Page 1

Use, Care, and Installation Guide

Guide d’utilisation, d’entretien et d’installation

Guía de instalación, uso y mantenimiento

READ AND SAVE THESE INSTRUCTIONS

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

LEA Y GUARDE ESTAS INSTRUCCIONES

LIB0107214A

02/17

Page 2

EN

Contents

page

2

FR

ES

Sommaire

Contenido

page

página

16

30

English

Contents

Important safety Notice................................................................................. 3

Electrical & Installation requirements ........................................................... 4

Before installing the hood ............................................................................. 4

List of Materials............................................................................................. 5

Parts supplied .............................................................................................. 5

Parts not supplied ........................................................................................ 5

Product Dimensions...................................................................................... 5

Countertop Cutout Dimensions................................................................... 6

Venting Requirements................................................................................... 6

Installation Instructions ................................................................................. 7

Determine which vent directioin is best for your installation ......................... 8

Rear mounting (reversible mode) ................................................................. 9

Complete Installation .................................................................................... 10

Control Installation ....................................................................................... 11

Electrical connection..................................................................................... 11

Check operation............................................................................................ 12

Downdraft use............................................................................................... 13

Vent system care........................................................................................... 13

Troubleshooting ............................................................................................ 14

Warranty ....................................................................................................... 15

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE

PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local

Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit

for the owner.

OWNER: Please retain these instructions for future

reference.

Safety Warning: Turn off power circuit at service panel and

lock out panel, before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit

2

Page 3

READ AND SAVE THESE INSTRUCTIONS

Important Safety Notice

CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS OR

VAPOURS.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer.

B. Before servicing or cleaning the unit, switch power off at service

panel and lock service panel disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

C. Installation work and electrical wiring must be done by qualied

person(s) in accordance with all applicable codes & standards,

including re-rated construction.

D. Sufcient air is needed for proper combustion and exhausting of

gases through the ue (Chimney) of fuel burning equipment to

prevent back- drafting. Follow the heating equipment

manufacturers guideline and safety standards such as those

published by the National Fire Protection Association (NFPA), the

American Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

E. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

F. Ducted systems must always be vented to the outdoors.

CAUTION

To reduce risk of re and to properly exhaust air, be sure to duct

air outside - do not vent exhaust air into spaces within walls,

ceilings, attics, crawl spaces, or garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT WORK.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE.

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

ambeing food (i.E. Crepes suzette, cherries jubilee, peppercorn

beef ambe’).

c) Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or lter.

d) Use proper pan size. Always use cookware appropriate for the

size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:

a) SMOTHER FLAMES with a close-tting lid, cookie sheet, or other

metal tray, then turn off the gas burner or the electric element. BE

CAREFUL TO PREVENT BURNS. If the ames do not go out

immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - you may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a class ABC extinguisher, and you already

know how to operate it.

2) The re is small and contained in the area where it started.

3) The re department is being called.

4) You can ght the re with your back to an exit.

a

Based on “Kitchen Fire Safety Tips” published by NFPA.

a

OPERATION

a. Always leave safety grills and lters in place. Without these components, operating blowers could catch onto hair, ngers and loose

clothing.

Install this hood in accordance with all requirements specied.

WARNING

To reduce the risk of re or electric shock, do not use this hood

with any external solid state speed control device.

The manufacturer declines all responsibility in the event of failure to

observe the instructions given here for installation, maintenance and

suitable use of the product. The manufacturer further declines all

responsibility for injury due to negligence and the warranty of the unit

automatically expires due to improper maintenance.

3

Page 4

Electrical & Installation requirements

Electrical requirements

IMPORTANT

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in conformance

with National Electrical Code, ANSI/NFPA 70 (latest edition), or CSA

Standards C22.1-94, Canadian Electrical Code, Part 1 and C22.2 No.

0-M91 (latest edition) and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended that a qualied electrician determine that the ground path is

adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• A 120 volt, 60 Hz., AC only, 15-amp, fused electrical circuit is

required.

• If the house has aluminum wiring, follow the procedure below:

1. Connect a section of solid copper wire to the pigtail leads.

2. Connect the aluminum wiring to the added section of copper wire

using special connectors and/or tools designed and UL listed for

joining copper to aluminum.

Follow the electrical connector manufacturer’s recommended

procedure. Aluminum/copper connection must conform with local

codes and industry accepted wiring practices.

• Wire sizes and connections must conform with the rating of the

appliance as specied on the model/serial rating plate. The model

serial plate is located on the front of the downdraft vent, above the

wiring box cover.

• Wire sizes must conform to the requirements of the National

Electrical Code, ANSI/NFPA 70 (latest edition), or CSA Standards

C22. 1-94, Canadian Electrical Code, Part 1 and C22.2 No. 0-M91

(latest edition) and all local codes and ordinances.

Before installing the hood

NOTE: Downdraft vent is installed directly behind the cooktop.

Install the downdraft vent rst, then install the cooktop.

IMPORTANT: Observe all governing codes and ordinances.

• Have a qualied technician install the downdraft vent. It is the

installer’s responsibility to comply with installation clearances

specied on the model/serial rating plate. The model/serial rating

plate is located on the front of the downdraft vent above the

terminal box cover.

• Downdraft vent location should be away from strong draft areas,

such as windows, doors, and strong heating vents or fans.

• Cabinet opening dimensions that are shown must be used. Given

dimensions provide minimum clearance.

• Consult the cooktop manufacturer installation instructions before

making any cutouts.

• Check that the downdraft vent and cooktop location will clear the

cabinet walls, backsplash, and rear wall studs inside the cabinet.

• Check for the minimum distance between the front edge of the

countertop and the front edge of the cooktop. The minimum

horizontal distance between the overhead cabinets is the same as

the width of the installed downdraft vent.

• All openings in ceiling and wall where the downdraft vent will be

installed must be sealed.

• Grounded electrical outlet is required. See “Electrical

Requirements” section.

• When installing the downdraft vent, the cabinet drawer will need to

be removed and the drawer front installed permanently to the

cabinet.

Cabinet Construction:

Downdraft vent is designed for use in a cabinet with a depth of

24” (61 cm). Some installations require a countertop deeper than

25” (63.5 cm). See the “Countertop Cutout Dimensions Chart.”

The maximum depth of the overhead cabinet is 13” (33 cm).

Overhead cabinets installed at either side of the downdraft vent

must be 18” (45.7 cm) above the cooking surface.

For Mobile Home Installations

The installation of this downdraft vent must conform to the

Manufactured Home Construction Safety Standards, Title 24

CFR, Part 328 (formerly the Federal Standard for Mobile Home

Construction and Safety, title 24, HUD, Part 280) or when such

standard is not applicable, the standard for Manufactured Home

Installation 1982 (Manufactured Home Sites, Communities and

Setups) ANSI A225.1/NFPA 501A, or latest edition, or with local

codes.

4

Page 5

List of Materials

Removing the packaging

CAUTION!

Remove carton carefully, wear gloves to protect against sharp edges.

WARNING!

Remove the protective lm covering the product before putting into

operation.

