Page 1

Installation

1. A single M1XOVR Expander can be mounted inside

the M1 enclosure on the left hand side of the M1 board

using the supplied ELK-SWG Circuit Board Glides. If

any additional expanders are required, they can be

mounted in either an ELK-SWB14 or ELK-SWB28

enclosure. Up to 8 expanders can be mounted in an

SWB14 while up to 16 expanders can be mounted in

an SWB28.

The ELK-SWG Circuit Board Glides attach to the

enclosure at strategically placed 2-hole punch patterns.

Note that one hole in each pattern is slightly larger than

the other. The small hole is for a 6/32 type “F” mounting

screw and the large hole is for a half-moon shape locator

tab on the bottom of each glide.

E

L

K

-

S

W

G

Output Expander

8 Voltage / 8 Relays

ELK-M1XOVR

APPLICATION:

The ELK-M1XOVR adds 8 Voltage outputs and

8 Relay outputs to the M1 Control. It operates on

the 4-wire data bus and features flash memory

for field updating of the operating firmware. The

M1G (Gold) Control can expand to 208 outputs

while the M1 Std can expand to 32 outputs.

2. Starting at the top left corner, loosely start a 6/32”

mounting screw in the small hole of the first 2-hole

pattern. Place the slotted edge of a board glide

under this screw, making sure that the half-moon tab

fits into the larger hole and the grooved edge is

facing down. Tighten the screw using a long shafted

screwdriver. Install a second board glide in the 2hole pattern located 6" below. Attach the second

board glide using the same procedures. The

grooved edge of this glide should face up.

3. Slide the expander board into the grooves provided

by the glides. The circuit board should slide freely.

If the board is loose or too tight, simply loosen one

of the mounting screws and adjust the glide to

assure a good fit.

Wiring Connections

1. Turn Control Panel Master Power Switch Off.

2. Use a 4 wire cable to connect terminals +VKP, Data

A, Data B, and Neg from Control to terminals 12V, A,

B, and Neg on the M1XOVR. IMPORTANT NOTE: If

the expander is remotely mounted, refer to information in the M1 Installation Manual for important

information about data bus devices connected to

multiple homerun cables.

4. Set Address Switches according to Table 1.

5. Turn the M1 Master Power Switch On.

6. Enroll the M1XOVR to the M1 Control using the

following procedure: Enter Installer level programming and select Menu 01-Bus Module Enrollment.

Press the right arrow key to start enrollment. To

view the results, press the right arrow "edit" key.

6. After enrollment, use the ELK RP Rules programming to assign the new outputs.

NOTE: If it becomes necessary to replace an enrolled

device, set the new unit to the same address and repeat

the enrollment. If permanently removing a device, unenroll it to prevent a trouble condition.

L529 10/05

Output Expander

8 Voltage / 8 Relays

ELK-M1XOVR

FEATURES:

•8 Voltage Outputs

•8 Single-Pole, Double-Pole Relay Outputs

•Operates on the 4-Wire Data Bus

•DIP Switch Address Settings

•Flash Memory for Firmware Updating

•One (1) - Twelve (12) Conductor "Flying Lead"

Wire Harness

•Voltage Outputs may be converted to Relays

using M1RB Relay Boards

•Status LED with Diagnostic Display

•Mounts in Enclosure using ELK-SWG Glides,

SWP or SWP3 Structured Wire Plates, or

Double Sided Foam Tape

SPECIFICATIONS:

•Voltage Outputs: 12 VDC @ 50 mA each

•Relay Contact Ratings:

7 Amps @ 28 VDC, 10 Amps @ 125 VAC *

•Wire Harness Length: 12"

•Operating Power Range: 9 to 14 VDC

•Current Draw: 65 mA Nom., 330 mA Max.

