Page 1

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

Installation/Care/Use Manual

EZH20 In Wall Bottle Filling Station

LZWSM8* LZWSMD* LZWSM8P* LZWSMDP*

EZWSM8* EZWSMD* EZWSM8P* EZWSMDP*

Installer

To assure you install this model easily and correctly,

PLEASE READ THESE SIMPLE INSTRUCTIONS BEFORE STARTING THE

INSTALLATION. CHECK YOUR INSTALLATION FOR COMPLIANCE WITH

PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. After installation,

leave these instructions inside the fountain for future reference.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO

WATER LINES IS A COMMON PROCEDURE. THIS GROUNDING MAY BE IN THE BUILDING OR MAY

OCCUR AWAY FROM THE BUILDING. THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNTAIN, CREATING AN ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN

INCREASE IN THE METAL CONTENT OF THE WATER. THIS CONDITION IS AVOIDABLE BY USING

THE PROPER MATERIALS AS INDICATED. ANY DRAIN FITTINGS PROVIDED BY THE INSTALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALLY ISOLATE THE FOUNTAIN FROM THE BUILDING

PLUMBING SYSTEM. WE SUGGEST THAT THE BOTTLE FILLER BE PROTECTED BY A GROUND

FAULT CIRCUIT INTERRUPTER (GFCI)