Parts supplied

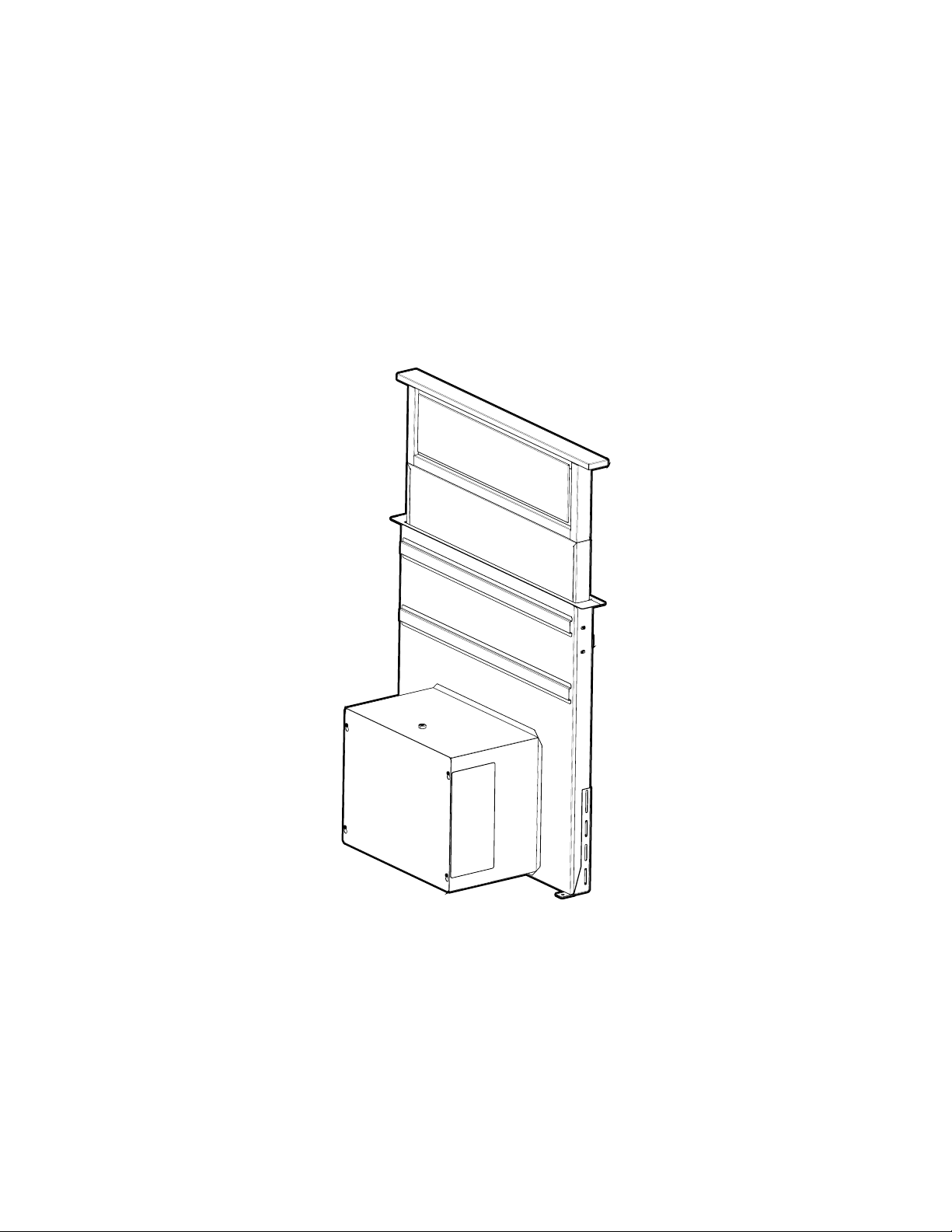

• Downdraft assembly with blower already installed

• Metal grease lters

• 2 - Lower support legs

• 2 - End caps

• 6” round air transition

1

• 3

⁄4”x10” rectangular air transition

• Metalic top trim

• Control assembly

• Hardware bag with:

• Use, care and installation guide

• Plastic control base

• 1 - Shrinkable wire tube

• 2 - Plastic wire ties

• 2 - Installation brackets

• 4 - Plastic clips for aspiration plate

• 7 - Adhesive wire clips

• 8 - 4 x 8 mm mounting screws

• 11 - 4.5 x 13 mm mounting screws

• 3 - 3.5 x 9.5 mm transition mounting screws

Parts needed

• Home power supply cable

• ½” (12.7 mm) UL listed or CSA approved strain relief

• 3 UL listed wire connectors

• 1 wall or roof cap

• 6” round metal vent system or 3

1

⁄4”x10” rectangular vent system

Tools/Materials required

• Level

• Drill with 1¼” (3.2 cm),⅛” (3.2 mm), and

drill bits

• Pencil

• Wire stripper or utility knife

• Tape measure or ruler

• Pliers

• Caulking gun and weatherproof caulking compound

• Vent clamps

• Jigsaw or keyhole saw

• Flat-blade screwdriver

• Metal snips

5

⁄16” (7.9 mm)

