Page 1

Edition: 04.2012 · 610.44436.40.000 Original operating instructions · English

Operating Instructions G-BH7

2BH72

2BH73

2BH74

2BH75

2BH76

G-Serie

G-Series

Seitenkanal

Side Channel

Page 2

Contents

Contents

1 Safety ..................................................................................................................................................3

1.1 Definitions .................................................................................................................................3

1.1.1 Safety alert symbol.......................................................................................................3

1.1.2 Signal words.................................................................................................................3

1.2 General safety precautions .......................................................................................................3

1.3 Residual risks............................................................................................................................6

2 Intended Use .......................................................................................................................................7

3 Technical Data ....................................................................................................................................8

3.1 Mechanical data ........................................................................................................................8

3.2 Electrical data..........................................................................................................................11

3.3 Operating conditions ...............................................................................................................11

4 Transport and Handling.....................................................................................................................12

5 Installation .........................................................................................................................................13

5.1 Installation ...............................................................................................................................14

5.2 Electrical connection (motor) ..................................................................................................16

5.3 Connecting pipes/hoses (vacuum pump/compressor)............................................................18

5.3.1 Inlet connection ..........................................................................................................19

5.3.2 Discharge connection.................................................................................................19

5.3.3 Procedure when connecting pipes/hoses ..................................................................19

6 Commissioning..................................................................................................................................20

6.1 Preparation..............................................................................................................................20

6.2 Start-up and shut-down...........................................................................................................22

7 Operation...........................................................................................................................................22

8 Shut-Down and Longer Standstills....................................................................................................22

8.1 Preparing for shut-down or longer standstill ...........................................................................22

8.2 Storage conditions ..................................................................................................................23

9 Servicing............................................................................................................................................23

9.1 Repairs/troubleshooting ..........................................................................................................24

9.2 Service/After-sales service......................................................................................................25

9.3 Decontamination and Declaration of Clearance .....................................................................25

10 Disposal.............................................................................................................................................25

11 Explosion-Protected Design ..............................................................................................................25

EU declaration of conformity ..................................................................................................................26

Form for statement on safety .................................................................................................................27

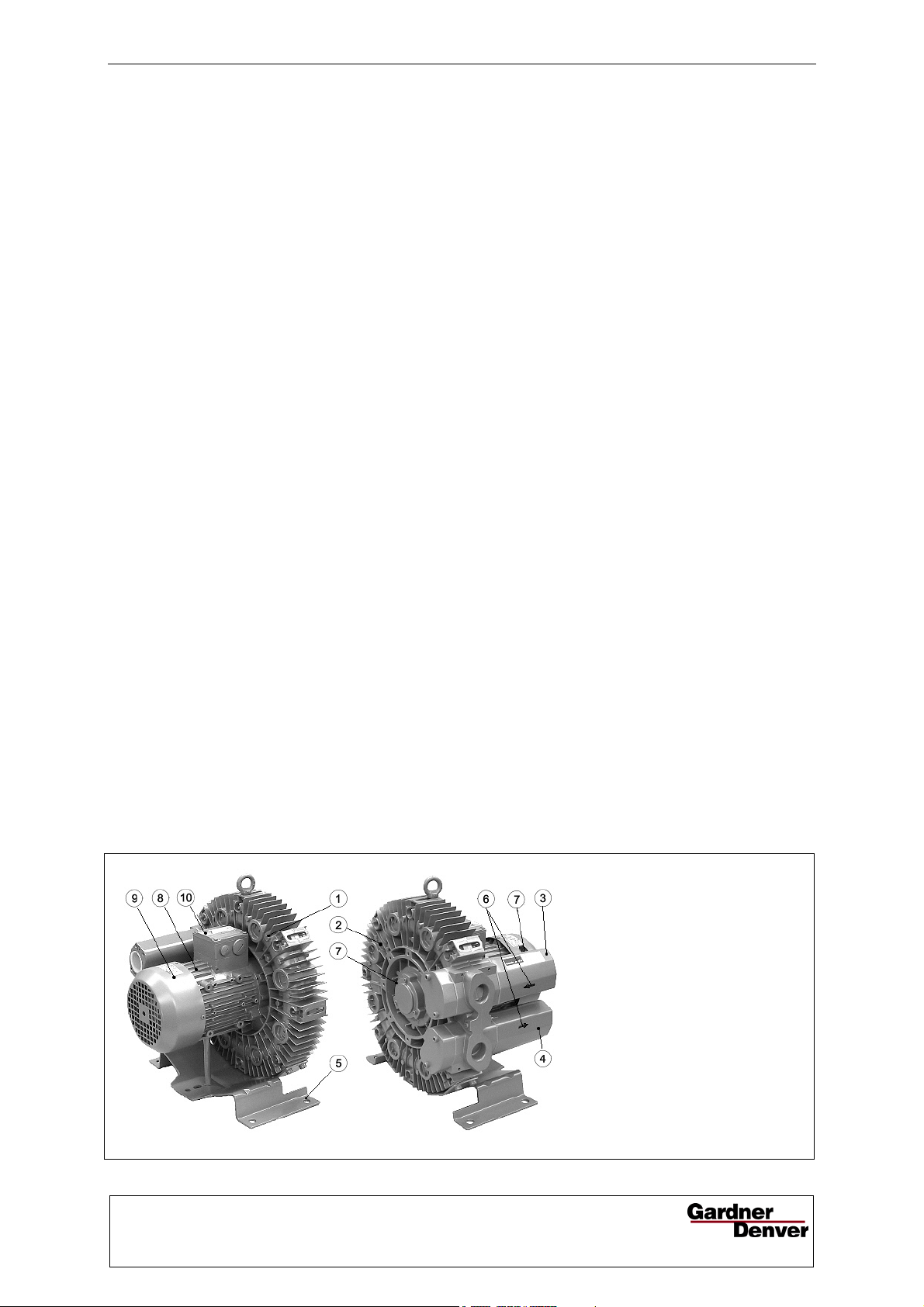

Fig. 1: Design of gas-ring

vacuum

pump/compressor

1 Vacuum pump/compressor

housing

2 Vacuum pump/compressor cover

3 Inlet connection with muffler

4 Discharge connection with

muffler

5 Base

6 Flow direction arrow

7 Rotating direction arrow

8 Drive motor

9 Fan guard (over external fan)

10 Terminal box

© 2009 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Germany

Replication, distribution and / or editing of this document and the use and distribution of its content is

prohibited unless explicitly permitted. Violation obligates compensation for damages.

All rights reserved in case of the issue of a patent, utility patent or design patent.

Page 3

1 Safety

1.1 Definitions

To point out dangers and important information,

the following signal words and symbols are used

in these operating instructions:

1.1.1 Safety alert symbol

The safety alert symbol is located in the

safety precautions in the highlighted heading field

on the left next to the signal word (DANGER,

WARNING, CAUTION).

Safety precautions with a safety alert symbol

indicate a danger of injuries.

Be sure to follow these safety precautions to

protect against injuries or death!

Safety precautions without a safety alert symbol

indicate a danger of damage.

1.1.2 Signal words

DANGER

WARNING

CAUTION

NOTICE

NOTE

Danger of injuries.

Indicates an imminently hazardous situation,

that will result in death or serious injury if the

corresponding measures are not taken.

Danger of injuries.

Indicates a potentially hazardous situation, that

could result in death or serious injury if the

corresponding measures are not taken.

Danger of injuries.

Indicates a potentially hazardous situation, that

may result in minor or moderate injury if the

corresponding measures are not taken.

The signal words are located in

the safety precautions in the

highlighted heading field.

They follow a certain hierarchy and

indicate (in conjunction with the

safety alert symbol, see

Chapter 1.1.1) the seriousness of

the danger and the type of

warning.

See the following explanations:

DANGER

WARNING

CAUTION

Safety

CAUTION

Danger of damage.

Indicates a potentially hazardous situation that

may result in property damage if the

corresponding measures are not taken.

NOTICE

Indicates a possible disadvantage, i.e.

undesirable conditions or consequences can

occur if the corresponding measures are not

taken.

NOTE

Indicates a possible advantage if the

corresponding measures are taken; tip.

1.2 General safety precautions

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

These operating instructions

must have been read completely and

understood before beginning any work with

or at the pump-motor unit,

must be strictly observed,

must be available at the operating location of

the pump-motor unit.

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Only operate the pump-motor unit

for the purposes indicated under "Intended

Use"!

with the fluids indicated under 'Intended Use'!

with the values indicated under 'Technical

Data'!

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

All work on and with the pump-motor unit

(transport, installation, operation, shut-down,

maintenance, disposal) may only be carried out

by trained, reliable expert personnel!

© Gardner Denver Deutschland GmbH 3 / 28 610.44436.40.000

Page 4

Safety

WARNING

When working on the pump-motor unit, there

is a danger of injury, e.g. in the form of

cuts/cutting off, crushing and burns!

During all work on and with the pump-motor unit

(transport, installation, operation, shut-down,

maintenance, disposal) wear personal safety

equipment (safety helmet, protective gloves,

safety shoes)!

