Page 1

Edition: 12.2009 · 610.44520.40.000 Original operating instructions · English

Operating Instructions G-BH7e

2BH72..-..N

2BH73..-..N

2BH74..-..N

2BH75..-..N

2BH76..-..N

G-Serie

G-Series

Seitenkanal

Side Channel

Page 2

Contents

Contents

Design of side channel blowers in conjunction with frequency inverters ........................................... 3

Quick start guide ................................................................................................................................ 4

1 Safety instructions ...............................................................................................................................5

1.1 Definitions .................................................................................................................................5

1.1.1 Safety alert symbols and signal words.........................................................................5

1.1.2 Signal words.................................................................................................................5

1.1.3 Abbreviations used.......................................................................................................5

1.2 General safety and application notes........................................................................................5

1.3 Residual risks............................................................................................................................7

1.4 Application as directed..............................................................................................................9

1.5 Foreseeable Misuse................................................................................................................10

2 Technical data ...................................................................................................................................11

2.1 Mechanical data ......................................................................................................................11

2.1.1 Weights ......................................................................................................................11

2.1.2 Noise level..................................................................................................................11

2.1.3 Temperature increase ................................................................................................12

2.2 Electrical data..........................................................................................................................12

2.3 General data/operating conditions..........................................................................................13

3 Transport and handling .....................................................................................................................14

3.1 Transport devices....................................................................................................................14

3.2 Transport types .......................................................................................................................14

4 Installation .........................................................................................................................................16

4.1 Installation ...............................................................................................................................17

4.1.1 Important notes ..........................................................................................................17

4.1.2 Free spaces................................................................................................................18

4.1.3 Mounting.....................................................................................................................19

4.1.4 Final works .................................................................................................................20

4.2 Mounting of the muffler ...........................................................................................................20

4.3 Connecting the pump-motor unit to the system ......................................................................20

4.3.1 Important notes ..........................................................................................................20

4.3.2 Connecting the inlet line.............................................................................................21

4.3.3 Connecting the pressure line .....................................................................................21

4.4 Electrical installation................................................................................................................22

4.4.1 Important notes ..........................................................................................................22

4.4.2 Preparing works .........................................................................................................23

4.4.3 Connecting frequency inverters 2FC4152-1NE00 and 2FC4222-1NE00..................23

4.4.4 Connecting frequency inverters 2FC4302-1NE00 ... 2FC4752-1NE00.....................26

4.4.5 Wiring of control connections .....................................................................................29

4.4.6 Final works .................................................................................................................32

5 Commissioning..................................................................................................................................34

5.1 Preparation..............................................................................................................................34

5.2 Parameter setting....................................................................................................................35

5.2.1 The hand-held keypad 2FX4506-0NE00....................................................................35

5.2.2 Code table ..................................................................................................................37

5.3 Start-up of the pump-motor unit ..............................................................................................39

5.4 Shut-down of the pump-motor unit..........................................................................................40

6 Operation...........................................................................................................................................41

7 Shut-down and longer standstills ......................................................................................................42

7.1 Preparation..............................................................................................................................42

7.2 Storage conditions ..................................................................................................................42

© 2009 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Germany

Transmittal, reproduction, dissemination and/or editing of this document as well as utilization of its

contents and communication thereof to others without express authorization are prohibited. Offenders

will be held liable for payment of damages. All rights created by patent grant or registration of a utility

model or design patent are reserved.

Page 3

Design of side channel blowers in conjunction with frequency inverters

Servicing............................................................................................................................................43

8

8.1 Repair/ troubleshooting...........................................................................................................43

8.1.1 Malfunctions at side channel blower ..........................................................................43

8.1.2 Frequency inverter status indications.........................................................................44

8.1.3 Fault indication at the keypad ....................................................................................45

8.1.4 Fault indication reset (TRIP-RESET) .........................................................................47

8.2 Service/ after-sales service .....................................................................................................47

8.3 Decontamination and declaration of clearance.......................................................................48

9 Disposal.............................................................................................................................................49

Declaration of conformity.................................................................................................................. 50

Form for statement on safety ........................................................................................................... 51

