Page 1

Edition: 04.2010 · 610.44431.40.000 Original Operating Instructions · English

Operating Instructions G-BH10

2BH10 02-.AB32

2BH10 02-.AB22

2BH10 02-.AA53

G-Serie

G-Series

Seitenkanal

Side Channel

Page 2

Table of Contents

Table of Contents

1

Safety and Residual Risks.......................................................................................................... 3

2 Intended Use .............................................................................................................................. 5

3 Technical Data............................................................................................................................ 6

3.1 Nominal and Limiting Values Pump......................................................................................... 6

3.2 Nominal and Limiting Values Motor and Electronics ............................................................... 7

4 Transport and Handling .............................................................................................................. 9

5 Installation and Commissioning................................................................................................ 10

5.1 Mounting ................................................................................................................................ 10

5.2 Connection ............................................................................................................................. 11

5.2.1 Electrical Connection (Motor)............................................................................................ 11

5.2.2 Pipe/ hose connections (pump) ........................................................................................ 17

5.3 Commissioning....................................................................................................................... 18

6 Operation .................................................................................................................................. 19

7 Servicing ................................................................................................................................... 20

7.1 Maintenance........................................................................................................................... 20

7.1.1 Cleaning............................................................................................................................ 20

7.1.2 Inspection.......................................................................................................................... 21

7.1.3 Lubrication......................................................................................................................... 21

7.2 Repair/ Troubleshooting.........................................................................................................22

8 Shutting Down and Measures for Prolonged Standstill............................................................ 23

EC Declaration of Conformity................................................................................................................ 24

© 2010 Gardner Denver Deutschland GmbH · Industriestraße 26 · 97616 Bad Neustadt · Deutschland

Replication, distribution and / or editing of this document and the use and distribution of its content is

prohibited unless explicitly permitted. Violation obligates compensation for damages.

All rights reserved in case of the issue of a patent, utility patent or design patent.

Page 3

1 Safety and Residual Risks

Safety and Residual Risks

Before beginning to work on the GBH100 or the system carry out the

following steps for both the G-BH100

and the entire system

– switch off electricity,

– lock against restart,

– ensure absence of electricity,

– ground and short-circuit instal-

lation,

– cover or bar adjacent live

parts,

– depressurise both pipes and

pump.

Do not wear long, loose hair! Use a

hair net! Never wear wide, loose

clothes!

Transport and handling as well as

assembly and disassembly may be

carried out by trained and responsible personnel only!

Operation of the G-BH100 only

– with the gases as indicated in

section 2, "Intended Use"!

– with the values as indicated in

section 3, "Technical Data"!

Check pipes/hoses and vessels for

sufficient strength!

Check pipe / hose connections for

tightness!

Operation of the G-BH100 only when

completely assembled and securely

fastened to the mounting surface!

Check fasteners for secure fixing at

regular intervals!

After loosening clampings and fastening elements some parts and

components are only held in place

by their centrings or seatings or are

no longer held in place at all so that

they might fall down.

Take the necessary care during disassembly and assembly!

Operation of the G-BH100 only with

the pump lid assembled!

Disassembly of the pump lid only

after the impeller has come to a

complete standstill!

Consider impeller run-out!

Operation of the G-BH100 only with

the pipes / hoses connected to the

suction and delivery branches!

WARNING!

In case of operation with open suction or delivery branches (drawing-in

of gases from or discharge of gases

into the surroundings) a piece of

pipe or hose with a length of at

least 120 mm must by all means be

connected to the branch in question

in order to prevent the impeller from

being reached by fingers!

Disassembly of the pipes / hoses

connected to the suction and delivery branches only after the impeller

has come to a complete standstill!

Consider impeller run-out!

Do not reach into the G-BH100

through open suction or delivery

branches!

Do not insert any objects into the GBH100 through the openings!

Operation of the G-BH100 only with

the motor cap assembled!

Disassembly of the motor cap is

prohibited.

Work on electrical installations may

be carried out by trained and authorised electricians only!

The electrical connections must be

surrounded by a housing which is

proof against foreign bodies, humidity, etc.!

Consider the life expectancy of the

seals and gaskets!

Ensure that no foreign bodies, humidity, etc. enter the motor interior!

For heat dissipation and cooling provide a minimum distance of 15 mm

on each side except for the pump lid

side on which a smaller distance of

at least 2 mm is permissible!

Burning and scalding hazard due to

hot surfaces of the G-BH100!

Do not touch during operation! Let

the unit cool after shut-down!

Provide a guard against accidental

contact!

© Gardner Denver Deutschland GmbH 3 / 30 610.44431.40.000

Page 4

Safety and Residual Risks

The motor of the G-BH100 including

its connecting leads must be protected against electrostatic dis-

i

Residual Risks

610.44431.40.000 4 / 30 © Gardner Denver Deutschland GmbH

charge (ESD).

Do not remove the ESD-prevention

bag surrounding the lead ends until

right before carrying out the electri-

cal connection (attaching the connector, connecting to a terminal strip,

or the like)!

Carry out the electrical connection

using the appropriate ESDprevention equipment!

Danger zone:

Hot surface.

Hazard:

Burning / scalding hazard.

Protective measures:

Attach warning sign "Warning of hot

surface".

Danger zone:

Impeller of the pump can be reached through open suction or delivery branches.

Hazard:

Severing of limbs.

Drawing-in and entanglement of

hair.

Protective measures:

Operation only with the pipes /

hoses connected to the suction

and delivery branches!

In case of operation with open

suction or delivery branches

(drawing-in of gases from or discharge of gases into the surroundings) a piece of pipe or hose with a length of at least 120

mm must by all means be connected to the branch in question!

Use a hair net!

Danger zone:

The vicinity of the unit during operation with open suction or delivery

branches (drawing-in of gases from

or discharge of gases into the surroundings)

Hazard:

Injuries due to contact with pres-

surised fluids or due to sudden

acceleration of parts.

Injuries due to parts thrown out of

the unit.

Protective measures:

Ensure that fluids discharged into

the surroundings are not expelled

close to people (e.g. work stations on machines)!

During work on or near the unit

wear personal protective equipment!

Page 5

2 Intended Use

Intended Use

These operating instructions

must be completely read and understood by

all operating and servicing personnel before

beginning to work with or on the G-BH100,

must be strictly observed,

must be available at the site of operation of

the G-BH100,

applies to Side channel blowers of the

G-Series G-BH100,

contains instructions bearing on transport and

handling, installation, commissioning, operation, servicing, shut-down, and storage of the

G-BH100.

The operating and servicing personnel working

with or on the G-BH100:

must be trained and authorised for the work to

be carried out.

Work on electrical installations may be carried

out by trained and authorised electricians

only.

The G-BH100

are single-stage gas-ring vacuum pumps /

compressors

are machines used to generate vacuum or

overpressure

are used to extract, to deliver and to com-

press the following pumped gases:

- air,

- other gases, which are not explosive,

flammable, aggressive or toxic

- The pumped gases must not contain any

solid bodies or impurities; those must be

separated before entering the unit by

means of a filter.

exist in six fundamental designs

- 2BH10 02-0AB32:

hose connection with enclosed motor

and integrated electronics

- 2BH10 02-0AB22:

hose connection with enclosed motor

and integrated electronics

- 2BH10 02-0AA53:

hose connection with enclosed motor

external electronics

- 2BH1002-1….: flange connection

are intended for industrial applications.

are designed for continuous operation; in case

of increased turn-on frequency or increased

intake and ambient temperature the limiting

overtemperature of the winding and the bearings must not be exceeded

(operation only according to "Fig. 3", page 9).

