EMASMB*A & LMASMB*A

INSTALLATION, CARE & USE MANUAL

EMASMB & LMASMB Surface Mount Bottle Filling Stations

IMPORTANT

FOR INDOOR USE ONLY!

ALL SERVICE TO BE PERFORMED BY AN

AUTHORIZED SERVICE PERSONNEL.

RATED FOR COMMERCIAL USE ONLY

TOOLS/ITEMS REQUIRED

BUT NOT SUPPLIED

- SERVICE STOP VALVE WITH 3/8"

COMPRESSION OUTLET

- FASTENERS FOR WALL TYPE (5 REQ’D.)

- SLIP JOINT DRAIN UNION OR

COMPRESSION CLAMP

- 5/32" HEX-WRENCH

Installer

To assure you install this model easily and correctly, PLEASE READ THESE

SIMPLE INSTRUCTIONS BEFORE STARTING THE INSTALLATION.

CHECK YOUR INSTALLATION FOR COMPLIANCE WITH ALL PLUMBING, ELECTRICAL AND OTHER APPLICABLE CODES. FOLLOW ALL

WARNINGS AND CAUTIONS CAREFULLY. After installation, leave these

instructions with the customer for future reference.

Warnings

1. Use with clean, clear, fresh potable drinking water only! Do not use with water that is microbiologically

unsafe or of unknown quality without adequate disinfection before the system.

2. These products are designed to operate on 20 to 105 psi (0.14-0.72 MPa) supply line pressure and a

maximum water temperature of 90°F (32°C). If inlet pressure is above 105 psi (0.72 MPa), a pressure

regulator must be installed in supply line. Any damage caused by reason of connecting this product to

supply line pressure lower than 20 psi or higher than 105 psi is not covered by warranty.

This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning use

of the appliance in a safe way and understand the hazards involved. Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children without supervision.

