Page 1

Edition 05.2014 · 610.00260.40.000 Original operating instructions · English

Operating Instructions

2FC4...-1ST | 2FC4...-1PB | 2FC4...-1PN |

2FC4...-1SC | 2FC4...-1CB

Page 2

Contents

1 Overview of sizes ......................................................................... 4

2 Further information ...................................................................... 5

2.1 Storing the documentation ............................................................. 5

2.2 Explanation of the terms and symbols ........................................... 5

2.3 Changes in comparison to the previous version ............................ 6

2.4 Other valid documents ................................................................... 6

3 Safety and responsibility ............................................................. 7

3.1 Explanation of warning signs ......................................................... 7

3.2 Safety instructions .......................................................................... 7

3.2.1 General information ........................................................................ 7

3.2.2 Transport and Storage ................................................................... 8

3.2.3 Commissioning ............................................................................... 9

3.2.4 Operation ........................................................................................ 10

3.2.5 Maintenance and inspection .......................................................... 10

3.2.6 Repairs ........................................................................................... 11

3.2.7 Disassembly and Disposal ............................................................. 12

3.3 Correct use of the equipment ........................................................ 12

3.4 Staff qualifications and training ...................................................... 12

3.5 Requirements of the operator ........................................................ 13

4 Product identification ................................................................... 14

4.1 Model description ........................................................................... 14

4.2 Description of the drive control ...................................................... 14

4.3 CE marking ..................................................................................... 14

5 Installation ..................................................................................... 15

5.1 Safety instructions for installation .................................................. 15

5.2 Installation requirements ................................................................ 15

5.2.1 Suitable ambient conditions ........................................................... 15

5.2.2 Suitable installation location for the motor-integrated drive control

......................................................................................................... 16

5.2.3 Basic connection variations ........................................................... 16

5.2.4 Short-circuit and earth-fault protection .......................................... 17

5.2.5 Wiring instructions .......................................................................... 17

5.2.6 Preventing electromagnetic interference ....................................... 18

5.3 Installation of the drive controller integrated in the motor ............. 18

5.3.1 Mechanical installation of sizes A - C ............................................ 18

5.3.2 Mechanical installation of size D .................................................... 20

5.3.3 Power connection of sizes A - C .................................................... 22

5.3.4 Power connection of size D ............................................................ 23

5.3.5 Connections for braking resistor .................................................... 24

5.3.6 Control terminals ............................................................................ 24

5.3.7 Wiring diagram ............................................................................... 25

5.4 Installing the wall-mounted drive controller ................................... 26

5.4.1 Installation location that is suitable for wall mounting ................... 26

5.4.2 Mechanical installation ................................................................... 27

5.4.3 Power connection .......................................................................... 30

5.4.4 Braking chopper ............................................................................. 30

5.4.5 Control terminals ............................................................................ 30

6 Commissioning ............................................................................. 31

6.1 Safety information for commissioning ............................................ 31

6.2 Communication .............................................................................. 32

6.3 Block diagram ................................................................................ 33

610.00260.40.000 · 05.2014

2 / 74

© Gardner Denver Deutschland GmbH

Page 3

A

A

A

A

A

Contents

6.4 Commissioning steps ..................................................................... 34

6.4.1 Start up the integrated drive control .............................................. 34

6.4.2 Commission the drive control wall assembly and replacement ..... 34

7 Parameters .................................................................................... 36

7.1 Safety instructions for handling the parameters ............................ 36

7.2 General information on parameters ................................................ 36

7.2.1 Explanation of operating modes .................................................... 36

7.2.2 Structure of parameter tables ........................................................ 39

7.3

pplication parameter .................................................................... 40

7.3.1 Basic parameters ........................................................................... 40

7.3.2 Fixed frequency .............................................................................. 44

7.3.3 Motor potentiometer ...................................................................... 45

7.3.4 PID process controller .................................................................... 46

7.3.5

nalogue inputs .............................................................................. 47

7.3.6 Digital inputs ................................................................................... 49

7.3.7

nalogue output ............................................................................. 50

7.3.8 Digital outputs ................................................................................ 51

7.3.9 Relay ............................................................................................... 52

7.3.10 External error .................................................................................. 53

7.3.11 Motor current limit .......................................................................... 53

7.3.12 Blocking detection ......................................................................... 54

7.4 Power parameters .......................................................................... 55

7.4.1 Motor data ...................................................................................... 55

7.4.2 I

2

T ................................................................................................... 57

7.4.3 Switching frequency ....................................................................... 57

7.4.4 Controller data ................................................................................ 57

7.4.5 Square-law characteristic ............................................................... 59

7.4.6 Controller data for synchronous motor .......................................... 59

8 Error detection and elimination .................................................. 61

8.1 Display of the LED flash codes for error detection ........................ 61

8.2 List of errors and system errors ..................................................... 62

9 Technical data .............................................................................. 64

9.1 General data ................................................................................... 64

9.2 Derating of output power ............................................................... 65

9.2.1 Derating through increased ambient temperature ......................... 66

9.2.2 Derating due to installation altitude ................................................ 67

9.2.3 Derating due to the clock frequency .............................................. 68

10 Optional accessories ................................................................... 69

10.1

dapter plates ................................................................................ 69

10.2 Hand-held unit MMI, including 3 m connection cable RJ11 to

connector M12 ............................................................................... 71

10.3 PC communication cable USB to connector M12 (RS485/RS232

converter integrated) ...................................................................... 71

11 Guidelines, norms and standards ............................................... 72

11.1 EMC limit classes ........................................................................... 72

11.2 Classification acc. to IEC/EN 61800-3 ........................................... 72

11.3 Standards and guidelines ............................................................... 72

11.4

pproval according to UL .............................................................. 73

© Gardner Denver Deutschland GmbH

3 / 74

05.2014 · 610.00260.40.000

Page 4

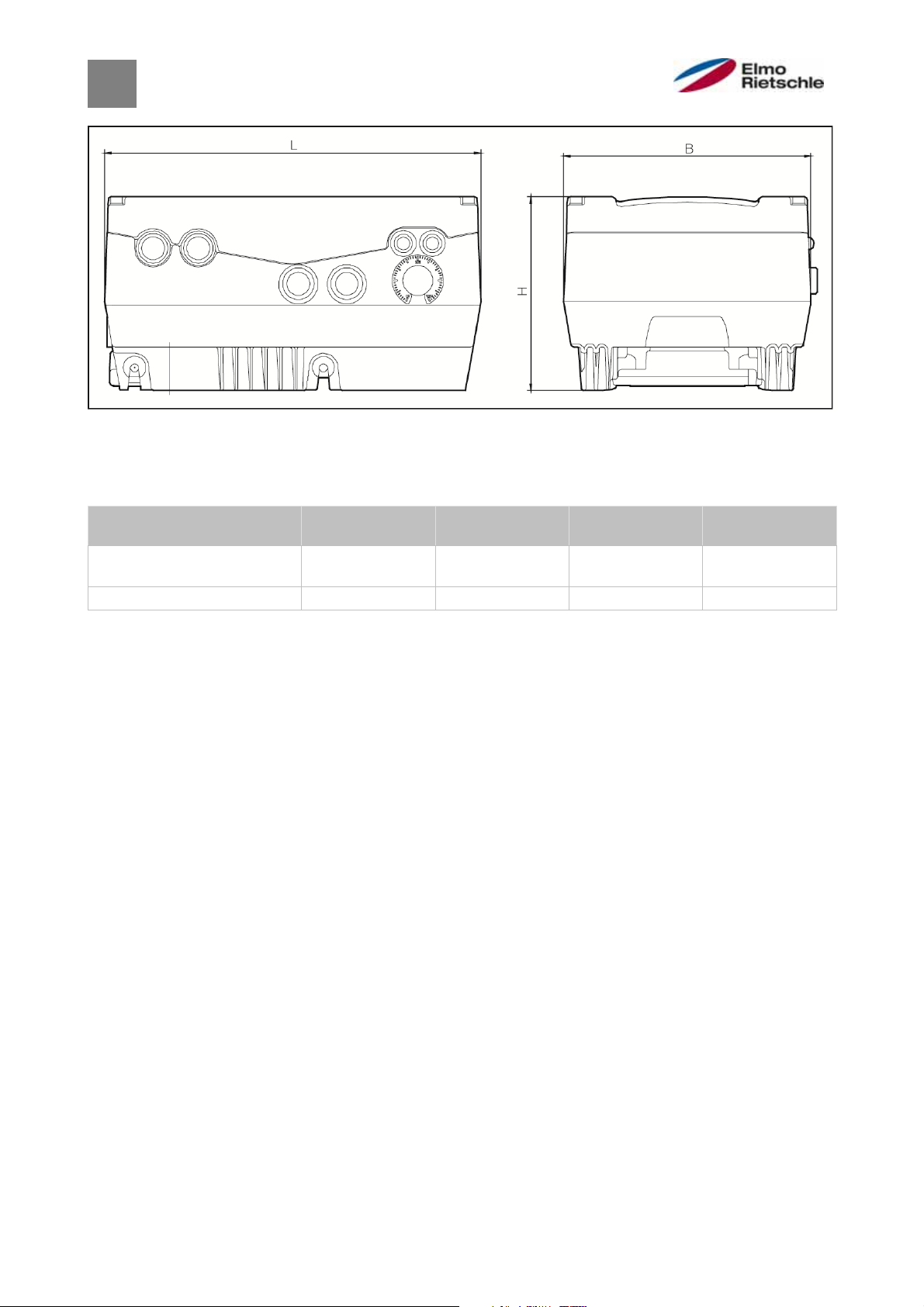

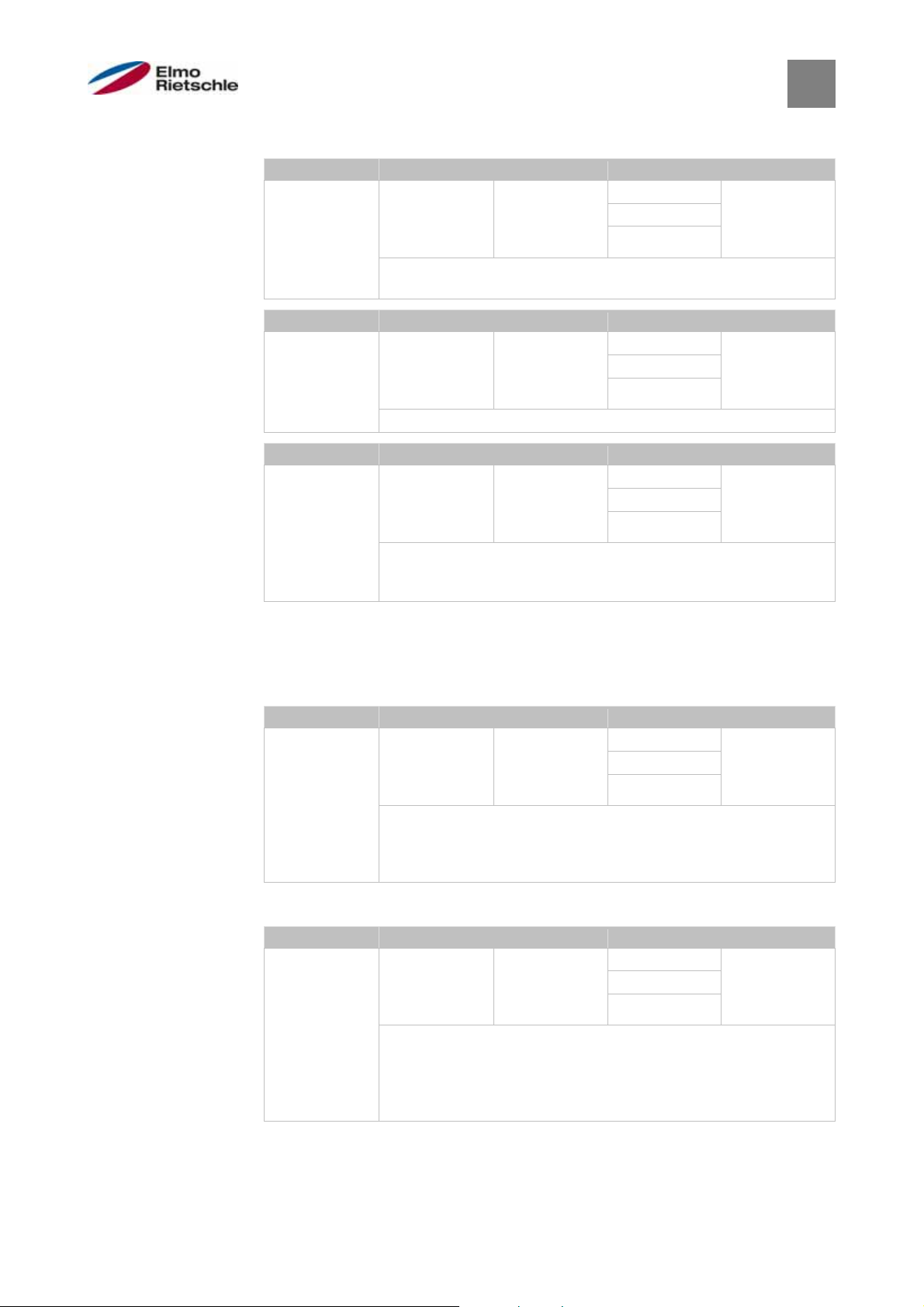

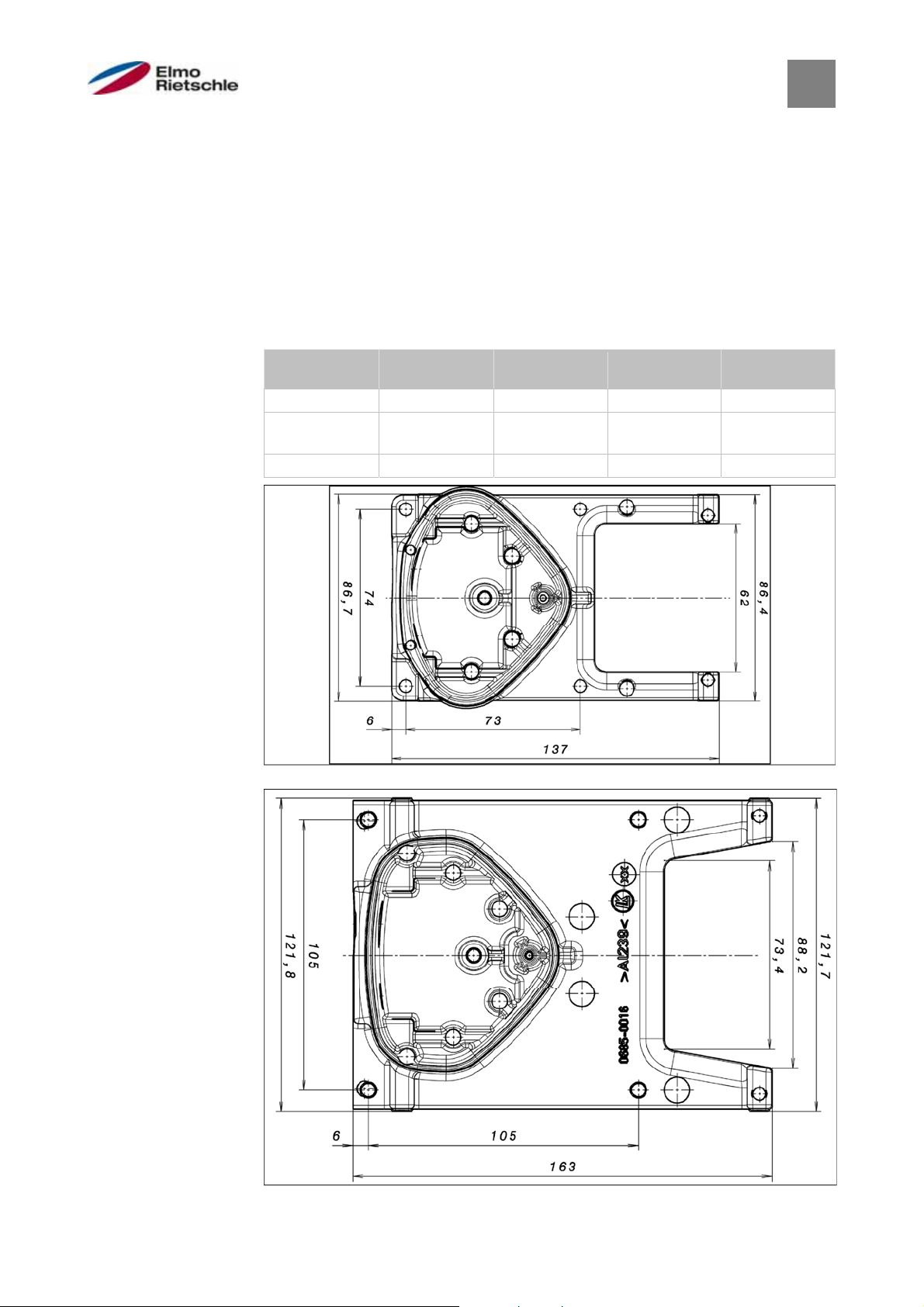

1

Overview of sizes

Overview of sizes

1

Dimensional drawings

The drive controls are available in the following performance classes with the

specified size names.

Sizes

Sizes drive controls motor

MA MB MC MD

integrated

Recommended motor power

[kW]

Dimensions L x B x H [mm] 233 x 153 x 120 270 x 189 x 140 307 x 223 x 181 414 x 294 x 232

1.5 2.2 / 3.0 / 4.0 5.5 / 7.5 11.0 / 15.0 /

18.5 / 22.0

610.00260.40.000 · 05.2014

4 / 74

© Gardner Denver Deutschland GmbH

Page 5

A

r

2

Further information

Storing the documentation

2.1

Store this manual and all other applicable documents safely so they are available

as and when required.

Provide the operator of the system with this manual so it is available as and when

required.

