Page 1

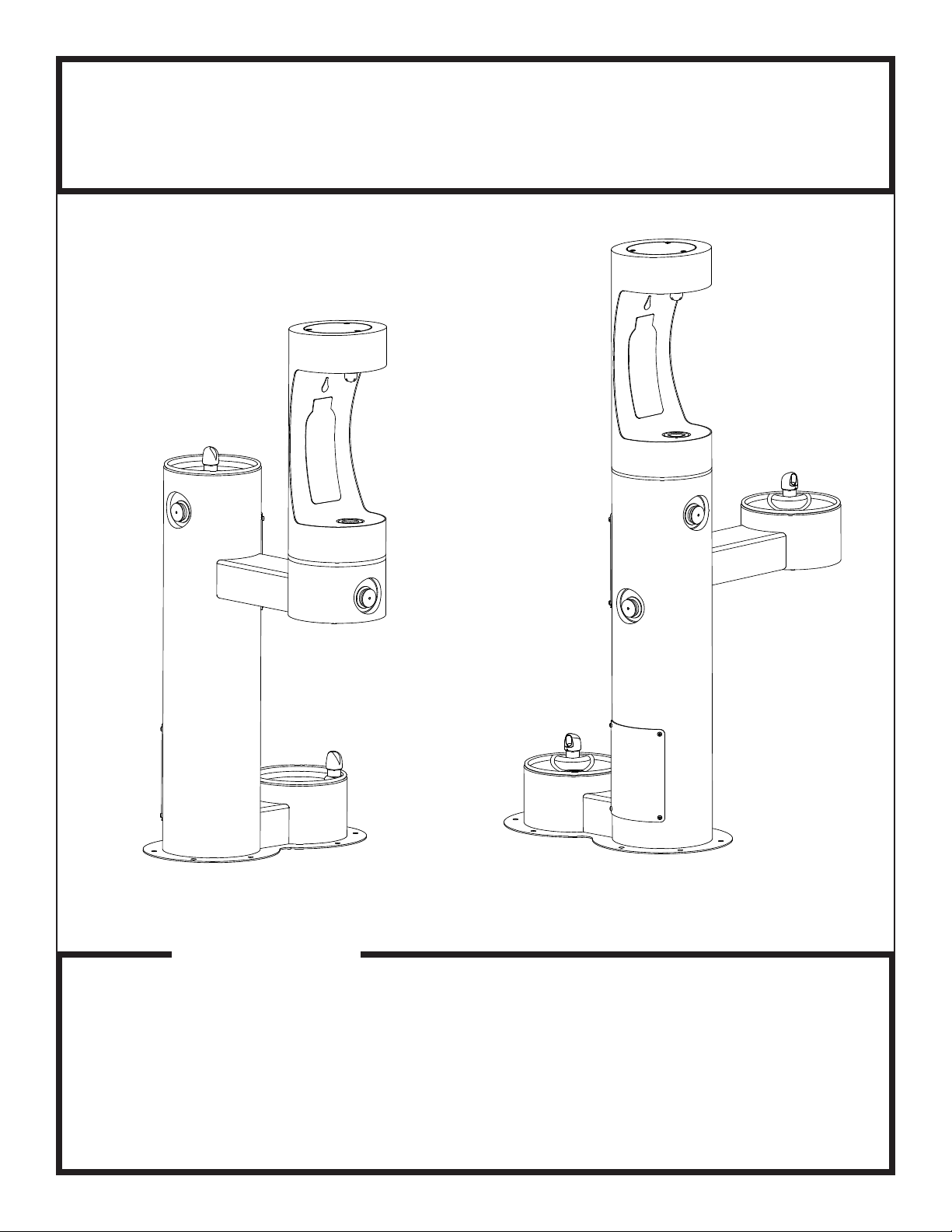

4420BFDB_FTN_A LK4420BFDB_FTN_A

Owners Manual

Models 4420BF1LDB* and 4420BF1UDB*

Bi-Level Tubular Bottle Filler Fountain with Pet fountain

Models (LK)4420BF1LDB* Models (LK)4420BF1UDB*

INSTALLER

4420BFDB Fountains are among the easiest to install Fountains on the market today.