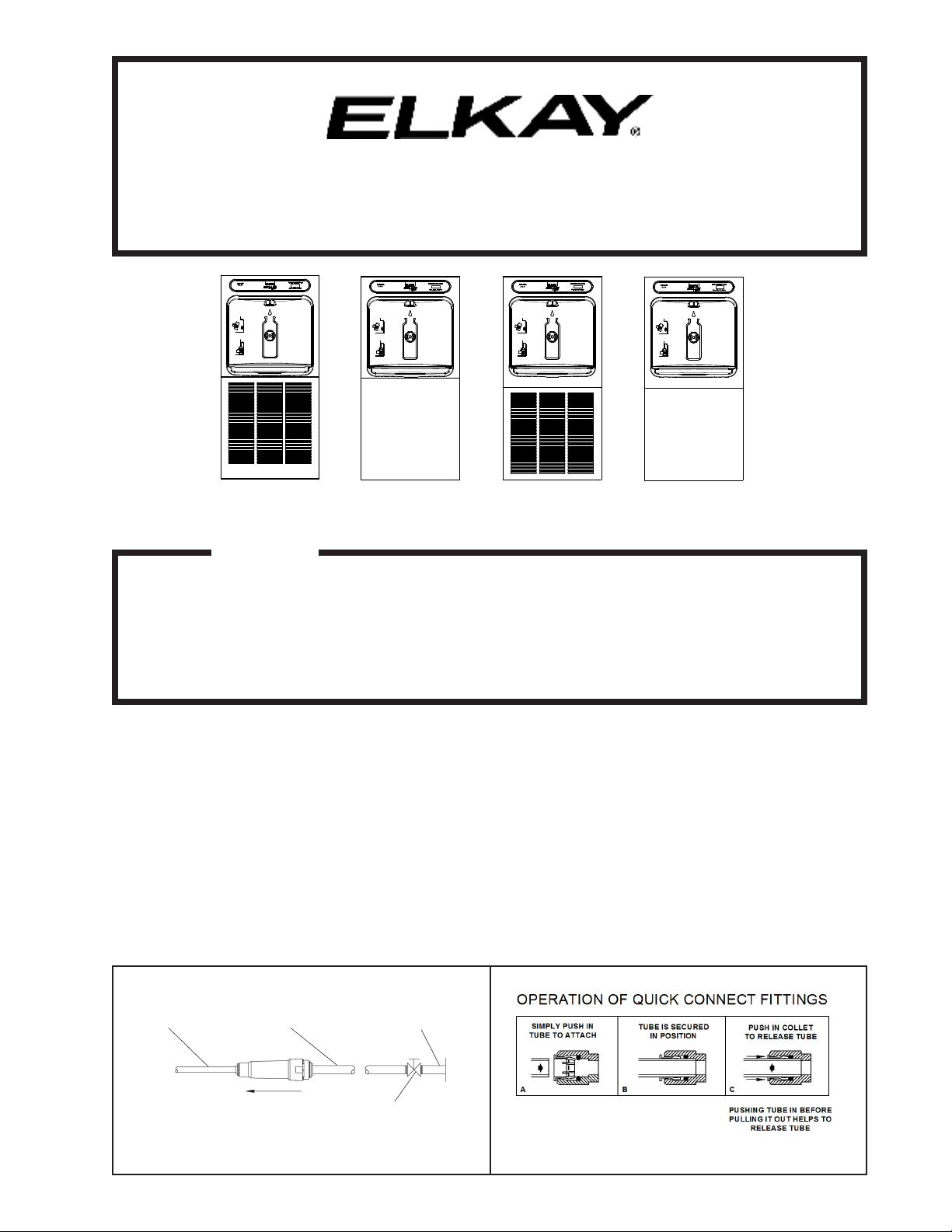

1/4” O.D. TUBE

WATER INLET

TO COOLER

Page 1 98557C (Rev. K - 11/14)

3/8” O.D. TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATERFLOW

DIRECTION

BUILDING WATER

INLET

SERVICE STOP

(NOT FURNISHED)

FIG. 2FIG. 1

Page 2

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

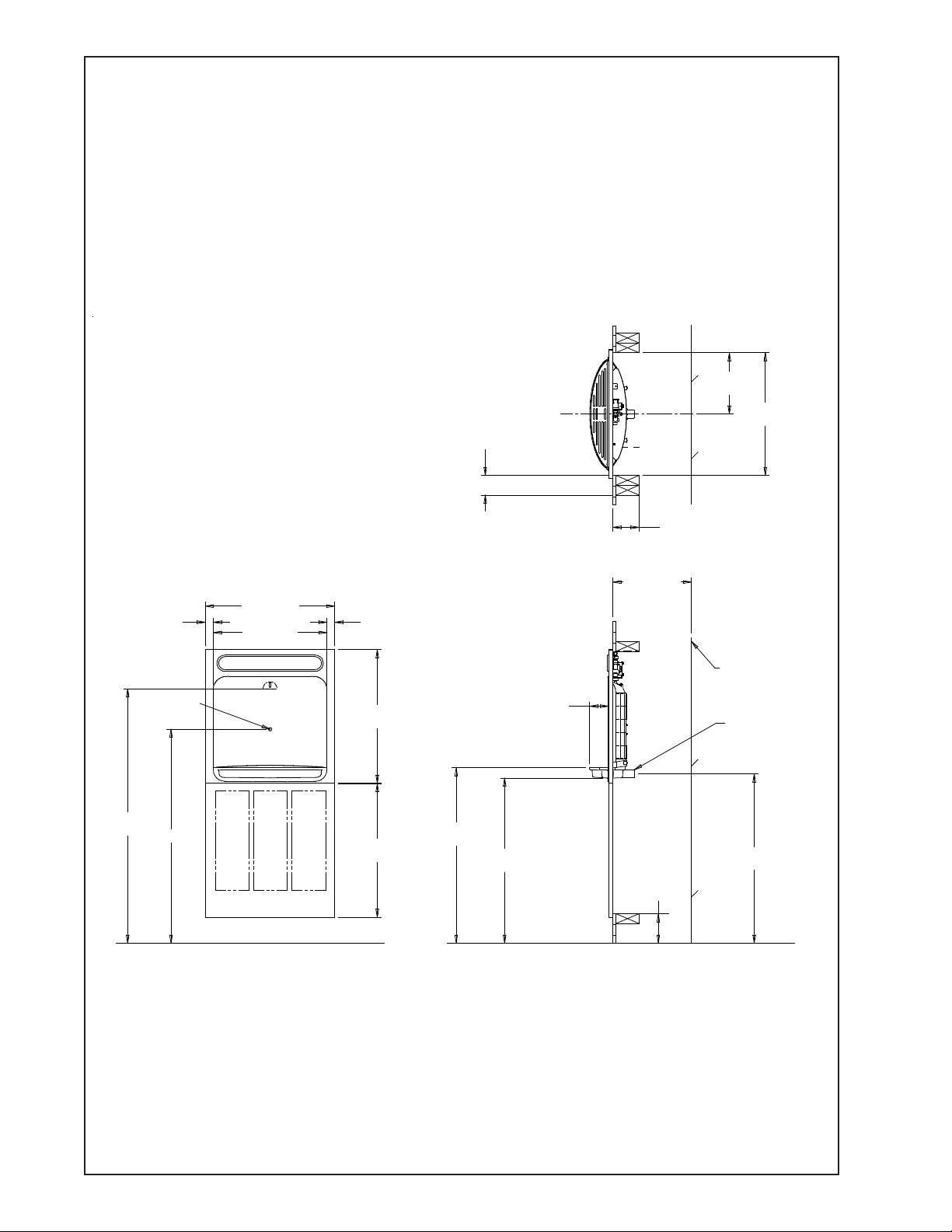

LZWSM8*, LZWSMD* EZWSM8*, EZWSMD* ROUGH-IN

9 3/8"

