Page 1

1

1302 WEST BEARDSLEY AVE • ELKHART, IN 46514 • 574-295-8330 • 800-346-0250 98370000 REV B

© 2012 ELKHART BRASS MFG. CO., INC. • WWW.ELKHARTBRASS.COM

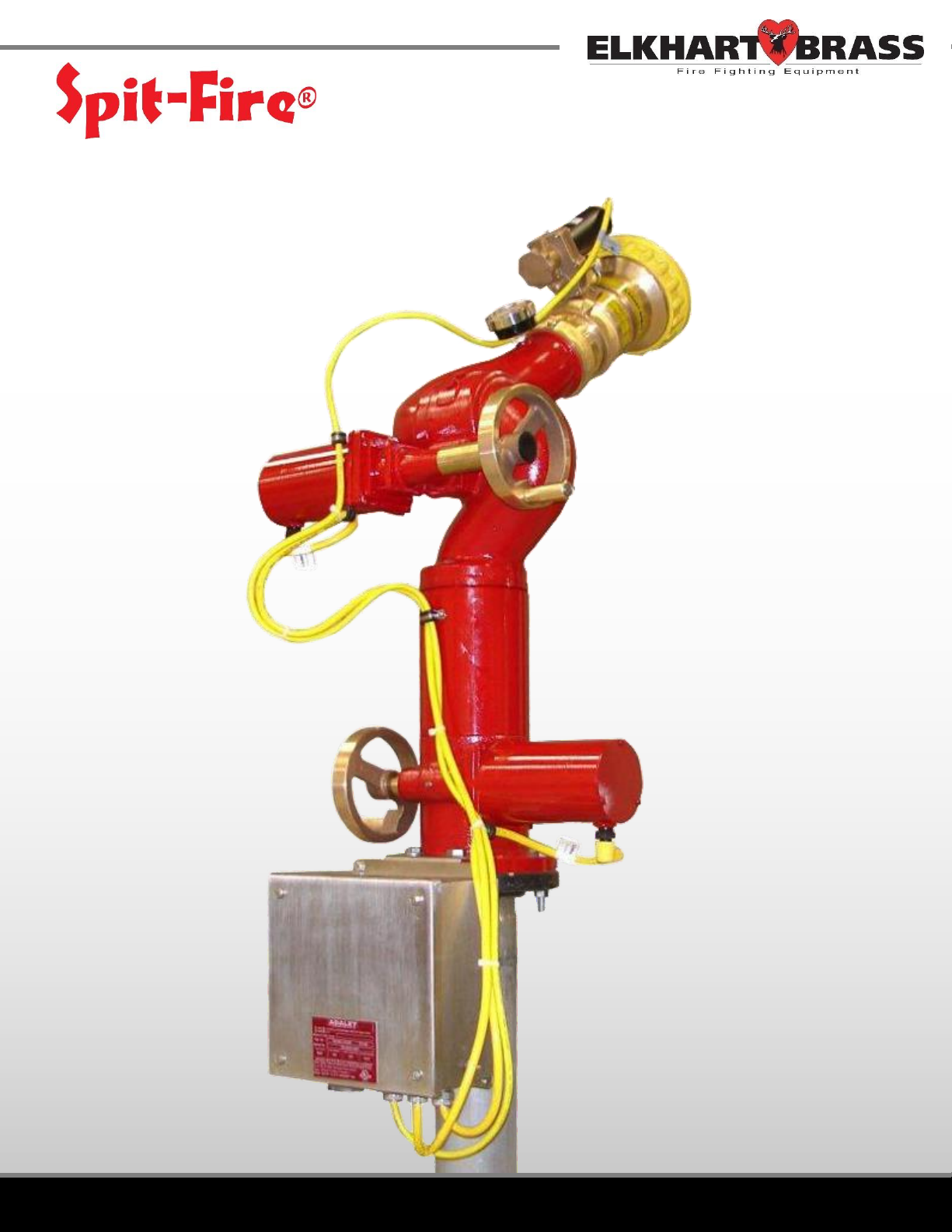

08394059 Monitor

Installation, Operation, & Maintenance Instructions

FOR ATEX APPLICATIONS

Page 2

2

TABLE OF CONTENTS

PRODUCT SAFETY INFORMATION 3

MONITOR CALLOUT DRAWING 4

OVERVIEW 5

INSTALLATION INSTRUCTIONS 6

OPERATING INSTRUCTIONS 9

MAINTENANCE 9

SPECIFICATIONS 10

MONITOR HYDRAULIC DATA 10

DIMENSIONAL DRAWINGS 11

WIRING 12

NOTES 13

Page 3

3

PRODUCT SAFETY INFORMATION

All personnel who may be expected to operate this equipment must be thoroughly trained in its safe

Important: Before installing and operating this equipment, read this manual

thoroughly. Proper installation is essential to safe operation.

