Chapter 7, "Commissioning", Pg. 16.

The decalcifier can be disposed of in the sewer system.

Dirt gets into the air

passages (fan guard,

external fan, cooling fins) of

the motor.

Clean the motor air passages regularly.

To do so, proceed as follows:

Carry out protective measures for the use of compressed air:

Wear personal protective equipment (protective gloves and safety

goggles),

secure surroundings. Remove objects lying around.

Blow in compressed air through the fan guard grate.

It is prohibited to remove the fan guard!

© Gardner Denver Deutschland GmbH 25 / 32 610.444430.40.000

Page 26

Servicing

6104443001004

Fig. 11: Pouring in decalcifying agent and freeing shaft by turning

10.2 Repairs/troubleshooting

Fault Cause Remedy Carried out by

Motor does

not start, no

running

noise.

Interruption of the

power supply,

with single-phase

model in one

Check fuses, terminals and cables for open

circuit. Eliminate open circuit.

Electrician

cable, with twophase model in at

least two cables.

Motor does

not start,

humming

One power

supply lead

interrupted.

Check fuses, terminals and cables for open

circuit. Eliminate open circuit.

Electrician

noises.

Impeller is

jammed.

Free shaft by turning.

See Chapter 10.1, "Maintenance", Pg. 24.

Operator

Decalcify vacuum pump/compressor.

Operator

See Chapter 10.1, "Maintenance", Pg. 24.

Drain and clean vacuum pump/compressor if

Operator

necessary.

See Chapter 10.1, "Maintenance", Pg. 24.

Check and correct impeller gap setting if

Service

necessary.

Impeller

Replace impeller. Service

defective.

Motor bearings

Replace motor bearings. Service

defective.

610.444430.40.000 26 / 32 © Gardner Denver Deutschland GmbH

Page 27

Servicing

Fault Cause Remedy Carried out by

Protective

motor switch

trips when

motor is

switched on.

consumption

too high.

Unit does not

generate

vacuum.

Winding shortcircuit.

Motor

overloaded.

Counter-pressure

at discharge

connection too

high.

Share of liquid

also fed too high.

Impeller is

jammed.

Lime or other

deposits.

No operating

liquid present.

Have winding checked. Electrician

Check operating-liquid flow rate and reduce if

Operator

necessary.

See Chapter 7.2, "Self-priming operation", Pg. 17

or 7.3, "Operation with operating-liquid feed",

Pg. 18.

Reduce counter-pressure. Operator

Reduce share of liquid also fed. Operator

See "Motor does not start, humming noises." Operator/Service

Decalcify vacuum pump/compressor.

Operator Power

See Chapter 10.1, "Maintenance", Pg. 24.

Clean vacuum pump/compressor.

Operator

See Chapter 10.1, "Maintenance", Pg. 24.

Ensure proper operating-liquid flow rate.

Operator

See Chapter 7.2, "Self-priming operation", Pg. 17

or Chapter 7.3, "Operation with operating-liquid

feed", Pg. 18.

Unit

generates

insufficient

vacuum.

Severe leak in the

Seal leak in the system. Operator

system.

Wrong direction

of rotation.

Reverse direction of rotation by interchanging two

connecting leads.

Electrician

Unit too small. Use larger unit. Operator

Operating-liquid

flow too low.

Increase operating-liquid flow rate to up to 2x the

nominal flow rate.

Operator

See Chapter 7.2, "Self-priming operation", Pg. 17

or Chapter 7.3, "Operation with operating-liquid

feed", Pg. 18.

Operating liquid

too warm

(nominal

temperature:

Cool or increase operating-liquid flow,

See Chapter 7.2, "Self-priming operation", Pg. 17

or 7.3, "Operation with operating-liquid feed",

Pg. 18.

Operator

15°C [59 °F]).

Inspect impeller. Replace impeller if necessary. Service Erosion.

Replace affected components. Service

Leak in system. Seal leak in the system. Operator

Mechanical seal

Replace mechanical seal. Service

leaky.

Screeching

noises.

Cavitation of

vacuum

pump/compressor

Connect cavitation-protection hose of liquid

separator or clean cavitation-protection

equipment.

Operator

.

© Gardner Denver Deutschland GmbH 27 / 32 610.444430.40.000

Page 28

Servicing

Fault Cause Remedy Carried out by

Operating-liquid

flow rate too high.

Check operating-liquid flow rate and reduce if

necessary.

Operator

See Chapter 7.3, "Operation with operating-liquid

feed", Pg. 18.

Pump-motor unit

is started while

flooded.

Check operating-liquid flow rate and reduce if

necessary. After switching off pump-motor unit,

no operating liquid may be fed in.

Operator

See Chapter 7.3,“Operation with operating-liquid

feed“, Pg. 18.

Unit leaky. Seals defective. Check seals. Service

610.444430.40.000 28 / 32 © Gardner Denver Deutschland GmbH

Page 29

10.3 Service/After-sales service

Our Service is available for work (in particular

the installation of spare parts, as well as

maintenance and repair work), not described in

these operating instructions (see front page of

these operating instructions).

Observe the following when returning pump-

motor unit:

Before shipping:

– Drain the pump-motor unit so that it is

residue-free,

as described in Chapter 9.1, "Draining",

Pg. 22.

– Clean the unit on the outside,

as described in Chapter 10.1,

"Maintenance", Pg. 24.

The pump-motor unit must be delivered

complete, i.e. not dismantled.

Only the original packing should be used for

shipment.

A declaration of clearance must be included

with the shipment,

as described in Chapter 10.4,

"Decontamination and Declaration of

Clearance", Pg. 29.

The original rating plate of the pump-motor

unit must be properly mounted, intact and

legible.