Page 1

1000002042 (Rev.E - 07/16

EMASMB*A & LMASMB*A

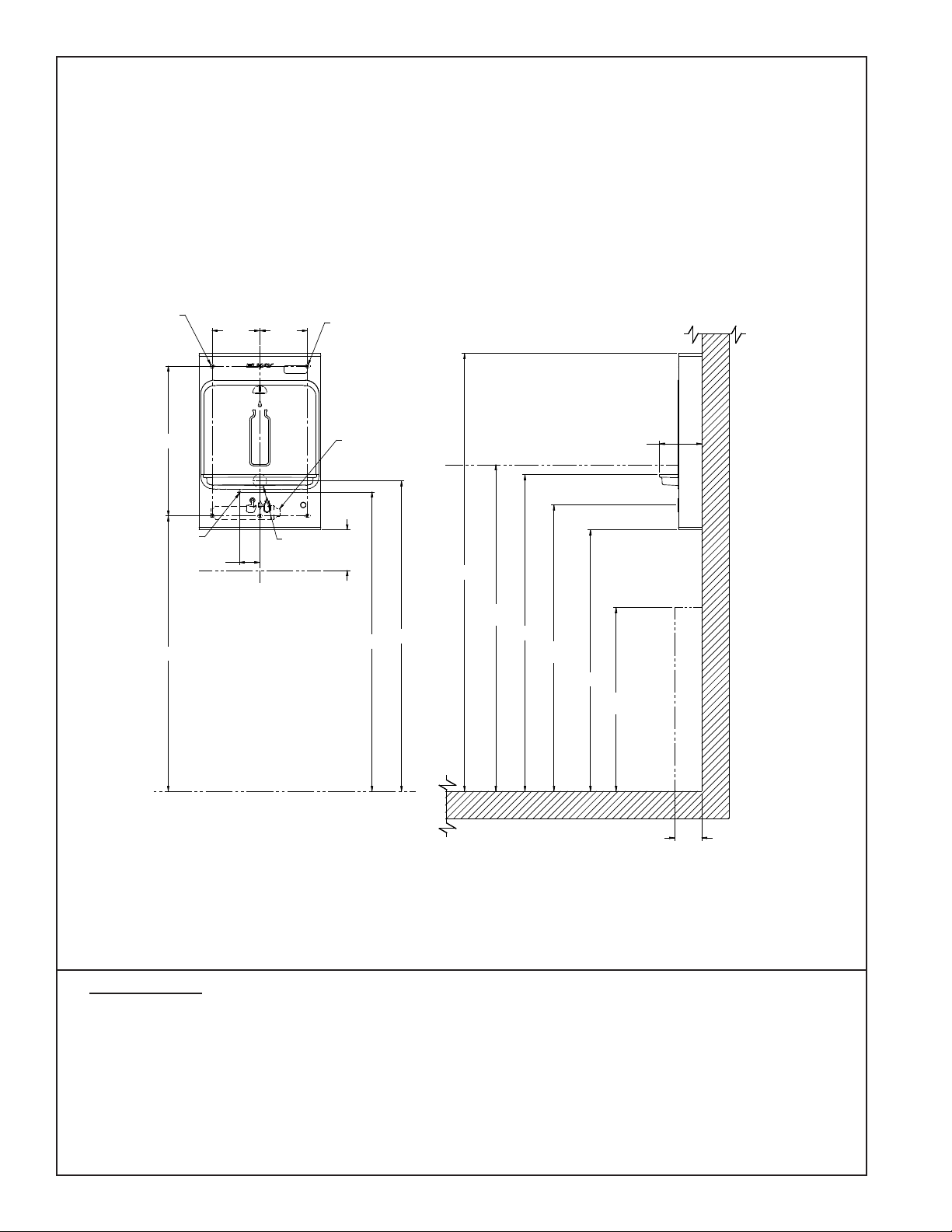

ROUGH-IN

EMASMB & LMASMB

ADA STAND ALONE MOUNTING

STAND ALONE MOUNTING

IMPORTANT!

INSTALLATION NOTES:

• Ensure wall is structurally sound to bear the loads imparted by the Surface Mount Bottle Filler.

• Ambient air temperature limits: 10°C - 38°C (50°F - 100.4°F). Climate Class SN-ST.

• Not suitable for installation in areas where water jets could be used.

7/16 X 3/4

11mm X 19mm

OBROUND

MOUNTING

HOLE (6)

"C"

22

559mm

40 1/2

1029mm

3/8"

9.5mm

WATER

INLET

"A"

3

76mm

7

178mm

3/8

(6)

O

1-1/4"

DRAIN

"B"

8mm

MOUNTING BOLT

FILTER USED ONLY

IN LMASMB UNITS

6

152mm

MINIMUM

CLEARANCE

1118mm

6 1/4

159mm

64 3/8

1635mm

48

1219mm

ADA HEIGHT

45 5/8

44

1159mm

46 1/2

1182mm

42 1/8

1069mm

‰ OF BUTTON

38 1/2

977mm

27

686mm

ADA HEIGHT

7

178mm

‰

31.7mm

FINISHED FLOOR

FINISHED FLOOR

4

102mm

ADA DEPTH

FIGURE 1

LEGEND:

A = RECOMMENDED WATER SUPPLY LOCATION; 1/2" IPS MAXIMUM PIPE SIZE. SERVICE STOP VALVE NOT FURNISHED.

B = RECOMMENDED WASTE LOCATION. WASTE SHOWN IN WALL BUT MAY BE BEHIND WALL.

OUTLET 1-1/4” O.D. (TRAP NOT FURNISHED)

C =7/16" X 3/4" OBROUND MOUNTING HOLES FOR FASTENING BACKPLATE TO WALL.

Pre-Installation (reference Rough-Ins, Fig. 1 and Fig. 2)

1. Ensure Wall is structurally sound to bear the loads imparted by the EMASMB or LMASMB Bottle Filler

(On-Wall Bottle Filler). If necessary, install a Wall Support Carrier (not supplied).

2. Ensure Water Supply Line and Drain Line are sized and located as specied the Rough-in diagram.

3. Attach Service Stop Valve (not supplied) to Water Supply line orienting the 3/8"O.D. female compression

outlet horizontally to the left. Purge water line and test for leakage. Correct any leakage.