WARNING

Hair and clothing can be pulled into the unit

or caught and wound up moving parts!

Do not wear long, loose hair or wide, loose

clothes! Wear a hair net!

DANGER

Electrical danger!

Work on electrical installations may be carried

out by trained and authorized electricians only!

DANGER

Electrical danger!

Before beginning work on the unit or system, the

following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

DANGER

Electrical danger!

Do not open the motor terminal box until

absence of electricity has been ensured!

WARNING

Danger due to vacuum and gauge pressure:

sudden escape of fluids (skin and eye

injuries),

sudden drawing in of hair and clothing!

Danger due to escaping fluid:

Burns!

Use mounting elements, connections, lines,

fittings and containers with sufficient freedom

from leaks and strength for the pressures which

occur.

Check the mounting elements, connections,

lines, fittings and containers for strength, leaks

and firm seating at regular intervals!

WARNING

Danger from rotating parts (external fan,

impeller, shaft):

Cutting/cutting off of extremities,

Grasping/winding up of hair and clothing!

Danger due to vacuum and gauge pressure:

sudden escape of fluids (skin and eye

injuries),

sudden drawing in of hair and clothing!

Danger due to escaping fluid:

Burns!

Start-up

and operation only under the following

conditions:

The pump-motor unit must be completely

assembled. When doing so, pay particular

attention to the following components:

– the vacuum pump/compressor cover,

– the muffler on inlet and discharge

connections,

– the fan guard.

The pipes/hoses must be connected to inlet

and discharge connections.

Inlet and discharge connections and the

connected pipes/hoses may not be closed,

clogged or soiled.

Check the mounting elements, connections

of the pipe/hose connections, lines, fittings

and containers for strength, leaks and firm

seating at regular intervals.

610.44436.40.000 4 / 28 © Gardner Denver Deutschland GmbH

Page 5

Safety

WARNING

Danger from rotating parts (external fan,

impeller, shaft):

Cutting/cutting off of extremities,

Grasping/winding up of hair and clothing!

Danger due to vacuum and gauge pressure:

sudden escape of fluids (skin and eye

injuries),

sudden drawing in of hair and clothing!

Danger due to escaping fluid:

Burns!

Before beginning work on the pump-motor unit

,

take the following measures:

Shut down pump-motor unit and secure

against being switched on again.

Attach a sign on the system controller and on

the control elements for the pump-motor unit:

"DANGER! Maintenance work on vacuum

pump/compressor! Do not switch on!"

Wait for pump-motor unit to come to a

complete stop. Observe run-on time!

Allow pump-motor unit to cool!

Shut-off lines. Release pressure.

Make sure that no vacuum or gauge pressure

is present in the lines/tanks to be opened.

Make sure that no fluids can escape.

WARNING

Danger from rotating impeller:

Cutting/cutting off of extremities!

The rotating impeller is accessible with the inlet

and discharge connections open!

Do not reach into the unit through open

connections!

Do not insert objects into the unit through the

openings!

WARNING

Danger from rotating impeller:

Cutting/cutting off of extremities!

The rotating impeller is accessible with the inlet

and discharge connections open!

With free entry and exit of gases, i.e. with direct

intake out of or direct feeding into the

atmosphere without piping, the following

therefore applies:

Provide the inlet and discharge connections of

the pump-motor unit either with additional

mufflers or with additional piping of a sufficient

length to prevent access to the impeller!

WARNING

Danger of burns from hot surfaces of the

pump-motor unit and from hot fluids!

High temperatures of up to approx. +160°C

[+320°F] can occur on the surface of the pumpmotor unit.

Cover the pump-motor unit with a suitable touch

protection (e.g. perforated plate cover or wire

cover).

Do not touch during operation!

Allow to cool after shut-down!

© Gardner Denver Deutschland GmbH 5 / 28 610.44436.40.000

Page 6

Safety

1.3 Residual risks

WARNING

Danger zone:

Hot surface up to approx. +160°C [+320°F]

Hazard:

Possible burns.

Protective measures:

Cover the pump-motor unit with a suitable touch

protection (e.g. perforated plate cover or wire

cover).

WARNING

Danger zone:

Fan guard

Hazard:

Long, loose hair can be drawn into external fan

through fan guard grate, even with fan guard

mounted!

Protective measures:

Wear hair net!

WARNING

Danger zone:

Missing or defective muffler inlet or discharge

connection.

Hazard:

Possible serious hearing damage due to emitted

noise.

Protective measures:

Have missing or defective mufflers replaced.

Conduct a noise measurement in the system

after installing the pump-motor unit.

The following measures must be taken by the

operator:

from 85 dB(A):

– Hearing protection must be provided.

from 90 dB(A):

– Mark noise area with a warning sign.

– Wear hearing protection.

WARNING

Danger zone:

Environment of pump-motor unit.

Hazard:

Possible serious hearing damage due to emitted

noise.

Protective measures:

Conduct a noise measurement in the system

during operation after installing the pump-motor

unit.

The following measures must be taken by the

operator:

from 85 dB(A):

– Hearing protection must be provided.

from 90 dB(A):

– Mark noise area with a warning sign.

– Wear hearing protection.

– With free entry and exit of gases, i.e. with

direct intake out of or direct feeding into

the atmosphere without piping, attach an

additional muffler.

610.44436.40.000 6 / 28 © Gardner Denver Deutschland GmbH

Page 7

2 Intended Use

These operating instructions

apply to gas-ring vacuum pumps/compressors

of the G-BH7 series, models 2BH72, 2BH73,

2BH74, 2BH75 and 2BH76,

contains instructions concerning transport and

handling, installation, commissioning,

operation, shut-down, storage, servicing and

disposal of the G-BH7,

must be completely read and understood by

all operating and servicing personnel before

beginning to work with or on the G-BH7,

must be strictly observed,

must be available at the site of operation of

the G-BH7.

About the operating and servicing personnel of

the G-BH7

These persons must be trained and

authorized for the work to be carried out.

Work on electrical installations may be carried

out by trained and authorized electricians

only.

The G-BH7s

are pump-motor units for generating vacuum

or gauge pressure;

are used to extract, pump and compress

the following gases:

– Air,

– Non-flammable, non-aggressive, non-toxic

and non-explosive gases or gas-air

mixtures.

– For differing gases/gas-air mixtures,

inquire with the Service Department.

are equipped with one of the following kind of

drive motors:

– 3-phase AC drive motor with a standard or

explosion-protected design

– Single-phase AC drive motor

These operating instructions apply only to

pump-motor units with a standard design.

For the explosion-protected design

the separate operating instructions.

exist in the following designs:

– single-impeller (single-stage)

– two-impeller (two-stage)

– three-impeller (three-stage)

Increased pressure differences can be

achieved with the two-impeller and threeimpeller pump-motor units.

, see

Intended Use

are primarily intended for higher pressure

conditions;

are designed for continuous operation.

With increased switch-on frequency (at equal

intervals of approx. 5x per hour) or increased

gas entry and ambient temperature, the over

temperature of the winding and the bearings

can be exceeded.

Consultation with the Service Department is

required for operating conditions of this kind.

When operating the G-BH7, the limits listed in

Chapter 3, "Technical Data", Pg. 8 ff. must

always be complied with.

Foreseeable Misuse

It is prohibited

to use the G-BH7 in applications other than

industrial applications unless the necessary

protection is provided on the system, e.g.

guards suitable for children's fingers;

to use the device in rooms in which explosive

gases can occur if the G-BH7 is not expressly

intended for this purpose;

to extract, to deliver and to compress

explosive, flammable, corrosive or toxic fluids,

unless the G-BH7 is specifically designed for

this purpose;

to operate the G-BH7 with values other than

those specified in Chapter 3, "Technical

Data", Pg. 8 ff.

Any unauthorized modifications of the G-BH7 are

prohibited for safety reasons.

The operator is only permitted to perform the

maintenance and service work described in these

operating instructions.