Warning: Do not attempt to disconnect or work on any electrical equipment in this

system unless power is removed or the area is known to be non-hazardous.

and proper use.

Before flowing water from this device, check that all personnel (fire service and civilian) are clear of

the stream path. Also confirm stream direction will not cause avoidable property damage.

Become thoroughly familiar with the hydraulic characteristics of this equipment, as well as the

pumping system used to supply it.

Whenever possible, this equipment should be operated from remote location to avoid exposing

personnel to dangerous fire conditions.

Always open and close valves slowly to avoid water hammer.

After each use, and on a scheduled basis, inspect equipment per instructions in the maintenance

section.

Keep fingers and hands clear of moving parts.

Disconnect power before servicing and electric valve or electric valve controller.

Any modifications to the electrical will destroy the IP-66 rating and void warranty coverage of the

enclosure and all components within.

All equipment must be installed in accordance with ATEX requirements (EN/IEC 60079-14) as

appropriate and in areas where equipment classification is suitable.

MONITOR INFORMATION:

SERIAL NUMBERS:__________________________________________________________________________

DETAILS:

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

Page 4

4

MONITOR CALLOUT

Figure 1: Monitor Callout Drawing

Pressure Gauge

Constant Torque /

Constant Current Motors

Manual Override

Double Race Bearings

Junction Box

4”-150# ANSI Flange

Page 5

5

OVERVIEW

Spit-Fire® Monitor Featuers:

Warning: DO NOT TAKE COVER OFF OR DISASSEMBLE MONITOR MOTORS. If

cover is/has been removed, the warranty is void and the service life of the motor is

significantly reduced.

Construction: All brass with vaned 4” waterway

Mounting Flange: 4” 150# flat-face ANSI flange raised face flange available as option

Discharge: 3½” NHT male outlet

Stream Shaper: #284-B brass shaper included

Flow: 2000 GPM max flow @ 200 PSI max working pressure

7600 LPM @ 14 BAR

Motors: 120 VAC NEMA 4 rated synchronous motors (non-arcing)

o Constant torque and current output in start, running, and stall

o ATEX Certified to II 3 G c (Ex nA II T4)

o Will not cause damage or increase in current when motor is stalled

o Instantaneous start, stop, and reverse

o Residual (Power Off) torque is always present

o Long life and exceptional reliability

o 120 VAC, 50/60 Hz., 1 Phase, 0.80 Amp current per motor

Junction Box: NEMA #4X (IP-66) water tight, corrosion resistant ATEX certified (Ex eII T6),

enclosure with terminals for hazardous locations. Stainless Steel motor

cable junction box with bracket to attach to monitor, flange base included.

Range of Motion: Monitor stops are factory set at 346° horizontal (+173° to -173° from front

center), and 135° vertical (+90° to -45°)

Rate of Horizontal Motion: 0.139 Sec/°

Manual Override: Hand wheels provided for vertical and horizontal movements. Hand wheel

will not rotate when monitor is operated electrically.

CE ATEX Certified (Group II, Category 3) II 3 G c T3

Page 6

6

INSTALLATION INSTRUCTIONS

Monitor Installation

Warning: When installing the monitor on a raised face companion flange or wafer

type valve, it is critical that the bolts be tightened uniformly to prevent misalignment

of the monitor relative to the flange or valve. If the monitor becomes misaligned, the

base flange will fracture and fail when the bolts on the “high” side are tightened.

1. Attach companion flange to water supply pipe so that the bolt pattern will allow the monitor to be

installed with the “straight ahead/neutral” position (see Dimensional Drawing section) properly

aligned. Alignment is correct when the “straight ahead/neutral” direction is centered between

adjacent flange bolt holes.

2. Install the monitor assembly on the water supply flange so that it matches up to a 4”-150# flat

faced ANSI flange on the inlet of the monitor, with a flange gasket between the flanges. Install

motor cable junction box by aligning the two-holed bracket with the flange mounting holes on the

rear of the monitor. Secure the inlet flange with eight (8) 5/8”-11 UNC Grade 5 hex head bolts.

Torque bolts to 60-70 ft-lbs.

3. Standpipe must be structurally strong enough to withstand reaction forces of the nozzle when

discharging a straight stream at 90° of the standpipe tower. The formula for calculating nozzle

reaction is: [REACTION FORCE = 0.0505 x GPM x √ PSI]

4. The inlet pressure at the base of the monitor must be high enough to allow for pressure loss

through the monitor. To accomplish this, use the pressure loss for GPM flowing and add to nozzle

pressure. See Monitor Hydraulic Data section for pressure loss chart.

