Elica EST319GL Use & Care

Use, Care, and Installation Guide

Guide d’utilisation, d’entretien et d’installation

Guía de instalación, uso y mantenimiento

READ AND SAVE THESE INSTRUCTIONS

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

LEA Y GUARDE ESTAS INSTRUCCIONES

English

French

Spanish

Contents page 3

Sommaire page 22

Contenido página 42

English

Contents

Important safety Notice................................................................................................4

Electrical & Installation requirements.........................................................................6

Electrical requirements.................................................................................................................................6

Before installing the hood.............................................................................................................................6

List of Materials.............................................................................................................7

Parts supplied...............................................................................................................................................7

Parts not supplied.........................................................................................................................................7

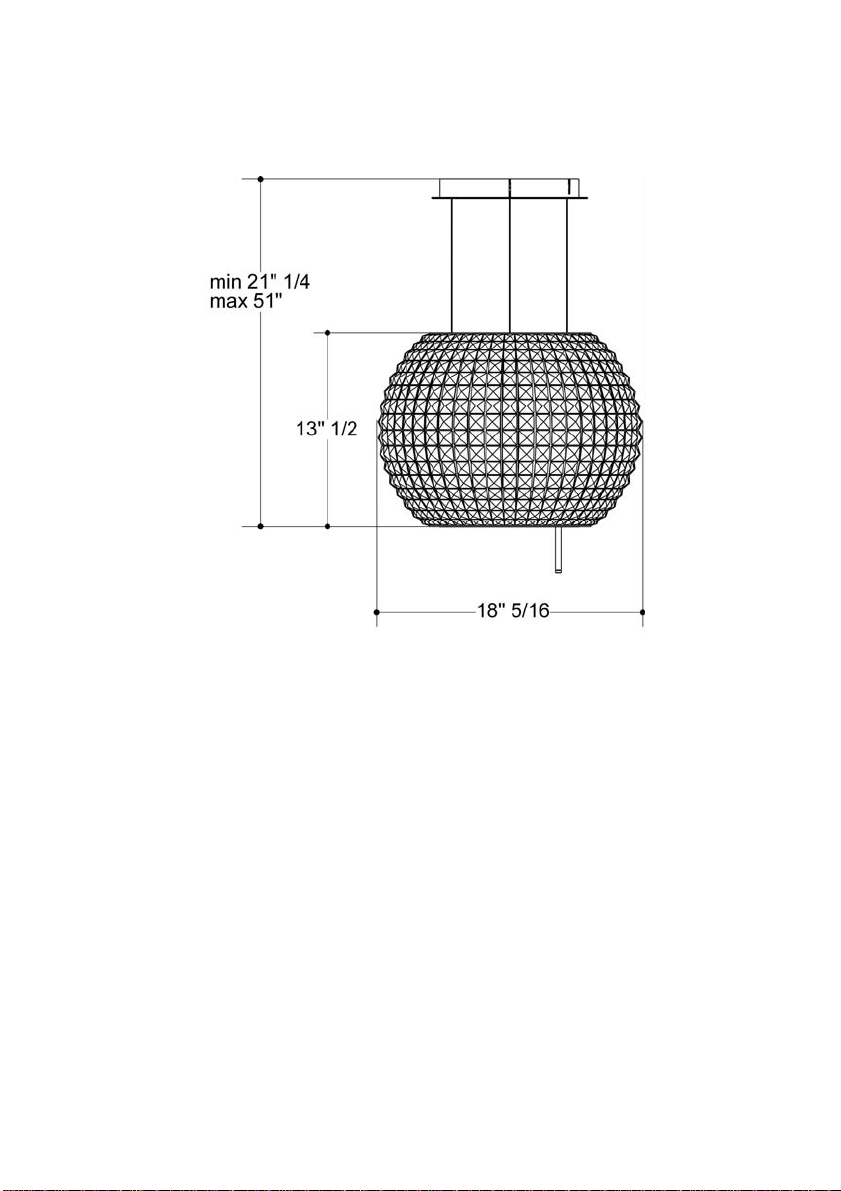

Dimensions and Clearances........................................................................................8

Ducting Options and Examples...................................................................................9

Venting methods ..........................................................................................................................................9

Preparation...................................................................................................................................................9

Installation................................................................................................................... 10

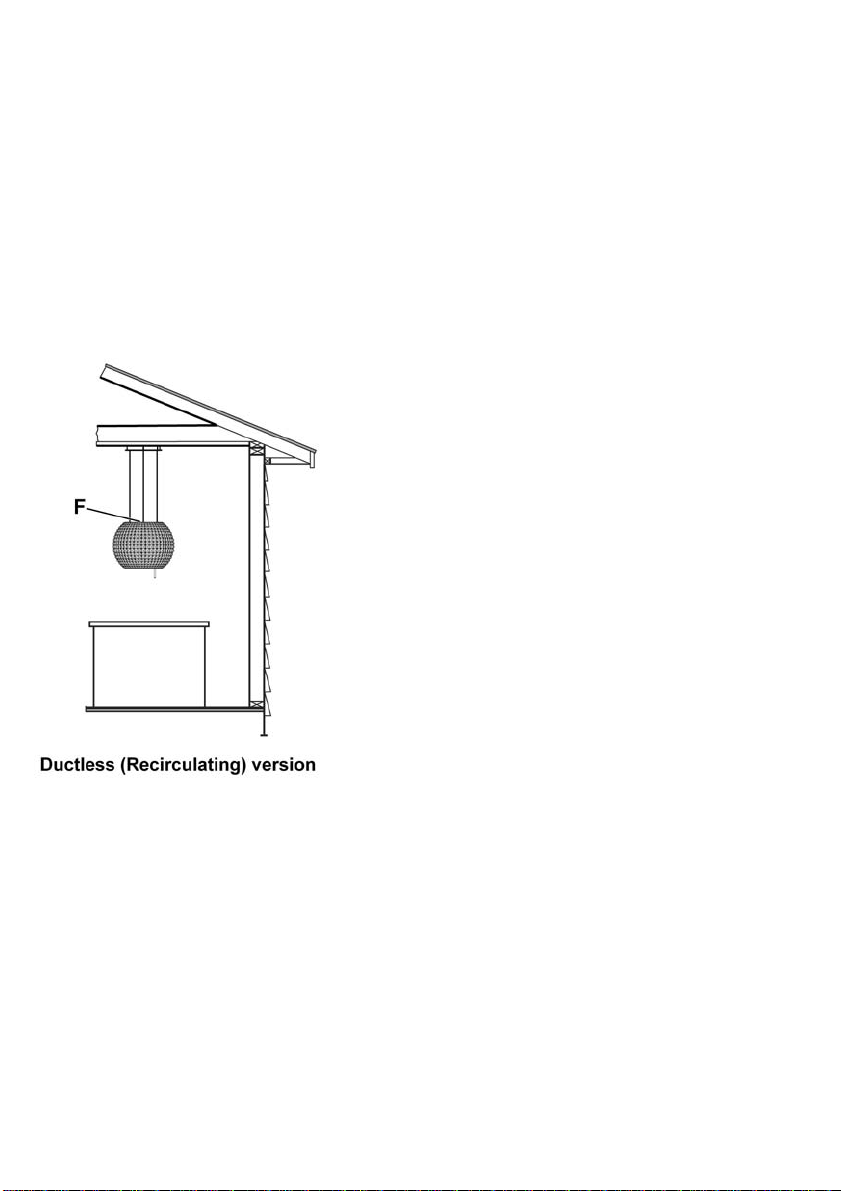

Installation - Ductless (Recirculating) version ............................................................................................10

Description of the hood & Controls .......................................................................... 16

Controls......................................................................................................................................................17

User Servicing and Maintenance Instructions.........................................................19

Cleaning.....................................................................................................................................................19

Grease Filter...............................................................................................................................................20

Replacing the light bulb..............................................................................................................................20

Charcoal Filter............................................................................................................................................20

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn off power circuit at service panel and lock out panel,

before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit

3

READ AND SAVE THESE INSTRUCTIONS

Important safety Notice

CAUTION

FOR GENERAL VENTILATING USE ONLY.