Any maintenance and service work which goes

beyond this many only be performed by

companies authorized by the manufacturer

(inquire with the Service Department).

are intended for industrial applications,

© Gardner Denver Deutschland GmbH 7 / 28 610.44436.40.000

Page 8

Technical Data

3 Technical Data

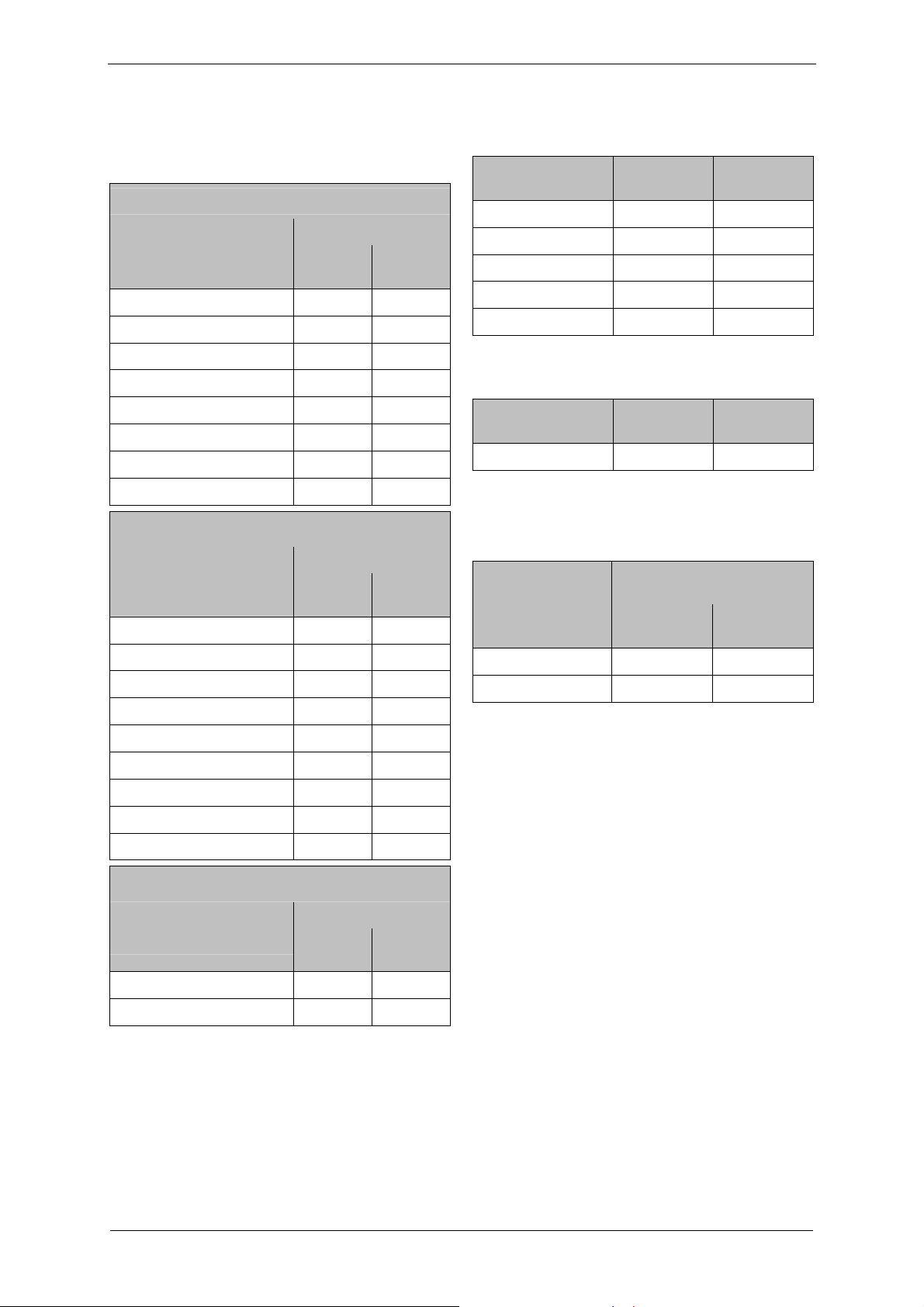

3.1 Mechanical data

Weight

Single-impeller design

Model Weight

[kg]

approx.

2BH7210-0..1.-.

2BH7310-0..1.-.

2BH7310-0..2.-.

2BH7410-0..1.-.

2BH7510-0..1.-.

2BH7510-0..2.-.

2BH7610-0..1.-.

2BH7610-0..3.-.

Two-impeller design

Model Weight

[kg]

2BH7220-0..2.-.

2BH7220-0..5.-.

2BH7320-0..5.-.

2BH7420-0..2.-.

2BH7420-0..5.-.

2BH7520-0..2.-.

2BH7520-0..7.-.

2BH7620-0..3.-.

2BH7620-0..5.-.

Three-impeller design

Model Weight

[kg]

2BH7530-0..8.-.

2BH7630-0..6.-.

16

16

17

23

26

29

32

35

approx.

24

28

30

33

39

40

51

48

65

approx.

68

94

[lbs]

approx.

35

35

38

51

57

64

71

77

[lbs]

approx.

53

62

66

73

86

88

112

106

143

[lbs]

approx.

150

207

Minimum distances

Minimum distance to fan guard (for sucking in

cooling air):

Model [mm]

approx.

2BH72

2BH73

2BH74

2BH75

2BH76

34

34

52

52

53

[inches]

approx.

1.34

1.34

2.05

2.05

2.09

Minimum distance to face of vacuum

pump/compressor cover:

Model [mm]

approx.

2BH7…

30

[inches]

approx.

1.18

Vibrations

The following table provides information on the

maximum permissible loading due to vibrations.

Model Vibration velocity

V

eff

[mm/s]

≤

2BH72.. - 2BH75..

2BH76..

3.0

3.5

[ft/s]

≤

0.010

0.011

610.44436.40.000 8 / 28 © Gardner Denver Deutschland GmbH

Page 9

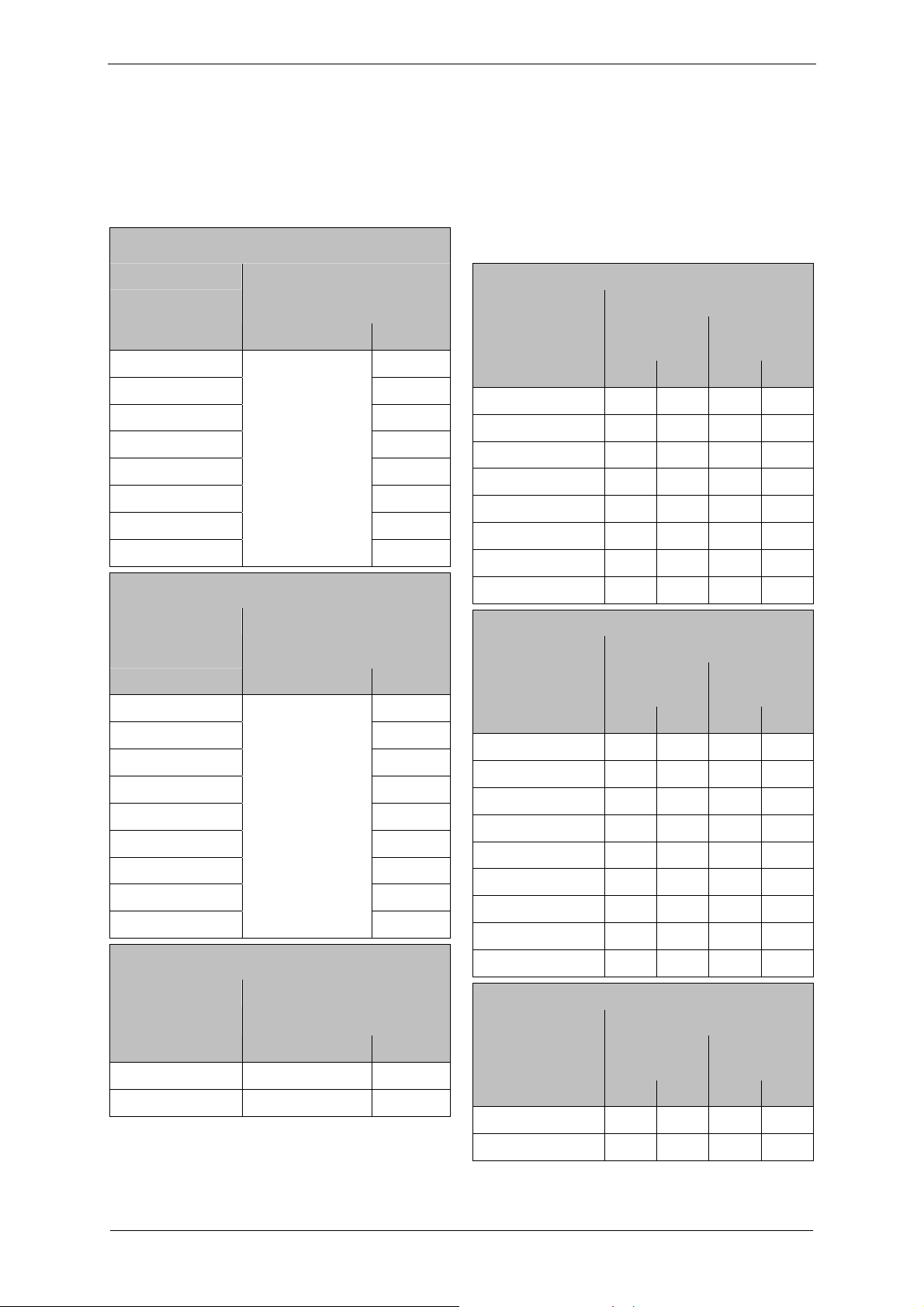

Noise level

Technical Data

Temperature increase

Measuring-surface sound-pressure level as per

EN ISO 3744, measured at a distance of 1 m

[3.28 ft] at an operating point of approximately

2/3 of the permissible total pressure difference

with the lines connected without a vacuum or

pressure relief valve, tolerance ±3 dB (A).