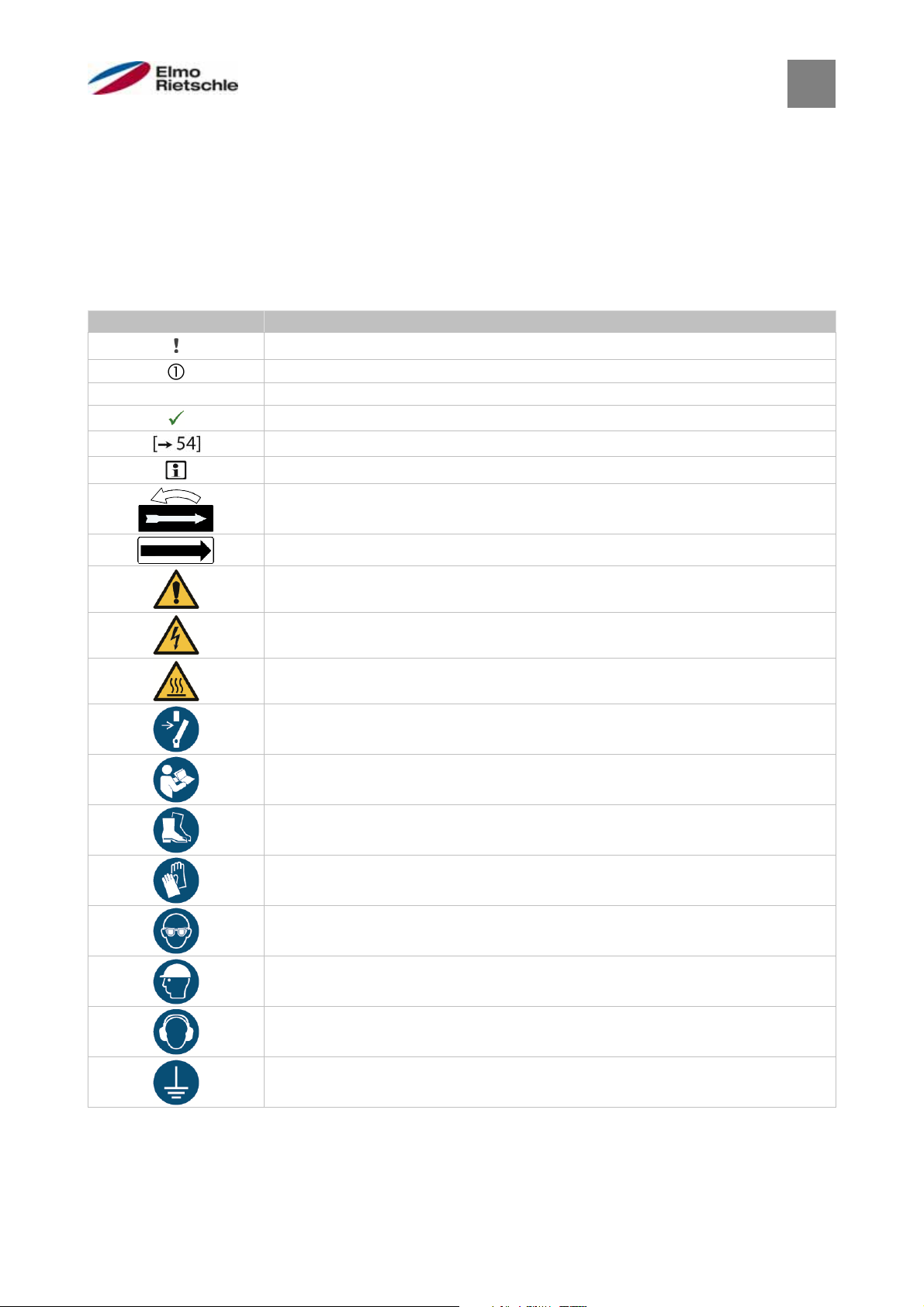

Explanation of the terms and symbols

2.2

In these instructions symbols and terms will be used to mean the following.

Symbol Explanation

Requirement, pre-requisite

One-step handling instructions

1 2 3 Multi-step handling instructions

Result

Cross reference with page reference

dditional information, tips

Direction of rotation arrow

Direction of conveyance arrow

General warning sign (warns of risk of injury)

Electrical voltage warning

Hot surface warning

Disconnect prior to maintenance or repai

Further information

2

Observe the instructions

Use foot protection

Use hand protection

Use eye protection

Use head protection

Use ear protection

Earth prior to use

© Gardner Denver Deutschland GmbH

5 / 74

05.2014 · 610.00260.40.000

Page 6

2

Further information

Term Explanation

Plant Part provided by the user in which the vacuum pump/compressor is installed.

Vacuum

pump/compressor

Ready to connect machine for the generation of a vacuum and/or overpressure.

The vacuum pump/compressor consists of a compressor part and motor, as well

as other accessories where applicable.

Motor Asynchronous motor for driving the vacuum pump/compressor.

Compressor Mechanical part of the vacuum pump/compressor without motor.

Assembly environment Space in which the vacuum pump/compressor is set up and operated (this may

differ from the suction environment).

Drive control Device for rotation speed control of the vacuum pump/compressor. The drive

control can be mounted close to the motor (wall assembly) or integrated into the

vacuum pump/compressor

Changes in comparison to the previous version

2.3

Amendments in comparison to version 02.2014

▪ 2.2 Explanation of the terms and symbols

▪ 5.3.6 Control terminals

Table: Terminal assignment X5 of the standard application card, terminal no. 6

▪ 6.4.1 Start up the integrated drive control

▪ 6.4.2 Commission the drive control wall assembly and replacement

▪ 7.2.1 Explanation of the operating modes

Table: Logic table of fixed frequencies parameter 1,020 deleted

▪ 7.3.1 Basic parameters

Parameter 1,131

Other valid documents

2.4

All instructions that describe the use of the drive control and if applicable, further

instructions of all accessory parts used, e.g.

Document number Purpose

— Vacuum pump/compressor operating ma

610.00260.01.010 *

610.00260.01.020 *

610.00260.01.030 *

Operating manual 2FC4...-1PB OR

Operating manual 2FC4...-1PN OR

Operating manual 2FC4...-1SC OR

610.00260.01.040 * Operating manual 2FC4...-1CB

610.00260.01.600 * MMI hand-held unit operating manual

*according to the model option or accessories

Download of 3D files (.stp) for drive control and adapter plates under www.gdelmorietschle.com.

To parameterise the drive control, the parameter description is ready to be

downloaded (www.gd-elmorietschle.com). The download contains all necessary

information for correct parameterisation.

nual

610.00260.40.000 · 05.2014

6 / 74

© Gardner Denver Deutschland GmbH

Page 7

3

Safety and responsibility

Safety and responsibility

3

The manufacturer is not liable for damage caused by the failure to observe these

instructions and the related documents [➙ 6].

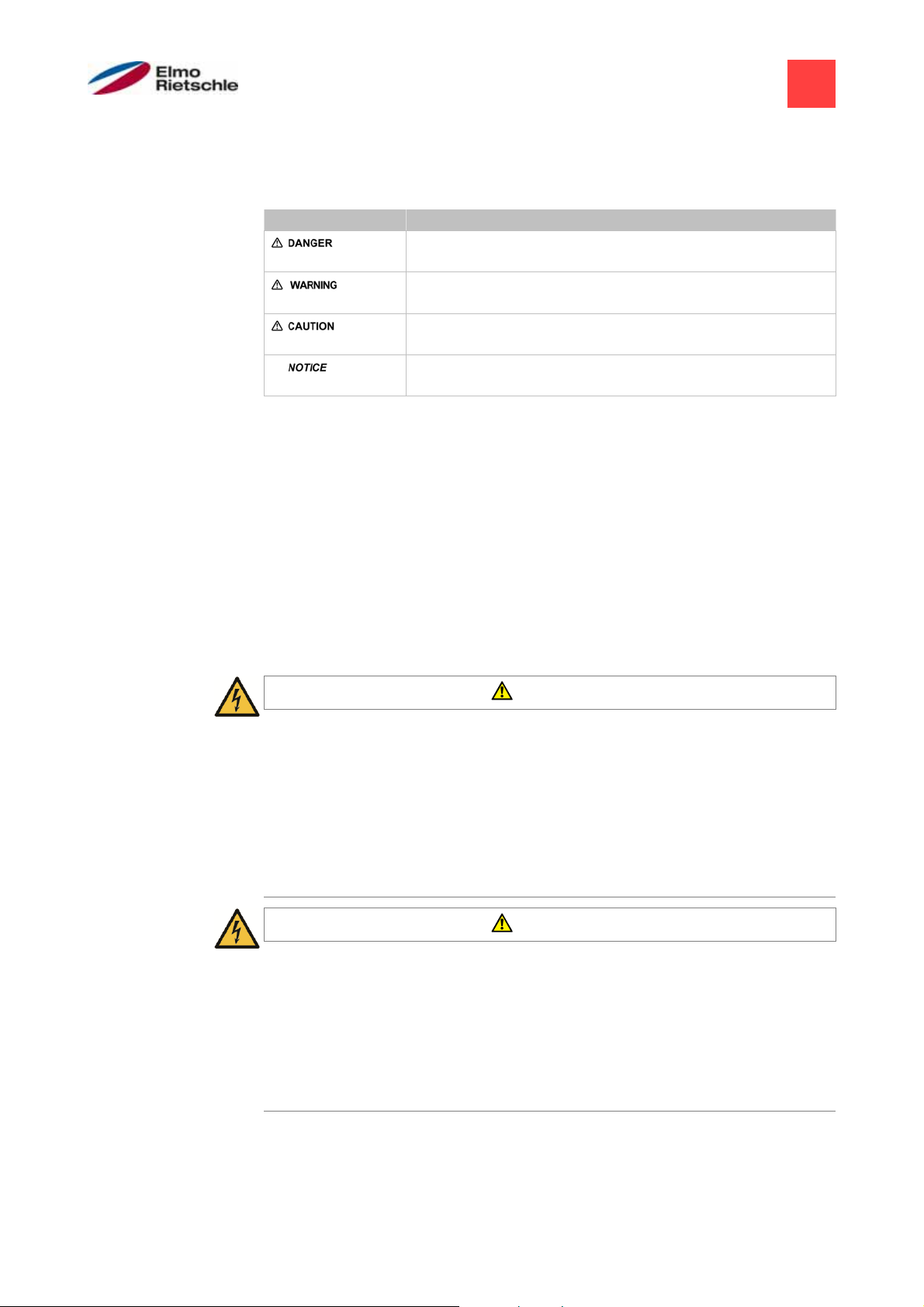

Explanation of warning signs

3.1

Warning sign Explanation

Danger that failure to observe the measures could lead to

death or serious physical injuries.

Danger that failure to observe the measures could lead to

death or serious physical injuries.

Danger that failure to observe the measures could lead to

minor physical injuries.

Danger that failure to observe the measures could lead to

3.2

Safety instructions

material damage.

The following warnings, precautionary measures and comments are provided for

your safety and serve to prevent damage to the drive control and the components

connected to it. This chapter contains warnings and information that are generally

applicable when handling drive controls. They are split into general information,

transport and storage, start-up, operation, repairs and dismantling & disposal.

Specific warnings and comments that apply to specific activities can be found at

the start of the appropriate chapters and are repeated and added to at various

critical points in these chapters.

Please read this information carefully as it is provided for your personal safety and

will also prolong the life of the drive control and connected devices.

3.2.1

General information

WARNING

This drive controller carries dangerous voltages and controls rotating mechanical parts which may be dangerous!

Disregarding the warnings or failure to follow the instructions contained in

this manual may lead to death, serious bodily injury or substantial property

damage.

Only qualified personnel should work on this drive controller. These personnel

must be thoroughly familiar with all safety instructions, installation, operation

and maintenance procedures contained in this manual. The smooth and safe

operation of the drive controller depends on proper handling, installation, operation and maintenance.

WARNING

Risk of fire or electric shock!

Improper use, modifications and the use of spare parts and accessories

that are not sold or recommended by the manufacturer of the drive controller can cause fire, electric shock and bodily injury.

The cooling element of the drive controller and motor can reach temperatures

of above 70°C [158 °F]. During installation, sufficient spacing between adjacent components should be maintained. Before working on the drive controller or motor, required cooling time must be ensured. If necessary, a protection

against accidental contact should be installed.

© Gardner Denver Deutschland GmbH

7 / 74

05.2014 · 610.00260.40.000

Page 8

3

Safety and responsibility

NOTICE

The drive controller may be operated safely only if the required ambient

conditions are met, see Suitable ambient conditions [➙ 15].

NOTICE

This operating manual must be kept in the vicinity of the equipment, so as

to be readily accessible to all users.

NOTICE

Please read these safety instructions and warnings carefully and all the

warning labels attached to the equipment before installing and commissioning. Make sure that the warning labels are kept in a legible condition and

replace missing or damaged labels.

3.2.2

Transport and Storage

NOTICE

Risk of damage to the drive controller!

The drive controller can be damaged in the case of non-compliance with

the instructions and destroyed during subsequent handling.

The smooth and safe operation of this drive controller requires proper mount-

ing, installation and assembly as well as careful operation and maintenance.

The drive controller must be protected during transport and storage against

mechanical shocks and vibration. The protection against excessive temperatures (see Technical data [➙ 64]) must be guaranteed.

610.00260.40.000 · 05.2014

8 / 74

© Gardner Denver Deutschland GmbH

Page 9

3.2.3

Commissioning

Safety and responsibility

3

DANGER

Risk of injury due to electric shock!

The non-observance of warnings can result in severe bodily injury or substantial property damage.

1. Only hard-wired grid connections are permitted. The device must be earthed

(DIN EN 61140; VDE 0140-1).

2. The drive controls may have contact currents > 3.5mA. According to DIN EN

61800-5-1 chapter 4.3.5.5.2, an additional protective earth conductor with the

same cross section as the original earth conductor must be attached. The

possibility of connecting a second protective earth conductor is located underneath the power supply (with marked ground symbol) on the outside of the

device. For the connection, a suitable M6x15 screw (torque: 4.0 Nm

[2.95 ft lbs]) is included in the scope of delivery of the adapter plates.

3. When using alternating current drive controls, conventional FI circuit breakers

of type A, also known as RCDs (residual current-operated protective devices)

are not permitted for the protection of direct or indirect contact! As per DIN

VDE 0160, section 5.5.2 and EN 50178, section 5.2.11.1, the FI circuit breaker

(RCD type B) must be suitable for all types of current.

4. The following terminals can also lead to dangerous voltages when the engine

is at a standstill:

the mains connection terminals X1: L1, L2, L3

the motor connection terminals X2: U, V, W

the connection terminals X6, X7: Relay contacts relays 1 and 2

the PTC connection terminals T1/T2

5. When using different voltage levels (e.g. +24V/230V), always ensure that lines

do not cross! Furthermore, the operator must ensure that the applicable regulations are adhered to (e.g. doubled or reinforced insulation according to DIN

EN 61800-5-1).

6. The drive control contains electrostatically sensitive assemblies. These assemblies can be destroyed due to improper handling, therefore safety measures against electrostatic loading must be adhered to when work must be

done on these assemblies.

© Gardner Denver Deutschland GmbH

9 / 74

05.2014 · 610.00260.40.000

Page 10

3

Safety and responsibility

3.2.4

Operation

DANGER

Risk of injury from electric shock or restarting motors!

The non-observance of warnings can result in severe bodily injury or substantial property damage.

Observe the following instructions during operation:

The drive controller operates at high voltages.

When operating electrical equipment, certain parts of the equipment carry

dangerous voltage.

Emergency stop devices according to EN 60204-1:2006 must remain op-

erative in all operating modes of the control unit. Resetting the emergency

stop device must not lead to uncontrolled or undefined restart.

Safe disconnection from the mains requires synchronous and all-pole dis-

connection of the mains supply line to the drive controller.

For devices with single-phase supply and for the BG D (11 to 22 kW), at

least 1 to 2 min break should be kept between successive connections to

the mains.

Certain parameter settings may cause the drive controller to restart auto-

matically after a power failure.

NOTICE

Risk of damage to the drive controller!

The drive controller can be damaged in the case of non-compliance with

the instructions and destroyed during subsequent handling.

1. Observe the following instructions during operation:

2. For a functioning motor overload protection, the motor parameters must be

configured correctly.

3. Ensure the motor overload protection via a PTC. In addition, the drive control

provides an internal motor protection. See also parameter 33.100 and 33.101.

According to the presetting, the I

eration without PTC.

4. The drive controller must not be used as an 'emergency stop device' (see EN

60204-1:2006).

2

T is OFF and must be activated during op-

3.2.5

610.00260.40.000 · 05.2014

Maintenance and inspection

Maintenance and inspection of the drive controllers must be performed only by

electrically certified, qualified person. Changes in hardware and software, unless

explicitly described in this manual, may only be performed by the manufacturer.

Cleaning the drive controllers

The drive controllers are maintenance-free when operated properly. In a dusty environment, the cooling ribs on the motor and the drive controller must be cleaned

regularly. For equipment that are equipped with integrated fans, option for BG C,

series in BG D, cleaning with compressed air is recommended.

Measurement of insulation resistance on the control unit

Insulation test at the input terminals of the control card is not permitted.