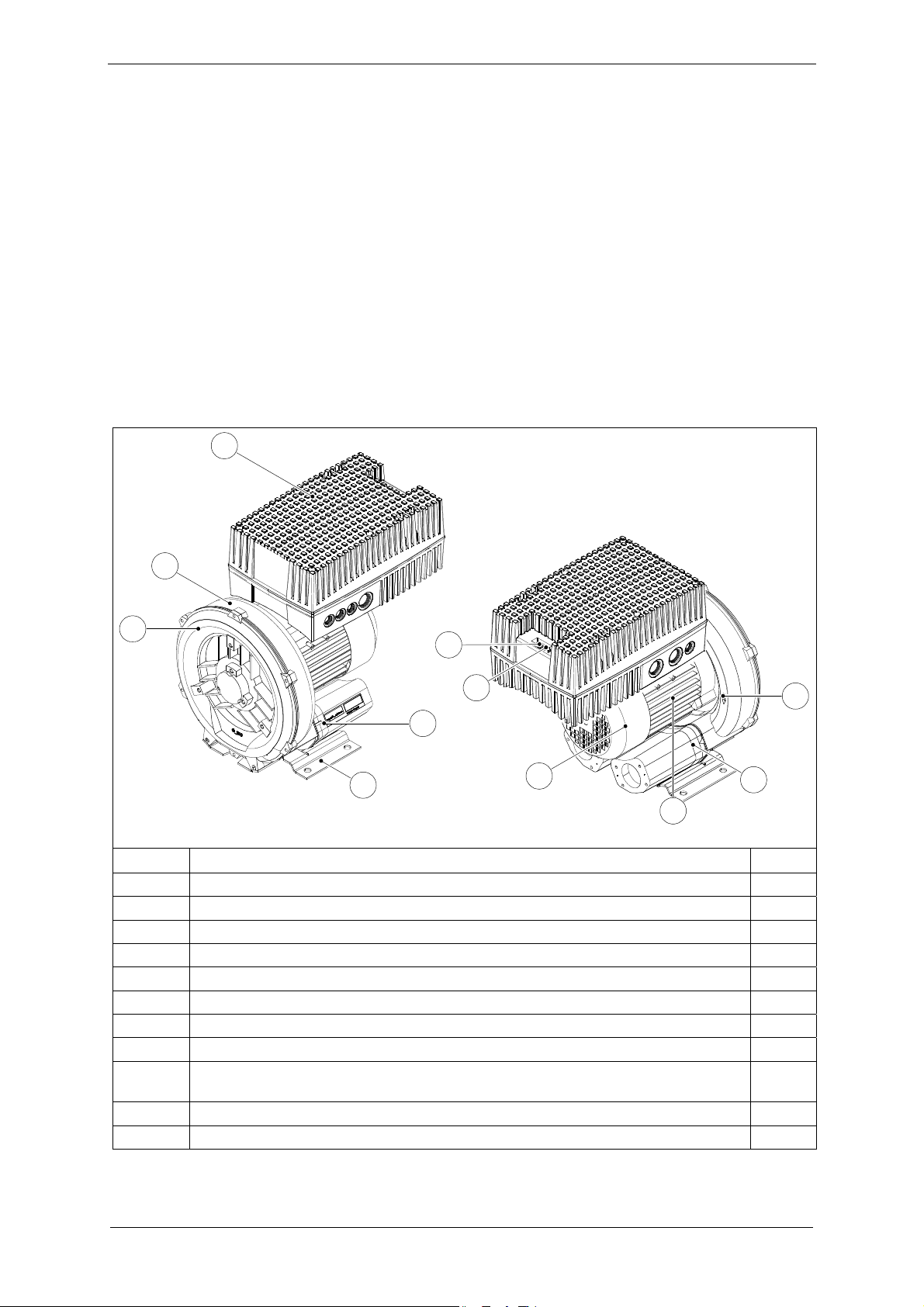

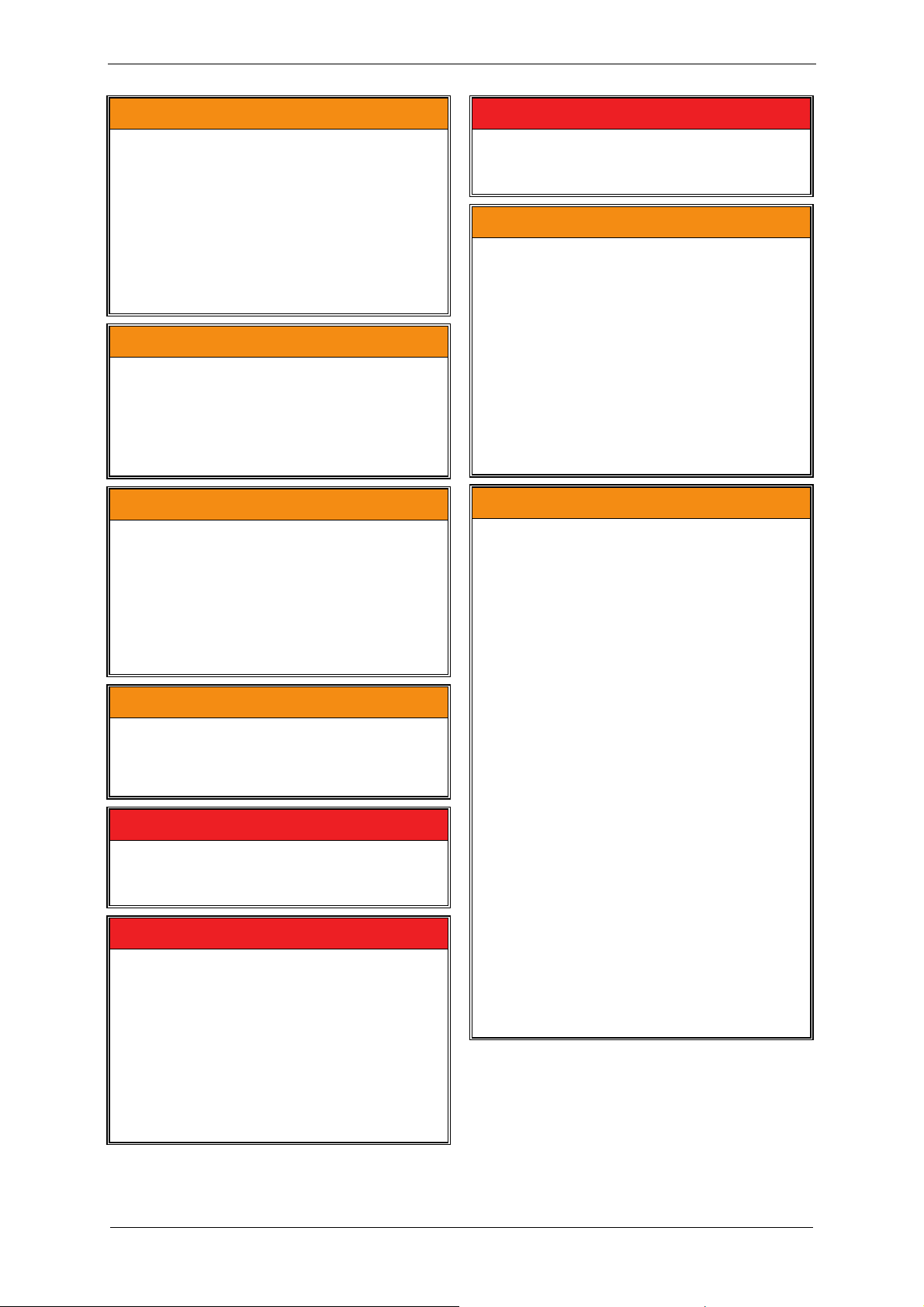

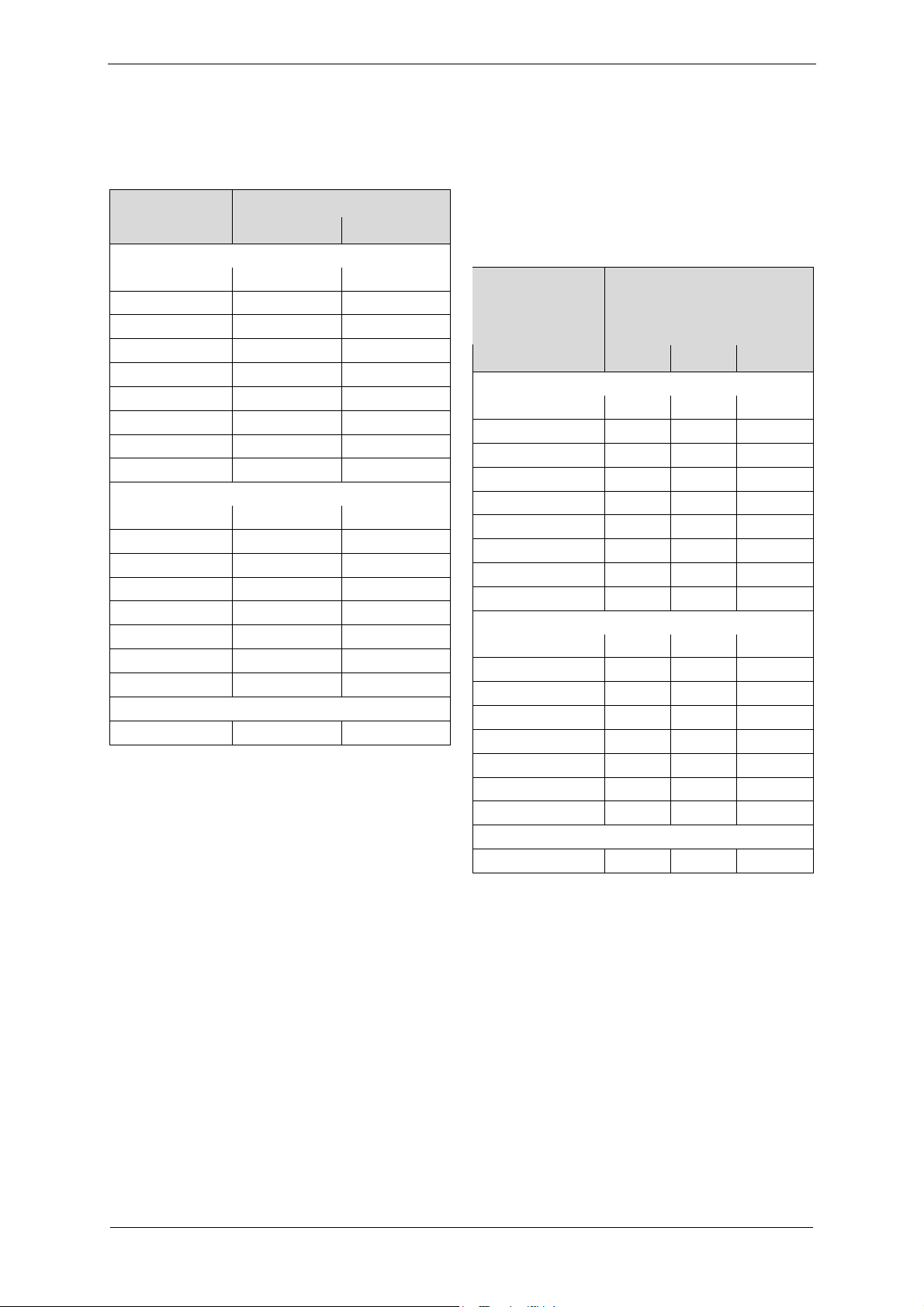

Design of side channel blowers in conjunction with frequency inverters

1

7

6

10

11

2

4

9

8

Position Description

1 Frequency inverter

2 Inlet connection with muffler and arrow indicating delivery direction

3 Discharge connection with muffler and arrow indicating delivery direction

4 Base

5 Arrow indicating direction of rotation

6 Blower cover

7 blower housing

8 Drive motor

9 Fan guard above the motor fan with rating plate, warning notices and arrow

indicating direction of rotation

10 Status display with 2 light-emitting diodes (red, green)

11 Communication interface for connecting the hand-held keypad

Fig. 1: Design of side channel blowers in conjunction with frequency inverters

5

3

2bhxn402

44

35

© Gardner Denver Deutschland GmbH 3 / 52 610.44520.40.000

Page 4

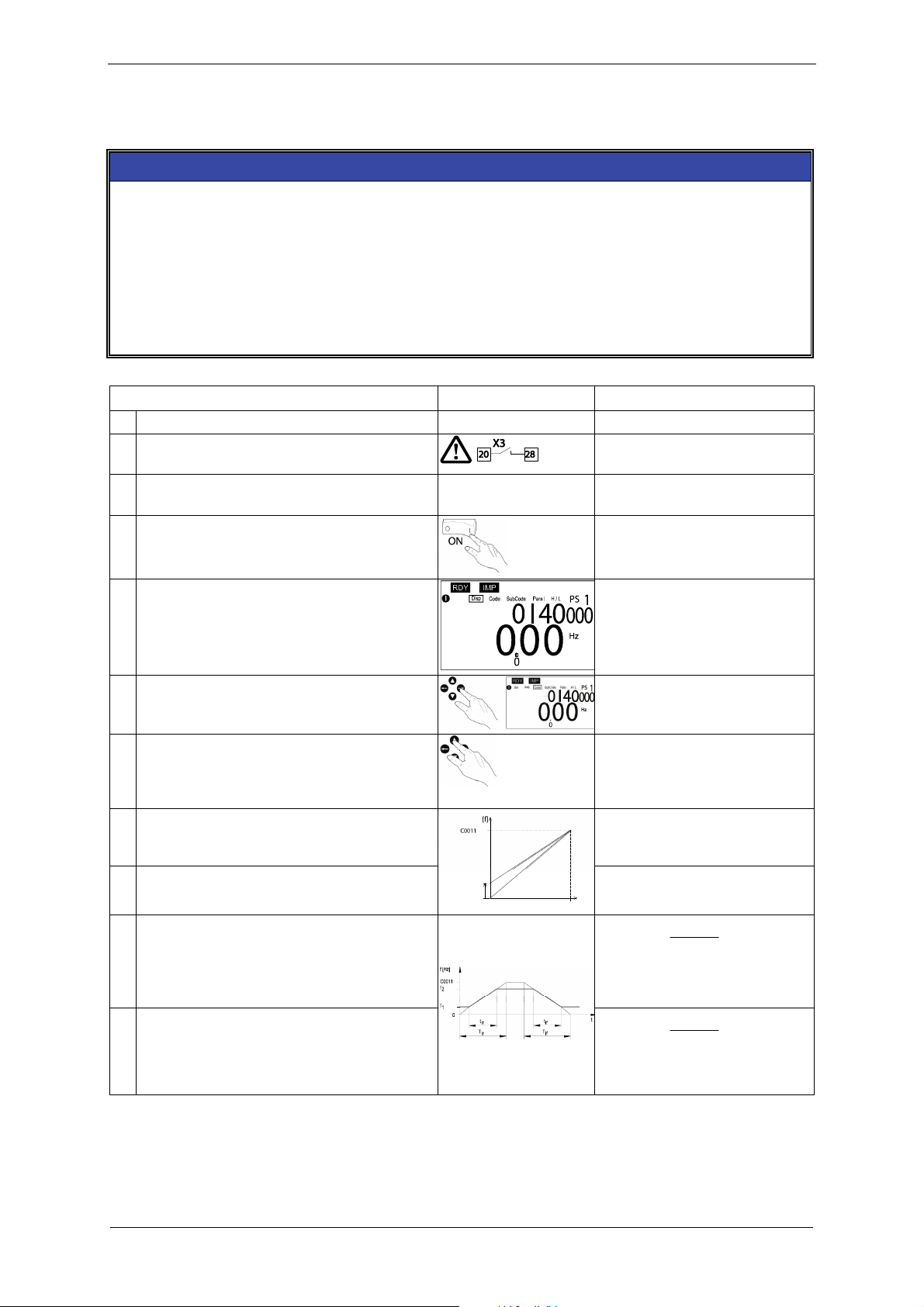

Quick start guide

Quick start guide

Side channel blowers are pre-configured for four

operating modes. It only takes a few steps and

they are ready for operation:

ACHTUNG

The drive motor is protected against

overheating by a thermal detector.

– If the drive motor gets too hot, the

frequency inverter will switch off the

pump-motor unit.

– Please contact the manufacturer if the

hydraulic process does not allow

immediate switch-off.

A minimum wiring is required for

commissioning! ( 22)

1 Read the safety instructions.

The safety instructions start on page 5.

2 Install the pump-motor unit and attach it.

Listing of the mounting steps starts on

3 Wire the pump-motor unit.

4 Put the pump-motor unit into operation.

5 Adapt important process parameters.

page 16.

Please observe that a minimum wiring is

required!

Otherwise commissioning of the pump-

motor unit is not possible.

Important notes concerning the wiring

start on page 22.

Description of the commissioning steps

starts on page 34.

Adapt acceleration and deceleration time to

the hydraulic process via C0012 and

C0013.

Description of parameter changing

starts on page 35.

6 Adjust the speed.

A) Speed adjustment using a potentiometer

The speed is adjusted via the analog input.

The speed can be adjusted between

aminimum and a maximum

value.Description of potentiometer wiring

starts on page 30.

B) Operation with several adjustable fixed

speeds

The speed of the pump−motor unit can be

adjusted in steps of 1000/min via the digital

inputs E3 and E4.

Description of the wiring of E3 and E4

starts on page30.

C) Operation with one fixed speed

Connect hand−held keypad.

Set required fixed speed under C0140.

Disconnect hand−held keypad.

The pump−motor unit will be operated with

this speed when switched on.

Description of hand−held keypad

connection and parameter changing

starts on page35.

D) Speed adjustment using the keypad

Connect hand−held keypad.

Select C0140.

Set the required speed during the

process using the keys _..

The pump−motor unit will be operated with

the last set speed when switched on.

Description of hand−held keypad

connection and parameter changing

starts on page35.