The information listed in the following tables

corresponds to the heating of vacuum

pump/compressor housings and the air exiting

compared to the ambient temperature during

operation with a permissible total pressure

difference and an air pressure of 1,013 mbar

[14.7 psi]. At lower air pressures these values

Single-impeller design

Model 1-m measuring-surface

sound pressure level L

[dB (A)]

50 Hz 60 Hz

2BH7210-0..1.-. 70

2BH7310-0..1.-. 70

2BH7310-0..2.-. 70

2BH7410-0..1.-. 70

70

2BH7510-0..1.-. 70

2BH7510-0..2.-. 70

2BH7610-0..1.-. 71

2BH7610-0..3.-.

71

Two-impeller design

Model 1-m measuring-surface

sound pressure level L

[dB (A)]

50 Hz 60 Hz

2BH7220-0..2.-. 70

2BH7220-0..5.-. 70

2BH7320-0..5.-. 70

2BH7420-0..2.-. 70

2BH7420-0..5.-. 70

70

2BH7520-0..2.-. 70

2BH7520-0..7.-. 71

2BH7620-0..3.-. 71

2BH7620-0..5.-.

72

Three-impeller design

Model

1-m measuring-surface

sound pressure level L

[dB (A)]

50 Hz 60 Hz

2BH7530-0..8.-. 67 73

2BH7630-0..6.-. 77 80

© Gardner Denver Deutschland GmbH 9 / 28 610.44436.40.000

increase.

Single-impeller design

Model Temperature increase

2BH7210-0..1.-.

2BH7310-0..1.-.

2BH7310-0..2.-.

2BH7410-0..1.-.

2BH7510-0..1.-.

2BH7510-0..2.-.

2BH7610-0..1.-.

2BH7610-0..3.-.

∆T [K]

approx.

∆ [F]

approx.

50 Hz 60 Hz 50 Hz 60 Hz

52 61

61 61

81 86

90 101

93 111

120 112

118 124

118 124

94 110

110 110

146 155

162 182

167 200

216 202

212 223

212 223

Two-impeller design

Model Temperature increase

2BH7220-0..2.-.

2BH7220-0..5.-.

2BH7320-0..5.-.

2BH7420-0..2.-.

2BH7420-0..5.-.

2BH7520-0..2.-.

2BH7520-0..7.-.

2BH7620-0..3.-.

2BH7620-0..5.-.

∆T [K]

approx.

∆ [F]

approx.

50 Hz 60 Hz 50 Hz 60 Hz

55 77

74 110

81 124

89 80

121 117

89 102

125 110

124 126

124 128

99 139

133 198

146 223

160 144

218 211

160 184

225 198

223 227

223 230

Three-impeller design

Model Temperature increase

2BH7530-0..8.-.

2BH7630-0..6.-.

∆T [K]

approx.

∆ [F]

approx.

50 Hz 60 Hz 50 Hz 60 Hz

120 120

120 120

216 216

216 216

Page 10

Technical Data

Tightening torques for screw connections

The following values apply if no other information

is available.

With non-electrical connections, property classes

of 8.8 and 8 or higher as per ISO 898-1 are

assumed.

Tightening torques for

non-electrical

Thread [Nm] [ft lbs]

M4

M5

M6

M8

21.6 - 26.4

connections

2.7 - 3.3

3.6 - 4.4

7.2 - 8.8

1.99 - 4.44

2.65 - 3.25

5.31 - 6.5

15.9 - 19.5

Thread [Nm] [ft lbs]

M12x1,5

M16x1,5

M25x1,5

M32x1,5

M40x1,5

Tightening torques for plastic

threaded

glands/unions

2 - 3.5

3 - 4

4 - 5

5 - 7

1.48 - 2.58

2.21 - 2.95

2.95 - 3.69

3.69 - 5.16

M10

M12

The following information for electrical connection

applies to all terminal board connections with the

exception of terminal strips.

37.8 - 46.2

63.0 - 77.0

27.9 - 34.1

46.5 - 56.8

Tightening torques for

electrical

Thread [Nm] [ft lbs]

connections

M4

M5

Especially for metal and plastic threaded cable

glands and pipe unions, the following values

apply:

0.8 - 1.2

1.8 - 2.5

0.59 - 0.89

1.33 - 1.84

Tightening torques for metal

threaded

Thread [Nm] [ft lbs]

M12x1,5

M16x1,5

M25x1,5

M32x1,5

M40x1,5

glands/unions

4 - 6

5 - 7.5

6 - 9

8 - 12

2.95 - 4.43

3.69 - 5.53

4.43 - 6.64

5.9 - 8.85

610.44436.40.000 10 / 28 © Gardner Denver Deutschland GmbH

Page 11

3.2 Electrical data

Technical Data

Pressures

See rating plate.

3.3 Operating conditions

Temperatures

Temperature of

pumped gases:

max. permissible temperature:

+40°C

Nominal value:

+15°C

Pump-motor units for higher fluid

temperatures on request.

Ambient

temperature

(standard

design)

1

:

max. permissible temperature:

+40°C

min. permissible temperature:

-15°C

Nominal value:

+25°C

Ambient temperatures between

25°C [+77°F] and 40°C [+104°F]

affect the permissible total

pressure difference (see Section

"Permissible total pressure

difference").

At higher temperatures the

winding may be damaged and

the grease change interval may

be shortened.

[+104°F]

[+59°F]

[+104°F]

[+5°F]

[+77°F]

Min. inlet

See rating plate.

pressure:

Max. discharge

See rating plate.

pressure during

compressor

operation:

Max. permissible

pressure in

pump-motor unit:

2.5 bar abs. [36.2 psia]

At this pressure the operation of

the pump-motor unit may be

considerably impaired.

Provide a corresponding

protective device (e.g. pressure

relief valve) if necessary.

Permissible total

pressure

difference:

The total pressure difference

specified on the rating plate only

applies under the following

conditions:

Ambient temperature:

Inlet temperature

Pressure:

At an ambient temperature of

40°C [104°F] the total pressure

difference specified on the rating

plate must be reduced by 10%.

If the ambient temperature is

between 25°C [77°F] and 40°C

[104°F], then the total pressure

difference specified on the rating

plate must be reduced linearly to

the temperature by between 0

and 10 %.

Installation altitude

25°C [77°F].

(temperature of pumped

gases at inlet connection):

15°C [59°F].

during vacuum-pump

operation:

1,013 mbar [14.7 psia] at

discharge connection;

during compressor

operation:

1,013 mbar [14.7 psia] at

inlet connection;

Max. of 1,000 m [3,280 ft] above sea level.

When installing the pump-motor unit at an

altitude of more than 1,000 m [3,280 ft] above

sea level, first inquire with the Service

department.

1

For design with frequency converter, see

separate operating instructions.

© Gardner Denver Deutschland GmbH 11 / 28 610.44436.40.000

Page 12

Transport and Handling

4 Transport and Handling

The transport must be carried out in different

ways depending on the model:

WARNING

Tipping or falling can lead to crushing,

broken bones etc.!

Sharp edges can cause cuts!

Wear personal safety equipment (gloves, safety

shoes and protective helmet) during transport!

WARNING

Danger from tipping or falling loads!

Prior to transport and handling make sure that

all components are securely assembled and

secure or remove all components the fasteners

of which have been loosened!

Manual handling:

WARNING

Danger from lifting heavy loads!

Manual handling of the unit is only permitted

within the following limits:

max. 30 kg [max. 66 lbs] for men

max. 10 kg [max. 22 lbs] for women

max. 5 kg [max. 11 lbs] for pregnant women

For the weight of the pump-motor unit, see

Chapter 3.1, "Mechanical data",

Section "Weight", Pg. 8.

For weights above the given values use suitable

lifting appliances and handling equipment!

Handling by means of lifting equipment:

WARNING

Danger from tipping or falling loads!

When transporting with lifting equipment,

observe the following basic rules:

The lifting capacity of lifting equipment and

lifting gear must be at least equal to the unit's

weight.

For the weight of the pump-motor unit, see

Chapter 3.1, "Mechanical data",

Section "Weight", Pg. 8.

The pump-motor unit must be secured so

that it cannot tip or fall.

Do not stand or walk under suspended loads!

Models 2BH72., 2BH73., 2BH74. [single-

impeller] and 2BH75. [single-impeller]:

Manual handling

Models 2BH74. [two-impeller], 2BH75. [two-

impeller] and 2BH76.:

Transport with crane, hooked onto eye bolt

(1 attachment point)

For transport with a crane, the pump-motor unit

can be hooked onto the crane hook as follows:

directly on the eye bolt

or possibly

with lifting belts.

Eye bolt:

All models are equipped with an eye bolt. The

eye bolt is mounted on the vacuum

pump/compressor housing.