DO NOT

OR EXPLOSIVE MATERIALS OR VAPOURS.

WARNING

TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer.

B. Before servicing or cleaning the unit,

C. Installation Work and Electrical Wiring

D. Sufficient air is needed for proper

E. When cutting or drilling into wall or

F. Ducted systems must always be vented

USE TO EXHAUST HAZARDOUS

switch power off at service panel and lock

service panel disconnecting means to

prevent power from being switched on

accidentally. When the service

disconnecting means cannot be locked,

securely fasten a prominent warning

device, such as a tag, to the service

panel.

Must Be Done By Qualified Person(s) In

Accordance With All Applicable Codes &

Standards, Including Fire-rated

Construction.

combustion and exhausting of gases

through the flue (Chimney) of fuel burning

equipment to prevent back- drafting.

Follow the heating equipment

manufacturers guideline and safety

standards such as those published by the

National Fire Protection Association

(NFPA), the American Society for

Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and

the local code authorities.

ceiling, do not damage electrical wiring

and other hidden utilities.

to the outdoors.

CAUTION

To reduce risk of fire and to properly

exhaust air, be sure to duct air outside do not vent exhaust air into spaces within

walls, ceilings, attics, crawl spaces, or

garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE

ONLY METAL DUCT WORK.

Install this hood in accordance with all

requirements specified.

WARNING

To Reduce The Risk Of Fire Or Electric

Shock, Do Not Use This Hood With Any

External Solid State Speed Control

Device.

WARNING

TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE.

a) Never leave surface units unattended at

high settings. Boilovers cause smoking

and greasy spillovers that may ignite.

Heat oils slowly on low or medium

settings.

b) Always turn hood ON when cooking at

high heat or when flambeing food (I.e.

Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambe’).

c) Clean ventilating fans frequently. Grease

should not be allowed to accumulate on

fan or filter.

d) Use proper pan size. Always use

cookware appropriate for the size of the

surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO

PERSONS, IN THE EVENT OF A RANGE

TOP GREASE FIRE, OBSERVE THE

FOLLOWING: *)

a) SMOTHER FLAMES with a close-fitting

lid, cookie sheet, or other metal tray, then

4

turn off the gas burner or the electric

element. BE CAREFUL TO PREVENT

BURNS. If the flames do not go out

immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - you

may be burned.

c) DO NOT USE WATER, including wet

dishcloths or towels - a violent steam

explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a class ABC

extinguisher, and you already know how to

operate it.

2) The fire is small and contain ed in

the area where it started.

3) The fire department is being

called.

4) You can fight the fire with your

back to an exit.

) Based on "Kitchen Firesafety Tips"

*

published by NFPA.

OPERATION

a. Always leave safety grills and filters in

place. Without these components, operating

blowers could catch onto hair, fingers and

loose clothing.

The manufacturer declines all responsibility

in the event of failure to observe the

instructions given here for installation,

maintenance and suitable use of the product.

The manufacturer further declines all

responsibility for injury due to neglige nce and

the warranty of the unit automatically expires

due to improper maintenance.

5

Electrical & Installation requirements

Electrical requirements

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsibility:

To contact a qualified electrical installer.

To assure that the electrical installation is

adequate and in conformance with National

Electrical Code, ANSI/NFPA 70 — latest

edition*, or CSA Standards C22.1-94,

Canadian Electrical Code, Part 1 and C22.2

No.0-M91 - latest edition** and all local

codes and ordinances.

If codes permit and a separate ground wire is

used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are

not sure range hood is properly grounded.

Do not have a fuse in the neutral or ground

circuit.

IMPORTANT

Save Installation Instructions for electrical

inspector’s use.

The range hood must be connected with

copper wire only.

The range hood should be connected directly

to the fused disconnect (Or circuit breaker)

box through metal electrical conduit.

Wire sizes must conform to the requirements

of the National Electrical Code ANSI/NFPA

70 — latest edition*, or CSA Standards

C22.1-94, Canadian Electrical Code Part 1

and C22.2 No. 0-M91 - latest edition** and all

local codes and ordinances.

A U.L.- or C.S.A.-listed conduit connector

must be provided at each end of the power

supply conduit (at the range hood and at the

junction box).

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

Batterymarch Park Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley

Road Cleveland, Ohio 44131-5575

Before installing the hood

1. For the most efficient air flow exhaust,

use a straight run or as few elbows as

possible.

CAUTION: Vent unit to outside of

building, only.

2. At least two people are necessary for

installation. Wear gloves to protect

against sharp edges.

3. Fittings material is provided to secure the

hood to most types of walls/ceilings,

consult a Qualified Installer, check if they

perfectly fit with your cabinet/wall.

4. COLD WEATHER installations should

have an additional backdraft damper

installed to minimize backward cold air

flow and a nonmetallic thermal break to

minimize conduction of outside

temperatures as part of the ductwork.

The damper should be on the cold air

side of the thermal break.

The break should be as close as possible

to where the ducting enters the heated

portion of the house.

5. Make up air: Local building codes may

require the use of Make-Up Air Systems

when using Ducted Ventilation Systems

greater than specified CFM of air

movement.

The specified CFM varies from locale to

locale. Consult your HVAC professional

for specific requirements in your area.

6

List of Materials

Parts supplied

• Blower unit housing

• Aesthetic covers x 3

• Stainless steel mesh filter

• Halogen light bulb x 1

• Hardware Packet:

Support bracket with cables and hooking

brackets x 1

Cover x 1

Aesthetic cover bracket x 1

Template

Use, Care and Installation Guide

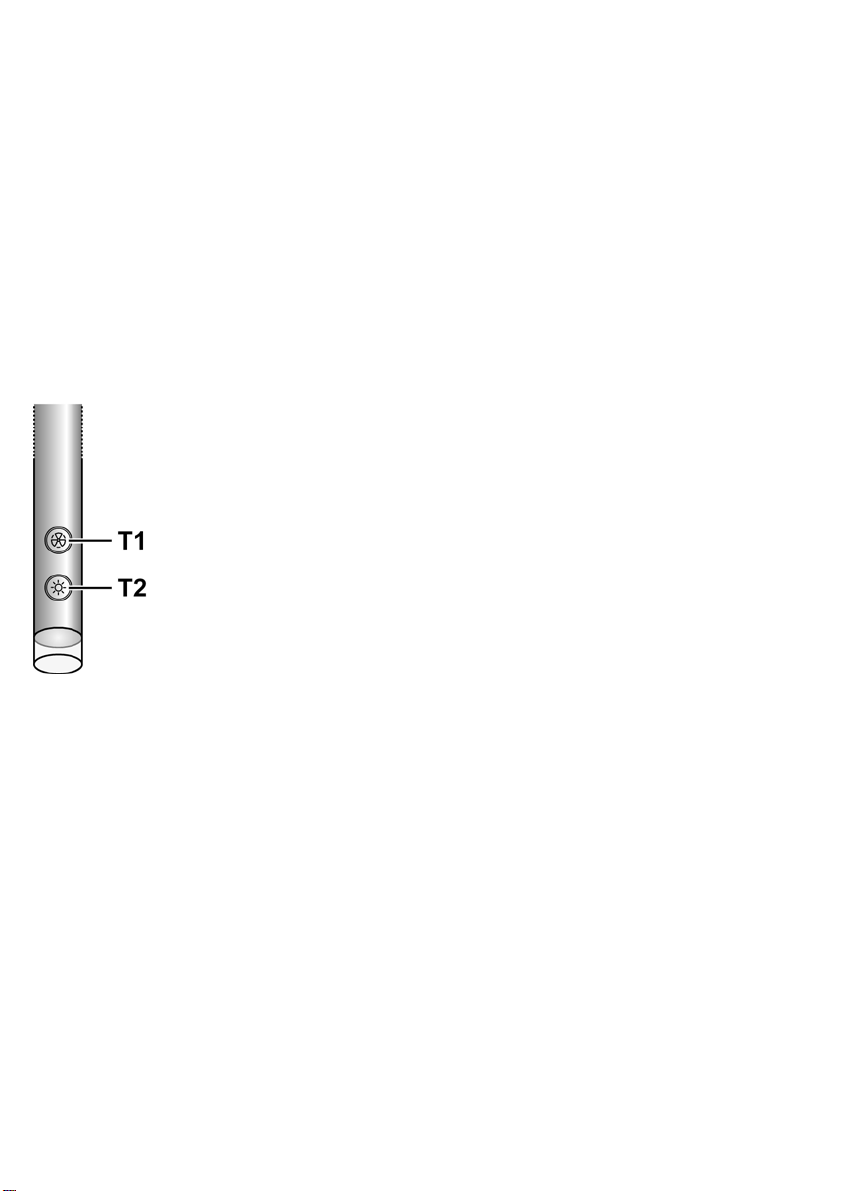

Torx adapter T10 x 1

Torx adapter T20 x 1

5x45 screws x 3 (To attach support

bracket to ceiling)

3,5x6,5 screws x 5 (2 To attach j-box to

support bracket, 3 for installing the

aesthetic cover bracket)

Knob x 6 (For fixing the aesthetic covers)

Parts not supplied

• Conduit and all tools required for

installation.

7

Dimensions and Clearances

8

Ducting Options and Examples

Closely follow the instructions set out in this manual.

All responsibility, for any eventual inconveniences, damages or fires caused by not complying

with the instructions in this manual, is declined.

Venting methods

The hood is supplied in the Ductless

(Recirculating) version and is used without

an extracted fumes discharger conduit .

Fumes and steam are recycled through the F

deflector.

Preparation

Do not cut a joist or stud unless absolutely

necessary. If a joist or stud must be cut, then

a supporting frame must be constructed.

Fittings material is provided to secure the

hood to most types of walls/ceilings.

However, a qualified technician must verify

suitability of the materials in accordance with

the type of wall/ceiling.

Before making cutouts, make sure there is

proper clearance within the ceiling or wall for

exhaust vent.

Hood installation height above cooktop is the

users preference. The lower the hood is

above the cooktop, the more efficient the

capturing of cooking odors, grease and

smoke.

CAUTION: FOR GAS RANGES

INSTALLATION: MOUNT THIS HOOD SO

THAT THE BOTTOM EDGE IS AT 30" (76,2

CM) ABOVE THE COOKING SURFACE.

FOR ELECTRIC RANGES INSTALLATION:

MOUNT THIS HOOD SO THAT THE

BOTTOM EDGE IS NOT LESS THAN 24"

(61 CM) AND NOT MORE THAT 30" (76,2

CM) ABOVE THE COOKING SURFACE.

HOUSEHOLD USE. PLEASE, READ

INSTALLATION MANUAL FOR SPECIFIC

APPLICATION.

Check your ceiling height and the hood

height maximum before you select your

hood.

9

Installation

Installation - Ductless (Recirculating) version

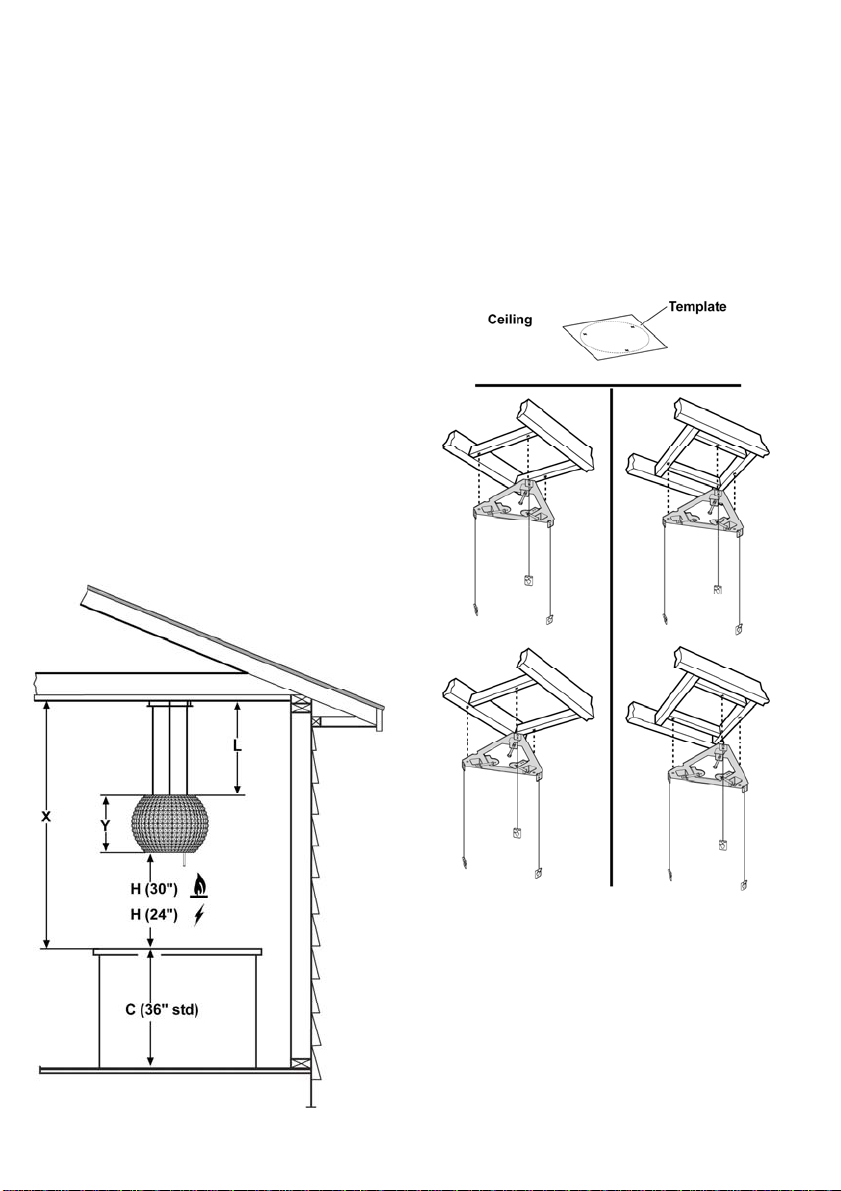

1. Pre-installation calculations

C = Counter Height (36" standard)

H = Prefered Height of Hood

Bottom above counter

L = Chimney Structure Height, your

installation.

L = X-Y-H+1" 3/16

a) Select a hood preference height H that is

comfortable for the user.

b) Calculate Hood height your installation L =

X-Y-H+1" 3/16 .

c) Confirm that H is within the range of min to

max H found for your model (See

“Dimensions and clearances” paragraph). If

not adjust your installation.