Page 7

7

Monitor Cable Routing

Figure 2: Monitor Cable Routing

1. Route cables as shown in Figure 2 below, so they will follow the vertical and horizontal movement

of the monitor. Make sure that the wire loops for horizontal and vertical movement is great

enough to eliminate any stretching of cables throughout the full movement of the monitor.

2. Wire tie cables together as shown in Figure 2 below. This will eliminate the cables from tangling.

3. Wire tie the nozzle cable to pressure gauge, allowing a long enough loop so vertical movement of

monitor will go to the full down position without stretching the cable.

Page 8

8

Monitor Safety Boot and Clamp Installation

Figure 3a: Monitor Motor Boots

Figure 3b: Nozzle Motor Boots

All Motor Cable Connections are provided with clamped safety boots. These boots must not be

removed when monitor motor control panel is energized and area is hazardous.

1. Install corrugated black plastic boot on cable connector as shown so split lines up with cable.

2. Install clamp around top of boot and connector swivel.

3. Tighten clamp down around swivel and boot.

Page 9

9

OPERATING INSTRUCTIONS

One Monitor Control

MAINTENANCE

Warning: Do not attempt to disconnect or work on any electrical equipment in this

system unless power is removed or the area is known to be non-hazardous.

This operator control panel has one set of switches and pilot lights to operate one monitor.

Monitor Functions – UP, DOWN, LEFT, & RIGHT are operated with spring return joysticks. This is

accomplished by using the proper selector/pushbutton joystick to move the monitor the direction

desired. When joystick is released, it will return to original (off) position, and monitor movement

will stop.

Monitor Manual Control

Vertical Manual Override – Push hand wheel inward to engage override. While holding the

hand wheel in, rotating it clockwise will raise the nozzle, and rotating it counter-clockwise will

lower the nozzle.

Horizontal Manual Override – Push hand wheel inward to engage override. While holding hand

wheel in, rotating it clockwise will move the monitor right, and rotating it counter-clockwise will

move the monitor left.

When monitor operation is completed, move vertical movement to full down position to allow water to

drain from nozzle. When water is drained from nozzle, move monitor to park position.

Monthly Inspection & Maintenance

Cycle all monitor functions (LEFT, RIGHT, UP, DOWN) to insure the complete system is fully

functional.

Six-Month Inspection & Maintenance

Grease monitor ball races through grease fittings located at each swivel joint. Recommended

grease for Industrial Spit-Fire® monitors is MOBILITH SHC – 100, High Performance Synthetic

Grease. Temperature range: -40°F (-26°C) to 400°F (250°C) or equal. Greasing procedures are

as follows:

o Apply approx. 5-7 pumps of grease in the lower grease fitting, and 2-3 pumps in the

upper grease fitting

Check motor control cables for water and connectors for damage.

Check motor cables for binding through full movement of monitor.

Check all painted surfaces for chips or scratches, and repaint as required.

Visually check all electrical equipment.

Page 10

10

SPECIFICATIONS

General Specs

MONITOR HYDRAULIC DATA

Figure 4: Monitor Friction Loss Chart

8394053 “ SPI TFI RE” M on it or

Pressure Drop Data

0

5

10

15

20

25

30

35

40

45

50

55

Pressure Drop (PSI )

200

400

600

800

1000

1200

1400

1600

1800

2000

Flow (GPM)

Input Power 120/240 VAC (50/60Hz.) 1 Phase

Electrical Load 2 AMPS Per Monitor / 0.80 AMPS Per Motor

Monitor Dimensions 23” dia. x 52” h

Monitor Weight Appox. 300 lbs.

Operating Temperature Range -40°C to +85°C

ATEX Product Marking

II 3 G c T3

Page 11

11

DIMENSIONAL DRAWING

Figure 5: Monitor Dimensional Drawing

Page 12

12

WIRING

Figure 6: Monitor Cable Wiring to Junction Box Terminals

Page 13

13

NOTES

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________

Page 14

ELKHART BRASS

1302 WEST BEARDSLEY AVE

P.O. BOX 1127

ELKHART, IN 46514

PHONE: 574-295-8330 • 800-346-0250

FAX: 574-293-9914

WWW.ELKHARTBRASS.COM

© ELKHART BRASS MFG. CO., INC. 2012

SPIT-FIRE®

08394059 MONITOR

INSTALLATION, OPERATION, & MAINTENANCE INSTRUCTIONS

FOR ATEX APPLICATIONS

98370000 REV. B

Loading...

Loading...