Page 1

ELKHART BRASS MANUFACTURING COMPANY

INSTALLATION and OPERATING INSTRUCTIONS

for

PRESSURE-MATIC®

I. Models and Sizes Covered:

UR-20, 1-1/2" size, bonnet types W,X,Y,YZ,Z,ZA,ZB,ZZ & ZZA

UR-25, 1-1/2" size, bonnet types W,X,Y,YZ,Z,ZA,ZB,ZZ & ZZA

UR-20, 2-1/2" size, bonnet types A,B,C,CD,D,DE,E,EF & F

UR-25, 2-1/2" size, bonnet types A,B,C,CD,D,DE,E,EF & F

UR-20S, 2-1/2" size, bonnet types A,B,C,CD,D,DE,E,EF & F

Inlet and Outlet Connections:

*NPT = American National Standard Taper Pipe Threads (ANSI/ASME B1.20.1-1983, R2006)

NH = American National Fire Hose Connection Screw Thread (NFPA 1963-2009 Ed.)

II. Application Guidelines:

A. Automatic Sprinkler Systems

Pressure-Matic® valves are most commonly used in automatic sprinkler systems as floor control valves in highrise buildings where supply riser pressures exceed 175 psi. These valves are listed by Underwriters Laboratories

as Special System Water Control Valves-Pressure Reducing and Pressure Control Type (VLMT), and also meet

the listing requirements for indicating valves. Requirements for the installation of pressure reducing valves in

automatic sprinkler systems are given in Section 4-6.1.2 of NFPA 13, Standard for the Installation of Sprinkler

Systems, Latest Edition. When designing Pressure-Matic® valves into a sprinkler system, the following maximum

flow rate limits should be observed:

