Page 1

Edition: 12.2009 · 610.44444.40.000 Original operating instructions · English

Operating instructions L-BL2

2BL2 041

2BL2 061

2BL2 141

2BL2 251

2BL2 101

2BL2 281

2BL2 341

L-Serie

L-Series

Flüssigkeitsring

Liquid Ring

Page 2

Contents

Contents

System design ..........................................................................................................................................3

1 Safety ..................................................................................................................................................4

1.1 Definitions .................................................................................................................................4

1.1.1 Safety alert symbol.......................................................................................................4

1.1.2 Signal words.................................................................................................................4

1.2 General safety precautions .......................................................................................................4

1.3 Residual risks............................................................................................................................6

2 Intended Use .......................................................................................................................................7

3 Technical Data ....................................................................................................................................8

3.1 Mechanical data ........................................................................................................................8

3.2 Electrical data..........................................................................................................................10

3.3 Operating conditions ...............................................................................................................10

4 Transport and Handling.....................................................................................................................11

5 Installation .........................................................................................................................................12

5.1 Installation ...............................................................................................................................12

5.2 Electrical connection (motor) ..................................................................................................14

5.3 Filling.......................................................................................................................................17

5.4 Connection of pipes/hoses......................................................................................................18

5.4.1 Inlet connection ..........................................................................................................18

5.4.2 Exhaust-air connection...............................................................................................19

5.5 Accessories.............................................................................................................................19

6 Commissioning..................................................................................................................................20

6.1 Preparation and start-up .........................................................................................................20

6.2 Shut-down ...............................................................................................................................20

7 Operation...........................................................................................................................................21

7.1 Start-up and shut-down...........................................................................................................21

7.2 Operation within the process ..................................................................................................21

7.2.1 Loss of operating liquid ..............................................................................................21

7.2.2 Increase in operating liquid ........................................................................................22

8 Shutting Down and Longer Standstill ................................................................................................23

8.1 Draining...................................................................................................................................23

8.2 Preparing for longer shut-down...............................................................................................23

8.3 Storage conditions ..................................................................................................................24

9 Servicing............................................................................................................................................25

9.1 Maintenance............................................................................................................................26

9.2 Repairs/troubleshooting ..........................................................................................................29

9.3 Service/After-sales service......................................................................................................33

9.4 Decontamination and Declaration of Clearance .....................................................................33

10 Disposal.............................................................................................................................................33

EU declaration of conformity ..................................................................................................................34

Form for statement on safety .................................................................................................................35

© 2009 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Germany

Replication, distribution and / or editing of this document and the use and distribution of its content is

prohibited unless explicitly permitted. Violation obligates compensation for damages.

All rights reserved in case of the issue of a patent, utility patent or design patent.

Page 3

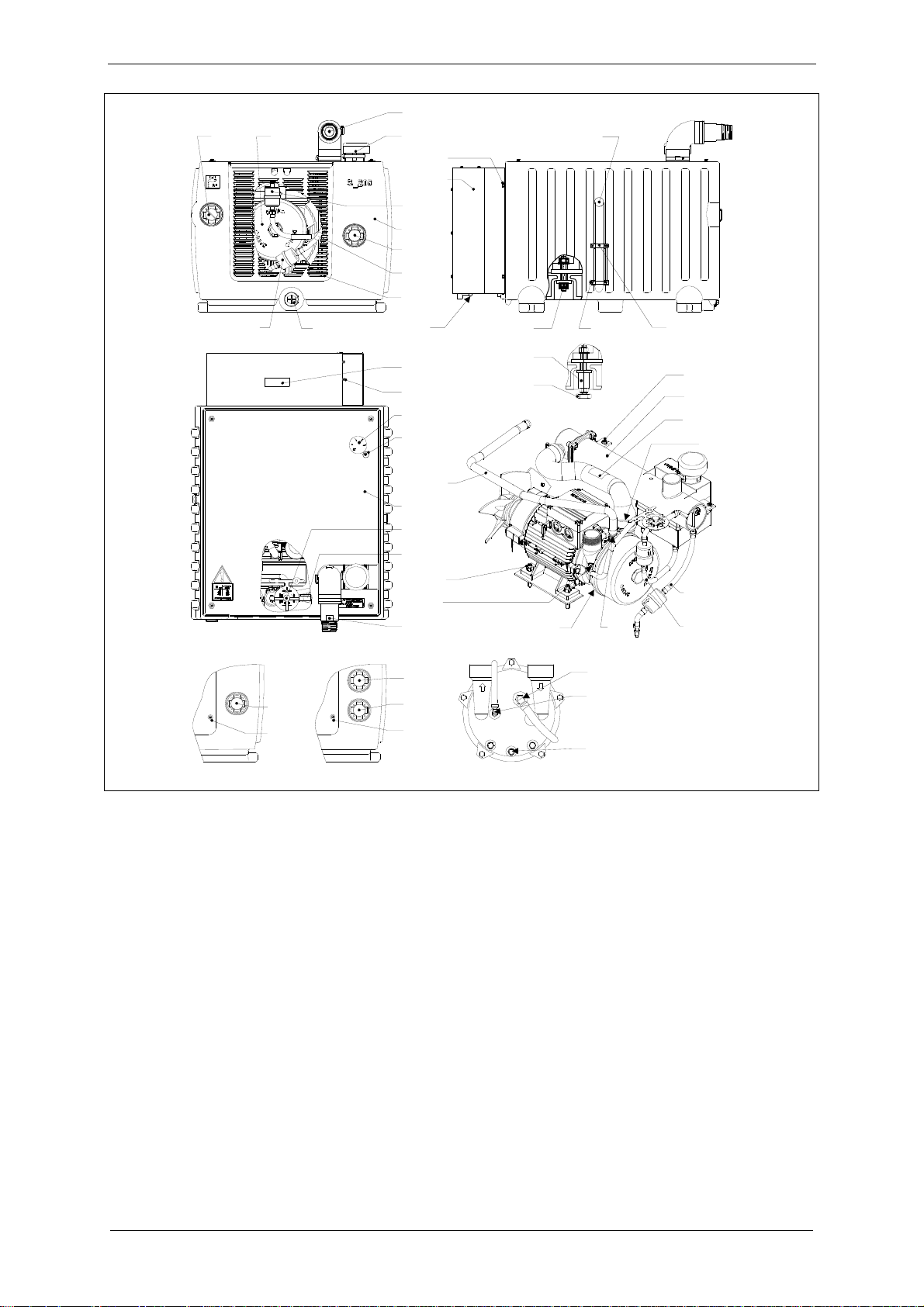

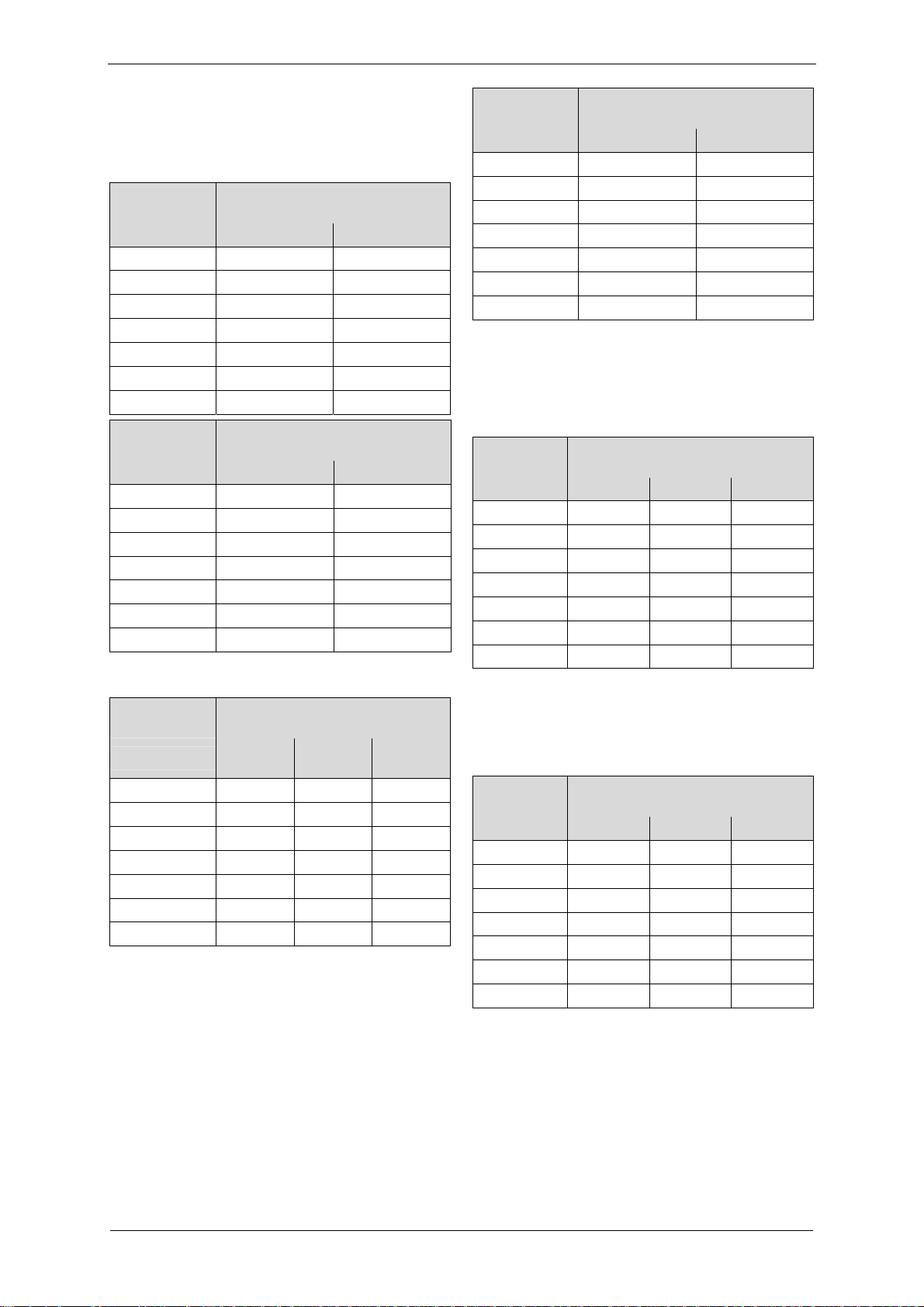

System design

007

System design

A

D

B

C

030

027

096

001

025

079

058

095

005

F

052

057

010

012

023

085

086

066

065

032

031

039

H

043

064

G

080

019

040

041

025

060

K

037

007

025

060

L_300

E

J

J

K

E

2BL2 141

Fig. 1: System design

A Inlet connection

B Exhaust-air connection

C Cable inlet

D Installed unit (L-BV7 pump)