610.44520.40.000 4 / 52 © Gardner Denver Deutschland GmbH

Page 5

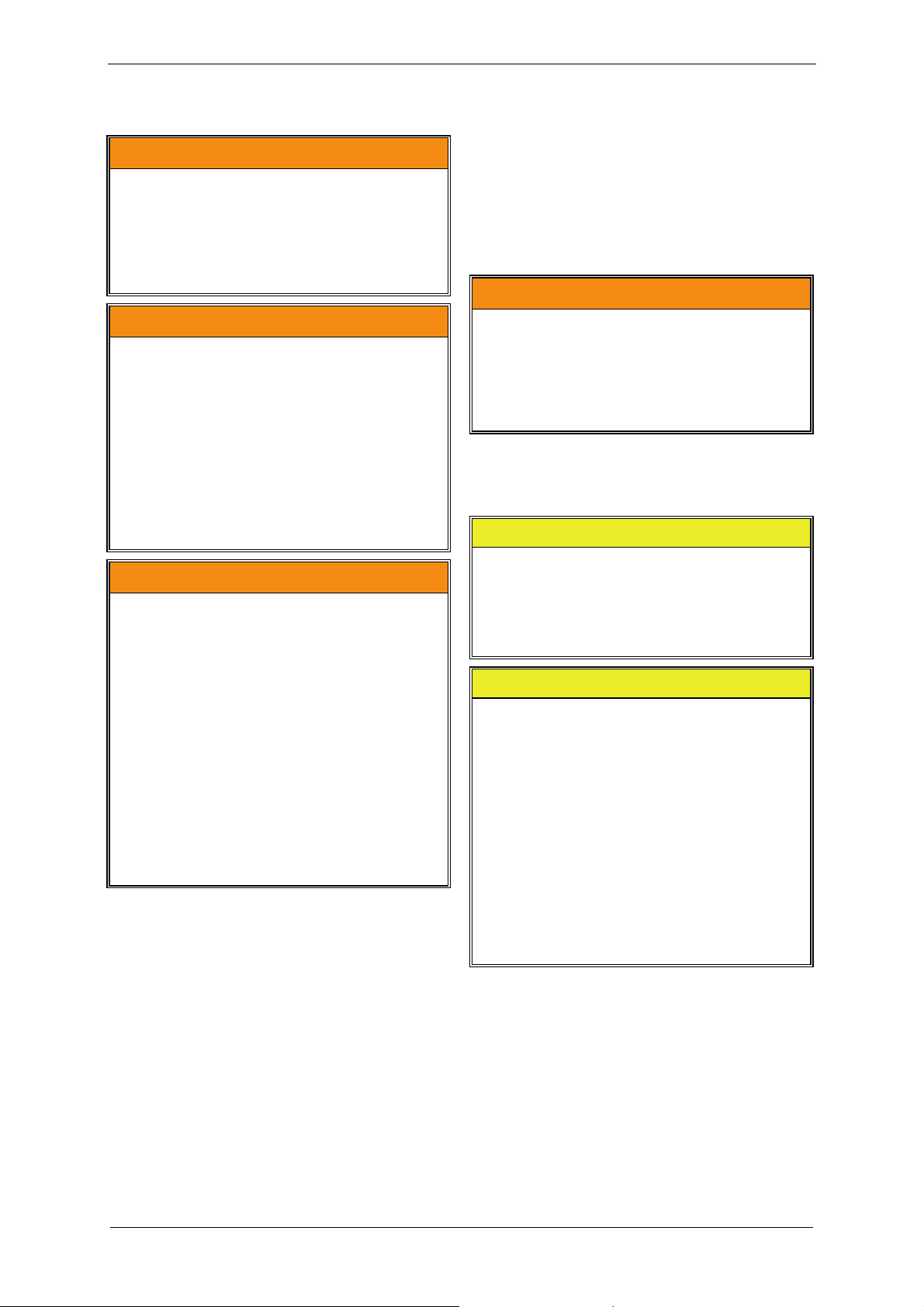

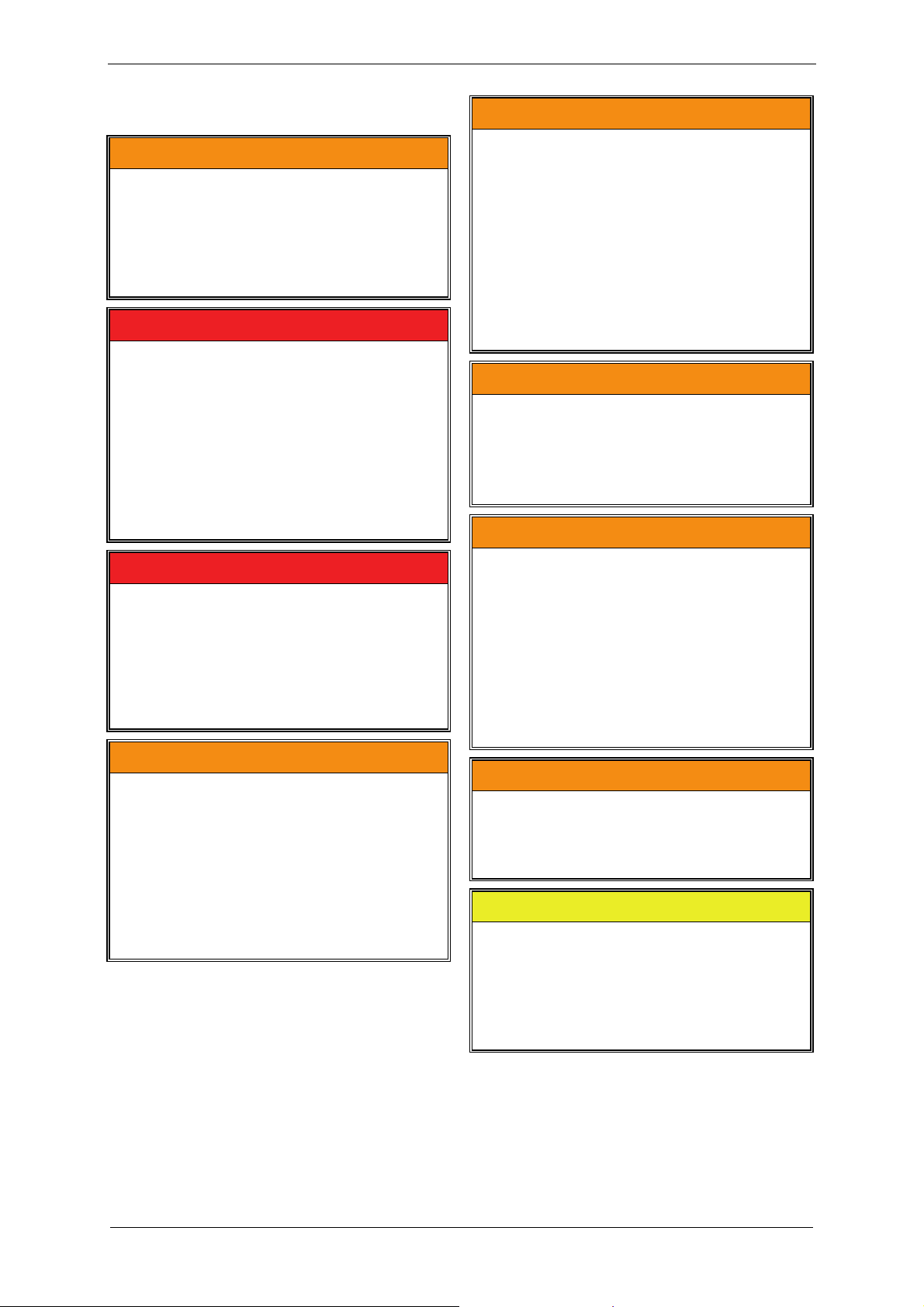

Safety instructions

1 Safety instructions

1.1 Definitions

To point out dangers and important information,

the following signal words and symbols are used

in these Operating Instructions:

1.1.1 Safety alert symbols and signal words

The safety alert symbol is located in the safety

instructions in the highlighted heading field on the

left next to the signal word (DANGER,

WARNING, CAUTION).

Safety instructions with a safety alert symbol

indicate a danger of injuries.

Be sure to follow these safety instructions to

protect against injuries or death!

Safety instructions without a safety alert symbol

indicate a danger of damage. – Be sure to follow

these safety instructions to avoid material

damage!

1.1.2 Signal words

DANGER

WARNING

CAUTION

NOTICE

NOTE

Danger of injuries.

Indicates an imminently hazardous situation,

that will result in death or serious injury if the

corresponding measures are not taken.

Danger of injuries.

Indicates a potentially hazardous situation, that

could result in death or serious injury if the

corresponding measures are not taken.

The signal words are located in

the safety precautions in the

highlighted heading field.

They follow a certain hierarchy

and indicate (in conjunction with

the safety alert symbol, see

Chapter 1) the seriousness of

the danger and the type of

warning.

See the following explanations:

DANGER

WARNING

CAUTION

Danger of injuries.

Indicates a potentially hazardous situation, that

may result in minor or moderate injury if the

corresponding measures are not taken.

CAUTION

Danger of damage.

Indicates a potentially hazardous situation that

may result in property damage if the

corresponding measures are not taken.

NOTICE

Indicates a possible disadvantage, i.e.

undesirable conditions or consequences can

occur if the corresponding measures are not

taken.

NOTE

Indicates a possible advantage if the

corresponding measures are taken; tip.

1.1.3 Abbreviations used

Product designation

For side channel blower in conjunction with

frequency inverters the term pump−motor unit is

used in these Instructions.

Cross−reference

Cross−references to other parts of these

Instructions are marked with a book symbol:

( 9)

1.2 General safety and application notes

WARNING

Improper use of the pump−motor unit can

result in serious or even fatal injuries!

These Operating Instructions

must have been read completely and

understood before beginning any work with

or at the pump−motor unit,

must be strictly observed,

must be available at the operating location of

the pump−motor unit.

© Gardner Denver Deutschland GmbH 5 / 52 610.44520.40.000

Page 6

Safety instructions

WARNING

Improper use of the pump−motor unit can

result in serious or even fatal injuries!

Only operate the pump−motor unit

for the purposes indicated under "Application

as directed"!

with the media indicated under "Application

as directed"!

with the values indicated under "Technical

data"!

WARNING

Improper use of the pump−motor unit can

result in serious or even fatal injuries!

All work on and with the pump−motor unit

(transport, installation, operation, shut−down,

maintenance, disposal) may only be carried out

by trained, reliable expert personnel!

WARNING

When working on the pump−motor unit,

there is a danger of injury, e.g. in the form

of cuts/cutting off, crushing and burns!

During all work on and with the pump−motor

unit (transport, installation, operation,

shut−down, maintenance, disposal) wear

personal safety equipment (safety helmet,

safety gloves, safety shoes)!

WARNING

Hair and clothing can be pulled into the

pump−motor unit or caught and wound up

by moving parts! Do not wear long, loose

hair or wide, loose clothing! Use a hairnet!

DANGER!

Electrical danger!

Work on electrical installations may be carried

out by trained and authorized electricians only!

DANGER!

Electrical danger!

Before beginning work on the pump−motor unit

or system, the following measures must be

carried out :

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short−circuit.

Cover or block off adjacent energized parts.

DANGER!

Electrical danger!

Do not open the frequency inverter until

absence of electricity has been ensured!

WARNING

Danger due to vacuum and gauge pressure:

sudden escape of media (skin and eye

injuries), sudden drawing−in of hair and

clothing!

Danger due to escaping media: burns!

Use mounting elements, connections, lines,

fittings and containers with sufficient freedom

from leaks and strength for the pressures which

occur.

Check the mounting elements, connections,

lines, fittings and containers for strength, leaks

and firm seating at regular intervals!

WARNING

Danger from rotating parts (motor fan,

impeller, shaft): cutting/cutting off of

extremities, grasping/winding up of hair and

clothing!

Danger due to vacuum and gauge pressure:

sudden escape of media (skin and eye

injuries), sudden drawing−in of hair and

clothing!

Danger due to escaping media: burns!

Commissioning and operation only under the

following conditions:

The pump−motor unit must be completely

assembled. When doing so, pay particular

attention to the following components:

– the blower cover,

– the mufflers on inlet and discharge

connections,

– the fan guard.

The pipes and hoses must be connected to

inlet and discharge connections.

Inlet and discharge connections and the

connected pipes/hoses may not be closed,

clogged or soiled.

Check the mounting elements, connections

of the pipe/hose connections, lines, fittings

and containers for strength, leaks and firm

seating at regular intervals.

610.44520.40.000 6 / 52 © Gardner Denver Deutschland GmbH

Page 7

Safety instructions

WARNING

Danger from rotating parts (motor fan,

impeller, shaft): cutting/cutting off of

extremities, grasping/winding up of hair and

clothing!

Danger due to vacuum and gauge pressure:

sudden escape of media (skin and eye

injuries), sudden drawing−in of hair and

clothing!

Danger due to escaping media: burns!

Before beginning work on the pump−motor unit,

take the following measures :

Shut down pump−motor unit and secure

against being switched on again.

Attach a sign on the system controller and

on the control elements for the pump−motor

unit: "DANGER! Maintenance work on the

vacuum pump/compressor! Do not switch

on!"

Wait for pump−motor unit to come to a

complete stop.

– Observe run−on time!

Allow pump−motor unit to cool!

Shut−off lines.

– Release pressure.

Make sure that no vacuum or gauge

pressure is present in the lines/tanks to be

opened.

Make sure that no media can escape.

WARNING

Danger from rotating impeller:

cutting/cutting off of extremities!

The rotating impeller is accessible with the inlet

and discharge connections open!

Do not reach into the pump−motor unit through

open connections!

Do not insert objects into the pump−motor unit

through the openings!

WARNING

Danger of burns from hot surface of the

pump−motor unit and from hot media!

High temperatures of up to approx. 160 °C

[320 °F] can occur on the surface of the

pump−motor unit:

Cover the pump−motor unit with a suitable

touch protection (e.g. perforated plate cover

or wire cover).

Do not touch during operation!

Allow to cool after shut−down!

1.3 Residual risks

WARNING

Danger zone:

Hot surface of up to approx.160 °C [320 °F].

Hazard:

Possible burns.

Protective measures:

Cover the pump−motor unit with a suitable

touch protection (e.g. perforated plate cover or

wire cover).

WARNING

Danger zone:

Fan guard

Hazard:

Long, loose hair can be drawn into motor fan

through the fan guard grate, even with

fan guard mounted!

Protective measures:

Wear hair net!

WARNING

Danger from rotating impeller:

cutting/cutting off of extremities!

The rotating impeller is accessible with the inlet

and discharge connections open!

With free entry and exit of gases, i.e. with direct

intake out of or direct feeding into the

atmosphere without piping, the following

therefore applies:

Provide the inlet and discharge connections

of the pump−motor unit either with additional

mufflers or with additional piping of a

sufficient length to prevent access to the

impeller!

© Gardner Denver Deutschland GmbH 7 / 52 610.44520.40.000

Page 8

Safety instructions

WARNING

Danger zone:

Missing or defective muffler on inlet or

discharge connection.

Hazard:

Possible serious hearing damage due to

emitted noise.

Protective measures:

Have missing or defective mufflers replaced.

Conduct a noise measurement in the system

after installing the pump−motor unit.

The following measures must be taken by the

operator:

from 85 dB(A):

– Hearing protection must be available.

from 90 dB(A):

– Mark noise area with a warning sign.

– Wear hearing protection.

WARNING

Danger zone:

Environment of pump−motor unit.

Hazard:

Possible serious hearing damage due to

emitted noise.

Protective measures:

Conduct a noise measurement in the system

during operation after installing the

pump−motor unit.

The following measures must be taken by the

operator:

from 85 dB(A):

– Hearing protection must be available.

from 90 dB(A):

– Mark noise area with a warning sign.

– Wear hearing protection.

– With free entry and exit of gases, i.e. with

direct intake out of or direct feeding into

the atmosphere without piping, attach an

additional muffler.

CAUTION

Danger zone:

Frequency inverter

Hazard:

Material damage at the frequency inverter

caused by switching on the device too

frequently with too short intervals.

Protective measures:

In the case of cyclic mains switching for a

longer time period, allow at least 3 minutes

between two switch−on actions.

CAUTION

Danger zone:

Side channel blower

Hazard:

Material damage at the side channel blower

caused by too high speeds.

Protective measures:

Do not set the output frequency at the

frequency inverter higher than the maximum

frequency specified in the documentation.

Use special overspeed monitors if

necessary.

610.44520.40.000 8 / 52 © Gardner Denver Deutschland GmbH

Page 9

Safety instructions

1.4 Application as directed

Validity of the Operating Instructions

These Operating Instructions are valid for G-BH7e series side channel blower in conjunction with

frequency inverters equipped with the following frequency inverters:

Type

Supply voltage

2FC 4 xxx - 1NE00 1x 35

4 = 400 V/500 V

Power

(e.g.152 = 15 ´ 10

(e.g.. 752 = 75 ´ 10

2

W = 1,5 kW)

2

W = 7,5 kW)