10 / 74

© Gardner Denver Deutschland GmbH

Page 11

Safety and responsibility

3

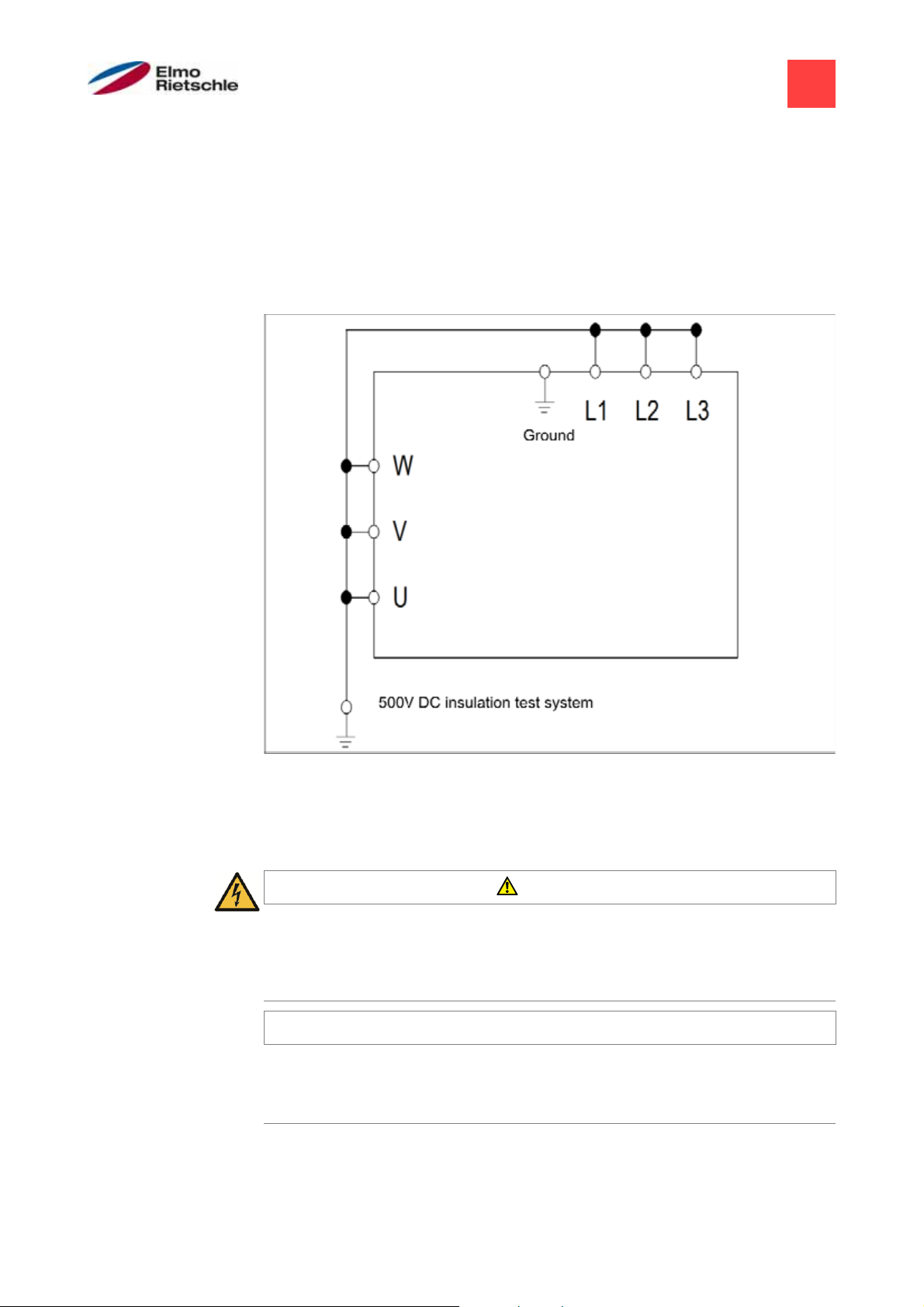

Measurement of insulation resistance on the power unit

In the course of the series testing, the power unit of the drive controller is tested

by applying 1.9 kV.

Should the measurement of insulation resistance be necessary in a system check,

then this can be carried out under the following conditions:

▪ an insulation test can be performed only for the power unit,

▪ to avoid impermissible high voltages, all connecting cables of the drive con-

troller must be disconnected prior to the test,

▪ a 500 V DC insulation tester is used.

Insulation test on the power unit

Pressure test on a DRIVE CONTROLLER

3.2.6

A pressure test of the drive controller is not allowed.

Repairs

DANGER

Danger of injury through electric shock!

Non-observance of warnings may result in serious injury or damage.

When the drive control is disconnected from the mains voltage, live device

parts and connections may not be touched immediately in case the condensers are still live.

NOTICE

Risk of damage to the drive control!

If the information is not observed, the drive control could be damaged and

destroyed during subsequent start-up.

Repairs to the drive control may only be performed by the manufacturer.

© Gardner Denver Deutschland GmbH

11 / 74

05.2014 · 610.00260.40.000

Page 12

3

Safety and responsibility

3.2.7

Disassembly and Disposal

Screw and snap-on connections are easy to release and allow the drive

control to be dismantled into its individual parts. These parts can be sorted

for recycling. Please comply with local regulations during disposal.

Components with electronic parts may not be disposed of along with normal household waste. They have to be collected separately with used electrical and electronic equipment in accordance with applicable legislation.

Correct use of the equipment

3.3

During installation in machinery, commissioning of the drive controller (i.e. starting

of intended operation) is prohibited until it is proven that the machine complies

with the regulations of the EC Directive 2006/42/EC (Machinery Directive); EN

60204-1:2006 is to be observed.

Commissioning (i.e. starting of intended operation) is only permitted if the EC Directive 2004/108/EC (EMC Directive) allows it.

The harmonised standards of the series EN 50178:1997 in conjunction with EN

60439-1/A1:2004 shall be applied to this drive controller.

This drive controller is not approved for operation in potentially explosive areas!

Repairs may only be carried out by authorised repair workshops. Unauthorised interventions can lead to death, bodily injury and property damage. The warranty

provided by the manufacturer expires in this case.

External mechanical loads, such as stepping on the casing are not allowed!

The use of the drive units in non-stationary equipment is considered as unusual environmental conditions, and is permitted only in accordance with

the locally applicable standards and guidelines.

Staff qualifications and training

3.4

All those who will work on the must have read and understood these instructions

and the related documents [➙ 6].

Personnel in training may only work on the under supervision of personnel who

have the required knowledge.

Only allow work on the to be carried out by personnel with the following knowledge:

In the context of this operating manual and the information relating to the product

itself, qualified staff refers to electronic specialists who are familiar with the installation, assembly, start-up and operation of the drive control and the dangers involved, and whose specialist training and knowledge of relevant standards and

regulations provide them with the necessary abilities.

610.00260.40.000 · 05.2014

12 / 74

© Gardner Denver Deutschland GmbH

Page 13

Requirements of the operator

3.5

Safety and responsibility

3

As a basic principle, electronic devices are not fail-proof. The operator and/or the

contractor setting up the machine or system is responsible for ensuring that the

drive switches to a safe state if the device fails.

The “Electrical equipment of machines” section in EN 60204-1, “Safety of machinery” describes the safety requirements for electrical control units. These are

provided for the safety of people and machines and must be observed in order to

retain the functional capability of the machine or system.

An emergency stop feature does not have to result in the power supply to the

drive being switched off. To avoid dangerous situations, it may be useful for individual drives to remain operational or for specific safety procedures to be initiated.

The effectiveness of emergency stop measures is evaluated by means of a risk

assessment for the machine or system and its electrical equipment, and is determined by selecting a circuit category according to EN 13849 “Safety of machinery

– Safety-related parts of control systems”.

The operator ensures that:

▪ All work on the is carried out by:

– personnel that have the necessary Staff qualifications and training [➙ 12]

– personnel that have been sufficiently informed of these instructions and all

related documents [➙ 6]

▪ Assignment, responsibility and supervision of personnel is regulated.

▪ The content of these and locally applicable instructions are always available to

personnel.

▪ All local and plant-specific safety measures are adhered to, such as:

– Prevention of accidents

– safety and operating regulations

– Utility company regulations

– Standards and laws

▪ Dangers due to electrical energy are not possible.

© Gardner Denver Deutschland GmbH

13 / 74

05.2014 · 610.00260.40.000

Page 14

V

4

4

Product identification

Product identification

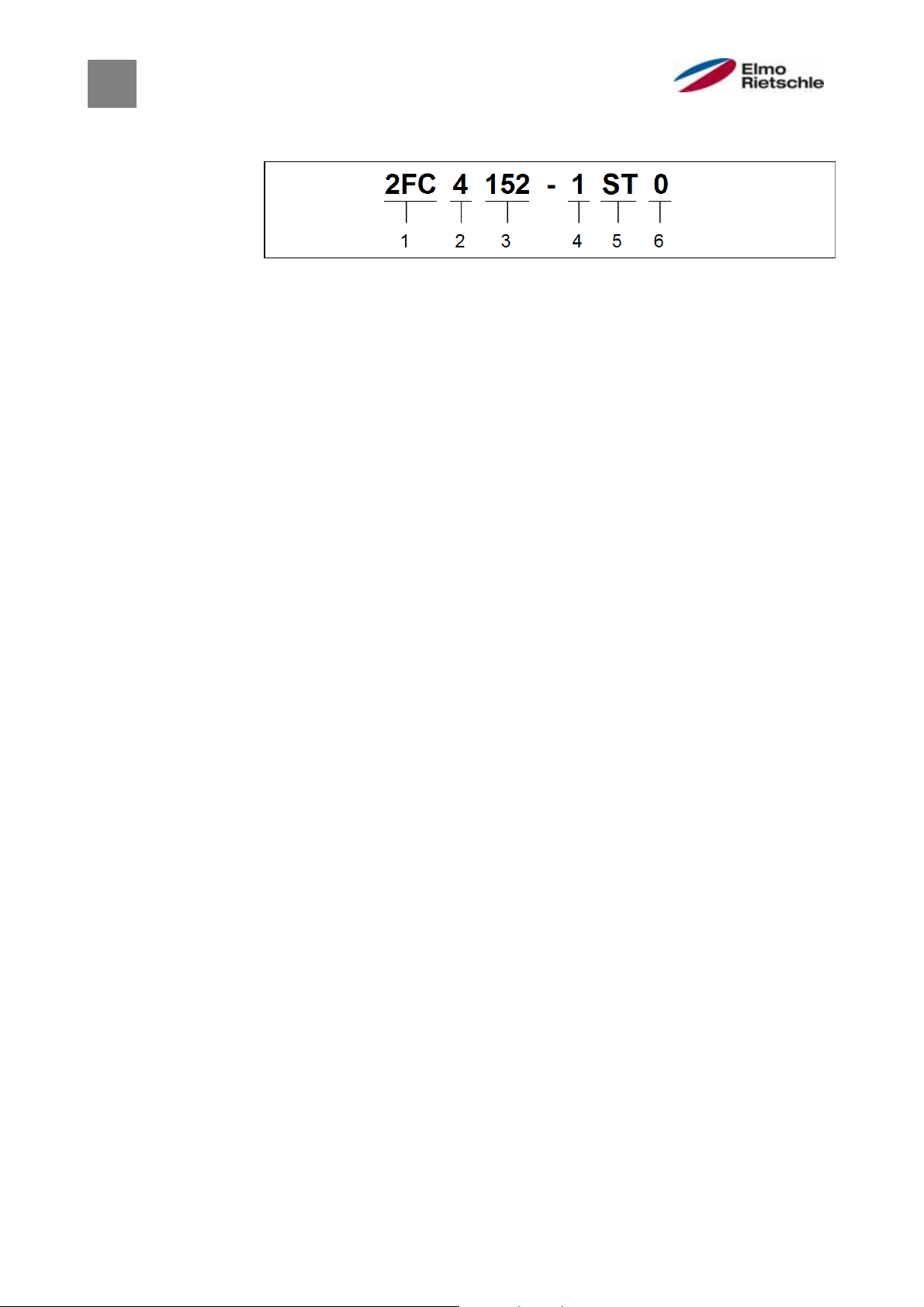

Model description

4.1

Item designation

1

2FC = drive control

4 Type of assembly:

1 = integrated drive control

2 Connection voltage:

4 = 400 V -15% — 480 V +10%

ersion:

5

ST = Standard

PB = Profibus

PB = Profinet

SC = Sercos III

CB = CANopen

3 Performance:

152 = 1.5 kW

6 reserved:

0 = Standard

222 = 2.2 kW

302 = 3.0 kW

402 = 4.0 kW

552 = 5.5 kW

4.2

752 = 7.5 kW

Description of the drive control

The drive control is a device for speed control in three-phase AC motors.

The drive control can be integrated in the motor (with the standard adapter plate)

or fitted close to the motor (with the wall installation adapter plate).

The permitted ambient temperatures specified in the technical data refer to operation at nominal load. In many cases, higher temperatures may be permitted after a

detailed technical analysis. These have to be approved by manufacturer on a

case-by-case basis.

4.3

610.00260.40.000 · 05.2014

CE marking

With the CE marking, we, as the manufacturer of the device, confirm that the drive

control meets the basic requirements of the following guidelines:

▪ Directive on Electromagnetic Compatibility (Directive 2004/108/EC)

▪ Low Voltage Directive (Directive 2006/95/EC)

You can download the declaration of conformity from www.gd-elmorietschle.com.

14 / 74

© Gardner Denver Deutschland GmbH

Page 15

A

A

5

Installation

Safety instructions for installation

5.1

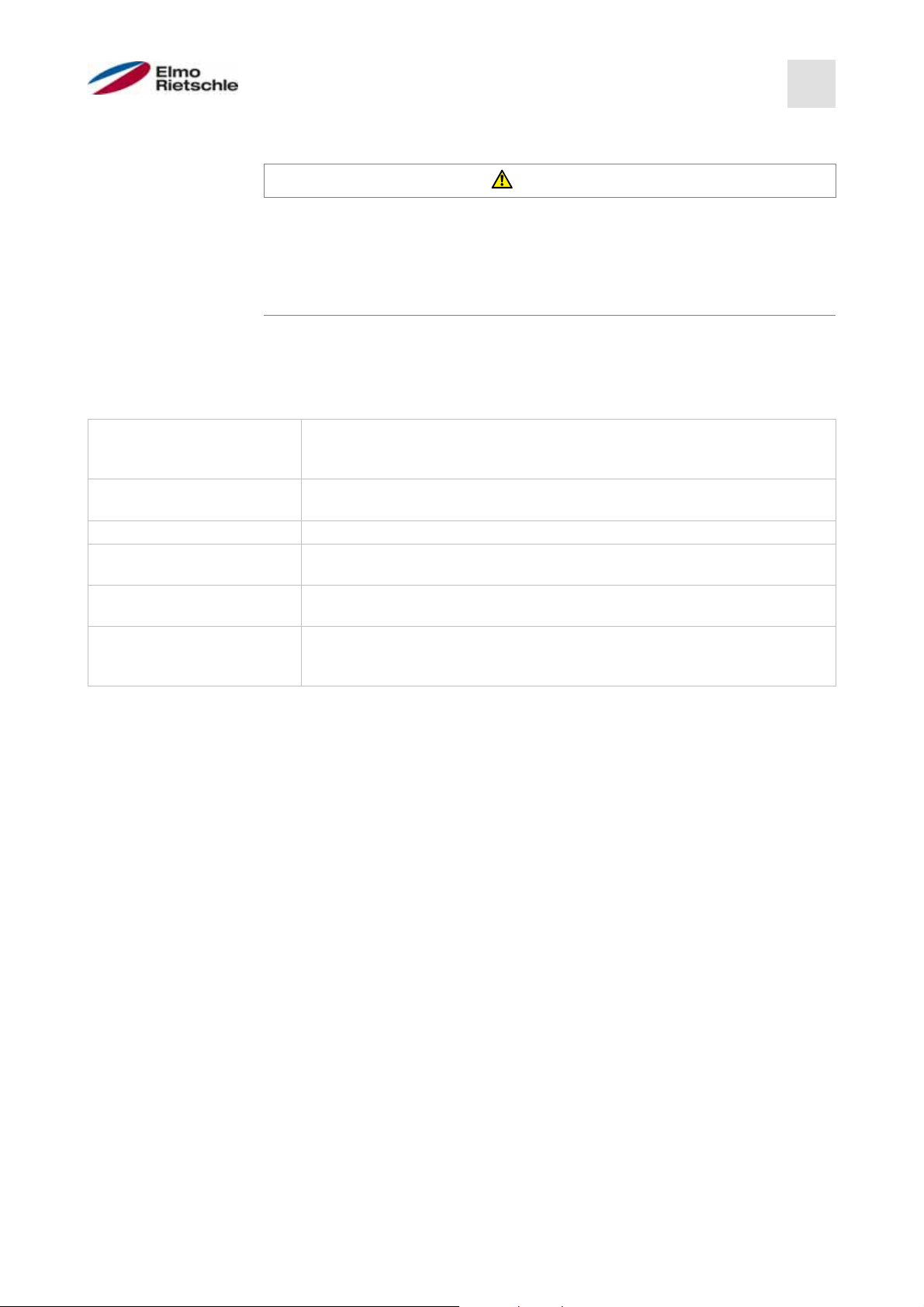

WARNING

1. Installation may only be performed by appropriately qualified employees who

are trained in the set-up, installation, start-up and operation of the product.

Work performed on the drive control by unqualified staff and non-observance

of warnings may result in serious injury or damage.

2. The device must be grounded in accordance with EN 61140, NEC and other

5.2

5.2.1

relevant standards. Mains connections must be hardwired.

Installation requirements

Suitable ambient conditions

Ambient conditions

ltitude of the installation

site:

Up to 1000 m above sea level [3280 ft above sea level] / over 1000 m

[3280 ft] with reduced performance (1% per 100 m [328 ft]) max. 2000 m

[6560 ft], see

mbient temperature:

-25°C [-13°F] to +50°C [122°F]

(different ambient temperatures may be possible in individual cases) , see

Relative humidity: ≤ 96%, condensation not permitted

Resistance to vibration and

shock:

Electromagnetic compatibil-

acc. to FN 942 017 part 4; 5.3.3.3 Combined test 2;

5...200 Hz for sinusoidal oscillation

Immune to interference acc. to EN 61800-3

ity:

Cooling: Surface cooling:

sizes A to C: free convection;

size D: with integrated fans

! Ensure that the housing type (protection type) is suitable for the operating en-

vironment:

1. Ensure that the seal between the motor and the adapter plate is inserted correctly.

2. All unused cable screw connections must be sealed.

3. Check that the cover of the drive control is closed and bolted down tightly.

Although the drive control can, in principle, be painted later on, the user must

nevertheless check the material compatibility of the intended paint. Failure to

comply with this requirement may eventually result in the loss of the protection

class (particularly in respect to seals and fibre-optic elements). The standard colour is black (RAL 9005).

