Page 1

ECDFPW314FP

Installation/Care/Use Manual

Soft Sides™ Freeze Resistant Fount ain

Installer

T o assure you install this model easily and correctly , PLEASE READ THESE SIMPLE

INSTRUCTIONS BEFORE ST ARTING THE INST ALLA TION. CHECK YOUR

INST ALLATION FOR COMPLIANCE WITH PLUMBING, ELECTRICAL AND OTHER

APPLICABLE CODES. After installation, leave these instructions inside the fountain for

future reference. This Freeze Resistant Fountain is shipped in two separate cartons.

The second carton contains the Freeze Resistant Package LKFRB1 that is installed on

an interior heated wall. The interior space must maintain a minimum temperature of 50°

F (10° C). Refer to the Freeze Resistant Package for the rough-in dimensions for installation.

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SER VICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. T O

WA TER LINES IS A COMMON PROCEDURE. THIS GROUNDING MA Y BE IN THE BUILDING OR MA Y

OCCUR A WA Y FROM THE BUILDING . THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK

INTO A FOUNT AIN, CREATING AN ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN

INCREASE IN THE MET AL CONTENT OF THE WA TER. THIS CONDITION IS A VOIDABLE BY USING

THE PROPER MA TERIALS AS INDICA TED. ANY DRAIN FITTINGS PROVIDED BY THE INST ALLER

SHOULD BE MADE OF PLASTIC TO ELECTRICALL Y ISOLA TE THE FOUNT AIN FROM THE BUILDING

PLUMBING SYSTEM.

Page 1

98011C (Rev. J - 1/08)