E Draining installed unit

F Draining cooler

G 3-way valve (only 2BL2 041 to 2BL2 141)

H Screw-in connecting sleeve

J Operating liquid hole

K Cavitation protection hole

001 U-separator

005 Drain opening

007 Filling opening and connection for drain

controller

010 Fill level indicator

012 Screw

019 Nut

023 Nut

025 Connection for supply or drain controller

© Gardner Denver Deutschland GmbH 3 / 36 610.44444.40.000

2BL2 251, 281, 341

027 Water or air water cooler

030 Screw

031 Condensation cooler

032 Screw

037 Connecting piece

039 Intake hose with check valve

040 Injection water pipe

041 Condensate pipe

043 Operating liquid pipe

052 Rating plate

057 Screw

058 Protective screen

060 Screw

064 Cover plate

065 Cord grip

066 Screw

079 Restrictor sleeve for water pipe

080 Restrictor sleeve for air pipe

095 Water filter

096 Air filter

Page 4

Safety

1 Safety

1.1 Definitions

To point out dangers and important information,

the following signal words and symbols are used

in these operating instructions:

1.1.1 Safety alert symbol

The safety alert symbol

safety precautions in the highlighted heading field

on the left next to the signal word (DANGER,

WARNING, CAUTION).

Safety precautions with a safety alert symbol

indicate a danger of injuries.

Be sure to follow these safety precautions to

protect against injuries or death!

Safety precautions without a safety alert symbol

indicate a danger of damage.

1.1.2 Signal words

DANGER

The signal words are located in

the safety precautions in the

WARNING

CAUTION

NOTICE

NOTE

highlighted heading field.

They follow a certain hierarchy and

indicate (in conjunction with the

safety alert symbol, see

Chapter 1.1.1) the seriousness of

the danger and the type of

warning.

See the following explanations:

DANGER

Danger of injuries.

Indicates an imminently hazardous situation,

that will result in death or serious injury if the

corresponding measures are not taken.

WARNING

Danger of injuries.

Indicates a potentially hazardous situation, that

could result in death or serious injury if the

corresponding measures are not taken.

CAUTION

is located in the

CAUTION

Danger of damage.

Indicates a potentially hazardous situation that

may result in property damage if the

corresponding measures are not taken.

NOTICE

Indicates a possible disadvantage, i.e.

undesirable conditions or consequences can

occur if the corresponding measures are not

taken.

NOTE

Indicates a possible advantage if the

corresponding measures are taken; tip.

1.2 General safety precautions

WARNING

Improper use of the system can result in

serious or even fatal injuries!

These operating instructions

must have been completely read and

understood before the start of any work with

or on the system,

must be strictly observed,

must be available at the system operating

location.

WARNING

Improper use of the system can result in

serious or even fatal injuries!

Only operate the system

for the purposes indicated under "Intended

Use"!

with fluids specified under "Proper use"!

with the values indicated under 'Technical

Data'!

WARNING

Danger of injuries.

Indicates a potentially hazardous situation, that

may result in minor or moderate injury if the

corresponding measures are not taken.

610.44444.40.000 4 / 36 © Gardner Denver Deutschland GmbH

Improper use of the system can result in

serious or even fatal injuries!!

All work on and with the system (transport,

installation, commissioning, shut-down,

maintenance, disposal) may only be carried

out by trained, reliable personnel!

Page 5

Safety

WARNING

When working on the system, there is

danger of injury,

e.g. due to cutting/cutting off, crushing and

burns!

During all work on and with the system

(transport, installation, operation, shut-down,

maintenance, disposal) wear personal safety

equipment (safety helmet, protective

gloves, safety shoes)!

WARNING

Hair and clothing can be pulled into the

system or caught and wound up by moving

parts!

Do not wear long, loose hair or loose-fitting

clothes!

Use a hair net!

DANGER

Electrical danger!

Before beginning work on the system, the

following measures must be carried out:

Deenergise.

Secure against being switched on again.

Determine whether deenergised.

Ground and short-circuit.

Cover or block off adjacent energised parts.

DANGER

Electrical danger!

Work on electrical installations may be carried

out by trained and authorised electricians only!

DANGER

Electrical danger!

Do not open the motor terminal box unless

absence of electricity has been ensured!

WARNING

Danger from vacuum!

Danger due to escaping fluid!

Relieve pressure or vacuum before beginning

to work on the system!

Make sure that pipes/hoses and vessels to be

opened have been relieved of pressure or

vacuum and that no fluids might leak out

before loosening any connectors and

fasteners.

WARNING

Danger from vacuum!

Danger due to escaping fluid!

Carry out the following tasks prior to

commissioning, after every disassembly and

reassembly and at regular intervals:

Check pipe/hose connections, pipes/hoses

and vessels for sufficient strength, tightness

and secure fixing!

Check fasteners for secure seating!

WARNING

Danger from vacuum!

Do not operate the unit unless the pipe / hose

has been fitted to the inlet connection!

In particular, do not look into the inlet

connection or move your eyes in front of the

inlet connection opening if the system might

start up and generate a vacuum!

WARNING

Danger due to rotating parts!

Only operate the system when fully

assembled:

with hoses connected to inlet and discharge

connection as well as to operating liquid

connection of installed unit

with the pipes/hoses and fasteners of the

operating-liquid circuit mounted

with cover plate and water cooler of

separator mounted.

Do not disassemble unless the system has

been shut down and come to a complete

standstill!

Consider that the system has a certain run-out!

© Gardner Denver Deutschland GmbH 5 / 36 610.44444.40.000

Page 6

Safety

WARNING

Danger due to rotating parts!

Do not reach into the installed unit through

opened intake or discharge connection!

Do not insert objects into the installed unit

through the openings!

WARNING

Danger of burns/scalding from hot fluids

and hot surfaces of the installed unit!

Allow to cool after shut-down!

CAUTION

Danger from excessive pressure!

Danger from system clogging!

Dirt can enter the system through the exhaustair connection! Clogging is possible!

Do not remove the protective cap from the

discharge connection!

NOTICE

The pumped gases/vapours are expelled into

the surrounding area via the exhaust-air

connection. They are not directed through a

pipe or a hose.

If delivery-side piping is desired:

Enquiry with Service is absolutely necessary!

WARNING

Danger from caustic or toxic fluids!

In case of corrosive of toxic fluids (operating

liquid, pumped gases/vapours):

Enquiry with Service is absolutely necessary!

Wear appropriate personal protective

equipment (protective gloves, safety goggles,

respiratory protection) when working on or

near the system.

If appropriate, attach appropriate warning

sign(s) to the system, e.g. 'Warning! Corrosive

materials!', 'Warning! Harmful or irritant

material!' or 'Warning! Toxic material'.

NOTE

For the system design, see Fig. 1, Pg. 3. The

item numbers (Item) specified in the text refer

to this illustration.

1.3 Residual risks

WARNING

Danger zone:

Not surfaces of installed unit.

Hazard:

Burns/scalding possible.

Protective measures:

Attach warning sign "Warning! Hot surface!" .

WARNING

Danger zone:

External fan of installed unit.

Hazard:

Long, open hair may be drawn into the external

fan of the installed unit with the cover plate and

protective screen of the system removed!

Protective measures:

Wear hair net!

610.44444.40.000 6 / 36 © Gardner Denver Deutschland GmbH

Page 7

Intended Use

2 Intended Use

These operating instructions

apply to vacuum pumps of the L-BL2 series,

models 2BL2 041, 2BL2 061, 2BL2 101,

2BL2 141, 2BL2 251, 2BL2 281 and 2BL2 341

contain instructions bearing on transport and

handling, installation, commissioning,

operation, shut-down, storage, servicing and

disposal of the L-BL2,

must be completely read and understood by

all operating and servicing personnel before

beginning to work with or on the L-BL2,

must be strictly observed,

must be available at the site of operation of

the L-BL2.

exist in the following designs:

– 2BL2 041

– 2BL2 061

– 2BL2 101

– 2BL2 141

– 2BL2 251

– 2BL2 281

– 2BL2 341

are oil-free and non-contacting units.

are air-cooled units.

are intended for industrial applications.

are designed for continuous operation.

When operating the L-BL2, the limits listed in

Chapter 3, "Technical Data", Pg. 8 ff. must

always be complied with.

Foreseeable Misuse

About the operating and servicing personnel of

the L-BL2:

These persons must be trained and

authorised for the work to be carried out.

Work on electrical installations may be carried

out by trained and authorised electricians

only.

The L-BL2s

are systems for generating a vacuum.

contain a liquid-ring vacuum pump of the L-

BV7 series, model 2BV7 or L-BV5,

model 2BV5 (in the following referred to as

"unit"), which is installed in a liquid separator

(in the following referred to as "separator").

are used to extract, transport and compress

the following pumped gases/vapours:

– all dry and moist gases,

which are not explosive, aggressive or

toxic,

– preferably air or air/vapor mixtures.

– For gases/vapours that differ, an enquiry

must be made with the Service

Department.

are designed for operation with the following

operating liquids:

– with a pH of 6 to 9,

which is free of solid materials (such as

sand),

– usually normal tap water.

