Page 1

Instructions for 242-95 portable eductor

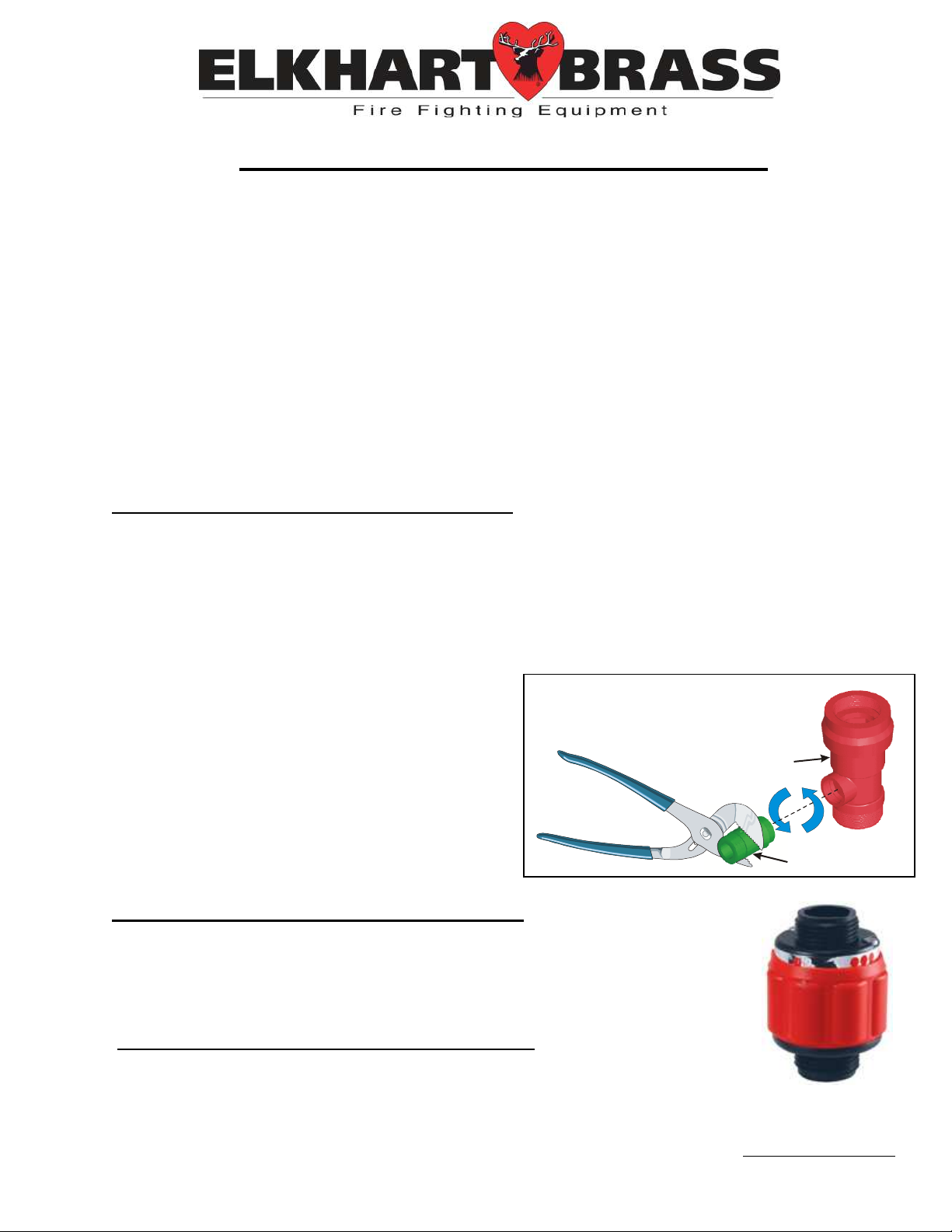

Removing the Checkvalve

The Elkhart 242-95 Eductor is a device used for educting a liquid concentrate solution into the

water stream of 1-1/2" fire hose lines.

The 242-95 Eductor is constructed of Armor-Lyte ™ composite material with stainless steel

components for resilience and durability. Armor-Lyte ™ is impervious to the corrosion caused by

high concentrate detergents, salt water and most chemicals.

The 242-95 Eductor is designed for use with nozzles calibrated for flow rates of 95gpm (356

lpm) at 100 psi (6.9 bar). Each Eductor comes equipped with a 1-1/2" NHT female swivel inlet

connection, a 1-1/2" NHT male outlet connection. The eductor comes with four metering/check

valves to choose from ( 1/2%, 1%, or 3% fixed orifice) or (1/2%, 1%, & 3% adjustable). Each

metering/check valve has a 3/4" male Garden Hose Thread inlet that the concentrate pick-up hose

assembly will attach to.

Installing a fixed orifice metering/check valve. Each of the three different fixed orifice

metering/check valves provides a different concentrate eduction rate. When installed, the Black

metering/check valve will educt at a 1/2% rate, the Purple metering/check valve will educt at a 1%

rate and the Green metering/check valve is for educting at a 3% rate. To install a fixed orifice

metering/check valve screw the male thread located on the end of the metering/check valve from

which the inner coil spring is visible into the female thread on the side of the eductor body as far

as possible by hand. Then gently grasp the metering/check valve body with pliers or vise grips

and tighten snuggly. There is no need to over tighten.

To remove a fixed orifice metering/check valve,

gently grasp the checkvalve body with pliers or vise

grips and unscrew. The illustration to the right

shows the method of removing the fixed orifice

Eductor Body

metering/check valves.

Installing the adjustable metering/check valve. Screw the male thread

located on the end of the adjustable metering/check valve with the chrome

position indicator label. (On the illustration to the right it’s shown at the top.)