1

:

When operating the G-BH100 it is imperative to

observe the limiting values given in section 3,

"Technical Data".

Foreseeable Misuse

It is prohibited:

to use the G-BH100 in applications other than

industrial applications,

to use the G-BH100 in areas where explosive

atmosphere might occur,

to extract, to deliver and to compress explo-

sive, flammable, aggressive or toxic fluids,

to operate the G-BH100 with values other

than those given in section 3, "Technical

Data".

Any unauthorised modifications of the G-BH100

are prohibited for safety reasons.

Maintenance work is only allowed to the extent

described in these operating instructions.

Any further maintenance work as well as repair

work may only be carried out by companies

authorised by the manufacturer (please contact

your sales engineer).

IMPORTANT!

The G-BH100 is a component

intended to be incorporated in a

i

i

machine or system. It is delivered

for this purpose to manufacturers

of such machinery or systems

(OEMs) only.

IMPORTANT!

The installation of the G-BH100 in

your machine or system must be

carried out in keeping with the

requirements on electromagnetic

compatibility according to the

EMC Directive.

1

In order to determine the design of your G-BH100

refer to the type number (MLFB) on the rating plate.

© Gardner Denver Deutschland GmbH 5 / 30 610.44431.40.000

Page 6

Technical Data

3 Technical Data

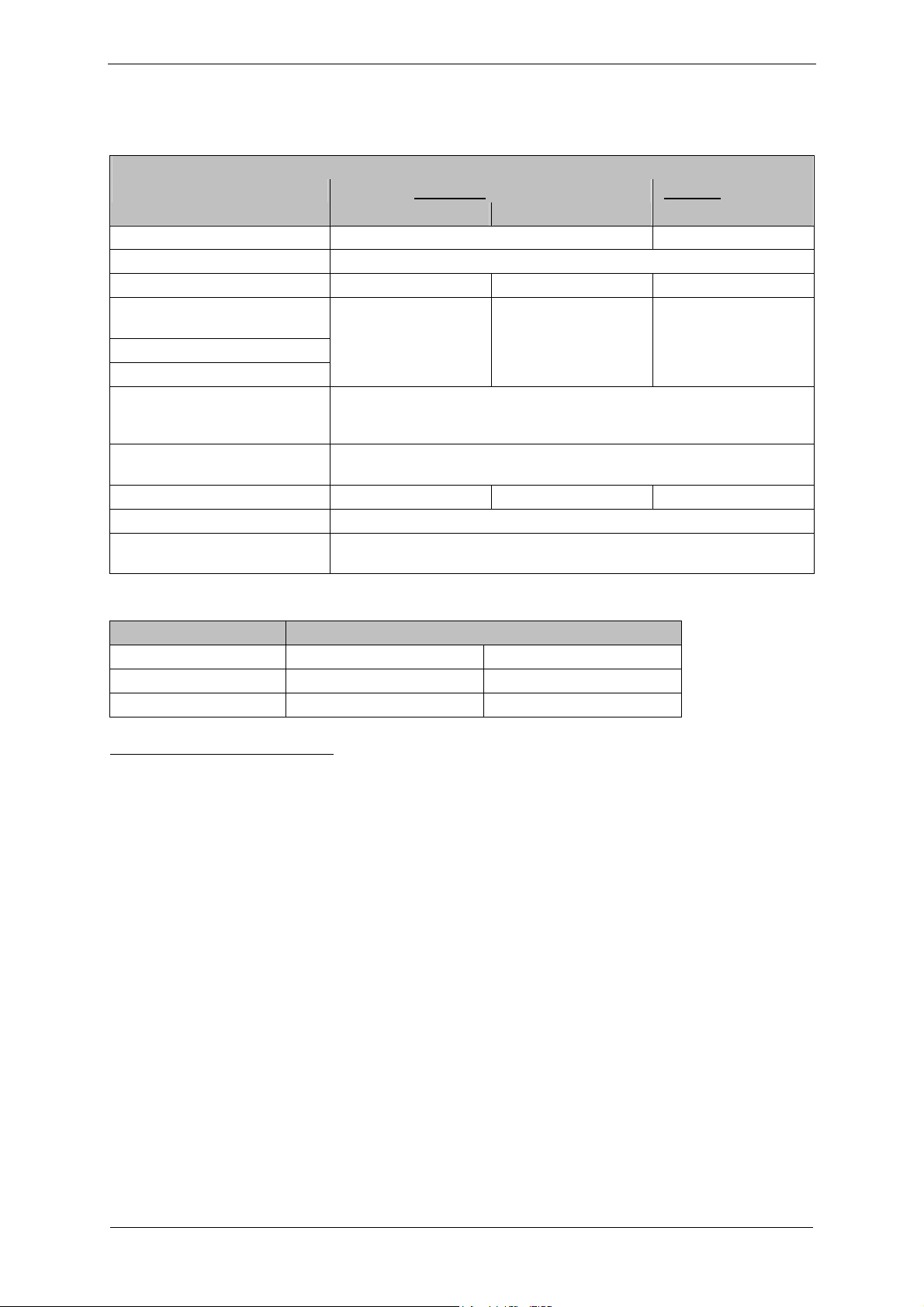

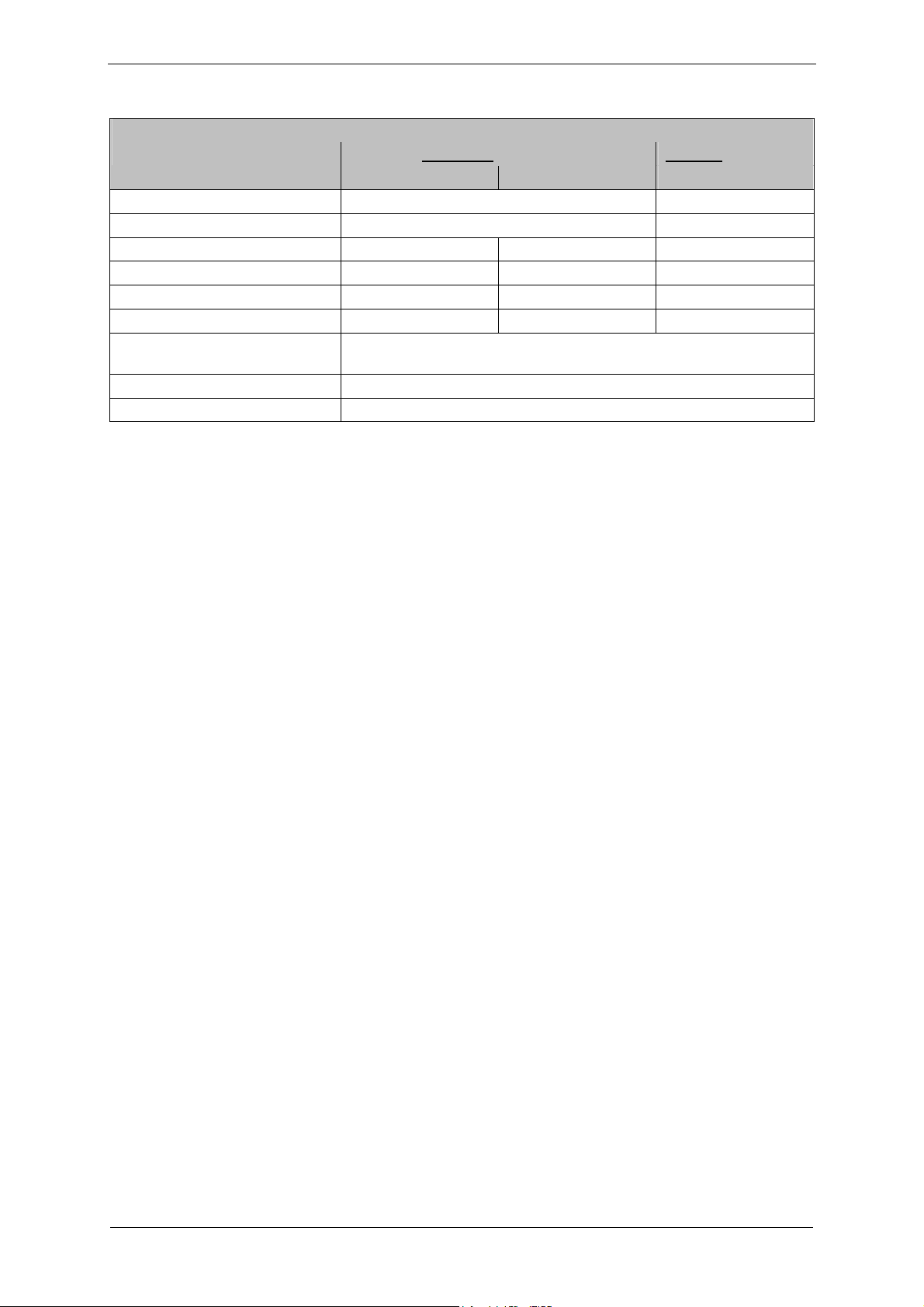

3.1 Nominal and Limiting Values Pump

G-BH100 with enclosed motor and

integrated electronics external electronics

2BH10 02-_AB32 2BH10 02-_AB22 2BH10 02-_AA53

Weight 1.2 kg [2.65 lbs] 1.5 kg [3.31 lbs]

Dimensions see Fig. 1 & Fig. 2, page 8

Sound level2 48 dB(A) 51 dB(A) 55 dB(A)

max. permissible total

differential pressure

3

at +15°C:

- vacuum pump operation4 100 mbar 105 mbar 185 mbar

- compressor operation5 105 mbar 105 mbar 190 mbar

max. permissible differential

pressure between pump interior

and surroundings

max. permissible intake and

ambient temperature

max. permissible speed6 9,500 min-1 12,000 min-1 15,000 min-1

bearing life L107 20,000 h

electrical data see section 3.2, "Nominal and Limiting Values Motor and Electronics",

page 7, and section 5.2.1, "Electrical Connection (Motor)", page 11

Max. permissible dynamic load of the G-BH100 due to vibrations from outside:

0.15 bar

+ 40°C [+104°F]

Vibration frequency Vibration value

< 6.3 Hz Vibration displacement s ≤ 0.16 mm

6.3 Hz ... 63 Hz Vibration velocity v

≤4.5 mm/s

eff

> 63 Hz Vibration acceleration a ≤ 2.55 m/s²

2

Surface sound pressure level (EN ISO 3744), measured at a distance of 1 m [3.28 ft] at an operating point of ap-