– If the pH values or operating liquids differ,

it is necessary to contact the Service

Department.

release gases with the following properties

into the environment during operation:

– discharge temperature ambient

temperature,

– discharge pressure ambient pressure,

– absolutely clean and dust-free.

It is prohibited

to use the L-BL2 in non-industrial applications,

unless the necessary protection is provided

on the system, e.g. guards suitable for

children's fingers,

to use the device in rooms in which explosive

gases can occur if the S

_200 is not expressly intended for this

purpose,

to extract, to deliver and to compress

explosive, flammable, corrosive or toxic fluids,

unless the S

_200 is specifically designed for this purpose,

to operate the L-BL2 with values other than

those specified in Chapter 3, "Technical

Data", Pg. 8 ff.

Any unauthorised modifications of the L-BL2 are

prohibited for safety reasons.

Maintenance and repair work by the operator are

only permitted in the scope described in these

operating instructions.

Any maintenance and repair work going beyond

this may only be conducted by companies

authorised by the manufacturer (enquiry with the

Service Department necessary).

This especially applies to the unit installed in the

L-BL2 (liquid-ring vacuum pump of the L-BV7

series, model 2BV7 or L-BV5, model 2BV5):

The installed unit may be neither removed nor

dismantled! any maintenance and repair work,

such as replacing worn or defective components,

may only be carried out by companies authorised

by the manufacturer (please contact the Service

Department).

© Gardner Denver Deutschland GmbH 7 / 36 610.44444.40.000

Page 8

Technical Data

3 Technical Data

3.1 Mechanical data

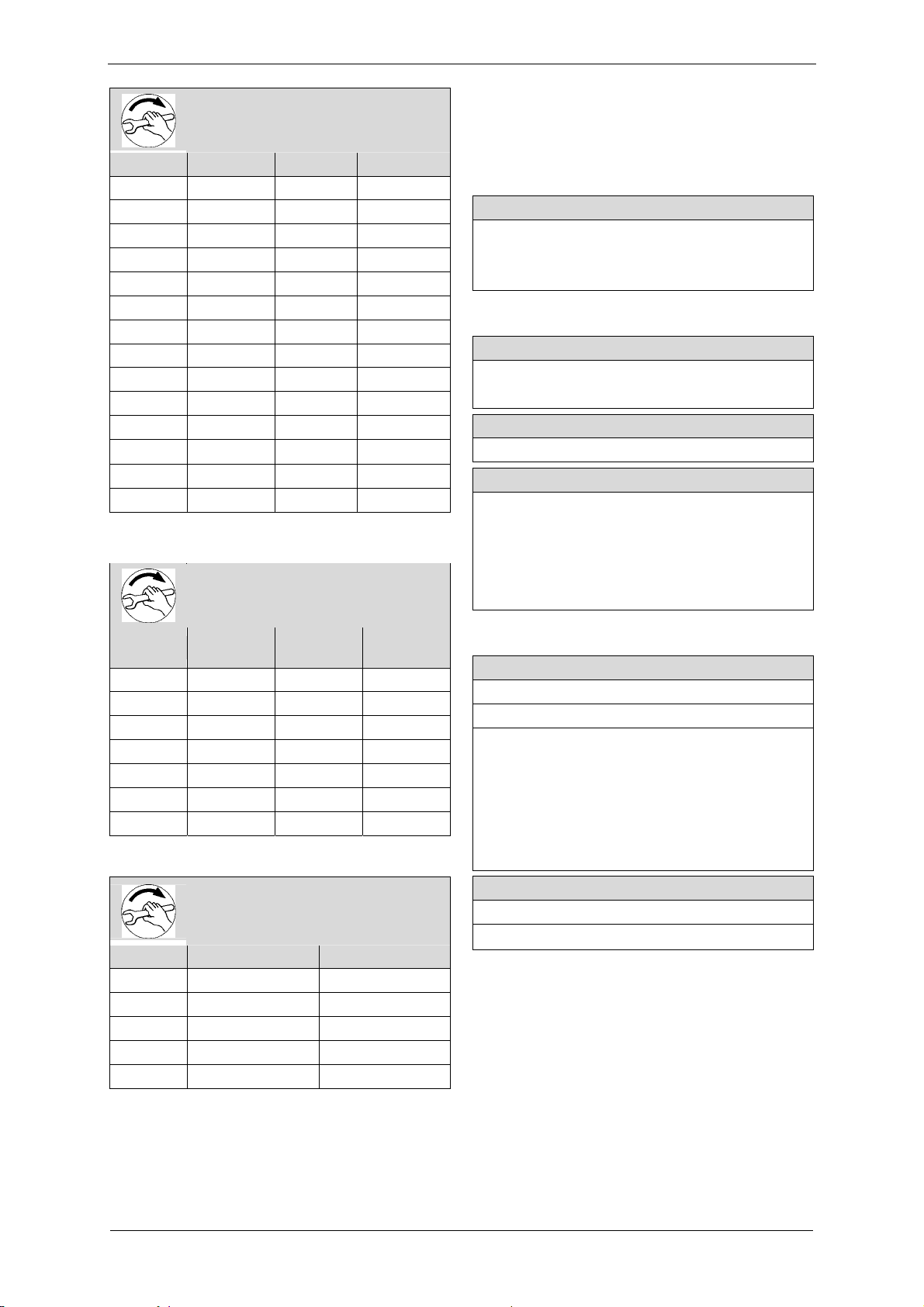

Weight

Weight

(when not filled with water)

Type approx. [kg] approx. [lbs]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

Weight

Type approx. [kg] approx. [lbs]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

Filling capacity of separator

Filling capacity for operating

Type

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

(Normal tap water should usually be used as

operating liquid.)

38 83.8

55 121

68 150

105 232

195 430

210 463

225 496

(when filled with water)

61 134

97 214

110 243

161 355

290 640

305 673

320 706

liquid

max.

[l]

max.

[gal(US)]

max.

[gal(UK)]

23 6.08 5.06

42 11.1 9.24

42 11.1 9.24

56 14.8 12.3

94 24.8 20.7

94 24.8 20.7

94 24.8 20.7

Filling capacity for antiliming

agent

Type approx. [kg] approx. [lbs]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

2 4.41

4 8.82

4 8.82

5 11

8 17.6

8 17.6

8 17.6

(Use pure granulated citric acid as antiliming

agent. The specified filling quantities for citric acid

refer to the medium filling of the separator with

operating liquid.)

Filling quantity of installed unit

Filling quantity for anti-corrosive

agent

Type [l] [gal (US)] [gal (UK)]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

0.6 0.159 0.132

1.0 0.264 0.220

1.0 0.264 0.220

1.0 0.264 0.220

5.5 1.453 1.210

6.3 1.664 1.386

7.0 1.849 1.540

(To ensure sufficient protection, the entire interior

of the installed unit must be filled with anticorrosive agent. Use only anti-corrosive agent

based on ethylene glycol without additives, e.g.

Antifrogen from Hoechst!)

Filling quantity for antiliming

liquid

Type [l] [gal (US)] [gal (UK)]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

0.6 0.159 0.132

1.0 0.264 0.220

1.0 0.264 0.220

1.0 0.264 0.220

5.5 1.453 1.210

6.3 1.664 1.386

7.0 1.849 1.540

(Use 10 % ethanoic acid as antiliming liquid.)

610.44444.40.000 8 / 36 © Gardner Denver Deutschland GmbH

Page 9

Technical Data

Minimum distances for heat dissipation

Minimum distance A

Type [m] [ft]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

(The dimensions are shown in Fig. 3, Pg. 13.)

≥ 0.5 ≥ 1.64

≥ 0.7 ≥ 2.30

≥ 0.7 ≥ 2.30

≥ 0.8 ≥ 2.60

≥ 1.0 ≥ 3.28

≥ 1.0 ≥ 3.28

≥ 1.0 ≥ 3.28

Minimum distance B

Type [m] [ft]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

(The dimensions are shown in Fig. 3, Pg. 13.)

≥ 1.4 ≥ 4.59

≥ 1.6 ≥ 5.25

≥ 1.6 ≥ 5.25

≥ 1.8 ≥ 5.90

≥ 1.9 ≥ 6.23

≥ 1.9 ≥ 6.23

≥ 1.9 ≥ 6.23

Type Minimum distance C

[m] [ft]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

≥ 0.4 ≥ 1.31

≥ 0.4 ≥ 1.31

≥ 0.4 ≥ 1.31

≥ 0.4 ≥ 1.31

≥ 0.4 ≥ 1.31

≥ 0.4 ≥ 1.31

≥ 0.4 ≥ 1.31

(The dimensions are shown in Fig. 3, Pg. 13.)

Spacing of securing eyes

Distance D

Type [mm] [inches]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

(The dimensions are shown in Fig. 3, Pg. 13.)

360 14.2

495 19.5

495 19.5

585 23

715 28.1

715 28.1

715 28.1

Distance E

Type [mm] [inches]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

(The dimensions are shown in Fig. 3, Pg. 13.)

345 13.6

450 17.7

450 17.7

570 22.4

755 29.7

755 29.7

755 29.7

Distance F

Type [mm] [inches]

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

--- ---

225 8.9

225 8.9

285 11.2

377 14.8

377 14.8

377 14.8

(The dimensions are shown in Fig. 3, Pg. 11.)

Noise level

1

Measuring-surface sound-pressure level as per

EN ISO 3744, measured at 1 m [3.28 ft] distance

with moderate throttling (100 mbar abs.

[1.45 psia]) and connected lines, tolerance

3 dB (A).

1-m measuring-surface sound

pressure level L [dB (A)]

Type at 50 Hz: at 60 Hz:

2BL2 041

2BL2 061

2BL2 101

2BL2 141

2BL2 251

2BL2 281

2BL2 341

70

70

70

74

77

74

76

73

Operating speed

See rating plate.