Tighten snuggly by hand only no tools are needed. There is no need to over

tighten.

Operating the adjustable metering/check valve. Rotate the red selector

ring to align it’s pointer with the desired eduction rate on the chrome label. The

red half dot indicates the 1/2% position, the red full dot indicates the 1%

position, and the three red dots indicate the 3% position. There is no OFF position.

98417000 (Rev-B)

Checkvalve

Elkhart Brass Mfg. Co., Inc. 1302 W. Beardsley Avenue • Elkhart, Indiana 46514 • 1-574-295-8330 • 1-800-346-0250

www.elkhartbrass.com

Page 2

Installing the pickup hose and wand. Thread the female end of the pickup hose onto the

Concentrate

metering/check valve and the pickup wand onto the male end of the pickup hose. Tighten both

snuggly, there is no need to over tighten.

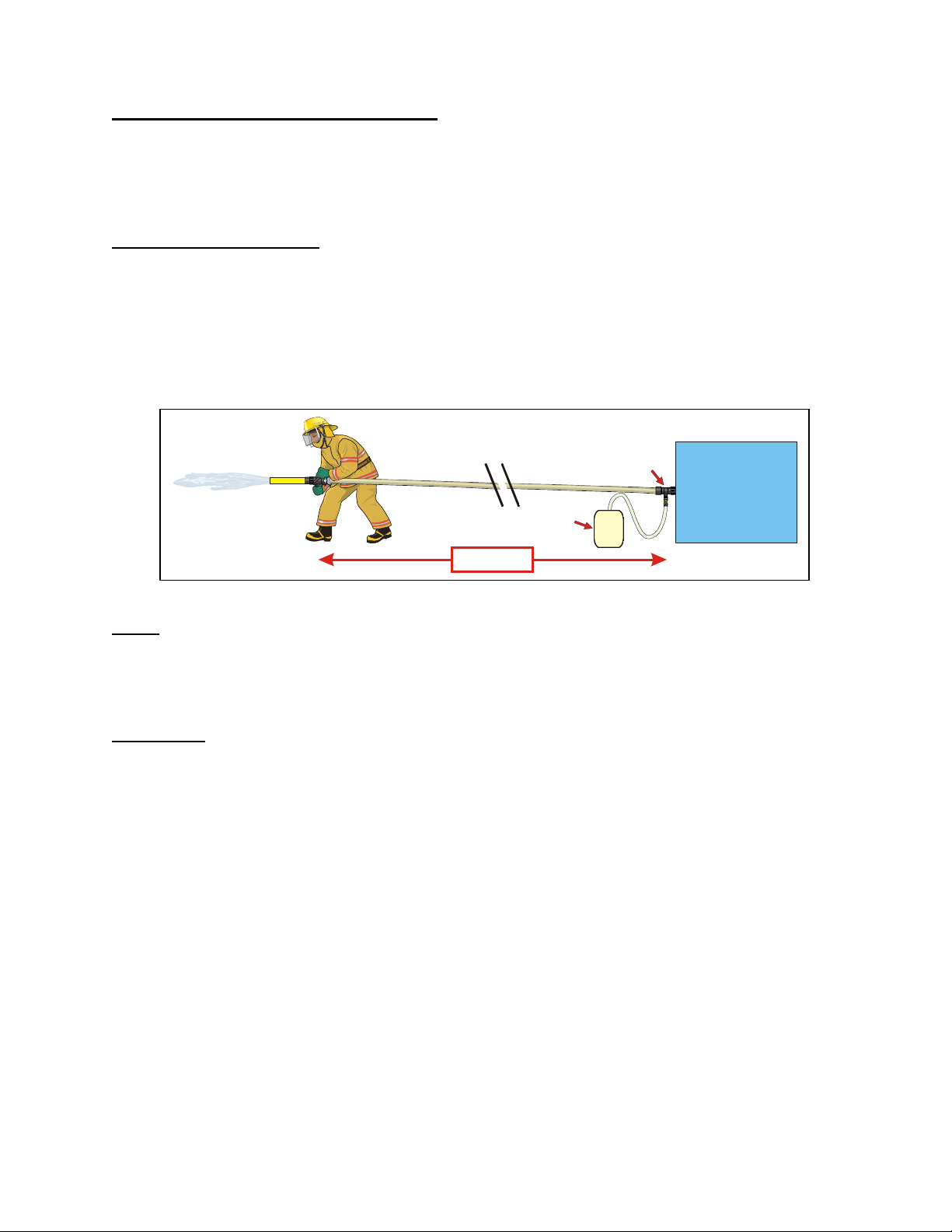

Eductor System set up. The illustration below shows a typical set-up. The eductor is

mounted on the discharge of the pump or fire truck, a liquid concentrate reservoir is placed nearby

with the 242-95 Eductors pick-up wand placed in it. A 1-1/2” hose lay of 150 ft. is attached to the

discharge of the eductor with a nozzle rated for 95gpm (356 lpm) at 100 psi (6.9 bar) at the end.

242-95s are restricted to a maximum hose length of 150 feet between the eductor and nozzle.

However, when using the 1/2% or 1% fixed orifice metering/check valve, the maximum

length for the 1-1/2” hose lay may be increased to 200 feet.

242-95 Eductor

PUMP

Reservoir

150 FEET

Note; The eductor to nozzle hose length can be increased to 300 ft. when using 1-3/4” hose.

Operation. The 242-95 Eductor is designed to operate at a maximum inlet pressure of 150 psi.

The minimum inlet pressure required for an effective nozzle stream is 75 psi.

Loading...

Loading...