Page 2

ECDFPW314FP

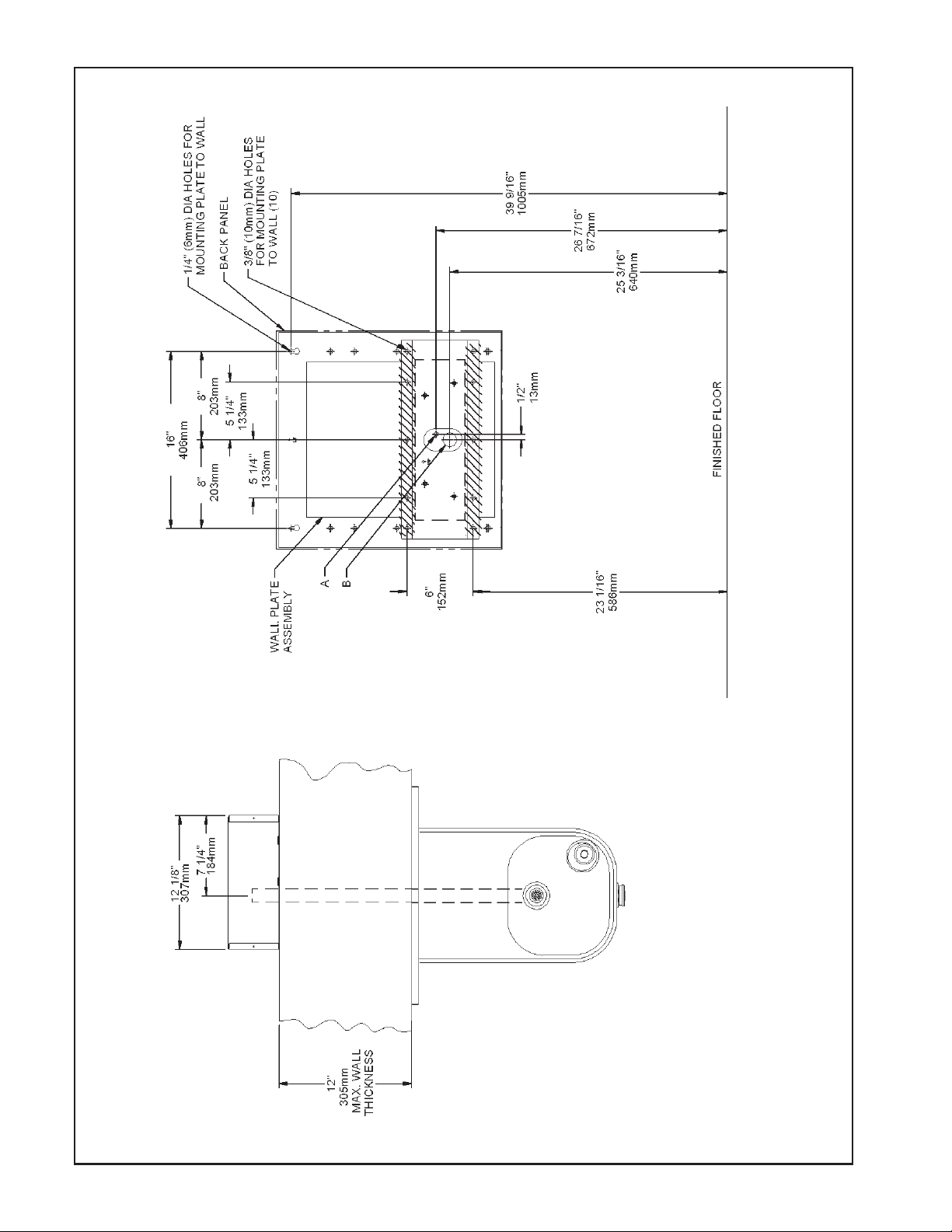

FIG . 1

ECDFPW314FPC

MOUNTING BOL T AND ACCESS HOLE LAYOUT

98011C (Rev. J - 1/08)

Page 2

LEGEND

A = RECOMMENDED W A TER SUPPL Y LOCA TION. 3/8 O.D. UNPLA TED

COPPER TUBE CONNECT STUBBED 1-1/2" (38mm) FROM WALL.

SHUT OFF BY OTHERS.

B = RECOMMENDED LOCATION FOR W ASTE OUTLET 1-1/4" O.D. DRAIN.

NOTE: REINFORCE THE WALL IN THE SHADED AREAS

Page 3

ECDFPW314FP

FIG . 2

ECDFPW314FPC

ROUGH-IN DRAWING

Page 3

1. Wall should already be framed for the fountains using dimensions shown in Fig. 1. Shown dimensions pertain to installation location.

These dimensions are required for compliance with ANSI Standard A117.1. and ADA (Framing shown for reference only).

2. Remove bottom covers from fountains and save the screws.

3. Install the fountains using bolts and washers (provided). Tighten securely.

4. Attach drain tubes to fountains and cut to required length using the freeze resistant boxes as guides.

5. Install freeze-resistant boxes - see box instructions.

6. Replace bottom covers.

98011C (Rev. J - 1/08)

Page 4

ECDFPW314FP

CABLE SHEA TH ADJUSTMENT

T o Increase Free Play

T o Reduce Free Play

FIG . 3

Note: Fountain Style May Vary

FIG . 4

See Fig. 7

See Fig. 3

98011C (Rev. J - 1/08)

FIG . 6

FIG . 5

FIG . 7

Page 4

Page 5

ECDFPW314FP

The freeze resistant package must be mounted on an interior wall in a heated area. The room temperature of the interior

heated area must be 50° F (10° C) or higher. The freeze resistant package may be surface or recessed mounted. If recess

mounted the surface of the cover must be flush with the interior wall surface. The package is furnished with screws for

mounting the cover to the box. If the box is recess mounted, do not fasten the top and bottom of the cover to the box. Use

the holes on the front only .

1. Assemble the operating cable to the fountain bracket. (Fountain should be mounted to exterior wall) Create a loop in

the cable and thread the free end of the cable through the wall into the freeze resistant box. The adjustment nuts should

be in the middle of threaded area on the operating cable. See Figure 7

2. Connect free end of operating cable to the valve-operating bracket. The end of the cables must be recessed into the

indents on the pivot brackets.