Tightening torques

Tightening torques

for screws (Fig. 1, Pg. 3)

Pos.: Thread [Nm] [ft lbs]

005 2.7 - 3.3 1.99 - 2.43

007 2.7 - 3.3 1.99 - 2.43

012 E-JOT4 0.72 - 0.88 0.53 - 0.65

© Gardner Denver Deutschland GmbH 9 / 36 610.44444.40.000

Page 10

Technical Data

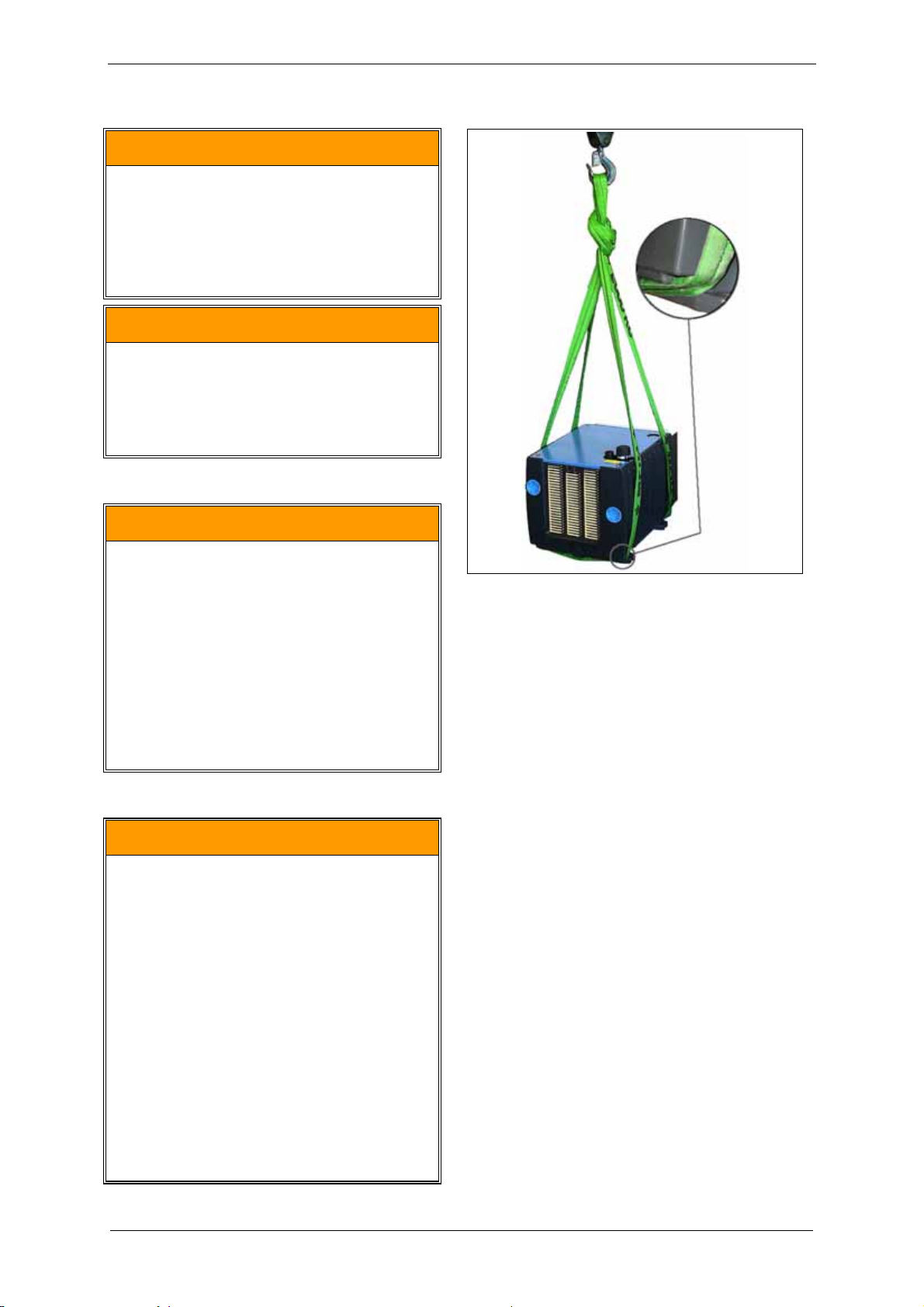

Tightening torques

for screws (Fig. 1, Pg. 3)

Pos.: Thread [Nm] [ft lbs]

019 M8 13.5 - 16.5 9.96 - 12.2

019 M10 21.6 - 26.4 15.9 - 19.5

023 M8 8.1 - 9.9 6.0 - 7.3

023 M10 13.5 - 16.5 9.96 - 12.2

025 2.7 - 3.3 1.99 - 2.43

030 M6/M8 8.1 - 9.9 6.0 - 7.3

032 E-JOT5 1.1 - 1.3 0.8 - 0.96

032 M6 4.5 - 5.5 3.3 - 4.05

057 St 4,2 2.7 - 3.3 1.99 - 2.43

060 M6 2.7 - 3.3 1.99 - 2.43

066 E-JOT4 0.72 - 0.88 0.53 - 0.65

E

G¼

2.25 - 2.75 1.66 - 2.0

E G⅜ 6.3 - 7.7 4.65 - 5.68

Clamps 2.7 - 3.3 1.99 - 2.43

The values specified here for tightening torques

apply unless other values are indicated.

Tightening torques for screw

connections (in general)

Thread

M4

M5

M6

M8

M10

M12

M16

Property

classes

[Nm] [ft lbs]

5.6 1.26 - 1.54 0.93 - 1.14

5.6 2.7 - 3.3 1.99 - 2.43

8.8 7.2 - 8.8 5.3 - 6.5

8.8 18 - 22 13.3 - 16.2

8.8 36 - 44 26.6 - 32.5

8.8 63 - 77 46.5 - 56.8

5.6 90 - 110 66.4 - 81.1

(These values apply to screw connections with

the exception of electrical connections.)

Tightening torques for electrical

connections (terminal board-

connections)

Thread [Nm] [ft lbs]

M4

M5

M6

M8

M10

0.9 - 1.1 0.66 - 0.81

2.0 - 2.4 1.47 - 1.77

2.7 - 3.3 1.99 - 2.43

6.3 - 7.7 4.65 - 5.68

10 - 12 7.34 - 8.85

These values for electrical connections apply to

all terminal board connections with the exception

of terminal strips.)

3.2 Electrical data

See rating plate on separator water cooler.

3.3 Operating conditions

Default conditions

Ambient temperature

Ambient pressure

Air saturation

+20 °C +68 °F

101.3 kPa 14.7 psi

50 %

Temperatures

Temperatures of pumped gases/vapours

Intake temperature

Delivery temperature

max. +60 °C max. +140 °F

Ambient temperature

Temperature of operating liquid

max. +60 °C max. +140 °F

Ambient temperature

max. +40 °C max. +104 °F

min. +10 °C min. +50 °F

With ambient temperature < 10 °C (< 50 °F):

Observe yellow adhesive label on cover plate.

Add ethylene glycol to operating liquid in separator

accordingly.

Pressures

Inlet pressure

min. 5 kPa abs. min. 0.725 psia

max. 80 kPa abs. max. 11.6 psia

At inlet pressures > 35 kPa abs. [5.08 psia], the

share of water vapour in the escaping gases may

be slightly above that of the gases sucked in. The

resulting water loss can automatically be

compensated by a feed regulator (see Chapter 5.5,

"Accessories", Pg. 19).

It is prohibited to connect piping to the discharge

side of the system!

Discharge pressure

approx. 101.3 kPa approx. 14.7 psi

Ambient pressure

610.44444.40.000 10 / 36 © Gardner Denver Deutschland GmbH

Page 11

4 Transport and Handling

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 4 f.?

Otherwise you may not carry out any work with

or on the system!

WARNING

Danger from tipping or falling loads!

Prior to transport and handling make sure that

all components are securely assembled and

secure or remove all components the fasteners

of which have been loosened!

Manual handling:

Transport and Handling

Transport with a crane and lifting belts, with

forklift truck or with low-lift platform truck.

WARNING

Danger from lifting heavy loads!

Manual handling of the unit is only permitted

within the following limits:

max. 30 kg [max. 66 lbs] for men

max. 10 kg [max. 22 lbs] for women

max. 5 kg [max. 11 lbs] for pregnant women

For the weight of the system, see Chapter 3.1,

"Mechanical data", Section "Weight", Pg. 8.

Above these limits, suitable lifting equipment

and/or means of transport must be used!

Transport with lifting equipment:

WARNING

Danger from tipping or falling loads!

When transporting with lifting equipment,

observe the following basic rules:

Use only suitable lifting gear (e.g. belts or

ropes) and means of transport (e.g. forklift

truck, low-lift platform truck, crane).

The lifting capacity of lifting equipment and

lifting gear must be at least equal to the

system's weight.

For the weight of the system, see

Chapter 3.1, "Mechanical data",

Section "Weight", Pg. 8.

The system must be secured so that it

cannot tip or fall.

Do not stand or walk under suspended

loads!