In case of possible removal and remounting of

the eye bolt, it must be ensured that the eye level

is positioned exactly in the axis direction of the

pump-motor unit. Lay shims under the eye bolt if

necessary.

The eye bolt must be firmly tightened.

Loads laterally to the ring level are not

permissible. Heavy impact loads during transport

must be avoided.

610.44436.40.000 12 / 28 © Gardner Denver Deutschland GmbH

Page 13

5 Installation

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Have you read the safety precautions in Chapter

1, "Safety", pg. 3 f.?

Otherwise you many not carry out any work with

or on the pump-motor unit!

DANGER

Danger from missing view into area of pumpmotor unit!

When operating the control elements without a

view into the area of the pump-motor unit, there

is a danger that the pump-motor unit will be

switched on while other persons are still

performing work on it. Extreme injuries are

possible!

Provide control elements at a location with a

view of the pump-motor unit.

DANGER

Electrical danger!

The pump-motor unit must be installed so that

the electrical device cannot be damaged by

external influences!

In particular, the feed pipes must be securely

routed, e.g. in cable ducts, in the floor etc.

WARNING

Danger from balance damage caused by

vibration!

Vibrating environments can cause balance

damage!

Install the pump-motor unit on a solid foundation

or on a solid mounting surface.

Check screw glands/unions for mounting the

pump-motor unit on the mounting surface

regularly for strength and firm seating.

WARNING

Danger from crushing due to pump-motor

unit tipping over!

Wear personal safety equipment (protective

gloves and safety shoes).

Handle the unit with the appropriate care.

Install the pump-motor unit on a solid foundation

or on a solid mounting surface!

Check screw glands/unions for mounting the

pump-motor unit on the mounting surface

regularly for strength.

Installation

WARNING

Danger of fire from flammable substances!

The pump-motor unit must never come into

contact with flammable substances.

For exact information on the temperature

increase, see Chapter 3.1, "Mechanical data",

Section "Temperature increase", Pg. 9.

WARNING

Danger of burns from hot surfaces of the

pump-motor unit and from hot fluids!

High temperatures of up to approx. +160°C

[+320°F] can occur on the surface of the pumpmotor unit.

The pump-motor unit must be installed so that

accidental touch of its surface is not possible.

Cover the pump-motor unit with a suitable touch

protection (e.g. perforated plate cover or wire

cover).

WARNING

Danger of injuries from flying parts!

Select installation so that parts that are thrown

out through the grate if the external fan breaks

cannot hit persons!

CAUTION

Danger of tripping and falling!

Make sure the unit does not present a danger of

tripping.

Lay cables and pipes so that they cannot be

reached during operation(recessed in floor, in

ducts on the wall etc.).

CAUTION

Danger of overheating due to hot surface of

pump-motor unit!

High temperatures can occur on the surface of

the pump-motor unit.

Temperature sensitive parts, such as lines or

electronic components, may not come into

contact with the surface of the pump-motor unit.

© Gardner Denver Deutschland GmbH 13 / 28 610.44436.40.000

Page 14

Installation

The pump-motor unit is ready to connect on

delivery.

The drive motors of the pump-motor units have

the following design:

However, if the time from delivery to

commissioning of the pump-motor unit exceeds a

certain period, the lubrication of the rolling

bearings must be renewed.

See Chapter 8.2, "Storage conditions",

Section "Lubrication of rolling bearings after

longer storage", Pg. 23 for information on this

topic.

Carry out the following work to install the pumpmotor unit:

Installation and securing,

Attachment of the included loose muffler if

necessary,

Attachment of threaded flange or hose flange

(available as accessories)

for the connection of inlet or discharge pipe to

the muffler,

Electrical connection,

Connection of inlet and discharge connection

to the system.

5.1 Installation

WARNING

For an installation that differs from the following

specifications, it is necessary to inquire with the

Service Department!

Ambient conditions:

The pump-motor unit is suitable for installation in

the following environments:

In a dusty or damp environment,

in buildings,

in the open.

When properly installed in the open, the

pump-motor unit must be protected from

exposure to intensive sunlight, e.g. by

attaching a protective roof. Otherwise, no

special protective devices against the effects

of weathering are required.

NOTICE

The maximum permissible loading due to

vibrations may not be exceeded!

See Chapter 3.1, "Mechanical data",

Section "Vibrations", Pg. 8 for information on

this topic.

with degree of protection IP55 (see rating

plate),

with tropicalized insulation.

Installation conditions:

The pump-motor unit must be installed as

follows:

on level surfaces,

at a maximum height of 1000 m [3,280 ft]

above sea level.

When installing at an altitude of more than

1,000 m [3,280 ft]above sea level, first inquire

with the Service Department.

Minimum distance:

To ensure sufficient cooling of the pump-motor

unit, it is absolutely necessary that the required

minimum distances to the fan guard and to the

face of the vacuum pump/compressor cover

be maintained.

See Chapter 3.1, "Mechanical data",

Section "Minimum distances", Pg. 8.

The compliance of the specified minimum

distance to the face of the vacuum

pump/compressor cover is especially important

when installing on the vacuum pump/compressor

cover or near a wall.

CAUTION

To ensure sufficient cooling of the pump-motor

unit, also observe the following:

Ventilation screens and openings must

remain clear.

Discharge air of other units may not be

directly sucked in again!

Noise radiation:

To reduce the noise radiation, the following must

be observed:

Do not mount pump-motor unit on noise-

conducting or noise-radiating parts (e.g. thin

walls or sheet-metal plates).

Provide pump-motor unit with sound-insulating

intermediate layers (e.g. rubber buffers under the

base of the pump-motor unit) if necessary.

Install the pump-motor unit on a stable

foundation or on a rigid mounting surface.

This provides for smooth, low-vibration

running of the pump-motor unit.

610.44436.40.000 14 / 28 © Gardner Denver Deutschland GmbH

Page 15

Installation

Components for reducing noise on the pumpmotor unit:

Mufflers (included as standard equipment):

On delivery the pump-motor units are

equipped with attached mufflers as standard.

The noise radiation is considerably reduced

by the mufflers. See Fig. 2 to Fig. 4, Pg. 18 ff.

Additional mufflers (available as an option):

The additional mufflers enable a further noise

reduction. They may only be used with free

entry and exit of gases, i.e. with direct intake

out of or direct feeding into the atmosphere

without piping.

Noise protection hoods (available as an

option):

Noise protection hoods are suitable for

installation in rooms and in the open. They

reduce both the total sound pressure level

and tonal components that are perceived as

particularly annoying.

Installation variants/axis position:

Basically, when installing the pump-motor unit,

Vertical installation on the vacuum

pump/compressor cover ("cover installation")

With vertical installation of the pump-motor unit

with the vacuum pump/compressor cover facing

downward, rubber feet must be used.

Proceed as follows:

The rubber feet are available as accessories.

They are delivered in a set of 3.

On the upper section they are provided with

stud bolts and on the lower section with a

threaded hole.

Mount the rubber feet on the pump-motor unit:

Screw the stud bolts of the rubber feed into

the holes on the face of the vacuum

pump/compressor cover and tighten them.

Mount the pump-motor unit together with the

rubber feet on the installation surface:

Select suitable mounting elements for the

threaded hole.

Screw the rubber feet to the surface or

foundation via the threaded hole.

Vertical mounting on the wall

the following variants are possible with a different

axis position (horizontal or vertical):

Horizontal installation

Vertical installation on the vacuum

pump/compressor cover ("cover installation")

Vertical mounting on the wall.

Basically, all variants are possible with all

models.

However, a distinction must be made between a

design with and a design without a condensed

water opening for the axis position:

The pump-motor units without a condensed

water opening can be installed and secured in

any axis position.

The pump-motor unit with a condensed water

opening may only be installed and secured

horizontally with the base at the bottom.

With vertical mounting of the pump-motor unit on

the wall, the pump-motor unit is mounted via the

holes in the base.

Proceed as follows:

Position the pump-motor unit as close to the

wall as possible on a stable supporting plate

with sufficient load-bearing capacity.

The pump-motor unit must be positioned with

the base toward the wall.

Provide the base of the pump-motor unit with

mounting holes.

Select the suitable screw type.

Screw the base of the pump-motor unit to the

wall with the screws.

When doing so, be sure to provide all

mounting holes with screws!

Remove the supporting plate.

Eye bolt:

Horizontal installation

Following installation, the eye bolt must be either

Screw the base of the pump-motor unit to the

surface with suitable mounting elements.

Proceed as follows:

Provide the base of the pump-motor unit with

mounting holes.

Select the suitable screw type.

Screw the base of the pump-motor unit to the

surface with the screws.

When doing so, be sure to provide all

mounting holes with screws!

firmly tightened or removed.

© Gardner Denver Deutschland GmbH 15 / 28 610.44436.40.000

Page 16

Installation

5.2 Electrical connection (motor)

Connection to drive-motor terminal box:

DANGER

Electrical danger!

Improper behavior can result in severe injuries

and material damage!

DANGER

Electrical danger!

The electrical connection may be carried out by

trained and authorized electricians only!