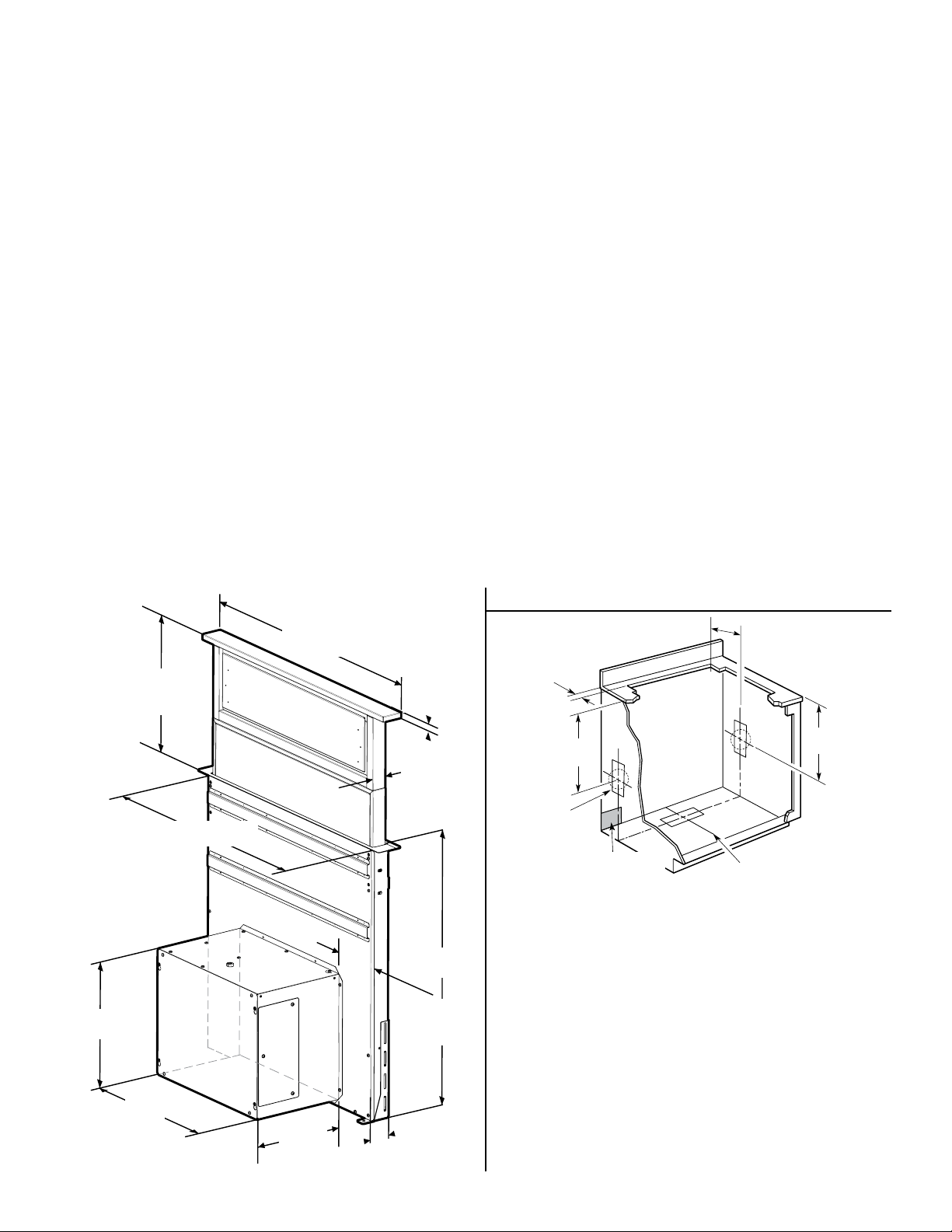

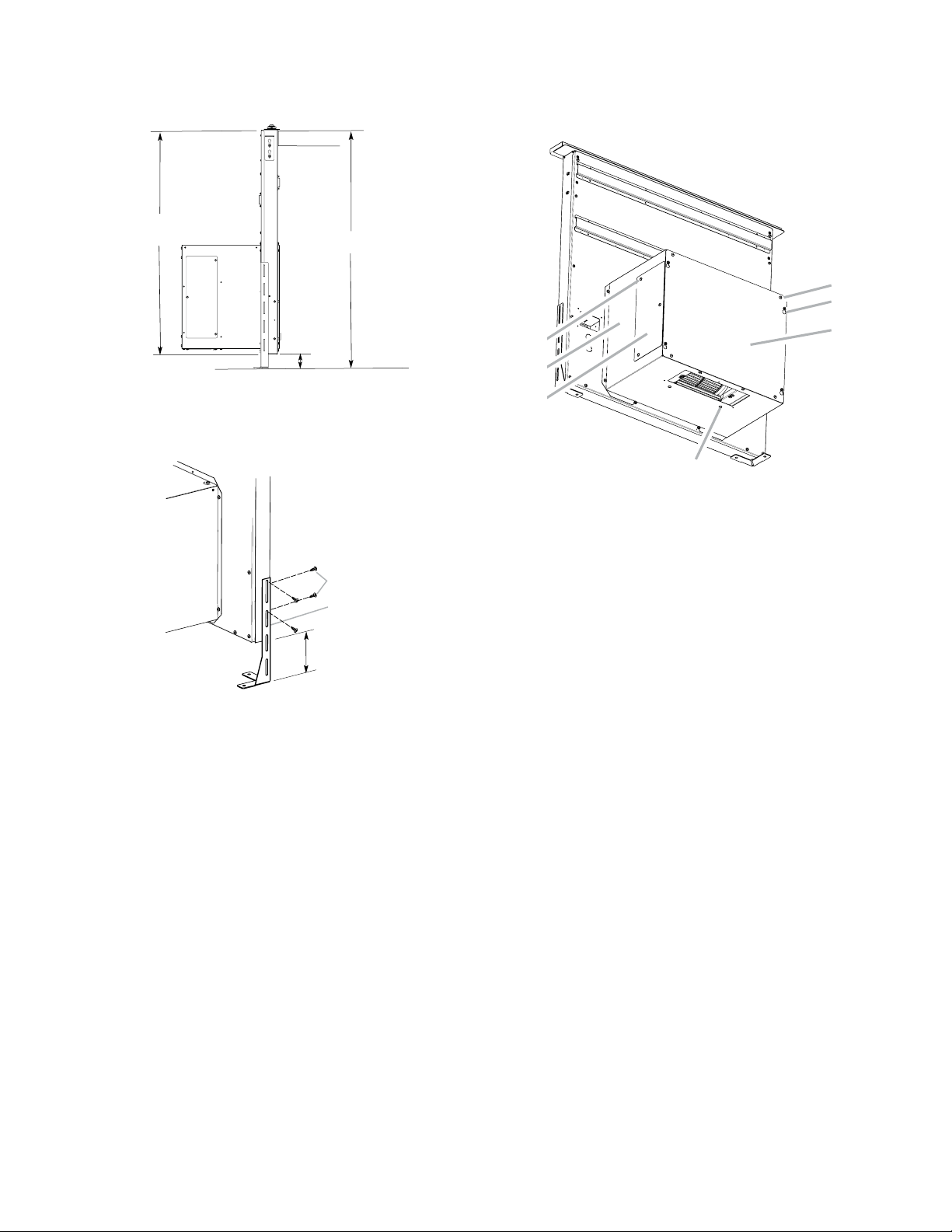

131⁄8”

(33.4 cm)

131⁄2” (34.3 cm)

retractable

vent height

27” (68.6 cm) for 30” model

33” (83.8 cm) for 36” model

Top trim widths:

30” (76.2 cm)

36” (91.4 cm)

Product Dimensions

Cabinet Dimensions

1

⁄2” (1.27 cm)

19

⁄32”

(1.5 cm)

11⁄2”

(3.8 cm)

281⁄2”

(72.6 cm)

51⁄4” (13.3 cm)

for 30” models

81⁄4” (21 cm)

for 36” models

rectangular or 6”

(15.2 cm) round

NOTES:

• See cooktop manufacturer’s instructions for cooktop cutout

depth and width.

• Use dimensions for vent system cutout location that applies to

your installation.

• Interior mounted blower systems connect with 3

(8.3 x 25.4 cm) rectangular or 6” (15.2 cm) round vent system.

The cutout locations for this vent system will depend on your

specic installation.

minimum

Cutouts are

for 31⁄4” x 10”

(8.3 x 25.4 cm)

vent system.

215⁄16”

(54.1 cm)

Locate power supply

junction box at lower

left hand rear corner

of the cabinet.

91⁄2”

(24.4 cm)

Centerline of

cooktop cutout

215⁄16”

(54.1 cm)

1

⁄4” x 10”

161⁄2”

(42 cm)

10”

(25.4 cm)

21⁄8”

(5.4 cm)