1NE00 = integrated inverter

Hardware version

Software version

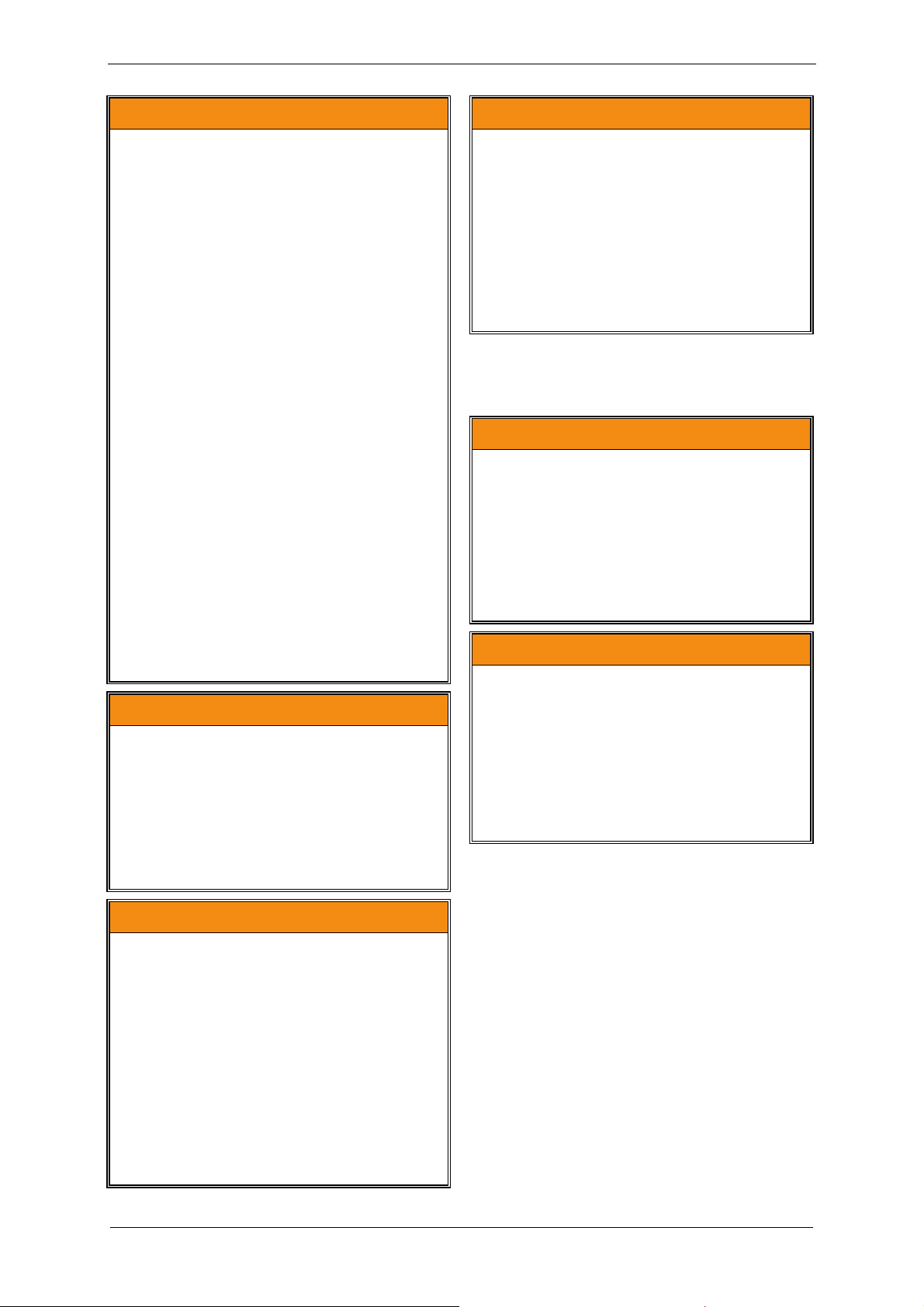

Fig. 2: Typschild

These Operating Instructions

contain instructions bearing on transport and

handling, installation, commissioning,

operation, shut−down, storage, servicing and

disposal,

must be completely read and understood by

all operating and servicing personnel before

beginning to work,

must be strictly observed,

must be available at the site of operation in a

complete and perfectly legible condition.

– With differing gases/gas−air mixtures,

inquire with the manufacturer.

are intended for industrial applications.

are designed for continuous operation:

– With increased switch−on frequency (at

equal intervals of approx. 5 times per hour)

or increased gas entry temperature and

ambient temperature, the limit

overtemperature of the winding and the

bearings can be exceeded.

– Consultation with the manufacturer is

required for operating conditions of this

kind.

Operating and servicing personnel

are equipped with a three−phase drive motor

These persons must be trained and

authorized for the work to be carried out.

Work on electrical installations may be carried

out by trained and authorized electricians

only.

G-BH1e series side channel blower in

conjunction with frequency inverters

with mounted frequency inverter.

are available in the following models:

– single−impeller (single−stage)

– two−impeller (two−stage)

– three−impeller (three−stage)

Higher pressure differences can be achieved with

the two−impeller and three−impeller pump−motor

units.

nash_elm o Industries Gmb H

Indust riestras se 26

D-97616 Ba d Neustadt

Prod.-ID

Prod.-No. Ser.-No.

Input

Output

Type

Version

2

3

1

ne2bhxn014

are pump−motor units for generating vacuum

or gauge pressure.

are used to extract, pump and compress the

following gases:

– Air,

– Non−flammable, non−aggressive,

non−toxic and non−explosive gases or

gas−air mixtures.

are primarily intended for higher pressure

conditions;

During operation the limit values listed under

"Technical data" must always be complied with.

( 11)

© Gardner Denver Deutschland GmbH 9 / 52 610.44520.40.000

Page 10

Safety instructions

1.5 Foreseeable Misuse

It is prohibited

to use the pump−motor units in applications

other than industrial applications unless the

necessary protection is provided on the

system, e.g. touch guards suitable for

children’s fingers,

to use the pump−motor units in rooms in

which explosive gases can occur,

to extract, deliver and compress explosive,

flammable, corrosive or toxic media,

to operate the pump−motor units with values

other than those specified in the chapter

"Technical data".

Any unauthorized modifications of the

pump−motor units are prohibited for safety

reasons.

The operator is only permitted to perform the

maintenance and service work described in these

Operating Instructions.

Any maintenance and service work which goes

beyond this many only be performed by

companies authorized by the manufacturer

(inquire with the manufacturer).

610.44520.40.000 10 / 52 © Gardner Denver Deutschland GmbH

Page 11

Technical data

2 Technical data

2.1 Mechanical data

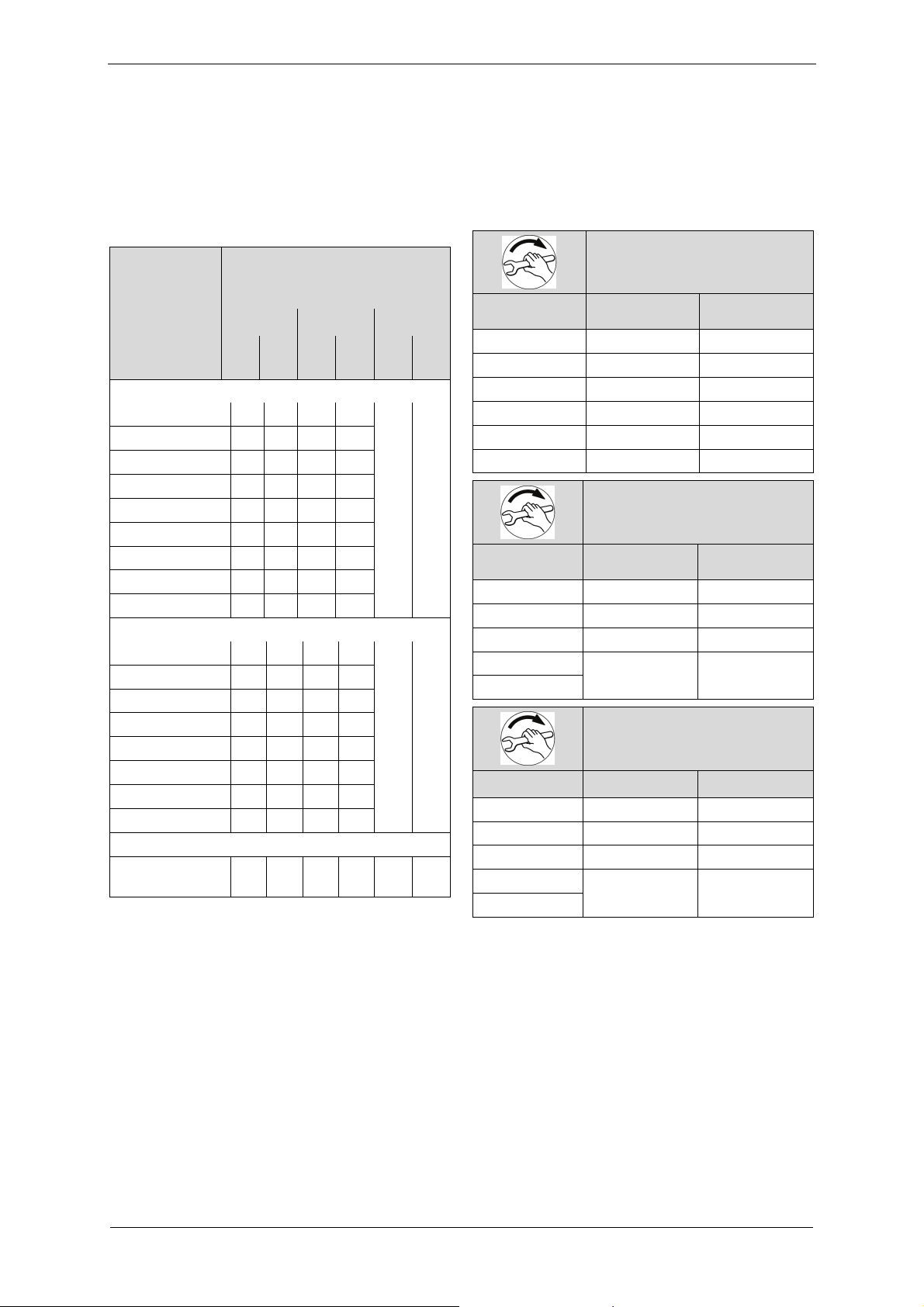

2.1.1 Weights

Weight Type

approx. [kg] approx. [lbs]

Single−impeller design

2BH7210−0.N1 20 44

2BH7210−0.N5 32 71

2BH7310−0.N2 20 44

2BH7310−0.N6 35 77

2BH7410−0.N1 27 60

2BH7410−0.N5 42 93

2BH7510−0.N2 39 86

2BH7510−0.N6 48 106

2BH7610−0.N3 45 99

Two−impeller design

2BH7220−0.N5 38 84

2BH7320−0.N5 40 88

2BH7320−0.N8 46 101

2BH7420−0.N2 43 95

2BH7420−0.N5 49 108

2BH7520−0.N7 61 134

2BH7620−0.N3 58 128

2BH7620−0.N4 68 150

Three-impeller design

2BH7630−0.N6 96 212

2.1.2 Noise level

Measurement conditions

Measuring-surface sound-pressure level as per

EN ISO 3744, measured at a distance of 1 m

[3.28 ft] at an operating point of approximately

2/3 of the permissible total pressure difference

with the lines connected without a vacuum or

pressure relief valve, tolerance 3 dB (A).

Type

Single−impeller design

2BH7210−0.N1 70 70 74

2BH7210−0.N5 70 70 74

2BH7310−0.N2 70 70 76

2BH7310−0.N6 70 70 76

2BH7410−0.N1 70 70 76

2BH7410−0.N5 70 70 76

2BH7510−0.N2 70 70 78

2BH7510−0.N6 70 70 78

2BH7610−0.N3 70 71 77

Two−impeller design

2BH7220−0.N5 70 70 74

2BH7320−0.N5 70 70 76

2BH7320−0.N8 70 70 76

2BH7420−0.N2 70 70 76

2BH7420−0.N5 70 70 76

2BH7520−0.N7 70 70 78

2BH7620−0.N3 70 71 80

2BH7620−0.N4 70 71 80

Three-impeller design

2BH7630−0.N6 77 80 80

1−m measuring−surface

sound−pressure level L for

operation with output

frequency [dB(A)]

50 Hz 60 Hz 86 Hz

© Gardner Denver Deutschland GmbH 11 / 52 610.44520.40.000

Page 12

Technical data

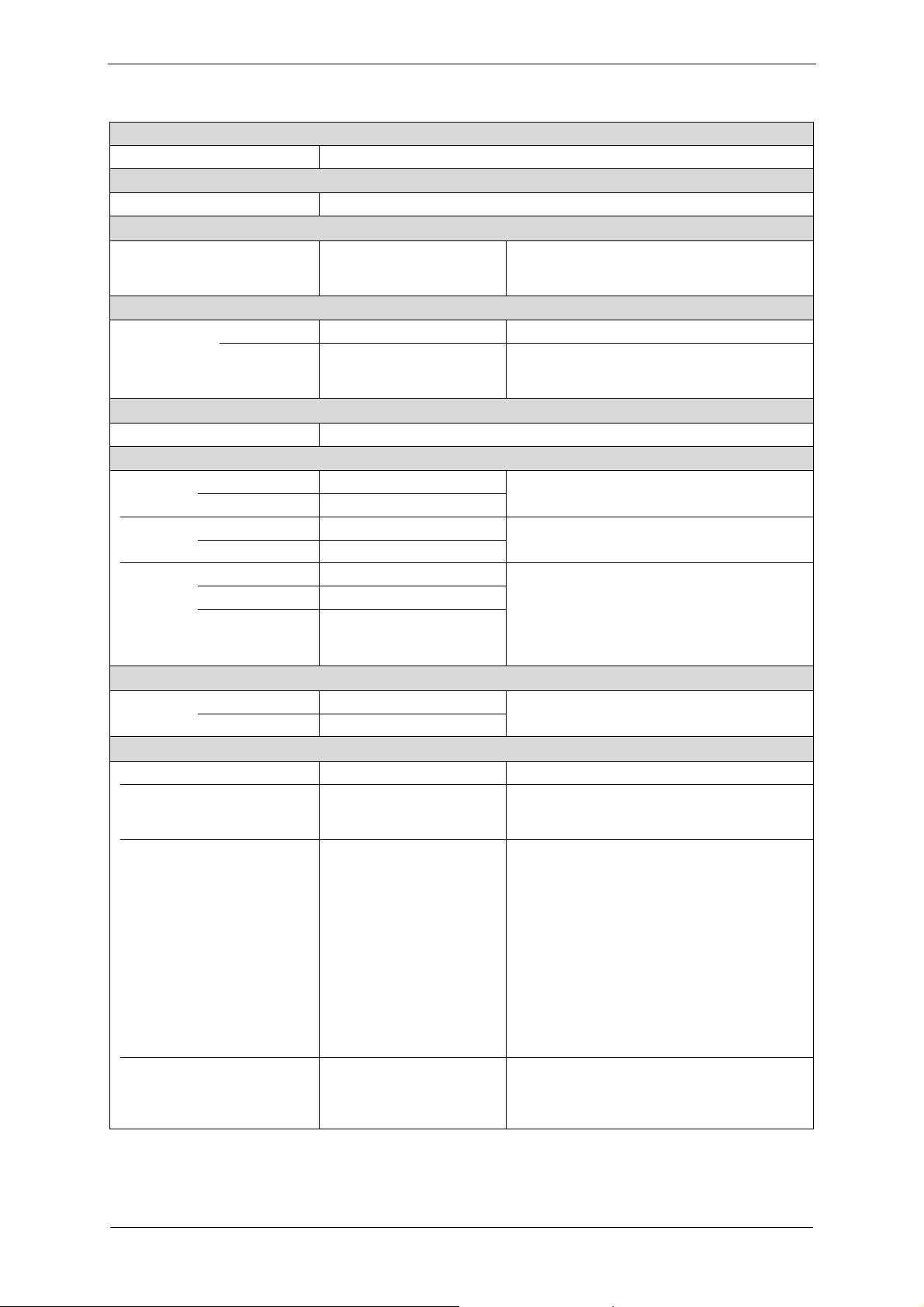

2.1.3 Temperature increase

The information listed in the following tables

corresponds to the heating of the side channel

housing and the air exiting compared to the

ambient temperature during operation with a

permissible total pressure difference and an air

pressure of 1013 mbar [14.7 psi]. At lower air

pressures these values increase.