98278000 Rev

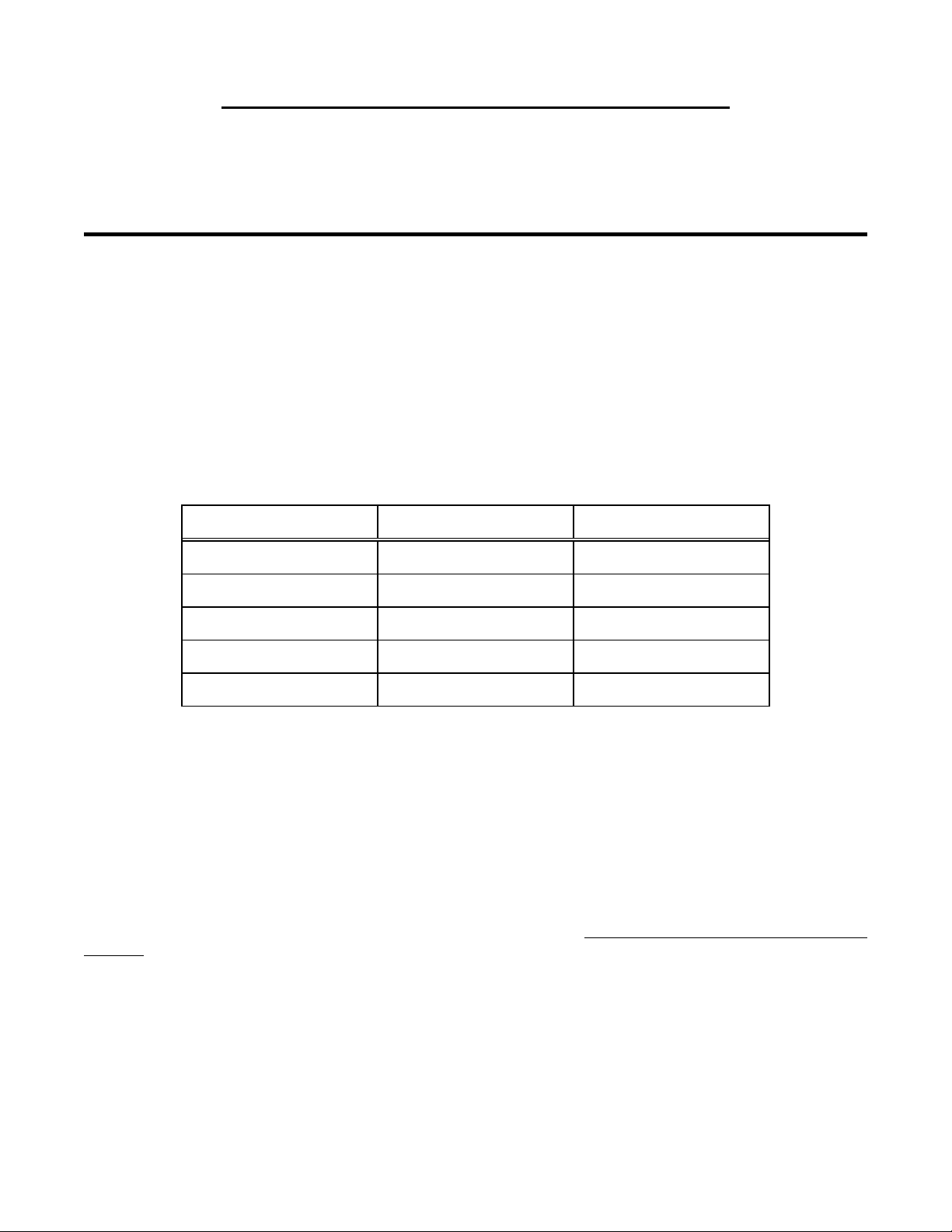

Valve Model & Size

UR-20, 1-1/2"

UR-25, 1-1/2"

UR-20, 2-1/2"

UR-25, 2-1/2"

UR-20S, 2-1/2"