5

Page 6

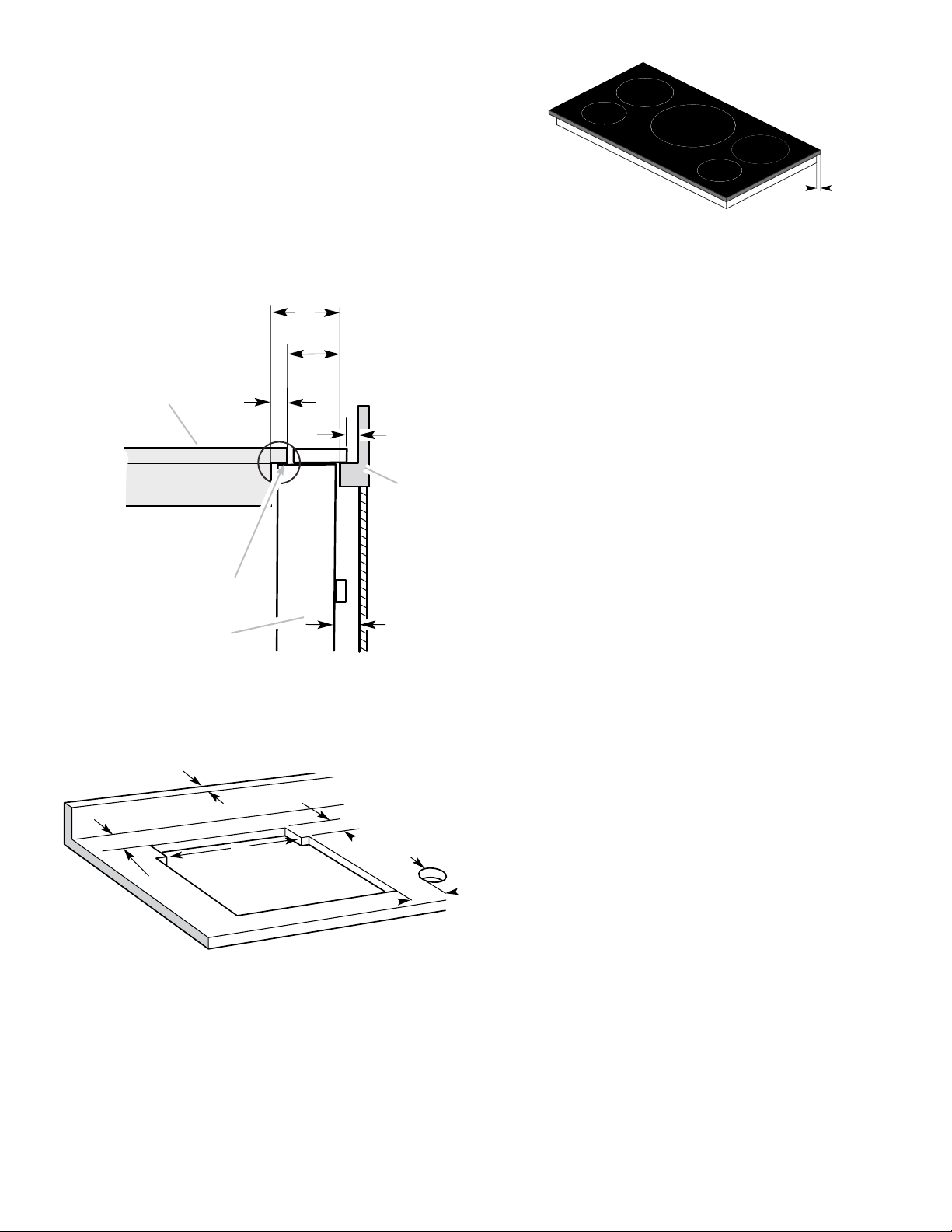

Countertop Cutout Dimensions

IMPORTANT: Countertops with a bull-nosed front edge are not rec-

ommended for these installations.

Some models require a countertop deeper than 25” (63.5 cm); see the

following “Countertop Cutout Dimensions Chart.”

To avoid mistakes, it is recommended that the cooktop and vent

cutouts be drawn on the countertop before making any cutouts.

See the Installation Instructions that came with your cooktop for complete cutout dimensions, location dimensions and installation

details.

NOTE: In order to avoid any possible whistle problem, it is recommended to keep at minimum the distance between the cooktop and

the downdraft vent (I). It is recommended a sealer application in that

area.

D

E

B

A. Downdraft vent

B. Cooktop

C.Measurement of cooktop rear overhang

D. D = Measurement of cooktop rear overhang (C) + 2

1

⁄2” [61 mm] (E)

C

F

G

I

A

E. 21⁄2” (61 mm)

F.¼” (6.4 mm) minimum

G. Countertop and backsplash

H. ½” (12.7 mm) minimum

I. Seal the cooktop / downdraft joint

H

Countertop Cutout Dimensions Chart

B

D

C

A

F

G

E

A. ½” (12.7 mm) minimum to backsplash or

rear wall

3

B.

⁄4” (19.1 mm) maximum backsplash depth

C. 27½” (69.9 cm) on 30” (76.2 cm) models

33½” (85.9 cm) on 36” (91.4 cm) models

D. D = E+ 21⁄2” (61 mm)

E. Cooktop rear overhang

F. Ø 29⁄16” (6.5 cm). The control can be

installed in both left or right sides.

G. Minimum distance from cooktop 4” (10 cm)

maximum distance from cooktop 8” (20 cm)

Venting Requirements

IMPORTANT: Make sure there is proper clearance within the wall

or oor before making exhaust vent cutouts.

• Use heavy (rigid) metal vent.

• Venting system must terminate to the outside.

• Do not terminate the vent system in an attic or other enclosed

area.

• Do not use 4” (10.2 cm) laundry-type wall caps.

• Do not install 2 elbows together.

• Do not use plastic or metal foil vent.

• The length of vent system and number of elbows should be

kept to a minimum to provide efcient performance.

• Use no more than three 90° elbows

• Make sure there is a minimum of 24” (61 cm) of straight vent

between the elbows if more than one elbow is used.

• Use clamps or duct tape to seal all joints in the vent system.

• Use caulking tape to seal the exterior wall or oor opening

around cap.

• Do not cut joist or stud. If vent cutout falls over a joist or stud,

a supporting frame must be constructed.

• Flexible metal vent is not recommended. If it is used, calculate

each foot of exible vent as 2 ft (0.6 m) of rigid metal vent.

Flexible elbows count twice as much as standard elbows.

Cold Weather Installations

An additional back draft damper should be installed to minimize

backward cold air ow and a thermal break should be installed to

minimize conduction of outside temperatures as part of the vent

system. The damper should be on the cold air side of the thermal

break.

The break should be as close as possible to where the vent

system enters the heated portion of the house.

Makeup Air

Local building codes may require the use of makeup air systems

when using ventilation systems greater than specied CFM of air

movement. The specied CFM varies from locale to locale.

Consult your HVAC professional for specic requirements in your

area.

6

Page 7

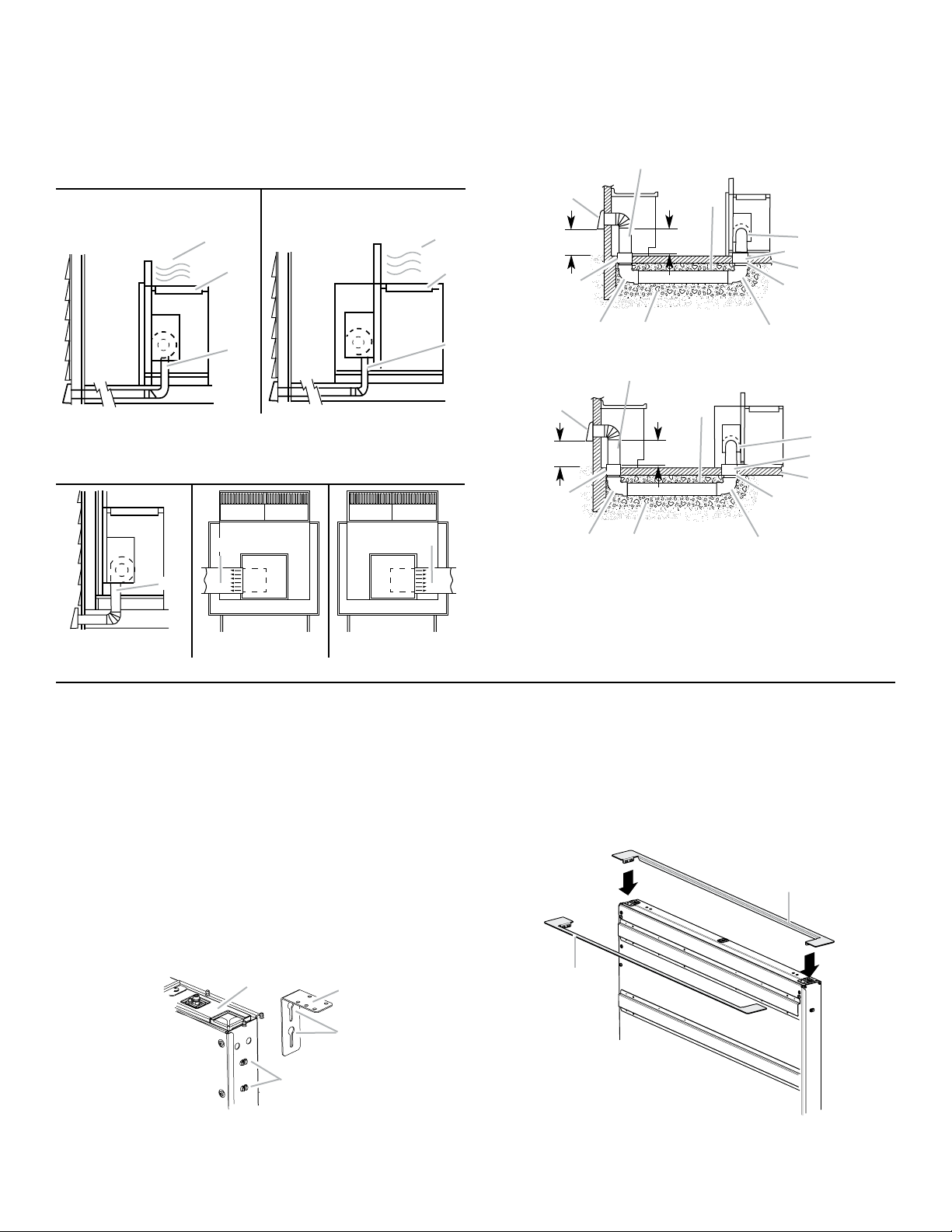

Installation Instructions

Venting Methods

Determine which venting method is best for your application.