2. Preparation of mounting surface

Installing supports above ceiling drywall.

Note: Take into consideration the hood

depth; the hood could be much deeper

than the cooktop.

a. Mark center lines of cooktop or range on

ceiling above. Use centerlines marked on

ceiling to position the mounting template.

Note location of hood front (that indicated

with a printed arrow), side, and mounting

holes indicated on template.

Note: Remember that printed arrow on

10

template corresponds to front of the hood

and consequently to side where control

panels will be located at the end of

installation)

b. Remove and save template. Cut and

remove ceiling drywall. Install suitable

length 2" x 4" lumber between joists to

provide support bracket mounting points

as shown above. Use template for

dimensions and required clearance.

Make sure to affix the added lumber

firmly and level. Consult a professional if

you have difficulties or your installation is

unique. Consult template and Figs.above.

c. Install drywall; then refinish ceilin g.

Determine the required position for the

conduit and cut a 1-1/4" (3.2 cm) hole at

this location.

Run wires through hole according the

National Electrical Code or CSA

Standards and local codes and

ordinances.

d. Tape Template in place and mount the

support bracket with wood screws

(Supplied in mounting hardware kit) on

locations marked on template, then

remove template.

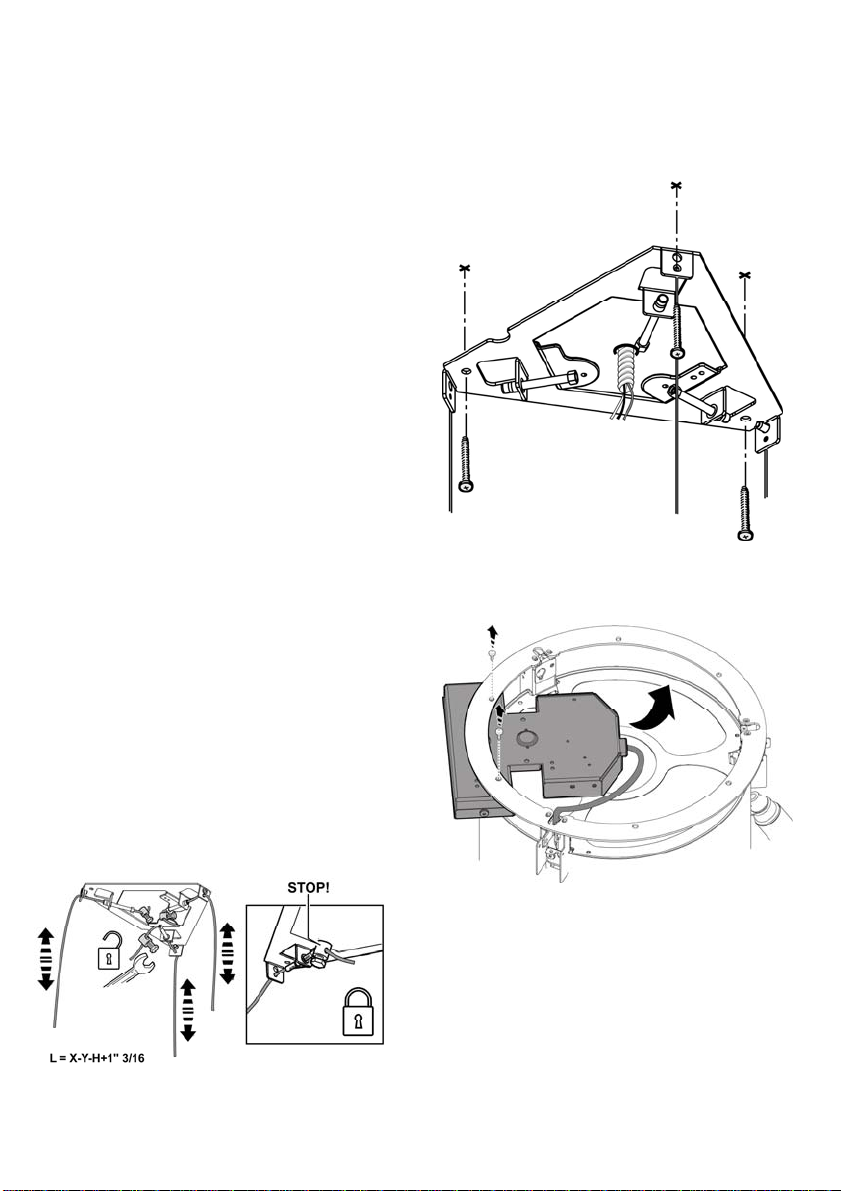

3. Prepare the support bracket, suitab ly

adjusting the length of the cables

according to the following formula:

L = X-Y-H+1" 3/16

L = truss extension

X = distance between the ceiling and the

bottom edge of the hood

After finding the right length, secure the

cables, tightening the lock nuts with a

spanner.

4. Apply the support bracket on the cei ling,

passing the cables for the electrical

connection through the middle hole.

Fix with 3 wood screws.

5. Remove the J-Box, fixed to upper bracket

to avoid damage during carriage.