1000002042 (Rev.E - 07/16)

Page 2

EMASMB*A & LMASMB*A

ROUGH-IN

EMASMB & LMASMB

ADA ABOVE COOLER MOUNTING

STAND ALONE MOUNTING

IMPORTANT!

INSTALLATION NOTES:

• Ensure wall is structurally sound to bear the loads imparted by the Surface Mount Bottle Filler.

• Ambient air temperature limits: 10°C - 38°C (50°F - 100.4°F). Climate Class SN-ST.

• Not suitable for installation in areas where water jets could be used.

7/16 X 3/4

11mm X 19mm

OBROUND

MOUNTING

HOLE (6)

"C"

25 7/8

658mm

22

559mm

40 1/2

1029mm

3/8"

9.5mm

WATER

INLET

"A"

7

178mm

76mm

17 7/8

454mm

3

7

178mm

‰

ADA HEIGHT

WATER COOLER

1-1/4"

31.7mm

DRAIN

"B"

8mm

MOUNTING

BOLT

FILTER USED ONLY

IN LMASMB UNITS

6

152mm

MINIMUM

CLEARANCE

3/8

O

44

1118mm

(6)

45 5/8

1159mm

64 3/8

1634mm

48

1219mm

ADA HEIGHT

46 1/2

1182mm

42 1/8

1069mm

‰ OF BUTTON

38 1/2

977mm

27

686mm

ADA

HEIGHT

6 1/4

159mm

FINISHED FLOOR

FINISHED FLOOR

4

102mm

ADA DEPTH

FIGURE 2

LEGEND:

A = RECOMMENDED WATER SUPPLY LOCATION; 1/2" IPS MAXIMUM PIPE SIZE. SERVICE STOP VALVE NOT FURNISHED.

B = RECOMMENDED WASTE LOCATION. WASTE SHOWN IN WALL BUT MAY BE BEHIND WALL.

OUTLET 1-1/4” O.D. (TRAP NOT FURNISHED)

C =7/16" X 3/4" OBROUND MOUNTING HOLES FOR FASTENING BACKPLATE TO WALL.

Pre-Installation (reference Rough-Ins, Fig. 1 and Fig. 2)

1. Ensure Wall is structurally sound to bear the loads imparted by the EMASMB or LMASMB Bottle Filler

(On-Wall Bottle Filler). If necessary, install a Wall Support Carrier (not supplied).

2. Ensure Water Supply Line and Drain Line are sized and located as specied the Rough-in diagram.

3. Attach Service Stop Valve (not supplied) to Water Supply line orienting the 3/8"O.D. female compression

outlet horizontally to the left. Purge water line and test for leakage. Correct any leakage.

Page 3

1000002042 (Rev.E - 07/16

EMASMB*A & LMASMB*A

INSTALLATION INSTRUCTIONS

EMASMB UNIT SHOWN

REGULATOR

ASSEMBLY

PLUMBING DIAGRAM

NON-FILTERED

INSTALLER TO SUPPLY:

SHUT OFF VALVE

TOP SCREWS

TOP COVER

OUTER

WRAPPER

BATTERY TRAY

BOTTOM COVER

BOTTOM SCREWS

BACK PANEL

REAR VIEW

Wall Mounting (reference Rough-Ins, Fig. 1 and Fig. 2)

1. Remove Top Cover from Bottle Filler by removing two (2) screws from bottom of unit. Use a 5/32" hex wrench

(not supplied).

2. Remove Bottom Cover from Bottle Filler by removing two (2) screws from bottom of unit. Use a 5/32" hex wrench

(not supplied).

3. With the Top and Bottom Covers removed, the Back panel is now free to be removed from Bottle Filler.

4.. Fasten Back Panel to structurally secure wall thru ve 7/16" obround holes with fasteners appropriate for wall type.

Locate Back Panel as specied in Rough-In. If necessary, attach to Wall Support Carrier (not supplied).

5. Ensure Back Panel is not obstructed by the roughed-in Water and Drain Lines. If Back Panel is prevented from

seating properly, reposition Water and/or Drain Lines slightly until the Bottom Cover ts easily.