•Size: 6" x 3.25" x .75" H

* For UL listed installations the maximum contact ratings

are 4 Amps @ 12 VDC

828-397-4200 Voice

828-397-4415 Fax

http://www.elkproducts.com

email: info@elkproducts.com

PO Box 100 • Hwy. 70W • Hildebran, NC 28637 • USA

Page 2

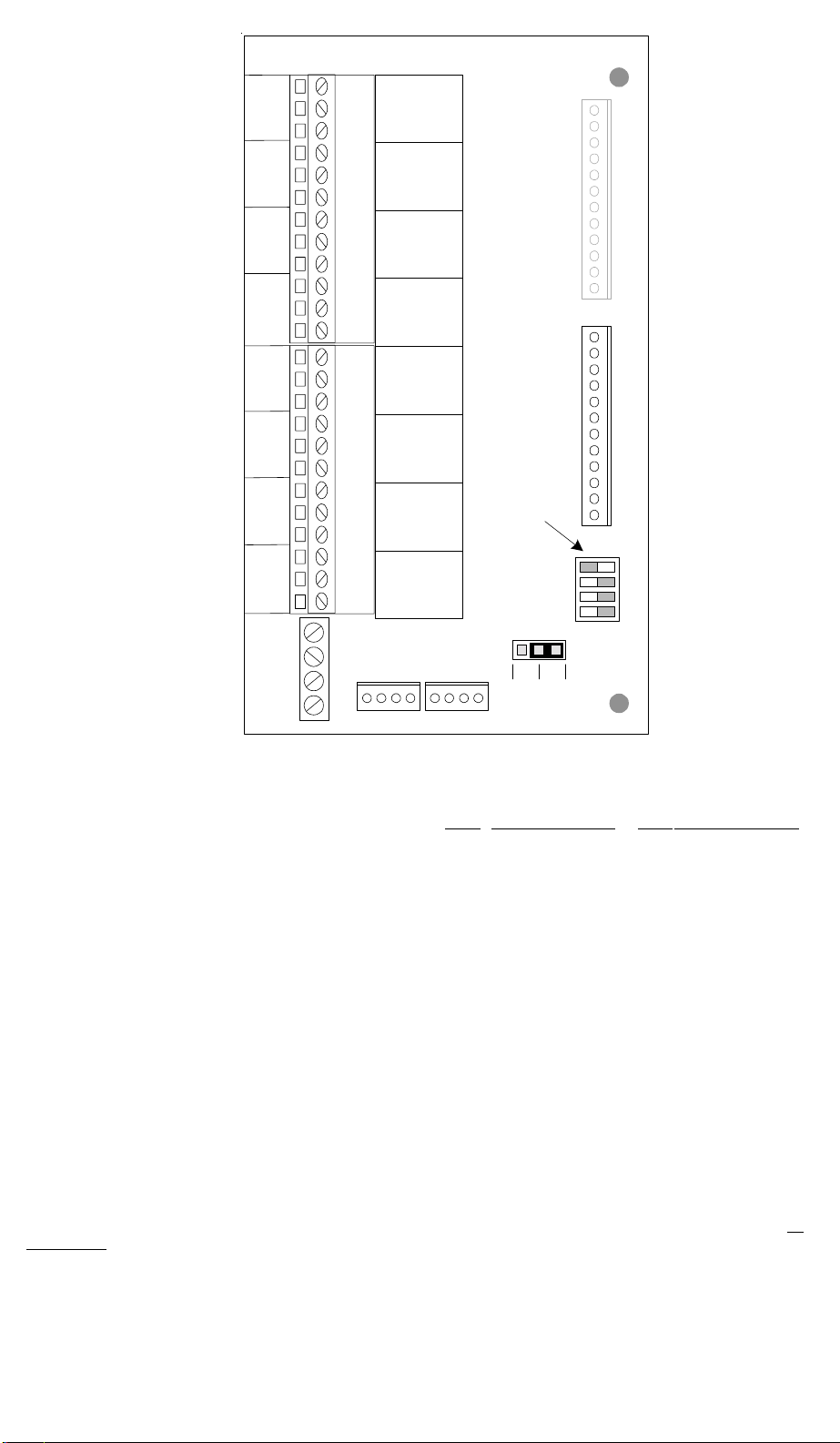

M1XOVR

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

+12

+-AB

A

B

NEG

OUT

1

SPDT

Relay

OUT

2

SPDT

Relay

OUT

3

SPDT

Relay

OUT

4

SPDT

Relay

OUT

5

SPDT

Relay

OUT

6

SPDT

Relay

OUT

7

SPDT

Relay

OUT

8

SPDT

Relay

J1

++--AB AB

Output Expander

8 Voltage / 8 Relays

O

U

T

P

U

T

S

N

U

M

B

E

R

S

A

R

(Address 2). Other switches Off.