Disassembling the circuit boards (even for the purpose of painting the housing

sections) renders the warranty void!

Mounting points and sealing surfaces must be kept free of paint for purposes of

EMC and grounding!

Installation

5

© Gardner Denver Deutschland GmbH

15 / 74

05.2014 · 610.00260.40.000

Page 16

5

Installation

5.2.2

Suitable installation location for the motor-integrated drive

control

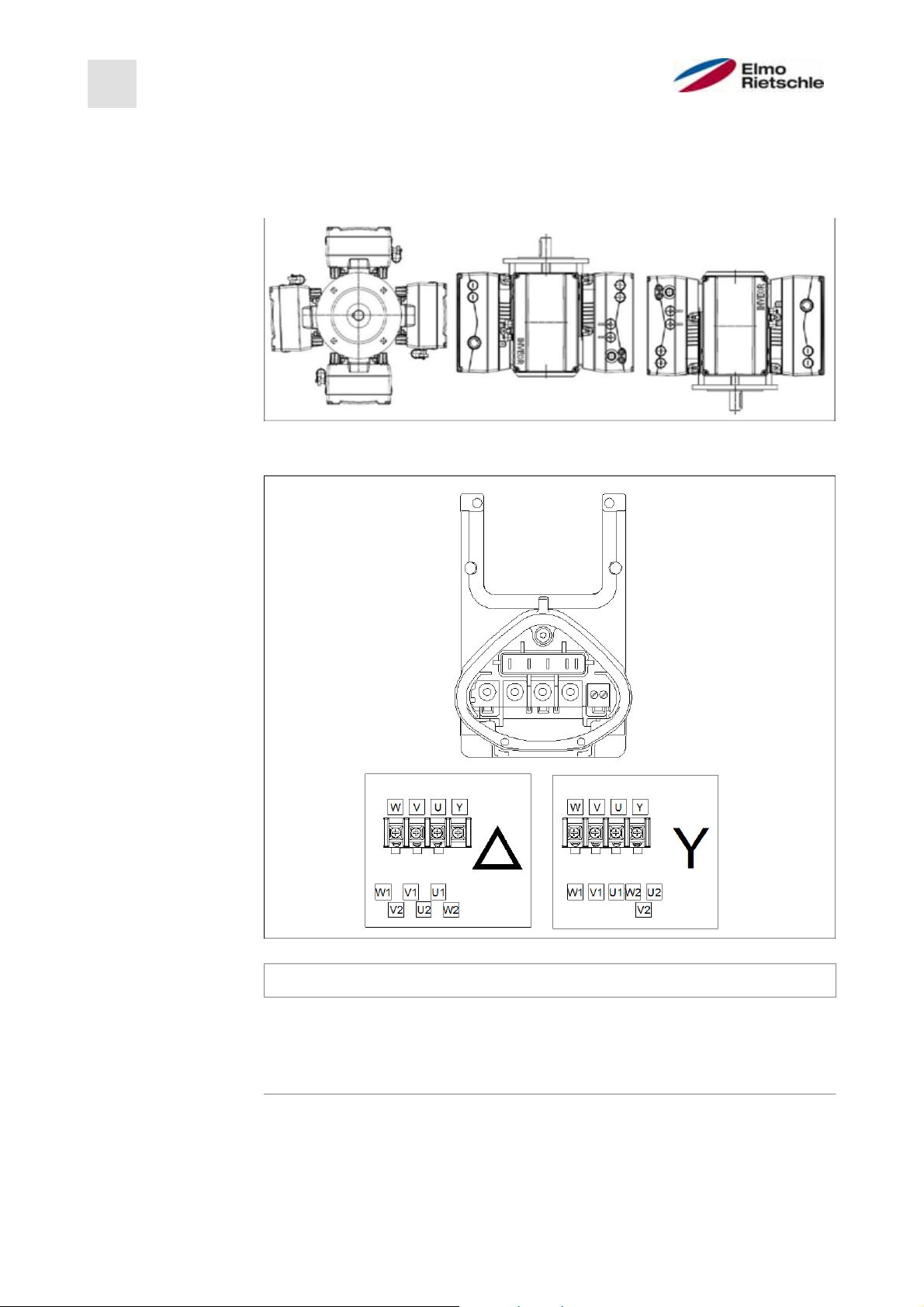

Ensure that the motor with a motor-integrated drive control is only installed

and operated if aligned as shown in the following diagram.

5.2.3

Motor installation location/permitted alignments

Basic connection variations

610.00260.40.000 · 05.2014

Star or delta connection with the drive controller integrated in the motor

NOTICE

Risk of damage to the drive controller!

When connecting the drive controller, the correct phase sequence must be

adhered to; otherwise, the motor can be overloaded.

Thus, the correct phase sequence should be ensured when connecting the

motor.

With the supplied installation material, wire-end sleeves and cable lugs can be

connected. The connection options are shown in Figure 4.

16 / 74

© Gardner Denver Deutschland GmbH

Page 17

A

r

Unused open cable ends in the motor connection box must be insulated.

If a PTC or Klixxon is used, the jumper, seated in the terminal for the PTC in

Installation

5

the delivery condition, must be removed.

The cross section of the mains supply line should be designed according to the

type of wiring and the max. current allowed. The mains supply protection must be

5.2.4

5.2.5

ensured by the system start-up engineer.

Short-circuit and earth-fault protection

The drive controller has an internal short-circuit and earth-fault protection.

Wiring instructions

The control terminals of the application card are located inside the drive controller.

Depending on the version, the pins may be allocated differently.

Terminals: Plug-in terminal connector with actuating pusher

(slot-head screwdriver, max. width 2.5 mm [0.098 in])

Connection crosssection:

Connection crosssection:

Connection crosssection:

0.5 to 1.5 mm

single wire, AWG 20 to AWG 14

0.75 to 1.5 mm

fine-wired, AWG 18 to AWG 14

0.5 to 1.0 mm

fine-wired

2

(0.02 to 0.06 inch2),

2

(0.03 to 0.06 inch2),

2

(0.02 to 0.04 inch2),

(wire-end sleeves with and without plastic collar)

Wire stripping length:

9 to 10 mm (0.35 – 0.40 inch)

The terminals for the mains supply line are within the drive controller. The drive

controller is fitted with terminals for connecting a braking resistor.

Depending on the version, the pins may be allocated differently.

Wire-end sleeves with plastic collar and lugs are recommended.

Terminals: Spring-loaded contact (slot-head screwdriver, max.

width 2.5 mm [0.098 in])

Connection crosssection:

Connection crosssection:

Connection crosssection:

Connection crosssection:

rigid 0.2 to 10 mm

flexible wire 0.2 to 6 mm

0.25 to 6 mm

(wire-end sleeves without plastic collar)

0.25 to 4 mm

(wire-end sleeves with plastic collar)

0.25 to 1.5 mm

same cross section

2

, (0.008 – 0.4 inch2)

2

(0.008 – 0.24 inch2)

2

(0.01 to 0.24 inch2)

2

(0.01 to 0.16 inch2)

2

( – 0.06 inch2) for 2 conductors with the

(twin wire-end sleeves with plastic collar)

Wire cross-section:

Wire stripping length:

Installation tempe

ture:

a-

WG 24 to AWG 8

15 mm [0.6 inch]

+5°C to +100°C [41 – 212°F]

© Gardner Denver Deutschland GmbH

17 / 74

05.2014 · 610.00260.40.000

Page 18

5

Installation

5.2.6

Preventing electromagnetic interference

For control circuits shielded cables must be used, where possible. At the cable

end, the shield should be applied with due care without leaving the wires unshielded over longer distances.

The shielding of analogue setpoints should only be applied on one side of the

drive controller.

Basically, the control wires should always be routed as far away as possible from

power cables; separate cable ducts may have to be used, if required. If lines

cross, an angle of 90° should be adhered to, where possible.

Upstream circuit elements, such as contactors and brake coils or circuit elements

which are connected across the outputs of the drive controllers must be suppressed in terms of interference. In AC contactors, RC (resistor-capacitor) circuits

can be used; suppressor diodes or varistors can be normally used for DC contactors. This interference suppressor is attached directly to the contactor coil. Basically, the power supply to a mechanical brake should not be routed in the same

cable!

Power connections between the drive controller and motor should always be used

in shielded or reinforced design and the shield must be earthed at both ends over

a large area! The use of EMC cable glands is recommended. These are not in-

5.3.1

cluded in the delivery.

Installation of the drive controller integrated in the motor

5.3

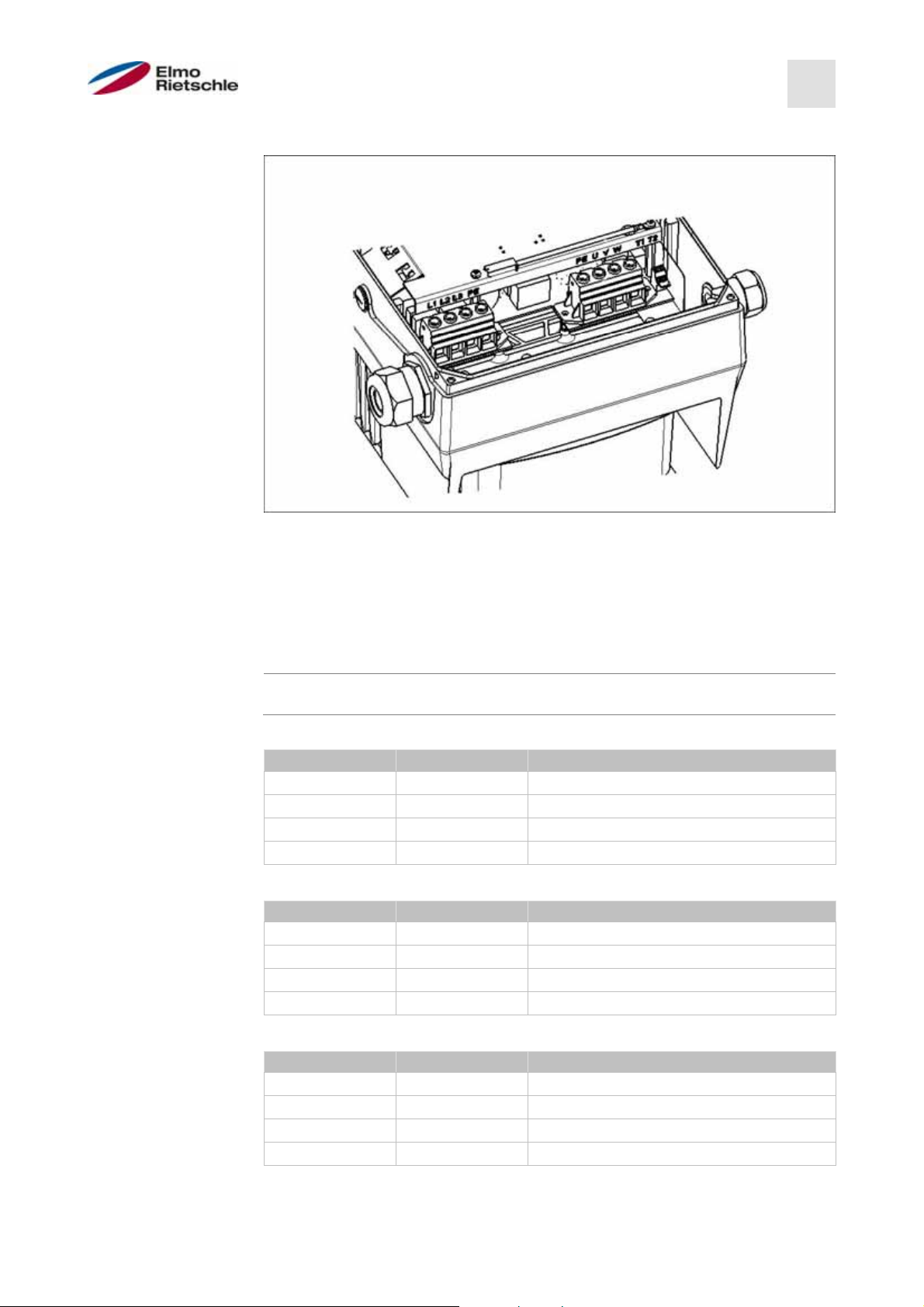

Mechanical installation of sizes A - C

For mechanical installation of the drive controller, proceed as follows:

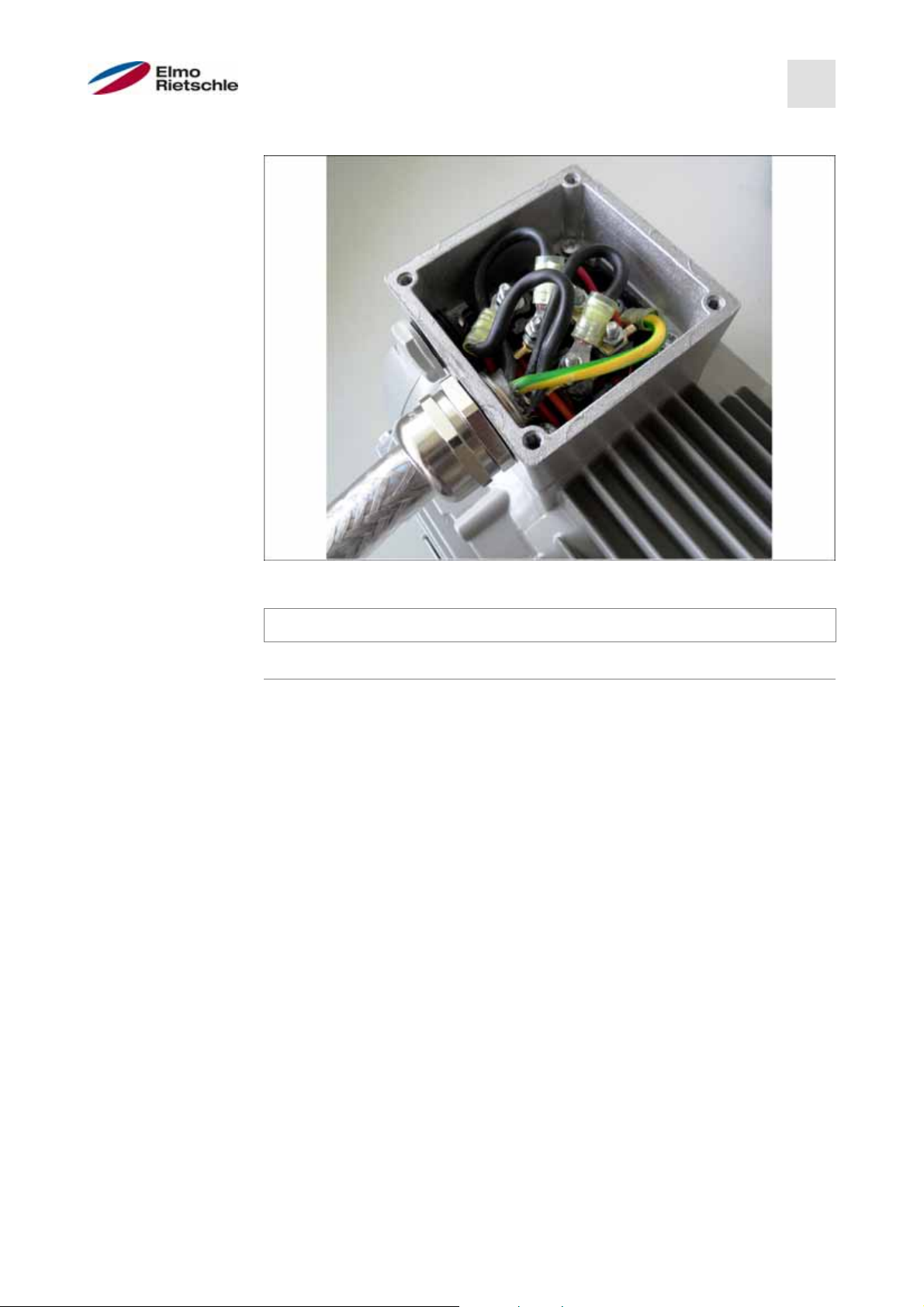

1. Open the standard motor connection box.

2. Disconnect the wires to the terminals. Remember or write down the connection sequence.

3. If necessary, remove the motor terminal block.

4. Remove the fastening screws securing the housing and remove the housing.

Be careful not to damage the gasket.