To assure you install these models easily and correctly, PLEASE READ THESE

SIMPLE INSTRUCTIONS BEFORE STARTING THE INSTALLATION. CHECK YOUR

INSTALLATION FOR COMPLIANCE WITH PLUMBING, ELECTRICAL, AND OTHER

APPLICABLE CODES. After installation, leave these instructions with the Fountain for

future reference.

PAGE 1

1000003948 (Rev. B - 03/20)

Page 2

4420BFDB_FTN_A LK4420BFDB_FTN_A

INSTALLATION INSTRUCTIONS

IMPORTANT

ALL SERVICE TO BE PERFORMED BY AN AUTHORIZED SERVICE PERSON

IMPORTANT! INSTALLER PLEASE NOTE.

THE GROUNDING OF ELECTRICAL EQUIPMENT SUCH AS TELEPHONE, COMPUTERS, ETC. TO WATER LINES

IS A COMMON PROCEDURE. THIS GROUNDING MAY BE IN THE BUILDING OR MAY OCCUR AWAY FROM THE

BUILDING. THIS GROUNDING CAN CAUSE ELECTRICAL FEEDBACK INTO A FOUNTAIN, CREATING AN

ELECTROLYSIS WHICH CAUSES A METALLIC TASTE OR AN INCREASE IN THE METAL CONTENT OF THE

WATER. THIS CONDITION IS AVOIDABLE BY USING THE PROPER MATERIALS AS INDICATED. ANY DRAIN

FITTINGS PROVIDED BY THE INSTALLER SHOULD BE MADE OF PLASTIC TO ELECTRICALLY ISOLATE THE

FOUNTAIN FROM THE BUILDING PLUMBING SYSTEM.

1. This fountain is to be mounted on a smooth, at, nished surface with adequate support structure. NOTE: Mounting structure

must be capable of supporting 300 lb. load on fountain.

2. Refer to rough-in for plumbing.

3. Install shut-o valve on water supply. (Valve not furnished)

4. Locate and install fountain using 3/8" minimum fasteners. (Fasteners not furnished)

5. Prior to installing the bottle ller to the center mounting position of fountain, insert the drain pipe (Item #15) by positioning the

short end of drain pipe through mounting plate of bottle ller. Next, place the aesthetic collar (item # 29) onto the center

mounting position of the fountain ensuring the vertical edge of the collar is upright and the curved edge sits below the mount

ing surface. Mount bottle ller to fountain with collar centered between the two pieces. Install bottle ller to fountain and secure

with supplied hardware.

6. Prior to installing the bottle ller to the arm mount of fountain, insert the drain pipe (Item #14) into the arm tunnel and adjust

drain to lean to the left side of the arm when facing the button. Next, place the aesthetic collar (Item # 29) onto the arm

mounting position of the fountain ensuring the vertical edge of the collar is upright and the curved edge sits below the

mounting surface. Mount bottle ller to arm with collar centered between the two pieces. Install bottle ller to arm being

sure drain tube is above mounting plate of ller. Install ller to fountain and secure with supplied hardware.

7. Connect water supply and fountain drain. Connect drain waste "Tee" to fountain drain tubes. Connect outlet of "Tee" to

drainage system. Water connection and drain must comply with local codes.

8. Turn on water supply and check all connections for leaks.

CAUTION: This fountain is rated for inlet water pressure of 20-105 PSI. A pressure reducing regulator should be used if the

inlet water supply exceeds 105 PSI. Any damage caused by reason of connecting this product to supply line

pressures lower than 20 PSI or higher than 105 PSI is not covered by warranty.

9. Water supply 3/8" O.D. unplated copper tube. Waste 1-1/2" IPS. Contractor to supply waste trap and service stop valve in

accordance with local code.

10. Connecting lines to be made of unplated copper and should be thoroughly ushed to remove all foreign matter before being

connected to fountain. This fountain is manufactured in such a manner that it does not in any way cause taste, odor,color,

or sediment problems.