Type

Temperature increase for

operation with output

frequency (approx.)

50 Hz 60 Hz 86 Hz

∆T

[K]

∆υ

[F]

∆T

[K]

∆υ

[F]

∆T

[K]

∆υ

[F]

Single−impeller design

2BH7210−0.N1 52 126 61 142

2BH7210−0.N5 52 126 77 171

2BH7310−0.N2 81 178 86 187

2BH7310−0.N6 88 190 112 234

2BH7410−0.N1 90 194 101 214

≤

120≤ 248

2BH7410−0.N5 114 237 120 248

2BH7510−0.N2 120 248 112 243

2BH7510−0.N6 120 248 120 248

2BH7610−0.N3 118 244 124 255

Two−impeller design

2BH7220−0.N5 55 131 86 186

2BH7320−0.N5 81 178 124 255

2BH7320−0.N8 120 248 120 248

2BH7420−0.N2 89 192 80 176

2BH7420−0.N5 121 250 117 243

≤

120≤ 248

2BH7520−0.N7 125 257 110 230

2BH7620−0.N3 124 255 126 259

2BH7620−0.N4 124 255 126 259

Three-impeller design

2BH7630−0.N6 120 248 120 248

≤

120≤ 248

Tightening torques for screw connections

The following values apply if no other data are

given.

With non−electrical connections, property classes

of 8.8 and 8 or higher as per DIN ISO 898 (DIN

EN 20898 / DIN ISO 898) are assumed.

Tightening torques for

non−electrical connections

Thread [Nm] [lb-in]

M4 2,7 … 3,3 23,9 … 29,2

M5 3,6 … 4,4 31,9 … 38,9

M6 7,2 … 8,8 63,7 … 77,9

M8 21,6 … 26,4 191 … 234

M10 37,8 … 46,2 335 … 409

M12 63,0 … 77,0 558 … 681

Tightening torques for cable

and conduit glands Metal

Thread [Nm] [lb-in]

M12x1,5 4,0 … 6,0 35,4 … 53,1

M16x1,5 5,0 … 7,5 44,3 … 66,4

M20x1,5 6,0 … 9,0 53,1 … 79,7

M32x1,5

M40x1,5

8,0 … 12,0 70,8 … 106

Tightening torques for cable

and conduit glands Plastic

Thread [Nm] [lb-in]

M12x1,5 2,0 … 3,5 17,7 … 31,0

M16x1,5 3,0 … 4,0 26,6 … 35,4

M20x1,5 4,0 … 5,0 35,4 … 44,3

M32x1,5

M40x1,5

5,0 … 7,0 44,3 … 62,0

2.2 Electrical data

See rating plate.

610.44520.40.000 12 / 52 © Gardner Denver Deutschland GmbH

Page 13

Technical data

2.3 General data/operating conditions

Conformity

CE Low−Voltage Directive

Vibration resistance

Acceleration resistant up to 2g (Germanischer Lloyd, general conditions)

Vibration velocity

max. v

4 mm/s [0,013 ft/s] Depending on the application case and the

eff

system type it may be necessary to use vibration

dampers.

Site altitude

min. 0 m üNN [0 ft amsl]

max. 1000 m üNN [3280 ft amsl] For installations above 1000 m amslA [3280 ft

amsl] consultation of the manufacturer is

required.

Climatic conditions

Class 3K3 to EN 50178 (without condensation, relative humidity 30 ... 95 %)

Ambient temperatures

Transport min. -25°C [-13°F]

max. +70°C [+158°F]

Storage min. -25°C [-13°F]

max. +60°C [+140°F]

Operation min. -20°C [-4°F]

max. +40°C [+104°F]

rated value +25°C [+77°F]

Between +25 °C [+77 °F] and +40 °C [+104 °F]

reduce the total pressure difference indicated on

the rating plate by 0.7 %/°C [0.4 %/°F].

Operation at higher temperatures may damage

the winding and shorten the grease change

interval.

Temperature of pumped gases

max. +40°C [+104°F]

rated value +15°C [+59°F]

Pump−motor units for higher media

temperatures Pump on request.

Pressures

Inlet pressure min. See rating plate

Discharge pressure

max. See rating plate

during compressor

operation

Permissible total

pressure difference

max. See rating plate The total pressure difference specified on the

rating plate only applies under the following

conditions:

Ambient temperature: 25 °C [77 °F]

Temperature of the pumped gas at the inlet

connection: 15 °C [59 °F]

Pressure:

– for vacuum−pump operation: 1013 mbar

[14.7 psia] at the discharge connection

– for compressor operation:

1013 mbar [14.7 psia] at the inlet

connection

zulässiger Druck im

Aggregat

max. 2 bar abs. [29 psia] At this pressure the operation of the

pump−motor unit may be considerably impaired.

Provide a corresponding protective device (e.g.

pressure relief valve) if necessary.

© Gardner Denver Deutschland GmbH 13 / 52 610.44520.40.000

Page 14

Transport and handling

3 Transport and handling

WARNING

Tipping or falling can lead to crushing,

broken bones etc.!

Sharp edges can cause cuts!

Wear personal safety equipment (safety

gloves, safety shoes and safety helmet)

during transport!

WARNING

Danger from lifting heavy loads!

Manual handling of the pump−motor unit is only

permitted within the following limits:

max. 30 kg [max. 66 lbs] for men

max. 10 kg [max. 22 lbs] for women

max. 5 kg [max. 11 lbs] for pregnant women

For weights above the given values use

suitable lifting appliances and handling

equipment!

Weight of the pump−motor units: ( 11)

WARNING

Danger from tipping or falling loads!

Prior to transport and handling make sure

that all components are securely assembled

and secure or remove all components the

fasteners of which have been loosened!

When transporting with lifting equipment,

observe the following basic rules:

– The lifting capacity of lifting equipment

and lifting gear must be at least equal to

the unit’s weight. For the weight of the

pump−motor units see:: ( 11)

– The pump−motor unit must be secured

so that it cannot tip or fall.

– Do not stand or walk under suspended

loads!

3.1 Transport devices

All pump−motor units with a weight of more than

30 kg are equipped with an eye bolt at the side

channel housing.

The crane hook can be hooked directly into the

eye bolt.

Alternatively the pump−motor units can be

transported with lifting belts.

WARNING

Danger from tipping or falling loads!

Place the lifting belts under the side channel

housing and under the motor.

Attach the lifting belts in such a way that the

suspending pump−motor unit is balanced

and cannot slip out of the lifting belts.

3.2 Transport types

CAUTION

Pump−motor unit damage caused by

improper manual handling!

Do not carry the pump−motor unit by holding

it at the frequency inverter!

Avoid heavy impact loads during transport.

CAUTION

Pump−motor unit damage caused by

improper transport with lifting appliances!

Do not attach the lifting appliances to the

frequency inverter!

The eye bolt at the side channel housing

must

– be screwed tightly.

– be exactly in axial direction of the

pump−motor unit. Lay shims under the

eye bolt if necessary.

Loads laterally to the ring level are not

permissible.

Avoid heavy impact loads during transport.

610.44520.40.000 14 / 52 © Gardner Denver Deutschland GmbH

Page 15

Transport and handling

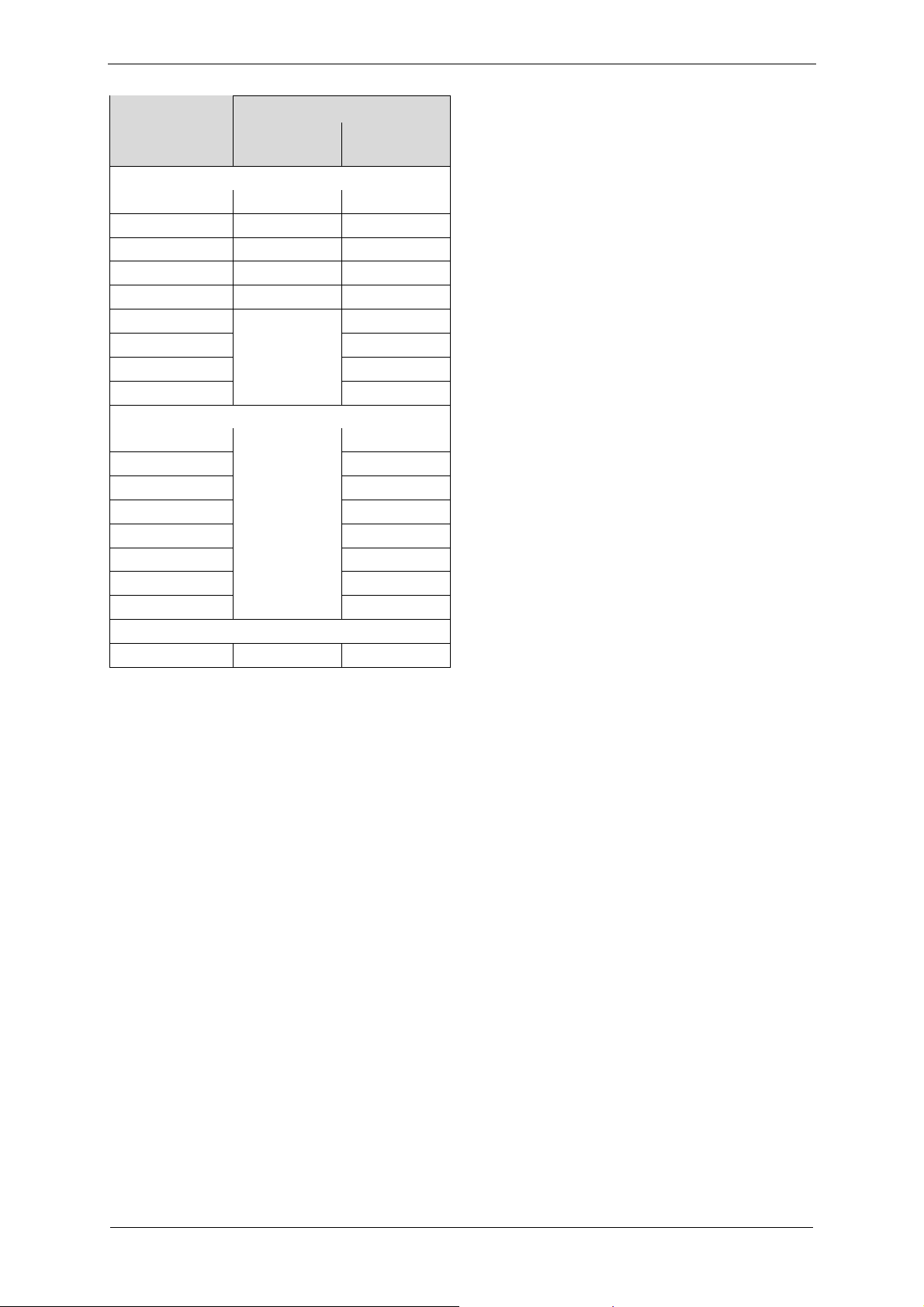

Type of transport Type

manually with lifting

appl.

Single−impeller design

2BH7210−0.N1 X

2BH7210−0.N5 X

2BH7310−0.N2 X

2BH7310−0.N6 X

2BH7410−0.N1 X

2BH7410−0.N5 X

2BH7510−0.N2 X

2BH7510−0.N6 X

2BH7610−0.N3

Two−impeller design

2BH7220−0.N5 X

2BH7320−0.N5 X

2BH7320−0.N8 X

2BH7420−0.N2 X

2BH7420−0.N5 X

2BH7520−0.N7 X

2BH7620−0.N3 X

2BH7620−0.N4

Three−impeller design

2BH7630−0.N6 X

X

X

© Gardner Denver Deutschland GmbH 15 / 52 610.44520.40.000

Page 16

Installation

4 Installation

WARNING

Improper use of the pump−motor unit can

result in serious or even fatal injuries!

Have you read the chapter "Safety

instructions"? ( 5)

Otherwise you may not carry out any work with

or on the pump−motor unit!

DANGER!

Danger from missing view into area of

pump−motor unit!