610.00260.40.000 · 05.2014

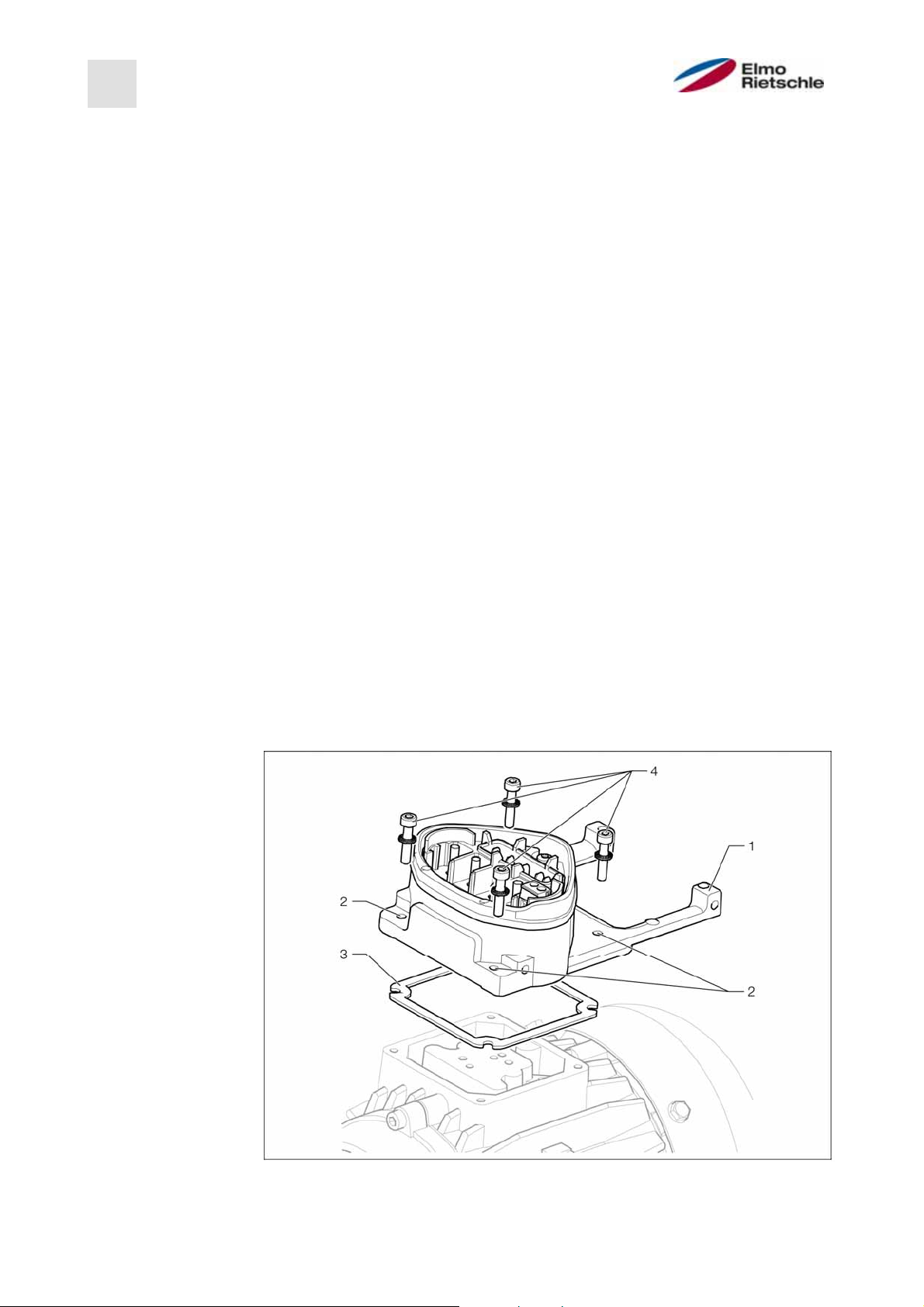

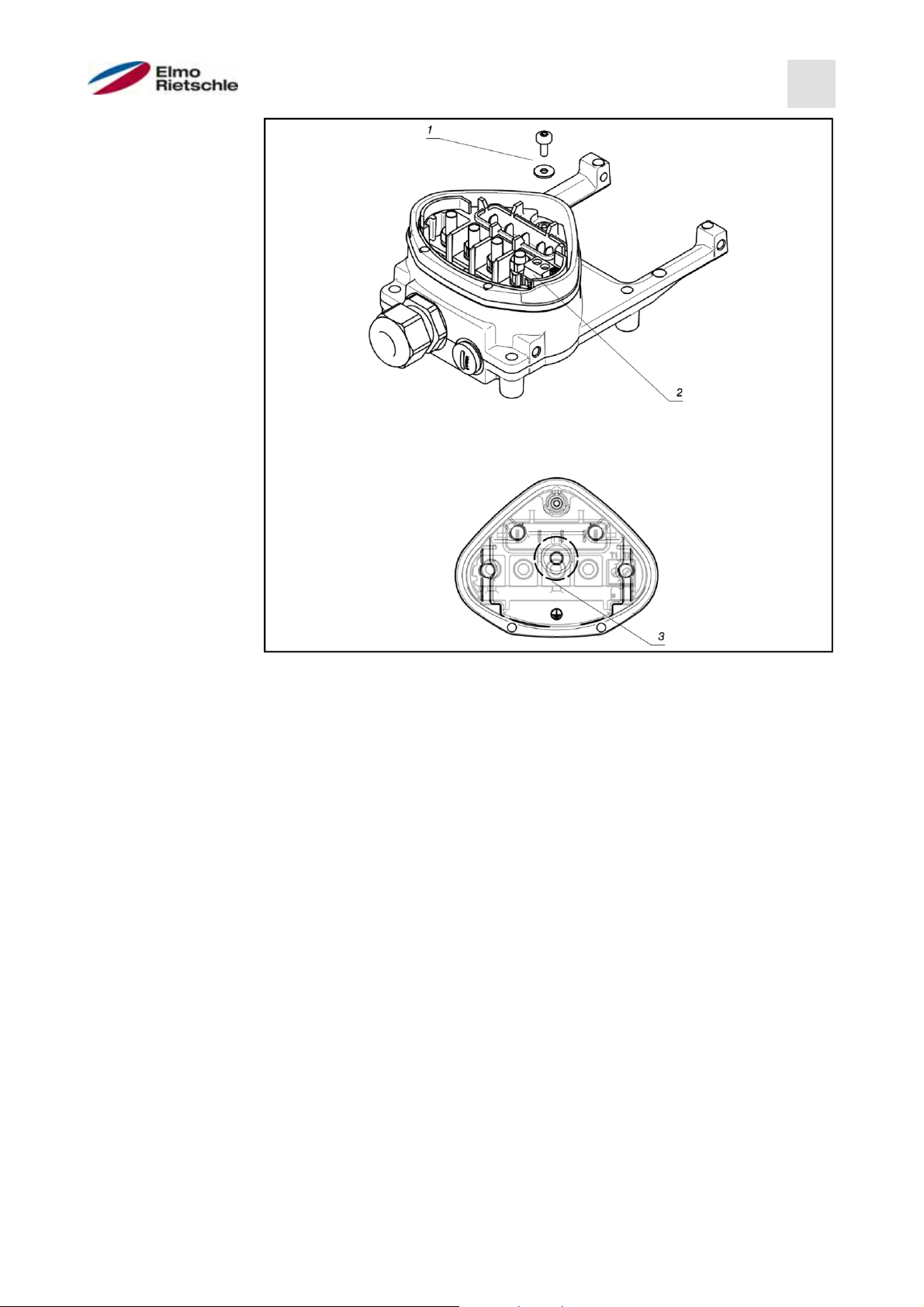

Assembly sequence: Junction box - adapter plate (BG A - C)

18 / 74

© Gardner Denver Deutschland GmbH

Page 19

The standard adapter plate is an adapter plate whose lower part has not

Installation

5

been refinished. No holes are drilled.

For the motors supplied, you can order adapter plates from the manufacturer.

5. Adjust them to the adapter plate (1) by drilling appropriate holes (2) in them

for attachment to the motor.

The system start-up engineer is responsible for maintaining the protection

class for the gasket of the adapter plate on the motor.

For questions, please contact your sales representative.

6. Insert the gasket (3).

7. Lead the motor connection cable through the adapter plate while bypassing

the terminal and screw the adapter plate onto the motor using four fastening

screws and four spring elements (4) (torque: 2.0 Nm [1.48 ft lbs]).

when mounting the adapter plates, ensure that all four screws, including the

spring elements are tightened by applying the correct torque! All contact

areas must be dirt/ paint-free, as correct protective earth connection cannot be ensured otherwise.

8. Connect the motor wires to the required interconnection, see also Figure 5

(Torque: 3.0 Nm [2.21 ft lbs]). We recommend using insulated M5 ring termi-

2

nals, with a connection cross-section of 4-6 mm

When installing the motor wires make sure that all bolts on the adapter

[0.16 to 0.24 inch2]

board are fitted with the enclosed nuts, even if the neutral point is not connected.

Jumper

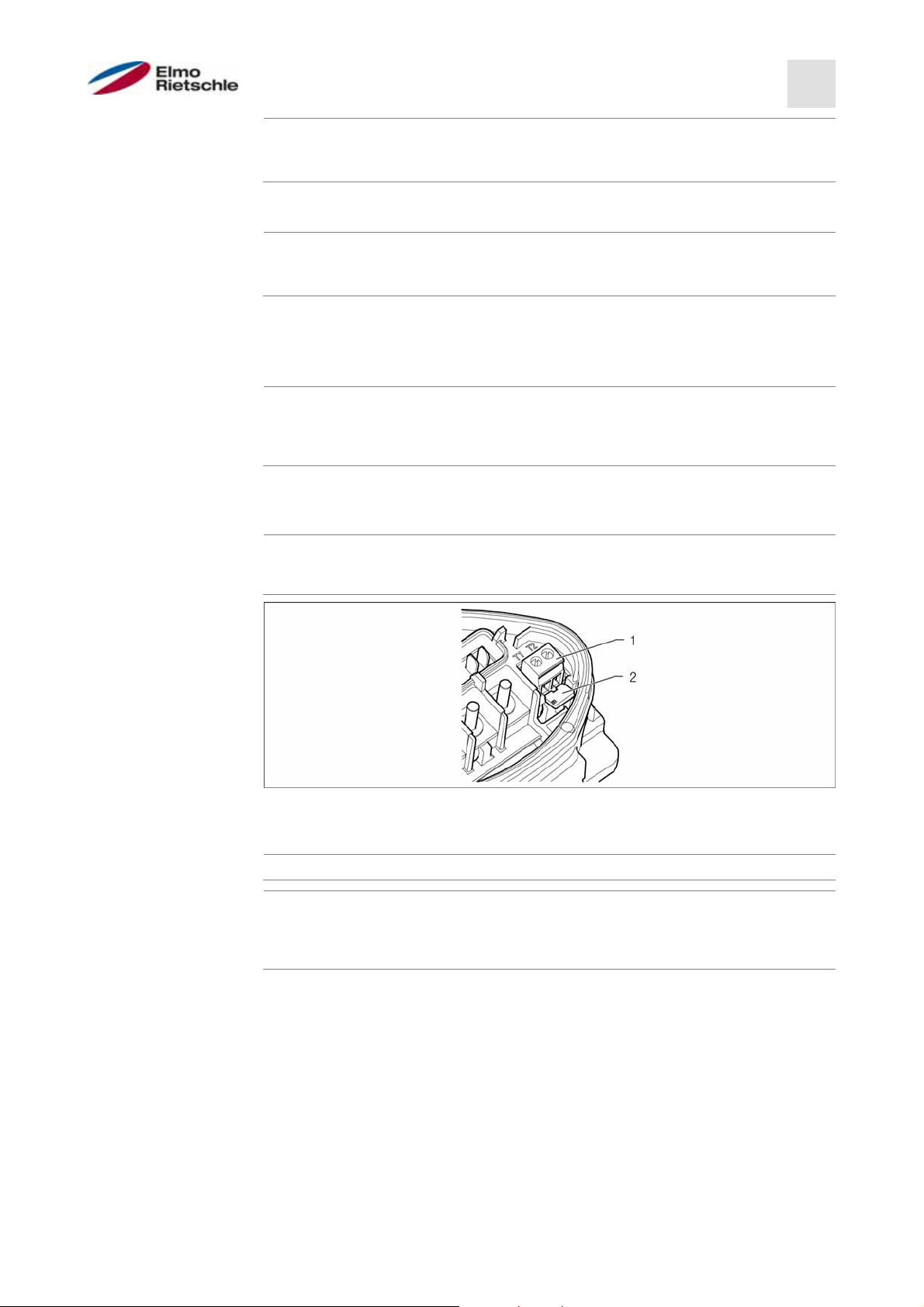

9. Wire any available connection cable of the Motor PTC/ Klixxon to terminals T1

when installing, make sure that the connection cables are not pinched.

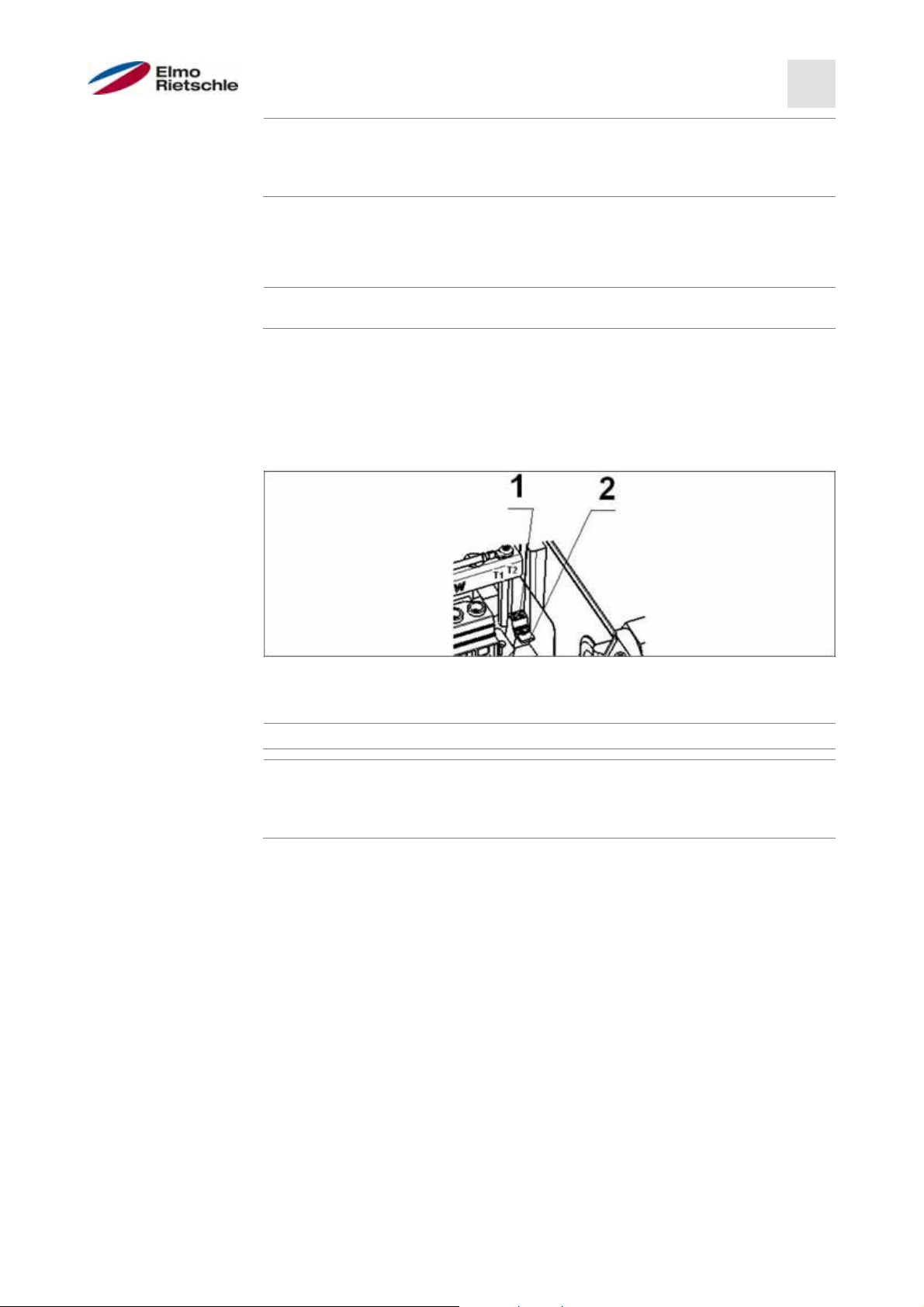

If the motor is equipped with a temperature sensor, it is connected to terminals T1 and T2 (1) and the jumper (2) included in the delivery must be removed. If the jumper is used, there is no temperature monitoring of the motor!

10. Plug the drive controller to the adapter plate and secure it evenly using the

© Gardner Denver Deutschland GmbH

and T2 (1) (torque: 0.6 Nm [0.44 ft lbs]).

four screws at the side (torque: 4.0 Nm [0.3 ft lbs]).

19 / 74

05.2014 · 610.00260.40.000

Page 20

5

Installation

5.3.2

Mechanical installation of size D

For mechanical installation of the drive controller, proceed as follows:

1. Open the standard motor connection box.

2. Remove the fastening screws securing the housing and remove the housing.

Be careful not to damage the gasket.