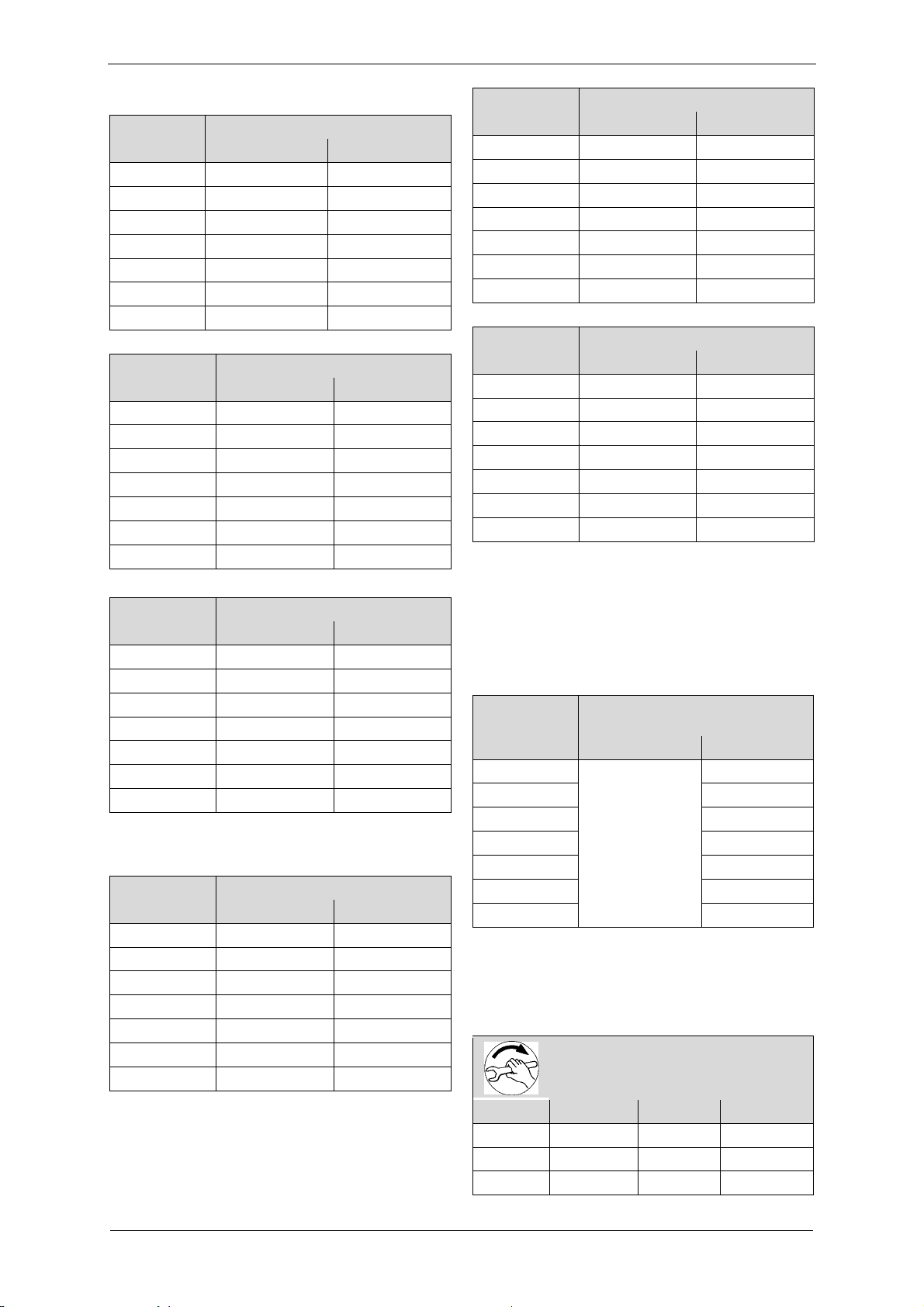

Fig. 2: Attachment points

Attach the strap belts as shown in Fig. 2, Pg. 11:

Use two lifting belts routed along below the

system.

The lifting belts should be securely seated in

the recesses shaped into the lower edges

(two on each of the long sides) of the system

so as to prevent the system from slipping out

of them.

The lifting belts must be sufficiently long

(spread angle smaller than 90°).

Make sure that no damage is caused to any

attached fittings.

© Gardner Denver Deutschland GmbH 11 / 36 610.44444.40.000

Page 12

Installation

5 Installation

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 4 f.?

Otherwise you may not carry out any work with

or on the system!

NOTE

For the system design, see Fig. 1, Pg. 3. The

item numbers (Item) specified in the text refer

to this illustration.

5.1 Installation

CAUTION

Danger of crushing from system tipping

over!

CAUTION

Danger of damage to the system due to

overheating!

When installing the system, make sure that

heat dissipation and cooling are not

obstructed. The minimum distances specified

in Chapter 3.1, "Mechanical data",

Section "Minimum distances for heat

dissipation", Pg. 9 must be complied with.

Discharge air of other machines/devices may

not be directly sucked in again!

WARNING

Danger from system tipping over or falling!

If the system is installed on moveable machine

parts or at a great height without any other

protection against falling down, it must by all

means be bolted to the bearing surface via the

securing eyes in its feet.

NOTE

In the unmounted state, the system can easily

tip due to its weight distribution!

Wear gloves and safety shoes! Handle the

system with the appropriate care!

CAUTION

Danger of tripping and falling!

Make sure the system does not present a

danger of tripping!

Block off the system with a guard fence or

mark with red-and-white tape etc. if necessary.

WARNING

Electrical danger!

The system must be installed so that the

electrical device cannot be damaged by

external influences!

In particular, the feed pipes must be securely

routed, e.g. in cable ducts or in the floor.

Note on later transport!

Install the system with the feet on strips or

similar supports to simplify transport later, e.g.

with a low-lift platform truck!

Space requirement and minimum distances:

The space requirement and positioning of the

hole for installing and securing the system are

shown in Fig. 3, Pg. 11.

For minimum clearances for heat dissipation

and cooling,

see Chapter 3.1, "Mechanical data",

Section "Minimum distances for heat

dissipation", Pg. 9.

Spacing of securing eyes:

see Chapter 3.1, "Mechanical data",

Section "Spacing of securing eyes", Pg. 9.

610.44444.40.000 12 / 36 © Gardner Denver Deutschland GmbH

Page 13

Installation

A

B

C

1 2

D

F

E

Fig. 3: Minimum distances for heat dissipation and spacing of securing eyes

A – C: Minimum clearance for heat dissipation

D – F: Spacing of securing eyes

See Chapter 3.1, "Mechanical data", Pg. 8 for

dimensions.

Installation conditions:

The system must be installed as follows:

on flat, level surfaces,

on stationary (fixed) surfaces or structures,

with the feet facing downward (no ringing off,

e.g. with the feet on the wall),

at a maximum height of 1000 m [3280 ft]

above sea level.

At installation altitudes of more than 1,000 m

[3,280 ft] above sea level, the Service

Department must be consulted.

1 Cooling air inlet

2 Cooling air outlet

3 Wall

The points on the system for measuring the

vibration speed are shown in Fig. 4, Pg. 13.

C

33 3

Observe the following when installing the system:

The load-bearing capacity of the installation

surface must at least be designed for the

weight of the system.

The vibration behaviour at the operating

location must be taken into account.

The total vibrations of the system are

dependent on the following factors:

– the characteristic vibrations of the system,

– the alignment and installation,

Fig. 4: Points for measuring the vibration

speed

– the condition (vibration behaviour) of the

load-bearing surface,

– the influences by vibrations of other parts

and system components (external

vibrations).

The maximum permissible value for vibrations

is v

= 4.5 mm/s [0.177"/s].

eff

To ensure proper operation and a long service

life of the system, this value may not be

exceeded.

Generally, this value can be adhered to

without a special foundation or a special base

plate.

© Gardner Denver Deutschland GmbH 13 / 36 610.44444.40.000

Page 14

Installation

Securing:

There are two options:

Install the system without securing.

OR

Screw the feet of the system to the surface

with suitable fasteners.

– Models 2BL2 041 - 141:

Screws 4 x M10

Washers as per ISO 7093-1

Tightening torque: 10 Nm [7.38 ft lbs]

– Models 2BL2 251 - 341:

Screws 4 x M12

Washers as per ISO 7093-1

Tightening torque: 20 Nm [14.81 ft lbs]

CAUTION

With the 2BL2 341 the 4 adjustment screws of

the hexagonal feet (see Fig. 1, Pg. 3) and the 3

strips of the separator must make contact over

the entire contact surface on the floor or the

raised sections.

5.2 Electrical connection (motor)

DANGER

Electrical danger!

Improper behaviour can result in severe

injuries and damage!

DANGER

Electrical danger!

The electrical connection may be carried out

by trained and authorised electricians only!

DANGER

Electrical danger!

Before beginning work on the system, the

following measures must be carried out:

Deenergise.

Secure against being switched on again.

Determine whether deenergised.

Ground and short-circuit.

Cover or block off adjacent energised parts.

DANGER

Electrical danger!

Replace loose connections, singed or burned

cables immediately!

DANGER

Electrical danger!

Lay the electrical connecting cables so that

they cannot be damaged by external

influences and are free from tensile stress!

WARNING

Danger due to gauge pressure and vacuum!

Danger due to escaping fluid!

Before beginning work on the system or line:

Interrupt supply of operating liquid.

Vent lines (depressurise).

CAUTION

Incorrect connection of the motor can lead to

serious damage to the system!

Regulations:

The electrical connection must be carried out as

follows:

according to the applicable national and local

laws and regulations,

according to the applicable system-dependent

prescriptions and requirements,

according to the applicable regulations of the

utility company.

Electrical power supply:

Observe the rating plate.

It is imperative that the operating conditions

correspond to the data given on the rating plate!

Deviations permissible without reduction in

performance:

±5 % voltage deviation

±2 % frequency deviation

Fit connecting cable:

Use a flexible cable as the electrical

connecting cable.

Open system:

Remove cover plate.

610.44444.40.000 14 / 36 © Gardner Denver Deutschland GmbH

Page 15

Fig. 5: Remove cover plate:

Unscrew screws

Insert the connecting cable:

Thread the connecting cable into the cord

grips on the side panel of the separator and

push it through the cable inlet into the interior

of the separator.

Route the connecting cable into the terminal

box of the installed unit via the cable entry

opening.

In order to relieve strain, secure the

connecting cable as follows:

– via the cable gland on the terminal box of

the installed unit

– via the cord grips on the outside of the

separator

– Tightening torques: see Chapter 3.1,

"Mechanical data", Section "Tightening

torques", Pg. 9.

Installation

Fig. 6: Strain relief:

Cord grips on the outside of the separator

Connection to drive-motor terminal box:

Carry out the connection and the arrangement of

the jumpers in accordance with the circuit

diagram in the terminal box.