When operating the control elements without a

view into the area of the pump−motor unit,

there is a danger that the pump−motor unit will

be switched on while other persons are still

performing work on it. Severest injuries are

possible!

Provide control elements at a location with a

view of the pump−motor unit.

DANGER!

Electrical danger!

The pump−motor unit must be installed so that

the electrical equipment cannot be damaged by

external influences!

In particular, the incoming cables must be

routed securely, e.g. in cable ducts, in the floor

etc.

WARNING

Danger of balance damage caused by

vibration!

Vibrating environments can cause balance

damage!

Install the pump−motor unit on a solid

foundation or on a solid mounting surface.

Check screw glands/unions for mounting the

pump−motor unit on the mounting surface

regularly for strength and firm seating.

WARNING

Danger of crushing due to pump−motor unit

tipping over!

Wear personal safety equipment (safety gloves

and safety shoes).

Handle the pump−motor unit with the

appropriate care.

Install the pump−motor unit on a solid

foundation or on a solid mounting surface!

Check screw glands/unions for mounting the

pump−motor unit on the mounting surface

regularly for strength.

WARNING

Danger of fire from flammable substances!

The pump−motor unit must never come into

contact with flammable substances.

For exact information on the temperature

increase see: ( 12).

WARNING

Danger of burns from hot surface of the

pump−motor unit and from hot media!

High temperatures of up to approx. 160 °C

[320 °F] can occur on the surface of the

pump−motor unit.

The pump−motor unit must be installed so that

accidental touch of its surface is not possible.

Cover the pump−motor unit with a suitable

touch protection (e.g. perforated plate cover or

wire cover).

WARNING

Danger of injuries from flying parts!

Select installation so that parts that are thrown

out through the grate if the motor fan breaks

cannot hit persons!

CAUTION

Danger of tripping and falling!

Make sure the pump−motor unit does not

present a danger of tripping.

Lay cables and pipes so that they cannot be

reached during operation (recessed in floor, in

ducts on the wall etc.).

610.44520.40.000 16 / 52 © Gardner Denver Deutschland GmbH

Page 17

Installation

CAUTION

Danger of overheating due to hot surface of

pump−motor unit!

High temperatures can occur on the surface of

the pump−motor unit.

Temperature−sensitive parts, such as cables or

electronic components, may not come into

contact with the surface of the pump−motor

unit.

CAUTION

Danger of pump−motor unit damage caused

by penetration of foreign bodies!

On delivery all connection openings are closed

in order to prevent the penetration of foreign

bodies. Remove the seals right before the

respective mounting step.

Installation sequence

The pump−motor unit is ready to connect on

delivery.

CAUTION

The pump−motor unit may be damaged if it

is installed and commissioned after longer

storage periods without special preparation!

If the pump−motor unit was stored for a longer

period prior to installation, it has to be prepared

for installation: ( 42)

Carry out the following steps to install the

pump−motor unit:

1 Set up the pump−motor unit and attach it.

2 Mount the muffler (supplied loose) if

necessary.

3 Mount the threaded flange or hose flange to

the muffler if necessary.

4 Connect inlet and discharge connections to

the system.

5 Establish electrical connection.

4.1 Installation

CAUTION

Pump−motor unit damage caused by

incorrect mounting or use under

impermissible ambient conditions!

Install and connect the pump−motor unit only

according to the instructions given in this

chapter.

If the pump−motor unit is to be used under

differing operating conditions, the manufacturer

must be consulted.

NOTE

Dimensioned drawings with detailed

dimensions, including fastening dimensions,

are provided by the manufacturer.

4.1.1 Important notes

Ambient conditions

The pump−motor unit is suitable for installation

in a dusty or damp environment,

in buildings,

in the open.

– For proper installation in the open, protect

the pump−motor unit from exposure to

intensive sunlight, e.g. by attaching a

protective roof.

– Further special protective devices against

the effects of weathering are not required.

The motors of the units are to enclosure IP55.

The insulation is tropic−proof.

Installation conditions

Attach the pump−motor unit only to even

surfaces.

Do not exceed the maximum permissible

vibration velocity veff = 4mm/s [0.013 ft/s].

Installation altitude max. 1000 m amsl [3280 ft

amsl].

– When installing at an altitude of more than

1000 m [3280 ft] above sea level, first

inquire with the manufacturer.

© Gardner Denver Deutschland GmbH 17 / 52 610.44520.40.000

Page 18

Installation

Noise radiation

In order to reduce the noise radiation,

do not mount pump−motor unit on

noise−conducting or noise−radiating parts

(e.g. thin walls or sheet−metal plates).

provide pump−motor unit with

sound−insulating intermediate layers (e.g.

rubber buffers under the base of the

pump−motor unit) if necessary.

install the pump−motor unit on a stable

foundation or on a rigid mounting surface.

This will ensure quiet and low−vibration

running of the pump−motor unit.

Components for reducing noise on the

pump−motor unit:

Muffler (included in the scope of supply)

– On delivery the pump−motor units are

equipped with attached mufflers as

standard.

– The mufflers considerably reduce the noise

radiation.

Additional muffler (available as accessories):

– The additional mufflers enable a further

noise reduction.

– They may only be used in systems without

piping, i.e. with direct intake out of the

atmosphere or direct feeding into the

atmosphere.

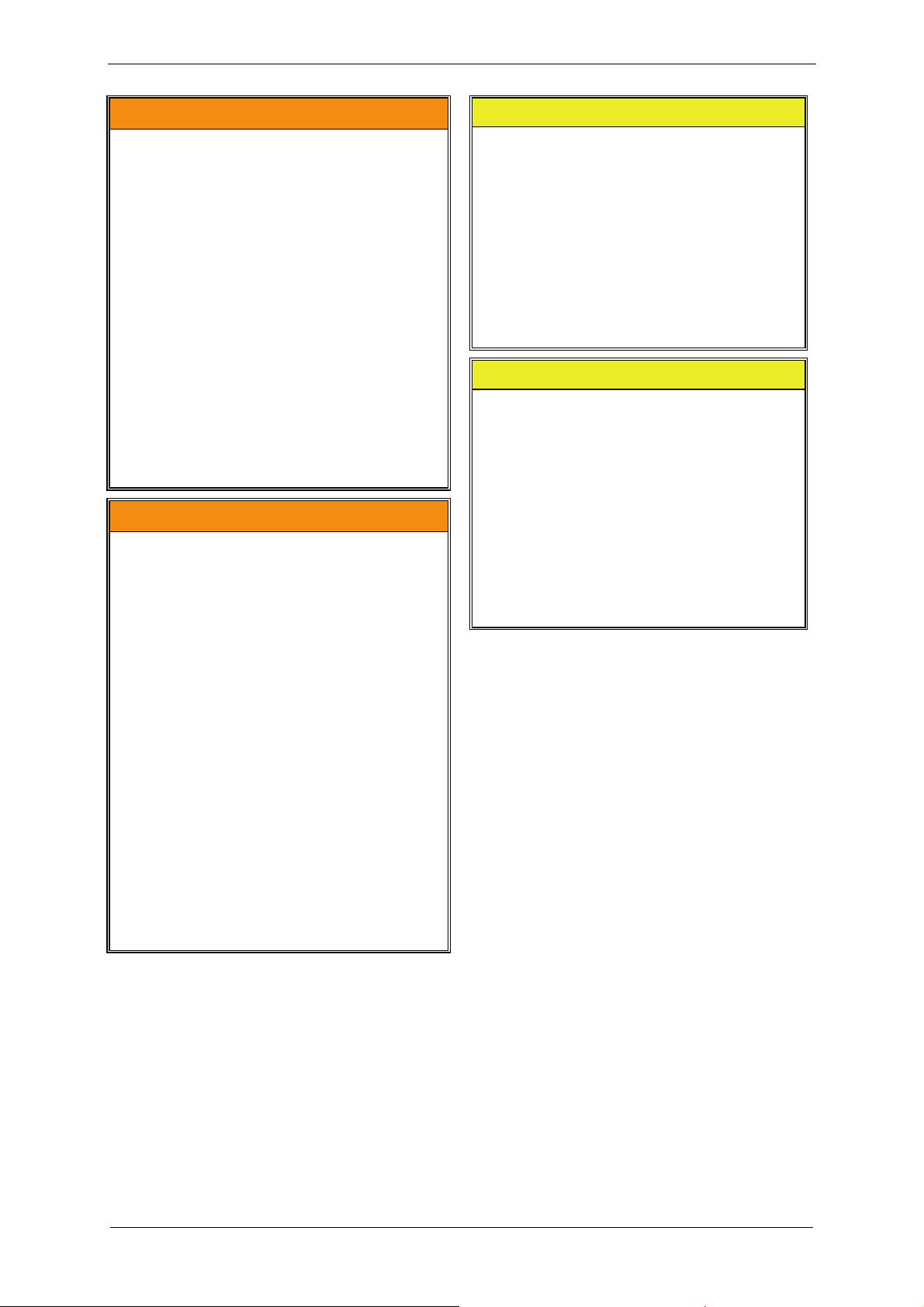

4.1.2 Free spaces

CAUTION

Material damage caused by overheating of

the pump−motor unit!

It is absolutely necessary to observe the

required free spaces in order to cool the

pump−motor unit sufficiently.

Ventilation screens and ventilation openings

must remain clear.

The discharge air of other pump−motor units

may not be directly sucked in again!

> 100 mm

[ > 4 in ]

> 100 m m > 100 m m

[ > 4 in ] [ > 4 in ]

Noise protection hoods (available as

accessories):

– Noise protection hoods are suitable for

installation in rooms and in the open.

– They reduce the overall sound pressure

level and tonal components that are

perceived as particularly annoying.

Installation variants

Units with motors without condensation water

openings can be installed in different ways:

horizontally,

vertically on the cover of the side channel

housing ("cover installation"),

vertically on a wall.

CAUTION

Danger of rusting due to collection of

condensed water in drive motor area!

Install and attach units with motors equipped

with condensation water openings only

horizontally, base at the bottom.

a

[mm] [in] [mm] [in]

2BH72..

2BH73..

2BH74..

> 30 > 1,18

2BH75..

2BH76..

Fig. 3: Free spaces

b

Ne2bhxn001

a b Type

> 34 > 1,34

> 52 > 2,05

> 53 > 2,09

610.44520.40.000 18 / 52 © Gardner Denver Deutschland GmbH

Page 19

4.1.3 Mounting

NOTE

Dimensioned drawings with detailed

dimensions, including fastening dimensions,

are provided by the manufacturer.

Horizontal installation

ne2bhxn002d

Fig. 4: Schematic diagram: horizontal installation

Mounting sequence:

1 Select suitable mounting elements.

2 Attach the pump−motor unit to the surface:

– Screw the base of the pump−motor unit to

the surface via the mounting holes.

– When doing so, be sure to provide all

mounting holes with screws!

Installation

ne2bhxn002c

Fig. 5: Schematic diagram: installation on the cover

of the side channel housing

Mounting sequence:

1 Attach the rubber feet to the pump−motor unit:

– Screw the stud bolts of the rubber feet into

the bore holes in the cover of the gas ring

blower housing.

– Tighten the rubber feet.

2 Mount the pump−motor unit together with the

rubber feet on the installation surface:

– Select suitable mounting elements for the

threaded hole.

– Screw the rubber feet to the installation

surface via the threaded holes.

Vertical mounting on a wall

Vertical installation on the cover of the gas

ring blower (”cover installation”)

NOTE

You need three rubber feet for the "cover

installation" of the pump−motor unit.

The rubber feet are available as accessories.

They come with a stud bolt on one side and a

threaded hole on the other side.

ne2bhxn002a

WARNING

Danger of crushing caused by pump−motor

unit tipping over!

Avoid free−standing installation of the

pump−motor unit!

Always screw the rubber feet to the foundation

or to the installation surface!

Check screw connections regularly for

tightness.

ne2bhxn002b

Fig. 6: Schematic diagram: vertical mounting on a

Mounting sequence:

© Gardner Denver Deutschland GmbH 19 / 52 610.44520.40.000

wall

Page 20

Installation

1 Select suitable mounting elements.

2 Position the pump−motor unit as close to the

wall as possible on a stable supporting plate

with sufficient load−bearing capacity.

– The pump−motor unit must be positioned

with the base towards the wall.

3 Attach the pump−motor unit to the wall:

– Screw the base of the pump−motor unit to

the wall via the mounting holes.

– When doing so, be sure to provide all

mounting holes with screws!

4 Remove the supporting plate.

4.1.4 Final works

After installing the pump−motor unit, the eye bolt

must be removed or screwed tightly.

4.2 Mounting of the muffler

The pump−motor units are supplied with mufflers

for inlet and discharge connections as standard.

The mufflers are marked by arrows in the

following drawings.

2BH721 ...2BH761 (single−impeller pump−motor

units)

ne2bhxn003a

Fig. 7: Mounting of the muffler 2BH721 ...2BH761.

With the following pump−motor units, the

inlet−side muffler is included loose for

packaging−related reasons. It must be mounted

by the operator.

2BH732 ... 2BH762 (two−impeller pump−motor

units with two−stage design)

ne2bhxn003b

Fig. 8: Mounting of the muffler 2BH732 ... 2BH762

2BH763 (three−impeller pump−motor unit with

three−stage design)

ne2bhxn003c

Fig. 9: Mounting of the muffler 2BH763

WARNING

Danger from rotating impeller:

cutting/cutting off of extremities!

The rotating impeller is accessible with the inlet

and discharge connections open!