11

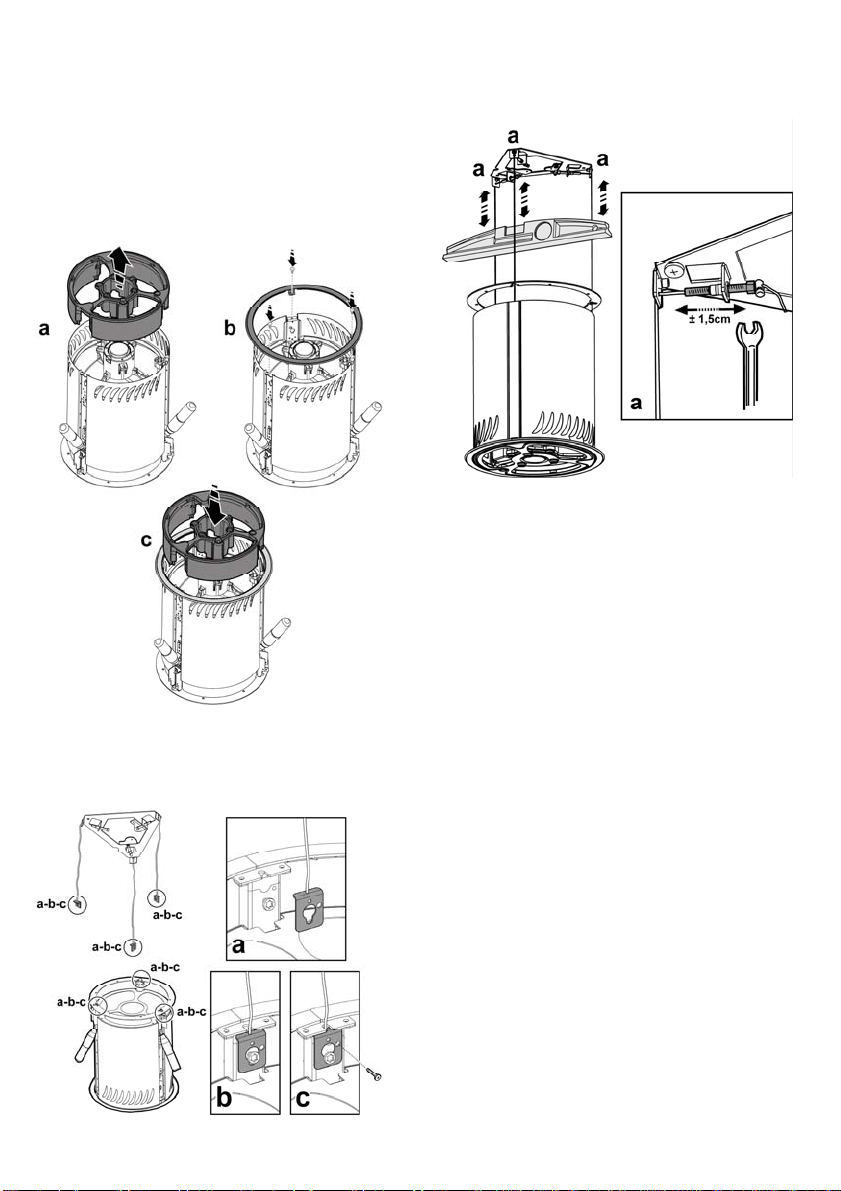

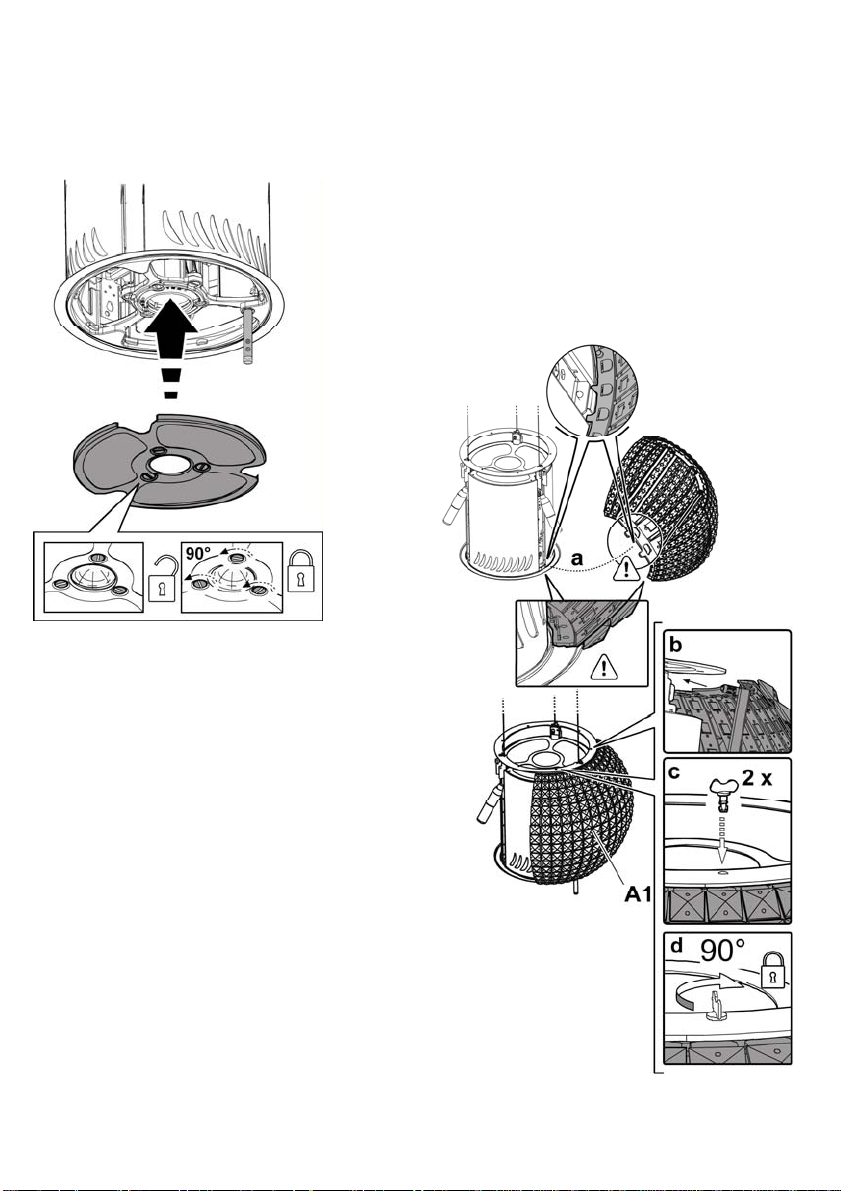

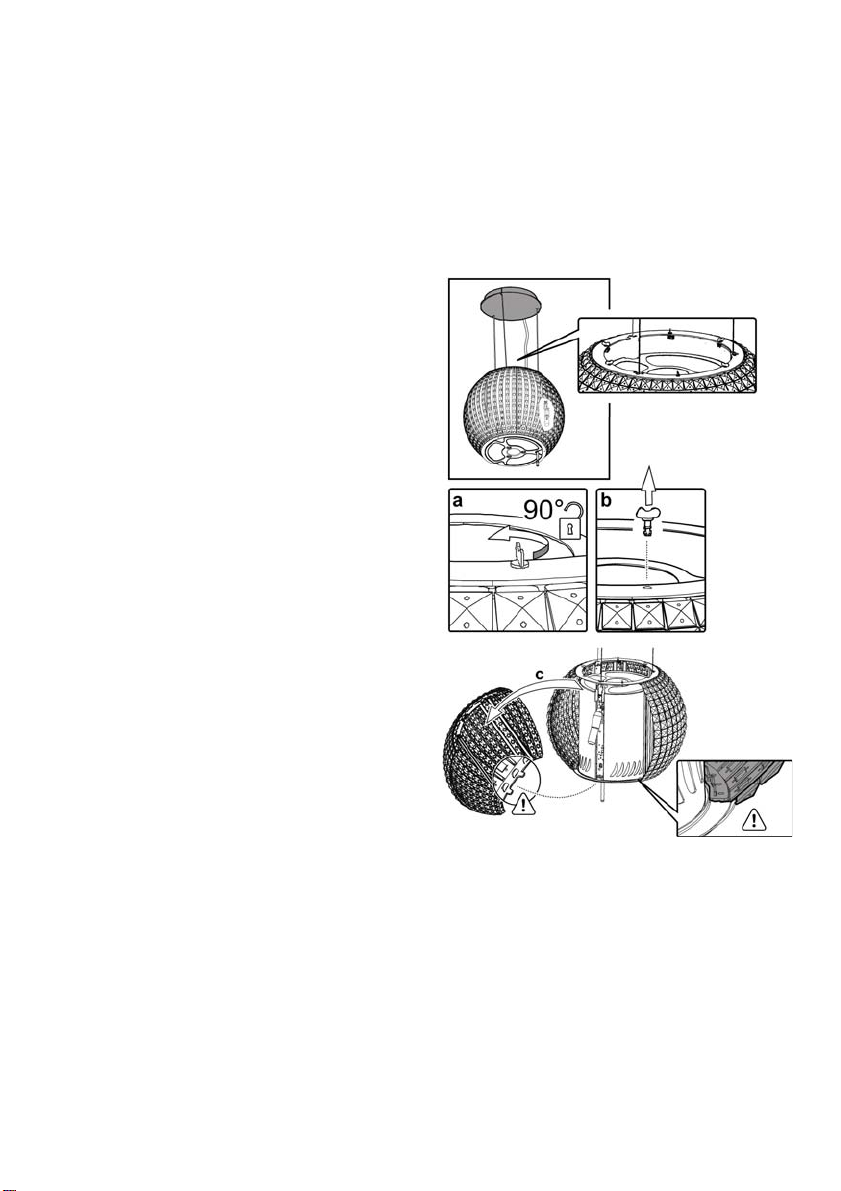

6. Turn the motor group upside down.

Remove the grease filter support rotating

the 3 fixing pins by 90°.