Connect the protective conductor to the terminal

with the following symbol:

The electrical connection must be carried out as

follows:

The electrical connection must be

permanently safe.

There may be no protruding wire ends.

Clearance between bare live parts and

between bare live parts and ground: ≥ 5.5 mm

[0.217"] (at a nominal voltage of UN ≤ 690 V).

Tightening torques for terminal plate

connections:

see Chapter 3.1, "Mechanical data",

Section "Tightening torques", Pg. 9.

Use suitable cable lugs.

For terminals with clamping straps, the

conductors must be inserted so that

approximately the same clamping height

results on both sides of the bar.

Individual conductors must therefore be bent

into a U-shape or connected with a cable lug.

All conductors under outer angled grounding

brackets must be bent into a "U" shape.

© Gardner Denver Deutschland GmbH 15 / 36 610.44444.40.000

Page 16

Installation

This also applies to:

the protective conductor,

the outer ground conductor.

Both conductors can be recognised from their

colour (green/yellow).

WARNING

Electrical danger!

Clearance between bare live parts and between

bare live parts and ground:

at least 5.5 mm [0.217"] (at a nominal voltage

of V

≤ 690V)

n

Make sure there are no protruding pieces of

wire!

WARNING

Electrical danger!

The terminal box must be free from

foreign bodies,

dirt,

humidity.

Terminal box cover and cable entries must be

tightly closed so as to make them dustproof and

waterproof.

Check for tightness at regular intervals.

For motor overload protection:

Use motor circuit breakers.

Set the motor circuit breakers to the nominal

current specified on the rating plate.

We recommend using slow-acting motor

circuit breakers.

Close system:

Fit cover plate.

WARNING

Danger from rotating external fan of

installed unit!

CAUTION

If the installed unit is run dry, the mechanical

seal will be destroyed in a matter of seconds!

DO NOT switch on until the following

conditions are met:

The separator must be correctly filled with

operating liquid.

The interior of the installed unit must be

filled with operating liquid.

Check direction of rotation:

Make sure that the following conditions are

met:

– The separator must be correctly filled with

operating liquid (watch fill level indicator).

– The interior of the installed unit must be

filled with operating liquid.

– The separator cover plate must be

mounted.

WARNING

Danger from vacuum!

If there is a danger that the system could suck

in:

Do not go near the inlet connection with

long, open hair or loose fitting clothing,

Do not look into the inlet connection or

move your eyes in front of the inlet

connection opening.

Do NOT connect the intake line to the inlet

connection yet.

Briefly turn power ON.

If the rotating direction is correct, cooling air

immediately exits from the protective screen.

Turn power OFF again.

If necessary, reverse the direction of rotation

of the motor.

WARNING

Only operate the system with the protective

screen and cover plate installed!

Malfunctions can result in serious damage

and injuries!

In case of conspicuous irregularities which

indicate malfunctions, take the following

measures:

If in doubt, shut off the operating

materials concerned immediately!

Determine cause immediately and

eliminate!

Also see Chapter 9, "Servicing", Pg. 25.

610.44444.40.000 16 / 36 © Gardner Denver Deutschland GmbH

Page 17

5.3 Filling

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Only operate the system

for the purposes indicated under "Intended

Use"!

with the fluids specified under "Proper use"!

with the values indicated under 'Technical

Data'!

WARNING

Danger from caustic or toxic fluids!

In case of corrosive of toxic fluids (operating

liquid, pumped gases/vapours):

Enquiry with Service is absolutely necessary!

Wear appropriate personal protective

equipment (protective gloves, safety goggles,

respiratory protection) when working on or

near the system.

If appropriate, attach appropriate warning

sign(s) to the system, e.g. 'Warning! Corrosive

materials!', 'Warning! Harmful or irritant

material!' or 'Warning! Toxic material'.

Proceed as follows:

Installation

Fig. 8: Filling separator

Models 2BL2 251 - 341 (via the filling opening)

Check the liquid level in the separator:

Check via the fill level indicator (Item 010). When

doing so, watch the maximum operating liquid

level.

NOTICE

Max. operating-liquid level:

Lower edge of the fill opening (Item 007) =

level-indicator pointer at 1 (Item 010).

Do not fill the separator above this level!

Fill the separator:

Fill operating liquid (usually ordinary tap water)

into the separator via the fill opening (Item 007),

Filling amount: See Chapter 3.1, "Mechanical

data", Pg. 8.

Fig. 7: Filling separator

Models 2BL2 041 - 141 (via the filling opening)

When the unit is filled for the first time:

Fill installed unit:

Pour additional operating liquid into the inlet

connection (Item A) of the system so that

operating liquid flows into the interior of the

installed unit.

Models 2BL2 041 - 2BL2 141:

1.5 l [0.396 gal (US); 0.330 gal (UK)]

Models 2BL2 251 - 2BL2 341:

7.0 l [1.32 gal (US); 1.1 gal (UK)]

© Gardner Denver Deutschland GmbH 17 / 36 610.44444.40.000

Page 18

Installation

Fig. 9: Filling installed unit (via inlet

connection)

CAUTION

If the installed unit is run dry, the mechanical

seal will be destroyed in a matter of seconds!

DO NOT switch on until the following

conditions are met:

The separator must be correctly filled with

operating liquid.

The interior of the installed unit must be

filled with operating liquid.

WARNING

Danger due to escaping fluid!

Make sure that all openings in the separator

(feed/drain regulator connection, fill opening,

drain opening) are tightly closed (by means of

screwed-in bung plugs or installed feed

regulator, drain regulator and drain valve)

when the separator is filled with operating

liquid.

5.4 Connection of pipes/hoses

WARNING

Danger from vacuum!

Do not operate the unit unless the pipe / hose

has been fitted to the inlet connection!

If there is a danger that the system could suck

in:

Do not go near the inlet connection with

long, open hair or loose fitting clothing,

Do not look into the inlet connection or

move your eyes in front of the inlet

connection opening.

WARNING

Danger from vacuum!

Danger due to escaping fluid!

During operation connected pipes and vessels

are vacuumised!

Make sure that all connections are sufficiently

tight! Use only pipes and vessels of sufficient

strength!

The pumped gases/vapours are sucked in via

the inlet connection

and discharged via the exhaust-air connection

(see Chapter 5.4.1, Pg. 18)

(see Chapter 5.4.2, Pg. 19).

5.4.1 Inlet connection

Remove sealing plug

To prevent the penetration of foreign bodies, the

connection opening on the inlet connection

(Item A) is sealed off on delivery.

Do not remove the sealing plug until immediately

before connecting the pipes/hoses.

Check valve:

In the following cases a check valve must be

attached to the inlet connection (Item A):

If two or more systems are operated in

parallel, e.g. reserve system.

(Note: A separate check valve must be

attached to the inlet connection on each

system.)

If a vacuum can occur for more than

one minute in the connected intake line on the

system switched off.

The check valve prevents the backflow of

pumped gases/vapours from the system during

an interruption in operation.

610.44444.40.000 18 / 36 © Gardner Denver Deutschland GmbH

Page 19

Connect the inlet pipe:

Installation

5.4.2 Exhaust-air connection

Connect the system-side line for the pumped

gases/vapours (intake line) to the connecting

piece of the inlet connection (Item 037).

2 3 1

Fig. 10: Connection of inlet line on connecting

piece of inlet connection

1 Inlet line

2 Connection thread

3 Connecting piece

CAUTION

Danger of damage to connecting piece!

The connection thread on the connecting piece

of the inlet connection is made of plastic, and

can therefore easily be damaged.

Exercise the appropriate caution when

connecting the inlet line.

The pumped gases/vapours are expelled into the

surrounding area via the exhaust-air connection

(Item B). They are not directed through a pipe or

a hose.

As a result, no assembly is required here.

CAUTION

Danger from excessive pressure!

Danger from system clogging!

Do not remove the protective cap from the

exhaust-air connection!

If delivery-side piping is desired:

Enquiry with Service is absolutely necessary!

5.5 Accessories

The following accessories are available

according to our catalogue:

Inlet Filter

Vacuum Control Valve

Feed Regulator

Outlet Regulator

Electrical Level Switch

Drain Valve

NOTICE

The tightening torque must always be adjusted

to match the connection thread material.

NOTICE

Attach pipes/hoses free of mechanical

tensions.

Support the weight of the pipes/hoses.

Fig. 11: Accessories

© Gardner Denver Deutschland GmbH 19 / 36 610.44444.40.000

Page 20

Commissioning

6 Commissioning

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 4 f.?

Otherwise you may not carry out any work with

or on the system!

WARNING

Danger from vacuum!

Danger due to escaping fluid!

Danger due to rotating parts!

The system may only be put into operation

when the following conditions are met:

The hoses on the inlet and discharge

connection and on the operating liquid

connection of the installed unit are

connected.

The cover plate and the water cooler of the

separator are fitted.

The lines and connection elements of the

operating liquid circuit are fitted.

The line on the system inlet connection is

connected.

The pipe/hose connections, pipes/hoses

and vessels have been checked for

sufficient strength and freedom from leaks!

The fasteners have been checked for

secure seating.

CAUTION

If the installed unit is run dry, the mechanical

seal will be destroyed in a matter of seconds!

DO NOT switch on until the following

conditions are met:

The separator must be correctly filled with

operating liquid.

The interior of the installed unit must be

filled with operating liquid.

NOTE

For the system design, see Fig. 1, Pg. 3. The

item numbers (Item) specified in the text refer

to this illustration.

6.1 Preparation and start-up

Proceed as follows:

Make sure that the following conditions are

met:

– The separator must be correctly filled with

operating liquid. (watch fill level indicator).

– The interior of the installed unit must be

filled with operating liquid.

– The separator cover plate must be

mounted.

Turn power ON.

The system begins to intake the pumped

gases/vapours.

NOTE

If, on being put into service for the first time,

the system does not generate a vacuum:

briefly throttle or close and reopen the inlet

side.