prox. 2/3 of the permissible total differential pressure with the pipes / hoses connected and without vacuum or

pressure limiting valve.

3

Permitted only with: unobstructed cooling,

an operating voltage of 24 V,

a speed reference value of 10 V and

left-handed rotation of the G-BH100.

The indicated temperature refers to the gas intake temperature. It is assumed that the gas intake temperature equals the ambient temperature of the

G-BH100.

IMPORTANT: For the max. permissible total differential pressure at temperatures other than +15°C

[+59°F]see

"Fig. 3", page 9.

In case of increased throttling inside the suction or delivery pipe a pressure relief valve must be provided.

In case of reduced speeds by means of a lower speed reference value the max. permissible total differential pressures change as well

4

Vacuum operation: extraction of air

.

having the indicated temperature at the suction branch and a pressure of 1013 mbar

5

Compressor operation: compression of air

at the delivery branch

.

having the indicated temperature at the suction branch and a pressure of 1013 mbar

6

Max. permissible speed due to the mechanical components and the design of the unit.

7

For: operation within the permissible operating range,

at the delivery branch

.

the max. permissible dynamic load due to vibrations from outside and

fastening by means of rubber / metal elements (available as accessories).

610.44431.40.000 6 / 30 © Gardner Denver Deutschland GmbH

Page 7

Technical Data

3.2 Nominal and Limiting Values Motor and Electronics

G-BH100 with enclosed motor and

integrated electronics external electronics

2BH10 02-0AB32 2BH10 02-0AB22 2BH10 02-0AA53

Voltage range 14...28 V DC 38...52 V DC

Nominal voltage 24 V DC 48 V DC

Max. input current 4.5 A 5.2 A 7.0 A

Nominal speed 9,500 min-1 11,500 min-1 15,000 min-1

Speed control range 1,000 - 9,500 min-1 1,000 - 12,000 min-1 1,000 - 15,000 min-1

Rated power 90 W 115 W 300 W

Internal resistance at desired

70

speed

Permissible ambient temperature -10…+40°C [+14…+104°F]

Relative humidity max. 95 %

Due to the PWM control of the electronics the power supply unit is loaded with short, high current pulses. For this reason the supply voltage must be blocked or filtered by means of a capacitor (low ESR

type, suitable type for high frequencies, high current switching, > 1000 µF) for noise suppression.

Usually this capacitor is part of the power supply unit. Switch-mode power supplies, however, are often provided with a capacitor of only very small capacitance at the output so that this kind of pulses

result in interference. In this case an additional capacitor must be connected as close to the motor as

possible.