Install the aesthetic cover bracket and

lock it with 3 screws.

Reinstall the grease filter support rotating

the 3 fixing pins by 90°.

8. Adjust the position of the hood by means

of the adjustment screws.

7. Fix the hood to the hooking brackets and

secure with 1 screw for each bracket

(COMPULSORY FIXING).

9. Electrical connection

WARNING

Electrical Shock Hazard

Warning: Turn off power circuit at the

service panel before wiring this unit.

120 VAC, 15 or 20 Amp circuit

required.

ELECTRICAL GROUNDING

INSTRUCTIONS

THIS APPLIANCE IS FITTED WITH AN

ELECTRICAL JUNCTION BOX WITH 3

WIRES, ONE OF WHICH

(GREEN/YELLOW) SERVES TO

GROUND THE APPLIANCE. TO

PROTECT YOU AGAINST ELECTRIC

SHOCK, THE GREEN AND YELLOW

WIRE MUST BE CONNECTED TO THE

GROUNDING WIRE IN YOUR HOME

ELECTRICAL SYSTEM, AND IT MUST

UNDER NO CIRCUMSTANCES BE CUT

OR REMOVED.

Failure to do so can result in death or

electrical shock.

12

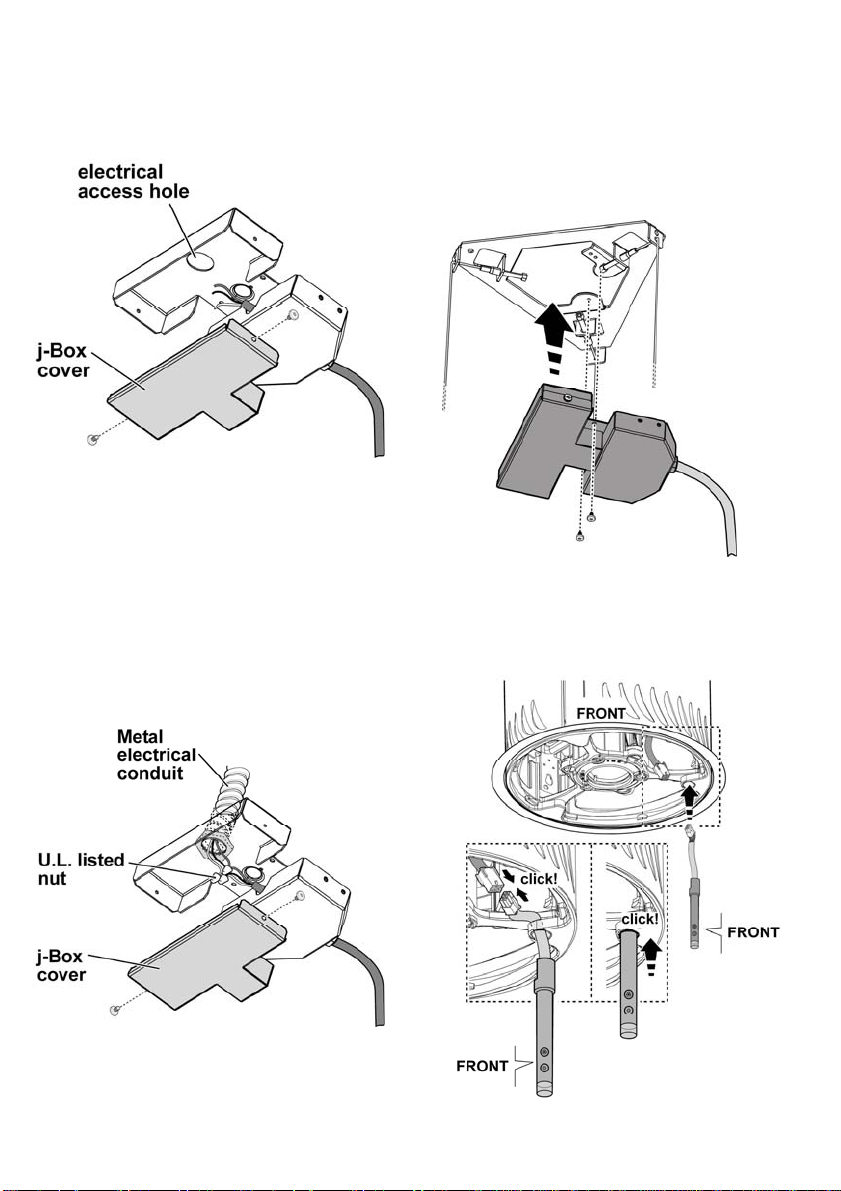

Remove the Junction box cover and

install the conduit connector (cULus

listed) in junction box.

12. Fix the junction box to the support bracket

on the ceiling with 2 screws.

Important! Replacement of the

interconnection cable must be carried out

by the authorised after-sales technical

service.

10. Run 3 wires; black, white and green

,according to the National Electrical Code

and local codes and ordinances, in 1/2"

conduit from service panel to junction

box.

11. Connect black wire from service panel to

black or red in junction box, white to white

and green to green-yellow.

Close and secure junction box cover.

13. Fit the control shaft in the correct position

by pushing it upwards.

Connect the electricity.

13

14. Insert the grease filter.

For locking, rotate the 3 fixing pins by

90°.

15. Apply the aesthetic covers.

For proper installation, insert the lower

tongues into the appropriate seat.

Fix the upper part inserting and rotating

the 2 knobs by 90°.

Repeat the operation for all the aesthetic

covers to be installed.

ATTENTION! Pay particular attention to the

position of the excess cable; the nonobservance of this direction might cause

serious damage to the appliance and/or

electrical shocks to the user or the installer.