( 238mm )

DOUBLE STUD OR 3" (76mm)

BETWEEN MOUNTING FRAMES

IF PLACED NEXT TO ANOTHER

FOUNTAIN OR WALL

18 3/4"

( 476mm )

1 3/16"

( 30mm )

ACTIVATION

SENSOR

38 7/8"

( 987mm )

32.673

19 3/4"

( 502mm )

17 3/8"

( 441mm)

FINISHED FLOOR

1 3/16"

( 30mm )

20 3/8"

( 518mm)

20 7/16"

( 519mm)

27"

( 681mm)

2 7/8"

( 73mm )

25 1/4"

( 641mm)

FINISHED FLOOR

( 102mm)

12"

( 305mm )

MINIMUM

DEPTH

4 1/2"

( 114mm)

4"

BACK WALL LINE

1-1/4" (32MM)

WASTE TUBE

FURNISHED

25 7/8"

( 657mm )

FIG. 3

98557C (Rev. K - 11/14) Page 2

Page 3

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

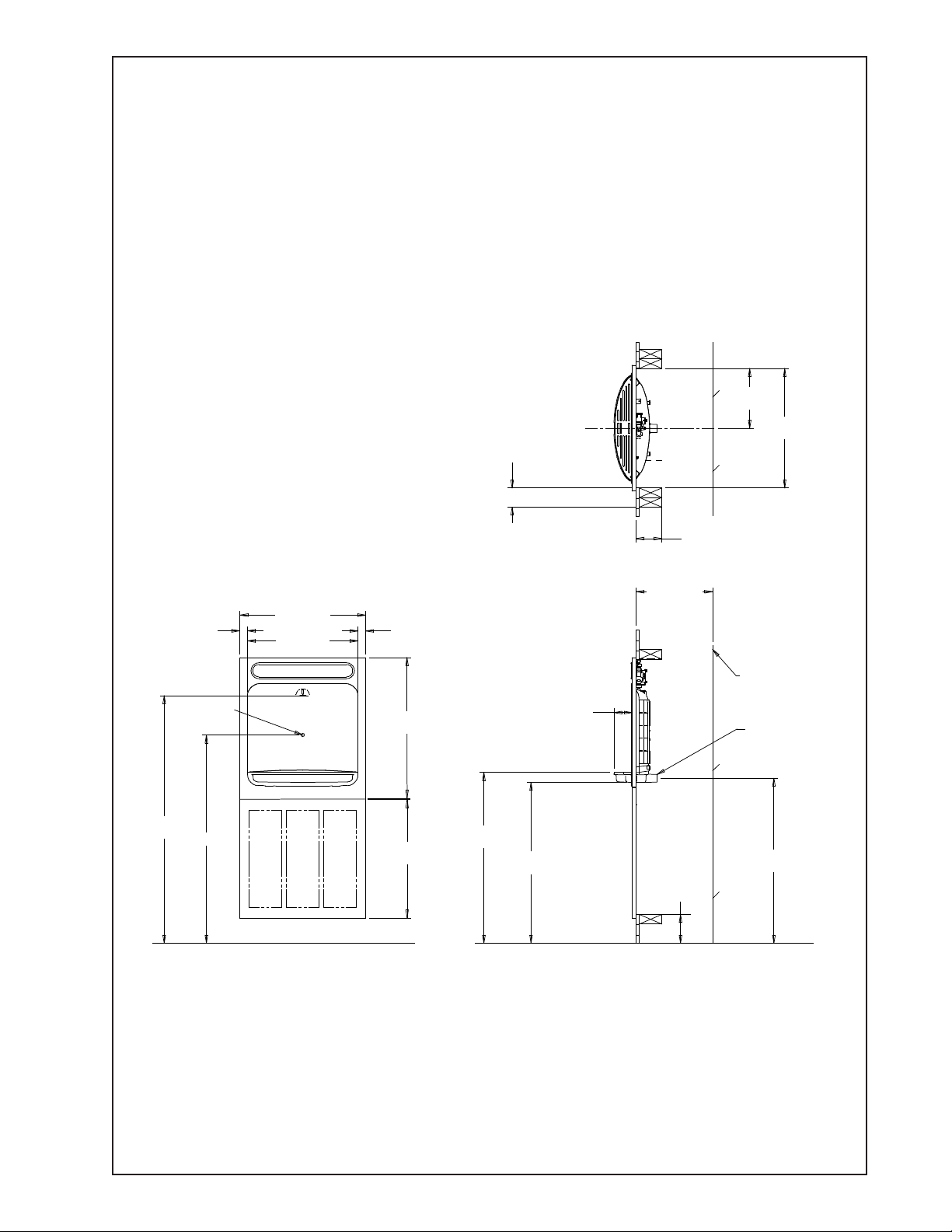

LZWSM8P*, LZWSMDP* EZWSM8P*, EZWSMDP* ROUGH-IN

9 3/8"

( 238mm )

DOUBLE STUD OR 3" (76mm)

BETWEEN MOUNTING FRAMES

IF PLACED NEXT TO ANOTHER

FOUNTAIN OR WALL

18 3/4"

( 476mm )

1 3/16"

( 30mm )

ACTIVATION

SENSOR

38 7/8"

( 987mm )

32.673

19 3/4"

( 502mm )

17 3/8"

( 441mm)

FINISHED FLOOR

1 3/16"

( 30mm )

21 15/16"

( 557mm)

18 7/8"

( 481mm)

27"

( 681mm)

2 7/8"

( 73mm )

25 1/4"

( 641mm)

FINISHED FLOOR

( 102mm)

12"

( 305mm )

MINIMUM

DEPTH

4 1/2"

( 114mm)

4"

BACK WALL LINE

1-1/4" (32MM)

WASTE TUBE

FURNISHED

25 7/8"

( 657mm )

FIG. 4

Page 3 98557C (Rev. K - 11/14)

Page 4

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

INSTALLATION INSTRUCTIONS

1. Install mounting frame. See mounting frame instructions.

2. Install remote chiller. See chiller instructions.

3. EWF3000 WATERSENTRY PLUS FILTER INSTALLATION

(Filtered units only. For non ltered units proceed to step 4b)

NOTICE: Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the system.

1)These lter kits must be installed in compliance with all state and local laws

and regulations governing the installation and use of this product. Maximum

inlet water temperature 100°F (38°C).