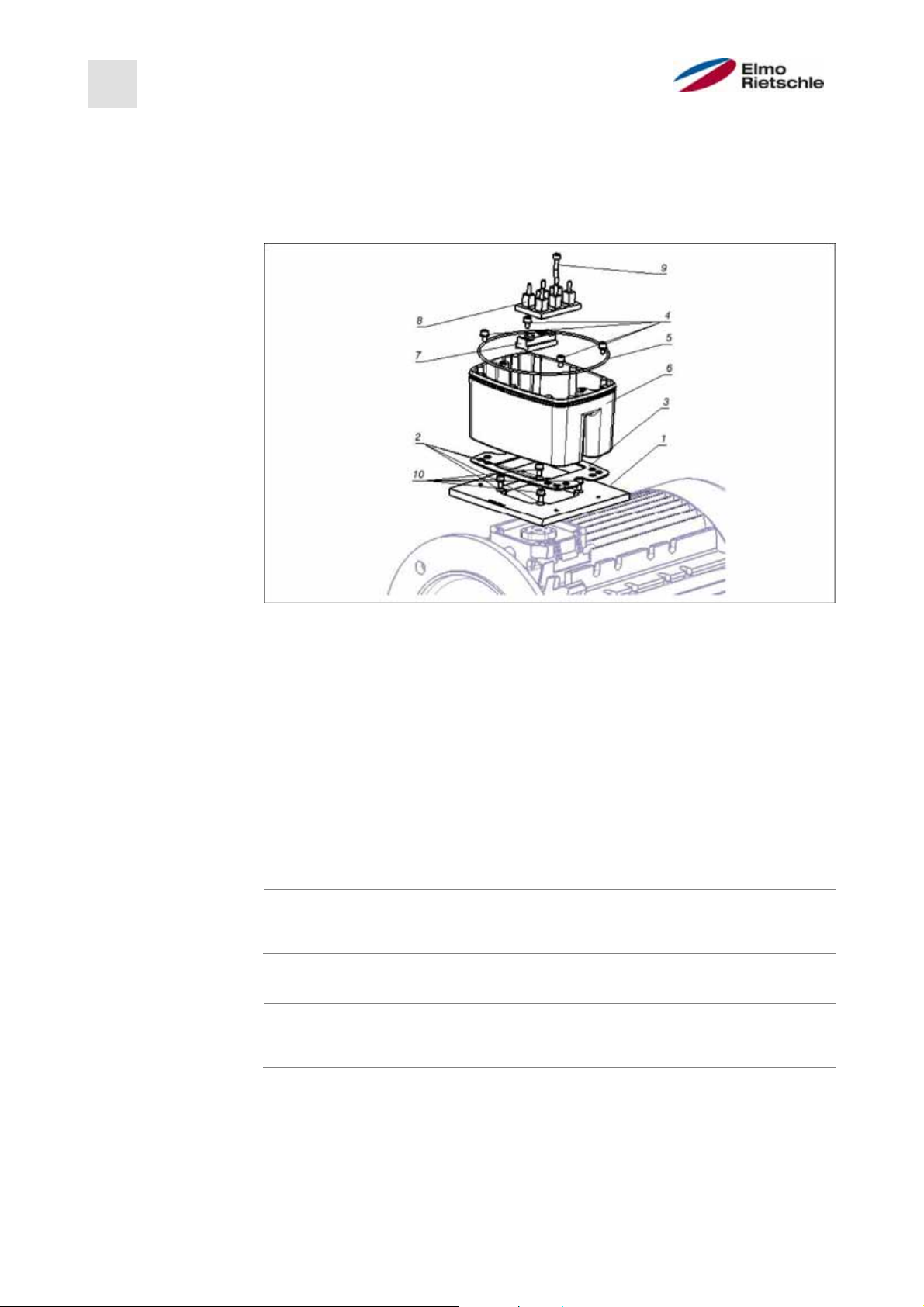

Assembly sequence: Junction box - adapter plate (BG D)

1 Adapter plate option (variant) 6

Support the drive controller /

adapter plate

2 Motor-dependent holes 7 Terminal board expansion option

3 Seal 8

Fastening screws with spring

4

elements

5 O-ring- gasket 10

The standard adapter plate is an adapter plate whose lower part has not

Original terminal board (not included in the delivery)

9 Elongated screw option (for 7)

Fastening screws with spring

elements option

been refinished. No holes are drilled.

For the motors supplied, you can order adapter plates from the manufacturer.

3. Adjust them to the adapter plate (1) by drilling appropriate holes (2) in them

for attachment to the motor.

The system start-up engineer is responsible for maintaining the protection

class for the gasket of the adapter plate on the motor.

For questions, please contact your sales representative.

4. Insert the gasket (3).

5. Screw the adapter plate onto the motor using the four fastening screws and

the four spring elements (10) (torque: M4 with 2.4 Nm [1.77 ft lbs], M5 with

5.0 Nm [3.70 ft lbs], M6 with 8.5 Nm [6.27 ft lbs]).

610.00260.40.000 · 05.2014

20 / 74

© Gardner Denver Deutschland GmbH

Page 21

when mounting the adapter plates, ensure that all four screws, including the

Installation

5

spring elements are tightened by applying the correct torque! All contact

areas must be dirt/ paint-free, as correct protective earth connection cannot be ensured otherwise.

6. Reattach the original terminal board (8) to the motor, possibly with the aid of

the terminal board expansion option (7) and the elongated screw option (9).

7. Connect four wires (PE, U, V, W) with the appropriate cross section (depending on the output of the drive controller used) to the original terminal board.

The connecting wires required for wiring the motor terminal board/ drive

controller are not include in the delivery in the case of spare parts.

8. Screw the support (6) onto the adapter plate using the four fastening screws

with spring elements (4). Please pay attention to the proper seating of the

gasket (5). Insert the four wires (PE, U, V, W) into the support of the drive controller.

9. Plug the drive controller onto the support (6) and secure it evenly using the

two M8 screws

(torque: max. 21.0 Nm [15.5 ft lbs]).

Jumper

10. Wire any available connection cable of the Motor PTC/ Klixxon to terminals T1

and T2 (1) (torque: 0.6 Nm [0.44 ft lbs]).

when installing, make sure that the connection cables are not pinched.

If the motor is equipped with a temperature sensor, it is connected to terminals T1 and T2 (1) and the jumper (2) included in the delivery must be removed. If the jumper is used, there is no temperature monitoring of the motor!

© Gardner Denver Deutschland GmbH

21 / 74

05.2014 · 610.00260.40.000

Page 22

5

Installation

5.3.3

Power connection of sizes A - C

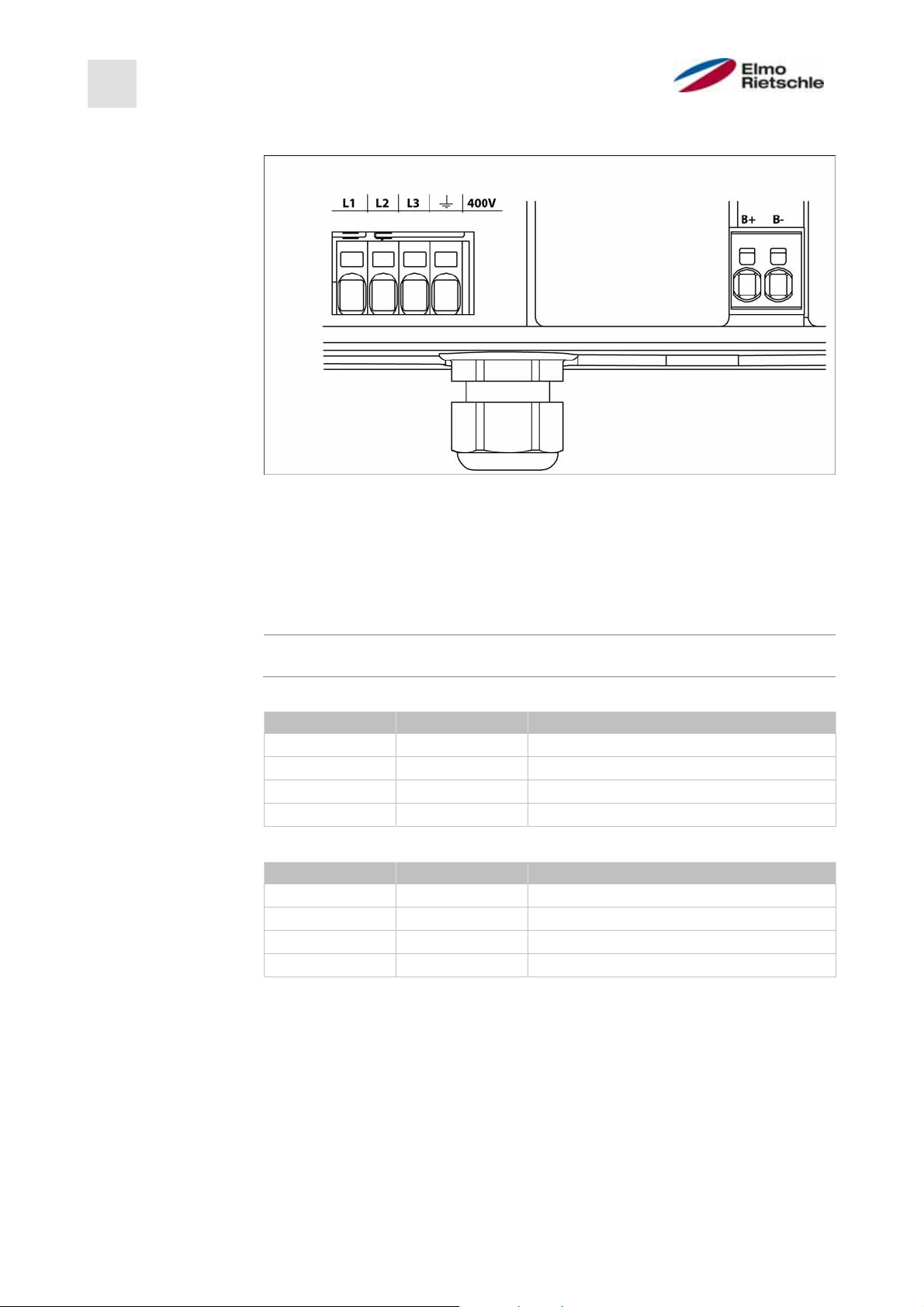

Power connection BG A - C

1. Unscrew the four screws from the housing cover of the drive controller and

remove the cover.

2. Run the mains cable through the threaded cable gland and connect the

phases with the contacts L1, L2, L3 for 400 V and the buried cable with the

PE contact on the terminal. The threaded cable gland provides cable relief,

the PE connection line must be connected as a leading contact (significantly

longer)!

When connecting a braking resistor to an optional brake module, shielded

and double-insulated cables must be used.

3 ~ 400 V terminal assignment X1

Terminal no. Designation (Terminal) assignment

1 L1 Mains phase 1

2 L2 Mains phase 2

3 L3 Mains phase 3

4 PE Buried cable

DC supply 250 to 750 V terminal assignment X1

Terminal no. Designation (Terminal) assignment

1 L1 DC network (+) (565V)

2 L2 Not assigned.

3 L3 DC network (-)

4 PE Buried cable

610.00260.40.000 · 05.2014

22 / 74

© Gardner Denver Deutschland GmbH

Page 23

V

5.3.4

Power connection of size D

Installation

5

Power connection BG D

1. Unscrew the four screws from the housing cover of the drive controller and

remove the cover.

2. Run the mains cable through the threaded cable gland and connect the

phases with the contacts L1, L2, L3 for 400 V and the buried cable with the

PE contact on the terminal. The threaded cable gland provides cable relief,

the PE connection line must be connected as a leading contact (significantly

longer)!

When connecting a braking resistor to an optional brake module, shielded

and double-insulated cables must be used.

3 ~ 400 V terminal assignment X1

Terminal no. Designation (Terminal) assignment

1 L1 Mains phase 1

2 L2 Mains phase 2

3 L3 Mains phase 3

4 PE Buried cable

DC supply 250 to 750 V terminal assignment X1

Terminal no. Designation (Terminal) assignment

1 L1 DC network (+) (565V)

2 L2 Not assigned.

3 L3 DC network (-)

4 PE Buried cable

Motor terminal assignment X4

Terminal no. Designation (Terminal) assignment

1 PE Buried cable

2UMotor phase 1

3

4WMotor phase 3

Motor phase 2

© Gardner Denver Deutschland GmbH

23 / 74

05.2014 · 610.00260.40.000

Page 24

A

A

5

Installation

5.3.5

5.3.6

610.00260.40.000 · 05.2014

Connections for braking resistor

Terminal assignment for braking chopper

Terminal no. Designation (Terminal) assignment

1 B+ Connection of braking resistor (+)

2 B- Connection of braking resistor (-)

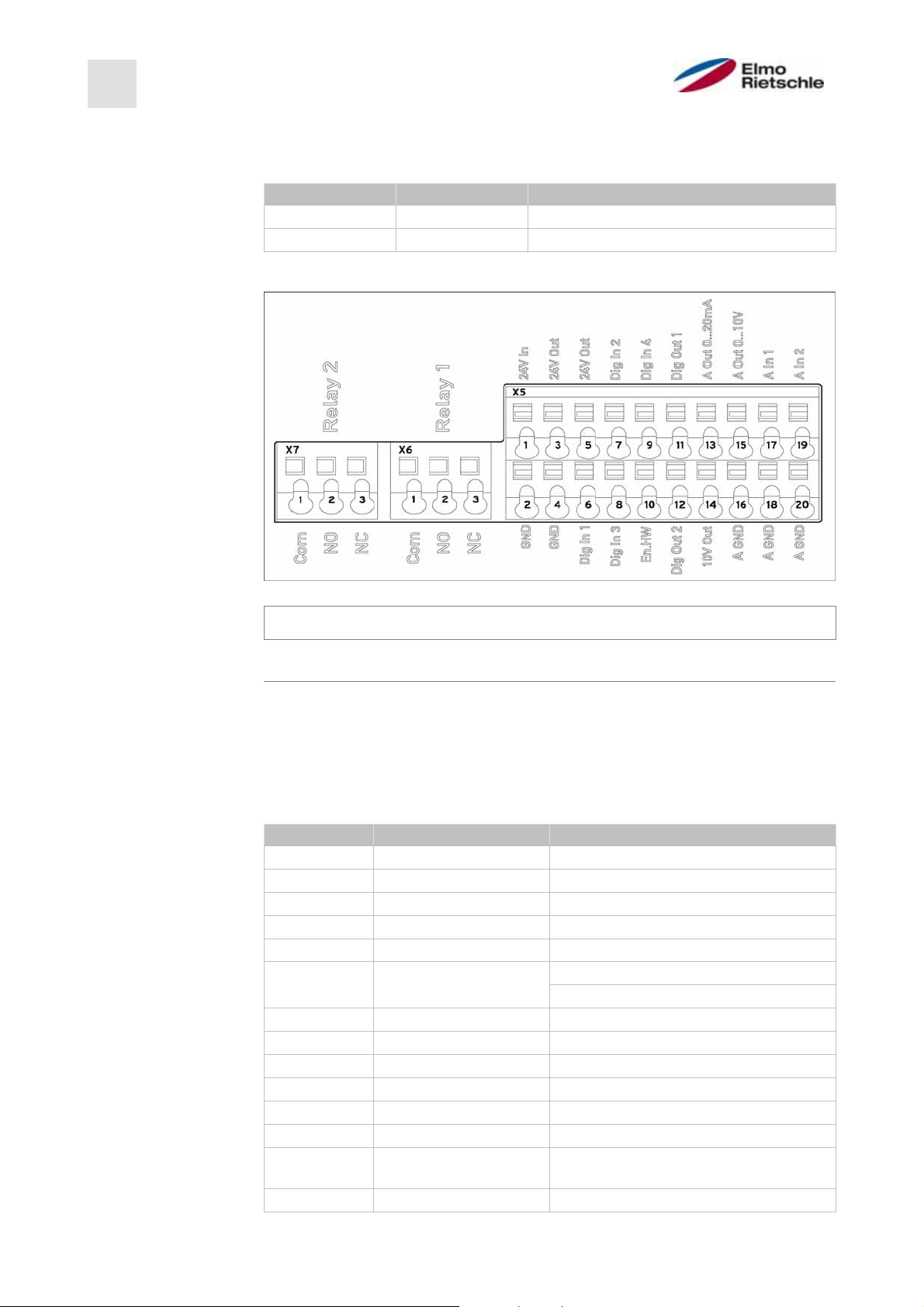

Control terminals

Control terminals of the standard application card

Risk of coupling of external signals!

Use shielded control wires.

1. Pass the required control wires through the threaded cable glands into the

housing.

2. Connect the control wires according to the picture and/or table. To do this,

use shielded control wires.

3. Put the lid on the housing of the drive controller and screw it in place.

Terminal assignment X5 of the standard application card

Terminal no. Designation (Terminal) assignment

1 24 V In External power supply

2 GND (Ground) Ground

3 24 V Out Internal power supply

4 GND (Ground) Ground

5 24 V Out Internal power supply

6 Dig. In 1 fixed frequency 1/3 (parameter 1,100)

7 Dig. In 2 fixed frequency 2/3 (parameter 1,100)

8 Dig. In 3 Fault reset (parameter 1,180)

9 Dig. In 4 External error (parameter 5,010)

10 En -HW (release) Hardware release

11 Dig. Out 1 Ready (parameter 4,150)

12 Dig. Out 2 Operation (parameter 4,170)

13

. Out 0 ... 20 mA

14 10 V Out For external voltage divider

24 / 74

NOTICE

Software release (parameter 1,131)

ctual frequency value (parameter

4,100)

© Gardner Denver Deutschland GmbH

Page 25

A

V

A

A

A

A

A

A

A

Installation

5

Terminal no. Designation (Terminal) assignment

15

. Out 0 ... 10

ctual frequency value (parameter

4,100)

16

17

GND (Ground 10 V) Ground

. In 1 External Setpoint source (parameter

1,130)

18

19

20

GND (Ground 10 V) Ground

. In 2

ctual PID value (parameter 3,060)

GND (Ground 10 V) Ground

Terminal assignment X6 (relay 1)

Terminal no. Designation (Terminal) assignment

1 COM Centre contact relay 1

2 NO Normally open contact relay 1

3 NC Normally closed contact relay 1

In the factory setting, relay 1 is programmed as "fault relay" (parameter

4,190).

Terminal assignment X7 (relay 2)

Terminal no. Designation (Terminal) assignment

1 COM Centre contact relay 2

2 NO Normally open contact relay 2

3 NC Normally closed contact relay 2

In the factory setting, relay 2 is programmed as "fault relay" (parameter

4,210).

5.3.7

Wiring diagram

Control terminals

The drive controller is ready for operation after connection to a 400 V AC power

supply (to the terminals L1 to L3) or after connection to a 565 V DC power supply

(to the terminals L1 and L3).

Alternately, there is the option to put the drive controller in operation by connecting an external 24 V voltage.

The required presetting is described in the chapter "System parameters".