DANGER

Electrical danger!

Before beginning work on the unit or system, the

following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

CAUTION

Incorrect connection of the motor can lead to

serious damage to the unit!

Regulations:

Open the required cable entry openings on the

terminal box. Here the following two cases are

differentiated:

The cable entry opening is prefabricated and

provided with a sealing plug.

Screw out sealing plug.

OR

The cable entry opening is closed off with a

casting skin (only on pump-motor units with

drive-motor axis heights of 100 to 160 in

standard design).

Break out casting skin using a suitable tool.

For example, use a metal pin with a

corresponding diameter or a chisel and

hammer.

CAUTION

When pounding out the casting skin on the

cable entry openings in the terminal box, the

terminal box or its parts can be damaged (e.g.

terminal board, cable connections).

Proceed with suitable caution and precision

when doing so!

Prevent flash formation!

Mount cable glands on the terminal box. Proceed

as follows:

Select one cable gland in each case which is

The electrical connection must be carried out as

follows:

according to the applicable national and local

laws and regulations,

according to the applicable system-dependent

prescriptions and requirements,

according to the applicable regulations of the

utility company.

Electrical power supply:

Observe the rating plate.

It is imperative that the operating conditions

correspond to the data given on the rating plate!

Deviations permissible without reduction in

performance:

±5 % voltage deviation

±2 % frequency deviation

suitable for the cable diameter.

Insert this cable gland in the opening of the

terminal box.

Use a reducer if necessary.

Screw on the cable gland so that no moisture,

dirt etc. can penetrate into the terminal box.

Carry out the connection and the arrangement of

the jumpers in accordance with the circuit

diagram in the terminal box.

Connect the protective conductor to the terminal

with the following symbol:

.

The electrical connection must be carried out as

follows:

The electrical connection must be

permanently safe.

There may be no protruding wire ends.

Clearance between bare live parts and

between bare live parts and ground: ≥ 5.5 mm

(at a nominal voltage of U

≤ 690V).

N

610.44436.40.000 16 / 28 © Gardner Denver Deutschland GmbH

Page 17

For the tightening torques for terminal board

connections (except terminal strips), see

Chapter 3.1, "Mechanical data",

Section "Tightening torques for screw

connections", Pg. 10.

For terminals with clamping straps (e.g. as per

DIN 46282), the conductors must be inserted

so that approximately the same clamping

height results on both sides of the bar.

Individual conductors must therefore be bent

into a U-shape or connected with a cable lug

(DIN 46234).

This also applies to:

the protective conductor,

the outer ground conductor.

Both conductors can be recognized from their

color (green/yellow).

DANGER

Electrical danger!

The terminal box must be free from

foreign bodies,

dirt,

humidity.

Terminal box cover and cable entries must be

tightly closed so as to make them dustproof and

waterproof. Check for tightness at regular

intervals.

DANGER

Electrical danger!

Clearance between bare live parts and between

bare live parts and ground:

at least 5.5 mm (at a nominal voltage of

U

≤ 690V).

N

There may be no protruding wire ends!

For motor overload protection:

Use motor circuit breakers.

This must be adjusted to the specified

nominal current (see rating plate).

DANGER

Electrical danger!

There is danger of an electrical shock when a

defective pump-motor unit is touched!

Mount motor circuit breaker.

Have electrical equipment checked regularly by

an electrician.

Installation

Interference immunity of drive motor:

For drive motors with integrated sensors, the

operator must provide for a sufficient interference

immunity itself. Select a suitable sensor signal

cable (e.g. with screening, connection as for a

motor power-supply cable) and analyzing unit.

Operation with frequency converter:

With a power supply by external frequency

converters, the following must be observed:

High-frequency current and voltage harmonics

in the motor supply cables can lead to emitted

electromagnetic interference. This is

dependent on the converter design (model,

manufacturer, interference suppression

measures).

Be sure to observe the EMC notes of the

converter manufacturer!

Use screened power supply cables if

necessary. For optimal screening, the screen

must be conductively connected over a large

area to the metal terminal box of the drive

motor with a screwed metal gland.

In the case of drive motors with integrated

sensors (e.g. PTC thermistors) interference

voltage can occur on the sensor cable

depending on the converter model.

Limit speed:

see specifications on the rating plate.

WARNING

Pump-motor units with a UL approbation may

not be operated on frequency converters in the

US without testing by a suitable test agency!

© Gardner Denver Deutschland GmbH 17 / 28 610.44436.40.000

Page 18

Installation

5.3 Connecting pipes/hoses (vacuum

pump/compressor)

Mufflers:

The pump-motor units are delivered with mufflers

(indicated with arrows in the following

illustrations) for the inlet and discharge

connections as standard equipment.

With single-impeller pump-motor units, the

mufflers are already mounted on delivery.

WARNING

Danger from rotating impeller:

Cutting/cutting off of extremities!

The rotating impeller is accessible with the inlet

and discharge connections open!

With free entry and exit of gases, i.e. with direct

intake out of or direct feeding into the

atmosphere without piping, the following

therefore applies:

Provide the inlet and discharge connections of

the pump-motor unit either with additional

mufflers or with additional piping of a sufficient

length to prevent access to the impeller!

Connections:

Fig. 2: 2BH721 ... 2BH761 (single-impeller pump-

motor units)

With two-impeller and three-impeller pumpmotor units, the inlet-side muffler is included

loose for packaging-related reasons and must be

mounted by the operator.

Fig. 3: 2BH722 ... 2BH762 (two-impeller pump-

motor units with two-stage design)

Fig. 4: 2BH723 ... 2BH763 (three-impeller pump-

motor units with three-stage design)

To prevent foreign bodies from entering the unit,

all connections are sealed off when delivered. Do

not remove the sealing plugs until immediately

before connecting the pipes/hoses.

The following applies for the arrangement of the

pipe/hose connections:

The pumped gases are sucked in via the inlet

connection (see Chapter 5.3.1, Pg. 19) and

discharged via the discharge connection

(see

Chapter 5.3.2, Pg. 19).

The rotating direction of the shaft is marked

with an arrow on the face of the vacuum

pump/compressor cover and on the fan guard

(Fig. 1, Pg. 2, Item 7).

The flow direction of the gases is marked with

arrows on both connections (Fig. 1, Pg. 2,

Item 6).

WARNING

Danger from interchanging inlet and

pressure line!

Interchanged inlet and pressure lines can lead

to damage to the pump-motor unit and the

system, and as a result of this to serious

injuries!

Make sure that the inlet and pressure line

cannot be confused when connecting.

Look for the clear marking with the flow direction

arrow on the inlet and discharge connections.

610.44436.40.000 18 / 28 © Gardner Denver Deutschland GmbH

Page 19

WARNING

Danger due to vacuum and gauge pressure!

Danger due to escaping fluid!

During operation, connected pipes and vessels

are vacuumized or pressurized!

Use only mounting elements, connections, lines,

fittings and containers with sufficient freedom

from leaks and strength for the pressures which

occur.

Make sure that the mounting elements and

connections are mounted sufficiently firmly and

leak-free!

CAUTION

If the pumped gases are passed on the

discharge side in a closed pipe system, then it

must be ensured that the pipe system is

adapted to the maximum discharge pressure.

See Chapter 3.3: "Operating conditions",

Section "Pressures", Pg. 11). Connect a

pressure relief valve upstream if necessary.

NOTICE

Attach pipes/hoses free of mechanical tensions.

Support the weight of the pipes/hoses.

Installation

5.3.1 Inlet connection

The inlet connection with the related muffler

(Fig. 1, Pg. 2, Item 3) is marked with an arrow

pointing into the vacuum pump/compressor.

Connect the inlet pipe here. The pumped gases

are sucked in via this.

Procedure: see Chapter 5.3.3.

WARNING

Danger from solid bodies and impurities in

the pump-motor unit!

If solid bodies penetrate into the pump-motor

unit, blades of the impellers can break and

broken pieces can be thrown out.

Install a filter in the inlet pipe.

Replace filter regularly!

5.3.2 Discharge connection

The discharge connection with the related muffler

(Fig. 1, Pg. 2, Item 4) is marked with an arrow

pointing out of the vacuum pump/compressor.

Connect the discharge pipe here. The pumped

gases are discharged via this.

Procedure: see Chapter 5.3.3.

5.3.3 Procedure when connecting

pipes/hoses

Attach the pipes/hoses to the unit as described in

the following.

The pipes/hoses are connected differently to inlet

and discharge connections depending on the

type of line (pipe or hose):

Muffler (with inside threads):

The pipe is screwed directly into the muffler.

Hose connection:

– Screw hose flange (available as an

accessory) onto the muffler.

– Push the hose onto the hose flange and

secure it with a hose clamp. See

Chapter 3.1, "Mechanical data",

Section "Tightening torques for screw

connections", Pg. 10 for information on this

topic.

© Gardner Denver Deutschland GmbH 19 / 28 610.44436.40.000

Page 20

Commissioning

6 Commissioning

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Have you read the safety precautions in Chapter

1, "Safety", Pg. 3 f.?