3. Remove cable free play by adjusting the jam nuts on the ends of the operating cable. See Figure 4

4. Connect water line from fountain bubbler into freeze resistant box. The connection to the box uses a quick connect

water fitting. Position the water line, in the fountain, to drain back into interior mounted box. Any water left standing, in

the exterior line, can freeze.

T o insert tubing, push tube straight into fitting until it reaches a positive stop. T o remove tubing from the fittings, relieve

water pressure, push in on dark gray collar while pulling out on the tubing. See Figure 9

5. Connect drain and water supply lines to the freeze resistant fountain. Refer to Figure 1 for component positions. Inline

strainer must be used on the inlet water line.

Start-up

1. Turn on building water supply and check all connections for leaks. Repair as required.

2. Stream height is factory set at 35 PSI. If stream height needs to be changed adjust the regulator in the freeze resist ant

package. Clockwise adjustment raises stream height, counter clockwise adjustment will lower stream.

3. Adjust operating cable as required. Cable system should have a minimal amount of free play to allow for proper valve

operation. If the system is too tight the valve will stay in the on position creating constant water flow . Too much free

play will result in non-operation of the valve with the push-buttons.

4. Note: Water from the drain back tube in the freeze resistant package, will continue to run while the valve is actuated.

5. After cable system is adjusted properly stuff flexible insulation into any openings between the outside wall and the

interior box.

6. Recheck all connections. If all connections are leak free replace cover on the freeze resistant box and fountain.

1/4" O.D. TUBE

WATER INLET

3/8" O.D. UNPLATED

COPPER TUBE CONNECT

COLD WA TER SUPPLY

BUILDING WA TER

INLET

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE IS

SECURED

IN POSITION

PUSH IN COLLET

TO RELEASE TUBE

NOTE: WA TER FLOW DIRECTION

FIG . 8

SERVICE STOP

(NOT FURNISHED)

FIG . 9

Page 5

PUSHING TUBE IN BEFORE

PULLING IT OUT HELPS TO

RELEASE TUBE

98011C (Rev. J - 1/08)

Page 6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

NS

PAR T NO.ITEM NO.

40575C

28824C

45662C

45737C

27945C

27946C

40206000

50198C

51667C

75672C

75570C

28790C

55000665

28290C

40045C

55919C

100322740560

15009C

98118C

56092C

28286C

45679C

45805C

50074C

70379C

75541C

111577243890

75520C

PAR TS LIST

DESCRIPTION

Drain - Strainer

Bracket-Regulator Mounting

Push Button

Push Button Sleeve

Bracket-Basin

Bracket-Basin Pivot

Retainer

Snap Bushing

Bumper-Reg. Valve Assy

Cap Screw

Screw #10 X .50 Pinned T orx

Fountain Arm - Long

Bottom Cover Plate - Long

Back Panel

Hex Nut

Push Button (Extension)

Gasket

Bubbler - Nipple

Bubbler Assembly

Poly Tubing (Cut To Length)

Mounting Plate Assy

Drain - T ailpipe

Drain Adapter

Gasket - Tail Pipe

Pivot Rod

Washer - Flat .339/.359ID Steel

Screw - Mach. 5/16-18 x 3/4

Bit-Pinned T orx

ECDFPW314FP

FIG . 10

20

19

17

18

14

26, 27

FIG . 1 1

21

11 13

22,23,24

FIG . 12

25

9

12

1

2

15

FIG. 10

5

4

16

3

8

6

8

7

98011C (Rev. J - 1/08)

10

FIG . 13

FOR PARTS, CONT ACT YOUR LOCAL DISTRIBUTOR OR CALL 1.800.323.0620

ELKAY MANUFACTURING COMP AN Y • 2222 CAMDEN COURT • OAK BROOK, IL 60523 • 630.574.8484

Page 6

Loading...

Loading...