2) See lter instructions for lter assembly. Insert 3/8" elbow tting into the

inlet side of lter head, insert 1/4" polytube or 1/4" x 90° elbow into outlet

of lter head prior to mounting the lter head assembly into the remote chiller.

3) Mount lter head to the side of the remote chiller using the lter mounting bracket and screws supplied.

CAUTION: If supply pressure will ever exceed 100 psi, install a pressure

regulator to limit the inlet pressure to the lter to 100 psi or below.

DO NOT ATTACH HOT WATER LINE TO FILTER. To make connections on the

lter head, loosen locknut. Push the tube end past both o-rings to a positive

stop in the lter head recess - approx. 1", locknut may have to be backed out a

little more. Screw the locknut hand tight to seal (See Fig. 5). Ends of tubing

must be cut square and free of burrs and sharp ends that could cut or nick the o-rings.

NOTE: SCREW THE LOCK-

NUT HAND TIGHT TO SEAL

FIG. 5

4a. Make water supply connections for Fltered units. Install a shut-off valve and union connection to building water supply (valve

and union not provided). Turn on the water supply and ush the line thoroughly.

4b. Make water supply connections for Non Fltered units. Install a shut-off valve and union connection to building water supply

(valve and union not provided). Turn on the water supply and ush the line thoroughly. Install the in-line strainer between the

valve and the cooler. The in-line strainer is not installed on ltered units.

5. (Filtered units only. For non ltered units proceed to step 7)

Make connection between lter head and building supply line. Insert the 3/8" water line into the inlet side of the lter head by

pushing it in until it reaches a positive stop, approximately 3/4" (19mm). Install two 1/4" x 1/4" unions (provided) on the chiller.

One on the inlet tube, and the other on the outlet tube.