6.2 Shut-down

Generally speaking, the system may be shut

down in any operating condition (i.e. regardless

of the actual pressure, temperature, etc.).

Take into consideration, however, whether the

process of your line allows for interrupting the

operation of the system.

Proceed as follows:

Turn power OFF.

The system interrupts the intake of the

pumped gases/vapours.

In case the unit is not to be put into service again

for an extended period of time:

observe the instructions in Chapter 8, "Shutting

Down and Longer Standstill", Pg. 23.

610.44444.40.000 20 / 36 © Gardner Denver Deutschland GmbH

Page 21

7 Operation

Start-up and shut-down in normal operation is

identical to the procedure for commissioning.

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 4 f.?

Otherwise you may not carry out any work with

or on the system!

Also be sure to read the safety precautions in

Chapter 6, "Commissioning", Pg. 20!

NOTE

Position

STANDARD

Position

HIGH VACUUM

Fig. 12: 3-way valve (only 2BL2 041 - 141)

7.2.1 Loss of operating liquid

Operation

For the system design, see Fig. 1, Pg. 3. The

item numbers (Item) specified in the text refer

to this illustration.

7.1 Start-up and shut-down

See:

Chapter 6.1, "Preparation and start-up",

Pg. 20.

Chapter 6.2, "Shut-down", Pg. 20.

7.2 Operation within the process

Continuous operation at maximum

vacuum/minimum inlet pressure (with the inlet

valve closed) is possible. The power

consumption of the system is at its lowest in this

case.

In case of no-load operation we recommend

operation at minimum inlet pressure (lowest

power consumption).

The following applies to models 2BL2 041 - 2BL2

141:

during operation at low inlet pressures

( 20 kPa abs. [2.90 psia]), the pumping capacity

of the system can be increased by switching over

the 3-way valve (Fig. 1, Pg. 3, Item G) to the

HIGH VACUUM position.

(Also see Fig. 12, Pg. 21).

During operation at inlet pressures 20 kPa abs.

[2.90 psia], this valve position can lead to the

formation of splash water on the exhaust-air

connection.

Switchover is not required for the models 2BL2

251 - 2BL2 341.

At a low humidity and a high inlet pressure

(> 35 kPa abs. [5.08 psia]), the water vapour

content in the escaping gases is slightly above

that of the gases sucked in. This results in a

slight loss of operating liquid.

NOTICE

Check the operating-liquid level in the

separator regularly by means of the level

indicator!

NOTICE

Do not operate the system with the operating

liquid level with the pointer in the 0 position!

Liquid level with pointer in 0 position:

At a liquid level with the pointer in the 0

position, the pumping capacity of the system will

be reduced. During longer operation under these

conditions, this leads to a dip in the vacuum and

may ultimately result in the system running dry!

When the pointer is in the 0 position (minimum),

take the following measures:

Interrupt system operation.

See Chapter 6.2, "Shut-down", Pg. 20.

Pour operating liquid into the separator via the

filling opening (up to pointer position 1 (lower

edge of the filling opening)).

© Gardner Denver Deutschland GmbH 21 / 36 610.44444.40.000

Page 22

Operation

NOTICE

Max. operating liquid level:

Lower edge of the filling opening

= level-indicator pointer at 1.

Do not fill the separator above this level!

Feed regulator:

In case of operating liquid loss, a feed regulator

(see Chapter 5.5, "Accessories", Pg. 19) can be

connected with which the liquid level is

automatically compensated.

7.2.2 Increase in operating liquid

In case of high air saturation and low inlet

pressure, the water vapour content of the

discharge gases is slightly below that of the inlet

gases. This results in a slight increase in

operating liquid.

Also, water entrained via the inlet pipe will

result in an increase in operating liquid.

NOTICE

Check the operating-liquid level in the

separator regularly by means of the level

indicator!

Overfilling cannot be checked via the fill level

indicator!

NOTICE

Do not operate the system with the operating

liquid level above pointer position 1!

Outlet regulator:

In case of operating liquid increase, a drain

regulator (see Chapter 5.5, "Accessories",

Pg. 19) must be connected with which the liquid

level is automatically compensated.

610.44444.40.000 22 / 36 © Gardner Denver Deutschland GmbH

Page 23

8 Shutting Down and Longer

Standstill

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 4 f.?

Otherwise you may not carry out any work with

or on the system!

NOTE

For the system design, see Fig. 1, Pg. 3. The

item numbers (Item) specified in the text refer

to this illustration.

8.1 Draining

Shutting Down and Longer Standstill

Remove the cover plate (Item 064) and

protective grille (Item 058) from the separator.

Have a suitable catch container ready.

Open the following drain openings (see Fig. 1,

Pg. 3):

– Drain opening on separator

(Item 005)

– Drain cooler

(Item. F)

– Drain installed unit

(Item E)

Allow the liquid to drain out.

Close all drain openings again.

(Tightening torques: see Chapter 3.1,

"Mechanical data", Section "Tightening

torques", Pg. 9.

Remount the cover plate (Item 064) and

protective grille (Item 058) on the separator.

8.2 Preparing for longer shut-down

DANGER

Electrical danger!

Before beginning work on the system, the

following measures must be carried out:

Deenergise.

Secure against being switched on again.

Determine whether deenergised.

Ground and short-circuit.

Cover or block off adjacent energised parts.

DANGER

Before a longer shut-down (from approx.

4 weeks) or in case of frost danger, proceed as

follows:

Drain system as described in Chapter 8.1,

"Draining", Pg. 23.

Have the cover plate (Item 064) and

protective grille (Item 058) removed from the

separator.

Models 2BL2 041 - 2BL2 141:

Disconnect pipe/hose from screw-in

connecting sleeve (Item H) of installed unit.

Models 2BL2 251 - 2BL2 341:

Disconnect pipe/hose from condensation

cooler (Item 031).

To remove the pipe/hose, open the clip with

Electrical danger!

Work on electrical installations may be carried

out by trained and authorised electricians only!

WARNING

special pliers or a screwdriver.

Choose a suitable preservative.

Use only anti-corrosive agent based on

ethylene glycol (e.g. Antifrogen from

Hoechst).

Pour the preservative into the open screw-in

connecting sleeve (Item H) using a funnel or

Danger from vacuum!

Danger due to escaping fluid!

Before beginning work on the system or line:

Interrupt supply of operating liquid.

Vent lines (depressurise).

Shut down system and disconnect mains

plug.

The above safety precautions apply when

working on the system or line.

If the feed regulator is installed:

Shut off the feed pipe. Remove the feed

regulator.

© Gardner Denver Deutschland GmbH 23 / 36 610.44444.40.000

hose. (See Fig. 13, Pg. 24.)

Filling amount: see Chapter 3.1, "Mechanical

data", Section "Filling quantity for anti-

corrosive agent", Pg. 8. The entire interior of

the installed unit must be filled with anti-

corrosive agent.

During filling turn the cooling fan by hand by

approx. one turn.

Reconnect the disconnected pipe/hose.

Remount the cover plate (Item 064) and

protective grille (Item 058) on the separator.

You have two options for the standstill:

Either the system remains connected in the

line,

or the system is removed for storage.

Page 24

Shutting Down and Longer Standstill

Fig. 13: Pouring preservative/antiliming liquid

into installed unit

(for models 2BL2 041 - 2BL2 141)

To prevent standstill damage during storage, the

environment must provide the following

conditions:

dry,

dust-free,

low-vibration (effective value of vibration

speed v

≤ 0.2 mm/s [0.008"/sec]).

eff

Take the following measures for commissioning

following a longer standstill:

Measure the insulation resistance of the

motor.

In case of values ≤ 1kΩ per volt of nominal

voltage, dry winding.

Drain off the anti-corrosive agent via the drain

opening of the installed unit, as described in

Chapter 8.1, "Draining", Pg. 23.

Dispose of preservative in accordance with

the manufacturer's specifications.

Then clean the system:

Pour operating liquid into the system via the

filling opening (Fig. 1, Pg. 3, Item 007).

If appropriate, Briefly operate the system to

circulate the operating liquid in the system.

See Chapter 6.1, "Preparation and start-up",

Pg. 20.

Switch off the system again. See Chapter 6.2,

"Shut-down", Pg. 20.

Drain the system. See Chapter 8.1,

"Draining", Pg. 23.

For new systems:

Install the system as described in Chapter 5,

"Installation", Pg. 12.

Commission the system as described in

Chapter 6, "Commissioning", Pg. 20.

For systems that are already installed in a

line:

Commission the system as described in

Chapter 6, "Commissioning", Pg. 20.

DANGER

Electrical danger!

Work on electrical installations may be carried

Fig. 14: Pouring preservative/antiliming liquid

into installed unit

(for models 2BL2 251 - 2BL2 341)

8.3 Storage conditions

This chapter applies in the following cases:

New systems,

Systems that are already installed in a system

out by trained and authorised electricians only!

WARNING

Danger of slipping due to escaping

operating liquid!

When draining the system, operating liquid will

be discharged downward via the opening in the

bottom of the separator. Have a catch

container ready under the system.

and were prepared for a longer standstill, as

described in Chapter 8.2, "Preparing for

longer shut-down", Pg. 23.

610.44444.40.000 24 / 36 © Gardner Denver Deutschland GmbH

Page 25

Servicing

9 Servicing

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Have you read the safety precautions in

Chapter 1, "Safety", Pg. 4 f.?

Otherwise you may not carry out any work with

or on the system!

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

All maintenance work on the system must

always be performed by the Service

Department!

Maintenance work on the system may only be

conducted by the operator itself when the

related maintenance manual on hand!

Inquire with the Service Department!

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Do not disassemble unless the system has

been shut down and come to a complete

standstill!

Consider that the system has a certain run-out!

WARNING

Cutting hazard!

Do not remove the protective grille from the

water cooler!

DANGER

Electrical danger!

Before beginning work on the system, the

following measures must be carried out:

Deenergise.

Secure against being switched on again.

Determine whether deenergised.

Ground and short-circuit.