B

AUTOMATIC PRESSURE REDUCING VALVES

*Inlet Thread

1-1/2" fem. NPT

1-1/2" fem. NPT

2-1/2" fem. NPT

2-1/2" fem. NPT

2-1/2" fem. NPT

*Outlet Thread

1-1/2" fem. NPT

1-1/2" male NH

2-1/2" fem. NPT

2-1/2" male NH

2-1/2" fem. NPT

1

Page 2

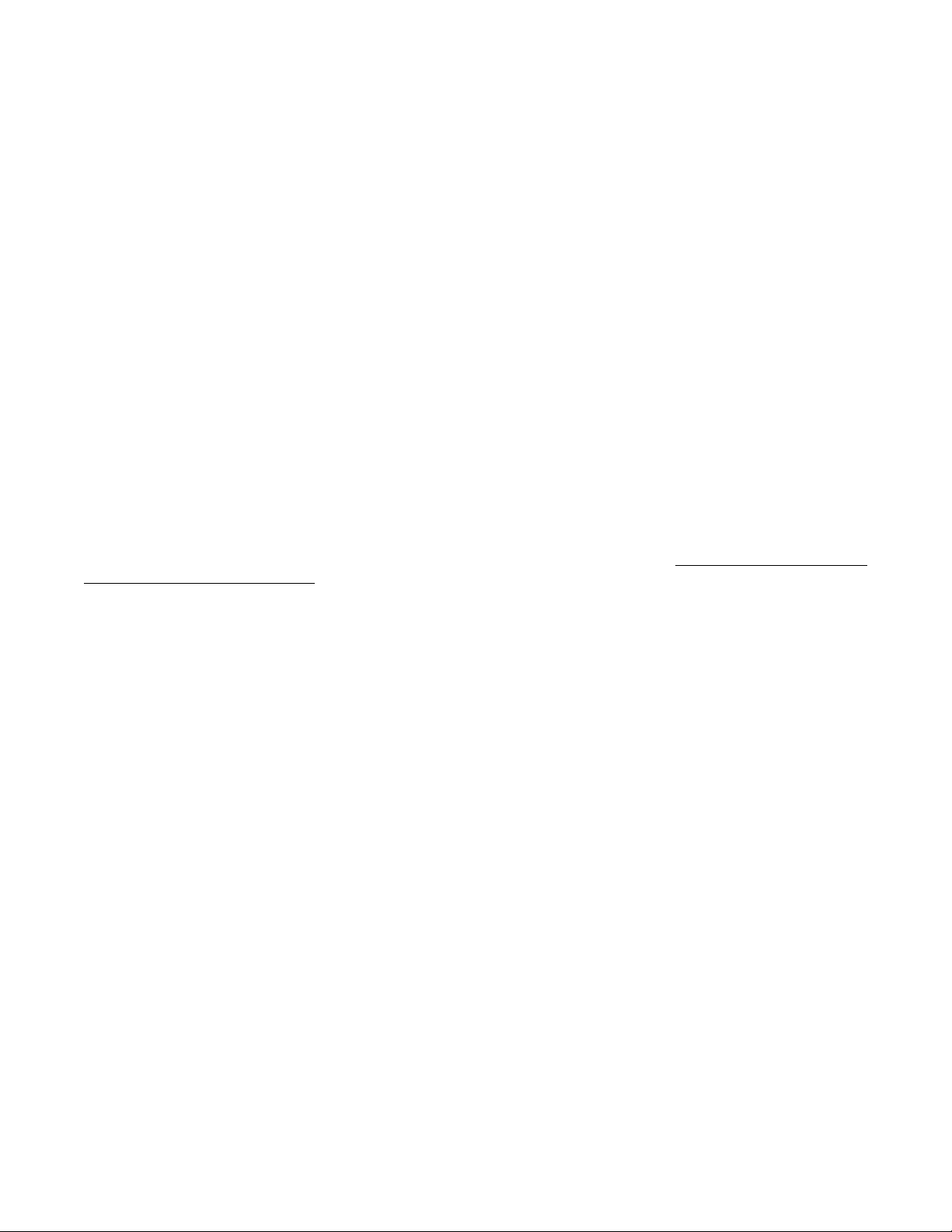

Valve Model Bonnet Type Max. Flow (gpm) Max. Pressure (PSI)

A 500 400

B 500 400

C 500 400

UR-20 & UR-25

2-1/2"

UR-20S

2-1/2”

UR-20 & UR-25

1-1/2"

* ULC rated to 400 PSI

** ULC rated to 394 PSI

*** ULC rated to 316 PSI

These valves are also listed as a checking device, which eliminates the need for a separate check valve. When

sprinklers on a given floor are fed from dual risers, the Pressure-Matic® valve acts as a check valve to prevent

loss of sprinkler water supply in the event of damage to one riser.

Supervisory Switch Mounting Brackets

Brackets are available for the attachment of the following listed supervisory switches to the Pressure-Matic®

valves.

Switch Mfr. & Model No. Bracket No.

Potter Electric

System Sensor

CD 500 400

D 500 360

DE 500 330

E 500 290

EF 500 250

F 500 220

A 400 400

400

B

C

CD

D

DE

E

EF

F

W 200

X

Y

YZ

Z

ZA

ZB

ZZ

ZZA 200

OSYS-B

PCVS

PIVS-B

" "

PIVSU-A1

PIVSU-A2

PIBV2

OSY2

400

400

400

400

400

400

400

300*

200

300*

200

300*

200

300**

200

300***

200

200

200

190

80738001

80574001

80736001(

80763001(

for sprinkler application)

hose valve application)

80823001

80823001

80574001

80574001

400

400

400

360

330

290

250

220

280

250

220

2

Page 3

For proper installation of bracket and switch, see instruction sheet which accompanies bracket kit, and also refer

to switch manufacturer's instructions.

Sprinkler System Installation Requirements

1. To permit easy replacement or repair of valve, pipe unions or rubber gasketed mechanical couplings should be

installed immediately upstream or downstream of the valve.

2. A relief valve of not less than 1/2 inch size is to be installed on the downstream side of each Pressure-Matic®

valve.

3. Pressure gauges are to be installed on the inlet and outlet sides of each pressure reducing valve.

4. Valve type should be selected to provide an outlet pressure not exceeding 165 psi at the maximum inlet

pressure.

5. Upon system completion, each Pressure-Matic® valve must be tested under both flow and no-flow conditions

to verify that static and residual outlet pressures and flow rates satisfy system design requirements, per

requirements of Section 8-2.5 of NFPA 13.

B. Standpipe System Applications

With their male hose thread outlet connections, the model UR-25 valves are intended for use as pressure

reducing hose valves in standpipe systems. When hose racks are used, the UR-20 valves can be utilized along

with a special hose nipple for support of the rack. The Pressure-Matic® valves are listed by Underwriters

Laboratories as Standpipe Equipment Pressure Reducing Devices (VUTX). Requirements for the installation of

pressure reducing valves in standpipe systems are given in Section 5-8 of NFPA-14, Standard for the Installation

of Standpipe and Hose Systems, Latest Edition. The 2-1/2" UR-25 can be used for both Class I and Class III

service, while the 1-1/2" version can used for Class II systems. NFPA 14 requires that hose valve outlet pressure

for Class I and Class III service be no greater than 175 psi, and no less than 100 psi. When permitted by the

authority having jurisdiction, pressures less than 100 psi may be allowed, but in no case shall the valve discharge

pressure be less than 65 psi. Class II hose valves must be limited to a maximum residual outlet pressure of 100

psi, but the minimum outlet pressure shall not be less than 65 psi.