6. Make connection between the lter head and the remote chiller. Insert end of 1/4" O.D. poly tubing from the lter head (pro-

vided) into union on chiller inlet.

7. Mount the upper panel to the mounting frame, aligning holes in the hinge brackets with holes in the mounting frame (three

places). Mount with adequate size screws (not provided). Close the door and verify that the lock brackets on the side and

bottom of the panel align with the slots on the mounting frame. Also verify that the panel is hanging high enough that it covers

the top of the mounting frame. If adjustments need to be made, open the door and loosen the three screws on the hinge and

adjust accordingly and then retighten the screws.

8. Connect water line from the water station by inserting the 1/4" O.D. poly tubing into the union on the chiller outlet.

9. Close the upper door and attach the drain ttings to drain tube. Re-attach elbow to p-trap and cut waste tube to required

length using plumbing hardware and trap as a guide.

PLUMBING DIAGRAM

FIG. 6

TO BOTTLE FILLER

TO BOTTLE FILLER

INLET

STRAINER

INLET

CHILLER

98557C (Rev. K - 11/14) Page 4

FILTER

CHILLER

NON FILTEREDFILTERED

Page 5

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

10. Lock the door in place using two set screws (provided) on the side of the panel, and a ¼ x 20 bolt through the front of the panel

into the nut in the frame.

11. (Filtered units only) Install lter cartridge, remove lter from carton, remove protective cap, attach lter to lter head by rmly

inserting into head and rotating lter clockwise.

12. Turn water supply on and inspect for leaks. Fix all leaks before continuing.

13. Once unit has been inspected for leaks, and any leaks found corrected, plug Bottle Filler into wall (power cord not supplied on

220V models). Be sure to reinstall fuse to the circuit or switch the circuit breaker back to the “ON” position.

14a. (Filtered units) Once power is applied to Bottle Filler, the GREEN LED light should illuminate showing good lter status along

with the LCD Bottle Counter.

14b.(Non Filtered units) Once power is applied to Bottle Filler, the LCD Bottle Counter should illuminate.

15. Verify proper dispensing by placing cup, hand, or any opaque object in front of sensor area and verify water dispenses.

Note: the rst initial dispenses might have air in line which may cause a sputter. This will be eliminated once all air is purged

from the line. A steady stream of water assures all air is removed. The sensor has a 30 second maximum ON time. It may be

necessary to step away from beam a few times to allow chiller tank to rell. Check for leaks.

16. Mount the lower panel to the mounting frame, aligning holes in the hinge brackets with holes in the mounting frame (three

places). Mount with adequate size screws (not provided). Close the door and verify that the lock brackets on the side of the

panel align with the slots on the mounting frame. If adjustments need to be made, open the door and loosen the three screws

on the hinge and adjust accordingly and then retighten the screws.

17. Lock the lower door in place using two set screws (provided) on the side of the panel.

MOUNTING FRAME

UPPER PANEL

LOWER PANEL

FILTER LOCA-

TION

(OPTIONAL)

HINGE BRACKETS

DRAIN LOCATION

CHILLER

FIG. 7

Page 5 98557C (Rev. K - 11/14)

Page 6

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

BF6-BF7-BF8 PROGRAMS

SETTING THE CONTROL BOARD

VERIFY CONTROL BOARD SOFTWARE

1) To verify the software program of the control board the

unit will need to be shut down and restarted. The chiller

(if present) does not need to be shut down and restarted.

2) The units lower panel must be open to access the power

cord and wall outlet.

3) Shut down the unit by unplugging the power cord from the

wall outlet.

4) Restart the unit by plugging the power cord back into the

wall outlet.

5) Upon start up the bottle count display will show the

software designation of BF6, BF7, BF8, BF9 or BF11.

6) Reference the BF6-BF7-BF8-BF9 or BF11 instructions for

setting the control board.

ACCESSING THE PROGRAMMING BUTTON

1) To access the program button the lower panel of the

unit must be must be opened. The programming button is

located at the bottom right corner of the upper panel.

This area of the unit is concealed by the lower panel.

1) Depress the program button for approximately 2 seconds

RESETTING BOTTLE COUNT

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“RST BCNT” – Reset Bottle Count

“RNG SET” – Range Set for IR Sensor

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to "RST BCNT", depress the

button again. The display will change to show current

bottle count value e.g. "00033183".