With free entry and exit of gases, i.e. with direct

intake out of the atmosphere or direct feeding

into the atmosphere without piping, the

following therefore applies:

Provide the inlet and discharge connections of

the pump−motor unit either with additional

mufflers or with additional piping of a sufficient

length to prevent access to the impeller!

4.3 Connecting the pump-motor unit to the

system

4.3.1 Important notes

Delivery direction of the gases

The pumped gases are sucked in via the inlet

connection and discharged via the discharge

connection.

The delivery direction of the gases is marked by

arrows on the connections:

The inlet connection with the corresponding

muffler is marked by an arrow pointing into the

pump−motor unit.

The discharge connection with the

corresponding muffler is marked by an arrow

pointing out of the pump−motor unit.

610.44520.40.000 20 / 52 © Gardner Denver Deutschland GmbH

Page 21

Installation

Rotation direction of the shaft

The rotation direction of the shaft is marked by an

arrow on the cover of the side channel housing

and by an arrow on the fan guard of the motor.

WARNING

Danger from interchanging inlet and

pressure line!

Interchanged inlet and pressure lines can lead

to damage to the pump−motor unit and the

system, and as a result of this to serious

injuries!

Make sure that the inlet and the pressure line

cannot be confused when connecting.

Pay attention to the clear marking with the

arrows indicating the delivery direction on the

inlet and discharge connections.

WARNING

Danger due to vacuum and gauge pressure!

Danger due to escaping media!

During operation, connected pipes and vessels

are vacuumized or pressurized!

Use only mounting elements, connections,

lines, fittings and containers with sufficient

freedom from leaks and strength for the

pressures which occur.

Make sure that the mounting elements and

connections are mounted firmly enough and

leak−free!

CAUTION

If the pumped gases are passed on the

discharge side in a closed pipe system, then it

must be ensured that the pipe system is

adapted to the maximum discharge pressure.

Connect a pressure relief valve upstream if

necessary.

NOTE

Attach pipes/hoses free of mechanical

tensions.

Support the weight of the pipes/hoses.

4.3.2 Connecting the inlet line

WARNING

Danger from solid bodies and impurities in

the pump−motor unit!

If solid bodies penetrate into the pump−motor

unit, blades of the impellers can break and

broken pieces can be thrown out.

Install a filter in the inlet line. Replace filter

regularly!

The pumped gases are taken in via the inlet line.

Connect the inlet line to the inlet connection.

– The inlet connection with the

corresponding muffler is marked by an

arrow pointing into the pump−motor unit.

A If you use an inlet pipe, you can screw it

directly into the muffler.

B If you use an inlet hose, you need a hose

flange available as accessories:

– Screw the hose flange to the muffler.

– Push the hose onto the hose flange and

secure it with a hose clamp.

– Observe tightening torques ( 12)

4.3.3 Connecting the pressure line

The pumped gases are discharged via the

pressure line.

Connect the pressure line to the discharge

connection.

– The discharge connection with the

corresponding muffler is marked by an

arrow pointing out of the pump−motor unit.

A If you use a pressure pipe, you can screw it

directly into the muffler.

B If you use a pressure hose, you need a hose

flange available as accessories:

– Screw the hose flange to the muffler

– Push the hose onto the hose flange and

secure it with a hose clamp.

– Observe tightening torques ( 12)

© Gardner Denver Deutschland GmbH 21 / 52 610.44520.40.000

Page 22

Installation

4.4 Electrical installation

DANGER!

Electrical danger!

Malpractice can result in severe injuries and

material damage!

DANGER!

Electrical danger!

The electrical connection may be carried out by

trained and authorized electricians only!

DANGER!

Electrical danger!

Before beginning work on the pump−motor unit

or system, the following measures must be

carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short−circuit.

Cover or block off adjacent energized parts.

DANGER!

Electrical danger!

The terminal box of the frequency inverter must

be free from

foreign bodies,

dirt,

humidity.

Frequency inverter and cable entries must be

tightly closed so as to make them dustproof

and waterproof. Check for tightness at regular

intervals.

DANGER!

Electrical danger!

Danger of electrical shock when a defective

pump−motor unit is touched!

Have electrical equipment checked regularly by

a qualified electrician.

4.4.1 Important notes

Regulations

The electrical connection must be carried out as

follows:

according to the corresponding VDE

regulations and national regulations.

according to the applicable national, regional

and system−dependent regulations and

requirements.

according to the regulations of the utility

company applying to the place of installation.

Electrical power supply

Observe the rating plate of the frequency

inverter. It is imperative that the operating

conditions correspond to the data given on the

rating plate.

Electrical connection ( 23), ( 26)

The electrical connection must be

permanently safe.

The electrical connection to the PE conductor

must be permanently safe.

There may be no protruding wire ends.

Control cable connection ( 29)

Use shielded incoming cables.

Do not route control cables together with

power cables in order to avoid interference

injections.

For optimum shielding use the shield

connections to ensure large−surface contact

when connecting the shield in the terminal

box.

Control cables

610.44520.40.000 22 / 52 © Gardner Denver Deutschland GmbH

Page 23

Installation

4.4.2 Preparing works

Open frequency inverter

2FC4152-1NE00 ... 2FC4222-1NE00

ne2bhxn222

Fig. 10: Open frequency inverters 2FC4152−1NE00

and 2FC4222−1NE00

2FC4302-1NE00 ... 2FC4752-1NE00

1 2

4.4.3 Connecting frequency inverters

2FC4152-1NE00 and 2FC4222-1NE00

DANGER!

Electrical danger!

Improper connection of the pump−motor unit

can result in an electric shock.

Observe the following basic rules:

The leakage current to earth (PE) is

>3.5 mA. The PE connection must meet EN

50178.

Observe national and regional regulations.

CAUTION

Danger of pump−motor unit damage caused

by improper connection!

Observe the permissible mains voltage. Any

higher mains voltage will destroy the frequency

inverter.

Wiring according to EMC requirements

(installation of a CE-typical drive system)

The pump−motor units meet the EU Directive on

"Electromagnetic Compatibility" if they are

installed in accordance with the specifications of

the CE−typical drive system. The end−user is

responsible for maintaining the EU Directive in

the overall system.

ne2bhxn422

Fig. 11: Open frequency inverters 2FC4302−1NE00 ...

2FC4752−1NE00

NOTE

Requirements for trouble−free operation:

Always shield control cables.

Provide large−surface contact between

shielding and shield sheet. Ensure good

electrical contact.

© Gardner Denver Deutschland GmbH 23 / 52 610.44520.40.000

Page 24

Installation

2FC4152-1NE00 ... 2FC4222-1NE00

B A

C

D

X1

X2

F

Fig. 12: Terminal box 2FC4152-1NE00 ... 2FC4222-

1NE00

Mains cable L1, L2, L3, PE

PE connection mains cable and motor cable

Shielded control cable

Shield connection for the control cable::

1 Prepare cable

E

1ne2bhxn101

X1 Terminal strip for mains connection and relay

output connection

X2 Terminal strip for motor connection and motor

temperature monitoring

PES HF shield termination by large−surface

connection to PE

Mains contactor, fuses and cable crosssections

NOTE

Observe the following when using earth

leakage circuit breakers:

Install earth leakage circuit breakers only

between the supply mains and the frequency

inverter.

The earth leakage circuit breaker may trip

incorrectly if several drives are

simultaneously connected to the mains.

Frequency

inverter

Type [kW] [kW] FI

2FC41521NE00

2FC42221NE00

Required mains

contactor K1

1,5

4

2,2

≥30 m

A

2)

2 Pass the cable through the eye of the

shield sheet and bend the eye.

3 Screw together eye and shield sheet:

– The shielding must have large−surface

contact to the shield sheet.

– The shielding must be connected tightly

to the shield sheet.

PES

Potential free terminal

Control terminal module

0.7 Nm

6lb-in

Fuses and cable cross sections Frequency

inverter

Type

2FC41521NE00

2FC42221NE00

Installation according

to EN 60204−1

M6 A B6 A 1 5 A 18

M10

B10 A 1,5 10 A 16

A

L1, L2,

L3, PE

[mm

Installation

according to

UL 1)

2

]

L1, L2,

L3, PE

[AWG]

Fuse

Circuit−breaker

1)

Use only UL−approved cables, fuses and fuse

holders. UL−fuse: voltage 500 ... 600 V,

tripping characteristic "H", "K5" or "CC"

2)

Pulse current sensitive or all current sensitive

e.l.c.b.

610.44520.40.000 24 / 52 © Gardner Denver Deutschland GmbH

Page 25

Installation

Relay data

NOTE

The service life of the relay depends on the

type of load (ohmic, inductive or capacitive)

and the value of the switching capacity.

Technical data

AC 250 V/3 A

DC 24 V/2 A ... DC 240 V/0.22 A

Connection

X1

0.5...0.6 Nm

4.4...5.3 lb-in

Function Relay

position

switched

X1/K11 Relay output

opened TRIP

normally−close

d contact

X1/K12 Relay

mid−position

contact

X1/K14 Relay output

closed TRIP

normally−open

contact

PES HF shield termination by large−surface

connection to PE

3/PE AC, 320 V ... 550 V, 45 ... 65 Hz

Displayed

message

PES

PES

X1 L3 L2 BR2 K14L1 BR1 K12BR0 K11

1.2...1.5 Nm

5.3 mm

10.7...13.3 lb-in

ne2bhxn231

Fig. 13: Frequency inverter 2FC4152-1NE00 ... 2FC4222-1NE00 1 connecting

1 Connecting the mains cable:

A Release two screws at terminal X1 and

remove the terminal.

B Pass the mains cable through the cable gland.

C Attach the ring cable lug ( 5.3 mm) to the PE

conductor.

D Screw the PE conductor onto the PE stud for

the mains cable:

– observe tightening torque!

E Connect cores L1, L2 and L3 to X1 in correct

phase relation:

– observe tightening torque!

2 Wiring the relay output (if necessary):

A Pass the cable through the cable gland.

B Connect the shield of shielded cables

according to EMC requirements ( 24).

C Connect cores to terminal X1:

© Gardner Denver Deutschland GmbH 25 / 52 610.44520.40.000

– observe terminal connection diagram and

tightening torque!

3 Re−insert terminal X1 and tighten with 2

screws:

– observe tightening torque!

4 Connecting the control cable shield:

A Pass the control cable through the cable

gland.

B Connect the shield according to EMC

requirements ( 24).

C Control cable connection: ( 29)

5 Tighten all cable glands.

Page 26

Installation

NOTE

Do not remove the jumper between terminals

BR1 and BR0!

Otherwise trouble−free functioning of the

pump−motor unit cannot be guaranteed.

4.4.4 Connecting frequency inverters

2FC4302-1NE00 ... 2FC4752-1NE00

DANGER!

Electrical danger!

Improper connection of the pump−motor unit

can result in an electric shock.

Observe the following basic rules:

The leakage current to earth (PE) is > 3.5

mA. The PE connection must meet EN

50178.

Observe national and regional regulations.

CAUTION

Danger of pump−motor unit damage caused

by improper connection!

Observe the permissible mains voltage. Any

higher mains voltage will destroy the frequency

inverter.

Wiring according to EMC requirements

(installation of a CE-typical drive system)

The pump−motor units meet the EU Directive on

"Electromagnetic Compatibility" if they are

installed in accordance with the specifications of

the CE−typical drive system. The end−user is

responsible for maintaining the EU Directive in

the overall system.

NOTE

Requirements for trouble−free operation:

Always shield control cables.

Provide large−surface contact between

shielding and shield sheet. Ensure good

electrical contact.

610.44520.40.000 26 / 52 © Gardner Denver Deutschland GmbH

Page 27

Realisation

E

Installation

BA

X1

G

H

X2

CD

Fig. 14: Electrical connections 2FC4302-1NE00 … 2FC4752-1NE00

Mains cable L1, L2, L3, PE

PE connection mains cable

Shielded control cable

Shield connection for the control cable: g:

1 Prepare cable..

2 Insert cable tie..

F

ne2bhxn045

ne2bhxn046

3 Insert cable and tighten cable tie:

Potential−free terminals

PE connection motor

Support for control terminal module

Control terminal module

X1 Terminal strip for mains connection and relay

output connection

X2 Terminal strip for motor connection

PES HF shield termination by large−surface

connection to PE

2ne2bhxn398

– The shielding must have large−surface

contact to the shield sheet.

– The shielding must be connected

tightly to the shield sheet.

ne2bhxn047

© Gardner Denver Deutschland GmbH 27 / 52 610.44520.40.000

Page 28

Installation

Mains contactor, fuses and cable crosssections

NOTE

Observe the following when using

earth−leakage circuit breakers:

Install earth−leakage circuit breakers only

between the supply mains and the frequency

inverter.

The earth−leakage circuit breaker may trip

incorrectly if several drives are

simultaneously connected to the mains.

Frequency

inverter

Required mains

contactor K1

Type [kW] [kW] FI

2FC43021NE00

2FC44021NE00

2FC45521NE00

2FC47521NE00

3 3

4 4

≥300 mA

5,5 5,5

7,5 7,5

Fuses and cable cross sections Frequency

inverter

Type

2FC43021NE00

2FC44021NE00

2FC45521NE00

2FC47521NE00

Installation according

to EN 60204-1

L1, L2,

L3, PE

2

[mm

]

M16

B16 A 2,5 15 A 14

A

M20

B20 A 4 20 A 12

A

M25

B25 A 4 25 A 10

A

M32

B32 A 6 35 A 8

A

Installation

according to

UL 1)

L1, L2,

L3, PE

[AWG]

Fuse

Circuit−breaker

1)

Use only UL−approved cables, fuses and fuse

holders. UL−fuse: voltage 500 ... 600 V,

tripping characteristic "H", "K5" or "CC"

2)

All−current sensitive e.l.c.b.