© Gardner Denver Deutschland GmbH 7 / 30 610.44431.40.000

Page 8

Technical Data

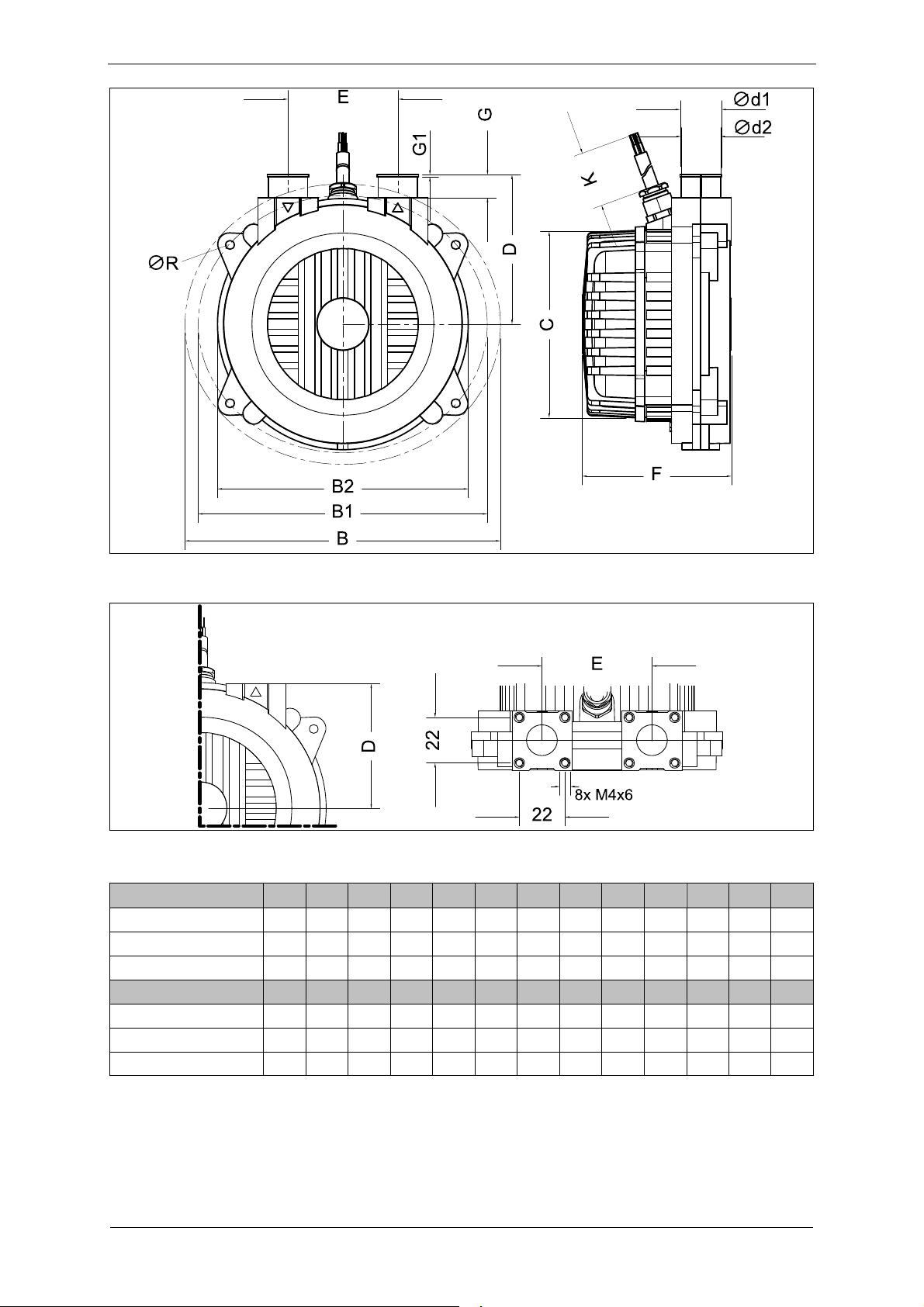

Fig. 1: Dimensions of the 2BH1002-0…. (hose connection)

Fig. 2: Dimensions of the 2BH1002-1…. (flange connection)

Hose connection B

2BH1002-0AB32

2BH1002-0AB22

2BH1002-0AA53

145 133 121 95 72 20 19 53 72 11 1 450 4.2

145 133 121 95 72 20 19 53 72 11 1 450 4.2

145 133 121 95 72 20 19 53 92 11 1 450 4.2

Flange connection

2BH1002-1AB32

2BH1002-1AB22

2BH1002-1AA53

145 133 121 95 60 20 19 53 72 11 1 450 4.2

145 133 121 95 60 20 19 53 72 11 1 450 4.2

145 133 121 95 60 20 19 53 92 11 1 450 4.2

B1 B2

C D

d1 d

E F G

2

G1

K

R

2

610.44431.40.000 8 / 30 © Gardner Denver Deutschland GmbH

Page 9

1.01

r

1

0.99

0.98

0.97

0.96

0.95

0.94

Conversion facto

0.93

0.92

Transport and Handling

0.91

-10

-20

0

10 20 30 40 50

Gas intake and ambient temperature t [°C]

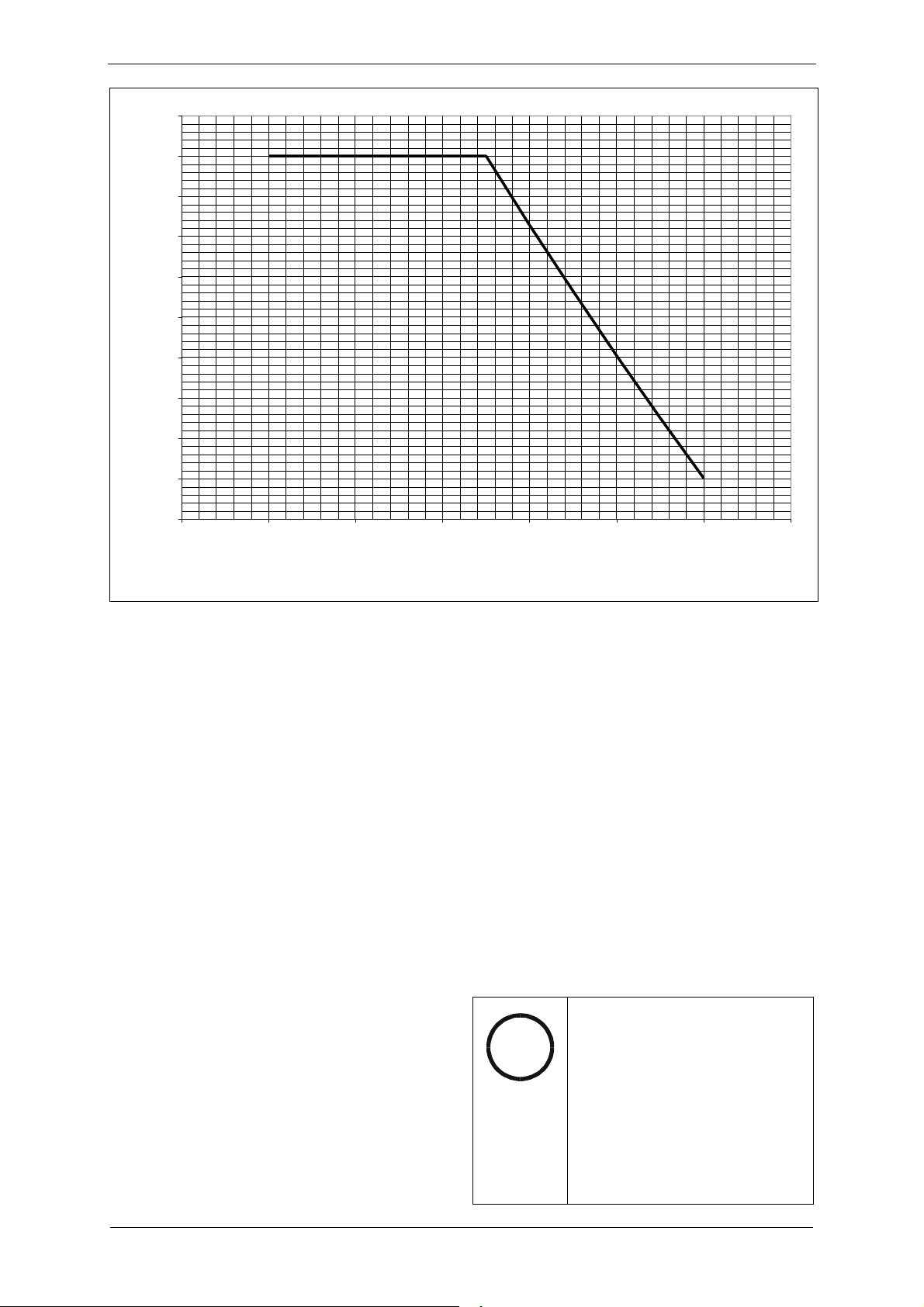

Fig. 3: Permissible total differential pressure / conversion factor

For the permissible total differential pressure at an intake and ambient temperature of +15°C [+59°F]

see the table in section 3.1, "Nominal and Limiting Values Pump", page 6.

In order to calculate the permissible total differential pressure for other intake and ambient temperatures proceed as follows:

Find out your system-dependent gas intake and ambient temperature.

Establish the conversion factor valid for these conditions by means of the above diagram.

(In order to do so mark your intake and ambient air temperature on the temperature axis. Draw a

vertical line from this value to the point of intersection with the curve. Now draw a vertical line from

the point of intersection to the conversion-factor axis where you can read the conversion factor

then.)