3) Depress the button again and the display will change to

"BTLCT=0" for approximately 2 seconds and then return

to run mode displaying 00000000.

4) You can test the bottle counter by running water

approximately 5 seconds to see bottle counter advance 1.

1) Instructions apply to ltered units only.

2) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through three messages:

“RST FLTR” – Reset Filter Status LED

“RST BCNT” – Reset Bottle Count

“RNG SET” – Range Set for IR Sensor

If the program button is not pushed again the display

will scroll through the three messages above for

three cycles and then default back to bottle count and

be back in run mode.

3) When the display changes to "RST FLTR", depress

the button again. The display will change to show

"FLT=". Depress the button again and the display will

show "FLTR=0".

4) The green LED should now be illuminated indicating

that the visual lter monitor has been reset.

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through three messages:

“RST FLTR” – Reset Filter Status LED

“RST BCNT” – Reset Bottle Count

“RNG SET” – Range Set for IR Sensor

2) If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

3) When display shows “RNG SET” push program button

once the display will show current value

(can be 1 – 10) e.g. “RNG = 3”.

4) Once display shows current value push the program

button to scroll through value of 1 – 10. Select the

desired range setting.

5) Once range is selected allow approximately 4 seconds

to pass and then the display will go back to bottle counter

and be in run mode.

6) Test bottle ller by placing bottle or hand in front of

sensor to make sure water is dispensed.

RESET THE FILTER MONITOR

SETTING RANGE OF THE IR SENSOR

98557C (Rev. K - 11/14) Page 6

Page 7

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

SETTING THE CONTROL BOARD

VERIFY CONTROL BOARD SOFTWARE

1) To verify the software program of the control board the

unit will need to be shut down and restarted. The chiller

(if present) does not need to be shut down and restarted.

2) The units lower panel must be open to access the power

cord and wall outlet.

3) Shut down the unit by unplugging the power cord from the

wall outlet.

4) Restart the unit by plugging the power cord back into the

wall outlet.

5) Upon start up the bottle count display will show the

software designation of BF6, BF7, BF8, BF9 or BF11.

6) Reference the BF6-BF7-BF8-BF9 or BF11 instructions for

setting the control board.

ACCESSING THE PROGRAMMING BUTTON

1) To access the program button the lower panel of the

unit must be must be opened. The programming button is

located at the bottom right corner of the upper panel.

This area of the unit is concealed by the lower panel.

RESET THE FILTER MONITOR

1) Instructions apply to ltered units only.

2) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Monitor

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count and

be back in run mode.

3) When the display changes to “RST FLTR”, depress

the button again. The display will change to show

“FLTR =”. Depress the button again and the display

will show “FLTR =0”

4) The Green LED should be illuminated indicating that

the visual lter monitor has been reset.

SETTING RANGE OF THE IR SENSOR

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET“- Range set for IR sensor.

“UNIT TYP“ - Type of unit (REFRIG or NON-RFRG)

“RST BCNT“ - Reset bottle count

3) When display shows “RNG SET” push program

button once the display will show current value

(can be 1 – 10) e.g. “RNG = 3”.

4) Once display shows current value push the

program button to scroll through value of 1 – 10.

Select the desired range setting.

5) Once range is selected allow approximately

4 seconds to pass and then the display will go

back to bottle counter and be in run mode.

6) Test bottle ller by placing bottle or hand in front

of sensor to make sure water is dispensed.

BF9 PROGRAM

SETTING UNIT TYPE

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET“- Range set for IR sensor.

“UNIT TYP“ - Type of unit (REFRIG or NON-RFRG)

“RST BCNT“ - Reset bottle count

3) When display shows “UNIT TYPE” push program

button once the display will show current value

Can be REFRIG or NON-RFRG

4) Push button once to change value. Once value is

selected the display will show the new value.

(Can be REFRIG or NON-RFRG)

“REFRIG“ - stands for refrigerated product. In this

setting the ow rate is estimated at 1.0 gallon per minute.

“NON-RFRG“ - stands for nonrefrigerated product.

In this setting the ow rate is estimated

at 1.5 gallons per minute.

Both “REFRIG“ and “NON-RFRG“ simulate

1 bottle equal to 20 oz.

5) Allow approximately 4 seconds to pass and the display

will return to bottle counter and be in run mode.

RESETTING BOTTLE COUNT

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET“- Range set for IR sensor.