11. Connect fountain to supply line with a shut-o valve and install a 3/8" unplated copper water line between the valve and

the fountain. Remove any burrs from outside of water line. Push the tubes straight into the ttings until they reach a

positive stop, approximately 3/4" (See Fig. 3). DO NOT SOLDER TUBES INSERTED INTO PLASTIC FITTINGS AS

DAMAGE TO THE O-RINGS MAY RESULT.

1000003948 (Rev. B - 03/20)

PAGE 2

Page 3

26"

4420BFDB_FTN_A LK4420BFDB_FTN_A

10"

254mm

O

* ADA REQUIREMENT

57 3/16"

1453mm

37 3/16"

14 9/16"

660mm

22"

559mm

3"

76mm

371mm

945mm

27 1/8"

689mm

*

C

4420BF1LDB

19"

483mm

29"

A

1-1/2" DRAIN

737mm

10"

254mm

FINISHED FLOOR

O

40 5/16"

1025mm

RIM

HEIGHT

12.00" B.C.

O

.500" HOLES

O

8 -

TWO

EQUALLY SPACED ON

14"

(2 PL)

356mm

O

10"

254mm

41 7/16"

HEIGHT

1053mm

ORIFACE

8"

203mm

O

B

B

PAGE 3

30"

6 9/16"

167mm

762mm

1000003948 (Rev. B - 03/20)

LEGEND

A = 3/8" O.D. UNPLATED COPPER TUBE CONNECT - SHUT OFF VALVE BY OTHERS

B = ACCESS PANEL ( 8" X 10" )

C = REMOVABLE BOTTOM COVER

Page 4

4420BF1UDB

4420BFDB_FTN_A LK4420BFDB_FTN_A

4420BF1UDB

10"

254mm

O

* ADA REQUIREMENT

3"

76mm

22"

559mm

10"

12.00" B.C.

O

.500" HOLES

O

EQUALLY SPACED ON

TWO

8 -

14"

356mm

(2 PL)

O

254mm

O

34 9/16"

878mm

HEIGHT

ORIFACE

RIM

33 7/16"

850mm

HEIGHT

27 1/8"

689mm

*

A

1-1/2" DRAIN

FINISHED FLOOR

19"

C

483mm

26"

29"

737mm

660mm

10"

254mm

O

14 9/16"

371mm

64 1/16"

1627mm

B

44 1/16"

1119mm

8"

203mm

B

6 9/16"

167mm

30"

762mm

1000003948 (Rev. B - 03/20)

PAGE 4

LEGEND

A = 3/8" O.D. UNPLATED COPPER TUBE CONNECT - SHUT OFF VALVE BY OTHERS

B = ACCESS PANEL ( 8" X 10" )