Multiply the established conversion factor with the max. permissible total differential pressure at

15°C as given in the table in section 3.1, "Nominal and Limiting Values Pump", page 6.

The result will be a pressure value. This is the max. permissible total differential pressure valid

for your G-BH100 at your system-dependent intake and ambient temperature.

4 Transport and Handling

Packaging:

On delivery the G-BH100 is packed up in a cardboard box. When there is no connector attached

to the electrical connecting cable the lead ends

are surrounded by an ESD-prevention bag.

i

IMPORTANT!

The motor of the G-BH100 including its connecting leads must be

protected against electrostatic

discharge (ESD).

Do not remove the ESDprevention bag surrounding the

lead ends until right before carrying out the electrical connection

(attaching the connector, connect-

© Gardner Denver Deutschland GmbH 9 / 30 610.44431.40.000

ing to a terminal strip, or the like)!

Page 10

Installation and Commissioning

5 Installation and Commissioning

5.1 Mounting

5

4

General view G-BH100 (pump side)

1. Delivery branch

2. Arrows indicating delivery direction

3. Fixing lugs for fastening to a mounting surface

4. Suction branch

5. Electrical connecting cable

Fig. 4: General view G-BH100

For the arrangement of the G-BH100 and its

components see

- Fig. 4: .

For the space required and the arrangement of

the mounting holes required for fastening the

G-BH100 to the mounting surface please refer to

- Fig. 1: , page 8,

The G-BH100 must be mounted as follows:

- the shaft being in any position,

- such as not to exceed the vibration values

given in section 3, "Technical Data",

- for heat dissipation and cooling

provide a minimum distance of 15 mm on

each side

except for the pump lid side on which a smaller distance of at least 2 mm is permissible

(in case of mounting using rubber / metal

elements, see page 10).

1

2

3

CAUTION!

Choose the place of installation /

the mounting surface of the

G-BH100 so that there is no hazard of tripping or bumping!

IMPORTANT!

Do not install theG-BH100 close

to heating surfaces! No direct in-

i

Sound and vibration attenuation:

In order to reduce sound emission fasten the

G-BH100 only to parts or components that do

not conduct or emit sound easily (e.g. thin

walls, plates).

Provide sound-absorbing shims, termed

rubber / metal elements (available as acces-

sories). These are rubber pads placed between the four fixing lugs and the mounting

surface and used to absorb vibrations.

i

Place the rubber / metal elements (rubber pads)

between the fixing lugs (Fig. 4, # 6) and the

mounting surface.

Fasten theG-BH100 to the mounting surface via

the fixing lugs using four suitable bolts or nuts.

Property class of the bolts or nuts: 8.8 according

to ISO 898.

Secure the four fixing bolts against unintentional

loosening due to vibrations.

solation!

CAUTION!

Lay the electrical connecting cable

so that it might not be damaged

by outer influences and is free

from tensile stress!

IMPORTANT!

During operation the surface of the

G-BH100 might have high temperatures of more than 100°C!

Temperature-sensitive parts or

components, e.g. electrical wires

or cables or electronic components must not be in contact with

or fastened to these surfaces!

CAUTION!

Burning and scalding hazard due

to hot surfaces of the G-BH100

during operation!

Provide a guard against accidental contact.

610.44431.40.000 10 / 30 © Gardner Denver Deutschland GmbH

Page 11

Installation and Commissioning

5.2 Connection

5.2.1 Electrical Connection (Motor)

WARNING!

Work on electrical installations may

be carried out by trained and authorised electricians only!

WARNING!

Before beginning any electrical work

on the G-BH100 or the system carry

out the following steps for both the

G-BH100 and the entire system

– switch off electricity,

– lock against restart,

– ensure absence of electricity,

– ground and short-circuit instal-

lation,

– cover or bar adjacent live

parts.

WARNING!

The connecting terminals

– must be installed such that

they cannot be touched during

operation!

– must be surrounded by a

housing which is proof against

foreign bodies, humidity, etc.!

Consider the life expectancy of

the seals and gaskets!

– must be separated by suffi-

cient distances (mind protruding wire ends)!

WARNING!

Ensure that no foreign bodies, humidity, etc. enter the motor interior!

The G-BH100 is operated using an electronics for

speed and direction of rotation control.

Depending on where this electronics is located

(inside or outside the G-BH100), two types of the

G-BH100 are distinguished

for external

page 11):

- 2BH10 02-0AA53

for integrated

tion 5.2.1.2, page 15):

- 2BH10 02-0AB32

- 2BH10 02-0AB22

In order to determine the type of your G-BH100

refer to the type number (MLFB) on the rating

plate.

© Gardner Denver Deutschland GmbH 11 / 30 610.44431.40.000

electronics (see section 5.2.1.1,

electronics (see sec-

i

5.2.1.1 G-BH100 for external electronics

With this type the electronics is located outside

the G-BH100. It is connected via the electrical

connecting cable.

i

i

i

i

IMPORTANT!

The motor of the G-BH100 including

its connecting leads must be protected against electrostatic discharge

(ESD).

Do not remove the ESD-prevention

bag surrounding the lead ends until

right before carrying out the electrical

connection (attaching the connector,

connecting to a terminal strip, or the

like)!

Carry out the electrical connection

using the appropriate ESDprevention equipment!

IMPORTANT!

The main or operating direction of

rotation of the G-BH100 is the coun-

ter-clockwise rotation, given by the

arrow indicating the direction of rotation on the pump lid

(see Fig. 4, # 5, page 10).

Only with the counter-clockwise rota-

tion the nominal values will be

achieved.

Clockwise rotation is only permissible

in special cases.

In this instance the G-BH100 will not

achieve its full output.

IMPORTANT!

The connecting cable between the

G-BH100 and the external electron-

ics must have a length of at maxi-

mum 0.5 m!

IMPORTANT!

When switching off the G-Bh100 or

rapidly reducing its speed a current

feed into the mains might occur.

This can be prevented by inserting a

diode (Schottky diode, size 10A) in

the 48-V supply lead (+U

IMPORTANT!

Provide good cooling of the sur-

roundings of the motor and the ex-

ternal electronics (e.g. mounting on

a good thermal conductor, sufficient

ventilation)! In case of temperatures

of > 50°C, measured at the surface

of the external electronics (Drivecon-

trol VT-D), the output power of the

pump might be reduced.

)

B

Page 12

Installation and Commissioning

r

Purchasing the external electronics (Drivecontrol VT-D) along with the G-BH100

For the order no. of this option please refer to our

catalogue.

The design of the external electronics (Drivecontrol) is as follows:

+U

B

A

B

Mode of operation

Output stage

PWM-generation

internal

signal processing

n

Soll

Gnd

IST

(MF-PIN)

Speed controller

+

-

Speed

evaluation

Supply voltage / control signal

connection (X3)

External electronics:

Block diagram of the control principle

Commutation-

logic

Current

measurement

Motor connection (X4)

external electronics

(commercial component)

Colours of the connecting leads of the motor:

L1 brown RLG1 green Gnd

L2 violet RLG2 white +V

L3 yellow RLG3 grey

Rotor position detecto

RLG1, RLG2, RLG3

Gnd

Hall

+V

Hall

Hall

red

Hall

L1

L2

L3

MOTOR

black

Fig. 5: External electronics: block diagram of the control principle

610.44431.40.000 12 / 30 © Gardner Denver Deutschland GmbH

Page 13

Installation and Commissioning

Supply voltage/ control signal connection side:

The connector for supply voltage / control signal connection (connector X3) is shown in Fig. 7,

page 14.