Acceptance Tests

Upon completion of system, each Pressure-Matic® hose valve shall be tested in accordance with paragraph 8-5.5

of NFPA 14 to verify that the installation is correct, that the valves are operating properly, and that the inlet and

outlet pressures at the valve are in accordance with the design.

III. Valve Performance Characteristics & Limitations:

A. Valve Construction & Operating Principle

The Pressure-Matic® is a fairly simple pressure reducing valve, which utilizes a hydraulic piston and cylinder

assembly within the valve bonnet to allow the valve to self-throttle in response to the pressure on the downstream

side of the valve. Because the piston, main stem and valve seat float freely from the manual valve stem and

handwheel assembly, the valve is able to self-close under static conditions, and maintain a reduced pressure

under no-flow conditions, as well as under flowing conditions. Valve discharge pressure is transmitted to the top

side of the piston through pressure passages in the main stem. The presence of the piston results in a net area

differential which produces a hydraulic balancing force in the closed direction. The magnitude of this balancing

force is in direct proportion to the hydraulic area of the piston.

The Pressure-Matic® is a non-adjustable pressure reducing valve design, which means that the pressure

reduction ratio of a given valve cannot be varied. However, the valves are available with any of nine (9) different

piston diameters in order to satisfy all expected inlet/outlet pressure ratios. The valve piston size is designated by

a "type" letter, ranging from "A" through "F" for the 2-1/2" valves, and from "W" through "ZZA" for the 1-1/2"

valves. Each valve "type" then provides a fixed pressure reduction ratio, meaning that the outlet pressure will

always be a fixed percentage of the inlet pressure, regardless of inlet pressure. It should be noted, however, that

3

Page 4

this pressure reduction ratio will tend to decrease with increase of flow rate through the valve. This behavior

results due to friction loss through the valve.

B. Valve Type Selection

To determine the correct type (bonnet) for each Pressure-Matic® valve in the system design, please use the

following steps.

1. Determine the standpipe or sprinkler riser residual pressure for each valve location. This is

the inlet pressure at each valve under design flow conditions. In order to accurately determine

these pressures, complete water supply data will be required, including results of municipal

supply flow test, and the pump performance curve. The Pressure-Matic® inlet pressure will be

equal to the sum of the pump discharge pressure and the municipal supply pressure at the design

flow rate, less piping friction loss, and elevation loss.

2. Turn to the appropriate valve performance chart (Figs. I through VIII), based on valve size

and body style. The valve flow range for each chart is indicated in the lower right corner of the

chart. Be sure to use the correct chart for the designed flow rate through the valve.

3. Locate the valve inlet residual pressure on the vertical axis of the chart and draw a line from

this pressure horizontally across the chart.

4. Locate the desired valve outlet residual pressure on the chart horizontal axis and draw a

vertical line from this pressure across the chart.

5. From the intersection of the inlet and outlet pressure lines constructed in (3) and (4) above,

move horizontally to the nearest valve performance curve (actually straight diagonal lines). This

will be the appropriate valve for the chosen location.

EXAMPLE: The residual inlet pressure at a straight pattern sprinkler system floor

control valve is 275 psi at a design flow demand of 280 gpm. The desired

residual outlet pressure is 120 psi. On the appropriate chart (Fig. III) it is seen

that the intersection of the residual inlet and outlet pressure lines fall very close

to the performance curve (straight line) for the "DE" valve. Therefore, the "DE"

valve would be chosen, and would provide an actual residual outlet pressure of

125 psi.

6. Determine the valve static inlet pressure. This will be the sum of the municipal supply static

pressure plus the pump churn pressure, less elevation loss.

7. To determine the valve static outlet pressure, refer to the appropriate static chart (Fig. IX or

X). Locate the valve static inlet pressure on the vertical axis of the chart. Follow across to the

appropriate valve curve (straight line) and drop down to the horizontal axis to read valve outlet

static pressure.

EXAMPLE: For the valve in step (5) above, the static inlet pressure is 290 psi.

Follow the 290 psi inlet pressure line across the chart horizontally to the "DE"

curve. Read the outlet static pressure of 153 psi on the horizontal axis directly

below the point of intersection.

NOTE: If static outlet pressure is found to exceed the maximum outlet pressure allowed by NFPA 13 or NFPA

14, it will be necessary to re-select a valve type to the left of the originally chosen type

4

Page 5

IV. Valve Care & Maintenance:

Pressure-Matic® valves require minimal maintenance, and can normally serve reliably for twenty years or longer

in fire protection systems. However, a routine inspection and testing program is essential for any fire protection

system to insure that it is in proper operating condition. NFPA 25, Standard for the Inspection, Testing and

Maintenance of Water-Based Fire Protection Systems should be consulted for a determination of required test

frequency and methods.