14

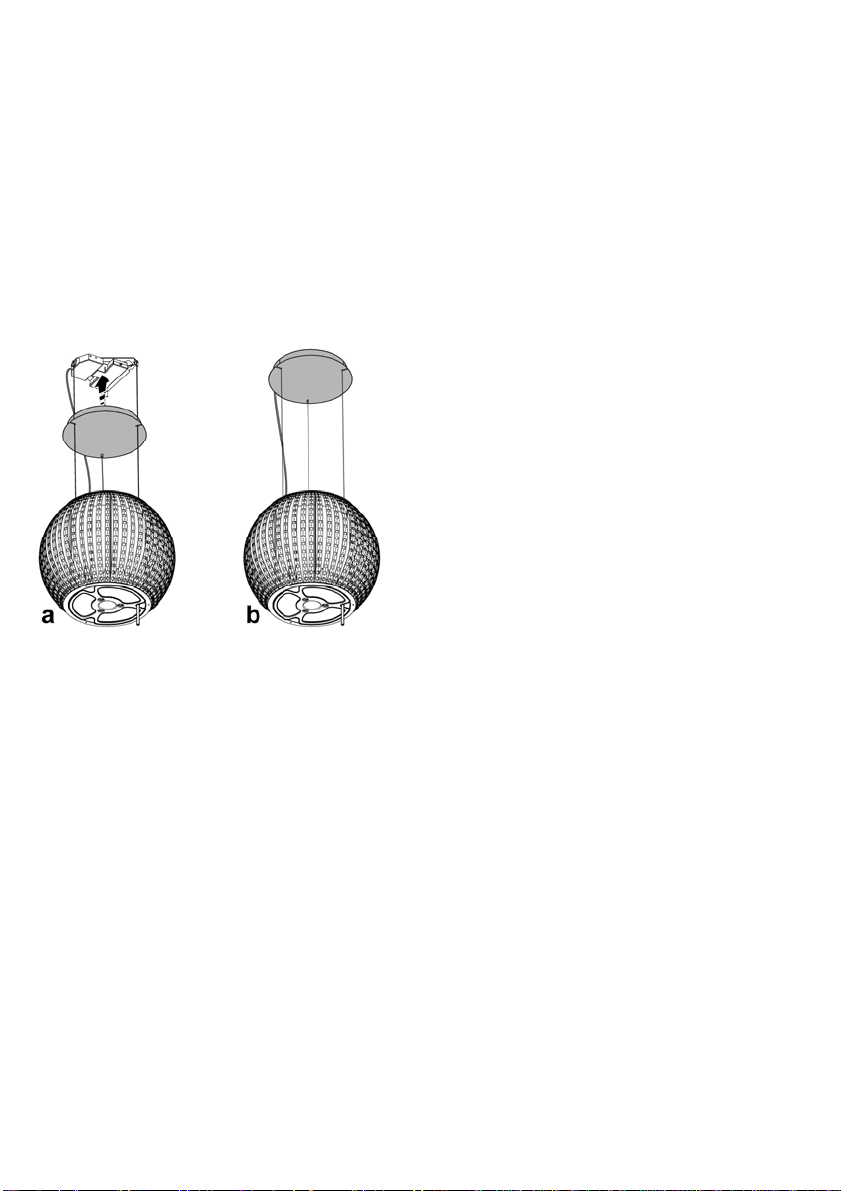

16. Insert the cover between the support

cables, making sure they enter the

special slots on the cover.

Important! Leave enough cable so that it

passes easily through the slot obtained in

the cover.

Secure the cover with 3 grub screws

already screwed on the support bracket.

Note: The 3 fixing screws secure the

cover by virtue of the friction they exert on

the cover itself, and therefore must not be

completely tightened.

17. Check all light bulbs to make sure they

are secure in their sockets.

Turn power (On) in service panel.

Check lights and blower operation.

If range hood does not operate:

• Check that the circuit breaker is not

tripped or the house fuse blown.

• Disconnect power supply. Check that

wiring is correct.

To get the most efficient use from your

new range hood, read the “Use and Care

Information” section.

Keep your Installation Instructions and

Use and Care Guide close to range hood

for easy reference.

15

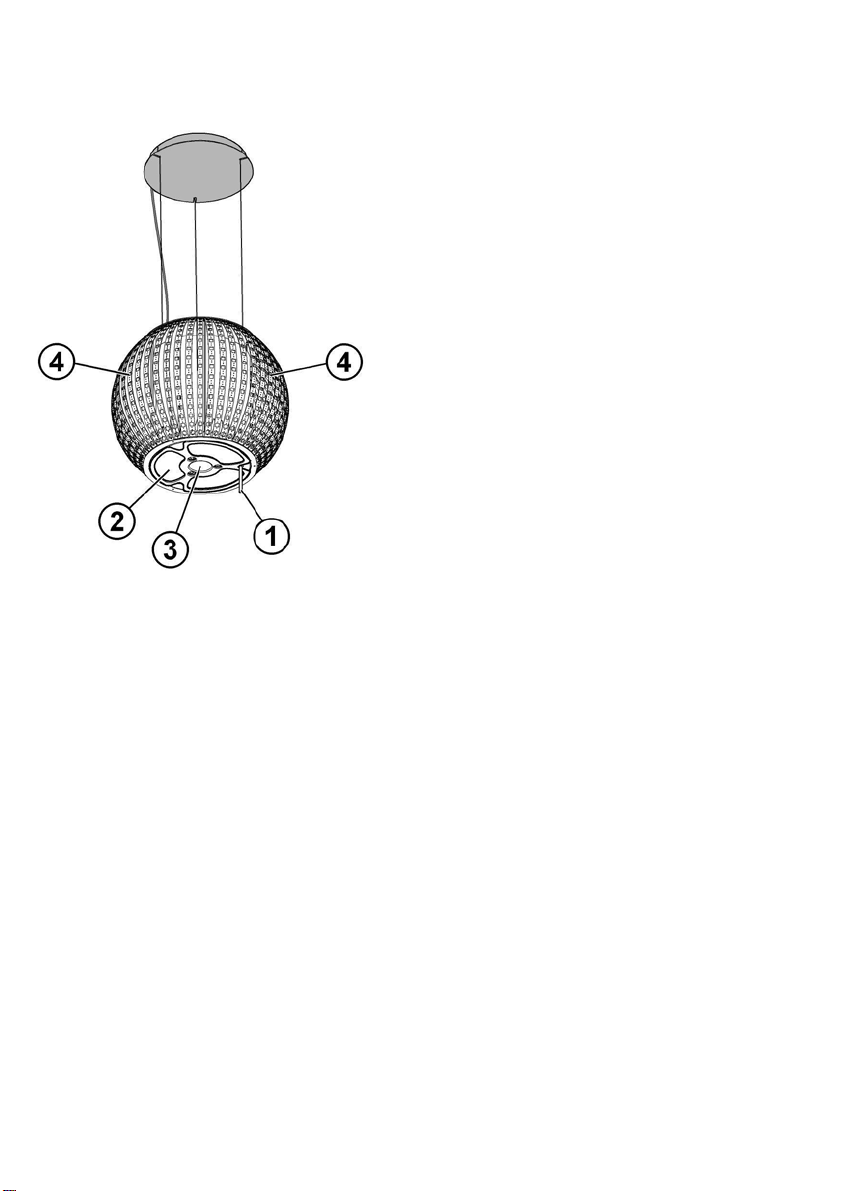

Description of the hood & Controls

1 Control panel

2 Grease filter

3 Halogen lamp

4 Aesthetic cover

16

Controls

Use the high suction speed in cases of

concentrated kitchen vapours. It is

recommended that the cooker hood suction

is switched on for 5 minutes prior to cooking

and to leave in operation during cooking and

for another 15 minutes approximately after

terminating cooking.

Description of control panel

The hood is equipped with a “TOUCH”

device to control the lights and speed.

For the correct use please carefully read th e

intructions below.

Automatic start-up function

The hood is equipped with a temperature

sensor which activates the motor to the first

suction speed (power) in the event that the

room temperature in the surrounding area is

higher than 70°C.

The user may switch off or modify the suction

speed (power) (see paragraph “suction

speed (power) control”).

Suction speed (power) control

The suction speed (power) is cyclical

depending on the speed sequence “stand-by

– 1-2-3-4- Stand by -1-2-...” therefore every

time the T1 button is pressed on the control

panel, the suction speed (power) is increased

by one level, in order to switch off (stand-by)

if the button is pressed again when the hood

is in suction speed (power) 4.

The hood may be switched off (stand-by)

while the hood is set on any speed by

holding down the T1 button on the control

panel for a bit longer (more than 3 seconds).

The hood's suction speed (power) may be

determined as the control panel is equipped

with a LED light that changes colors as

follows, depending on the suction speed

(power):

Hood in stand-by: LED LIGHT SWITCHED

OFF

1st suction speed (power) -GREEN LED

LIGHT

2nd suction speed (power) – ORANGE

LED LIGHT (amber)

3rd suction speed (power) - RED LED

LIGHT

4th suction speed (power) - RED LED

LIGHT (FLASHING)

Note: The 4th suction speed (power) stays

on for 5 minutes, after which the suction

motor will position itself on the 2nd speed.

If pressed again, the suction motor will switch

off (stand-by).