On the supply voltage / control signal connection side the assignment is as follows:

Symbol Description Lead colour Pin

A Mode of operation States:

white Pin 1

1 (High): 5…24 V

0 (Low): < 0.5 V

+UB + Operating voltage 38 ... 52 V red Pin 2

- Not used violet Pin 3

n

) Speed reference value Control voltage: 0…10 V

Soll (S+

green Pin 4

Reference value of the desired speed of the

G-BH100.

B Mode of operation States:

grey Pin 5

1 (High): 5…24 V

0 (Low): < 0.5 V

IST Actual speed (optional) Open Collector output

yellow Pin 6

Here the rotor speed can be read

Gnd - Operating voltage 0 V black Pin 7

S - Ground Set Value input 0 V brown Pin 8

Via the digital control inputs A and B the direction/mode of operation is determined.

The following states are possible:

Level A Level B Mode of operation

0 0 Output stage disabled (no current).

0 1 Counter-clockwise rotation

(according to the arrow indicating the direction of rotation on the pump lid):

Main / operating direction of rotation of the G-BH100!

1 0 Clockwise rotation

(opposed to the arrow indicating the direction of rotation on the pump lid):

1 1 Breaking

Please take also note of the following data:

Wire cross section of the connecting cable 0.5 mm²

Control current on the supply voltage /

control signal connection side

max. 9 A

Motor connection side:

The connector for motor connection (connector X4) is shown in Fig. 7, page 14.

On the motor connection side the assignment is as follows:

Symbol Description Lead colour Pin

L1 Motor phase 1 brown Pin 6

L2 Motor phase 2 violet Pin 5

L3 Motor phase 3

RPD1 Hall signal 1 green Pin 4

RPD2 Hall signal 2 white Pin 3

RPD3 Hall signal 3

+V

Hall supply red Pin 2

Hall

Gnd

Hall supply

Hall

Terminals of the motor windings.

Operating voltage: 48 V against electronics

max. winding peak current: 13 A

max. winding temperature: 115°C

Rotor position detectors.

Hall ICs with open collector output.

They must be wired to an external pull-up

resistor.

Feeder line of the hall ICs.

yellow Pin 1

grey Pin 8

black Pin 7

© Gardner Denver Deutschland GmbH 13 / 30 610.44431.40.000

Page 14

Installation and Commissioning

6,5

92

80

3

84

112

PAPST

Drivecontrol VT-D

Gardner Denver Deutschland GmbH-Ident.-Nr.:

519_00082_01_000

13

Control sig-

nal connector

(X3)

Motor-

connector

(X4)

Fig. 6: External electronics

Control signal connections

(X3)

Mating connector type:

MOLEX - 39-01-2085

Slot for lug

S

Gnd IST

-

8765

4

321

Not

S

+

used

+Ub

B

A

Motorconnections

(X4)

Mating connector type:

MOLEX - 39-01-2085

Slot for lug

RLG3 Gnd L1 L2

8 7

4

3 2 1

RLG1 RLG2 +U

lug

8

76

5

1

6

5

L3

Hall

Mating connector

(connected to motor cable)

432

Fig. 7: Connector pin assignment and mating connector

If there is no connector (mating connector to the

external electronics) connected to the motor cable of the G-BH100, the loose lead ends are surrounded by an ESD-prevention bag. In this case,

the socket connector must first be connected to

the motor cable.

i

IMPORTANT!

The motor of the G-BH100 including

its connecting leads must be protected against electrostatic discharge (ESD).

Do not remove the ESD-prevention

bag surrounding the lead ends until

right before carrying out the electrical connection (attaching the connector, connecting to a terminal strip,

or the like)!

Carry out the electrical connection

using the appropriate ESDprevention equipment!

610.44431.40.000 14 / 30 © Gardner Denver Deutschland GmbH

Page 15

The scope of supply of the external electronics

(Drivecontrol VT-D) includes a connector with a

300 mm wiring harness to connect the Drivecontrol to the supply voltage and control voltage.

In order to meet the requirements bearing on

electromagnetic compatibility a suitable EMI

filter (e.g. CORCOM, Type 6ET1, 10A) must be

connected in series with the external-electronics.

The connecting cable between the EMI filter and

the G-BH100 must have a length of at maximum

0,3 m.

5.2.1.2 G-BH100 with integrated

electronics

With this type the electronics is located inside the

motor.

IMPORTANT!

With the integrated-electronics type

G-BH100 the electronics is particu-

i

larly sensitive to overheating!

It is imperative to ensure sufficient

heat dissipation and cooling!

Cable

old version

pink red +VCC

yellow black Gnd

green green n

white white A

grey grey B

blue blue n

brown -- not connected

red -- not connected

Installation and Commissioning

On delivery the integrated-electronics type GBH100 is not equipped with a connector at the

connecting cable. In this instance the operator

can, according to the requirements of the system,

connect a connector at his option, connect the

terminals to a terminal strip, etc.

The electrical connection is to be carried out:

according to the applicable national and local

laws and prescriptions

according to the applicable system-dependent

prescriptions and requirements

according to the applicable prescriptions of

the utility company

Via the motor connecting cable the supply voltage as well as the different control signals are

applied to the integrated electronics.

For the assignment of the leads or strands please

refer to Fig. 8 as well as the following table.

Lead colour Assignment

Cable

new version

des

Ist

G-BH100

Fig. 8: Connection of the integrated electronics type

© Gardner Denver Deutschland GmbH 15 / 30 610.44431.40.000

Page 16

Installation and Commissioning

Lead colour Symbol Description Level

Cable

old version

+UB

Gnd

n

Speed reference value:

des

n

Frequency output representing the actual

act

A white white

B

-- not connected -- brown --

-- not connected -- red --

In order to meet the requirements bearing on

electromagnetic compatibility an EMI filter

from Messrs CORCOM, Type 6ETI F7003, 6A,

must be connected in series with the integratedelectronics type G-BH100. The connecting cable

between the EMI filter and the G-BH100 must

have a length of at maximum 0.5 m.

i

i

610.44431.40.000 16 / 30 © Gardner Denver Deutschland GmbH

DC operating voltage 24 V (max. 28 V)

DC operating voltage,

reference potential for all signals

Reference value of the desired speed of

the G-BH100.

speed:

open collector signal which must be wired

to an external pull-up resistor.

Output frequency / motor speed ratio:

1 Hz = 10 min

Control signals A and B are digital inputs.

Broad voltage-range input compatible with

TTL / PLC signals.

In all four possible combinations:

A B Function

0 0 Motor disabled (no current)

0 1 CCW rotation

1 0 CW rotation

1 1 Motor disabled

IMPORTANT!

The main or operating direction of

rotation of the G-BH100 is the

counter-clockwise rotation, given

by the arrow indicating the direction

of rotation on the pump lid.

Only with the counter-clockwise rotation the nominal values will be achieved.

Clockwise rotation is only permissible in special cases.

In this instance the G-BH100 will not

achieve its full output.

IMPORTANT!

The connecting cable between the

G-BH100 and the external electronics must have a length of at maxi-

mum 0.5 m!

-1

0 V

0 ... 10 V DC green green

Open collector

max. 24 V / 10 mA

Low (0): < 0.5 V DC

High (1): > 4 V DC

max. 30 V DC

IMPORTANT!

When switching off the G-BH100 or

rapidly reducing its speed a current

i

feed into the mains might occur.

This can be prevented by inserting a

diode (Schottky diode, size 6A) in

the 24-V supply lead (+U

pink red

yellow black

blue blue

grey grey

Cable

new version

).