© Gardner Denver Deutschland GmbH

25 / 74

05.2014 · 610.00260.40.000

Page 26

5

Installation

Installing the wall-mounted drive controller

5.4

5.4.1

Installation location that is suitable for wall mounting

! Please make sure that the installation location for wall mounting meets the

following conditions:

1. The drive controller must be mounted on a flat, solid surface.

2. The drive controllers may only be mounted on non-combustible surfaces.

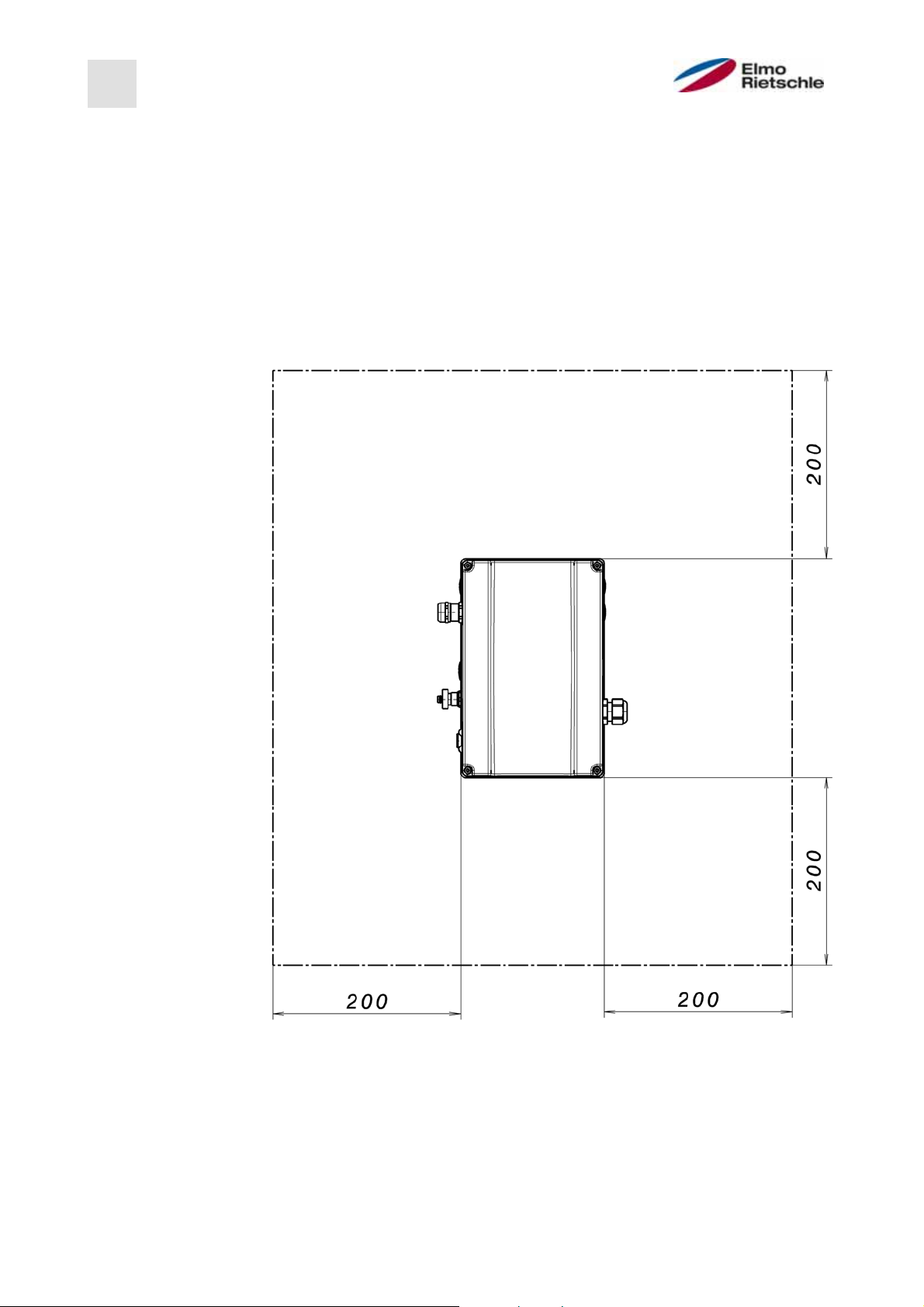

3. There must be at least a 20-cm-wide clearance all around the drive controller

to ensure free convection.

The following figure gives you the mounting dimensions and the necessary clearance for the installation of the drive controller.

610.00260.40.000 · 05.2014

Minimum distances

For wall mounting, a maximum line length of 5 m is permitted between the motor

and the drive controller. A shielded cable with the cross section required in each

case should be used. A PE connection should be established (below the terminal

board the wall adapter)!

26 / 74

© Gardner Denver Deutschland GmbH

Page 27

5.4.2

Mechanical installation

Installation

5

Wiring at the motor connection box

1. Open the motor connection box.

NOTICE

Depending on the desired motor voltage, star or delta connection should be

made in the motor connection box.

2. When connecting the shielded motor cable to the motor connection box, use

suitable EMC fittings and ensure proper (large surface) contact with the

shield.

3. Connecting a PE connection to the motor connection box is mandatory.

4. Reconnect the motor connection box.

© Gardner Denver Deutschland GmbH

27 / 74

05.2014 · 610.00260.40.000

Page 28

5

Installation

Mounting the adapter plate to a wall

WARNING

Risk of injury due to incorrect assembly!

The drive controller may not be installed without an adapter plate.

5. Find a location that corresponds to the required ambient conditions, as described in the "Installation requirements" section.

6. In order to achieve optimum self-convection of the drive controller, it must be

ensured during assembly that the (EMC) fitting points upward.

7. Without additional ventilation of the drive controller, only vertical mounting is

allowed.

610.00260.40.000 · 05.2014

28 / 74

© Gardner Denver Deutschland GmbH

Page 29

Installation

5

Wiring

8. Loosen the screw (1) to remove the contact plate from the adapter plate. Below this contact plate is the (M6x15) PE connection (3).

9. Lead the connection cable from the motor via the integrated EMC fitting into

the adapter plate.

10. This PE connection (torque: 4.0 Nm [2.95 ft lbs]) must be connected to the

same earth potential of the motor. The cross section of the equipotential

bonding conductor must correspond to at least the cross-section of the

mains cable.

11. Reattach the contact plate using the screw (1).

12. Wire the motor cable to the contacts U, V and W (possibly also the neutral

point) in the terminal, as described in "Basic connection variations" section.

Use the cable lugs (M5) for this.

13. Before connecting a possibly existing motor PTC to the terminals T1 and T2,

please remove the pre-assembled jumper (2).

The PTC motor is not electrically isolated following connection of the drive

controller. Therefore, the connection must be made using a separate motor

cable.

To this end, the dummy plug must be replaced with a suitable standard screw

fitting and insert the two ends onto T1 and T2.

© Gardner Denver Deutschland GmbH

29 / 74

05.2014 · 610.00260.40.000

Page 30

5

Installation

Mount the drive controller

14. Place the drive controller (1) on the adapter plate (2) such that the collar of the

adapter dips into the opening at the bottom of the cooling element.

15. Secure the drive controller to the adapter plate using the screws (3) (torque:

5.4.3

4.0 Nm [2.95 ft lbs]).

Power connection

The power connections are made as described in the sections Power connection

5.4.4

of sizes A - C [➙ 22] and Power connection of size D [➙ 23].

Braking chopper

The braking connections are made as described in the section Connections for

5.4.5

braking resistor [➙ 24].

Control terminals

The control terminals are provided as described in the section Control terminals

[➙ 24].

610.00260.40.000 · 05.2014

30 / 74

© Gardner Denver Deutschland GmbH

Page 31

6

Commissioning

Safety information for commissioning

6.1

WARNING

Commissioning

6

Risk of injury!

The non-observance of warnings can result in severe bodily injury or substantial property damage.

1. Make sure that the power supply provides the correct voltage and is designed

for the necessary current.

2. Use suitable circuit breaker with the specified nominal current between the

mains supply and drive controller.

3. Use appropriate fuses with the corresponding current values between the

mains supply and the drive controller (see Technical data [➙ 64]).

4. The drive controller must be correctly earthed to the motor. Not doing so may

result in serious injury.

NOTICE

Risk of damage!

The drive controller can be damaged in the case of non-compliance with

the instructions and destroyed during subsequent handling.

Commissioning may only be carried out by qualified personnel. Safety precau-

tions and warnings must always be observed.

© Gardner Denver Deutschland GmbH

31 / 74

05.2014 · 610.00260.40.000

Page 32

6

Commissioning

Communication

6.2

The drive controller can be put into operation in the following ways:

▪ using the PC software

PC software - start screen

▪ via the hand-held unit MMI

MMI hand-held unit

610.00260.40.000 · 05.2014

32 / 74

© Gardner Denver Deutschland GmbH

Page 33

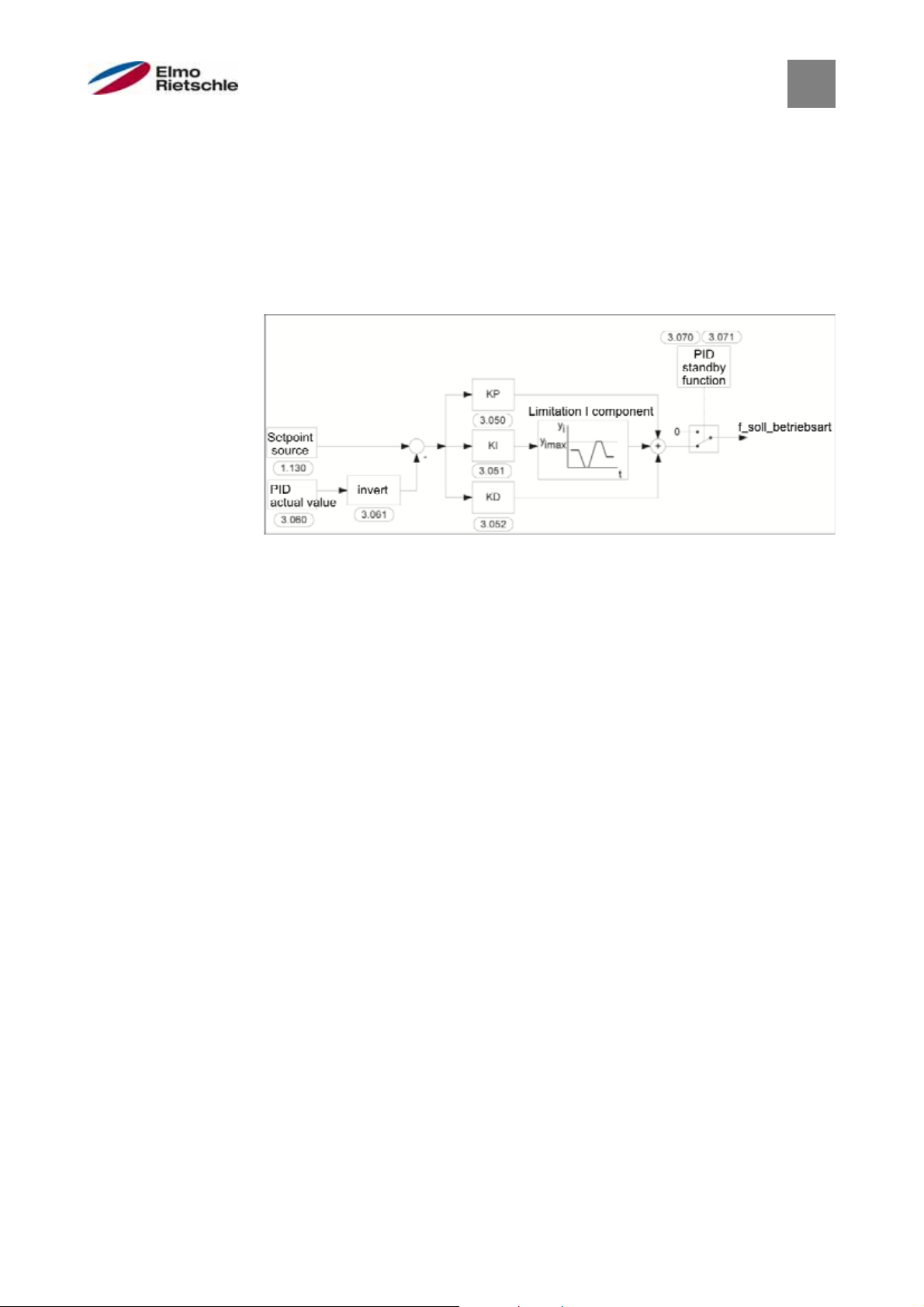

Block diagram

6.3

Commissioning

6

General structure setpoint generation

© Gardner Denver Deutschland GmbH

33 / 74

05.2014 · 610.00260.40.000

Page 34

6

Commissioning

Commissioning steps

6.4

The drive control can be parameterised on the motor prior to installation.

To this end, the drive controller has a 24-V low-voltage input, which powers

the electronic parts, and without which a mains voltage must be supplied.

Commissioning can be done with a USB PC communication cable to connector

M12 with integrated RS485/RS232 interface converter (2FC4521-0ER00) or via the

MMI hand-held unit, including connection cable RJ11 to connector M12

(2FX4520-0ER00).

6.4.1

Start up the integrated drive control

Prior to delivery, the motor data set was installed on the drive control and requires

no further settings.

With a high signal on terminal strip X5 through the hardware release (En-HW) on

terminal no. 10 and software release on terminal no. 6 (digital input 1), the drive

6.4.2

control can be put into operation (e.g. control via analogue input 1 with 0-10 V).

Commission the drive control wall assembly and replacement

Commissioning with PC

1. Install PC software (you can obtain program software free of charge from the

manufacturer or at www.gd-elmorietschle.de).

Required operating system Windows XP or Windows 7 (32/64 bit). It is recommended to carry out the installation as the administrator.

2. Connect the PC via connection cable to the M12 connector M1.

3. Load the motor data set and continue with the application settings.

OR

determine the motor data set (parameters 33,030 to 33,050). If necessary, optimise the speed controller (parameter 34.100 to 34.101).

610.00260.40.000 · 05.2014

Motor data rating plate (example)

34 / 74

© Gardner Denver Deutschland GmbH

Page 35

Commissioning

6

4. Perform motor identification.

5. Implement application settings (ramps, inputs, outputs, setpoints, etc.).

6. Optional: Define access level (1 - HAND-HELD UNIT MMI, 2 - user 3 - manufacturer).

7. Once all settings have been implemented, with a high signal on terminal strip

X5 through the hardware release (En-HW) on terminal no. 10 and software release on terminal no. 6 (digital input 1), the drive control can be put into operation (e.g. control via analogue input 1 with 0-10 V).

For an optimum operating structure of the PC software, the parameters are divided into access levels. A distinction is made between:

1. Hand-held unit - the drive controller is programmed using the hand-held unit.

2. User - the drive control can be programmed with the basic parameters using

the PC software.

3. User - the drive control can be programmed with an advanced selection of pa-

rameters using the PC software.

Commissioning with the MMI hand-held unit

For commissioning with the MMI hand-held unit, see MMI hand-held unit operating manual [➙ 6].

© Gardner Denver Deutschland GmbH

35 / 74

05.2014 · 610.00260.40.000

Page 36

7

7

Parameters

Parameters

In this chapter, you will find

▪ an introduction to the parameters

▪ an overview of the most important commissioning and operating parameters

Safety instructions for handling the parameters

7.1

WARNING

Risk of injury from restarting motors!

The non-observance of warnings can result in severe bodily injury or substantial property damage.

Certain parameter settings and the changing of parameter settings during

operation can cause the drive controller to restart automatically after a power

7.2

failure, or cause undesirable changes in the operating characteristics.

If parameters are changed during operation, it may take a few seconds before the effect becomes apparent.

General information on parameters

7.2.1

Explanation of operating modes

The operating mode is the instance in which the actual setpoint value is generated. This is a simple conversion of the raw input setpoint value into a speed setpoint in the case of the frequency setting mode and control of a specific process

variable by comparing the setpoint and actual values in the case of the PID process control.

Frequency setting mode:

The setpoints from the "setpoint source" (1,130) are rescaled into frequency setpoints. 0% corresponds to the "minimum frequency" (1,020), 100 % corresponds

to the " maximum frequency" (1,021).

The prefix of the setpoint is the decisive factor in rescaling.

PID process control:

The setpoint for the PID process controller is read as percentage in the "frequency

setting mode" operating mode. 100% corresponds to the working range of the

connected sensor, which is read from the actual value input (selected by the "PID

feedback").

Depending on the control deviation, a speed controller output is issued at the controller output, based on the amplification factors for the P component (3,050), I

component (3,051) and D component (3,052). In order to prevent the increase of

the integral component to infinity in the case of uncontrollable control deviations,

it is also limited to the controller output threshold when reaching the same (corresponds to "maximum frequency" (1,021).

610.00260.40.000 · 05.2014

36 / 74

© Gardner Denver Deutschland GmbH

Page 37

Parameters

7

PID inverse:

Inversion of the PID feedback can be done with the help of parameter 3,061. The

actual value is read inverted, i.e. 0V…10V correspond internally to 100% ... 0%.

Please bear in mind that the setpoint should also be specified inversely!

An example:

A sensor with an analogue output signal (0V…10V) is to be operated as the actual

value source (at AIx). At an output quantity of 7V (70%), it should be regulated inversely. The internal actual value then corresponds to 100% - 70% = 30%. That

is, the setpoint to be specified is 30%.

PID process control

Standby function for PID process control:

This function can be used in applications such as pressure boosting systems, in

which it is controlled to a specific process variable using the PID process control

and the pump should run at a "minimum frequency" (1020) to lead to energy savings. Since the inverter reduces the pump speed with decreasing process variable

during normal operation, but can never go below the "minimum frequency"

(1,020), it is possible to stop the motor when it runs at the "minimum frequency"

(1,020) for a wait time, the "PID standby time" (3,070).

After the actual value deviates from the setpoint by the set % value, the "PID

standby hysteresis" (3,071), the (motor) control is restarted.

© Gardner Denver Deutschland GmbH

37 / 74

05.2014 · 610.00260.40.000

Page 38

7

Parameters

Standby function for PID process control

Fixed frequency:

In this operating mode, fixed frequency setpoints are passed on to the motor control. There are 7 fixed frequencies (2,051 - 2,057) which are linked in BCD format

to the digital inputs 1 to 3. These seven fixed frequencies can be enabled via the

parameter "Auswahl_Festfrequenz(Selection_fixed_frequency)" (2,050) into three

groups:

0 = fixed frequency 1, 1 = fixed frequency 1 to 3, 2 = fixed frequency 1 to 7.