All warranty claims are voided for pumpmotor units delivered for a damage

expertise without the original rating plate or

with a destroyed original rating plate.

In case of warranty claims, the

manufacturer must be informed of the

operating conditions, operating duration etc.

and additional detailed information provided

on request if necessary.

10.4 Decontamination and Declaration of

Clearance

WARNING

Danger from flammable, caustic or toxic

substances!

To protect the environment and persons, the

following applies:

Pump-motor unit which have come into contact

with dangerous substances must always be

decontaminated before being passed on to a

workshop!

Disposal

A so-called Declaration of Clearance must be

included with each pump-motor unit that is

given to a workshop for inspection,

maintenance or repair.

The declaration of clearance

is provided as a pre-printed form for

photocopying on page 31,

is legally binding,

must be filled out and signed by authorized,

qualified personnel,

must be issued for each unit sent in (i.e. a

separate declaration for each unit),

must be attached outside on the packing of

the unit,

should be sent to as a copy by fax the

workshop conducting the work prior to

shipment.

This ensures

that the unit has not come into contact with

dangerous substances,

that a unit that has come into contact with

dangerous substances has been sufficiently

decontaminated,

that the inspection, maintenance or repair

personnel can take the required protective

measures if necessary.

NOTICE

The inspection/maintenance/ repair of the unit

at the workshop will not be begun

until the declaration of clearance has been

received!

If the declaration of clearance is not included

with the shipment,

delays may result!

11 Disposal

Have the entire pump-motor unit scrapped by a

suitable disposal company. No special

measures are required when doing so.

For additional information on disposing of the

unit, ask the Service Department.

© Gardner Denver Deutschland GmbH 29 / 32 610.444430.40.000

Page 30

EC Declaration of Conformity

EC Declaration of Conformity

EU declaration of conformity

Manufacturer:

Gardner Denver Deutschland GmbH

P.O. Box 1510

D-97605 Bad Neustadt / Saale

Responsible for documentation:

Holger Krause

P.O. Box 1510

D-97605 Bad Neustadt / Saale

Designation:

Liquid ring vacuum pumps/ compressors

L-BV3

Types 2BV3151

The liquid ring vacuum pump/compressor described above meets the following applicable Community

harmonisation legislation:

2006/42/EC

Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery,

and amending Directive 95/16/EC

The protection targets of the directive 2006/95/EC have been met

Harmonised standards applied:

EN 1012-1:1996

EN 1012-2:1996

Compressors and vacuum pumps — Safety requirements — Part 1: Compressors

Compressors and vacuum pumps — Safety requirements — Part 2: Vacuum pumps

Bad Neustadt/Saale, 2009-12-29

(Place and date of issue)

ppa. Fred Bornschlegl

(Name and function) (Signature)

664.44430.40.000

610.444430.40.000 30 / 32 © Gardner Denver Deutschland GmbH

Page 31

Form for statement on safety

Form for statement on safety

For the safety of our employees and to comply with statutory requirements on handling substances harmful to the health and

Statement on health safety and on the protection of the environment

the environment, this statement must be enclosed, fully completed, with each unit/system sent.

Without the fully completed statement, repair/disposal is not possible and delays are unavoidable!

The statement is to be completed and signed by suitably qualified, authorised personnel at the operating organisation.

In the case of shipment to Germany, the statement is to be completed in German or English.

The statement is to be attached to the outside of the packing on shipment.

If necessary, the carrier is to be informed.

1. Product designation (type):

2. Serial number (no. BN):

3. Reason for sending:

4. The unit/system

has not come into contact with hazardous substances. There will be no hazards for personnel or the environment during

repair/disposal. Continue with "6. Legally binding statement“

has come into contact with hazardous substances. Continue with "5. Information on the contamination“

5. Information on the contamination

(if necessary provide more information on an additional sheet)

The unit/system was used in the following application:

and has come into contact with the following classifiable substances or substances presenting a hazard to health/environment:

Trade name: Chemical designation:

Hazardous

substance class:

Properties (e.g. toxic, inflammable,

caustic, radioactive):

The unit/system has been emptied in accordance with the operating instructions, flushed and cleaned externally.

Safety data sheets in accordance with the applicable regulations are enclosed ( sheet).

The following safety precautions are necessary for handling (e.g. personal protective equipment):

6. Legally binding statement

I herewith guarantee that the details specified are true and complete and that I, as signatory, am in a position to judge that this is

so.

We are aware that we are liable to the contractor for any damages arising from incomplete or incorrect specifications. We are

obliged to indemnify the contractor against claims for damages by third parties arising from incomplete or incorrect specifications.

We are aware that, irrespective of this statement, we are directly liable to third parties - in particular including the contractor's

employees tasked with repair/disposal.

Company/institute:

Name, position: Phone:

Street: Fax:

Post code, city:

Country: Stamp:

Date, signature:

© Gardner Denver Deutschland GmbH 610.00250.40.905

P.O. box 1510 Phone: +49 7622 392 0 E-mail: er.de@gardnerdenver.com 10.2009

97605 Bad Neustadt Fax: +49 7622 392 300 Internet: www.gd-elmorietschle.com English

© Gardner Denver Deutschland GmbH 31 / 32 610.444430.40.000

Page 32

Elmo Rietschle is a brand of

Gardner Denver‘s Industrial Products

Group and part of Blower Operations.

www.gd-elmorietschle.de

er.de@gardnerdenver.com

Gardner Denver

Schopfheim GmbH

Roggenbachstraße 58

79650 Schopfheim · Deutschland

Tel. +49 7622 392-0

Fax +49 7622 392-300

Gardner Denver

Deutschland GmbH

Industriestraße 26

97616 Bad Neustadt · Deutschland

Tel. +49 9771 6888-0

Fax +49 9771 6888-4000

Loading...

Loading...