Vent system can terminate either through the wall or oor.

Island locations

Front (standard) mounted

blower motor

C

Rear mounted blower motor

(Reversible version)

B

A

Island locations

Vent systems installed under a concrete slab using PVC sewer

pipe.

Front (standard) mounted blower motor

B

A

C

B

L

K J I

A

Rear mounted blower motor (reversible aspiration plate)

B

D

CM

F

H

E

G

A. Down vent

B. Cooktop

C. Aspiration plate

Built-in cabinet locations

B

A

A. Down vent B. Left vent C. Right vent

C

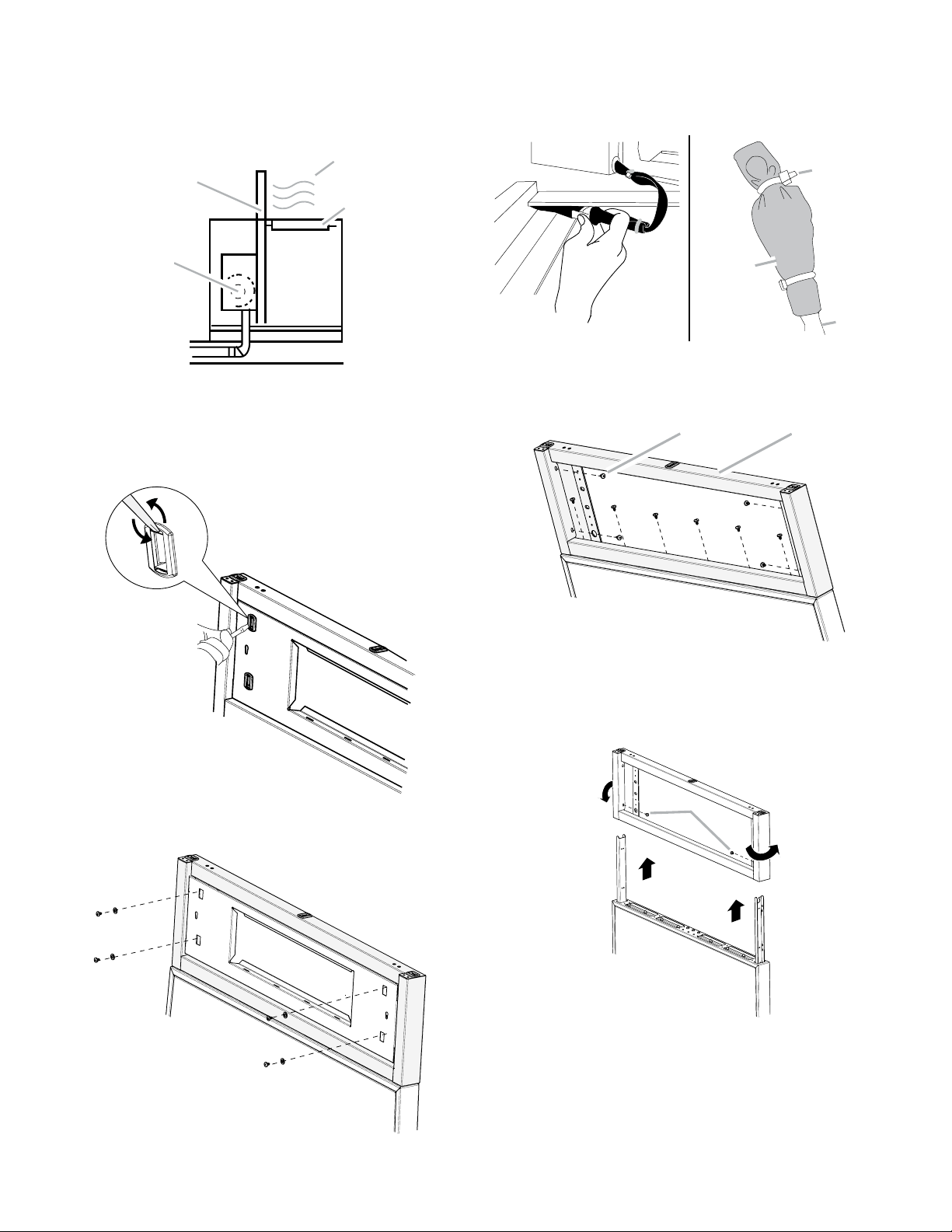

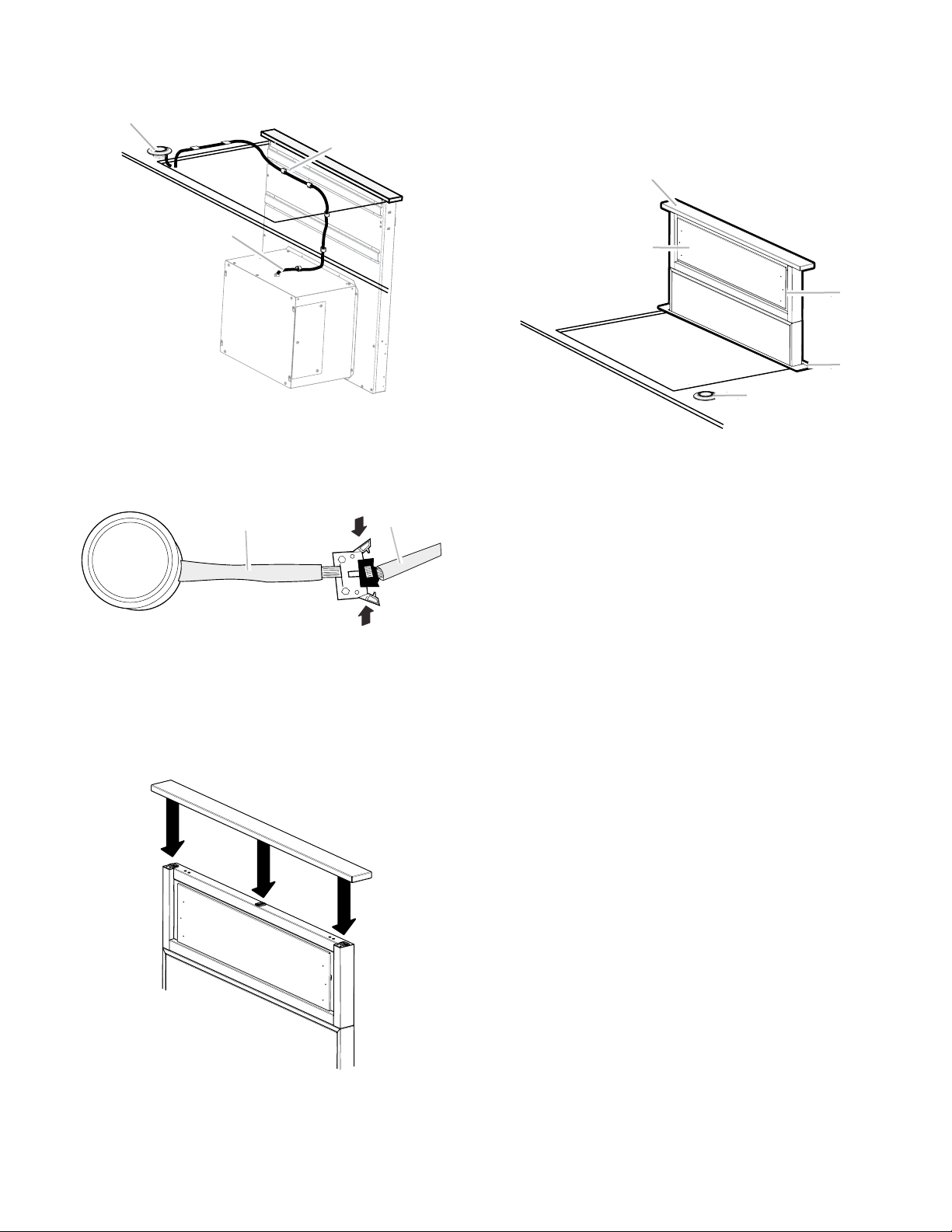

Installing the vent system

WARNING

Excessive Weight Hazard

Use two or more people to move and install downdraft vent.