J2

E

R

E

L

A

T

I

V

E

T

O

T

H

I

S

B

O

A

R

D

O

N

L

Y

Switch 2 shown in ON position

Address

Yes No

JP1

NC

NC

1

2

3

4

5

6

7

8

+

J4

NC

NC

9

10

11

12

13

14

15

16

-

+

J3

1248

Terminate

Data Bus

ADDRESS SETTING: Locate the four "Address"

switches. Each has a position of OFF or ON (binary 0

or 1) with a decimal equivalent of (1, 2, 4, or 8). The

total decimal value for the "ON" switches sets the bus

address. This determines which outputs (banks of 16)

are assigned to the expander. E.G. Address 5 would

be set with switches 1 and 4 ON (1+4=5) and switches

2 and 3 OFF. Outputs Expanders are factory pre-set

to address 2 (Outputs 17 to 32).

Addr Output Expander AddrOutput Expander

1 = Outputs 1-16 8 = Outputs 113-128*

2 = Outputs 17-32 9 = Outputs 129-144*

3 = Outputs 33-48* 10 =Outputs 145-160*

4 = Outputs 49-64* 11 =Outputs 161-176*

5 = Outputs 65-80* 12 =Outputs 177-192*

6 = Outputs 81-96* 13 =Outputs 193-208*

7 = Outputs 97-112* * M1G Only

TABLE 1

Utilizing an M1DBH Data Bus Hub

Since the M1XOVR connects to the M1's RS-485 Data Bus, it can be installed inside the Control or virtually anywhere

along the data bus. The Data Bus requires only 4 wires, 2 for power + 2 for data. However, due to the relatively high

speed of the data bus, special wiring connections are necessary to avoid data reflection errors on long cables OR

multiple cable "homeruns". See the M1 Installation Manual for important information about Data Bus termina-

tion, including methods and recommendations for avoiding data bus problems. The primary goal is to have no

more than 2 data bus branches (cables) running from the control, with each being terminated at its end using a 120

Ohm end of line resistor. There are two ways to accomplish this goal. 1) Using 4-wire cable, run no more than 2

cables and connect all devices paralleled (daisy chained) along this cable path. OR 2) Using 6 or 8 wire cables

(CAT5 or CAT6 is ideal), run as many cables as you want so long as the data A & B wires are connected to a spare

pair of wires so that they double back (return) to the control and are connected in series to the outgoing data A & B

lines of the next cable. By keeping the data lines in a series circuit it will appear to be one long cable. This virtually

eliminates data reflection errors. This is easily done using an ELK-M1DBH Data Bus Hub.

Page 3

Do Not Use the 8 M1XOVR Voltage outputs to directly drive

IMPORTANT INFORMATION

high (large) current loads. Each output is limited to 50 mA.

Also, when calculating the M1 total current load, keep in mind

that if all 8 outputs from an M1XOV were turned on and were

drawing the maximum of 50 ma each, the resulting total load

would be 400 mA from the M1. An auxiliary power supply may

be required and is strongly recommended if the M1XOVR is

remotely mounted from the M1 Control.

Door

Strike

8 Voltage / 8 Relays

SPDT

Relay

SPDT

Relay

SPDT

Relay

SPDT

Relay

SPDT

Relay

SPDT

Relay

SPDT

Relay

SPDT

Relay

J1

J2

++--AB AB

Output Expander

O

U

T

P

U

T

S

N

U

M

B

E

R

S

A

R

(Address 2). Other switches Off.

Switch 2 shown in ON position

E

R

E

L

A

T

I

V

E

T

O

T

H

I

S

B

O

A

R

D

O

N

L

Y

Yes No

JP1

Address

-

24V AC

Transformer

Garage Door

Opener

M1XOVR

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

+

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

N/O

COM

N/C

+12

NEG

A

B

+-AB

OUT

1

OUT

2

OUT

3

OUT

4

OUT

5

OUT

6

OUT

7

OUT

8

+

Green

+

Red

-

LED

Status

Plate

Using the M1XOVR

to drive two (2)

indicator LEDs on an

LED Status Plate

NC

NC

1

2

3

4

5

6

7

8

+

J4

NC

NC

9

10

11

12

13

14

15

16

-

+

J3

1248

Terminate

Data Bus

Tan - Not Used

Pink - Not Used

Gray - Output 09

Purple - Output 10

Yellow - Output 11

Orange - Output 12

Blue - Output 13

Brown - Output 14

Green - Output 15

White - Output 16

Black - Negative

Red - +12 VDC

+VKP A B Neg

To M1 Control

Data Bus

Terminals

Examples of Hookups using ELK-M1OV Output Board

Page 2

Loading...

Loading...