Cover or block off adjacent energised parts.

DANGER

Electrical danger!

Replace loose connections, singed or burned

cables immediately!

DANGER

Electrical danger!

Work on electrical installations may be carried

out by trained and authorised electricians only!

DANGER

Only the following components may be

removed:

The hoses on the inlet and discharge

connection and on the operating liquid

connection of the installed unit

The cover plate and the water cooler of the

separator

The pipes/hoses and connection elements

of the operating-liquid circuit

The line on the system inlet connection

WARNING

Danger from rotating impeller of installed

unit!

The unit installed in the system may be neither

removed nor dismantled!

Electrical danger!

Do not open the motor terminal box until

absence of electricity has been ensured!

WARNING

Danger from vacuum!

Danger due to escaping fluid!

Before beginning work on the system or line:

Interrupt supply of operating liquid.

Vent lines (depressurise).

WARNING

Danger from rotating external fan of

installed unit!

Only operate the system with the protective

screen and cover plate installed!

© Gardner Denver Deutschland GmbH 25 / 36 610.44444.40.000

Page 26

Servicing

WARNING

Danger of burns and scalding from hot

surfaces of the installed unit and from hot

fluids!

Only operate the system with the protective

screen and cover plate installed!

Allow to cool after shut-down!

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Do not reach into the installed unit through

the opened intake or discharge connection!

Do not insert objects into the installed unit

through the openings!

WARNING

Danger from tipping or falling loads!

If the system is installed on moveable machine

parts or at a great height without any other

protection against falling, the following applies:

If the screw connection to the installation

surface is unscrewed for maintenance

work, then the system must be placed on a

flat, rigid (stationary) surface.

If appropriate, secure the system against

falling from a great height.

WARNING

Improper use of the system can result in

serious or even fatal injuries!!

Do not disassemble unless the system has

been shut down and come to a complete

standstill!

Consider that the system has a certain run-out!

Only restart when the following conditions are

met:

The system is completely assembled.

The pipe/hose connections, pipes/hoses

and vessels have been checked for

sufficient strength, freedom from leaks and

secure seating!

The fasteners have been checked for

secure seating!

NOTE

For the system design, see Fig. 1, Pg. 3. The

item numbers (Item) specified in the text refer

to this illustration.

9.1 Maintenance

The system is largely maintenance-free.

The following maintenance work is necessary:

If limy water is used as the operating liquid,

the operating liquid must be softened or the

entire system and the installed unit must be

decalcified at regular intervals.

Check the hoses and hose connections for

any leaks and for firm seating!

If dirt or solid materials (e.g. dust or sand) of

lime deposits enter the system through the

operating liquid and/or the pumped

gases/vapours, it must be cleaned at regular

intervals. This will prevent impeller jamming

as well as the wear of individual system

components.

Refer to the following table:

610.44444.40.000 26 / 36 © Gardner Denver Deutschland GmbH

Page 27

Contamination/Problem Remedy

Servicing

Water consumption

increases considerably after

an extended period of

operation.

Ambient air is highly

contaminated.

Dirt particles (e.g. dust) enter

system with pumped

gases/vapours and collect in

separator.

Clean cooling fins of water cooler.

To do so, proceed as follows:

Carry out protective measures for the use of compressed air:

– wear personal protective equipment (protective gloves and safety

goggles),

– secure surrounding area.

blow compressed air through cooling fins of water cooler (Item 027).

Replace water filter (Item 095) and air filter (Item 096).

Clean cooling fins of water cooler (Item 027) regularly.

See "Water consumption increases considerably after an extended period of

operation".

Clean separator.

Clean separator (Item 001) regularly (interval is dependent on concentration

of dirt particles in pumped gases/vapours):

Shut down system.

Drain system as described in Chapter 8.1, "Draining", Pg. 23.

Purge separator with clean water.

When using cleaning agents, you must consult Service Department.

If appropriate, Replace water filter (Item 095) and air filter (Item 096).

OR

Connect inlet filter (see Chapter 5.5, "Accessories", Pg. 19) upstream on

inlet side of system.

If appropriate, Replace water filter (Item 095) and air filter (Item 096).

Fine-grain dirt (e.g. sand)

enters installed unit with

operating liquid or pumped

gases/vapours.

Clean installed unit.

Clean installed unit (Item D) at regular intervals. (Intervals are dependent on

degree of soiling, approx. 1x per year.)

To do so, proceed as follows:

Shut down system and secure against being switched on again.

Remove cover plate (Item 064) and protective grille (Item 058).

Have a catch container ready under the system.

Open drain hole G¼ (Item E) of installed unit. Then operating liquid flows

out. It is discharged downward via the opening in the bottom of the

separator.

WARNING: Danger from rotating external fan of installed unit! To ensure

safety, remount the cover plate (Item 064) and protective grille (Item 058)

on the separator!

Briefly switch on system. Dirt will be flushed out of installed unit along

with operating liquid and will be discharged downward through opening in

bottom of separator.

Shut down system again, secure and open as described above.

Close drain hole G¼ (Item E) of installed unit again.

Completely reassemble system.

© Gardner Denver Deutschland GmbH 27 / 36 610.44444.40.000

Page 28

Servicing

Contamination/Problem Remedy

Impeller of installed unit is

jammed.

Free shaft by turning.

To do so, proceed as follows:

Shut down system and secure against being switched on again.

Remove cover plate (Item 064).

Turn shaft of installed unit (Item D) by hand at fan impeller.

If shaft cannot be freed by turning, installed unit must be decalcified.

Extremely hard water used

as operating liquid

Lime content > 15°dH).

Soften operating liquid.

OR

Decalcify installed unit.

Decalcify installed unit (Item D) at regular intervals. (Intervals are depending

on calcification.)

To do so, proceed as follows:

Wear personal protective equipment (protective gloves and safety

goggles),

Shut down system and secure against being switched on again.

Drain system as described in Chapter 8.1, "Draining", Pg. 23.

Have the cover plate (Item 064) and protective grille (Item 058) removed

from the separator.

Models 2BL2 041 - 2BL2 141:

Disconnect pipe/hose from screw-in connecting sleeve (Item H) of

installed unit.

Models 2BL2 251 - 2BL2 341:

Disconnect pipe/hose from condensation cooler (Item 031).

To remove the pipe/hose, open the clip with special pliers or a

screwdriver.

Use 10 % ethanoic acid as antiliming liquid.

WARNING: Danger from ethanoic acid! Ethanoic acid can cause heavy

acid burns! Observe applicable laws and regulations as well as accident

prevention regulations concerning hazardous substances and

manufacturer's safety data sheet!

Fill interior of installed unit with antiliming liquid.

To do so, proceed as follows:

Pour antiliming liquid into the open screw-in connecting sleeve (Item H)

using a funnel or hose. (See Fig. 13, Pg. 24.)

Filling amount: see Chapter 3.1, "Mechanical data", Section "Filling

quantity for antiliming liquid", Pg. 8. The entire interior of the installed unit

must be filled with antiliming liquid.

CAUTION: Various system seals can be damaged by prolonged contact

to ethanoic acid. The ethanoic acid may only enter the interior of the

installed unit.

610.44444.40.000 28 / 36 © Gardner Denver Deutschland GmbH

Page 29

Contamination/Problem Remedy

Servicing

Allow decalcifying liquid to soak for at least 30 minutes.

During this time occasionally turn shaft by hand at fan impeller.

Have a catch container ready under the system.

Drain installed unit:

Open drain hole G¼ (Item E) of installed unit. The antiliming liquid will be

discharged downward via the opening in the bottom of the separator. This

will not cause chemical corrosion of the separator. Close the drain hole

again.

Reconnect pipe/hose to screw-in connecting sleeve (Item H) or to

condensation cooler (Item 031).

Remount cover plate (Item 064) and protective grille (Item 058) on

separator.

Completely reassemble system.

Antiliming liquid can be disposed of in sewerage system.

OR

Decalcify the entire system.

Depending on the operating conditions and the lime content of the operating

liquid, it may be necessary to decalcify the entire system. To do so, proceed

as follows:

Use citric acid as antiliming liquid.

Pour citric acid into system via filling opening (Item 007). Filling quantity

of pure citric acid (in the form of granules), the system being at a medium

operating-liquid level: See Chapter 3.1, "Mechanical data",

Section "Filling capacity for antiliming agent", Pg. 8.

Operate system approx. 10 h with operating liquid with citric acid added.

Citric acid will dissolve lime in the process.

Then drain system as described in Chapter 8.1, "Draining", Pg. 23.

Flush system several times with clean water.

9.2 Repairs/troubleshooting

NOTICE

NOTE

If the fault cannot be eliminated using the fault

table etc., it is necessary to consult the Service

Department.

During assembly, the tightening torques of the

screws/bolts according to Chapter 3.1,

"Mechanical data", Section "Tightening

torques" Pg. 8, must be observed.

NOTICE

Have spare parts installed exclusively by the

Service Department!

© Gardner Denver Deutschland GmbH 29 / 36 610.44444.40.000

Page 30

Servicing

Fault Cause Remedy Carried out by

Motor does

not start, no

running

noise.

Motor does

not start,

humming

noises.

Protective

motor switch

trips when

motor is

switched on.

At least two

power supply

leads interrupted.

One power

supply lead

interrupted.

Impeller of

installed unit is

jammed.

Protective motor

switch setting too

low.

Winding shortcircuit.

Counter pressure

at discharge

connection too

high.

Eliminate interruption by fuses, terminals or

Electrician

supply cables.

Eliminate interruption by fuses, terminals or

Electrician

supply cables.

Free shaft by turning.

Operator/Service

See Chapter 9.1, "Maintenance", Section "Free

shaft by turning", Pg. 28.

Decalcify installed unit.

Operator

See Chapter 9.1, "Maintenance",

Section "Decalcify installed unit", Pg. 28.

Set the protective motor switch to the rated

Electrician

current indicated on the rating plate.

Have winding checked. Electrician/Servic

e Dept.