Otherwise you many not carry out any work with

or on the pump-motor unit!

WARNING

Danger from rotating parts (external fan,

impeller, shaft):

Cutting/cutting off of extremities,

Grasping/winding up of hair and clothing!

Danger due to vacuum and gauge pressure:

sudden escape of fluids (skin and eye

injuries),

sudden drawing in of hair and clothing!

Danger due to escaping fluid:

Burns!

Start-up

conditions:

The pump-motor unit must be completely

The pipes/hoses must be connected to inlet

Inlet and discharge connections and the

Check the mounting elements, connections

and operation only under the following

assembled. When doing so, pay particular

attention to the following components:

– the vacuum pump/compressor cover,

– the muffler on inlet and discharge

connections,

– the fan guard.

and discharge connections.

connected pipes/hoses may not be closed,

clogged or soiled.

of the pipe/hose connections, lines, fittings

and containers for strength, leaks and firm

seating at regular intervals.

6.1 Preparation

WARNING

Danger from closed connections!

With closed/soiled intake or discharge

connections vacuum or gauge pressure results

in the pump-motor unit.

This can overheat and damage the drive motor

winding.

Before start-up, make sure that the inlet and

discharge connections are not closed, clogged

or soiled!

CAUTION

Before starting up again after a longer standstill:

Measure the insulation resistance of the motor.

With values ≤ 1 kΩ per volt of nominal voltage,

the winding must be dried.

Measures before start-up:

If a shut-off device is installed in the discharge

pipe:

Make sure that the unit is NOT operated with

the shut-off device closed.

Before starting up the pump-motor unit,

observe the values specified on the rating

plate. Specifications on the drive-motor

nominal current apply at a gas entry and

ambient temperature of +40 C [+104°F].

Adjust the motor circuit breaker to the drive-

motor nominal current.

Check direction of rotation:

The intended rotating direction of the shaft is

marked with an arrow on the face of the

vacuum pump/compressor cover and on the

fan guard (Fig. 1, Pg. 2, Item 7).

The flow direction is marked with arrows on

the inlet and discharge connections (Fig. 1,

Pg. 2, Item 6).

Make sure the pipes/hoses on the inlet and

discharge connections are properly

connected.

Switch the pump-motor unit on briefly and

then off again.

Compare the actual rotating direction of the

external fan with the intended shaft rotating

direction indicated with the arrows shortly

before the pump-motor unit comes to a

standstill.

If necessary, reverse the direction of rotation

of the motor.

610.44436.40.000 20 / 28 © Gardner Denver Deutschland GmbH

Page 21

Commissioning

WARNING

Danger due to rotating parts!

Danger due to vacuum and gauge pressure!

Danger due to escaping fluid!

Test runs may also only be conducted with the

pump-motor unit completely mounted.

DANGER

Electrical danger!

The electrical connection may be carried out by

trained and authorized electricians only!

DANGER

Electrical danger!

Before beginning work on the unit or system, the

following measures must be carried out:

Deenergize.

Secure against being switched on again.

Determine whether deenergized.

Ground and short-circuit.

Cover or block off adjacent energized parts.

Check operating speeds:

Observe the operating speed specified on the

rating plate. This may not be exceeded, as

otherwise the noise radiation, vibration behavior,

grease consumption duration and bearing

change interval worsen. To prevent damage as a

result of higher speeds, it may be necessary to

inquire with the Service Department as to the

maximum speed.

WARNING

Danger of hearing damage due to noise

radiation!

For the noise emission of the pump-motor unit

measured by the manufacturer, see Chapter 3.1,

"Mechanical data", Section "Noise level", Pg. 9.

However, the actual noise emission during

operation is highly dependent on the installation

and system conditions.

Conduct a noise measurement in the system

during operation after installing the pump-motor

unit.

The following measures must be taken by the

operator:

from 85 dB(A):

– Hearing protection must be provided.

from 90 dB(A):

– Mark noise area with a warning sign.

– Wear hearing protection.

– With free entry and exit of gases, i.e. with

direct intake out of or direct feeding into

the atmosphere without piping, attach an

additional muffle

© Gardner Denver Deutschland GmbH 21 / 28 610.44436.40.000

Page 22

Operation

6.2 Start-up and shut-down

Start-up

Open shut-off device in intake/discharge pipe.

Switch on power supply for drive motor.

Shut-down:

Switch off power supply for drive motor.

Close shut-off device in intake/discharge pipe.

7 Operation

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Have you read the safety precautions in Chapter

1, "Safety", Pg. 3 f.?

Otherwise you many not carry out any work with

or on the pump-motor unit!

Also be sure to read the safety precautions in

Chapter 6, "Commissioning", Pg. 20!

Starting up and shutting down

See Chapter 6, "Commissioning", SubChapter 6.2, "Start-up and shut-down", Pg. 22.

Also be sure to observe the following important

notes especially for operation:

WARNING

Danger of burns from hot surfaces of the

pump-motor unit and from hot fluids!

High temperatures of up to approx. +160°C

[+320°F] can occur on the surface of the pumpmotor unit.

Do not touch during operation!

Allow to cool after shut-down!

CAUTION

Danger of overheating due to hot surface of

pump-motor unit!

High temperatures of up to approx. +160°C

[+320°F] can occur on the surface of the pumpmotor unit.

Temperature sensitive parts, such as lines or

electronic components, may not come into

contact with the surface of the pump-motor unit.

CAUTION

Danger of overheating!

During operation the standstill heating may, if

installed, not be switched on!

CAUTION

Danger of rusting due to collection of

condensed water in drive motor area!

On drive motors with closed condensed water

openings:

Remove closures occasionally to allow any

water which has collected to drain off.

CAUTION

Danger of bearing damage!

Heavy mechanical impacts must be avoided

during operating and while at a standstill.

8 Shut-Down and Longer Standstills

8.1 Preparing for shut-down or longer

standstill

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Have you read the safety precautions in Chapter

1, "Safety", Pg. 3 f.?

Otherwise you many not carry out any work with

or on the pump-motor unit!

CAUTION

Danger of rusting due to collection of

condensed water in drive motor area!

On drive motors with closed condensed water

openings:

Remove closures occasionally to allow any

water which has collected to drain off.

CAUTION

Danger of bearing damage!

Heavy mechanical impacts must be avoided

during operating and while at a standstill.

Prior to shut-down or longer standstill, proceed

as follows:

Switch off the pump-motor unit.

Close shut-off device in inlet and pressure line

if installed.

Disconnect pump-motor unit from power

supply.

Release pressure.

When doing so, open pipes/hoses slowly and

carefully so that the vacuum or gauge

pressure in the pump-motor unit can be

released.

Remove pipes/hoses.

610.44436.40.000 22 / 28 © Gardner Denver Deutschland GmbH

Page 23

Provide mufflers on inlet and discharge side

with sealing plugs.

8.2 Storage conditions

To prevent standstill damage during storage, the

environment must provide the following

conditions:

dry,

dust-free,

low-vibration (effective value of vibration speed

≤ 2.8 mm/s).

v

eff

Ambient temperature: max. +40°C [+104°F].

CAUTION

Danger of overheating due to high

temperature!

When storing in an environment with a

temperature of over +40°C [+104°F] the winding

may be damaged and the grease change

interval may be shortened.

Lubrication of rolling bearings after longer

storage:

The new pump-motor unit may at first be stored

following delivery.

If the time from deliver to commissioning exceeds

the following periods, the lubrication of the rolling

bearings must be renewed:

Under advantageous storage conditions

(as specified above): 4 years.

Under disadvantageous storage conditions

(e.g. high humidity, salty air, sandy or dusty

air): 2 years.

In these cases open rolling bearings must be

relubricated and closed rolling bearings must be

completely replaced. In this case be sure to

inquire with the Service Department. In particular,

exact information with regard to the procedure

and grease type are required.

Servicing

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

All maintenance work on the pump-motor unit

must always be performed by the Service

Department!

Maintenance work on the pump-motor unit may

only be conducted by the operator itself when

the related maintenance manual on hand!

Inquire with the Service Department!

Commissioning after longer standstill:

Before recommissioning after a longer standstill,

measure the insulation resistance of the drive

motor. With values ≤ 1 kΩ per volt of nominal

voltage, the winding must be dried.

9 Servicing

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

Have you read the safety precautions in Chapter

1, "Safety", Pg. 3 f.?

Otherwise you many not carry out any work with

or on the pump-motor unit!

WARNING

Improper use of the unit can result in

serious or even fatal injuries!

All maintenance work on the pump-motor unit

must always be performed by the Service

Department!

Maintenance work on the pump-motor unit may

only be conducted by the operator itself when

the related maintenance manual on hand!

Inquire with the Service Department!

© Gardner Denver Deutschland GmbH 23 / 28 610.44436.40.000

Page 24

Servicing

9.1 Repairs/troubleshooting

Fault Cause Remedy Carried out by

Motor does not

start;

no motor

noise.