C = REMOVABLE BOTTOM COVER

Page 5

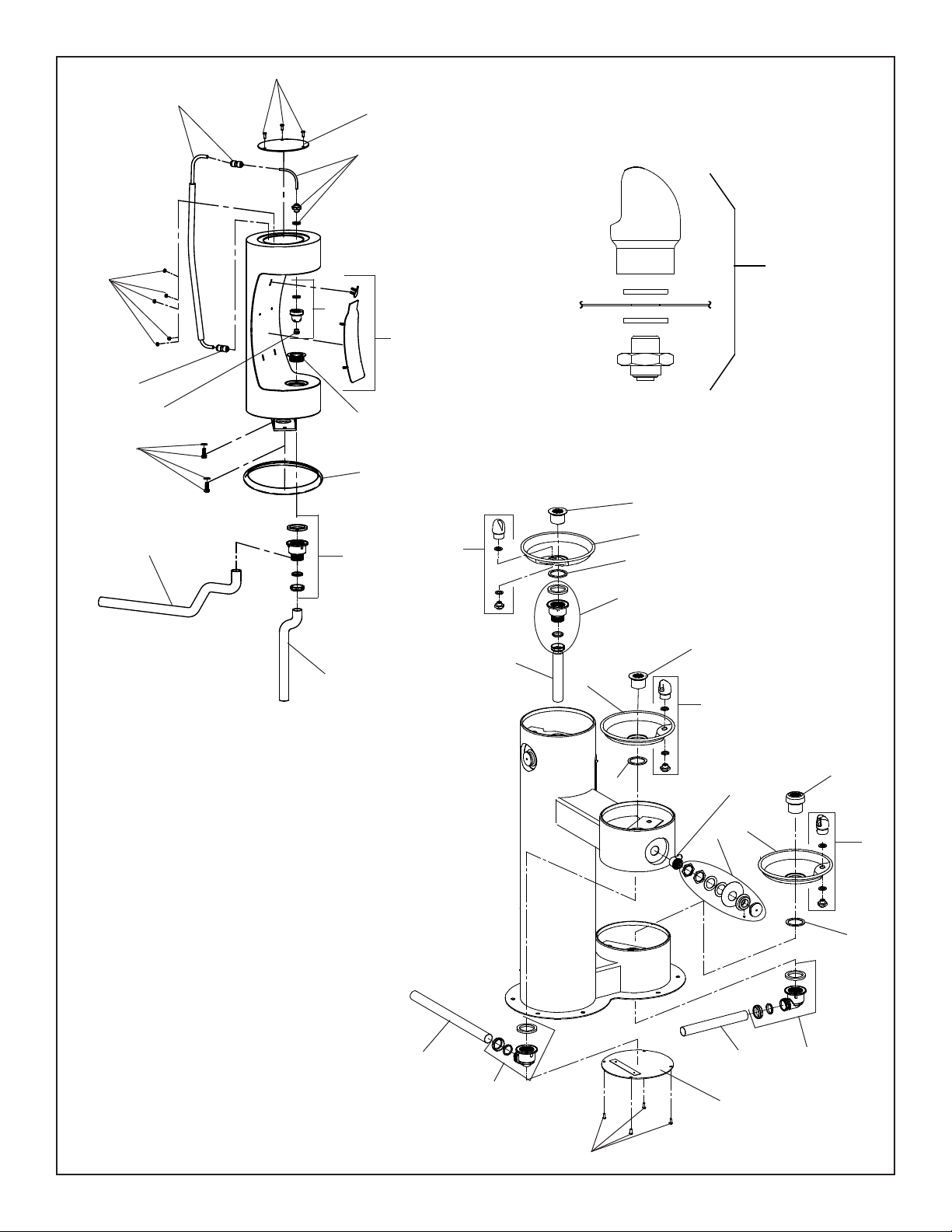

21

27

38

62

11

24

22

27

13

10

42

62

49

30

61

63

20

29

6 SEE NOTE 13

78SEE NOTE 11

20

28

3748

21

10

13

1659

52 OR

33

25

43

43

61

16

3SEE NOTE 5

34

33 45

63

29

22

24

24

11

11

37

3748

48

52 OR

22

20

29

28

63

61

45

8SEE NOTE 13

61

62

61

62

61

62

61

59

28

4420BFDB_FTN_A LK4420BFDB_FTN_A

18, 27

2

28

27

28

22

27

ARM ONLY 14

21

15

25

11

29

23

13

16

PAGE 5

26

3

BASIN

Vandal-Resistant Bubbler

FIG. 1

4

1

4

25

19, 27

1

4

16

4

16

20

24

1

8

26

10

9

17

6

1000003948 (Rev. B - 03/20)

Page 6

4420BFDB_FTN_A LK4420BFDB_FTN_A

RE

O

TROUBLESHOOTING AND MAINTENANCE

ACTUATION OF QUICK CONNECT WATER FITTINGS:

Fountain is provided with lead-free connectors which utilize an

o-ring water seal. To remove tubing from the tting, relieve water

pressure, push in on the gray collar while pulling on the tubing. (see

Fig.2) To insert tubing, push tube straight into tting until it reaches

a positive stop, approximately 3/4".