Failure to do so can result in back or other injury.

1. Place cardboard or similar material on top of a at surface where

you can easily assemble the downdraft vent system.

2. Remove parts packages, downdraft vent and blower box from the

carton.

3. Remove all shipping materials, tape and lm from the downdraft

vent and blower box.

4. Install the right and left undercounter mounting brackets to the

vent box. Slide the keyhole slots over the guide tabs and push

the brackets up to set them in place.

A

B

A

M C

L

A. Wall cap

B. 6” (15.2 cm) round metal vent

C.16” (40.6 cm) maximum

D. 6” (15.2 cm) round PVC swer pipe

E. 6” (15.2 cm) round metal vent transi-

tion with damper (supplied)

F. 6” (15.2 cm) round PVC coupling

G. Concrete slab

H. 6” (15.2 cm) round PVC sewer pipe

D

E

F

G

H

IJK

I. 6” (15.2 cm) round 90º PVC sewer

pipe elbow

J. Tightly pack gravel or sand

completely around pipe

K. 6” (15.2 cm) round 90º PVC sewer

pipe elbow

L. 6” (15.2 cm) round PVC coupling

M. 12” (30.5 cm) minimum

5. Attach the end cap to the vent box, depending on what vent

position you choose (standard or reversible). Place the tabs into

the mounting slots at each end of the downdraft vent as shown

and push down to lock into place.

B

A

A. Vent box

B. Undercounter mounting bracket

D

C. Keyhole slots

D. Guide tabs

C

A. Standard installation cap

B. Reversible installation cap

NOTE: Only one cap must be mounted A or B

7

Page 8

6. Measure distance “X” from the cabinet oor to the top of the

countertop. Subtract 28

dimension “Y” (X - 28

281⁄2”

(73 cm)

1

⁄2” from distance “X” to determine

1

⁄2 = Y).

Top of countertop

Downdraft

vent

“X”

Left or right venting:

1. Using two or more people, place the downdraft vent system on its

back.

2. Remove the 4 screws from the cover plate mounted to the face of

the motor box and set them aside.

B

C

“Y”

Cabinet oor

7. Attach the support legs to the side of the vent box with

4 - 4 x 8 mm screws in each support leg. Adjust to dimension

“Y” from the bottom of the vent box to the bottom of the support

legs. Tighten screws.

A

A. Motor box

B. Support leg

C. Installation screws

C

B

dim. “Y”

Determine which vent direction

is best for your installation

When installed in a cabinet, vent system can exhaust through the

bottom, right or left of the cabinet.

IMPORTANT: When using the 6” (15.2 cm) vent transition (supplied)

for 6” round venting, only left or right venting is recommended.

G

F

E

D

A.Cover plate

B. Cover plate screws

C. Cover plate keyhole slot shoulder screws

D.Motor mounting screws

E. Vent cover plate

F. Motor box

G. Vent cover screws

A

3. Slide the cover plate up and slip it over the keyhole slot shoulder

screws. Set the cover aside.

4. Remove 4 screws from the bottom of the motor box that hold

the motor assembly to the motor box.

NOTE: Disconnect the electrical wiring connection from motor if

needed.

5. Remove 3 screws and the vent cover plate from the left or right

side of the motor box for the venting direction to be used.

6. Rotate the blower motor assembly 90 degrees to the left or right

side to the chosen venting direction and secure to the blower box

with motor mounting screws previously removed. Do not twist or

bind the wires.

7. Install the vent cover plate over the rectangular opening in the

bottom of the motor box and secure with vent cover screws.

NOTE: Reinstall the electrical wiring connection to motor if

removed.

8. Reinstall the cover plate to the face of the motor box and secure

with 4 cover plate screws previously removed.

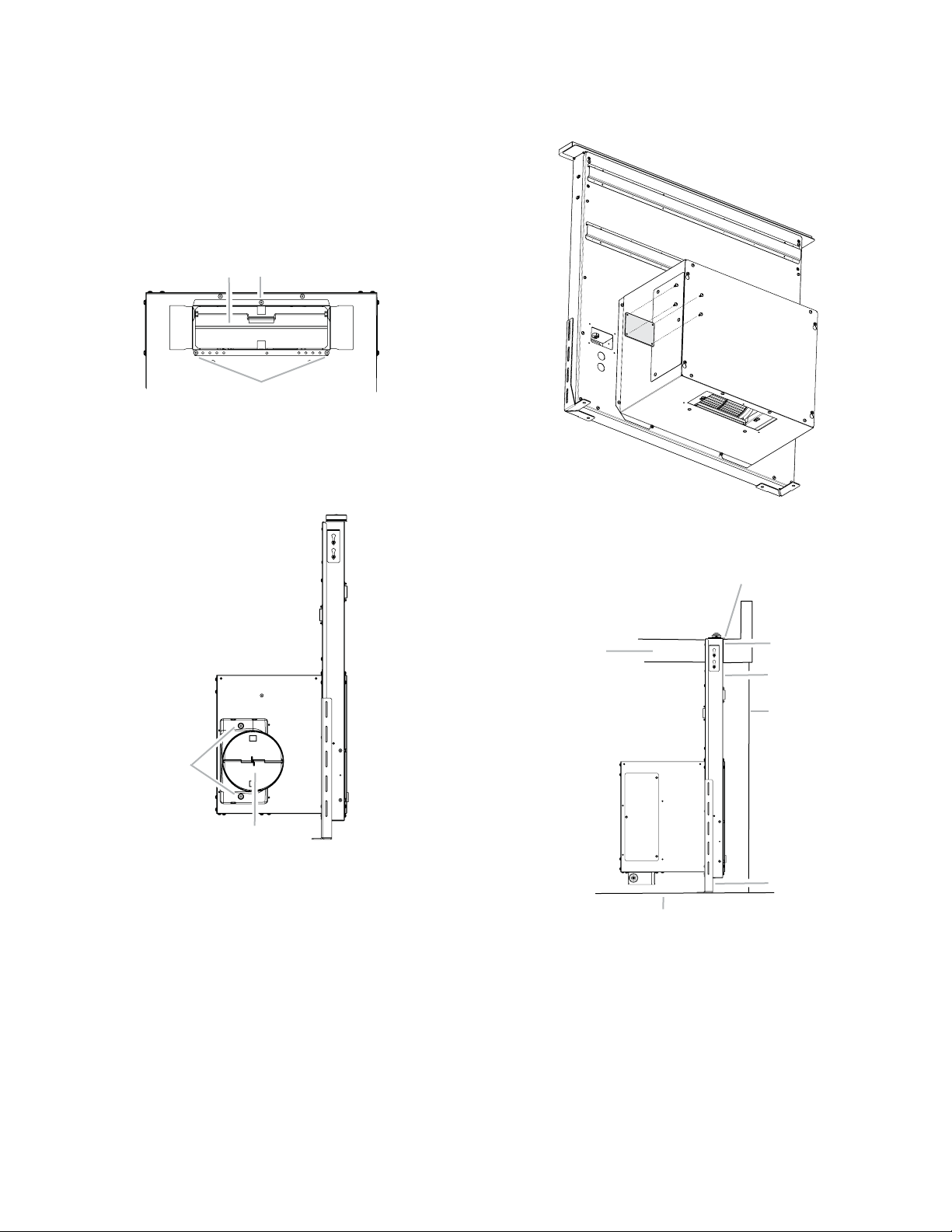

Bottom venting

NOTE: If installing the vent damper in the down position, a wall or

roof cap with a damper at the exit end of the vent system is required.