Motor does not

start; humming

noise.

Protective

motor switch

trips when

motor is

switched on.

Power

consumption

too high.

At least two power supply

leads interrupted.

One power supply lead

interrupted.

Eliminate interruption by fuses, terminals or

power supply cables.

Eliminate interruption by fuses, terminals or

power supply cables.

Open vacuum pump/compressor cover,

Electrician

Electrician

Service*) Impeller is jammed.

remove foreign body, clean.

Check or correct impeller gap setting if

Service

necessary.

Impeller defective. Replace impeller. Service*)

Rolling bearing on drive

motor side or vacuum

Replace motor bearing or vacuum

pump/compressor bearing.

Service*)

pump/compressor side

defective.

Winding short-circuit. Have winding checked. Electrician

Reduce throttling. Service*) Motor overloaded. Throttling

does not match specification

on rating plate.

Compressor is jammed. See fault: "Motor does not start; humming

Clean filters, mufflers and connection pipes

if necessary.

Service*)

Service*)

noise" with cause: "Impeller is jammed.".

Pump-motor

unit does not

generate any

or generates

insufficient

pressure

difference.

noises.

Abnormal

running noise.

leaky.

Leak in system. Seal leak in the system. Operator

Wrong direction of rotation. Reverse direction of rotation by

Electrician

interchanging two connecting leads.

Incorrect frequency (on

Correct frequency. Electrician

pump-motor units with

frequency converter).

Shaft seal defective. Replace shaft seal. Service*)

Different density of pumped

gas.

Change in blade profile due

to soiling.

Flow speed too high. Clean pipes. Use pipe with larger cross-

Take conversion of pressure values into

account. Inquire with Service Department.

Clean impeller, check for wear and replace

if necessary.

Service

Service*)

Operator Abnormal flow

section if necessary.

Muffler soiled. Clean muffler inserts, check condition and

Service*)

replace if necessary.

Ball bearing lacking grease

Regrease or replace ball bearing. Service*)

or defective.

Seals on muffler defective. Check muffler seals and replace if

Service*) Compressor

necessary.

Seals in motor area

defective.

Check motor seals and replace if

necessary.

Service

*) Only when the maintenance manual is at hand: rectification by the operator.

610.44436.40.000 24 / 28 © Gardner Denver Deutschland GmbH

Page 25

9.2 Service/After-sales service

Our Service is available for work (in particular the

installation of spare parts, as well as

maintenance and repair work), not described in

these operating instruction.

A list of spare parts with an exploded drawing is

available on the Internet at

www.gd-elmorietschle.com.

Observe the following when returning pumpmotor unit:

The pump-motor unit must be delivered

complete, i.e. not dismantled.

The pump-motor unit may not present a

danger to the workshop personnel.

If the pump-motor unit has come into contact

with dangerous substances, then the

procedure described in Chapter 9.3,

"Decontamination and Declaration of

Clearance", Pg. 25, must be used.

The original rating plate of the pump-motor

unit must be properly mounted, intact and

legible.

All warranty claims are voided for pump-motor

units delivered for a damage expertise without

the original rating plate or with a destroyed

original rating plate.

In case of warranty claims, the manufacturer

must be informed of the operating conditions,

operating duration etc. and additional detailed

information provided on request if necessary.

9.3 Decontamination and Declaration of

Clearance

Disposal

10 Disposal

Have the entire pump-motor unit scrapped by a

suitable disposal company. No special measures

are required when doing so.

For additional information on disposing of the

unit, ask the Service Department.

11 Explosion-Protected Design

An additional set of operating instructions with

supplementary or specific information is provided

with these pump-motor units.

WARNING

Danger from flammable, caustic or toxic

substances!

To protect the environment and persons, the

following applies:

Pump-motor unit which have come into contact

with dangerous substances must always be

decontaminated before being passed on to a

workshop!

To provide proof that the decontamination was

carried out, a so-called declaration of clearance

must be included with the pump-motor unit on

delivery to the workshop.

The form required for this purpose is available

from the Service Department.

© Gardner Denver Deutschland GmbH 25 / 28 610.44436.40.000

Page 26

EU declaration of conformity

*)

EU declaration of conformity

EU declaration of conformity

Manufacturer:

Gardner Denver Deutschland GmbH

Industriestraße 26

97616 Bad Neustadt • Germany

Representative for the compilation of technical documents:

Description and identification

of the machine:

Holger Krause

Industriestraße 26

97616 Bad Neustadt • Germany

Vacuum pumps/Compressors (Side channel blower)

Series G-BH7

Types 2BH72..-.....-. 2BH73..-.....-.

2BH74..-.....-. 2BH75..-.....-.

2BH76..-.....-.

The machine described above meets the following applicable Community harmonisation legislation:

2006/42/EC

European Parliament and Council Directive 2006/42/EC from 17th May 2006 on machinery

and amending Directive 95/16/EC.

2004/108/EC*)

Directive 2004/108/EC of the European Parliament and Council from 15th December 2004

for the application of the legal regulations of the EU member states concerning electrical

devices and repealing Directive 89/336/EEC

Harmonised standards applied:

EN 1012-1:2010

EN 1012-2:1996

Compressors and vacuum pumps - Safety requirements - Part 1: Compressors

Compressors and vacuum pumps - Safety requirements - Part 2: Vacuum pumps

+A1:2009

EN ISO 12100:2010

Safety of machinery - General principles for design -

Risk assessment and risk reduction (ISO 12100:2010)

EN 60204-1:2006

Safety of machinery - Electrical equipment of machines Part 1:

General requirements IEC 60204-1:2005 (amended)

EN 60034-1:2010/

AC:2010

Rotating electrical machines - Part 1:

Rating and performance IEC 60034-1:2010 (amended)

Bad Neustadt, 18.04.2012

(Place and date of issue)

Andreas Bernklau, product management/attorney Dr. Rudi Dittmar, development

(Name and function)

Only applicable for version with frequency converter 2FC

(Name and function)

664.44436.40.000

610.44436.40.000 26 / 28 © Gardner Denver Deutschland GmbH

Page 27

Form for statement on safety

Form for statement on safety

For the safety of our employees and to comply with statutory requirements on handling substances harmful to the health and

Statement on health safety and on the protection of the environment

the environment, this statement must be enclosed, fully completed, with each unit/system sent.

Without the fully completed statement, repair/disposal is not possible and delays are unavoidable!

The statement is to be completed and signed by suitably qualified, authorised personnel at the operating organisation.

In the case of shipment to Germany, the statement is to be completed in German or English.

The statement is to be attached to the outside of the packing on shipment.

If necessary, the carrier is to be informed.

1. Product designation (type):

2. Serial number (no. BN):

3. Reason for sending:

4. The unit/system

has not come into contact with hazardous substances. There will be no hazards for personnel or the environment during

repair/disposal. Continue with "6. Legally binding statement“

has come into contact with hazardous substances. Continue with "5. Information on the contamination“

5. Information on the contamination

(if necessary provide more information on an additional sheet)

The unit/system was used in the following application:

and has come into contact with the following classifiable substances or substances presenting a hazard to health/environment:

Trade name: Chemical designation:

Hazardous

substance class:

Properties (e.g. toxic, inflammable,

caustic, radioactive):

The unit/system has been emptied in accordance with the operating instructions, flushed and cleaned externally.

Safety data sheets in accordance with the applicable regulations are enclosed ( sheet).

The following safety precautions are necessary for handling (e.g. personal protective equipment):

6. Legally binding statement

I herewith guarantee that the details specified are true and complete and that I, as signatory, am in a position to judge that this is

so.

We are aware that we are liable to the contractor for any damages arising from incomplete or incorrect specifications. We are

obliged to indemnify the contractor against claims for damages by third parties arising from incomplete or incorrect specifications.

We are aware that, irrespective of this statement, we are directly liable to third parties - in particular including the contractor's

employees tasked with repair/disposal.

Company/institute:

Name, position: Phone:

Street: Fax:

Post code, city:

Country: Stamp:

Date, signature:

© Gardner Denver Deutschland GmbH 610.44436.40.000

P.O. box 1510 Phone: +49 7622 392 0 E-mail: er.de@gardnerdenver.com Edition: 04.2012

97605 Bad Neustadt Fax: +49 7622 392 300 Internet: www.gd-elmorietschle.com English

© Gardner Denver Deutschland GmbH 27 / 28 610.44436.40.000

Page 28

Elmo Rietschle is a brand of

Gardner Denver‘s Industrial Products

Group and part of Blower Operations.

www.gd-elmorietschle.de

er.de@gardnerdenver.com

Gardner Denver

Schopfheim GmbH

Roggenbachstraße 58

79650 Schopfheim · Deutschland

Tel. +49 7622 392-0

Fax +49 7622 392-300

Gardner Denver

Deutschland GmbH

Industriestraße 26

97616 Bad Neustadt · Deutschland

Tel. +49 9771 6888-0

Fax +49 9771 6888-4000

Loading...

Loading...