1/4" O.D. TUBE

WATER INLET

TO COOLER

FIG. 2

OPERATION OF QUICK CONNECT FITTINGS

OPERATION OF QUICK CONNECT FITTINGS

SIMPLY PUSH IN

SIMPLY PUSH IN

TUBE TO ATTACH

TUBE TO ATTACH

A B C

3/8" O.D. UNPLATED COPPER TUBE CONNECT

COLD WATER SUPPLY

NOTE: WATER FLOW

DIRECTION

TUBE IS SECURED

TUBE IS SECURED

IN POSITION

B CA

IN POSITION

BUILDING WATER INLET

SERVICE STOP

(NOT FURNISHED)

PUSH IN COLLET

PUSH IN COLLET

TO RELEASE TUBE

TO RELEASE TUBE

PUSHING TUBE IN BEFORE

PUSHING TUBE IN BEFO

PULLING IT OUT HELPS TO

PULLING IT OUT HELPS T

RELEASE TUBE

FIG. 3

ITEMIZED PARTS LIST

ITEM

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

NS

NS = Not Shown

*select color option to complete part number

PART NO.

28467C

1000003814*

40551C

0000000325

1000003812*

1000003813*

45926C

45724C

45726C

0000000466

45931C

55996C

66346C

66816C

66815C

97446C

101570540560

75724C

97247C

98678C

98530C

98679C

98680C

98681C

1000003692

1000003693

98682C

1000003694

1000003695

98683C

98684C

98685C

98686C

1000005456

1000003490

Basin

Cover - Round Plate

Tailpipe

Kit - Drain Plug/Gasket

Access Panel

Bottom Cover

Drain Tube - 1-1/2" x 27-1/2" Lg.

Tailpipe - 1-1/4" x 10"Lg.

Drain Plug 1-1/2" (Dog Bowl)

Kit - Bubbler (Dog Bowl)

Plug - Drain (BF)

In - Line Strainer

Drain Tube

Tube - Drain (Arm Only)

Tube - Drain

Kit - Bubbler (VR)

Gasket

Screw - 1/4"x20 x 3/4" LG. Pinned Torx

Kit - VR Torx Screws/Bit

Kit - 1.0 GPM Regulator (BF Only)

Kit Kit - Nozzle

Kit - Aerator/Key

Kit - Blank Bottle Filler Trim

Kit - LK4420BFDB Bottle Filler Trim

Kit - 4420BFDB Bottle Filler Trim

Kit - Push Button w/Blank Nameplate

Kit - Push Button w/LK4420BFDB Nameplate

Kit - Push Button w/4420BFDB Nameplate

Kit - Plastic Drain

Kit - 90° Plastic Drain

Kit - 4400 Series Hardware

Kit - Bottle Filler Waterway

Aesthetic Collar

Drain Tube (Not Shown)

DESCRIPTION

FIG. 4

STREAM HEIGHT ADJUSTMENT:

Stream height is factory set at 35 PSI. If supply pressure

varies greatly from this, insert a small straight bladed

screwdriver through the access hole in the center of the

push button and turn the adjustment screw. Clockwise

adjustment will raise the stream and counterclockwise

adjustment will lower the stream. For best adjustment,

the stream should be approximately 1 1/2" above the

top of the bubbler . (See Fig. 4)

See Fig. 4

12

5

27

10

11

5

*FINISH COLOR OPTIONS – Choose color option to

complete your model number, add as sux example:

4420BF1UDBEVG

Matte nish: Evergreen = EVG

Gloss nish:

Beige = BGE Gray = GRY Terracotta = TER

Black = BLK Orange = ORN White = WHT

Blue = BLU Purple = PUR Yellow = Y LW

Brown = BRN Red = RED

7

PRINTED IN U.S.A.

Halsey Taylor – halseytaylor.com

Elkay – elkay.com

1000003948 (Rev. B - 03/20)

FOR PARTS CONTACT YOUR LOCAL DISTRIBUTOR OR CALL TECHNICAL SERVICES AT 1.800.834.4816

1333, BUTTERFIELD ROAD, DOWNERS GROVE, ILLINOIS 60515

PAGE 6

Loading...

Loading...