B

Page 17

Installation and Commissioning

5.2.2 Pipe/ hose connections (pump)

On delivery the suction and delivery branches of

the G-BH100 are sealed up in order to prevent

foreign bodies from entering the pump.

Do not remove the seals until right before connecting the pipes/ hoses.

IMPORTANT!

The G-BH100 must not be operated

with the suction or delivery branches

i

For the arrangement of the branches see Fig. 4,

page 10.

The operating direction of the G-BH100 is indicated by means of arrows:

The direction of rotation is indicated by an

arrow on the pump casing.

The delivery direction is indicated by arrows

on the suction and delivery branches.

i

The pumped gases / vapours are taken in via the

suction branch and are expelled via the delivery

branch.

The suction branch (see Fig. 4 # 4, page 10) is

indicated by an arrow pointing into the pump.

Connect the suction pipe to this branch.

The delivery branch (see Fig. 4 # 1, page 10) is

indicated by an arrow pointing out of the pump.

Connect the delivery pipe to this branch.

i

Make sure to connect the pipes / hoses so that

the G-BH100 will not be subject to any stress or

strain.

© Gardner Denver Deutschland GmbH 17 / 30 610.44431.40.000

sealed up or jammed!

IMPORTANT!

The main or operating direction of

rotation of the G-BH100 is the counter-clockwise rotation, given by the

arrow indicating the direction of rotation on the pump lid.

Only with the counter-clockwise rotation the nominal values will be

achieved.

Clockwise rotation is only permissible in

special cases. In this instance the GBH100 will not achieve its full output.

IMPORTANT!

These instructions apply to the counter-clockwise rotation!

In case of clockwise rotation the suction and delivery branches are exchanged!

i

i

WARNING!

Rotating impeller - hazard of severing limbs!

In case of operation with open suction or delivery branches (drawing-in

of gases from or discharge of gases

into the surroundings) a piece of

pipe or hose with a length of at

least 120 mm must by all means be

connected to the branch in question

in order to prevent the impeller from

being reached by fingers!

IMPORTANT!

The pipes/ hoses must be attached

in a secure and tight fashion.

They must be locked against unintentional loosening e.g. due to vibrations, thermal expansion, etc.

WARNING!

Check pipes/ hoses and vessels for

sufficient strength!

WARNING!

Check pipe/ hose connections for

tightness!

IMPORTANT!

Provide a shut-off device and / or a

means for depressurisation in both

the suction and the delivery pipes.

Page 18

Installation and Commissioning

5.3 Commissioning

speed reference and applied to n

des

(0 to

10 V) to your desired value or the value given

WARNING!

Operation of the G-BH100 only:

with the pump lid assembled

with the pipes/ hoses connected to

the suction and delivery branches

or

in case of operation with open

suction or delivery branches

(drawing-in of gases from or discharge of gases into the surroundings)

with a piece of pipe or hose hav-

ing a length of at least 120 mm

connected to the branch in question

with bearing end housing

WARNING!

Do not reach into the G-BH100

through open suction or delivery

branches!

Do not insert any objects into the GBH100 through the openings!

IMPORTANT!

The G-BH100 must not be operated

with the suction or delivery branches

i

sealed up or jammed!

WARNING!

Before start-up

check pipes / hoses and vessels

for sufficient strength!

check pipe / hose connections for

tightness!

check fasteners for secure fixing

Proceed as follows:

Make sure

- that the suction and delivery pipes are cor-

rectly connected,

- that in case of operation with open suction

or delivery branches (drawing-in of gases

from or discharge of gases into the surroundings)

a piece of pipe or hose having a length of

at least 120 mm is connected to the

branch in question in order to prevent the

impeller from being reached by fingers.

- that the suction and delivery pipes are not

jammed,

- that all fasteners are properly tightened,

- that the correct voltage and current are

applied.

Set the control voltage serving as speed ref-

erence and applied to n

to 0 V at first.

des

Turn on the indicated operating voltage.

Now increase the control voltage serving as

610.44431.40.000 18 / 30 © Gardner Denver Deutschland GmbH

on the data sheet. By means of this speed

control the operating point of the G-BH100 is

adapted to the operating point of the system.

Check the connections for tightness (ensure

that there is no fluid leakage).

Page 19

6 Operation

Operation

WARNING!

Operation of the G-BH100 only:

with the pump lid assembled

with the pipes / hoses connected

to the suction and delivery branches or

in case of operation with open suction or delivery branches (drawingin of gases from or discharge of

gases into the surroundings) with

a piece of pipe or hose having a

length of at least 120 mm connected to the branch in question

with the bearing end housing

IMPORTANT!

The G-BH100 must not be operated

with the suction or delivery branches

i

Speed control:

During operation the speed of the G-BH100 can

be modified. This allows to adapt the operating

point of the G-BH100 to changes in the operating

point of the system.

In order to do so adjust the control voltage applied to n

sealed up or jammed!

CAUTION!

Burning and scalding hazard due to

hot surfaces of the G-BH100!

Do not touch during operation!

WARNING!

Before start-up and at regular intervals

check pipes / hoses and vessels

for sufficient strength!

check pipe / hose connections for

tightness!

check fasteners for secure fixing

within a range of 0 to 10 V.

des

© Gardner Denver Deutschland GmbH 19 / 30 610.44431.40.000

Page 20

Servicing

7 Servicing

WARNING!

Before beginning to work on the GBH100 or the system carry out the following steps for both the G-BH100 and

the entire system

switch off electricity,

lock against restart,

ensure absence of electricity,

ground and short-circuit installation,

cover or bar adjacent live parts,

depressurise both pipes and pump.

WARNING!

Disassembly of

the pump lid

the pipe / hose connections

the guard in front of the motor

only after the impeller and the rotor

have come to a complete standstill!

Consider run-out!

Disassembly of the bearing end housing is prohibited!

CAUTION!

Burning and scalding hazard due to hot

surfaces of the G-BH100!

Let the unit cool after shut-down!

WARNING!

Do not reach into the G-BH100 through

open suction or delivery branches!

Do not insert any objects into the GBH100 through the openings!

CAUTION!

After loosening clampings and fastening elements some parts and components are only held in place by their

centrings or seatings or are no longer

held in place at all so that they might

fall down.

WARNING!

Before recommissioning

completely re-assemble the G-

BH100

check if all fasteners have been re-

assembled and tightened

check pipes / hoses and vessels for

sufficient strength

check pipe / hose connections for

tightness

7.1 Maintenance

7.1.1 Cleaning

Exterior:

In case of lint or dust on the pump:

Interior:

See also Fig. 9, page 21

Disassemble pump lid (# 3).

Remove lint using e.g. a pair of tweezers.

Re-assemble pump lid (# 3).

Screw in the bolts (# 1)

WARNING!

Work on electrical installations may be

carried out by trained and authorised

electricians only!

Clean the entire surface of the G-BH100 wiping it with a wet cloth.

In order to do so loosen the four bolts (# 1)

and carefully pull off the lid in axial direction

(see arrow) so that the pin is not bent.

IMPORTANT!

Don not detach the impeller nut

(# 4)! Do not disassemble the impel-

i

i

In order to do so carefully set the lid to the

pump so that the pin is inserted in the hole

and thus the lid is aligned. Carefully place the

lid on the pump in axial direction (see arrow)

so that the pin is not bent.

securing them using Loctite 243.

Fastening torque of the bolts:

= 2 Nm 0.2

T

f

ler (# 4)!

Otherwise, inside the motor the rotor

would be displaced by a spring resulting in the G-BH100 having to be

completely disassembled and reassembled!

IMPORTANT!