Grease filters need cleaning: FLASHING

GREEN LED light (read instructions found

under “Reset and configuration for filter

saturation signal”)

Coal filters must be cleaned or replaced:

FLASHING ORANGE (amber) LED light

(read instructions found under “Reset and

configuration for filter saturation signal”)

Note: The reset procedure may be activated

by both the control panel and the remote

control.

Center light check

The center light may be switched on and off

by pressing the T2 button on the control

panel.

Side light check (when scheduled)

The side lights may be switched on and off

by pressing AND HOLDING DOWN the T2

button on the control panel.

17

Reset and configuration for filter

saturation signal

Switch on hood to any speed (see above

paragraph “Suction speed (power) selection”)

Reset grease filter saturation signal

(FLASHING GREEN LIGHT on control

panel)

First proceed with filter maintenance as

described in corresponding paragraph.

Press and hold down (for more than 3

seconds) the T1 button on the control panel,

the LED light will stop flashing indicating that

the signal reset has been carried out, the

hood will switch off.

Reset coal filter saturation signal

(FLASHING ORANGE (amber) LED light)

First proceed with filter maintenance as

described in corresponding paragraph.

Press and hold down (for more than 3

seconds) the T1 button on the control panel,

the LED light will stop flashing indicating that

the signal reset has been carried out, the

hood will switch off.

Coal filter saturation signal disactivaction

(for particular applications)

Switch off hood (see above paragraph

“suction speed (power) selection”).

Press and hold down (for more than 5

seconds) the T1 button on the control panel,

the LED light will start flashing GREEN

indicating that the coal filter saturation signal

has been disactivated.

In order to reactivate the coal filter saturation

signal, repeat operation, the LED light will

flash ORANGE (amber)

18

User Servicing and Maintenance Instructions

ATTENTION! Before performing any maintenance operation, isolate the hood from the electrical

supply by switching off at the connector and removing the connector fuse.

Or if the appliance has been connected through a plug and socket, then the plug must be

removed from the socket.

Cleaning

The cooker hood should be cleaned reg ularly

(at least with the same frequency with which

you carry out maintenance of the fat filters)

internally and externally. Clean using the

cloth dampened with neutral liquid detergent .

Do not use abrasive products. DO NOT USE

ALCOHOL!

WARNING: Failure to carry out the basic

cleaning recommendations of the cooker

hood and replacement of the filters may

cause fire risks.

Therefore, we recommend oserving these

instructions.

The manufacturer declines all responsibility

for any damage to the motor or any fire

damage linked to inappropriate maintenance

or failure to observe the above safety

recommendations.

To clean the aesthetic covers, dismantle

them and wash them by hand in hot water

and neutral detersives.

19

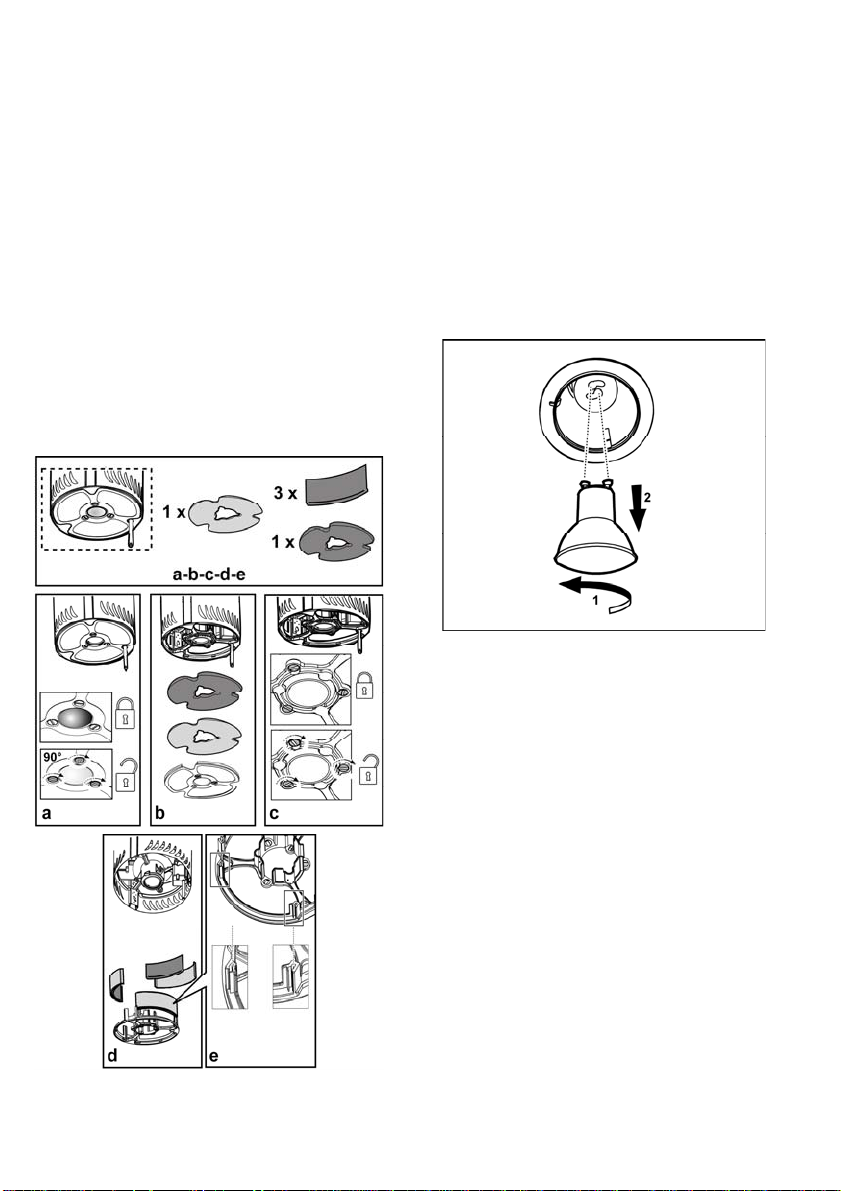

Grease Filter

Traps cooking grease particles.

The grease filter must be cleaned once a

month using non aggressive detergents,

either by hand or in the dishwasher, which

must be set to a low temperature and a short

cycle. When washed in a dishwasher, the

grease filter may discolour slightly, but this

does not affect its filtering capacity.

The metal grease filter and the carbon filter

are installed coupled at the bottom

(extraction area).

To remove or refit them, proceed as follows:

a+c. turn the three screws 1/4 turn.

b+d+e. remove the filter holder frame and

the metal grease filter (and the carbon filter).

Proceed in reverse order to refit.

Replacing the light bulb

Disconnect the hood from the electricity.

Warning! Prior to touching the light bulbs

ensure they are cooled down.

Replace Lights

• Remove the damaged light (twist counter

clockwise) and replace with a new 120

Volt, 50 Watt (maximum) 50° halogen

light made for a GU10 base, suitable for

use in open luminarie.

Some models envisage lateral lamps:

Replace them with identical forms of 40W

(E12) max).

Remove cover to access the lamp housing.

If the lights do not work, make sure that the

lamps are fitted properly into their housings

before you call for technical assistance.

Charcoal Filter

It absorbs unpleasant odours caused by

cooking.

The charcoal filter can be washed once every

two months using hot water and a suitable

detergent, or in a dishwasher at 65°C (if the

dishwasher is used, select the full cycle

function and leave dishes out).

Eliminate excess water without damaging the

filter, then remove the mattress located

inside the plastic frame and put it in the oven

for 10 minutes at 100° C to dry completely.

Replace the mattress every 3 years and

when the cloth is damaged.

20

Loading...

Loading...