• Downdraft vent is shipped with blower in down venting position so

no modication is required.

• If rear mounting of the blower motor is not required, go to the

“Complete Installation” section.

• To mount the blower motor to the rear side of the vent box, go to

the “Rear Mounting (reversible mode)” section.

8

Page 9

Rear mounting (reversible mode)

An optional aspiration assembly mounting position (opposite side)

for island cabinet locations. The aspiration assembly (metalic plate,

lters), can be moved to the opposite side (rear) of the vent.

B

D

C

4. Unplug the aspiration assembly’s electrical connection, and

remove it from the hood.

NOTE: Once you have unplug the connector, cover it with the shrinkable wire tube and the plastic ties as shows the image below. Set free

the opposite connector.

A

A

A. Motor box

B. Aspiration orientation

C. Cooktop

D. Ensamble de aspiración

1. Move the aspiration plate and the grease lters and put them

aside. (See the Cleaning section).

2. With the help of a at head screwdriver, gently take off the

aspiration plate plastic clips.

B

C

A.Plastic wire clip

B. Shrinkable wire tube

C. Aspiration assembly connection

5. Remove the mounting screws from the aspiration structure as

shown the image below.

B

A. Aspiration structure

B. Installation screws

A

6. Lift the structure and ip it to the opposite side and x it with the

same screws previously removed.

NOTE: In order to properly align the structure, begin installing the

screws shown in the drawing.

3. Once the clips were removed from the aspration assembly, retire

the screws and washer as shown the image below. Put the

screws aside.

A

A. Installation screws

7. Plug the electrical conexion and put it into place.

8. Put back the screws and metal washers to the aspiration

assembly. Insert the plastic clips back.

9. Relocate the grase lters and the aspiration plate.

9

Page 10

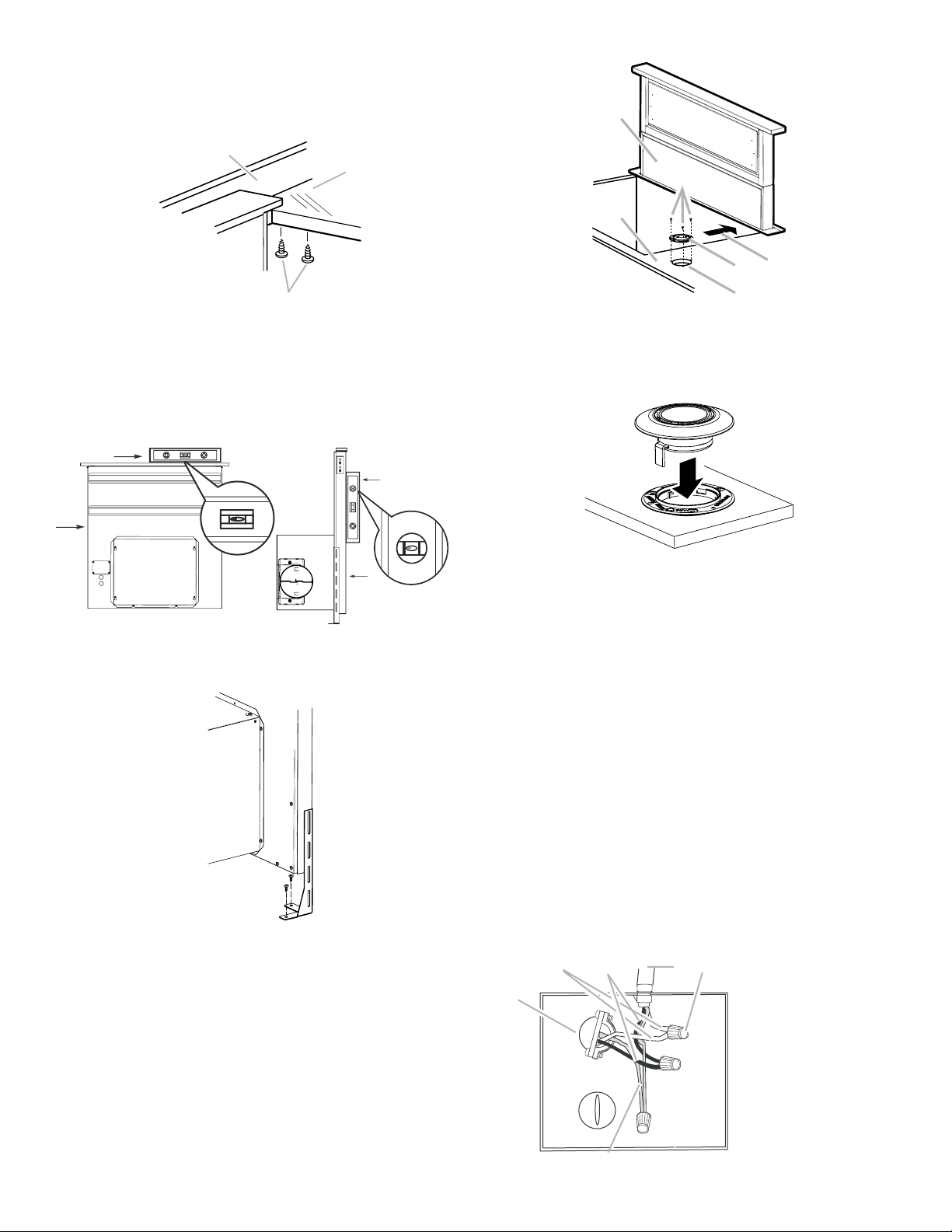

Complete Installation

NOTE: The downdraft vent system is supplied with a 31⁄4” x 10”

(8.3 x 25.4 cm) rectangular vent transition and a 6” (15.2 cm) round

vent transition with damper. Refer to “3

draft damper” or “6” (15.2 cm) round vent transition with

damper,” depending upon the type of venting you are using.

1

3

⁄4” x 10” (8.3 x 25.4 cm) back draft damper

1. Attach the 3¼” x 10” (8.3 x 25.4 cm) back draft damper to the

vent opening in the blower motor box, using three 3.5 x 9.5 mm

screws.

B. 3¼” x 10” (8.3 x 25.4 cm) back draft damper

A. 3.5 x 9.5 mm screws

6” (15.2 cm) round vent transition with damper

2. Attach the 6” (15.2 cm) round vent transition to vent opening

(left or right side venting only is recommended), using two

3.5 x 9.5 mm screws.

1

⁄4” x 10” (8.3 x 25.4 cm) back

AB

A

3. Remove 4 screws attaching the terminal box cover.

4. Determine which direction (front or rear) the home power supply

cable will enter the terminal box. Remove the appropriate

knockout from the front or rear panel and install a ½” (12.7 mm)

UL listed or CSA approved conduit connector.

5. Using 2 or more people, insert the downdraft vent into the

countertop cutout. Position downdraft vent so it is centered in the

cutout with the rear ange over the edge of the cutout and the

rear of the vent box against the edge of the cutout.

A

A

B

B. 6” (15.2 cm) round vent transition with damper

A. 3.5 x 9.5 mm screws

G

A. Rear ange of downdraft vent

B. Edge of cutout in countertop

C. Rear of downdraft vent

D. Cabinet back

B

C

D

E

F

E. Lower support leg

F. Cabinet oor

G. Countertop

10

Page 11

6. Drill 2 pilot holes through each of the undercounter mounting

brackets into the underside of the countertop. Using

2 - 4.5 x 13 mm screws, mount the brackets to the countertop.

IMPORTANT: Select a screw length that will not allow the screws to

go through the countertop when tightened.