“UNIT TYP“ - Type of unit (REFRIG or NON-RFRG)

“RST BCNT“ - Reset bottle count

If the button is not pushed again the display will scroll

through the three messages above for the cycles and

return to run mode.

3) When display shows “RST BCNT” push program button

once the display will show current value e.g. “00033183”.

4) Once display shows current value push the program

button once more to reset back to 0. The display will

show BTLCT = 0 for approximately 2 seconds and

then return to run mode showing 00000000 bottles.

5) Testing the bottle counter:

REFRIG units: Place bottle or hand in front of sensor

for 9.4 seconds to see bottle counter count 00000001.

(This is based on lling a 20 oz. bottle)

NON-RFRG units: Place bottle or hand in front of sensor

for 6.25 seconds to see bottle counter count 00000001.

(This is based on lling a 20 oz bottle)

Page 7 98557C (Rev. K - 11/14)

Page 8

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

BF11 PROGRAM

SETTING THE CONTROL BOARD

1) To verify the software program of the control board the

VERIFY CONTROL BOARD SOFTWARE

unit will need to be shut down and restarted. The chiller

(if present) does not need to be shut down and restarted.

2) The units lower panel must be open to access the power

cord and wall outlet.

3) Shut down the unit by unplugging the power cord from the

wall outlet.

4) Restart the unit by plugging the power cord back into the

wall outlet.

5) Upon start up the bottle count display will show the

software designation of BF6, BF7, BF8, BF9 or BF11.

6) Reference the BF6-BF7-BF8-BF9 or BF11 instructions for

setting the control board.

ACCESSING THE PROGRAMMING BUTTON

1) To access the program button remove the top cover of

the bottle ller. Remove the two (2) screws holding top

cover to bottle ller with a 5/32” allen wrench . Remove

top cover. Do not discard mounting screws, they will be

needed to reinstall the top cover after programming

operations are completed. The programming button is

located at the top right side of the unit on the control board.

RESET THE FILTER MONITOR

1) Instructions apply to ltered units only.

2) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Monitor

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count and

be back in run mode.

3) When the display changes to “RST FLTR”, depress

the button again. The display will change to show

“FLTR =”. Depress the button again and the display

will show “FLTR =0”

4) The Green LED should be illuminated indicating that

the visual lter monitor has been reset.

SETTING RANGE OF THE IR SENSOR

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET” - Range set for IR sensor.

“UNIT TYP” - Type of unit (REFRIG or NON-RFRG)

“FLT SIZE” - Select lter capacity

“RST BCNT” - Reset bottle count

3) When display shows “RNG SET” push program

button once the display will show current value

(can be 1 – 10) e.g. “RNG = 3”.

4) Once display shows current value push the

program button to scroll through value of 1 – 10.

Select the desired range setting.

5) Once range is selected allow approximately

4 seconds to pass and then the display will go

back to bottle counter and be in run mode.

6) Test bottle ller by placing bottle or hand in front

of sensor to make sure water is dispensed.

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET” - Range set for IR sensor.

“UNIT TYP” - Type of unit (REFRIG or NON-RFRG)

“FLT SIZE” - Select lter capacity

“RST BCNT” - Reset bottle count

3) When display shows “UNIT TYPE” push program

button once the display will show current value

Can be REFRIG or NON-RFRG

4) Push button once to change value. Once value is

selected the display will show the new value.

(Can be REFRIG or NON-RFRG)

“REFRIG“ - stands for refrigerated product. In this

setting the ow rate is estimated at 1.0 gallon per minute.

“NON-RFRG“ - stands for nonrefrigerated product.

In this setting the ow rate is estimated

at 1.5 gallons per minute.

Both “REFRIG“ and “NON-RFRG“ simulate

1 bottle equal to 20 oz.

5) Allow approximately 4 seconds to pass and the display

will return to bottle counter and be in run mode.

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET”- Range set for IR sensor.

“UNIT TYP” - Type of unit (REFRIG or NON-RFRG)

“FLT SIZE” - Select lter capacity

“RST BCNT” - Reset bottle count

If the button is not pushed again the display will scroll

through the four messages above for three cycles and

return to run mode.

3) When display shows “RST BCNT” push program button

once the display will show current value e.g. “00033183”.

4) Once display shows current value push the program

button once more to reset back to 0. The display will

show BTLCT = 0 for approximately 2 seconds and

then return to run mode showing 00000000 bottles.