6. Before hanging the On-Wall Bottle Filler, ensure the Insulated Waterline is routed inside of the Wrapper If outside

the Wrapper, reposition to inside or else the unit cannot be installed properly.

7. Hang the Bottle Filler onto the Back Panel, aligning two tabs onto the top of the Back Panel.

8. Secure Bottle Filler to Back Panel by replacing Top Cover on top of unit and fastening with two (2) supplied screws.

9. Replace the Bottom Cover on bottom of the unit and fasten in place with two (2) supplied screws.

Plumbing Connections

• Ensure lines and ports remain clean and free of contaminants during assembly.

• Purge each component if necessary.

• To ensure quick-connect connections seal properly, follow instructions per Figure 3.

Connect Plumbing Lines. NOTE: Connecting to water mains must be in compliance with local and national laws.

1. Connect water supply line to unit: NOTE: Hose-sets are not to be used for connecting to water mains.

2. Connect the 3/8"O.D. Copper tube from the in-line strainer to the 3/8" to the Service Stop Valve.

3. Connect the 1-1/4"O.D. Drain Tray Outlet to the in-wall Drain Line using a Slip Joint Drain Union or compression

clamp (not supplied). Tighten all connections water tight.

4. Turn water supply on, inspect for leaks and correct any leaks before continuing.

1000002042 (Rev.E - 07/16)

Page 4

EMASMB*A & LMASMB*A

Instruction for Use

1. Place container under the dispenser nozzle and depress the actuator button. Hold until container is lled to the level

desired.

2. To stop water ow, release actuator button. Pull container away from dispenser nozzle.

Installing/Replacing Batteries:

1. Remove Bottom Cover from Bottle Filler by removing two (2) screws from bottom of unit. Use a 5/32" hex wrench

(not supplied). The battery tray is located on the bottom cover. Install the (3) "AA" batteries in the battery tray.

2. Conrm unit is on: Display will show 00000000

2.1. Filtered Units: The Filter Status Green LED will be illuminated momentarily to show lter status when button is

pushed and the Bottle Counter LCD on the Nameplate displays bottle count.

2.2. Non-Filtered Units: The Bottle Counter LCD on the Nameplate displays bottle count.

3. Ensure water dispenses: Activate unit by depressing the button. Water should ow. It is normal for the water stream

to sputter with air when the unit is new or a new lter cartridge is installed.

4. Ensure a steady water ow is obtained: Activate unit per above and hold until all air entrapped in lines and lter is

purged. Multiple activations may be required.

5. Inspect for leaks and if any found, correct before continuing.

6. If setting up the Control Board for the rst time, go to Setting the Control Board section before continuing.

7. Place Bottom Cover in position on underside of unit with long tab against wall and slide up into Back Panel

opening. Secure with two supplied Allen head screws using a 5/32" hex-wrench (not supplied).

Changing the Filter

1. Remove the Bottom Cover of the Bottle Filler by removing the two (2) screws.

2. Remove (1) screw and loosen other on lter tray and slide out to allow access to the lter.

3. Release lter from water lines (see Figure 2 for operation of quick connect ttings).

4. Remove new lter from carton, remove protective cap; cap may be placed on an old lter to reduce the chance of

the water spilling from lter housing.

5. Attach lter to water lines (see Figure 2 for operation of quick connect ttings).

6. Actuate Bottle Filler until approximately 1 gallon of water is dispensed. This ushing procedure purges

air and ne carbon particles from the lter.

Warm, soapy water or mild household cleaning

products can be used to clean the exterior

panels of the EZ coolers. Extra caution should

be used to clean the mirror nished stainless

steel panels. They can be easily scratched and

should only be cleaned with mild soap and water

or Windex glass cleaner and a clean, soft cloth.

Use of harsh chemicals or petroleum based or

abrasive cleaners will void the warranty.

REGULATOR

ASSEMBLY

INSTALLER TO SUPPLY:

LMASMB UNIT

SHOWN SHOWN

IN

PLUMBING DIAGRAM

FILTERED

SHUT OFF VALVE

OUTER

WRAPPER

FILTER

FILTER/

BATTERY

BOTTOM

COVER

BOTTOM

SCREWS

TOP

SCREWS

TOP COVER

BACK

PANEL

TRAY

REAR

VIEW

Page 5

1000002042 (Rev.E - 07/16

EMASMB*A & LMASMB*A

SETTING THE CONTROL BOARD

VERIFY CONTROL BOARD SOFTWARE

1) To verify the software program of the control board the unit will

need to be shut down and restarted. The chiller (if present)

does not need to be shut down and restarted.

2) Shut down the unit by removing a battery.

3) Restart the unit by installing the batteries

4) Upon start up the bottle count display will show the software

designation of 'ELKAY BC'.

ACCESSING THE PROGRAMING BUTTON

1) To access the program button, remove the two (2) screws

holding the Bottom Cover in place. Button is located within

nger reach from the underside of the unit on the back right

hand side of the battery/lter tray.

2) When nished setting control board, reinstall the Bottom Cover

and secure with the same two (2) screws.

RESET THE FILTER MONITOR

1) Instructions apply to ltered units only.

2) Depress the program button momentarily. The display changes

when released. The display will change and scroll through four

messages:

“RST FLTR” – Reset Filter Status LED

“NO FLTR” – EMASMB or non-ltered mode

"500G FLT" – LMASMB or Filtered mode

"RST BCNT“ - Reset bottle count

If the program button is not pushed again the display will scroll

through the four messages above for and then default back to

bottle count and be back in run mode.

3) When the display changes to “RST FLTR”, depress the button

again. The display will change to show “FC RESET”. Depress

the button again and the display will show “00000000”

4) There are three (3) LED's that indicate the following:

Green: LED (Good) indicates that the lter is operating

within 0% - 80% of its life.

Yellow: LED indicates that the lter is operating within

80% - 100% of its life.

Red: LED (Replace) indicates that the lter needs to be

replaced since it has reached end of lter life and ow

restrictions.

RESETTING BOTTLE COUNT

1) Depress the program button momentarily. The display will

change and scroll through four messages:

“RST FLTR” – Reset Filter Status LED

“NO FLTR” – EMASMB or non-ltered mode

"500G FLT" – LMASMB or Filtered mode

"1500G FLT" – NOT AVAILABLE - LMASMB

"3000G FLT" – NOT AVAILABLE - LMASMB

"6000G FLT" – NOT AVAILABLE - LMASMB

“RST BCNT“ – Reset bottle count

If the program button is not pushed again the display will scroll

through the four messages above for and then default back to

bottle count and be back in run mode. 2) When the display

changes to “RST BCNT”, push the button again and the display

will show “BC RESET” If the button is not pushed again the

display will return to run mode.

3) Push the program button once more to reset back to 0. The

display will and then return to run mode showing 00000000

bottles.

NOTE: Once the bottle count is reset to zero there is no way

to return to the previous bottle count.

4) Testing the bottle counter:

EMASMB units: Push button for approximately 9 seconds to see

bottle counter count 00000001.

NOTE: Bottle count is approximate and is dependent on water

pressure and ow through the lter. LMASMB units: Push

button for approximately 19 seconds to see bottle counter count

00000001. NOTE: Bottle count is approximate and is dependent

on water pressure and ow restrictions.

OPERATION OF QUICK CONNECT FITTINGS

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE TO ATTACH

A B C

TUBE IS SECURED

TUBE IS SECURED

IN POSITION

IN POSITION

B CA

PUSH IN COLLET

PUSH IN COLLET

TO RELEASE TUBE

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

PULLING IT OUT HELPS TO

RELEASE TUBE

RELEASE TUBE

FIGURE 3

REGULATOR

FILTER

AERATOR

BATTERY CONFIGURATION RESET SWITCH

REPLACEMENT PARTS

PART NO.

1000001673

98546C

56192C

KIT-1.0 GPM REGULATOR KIT

KIT-AERATOR

REPLACEMENT FILTER

DESCRIPTION

1000002042 (Rev.E - 07/16)

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

ELKAY MANUFACTURING COMPANY • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.834.4816

Page 6

Loading...

Loading...