Logic table of fixed frequencies

DI 3 DI 2 DI 1 Selection Parameters Presetting

0 0 1 Fixed fre-

2,051 34 Hz

quency 1

0 1 0 Fixed fre-

2,052 67 Hz

quency 2

0 1 1 Fixed fre-

2,053 50 Hz

quency 3

1 0 0 Fixed fre-

2,054 0 Hz

quency 4

1 0 1 Fixed fre-

2,055 0 Hz

quency 5

1 1 0 Fixed fre-

2,056 0 Hz

quency 6

1 1 1 Fixed fre-

2,057 0 Hz

quency 7

610.00260.40.000 · 05.2014

38 / 74

© Gardner Denver Deutschland GmbH

Page 39

r

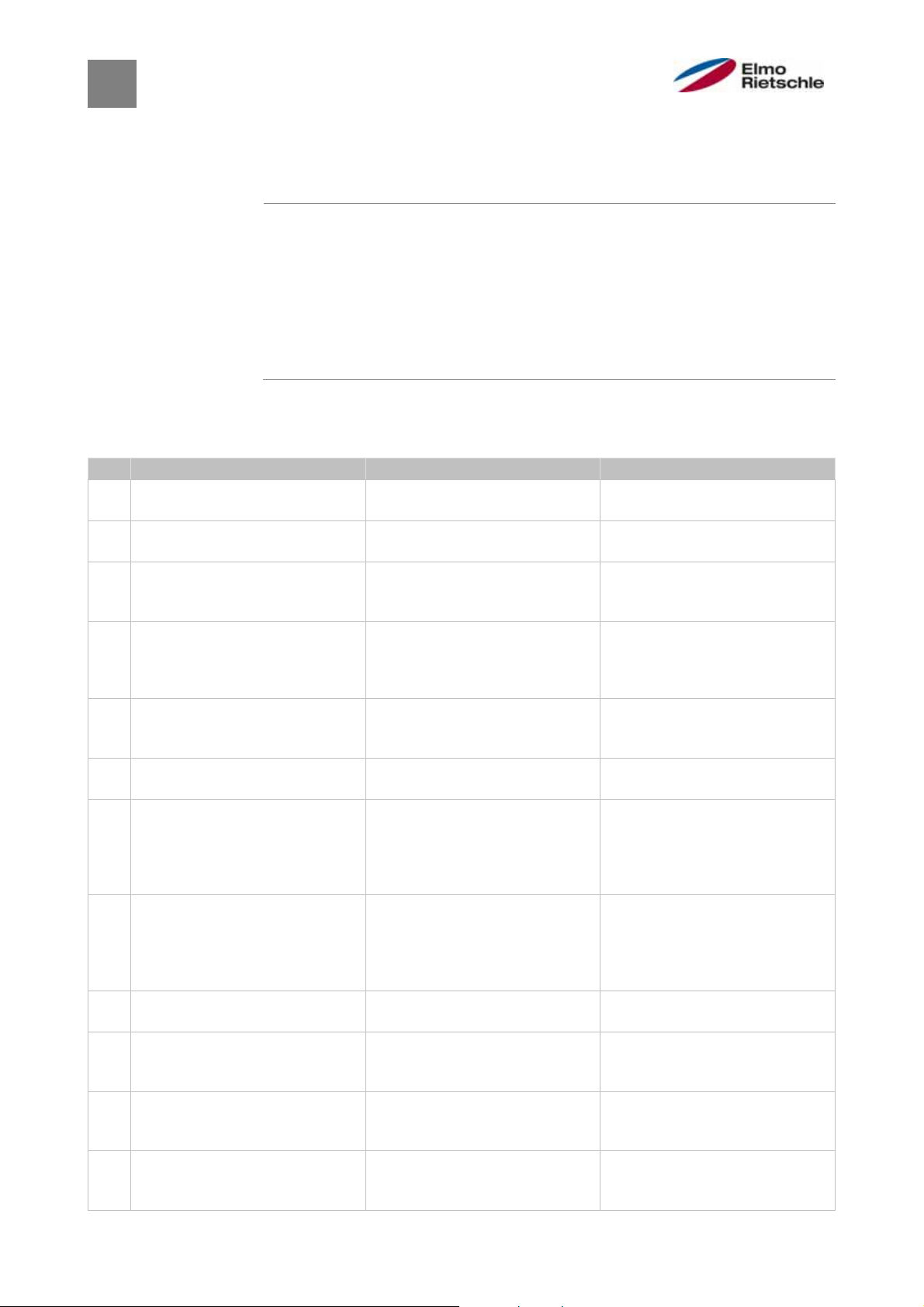

7.2.2

Structure of parameter tables

Parameters

7

Example of parameter table

1 Parameter numbe

Description in the parameters

2

manual on page...

6 Unit

Box for entering the inherent

7

value

3 Parameter name 8 Explanation of the parameters

Transfer status

0 = turn on and off to take over

4

the drive controller

1 = at speed 0

Other parameters related to this

9

parameter

2 = in operation

Range of values (from - to - fac-

5

tory setting)

© Gardner Denver Deutschland GmbH

39 / 74

05.2014 · 610.00260.40.000

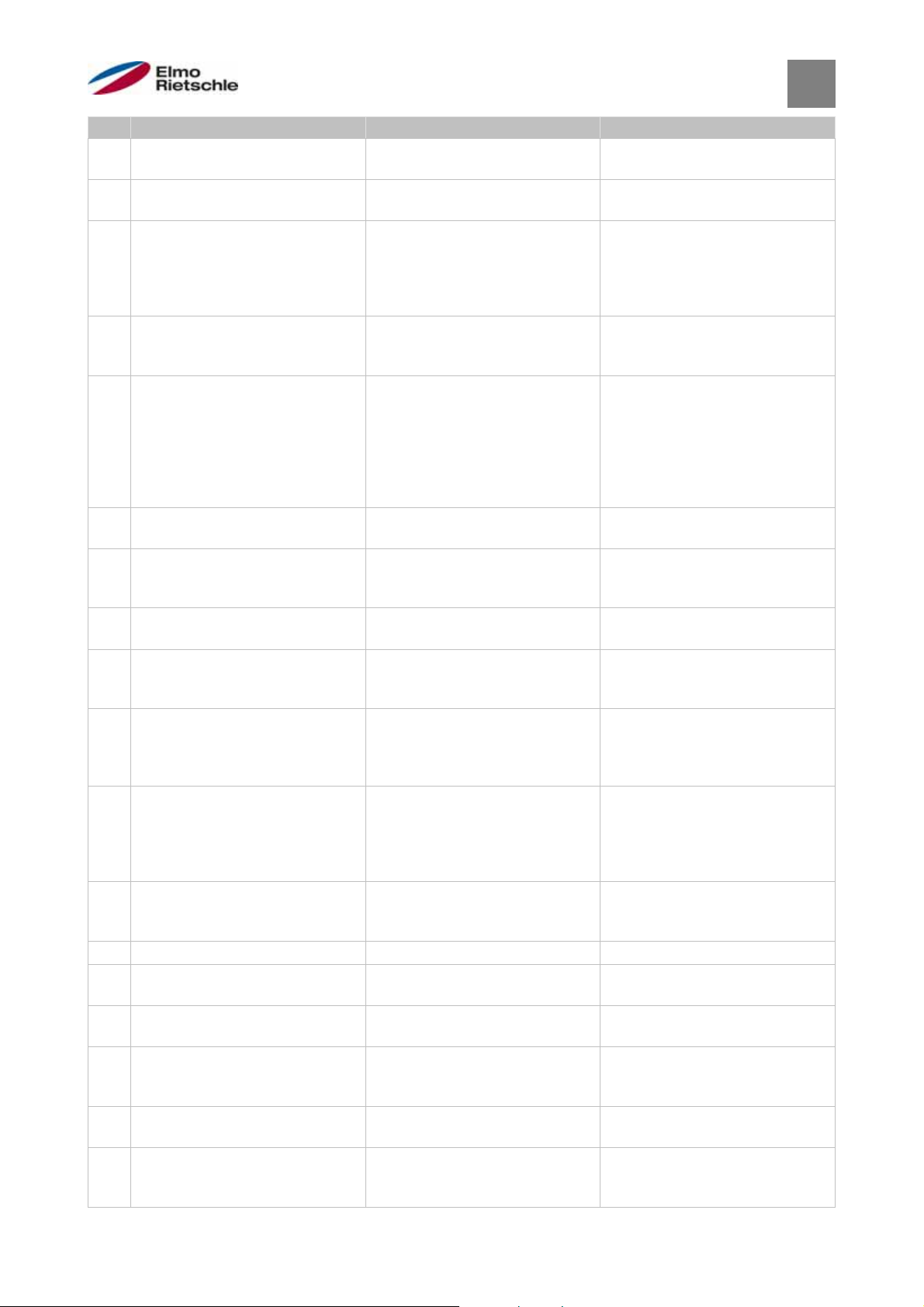

Page 40

7

Parameters

Application parameter

7.3

7.3.1

Basic parameters

1,020 Minimum frequency Unit: Hz

Relationship to

parameter:

1.150

3.070

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 400

Def: 25

(to be en-

tered!)

The minimum frequency is the frequency that is supplied by the

drive controller as soon as it is released and no additional setpoint is pending.

This frequency is not reached if

a) it is accelerated from the stationary drive.

b) the FI is locked. The frequency is then reduced to 0 Hz before

it is locked.

c) of the FI is reversed (1,150). Reversing the field of rotation

occurs at 0 Hz.

d) the standby function (3,070) is active.

1,021 Maximum frequency Unit: Hz

Relationship to

parameter:

1.050

1.051

Parameter HB:

S. xy

Transfer

status:

2

min: 5 Intrinsic value

max: 400

Def: see data

(to be en-

tered!)

plate

The maximum frequency is the highest frequency issued by the

converter as a function of the setpoint.

1,050 Braking time Unit: s

Relationship to

parameter:

1.021

1.054

Parameter HB:

S. xy

Transfer

status:

2

min: 0.1 Intrinsic value

max: 1000

Def: Type-

(to be en-

tered!)

specific

The braking time 1 is the time it takes for the inverter to decelerate from the max. frequency (1,021) to 0 Hz.

If the set braking time cannot be met, the fastest possible braking time is implemented.

1,051 Power-up time 1 Unit: s

Relationship to

parameter:

1.021

1.054

Parameter HB:

S. xy

Transfer

status:

2

min: 0.1 Intrinsic value

max: 1000

Def: Type-

(to be en-

tered!)

specific

The power-up time 1 is the time it takes the inverter to accelerate from 0 Hz to the max. frequency.

The power-up time may become longer during certain states,

e.g. overload of the drive controller.

610.00260.40.000 · 05.2014

40 / 74

© Gardner Denver Deutschland GmbH

Page 41

Parameters

7

1,052 Braking time 2 Unit: s

Relationship to

parameter:

1.021

1.054

Parameter HB:

S. xy

Transfer

status:

2

min: 0.1 Intrinsic value

max: 1000

Def: 10

(to be en-

tered!)

The braking time 2 is the time it takes for the inverter to decelerate from the max. frequency (1,021) to 0 Hz.

If the set braking time cannot be met, the fastest possible braking time is implemented.

1,053 Power-up time 2 Unit: s

Relationship to

parameter:

1.021

1.054

Parameter HB:

S. xy

Transfer

status:

2

min: 0.1 Intrinsic value

max: 1000

Def: 10

(to be en-

tered!)

The power-up time 2 is the time it takes the inverter to accelerate from 0 Hz to the max. frequency.

The power-up time may become longer during certain states,

e.g. overload of the drive controller.

1,054 Ramp selection Unit: integer

Relationship to

parameter:

1,050 – 1,053

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 6

Def: 0

(to be en-

tered!)

Selection of the used pair of ramps.

0 = braking time 1 (1,050) / power-up time 1 (1,051)

1 = braking time 2 (1,052) / power-up time 2 (1,053)

2 = digital input 1 (false = pair of ramps 1 / true = pair of ramps

2)

3 = digital input 2 (false = pair of ramps 1 / true = pair of ramps

2)

4 = digital input 3 (false = pair of ramps 1 / true = pair of ramps

2)

5 = digital input 4 (false = pair of ramps 1 / true = pair of ramps

2)

6 = customer PLC

1,100 Operating mode Unit: integer

Relationship to

parameter:

1,130

1,131

2,051 – 2,057

3,050 – 3,071

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 3

Def: 0

(to be en-

tered!)

Selection of operating mode.

Following the software release (1,131) and hardware release, the

drive controller runs with the setpoint of the selected setpoint

source (1,130) at

0 = frequency setting mode, with the setpoint of the PID process

controller (3,050 - 3,071) at

1 = PID process controller, with the frequencies specified in the

parameters 2,051 - 2,057 at

2 = fixed frequencies, and via integrated soft PLC at

3 = selection

© Gardner Denver Deutschland GmbH

41 / 74

05.2014 · 610.00260.40.000

Page 42

7

Parameters

1,130 Setpoint source Unit: integer

Relationship to

parameter:

3,062 – 3,069

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 10

Def: 1

(to be en-

tered!)

Specifies the source from which the setpoint is to be read.

0 = internal potentiometer

1 = analogue input 1

2 = analogue input 2

3 = MANUAL CONTROL UNIT MMI/PC

4 = SAS

6 = motor potentiometer

7 = total analogue inputs 1 and 2

8 = PID fixed setpoints (3,062 - 3,069)

9 = fieldbus

10 = integrated soft PLC

1,131 Software release Unit: integer

Relationship to

parameter:

1,132

1,150

2,050

4,030

4,050

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 13

Def: 0

(to be en-

tered!)

WARNING! Depending on the change made, the motor

may start to run directly.

Selection of the source for the control release.

0 = digital input 1

1 = digital input 2

2 = digital input 3

3 = digital input 4

4 = analogue input 1 (must be selected in parameter 4,030)

5 = analogue input 2 (must be selected in parameter 4,050)

6 = field bus

7 = SAS

8 = digital input 1 right / digital input 2 left

1,150 must be set to "0"

9 = autostart

10 = integrated soft - PLC

11 = fixed frequency inputs (all inputs that have been selected in

parameter 2,050)

12 = internal potentiometer

13 = membrane keyboard (start & stop buttons)

If the hardware release and a setpoint are applied, the motor

may start to run directly!

This cannot be prevented even with parameter 1,132.

610.00260.40.000 · 05.2014

42 / 74

© Gardner Denver Deutschland GmbH

Page 43

Parameters

7

1,132 Non-tarnish protection Unit: integer

Relationship to

parameter:

1,131

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 6

Def: 0

(to be en-

tered!)

Selection of characteristics on the control release (parameter

1,131).

No effect if autostart was selected.

0 = immediate start at a high signal at the start input of control

release

1 = start only with increasing slope at the start input of control

release

2 = digital input 1 (function active at high signal)

3 = digital input 2 (function active at high signal)

4 = digital input 3 (function active at high signal)

5 = digital input 4 (function active at high signal)

6 = integrated soft PLC

1,150 Direction of rotation Unit: integer

Relationship to

parameter:

1,131

4,030

4,050

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 12

Def: 1

Selection of the specified direction of rotation.

(to be en-

tered!)

0 = setpoint-dependent (depending on the prefix of the setpoint:

reverse)

1 = forward only (change in the direction of rotation not possible)

2 = reverse only (change in the direction of rotation not possible)

3 = digital input 1 (0V = forward, 24V = reverse)

4 = digital input 2 (0V = forward, 24V = reverse)

5 = digital input 3 (0V = forward, 24V = reverse)

6 = digital input 4 (0V = forward, 24V = reverse)

7 = integrated soft PLC

8 = analogue input 1 (must be selected in the parameter 4,030)

9 = analogue input 2 (must be selected in parameter 4,050)

10 = membrane keyboard with button for reversal of the direction of rotation (only with running motor)

11 = membrane keyboard with button 1 for forward / 2 for reverse (reverse is always possible)

12 = membrane keyboard with button 1 for forward / 2 for reverse (reverse only possible when the motor is not running)

© Gardner Denver Deutschland GmbH

43 / 74

05.2014 · 610.00260.40.000

Page 44

A

A

r

A

7

Parameters

1,180

Relationship to

parameter:

1.181

1.182

cknowledgement function Unit: integer

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 5

Def: 3

(to be en-

tered!)

Selects the source for the error acknowledgement.

Errors can only be acknowledged if the error is no longer present.

Certain errors can only be acknowledgement by switching the

controller on and off, see list of errors.

Automatic acknowledgement via parameter 1,181

0 = no manual acknowledgement possible

1 = increasing slope at the digital input 1

2 = increasing slope at the digital input 2

3 = increasing slope at the digital input 3

4 = increasing slope at the digital input 4

1,181

5 = membrane keyboard (Reset button)

utomatic acknowledgement

Unit: s

function

Relationship to

parameter:

1.180

1.182

ameter HB:

Pa

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 1000000

Def: 0

(to be en-

tered!)

Besides the acknowledgement function (1,180), automatic fault

acknowledgement can also be selected.

0 = no automatic acknowledgement

1,182

> 0 = time for the automatic reset of the error in seconds

utomatic acknowledgement

Unit:

count

Relationship to

parameter:

1.180

1.181

Parameter HB:

S. xy

Transfer

status:

2

min: 0 Intrinsic value

max: 500

Def: 5

(to be en-

tered!)

In addition to the automatic acknowledgement function (1,181),

the maximum number of automatic acknowledgements can be

limited here.

0 = no limit for the number of automatic acknowledgements

> 0 = number of maximum automatic acknowledgements allowed

7.3.2

Fixed frequency

This mode must be selected in parameter 1,100, see also selection of the operating mode.

2.050 Fixed frequency mode Unit: Integer

Relationship to

parameter:

1.100

2.051 – 2.057

Parameter HB:

Transfer

status:

min: 0 Intrinsic value

max: 3

Def: 1

(to be en-

tered!)

Selection of the digital inputs used for the fixed frequencies.

0 = digital input 1 (fixed frequency 1) (2,051)

1 = digital input 1, 2 (fixed frequencies 1 - 3) (2,051 - 2,053)

2 = digital input 1, 2, 3 (fixed frequencies 1 - 7) (2,051 - 2,057)