5) Testing the bottle counter:

REFRIG units: Place bottle or hand in front of sensor

for 9.4 seconds to see bottle counter count 00000001.

(This is based on lling a 20 oz. bottle)

NON-RFRG units: Place bottle or hand in front of sensor

for 6.25 seconds to see bottle counter count 00000001.

(This is based on lling a 20 oz bottle)

CONTINUED ON

SETTING UNIT TYPE

RESETTING BOTTLE COUNT

PAGE 9

98557C (Rev. K - 11/14) Page 8

Page 9

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

BF11 PROGRAM

SETTING THE CONTROL BOARD

1) Depress the program button for approximately 2 seconds

until the display changes then release. The display will

change and scroll through two messages:

“RST FLTR” – Reset Filter Status LED

“SETTINGS” – System Settings Sub Menu

If the program button is not pushed again the display

will scroll through the two messages above for

three cycles and then default back to bottle count

and be back in run mode.

2) When the display changes to “SETTINGS”, depress

the button again. The display will change to show

“RNG SET“- Range set for IR sensor.

“UNIT TYP“ - Type of unit (REFRIG or NON-RFRG)

“FLT SIZE” - Select lter capacity

“RST BCNT“ - Reset bottle count

If the button is not pushed again the display will scroll

through the four messages above for three cycles and

return to run mode.

3) When display shows “FLT SIZE” push program button

once. The display will show current value. Can be

3000GAL or 6000GAL.

4) Push program button again to display the desired “FLT SIZE”.

5) Allow approximately 4 seconds to pass and the display will

return to bottle counter and be in run mode.

SETTING FILTER CAPACITY

Page 9 98557C (Rev. K - 11/14)

Page 10

EZWSMD*1A EZWSM8*1A EZWSM8*2A LZWSMD*1A LZWSM8*1A LZWSM8*2A

WATERSENTRY® PLUS FILTER PARTS LIST

(See Fig. 8)

ITEM

NO.

1

2

3

4

5

6

7

2

PART NO.

51294C

70792C

70823C

70822C

51300C

70818C

22490C

DESCRIPTION

Filter Head Assy.

Screw #8-18 x .75 PH

Fitting - Superseal 3/8” (10 mm)

Fitting - Superseal 1/4” (6 mm)

Filter Assy

Elbow - 3/8” (10mm)

Bracket

7

4

3

1

5

LISTA DE PIEZAS DEL

FILTRO (Vea Fig. 8)

DESCRIPCIÓN DESCRIPTION

Ensamblado de la Cabeza del Filtro

Tornillo #8-18 x .75 PH

Accesorio - Supersello 3/8" (10mm)

Accesorio - Supersello 1/4" (6 mm)

Ensamblado del Filtro

Codo - 3/8" (10 mm)

Fijador

6

LISTE DES PIÈCES DU FIL-

TRE (Voir Fig. 8)

Ens. de tête de ltre

Vis #8-18 x .75 hp

Raccord - Superseal 3/8" (10mm)

Raccord - Superseal 1/4" (6mm)

Ens. ltre

Coude - 3/8" (10mm)

Support

PRINTED IN U.S.A.

IMPRESO EN LOS E.E.U.U.

IMPRIMÉ AUX É.-U.

WATER FILTER EXPLODED

VIEW

FIG. 8

FIG. 9

REPLACEMENT PART KITS

PART NO.

98543C

98544C

98545C

98546C

98549C

98631C

98632C

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

INFORMATIONS POUR LE SERVICE PAR NUMERO SANS FRAIS 1.800.260.6640

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.834.4816

POUR OBTENIR DES PIÈCES, CONTACTEZ VOTRE DISTRIBUTEUR LOCAL OU COMPOSEZ LE 1.800.834.4816

PARA PIEZAS, CONTACTE A SU DISTRIBUIDOR LOCAL O LLAME AL 1.800.834.4816

ELKAY MANUFACTURING COMPANY • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484

NÚMERO GRATIS DE SERVICIO 1.800.260.6640

DESCRIPTION

Kit - Electrical Package

Kit - EE Sensor

Kit - Solenoid Valve Replacement

Kit - Aerator Replacement

Kit - Hardware & Waterway Parts

Kit - Electrical Package 220V

Kit - Solenoid Valve Replacement 220V

98557C (Rev. K - 11/14) Page 10

Loading...

Loading...