Do not use compressed air in order

to clean the pump interior since this

might result in dirt entering the motor

interior.

610.44431.40.000 20 / 30 © Gardner Denver Deutschland GmbH

Page 21

Servicing

1 Bolts

2 Impeller

1

3

4

2

3 Pump lid

4 Impeller nut

Fig. 9: Disassembly/ assembly of the pump lid

7.1.2 Inspection

Carry out the following tasks on the G-BH100 at

regular intervals:

Fastening to the mounting surface:

Tighten fixing bolts.

Fastening torque: according to property class

8.8 of the bolts or nuts

used as given in ISO 898

Cable entry:

Tighten screwed cable glands.

Fastening torques:

- on casing side: T

- on cable side: T

Suction and delivery branches:

Check pipe / hose connections for secure fixing and tightness.

Check pipes / hoses for tightness.

Consider material fatigue!

Replace worn parts.

© Gardner Denver Deutschland GmbH 21 / 30 610.44431.40.000

= 3.2 Nm ± 0.2

f

= 1.5 Nm ± 0.2

f

7.1.3 Lubrication

IMPORTANT!

The bearings of the G-BH100 are

provided with a lifetime lubrication

i

and assembled in the pump by adhesive bonding.

Page 22

Servicing

7.2 Repair/ Troubleshooting

Fault Cause Remedy Carried out by

Motor does

not start, no

motor noise.

Motor does

not start,

humming

noise.

At least two power supply

leads interrupted.

No signal at control signal

inputs A and B.

No speed reference value

given.

Impeller jammed. Open pump lid, remove dirt and foreign bodies,

Check fuses, terminals and supply leads and

close circuit where interrupted.

Apply control signals, see section 5.2.1,

"Electrical Connection (Motor)", page 11.

Set speed reference value, see section 5.2.1,

"Electrical Connection (Motor)", page 11.

as described in section 7.1.1, "Cleaning", page 20.

Electrician

Electrician

Electrician

Qualified personnel

Impeller damaged. Replace impeller. Service

Motor bearing damaged. Replace "complete casing" (i.e. the unit consist-

Service

ing of casing, stator and two ball bearings).

Wrong connection of motor connecting leads.

Check and, if necessary, correct the connection

of the motor phases and hall signals to the drive

Electrician

electronics, see section 5.2.1, "Electrical Connection (Motor)", page 11.

Power consumption too

high.

Winding short-circuit. Have winding checked. Electrician

Motor overload. Reduce operating pressure. If necessary, clean

filter, silencers, and pipes.

Qualified personnel

Impeller jammed. See "Motor does not start, humming noise". Qualified per-

sonnel

No vacuum /

pressure or

too little vacuum / pressure generated.

Leak in the system. Seal leak in the system. Qualified per-

sonnel

Wrong direction of rotation.

Reverse direction of rotation by applying the

correct signals to the control signal inputs A and

Electrician

B see section 5.2.1, "Electrical Connection (Motor)", page 11.

Speed reference value

representing the desired

speed (n

) too low.

des

Temperature of the electronics too high.

Adjust speed reference value (n

range of 0...10 V.

) within a

des

Qualified personnel

Provide sufficient heat dissipation and cooling. Qualified per-

sonnel

Blower too small. Use bigger blower. Operator /

qualified personnel

Density of the pumped

gas unequal 1.23 g/m³

(= density of air at 15°C

Use bigger blower. Operator /

qualified personnel

[59°F] and 1013 mbar).

Abnormal

screeching

noise.

Impeller dirty. Clean impeller;

if worn, have impeller replaced.

Flow rate too high. Increase pipe cross section, clean pipe. Qualified per-

Ball bearing damaged. Replace "complete casing" (i.e. the unit consist-

Qualified personnel / Service

sonnel

Service

ing of casing, stator and two ball bearings).

Impeller leak. Relative pressure be-

tween blower and surroundings too high.

The permissible differential pressure between

the pump interior and the surroundings has

been exceeded. Make sure that the differential

Qualified personnel

pressure is not exceeded.

Current feed

to the mains.

Caused by switching off

or rapidly reducing the

speed of the blower.

Insert a diode (Schottky diode, size 6A respectively10A) in the 24V respectively 48V supply

lead (+V

CC

).

Electrician

610.44431.40.000 22 / 30 © Gardner Denver Deutschland GmbH

Page 23

Shutting Down and Measures for Prolonged Standstill

8 Shutting Down and Measures for Prolonged Standstill

IMPORTANT!

If the storage period exceeds one

year the life expectancy of the bear-

i

Measures after shutdown / before storage:

Seal up the suction and delivery branches.

Provide loose lead ends with an ESD-

prevention bag.

Ensure the correct storage conditions (see

below).

Storage conditions:

Ambient temperature -20°C...+70°C

Relative humidity 10% ... 95%

Atmospheric pressure 500 hPa ... 1,100 hPa

Vibrations see section 3, "Technical

Measures before recommissioning after storage:

ings might be reduced.

(-4°F…+158°F)

Data", page 6.

Make sure that there is no oxide layer on the

contacts. If necessary, remove oxide layer.

Make sure that the insulation of the electrical

connecting cable has not become porous.

© Gardner Denver Deutschland GmbH 23 / 30 610.44431.40.000

Page 24

EC Declaration of Conformity

EC Declaration of Conformity

EU declaration of conformity

Manufacturer:

Gardner Denver Deutschland GmbH

P.O. Box 1510

D-97605 Bad Neustadt / Saale

Responsible for documentation:

Holger Krause

P.O. Box 1510

D-97605 Bad Neustadt / Saale

Designation:

G series Side channel blower

G-BH10

Types 2BH10 02-.AB32

2BH10 02-.AB22

2BH10 02-.AA53

The side channel blower described above meets the following applicable Community harmonisation legislation:

2004/108/EC*)

Directive 2004/108/EC of the European Parliament and of the Council of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC

2006/42/EC

Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC

The protection targets of the directive 2006/95/EC have been met

Harmonised standards applied:

EN 1012-2:1996

Compressors and vacuum pumps — Safety requirements — Part 2: Vacuum pumps

+A1:2009

Other technical standards and specifications used:

EN 1012-1:1996

Compressors and vacuum pumps — Safety requirements — Part 1: Compressors

Bad Neustadt/Saale, 23.04.2010

(Place and date of issue)

Thomas Kurth, Managing Director

(Name and function) (Signature)

*)

applies only to 2BH10 02-_AB32 664.44431.40.000

610.44431.40.000 24 / 30 © Gardner Denver Deutschland GmbH

Page 25

© Gardner Denver Deutschland GmbH 25 / 30 610.44431.40.000

Page 26

610.44431.40.000 26 / 30 © Gardner Denver Deutschland GmbH

Page 27

© Gardner Denver Deutschland GmbH 27 / 30 610.44431.40.000

Page 28

610.44431.40.000 28 / 30 © Gardner Denver Deutschland GmbH

Page 29

© Gardner Denver Deutschland GmbH 29 / 30 610.44431.40.000

Page 30

Elmo Rietschle is a brand of

Gardner Denver‘s Industrial Products

Group and part of Blower Operations.

www.gd-elmorietschle.de

er.de@gardnerdenver.com

Gardner Denver

Schopfheim GmbH

Roggenbachstraße 58

79650 Schopfheim · Deutschland

Tel. +49 7622 392-0

Fax +49 7622 392-300

Gardner Denver

Deutschland GmbH

Industriestraße 26

97616 Bad Neustadt · Deutschland

Tel. +49 9771 6888-0

Fax +49 9771 6888-4000

Loading...

Loading...