Relay data

NOTE

The service life of the relay depends on the

type of load (ohmic, inductive or capacitive)

and the value of the switching capacity.

Technical data

AC 250 V/3 A

DC 24 V/2 A … DC 240 V/0.22 A

Function Relay

position

switched

2)

X1/K11 Relay output

normally−close

opened TRIP

d contact

X1/K12 Relay

mid−position

contact

X1/K14 Relay output

closed TRIP

normally−open

contact

PES HF shield termination by large−surface

connection to PE

Displayed

message

610.44520.40.000 28 / 52 © Gardner Denver Deutschland GmbH

Page 29

Connection

Installation

3/PEAC, 320 V ... 550V, 45 ... 65 Hz

1.1 Nm

9.7 lb-in

Fig. 15: Connectiing frequency inverter 2FC4302-1NE00 ... 2FC4752-1NE00

4.3 mm

PES

PES

X1 L3 L2 L1K14 K12 K11

1.2...1.5 Nm

10.7...13.3 lb-in

1 Connecting the mains cable:

A Pass the mains cable through the cable gland.

B Attach the ring cable lug (Ø 4.3 mm) to the

PE conductor.

C Screw the PE conductor onto the PE stud for

the mains cable:

– observe tightening torque

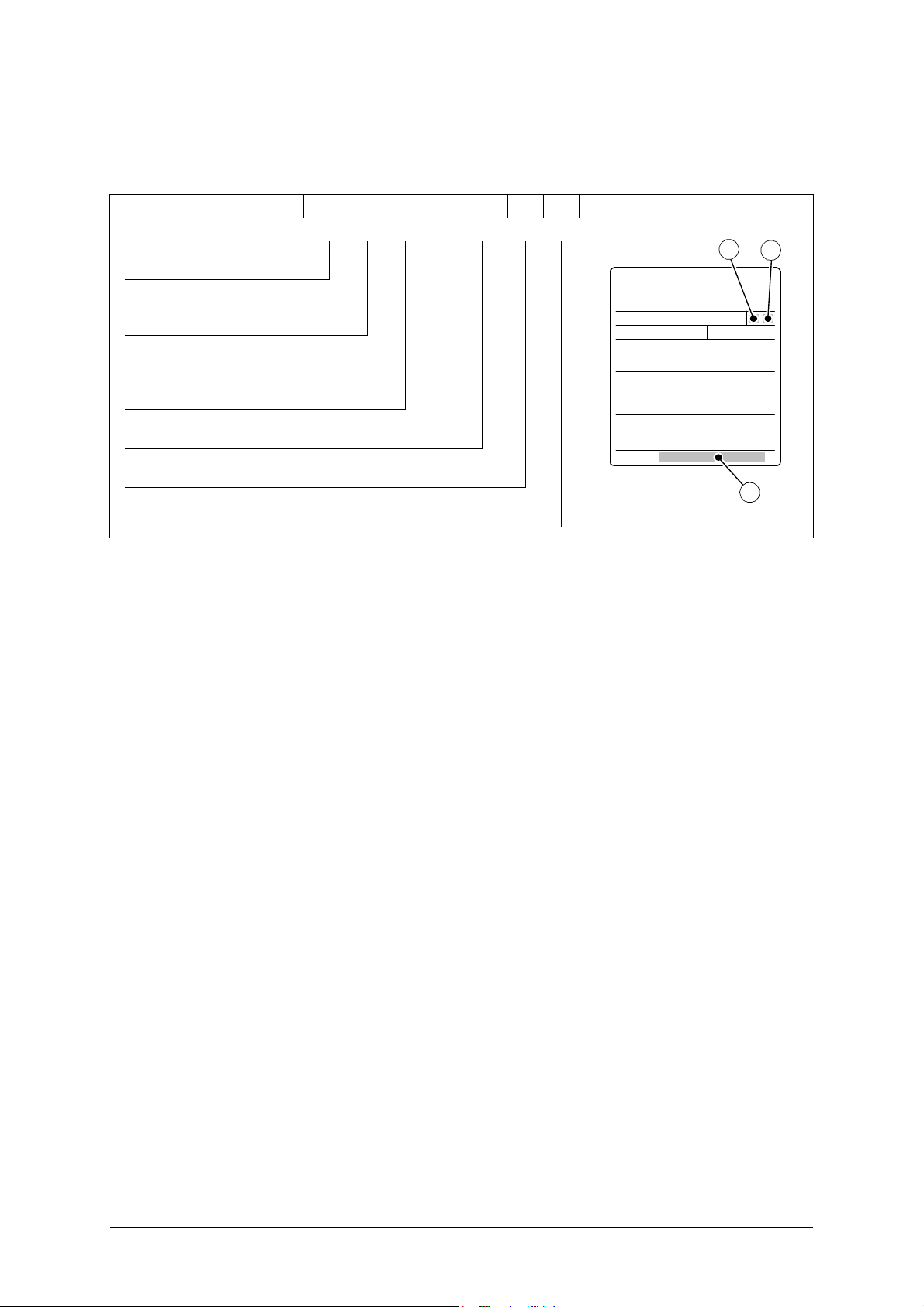

4.4.5 Wiring of control connections

The control connections are on the control

terminal module 2FX4501−0NE00 which is

included in the scope of supply.

Install the control terminal module in the terminal

box of the frequency inverter before starting to

wire the control connections.

D Connect cores L1, L2 and L3 to X1 in correct

phase relation:

– observe tightening torque!

2 Wiring the relay output (if necessary):

A Pass the cable through the cable gland.

B Connect the shield of shielded cables

according to EMC requirements (

27).

C Connect cores to terminal X1:

– observe terminal connection diagram and

X3

tightening torque!

3 Connecting the control cable shield:

A Pass the control cable through the cable

Fig. 16: Control connections 2FX4501-0NE00

gland.

B Connect the shield according to EMC

requirements (

C Control cable connection: ( (

27).

29)

4 Tighten all cable glands.

Mount control terminal module

If the cap is plugged on the socket

connector when assembling the frequency

inverter, the control terminal module will be

damaged!

Remove the cap from the socket connector

at the control terminal module.

Keep the cap.

6 mm

62 7 78 9 20 28 E1E2 E3 E4 39 A1 59

CAUTION

ne2bhxn431

n_e2fx1006

© Gardner Denver Deutschland GmbH 29 / 52 610.44520.40.000

Page 30

Installation

A

2FC4152-1NE00 … 2FC4222-1NE00

1

2

3

C L

CK

Fig. 17: Control terminal module installation in

frequency inverters 2FC4152−1NE00 and

2FC4222−1NE00

2FC4302-1NE00 … 2FC4752-1NE00

1

1.1 Nm

9.7 lb-in

2

ne2bhxn147

Screw terminal data

Electrical

Terminal strip with screw connection

connections

Possible

connections

rigid:

1,5 mm

2

(AWG 16)

flexible:

without wire end ferrule

1,0 mm

2

(AWG 18)

without wire end ferrule,

without plastic sleeve

0,5 mm

2

(AWG 20)

with wire end ferrule, with

Tightening

plastic sleeve

0,5 mm

0,22 … 0,25 Nm (1,9 … 2,2 lb-in)

2

(AWG 20)

torque

Bare end 5 mm

Wiring

NOTE

Always shield control cables in order to avoid

interference injections!

GND2

3

4

CLACK

Fig. 18: Control terminal module installation in

frequency inverters 2FC4302−1NE00 ...

2FC4752−1NE00

ne2bhxn447

GND1

62 8 9 20 28 E1 E2 E3 E4 39 A1 59

X3

Fig. 19: Supply via the internal voltage source (X3/20)

X3

77

AIN1AO UT1 DIGOUT 1

GND1

7

62

AIN1AOU T1

GND1

+5V +20V

897

Required minimum wiring for operation

n_e2fcx072

GND2

GND1

+20V

+5V

8 9 20 28 E1 E2 E3 E4 39 A1 59

7

DIGOUT1

897

_

24 V ext.

(+12 V DC - 0%

...

+30 V DC + 0%

max. 120 mA

Required minimum wiring for operation

n_e2fcx073

+

Fig. 20: Supply via an external voltage source

610.44520.40.000 30 / 52 © Gardner Denver Deutschland GmbH

Page 31

Terminal assignment

Installation

X3/3 Signal

Function Level

type

X3/62 Analog

Output frequency 0 ... + 6 V

output

X3/7 - GND1, reference potential for analog signals X3/8 Analog

input

Setpoint input Change setpoint selection

range via DIP switch

0 ... +5 V (default setting)

0 ... +10 V

0 ... +20 mA

X3/9 - Internal, stabilised DC voltage source for

+5,2 V (ref.: X3/7)

setpoint potentiometer

X3/20 - Internal DC voltage source to control digital

+20 V ± 10 % (ref.: X3/7)

inputs and digital outputs

Digital

inputs

HIGH

LOW

X3/E1 Reset fault (TRIP−Reset) HIGH

X3/E2 External fault

HIGH

START X3/28 Controller inhibit

STOP

Reset fault

Switch−off with fault indication

"EEr"

No fault

Activation of fixed speeds

Adjust maximum frequency C0011 in order

to go through the complete speed range.

Maximum value of C0011 = 87 Hz (5000/

min)

LOW

E3 E4 X3/E3

34 Hz (2000/min) HIGH LOW

67 Hz (4000/min) LOW HIGH X3/E4

50 Hz (3000/min) HIGH HIGH

X3/39 - GND2, reference potential for digital signals X3/A1 Digital

"Pulse inhibit active" message HIGH

pulse inhibit active

output

X3/59 - DC supply for X3/A1

+20 V Internal voltage source (jumper to

X3/20)

+24 V External voltage source

ON

OFF

n_e2fcx070

Switch position

Signal at X3/8 1 2 3 4 5

0 ... 5 V (default

OFF OFF ON OFF OFF

setting)

0 ... 10 V OFF OFF ON OFF ON

0 ... 20 mA OFF OFF ON ON OFF

Fig. 21: Switch position control terminal module

© Gardner Denver Deutschland GmbH 31 / 52 610.44520.40.000

Page 32

Installation

Electrical data of the terminals

X3/

X3/62

Resolution 10 bits

Linearity error ±0,5 %

Temperature

0,3 % (0 … +60°C)

error

X3/8

Load capacity I

Resolution 10 bits

= 2 mA

max

Linearity error ±0,5 %

Temperature

0,3 % (0 … +60°C)

error

Load capacity I

= 2 mA

max

Input resistance Voltage signal: >50 kΩ

Current signal: 250 Ω

X3/9 Load capacity I

= 10 mA

max

X3/7 Isolated from terminal X3/39 (GND2)

Load capacity 3,3 kΩ X3/28

HIGH +12 … +30 V, SPS- level,

X3/E1

…

X3/E4

LOW 0 … +3 V, SPS- level,

HTL

HTL

X3/39 Isolated from terminal X3/7 (GND1)

X3/A1 Load capacity For internal supply:

I

= 10 mA

max

For external supply:

= 50 mA

I

max

4.4.6 Final works

CAUTION

Improper closing of the frequency inverter

may damage the contacts of the control

terminal module.

Observe the following points to avoid

damages:

Place the heatsink of the frequency inverter

carefully on the terminal box.

Place the heatsink upright on the terminal

box from above, do not tilt it!

When placing the heatsink upon the terminal

box, pay attention to placing the plug at the

heatsink exactly upon the socket connector

at the control terminal module.

Never force the heatsink upon the terminal

box.

CAUTION

If the cap is plugged on the socket

connector when assembling the frequency

inverter, the control terminal module will be

damaged!

Remove the cap from the socket connector

at the control terminal module.

Keep the cap..

2FC4152-1NE00 … 2FC4222-1NE00

2.4 Nm

21 lb-in

Close frequency inverter

DANGER!

IP65

Electrical danger!

The terminal box of the frequency inverter must

be free from

foreign bodies,

dirt,

humidity.

Frequency inverter and cable entries must be

Fig. 22: Close frequency inverters 2FC4152−1NE00

and 2FC4222−1NE00

ne2bhxn227

tightly closed so as to make them dustproof

and waterproof. Check for tightness at regular

intervals.

DANGER!

Electrical danger!

Danger of electrical shock when a defective

pump−motor unit is touched!

Have electrical equipment checked regularly by

a qualified electrician.

610.44520.40.000 32 / 52 © Gardner Denver Deutschland GmbH

Page 33

Installation

2FC4302-1NE00 … 2FC4752-1NE00

1.1 Nm

9.7 lb-in

IP65

ne2bhxn459

Fig. 23: Close frequency inverters 2FC4302−1NE00

... 2FC4752−1NE00

© Gardner Denver Deutschland GmbH 33 / 52 610.44520.40.000

Page 34

Commissioning

5 Commissioning

WARNING

Improper use of the pump−motor unit can

result in serious or even fatal injuries!

Have you read the chapter "Safety

instructions"? (

5)

Otherwise you may not carry out any work with

or on the pump−motor unit!

WARNING

Danger from rotating parts (motor fan,

impeller, shaft): cutting/cutting off of

extremities, grasping/winding up of hair and

clothing!

Danger due to vacuum and gauge pressure:

sudden escape of media (skin and eye

injuries), sudden drawing−in of hair and

clothing!

Danger due to escaping media: burns!

Commissioning and operation only under the

following conditions:

The pump−motor unit must be completely

assembled. When doing so, pay particular

attention to the following components: