Page 1

ECH8*2MQ

Refrigeration Package

INSTALLATION, CARE & USE MANUAL

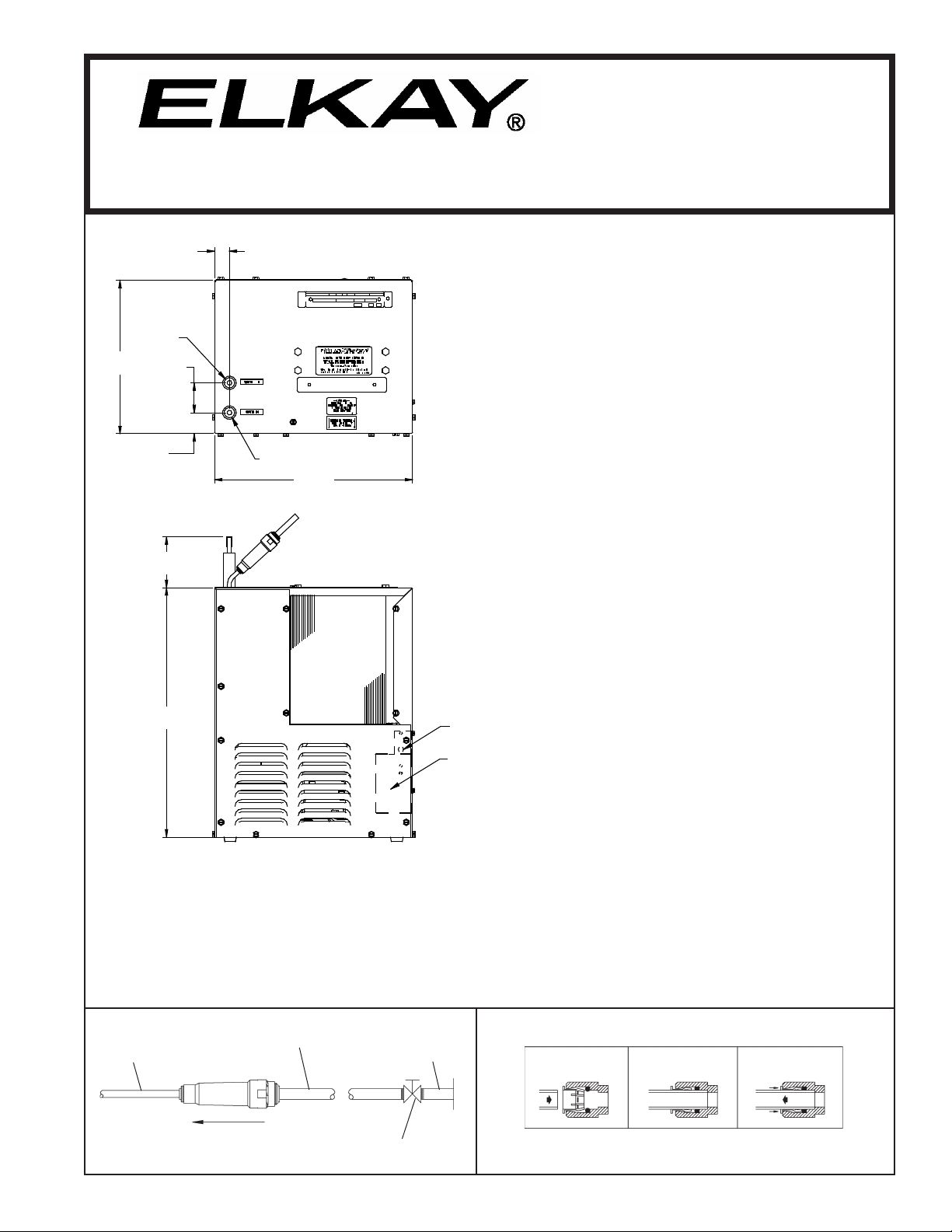

10 1/4"

261mm

50mm

1 3/8"

35mm

1 3/4"

95mm

1"

25mm

A

2"

REF.

1. When mounting unit in an open area, to insure proper ventilation,

maintain a 4" (102mm) clearance from cabinet louvers on each side

of cooler . When mounting unit in a cavity or behind a wall maintain

minimum space of 4" (102mm) on each side, 4" (102mm) on the top

and a depth of 12" (305mm).

2. Water inlet is 1/4" (6 mm) O.D. tube. Contractor to supply the

connections as required.

3. Connecting lines to be of unplated copper, thoroughly ushed to

remove all foreign matter before being connected to cooler. If

ushing does not remove all particles, a water strainer should be

installed in supply line. This cooler is manufactured in such a manner

that it does not in any way cause taste, odor, color or sediment

problems.

B

13 1/4"

338mm

4. Connect cooler to building supply line with a shut-off valve and

install the in-line strainer between the valve and cooler.

5. Electrical: Make sure power supply is identical in voltage, cycle,

and phase to that specied on cooler serial plate. Never wire

compressor directly to the power supply.

6. This chiller has been designed for use with potable water ONLY.

START-UP

INSTALLATION

1. Open supply line valve.

2. Purge air from all water lines by operating bubbler valve of

fountain to which cooler is connected. Steady stream assures all

air is removed.

3. Rotate fan to insure proper clearance and free fan action.

4. Connect to electrical power.

TROUBLE SHOOTING & MAINTENANCE

16 3/4"

425mm

1/4" O.D. TUBE

WATER INLET

TO CHILLER

LEGEND

A = 1/4" O.D. TUBE WATER OUTLET

B = 1/4" O.D. TUBE WATER INLET

C = TEMPERATURE ADJUSTMENT

D = ELECTRICAL

3/8" O.D. UNPLATED COP-

PER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

BUILDING WATER INLET

SERVICE STOP

(NOT FURNISHED)

Temperature Control: Factory set at 50°F (± 5°) under normal

C

conditions. For colder water, adjust screw on item no. 9 in

clockwise direction.

Ventilation: Cabinet louvers and condenser ns should be

D

periodically cleaned with brush, air hose or vacuum cleaner.

Excess dirt or poor ventilation can cause no cold water and

compressor cycling on the compressor overload protector.

Lubrication: Motors are lifetime lubricated.

Actuation of Quick Connect Water Fittings: Cooler is provided

with lead-free connectors which utilize an o-ring seal. To remove

tubing from the ttings, relieve water pressure, push in on gray

collar while pulling on the tubing. To insert tubing, push tube

straight into tting until it reaches a positive stop, approximately 3/4”.

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

1000002230 (Rev. A - 11/14)

Page 2

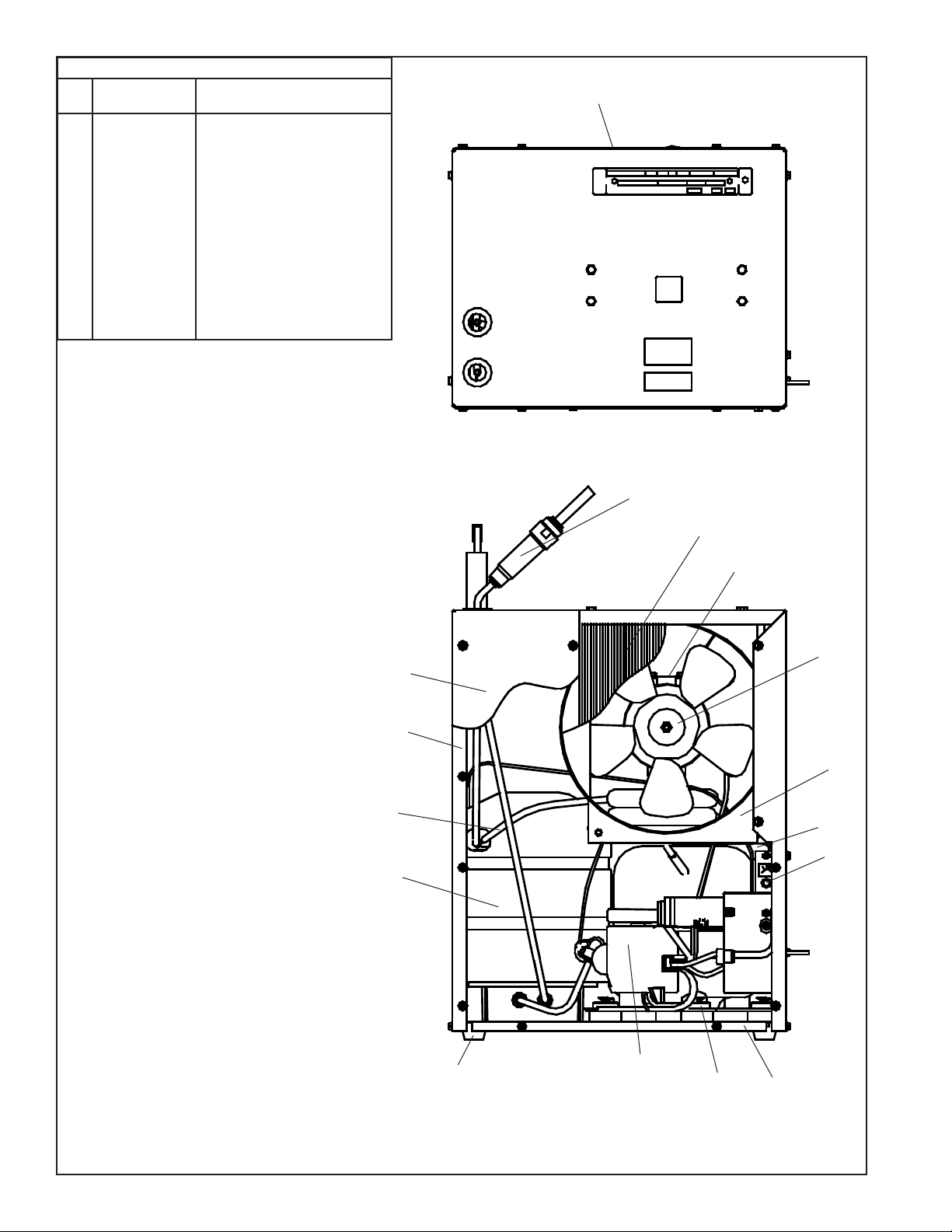

220V - 240/50Hz

ITEM

NO.

*8

10

11

12

13

14

15

16

17

*INCLUDES RELAY & OVERLOAD. IF UNDER WARRANTY,

REPLACE WITH SAME COMPRESSOR USED IN ORIGINAL

ASSEMBLY.

NOTE: All correspondence pertaining to any of the above water

cooler or orders for repair parts MUST include model number and

serial number of cooler, name and part number of replacement

part.

1

2

3

4

5

6

7

9

PART NO.

98724C

28478C

98776C

0000000244

20282C

98778C

66703C

1000002194

98773C

28477C

1000002195

0000000255

50930C

27303C

22300C

55996C

56237C

KIT - EVAP REPLACE ASSY

CABINET

KIT - CONDENSER/DRIER

KIT - FAN MTR/BLADE/NUT/SHROUD

BRACKET - FAN MOUNTING

KIT - HEAT EXCHANGER/DRIER

DRIER

COMPRESSOR SERVICE PAK

KIT - COLD CONTROL/SCREWS

PANEL - FRONT

KIT - ELECT/RELAY/COVER/OL

KIT - COMPRESSOR MTG HDWE

BUMPER

BASEPLATE

PANEL - REAR

IN-LINE STRAINER

SHROUD

DESCRIPTION

ECH8*2MQ

15

16

3

5

4

10

2

17

6

7

9

1

PRINTED IN U.S.A.

1000002230 (Rev. A - 11/14)

13

REPAIR SERVICE INFORMATION TOLL FREE NUMBER 1.800.260.6640

FOR PARTS, CONTACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.834.4816

ELKAY MANUFACTURING COMPANY • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484

8,11

12

14

Loading...

Loading...