Below is a summary of the required frequency of inspections and testing for pressure reducing valves:

Valve Application

sprinkler system pressure regulating

control valve

hose connection and hose rack assembly

pressure regulating valve

Flow test results should be compared to previous test results, and to system performance criteria. Because the

Pressure-Matics® are non-adjustable type valves, test results should not vary significantly from previous test

results unless the water supply or pump characteristics have changed, resulting in a higher or lower inlet pressure

to the Pressure-Matic® valve. If changes to the water supply result in unsatisfactory performance of the PRV, the

upper bonnet subassembly may be field replaced with a different type to achieve a different reduction ratio.

For information on bonnet subassembly replacement or on any repair parts, please contact:

NOTE: The outlet pressure shown on the following charts

Inspection

quarterly

quarterly

Elkhart Brass Mfg Co

PO Box 1127

Elkhart, IN 46514

574-295-8330

are subject to a tolerance of ±10%.

Flow Test

annually

5-years

5

Page 6

Fig. I Model UR-20S, 2-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

A

B

VALVE OUTLET PRESSURE (PSI)

CCD

D

USE THIS CHART FOR

50-100 GPM FLOW

DE

E

EF

F

Fig. II Model UR-20S, 2-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

A

B

VALVE OUTLET PRESSURE (PSI)

CCD

D

DE

USE THIS CHART FOR

100-200 GPM FLOW

E

EF

F

6

Page 7

Fig. III Model UR-20S, 2-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

A

B

VALVE OUTLET PRESSURE (PSI)

CCD

D

USE THIS CHART FOR

DE

E

EF

F

200-300 GPM FLOW

Fig. IV Model UR-20S, 2-1/2"

A

80

60

50 75 100 125 150 175

PRESSURE (PSI)

VALVE INLET RESIDUAL

400

380

360

340

320

300

280

260

240

220

200

180

160

140

120

100

B

CCD

D

EF

VALVE OUTLET PRESSURE (PSI)

DE

E

F

USE THIS CHART FOR

300-400 GPM FLOW

7

Page 8

Fig. V Model UR-20 & 25, 2-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

A

B

VALVE OUTLET PRESSURE (PSI)

CCD

D

USE THIS CHART FOR

50-400 GPM FLOW

DE

E

EF

F

Fig. VI Model UR-20 & 25, 2-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

A

B

VALVE OUTLET PRESSURE (PSI)

CCD

D

USE THIS CHART FOR

400-500 GPM FLOW

DE

E

EF

F

8

Page 9

ULC APPROVED

Fig. VII Model UR-20 & 25, 1-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

W

X

VALVE OUTLET PRESSURE (PSI)

Y

TO 400 PSI

YZ

Z

ZA

ZB

ZZ

ZZA

USE THIS CHART FOR

50-200 GPM FLOW

ULC APPROVED

Z

ZA

ZB

ZZ

TO 400 PSI

USE THIS CHART FOR

200-250 GPM FLOW

Fig. VIII Model UR-20 & 25, 1-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET RESIDUAL

180

160

140

120

100

80

60

50 75 100 125 150 175

W

X

Y

YZ

ZZA

VALVE OUTLET PRESSURE (PSI)

UL APPROVED

TO 300 PSI

UL APPROVED

TO 300 PSI

9

Page 10

Fig. IX Model UR-20, UR-25 & UR-20S, 2-1/2"

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET STATIC

180

160

140

120

100

80

60

50 75 100 125 150 175

A

VALVE OUTLET PRESSURE (PSI)

B

CCD

USE THIS CHART FOR

STATIC OUTLET

D

DE

E

EF

F

Fig. X Model UR-20 & 25, 1-1/2"

UL APPROVED

400

380

360

340

320

300

280

260

240

220

200

PRESSURE (PSI)

VALVE INLET STATIC

180

160

140

120

100

80

60

50 75 100 125 150 175

TO 300 PSI

W

VALVE OUTLET PRESSURE (PSI)

X

ULC APPROVED

TO 400 PSI

STATIC OUTLET PRESSURE

Y

USE THIS CHART FOR

YZ

Z

ZA

ZB

ZZ

ZZA

10

Loading...

Loading...