B

C

E

D

A

F

C

A

A. Screws

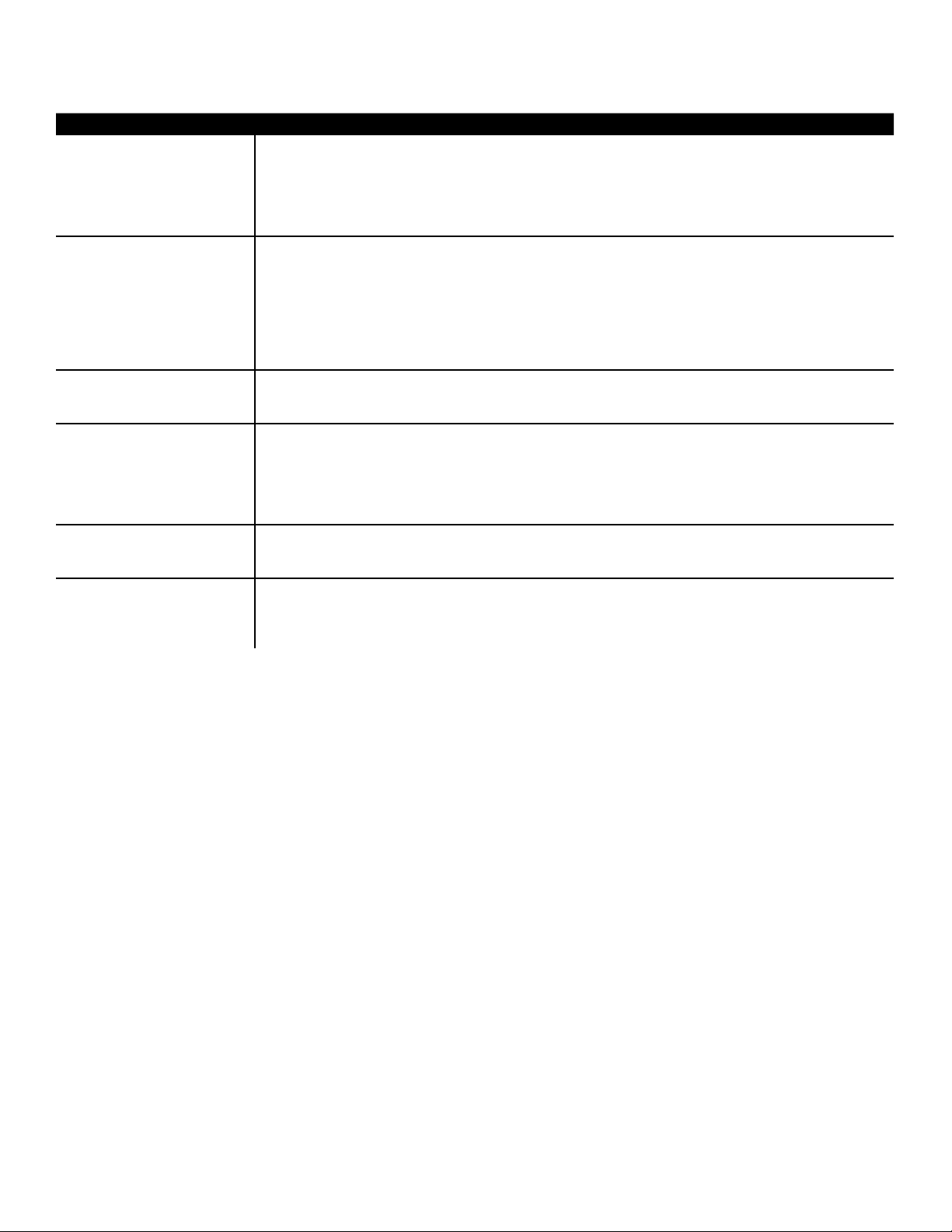

B. Backsplash

C. Countertop

7. Check that the downdraft vent is level vertically. Loosen the lower

support legs screws and position the legs against the cabinet

oor.

IMPORTANT: Verify with a level, that the vertical tower is installed

perfectly perpendicular to the ground. Installing the tower out of level

or square, will negatively impact fume and moisture capture efciency.

B

B

A

A

A. Downdraft

B. Level

9. Fasten the lower support legs to the cabinet oor with 2 - 4.5 x 13

screws (on each leg).

B

A. Countertop

B. Control cutout

C. Control base

D. Mounting screws

E. Hood’s front

F. Control base installation

• Run the control cable through the countertop hole.

• Push down the control assembly against the control base, until

you hear the click.

Electrical connection

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Disconnect power.

2. Feed the power supply cable through the conduit connector

and into the terminal box.

WARNING

Electrical Shock Hazard

Electrically ground blower.

Connect ground wire to green and yellow ground wire in terminal

box.

Failure to do so can result in death or electrical shock.

10. Tighten the lower support legs screws.

Control Installation

• Before the control installation, make sure you have made the

cutouts to proceed (see “Countertop Dimensions Chart”).

• Place the control base on location and mark the holes with a

pencil.

• Drill on the marked locations.

• Place the control base on the countertop and drive

3 - 4.5 x 13 mm installation screws.

NOTE: The legend “Front” is writen on the control base. This legend

always must be oriented to the hood’s front (F).

3. Connect the green (or green/yellow) ground wire to the green

or yellow/green ground wire using UL listed wire connectors.

4. Tighten the screw on the conduit connector.

5. Connect the 2 white wires together using UL listed wire

connectors.

B

E

D

A

C

F

A. Green or green and yellow

ground wire

B.White wires

C. UL listed wire connectors

D. Black wires

E. UL listed or CSA approved

conduit connector

F. Downdraft vent wiring

11

Page 12

Control connection

1. Run the control wire from the motor box to the location of the

control assembly (see the image below).

A

B

C

Check operation

1. Push and hold the control button for a few seconds. The

retractable section of the downdraft vent will rise, and the blower

will start. Position the top trim over the retractable section and

snap trim into place.

A

B

C

D

A. Control

B. Adhesive wire clips

C. Control connection wire

NOTE: It is recommended to guide the connection wire as close

as posible to the motor box, avoiding to get the wire loose. Use the

provided adhesive wire clips.

2. Plug both wire connectors.

A

A. Control wire

B. Motor box wire

B

3. Check the operation.

Installing the Top trim

1. Push down the top trim against the downdraft top. The top trim’s

pins must enter into the downdraft plastic clips.

E

A. Top trim

B. Aspiration plate

C. Grease lters

D. End cap

E. Control

2. If the blower does not operate:

• Check that aspiration plate is pressed in as far as they will go.

• Check that the circuit breaker has not tripped or a household

fuse blown.

3. Connect vent system to blower. Vent system must end with a

wall or roof cap. Use clamps or duct tape to seal all joints.

4. Install cooktop according to manufacturer’s instructions.

VENT SYSTEM USE

The retractable downdraft vent system is designed to remove

smoke, cooking vapors and odors from the cooktop area.

• For best results, the vent should be operating before cooking is

started.

• If you use large or tall utensils, place them on the large rear

element or burner surface.

• A higher heat setting than normally used may be needed when

the downdraft vent is operating.

• For gas cooktops, the downdraft vent system may affect the

ame stability and cooking performance. To improve the burner

performance, either decrease the downdraft vent blower speed or

increase the cooktop burner ame setting.

• For gas cooktops with ame sensing ignitions, the downdraft vent

system may disperse the ame away from the spark igniter and

may cause it to continually spark while trying to reignite a burner

that is already lit. To resolve the issue of the cooktop igniter

continuously sparking, either decrease the downdraft vent blower

speed or increase the cooktop ame setting for that burner.

12

Page 13

Downdraft Use

Use the high suction speed in cases of concentrated kitchen vapours.

It is recommended that the cooker hood suction is switched on for 5

minutes prior to cooking and to leave in operation during cooking and

for another 15 minutes approximately after terminating cooking.

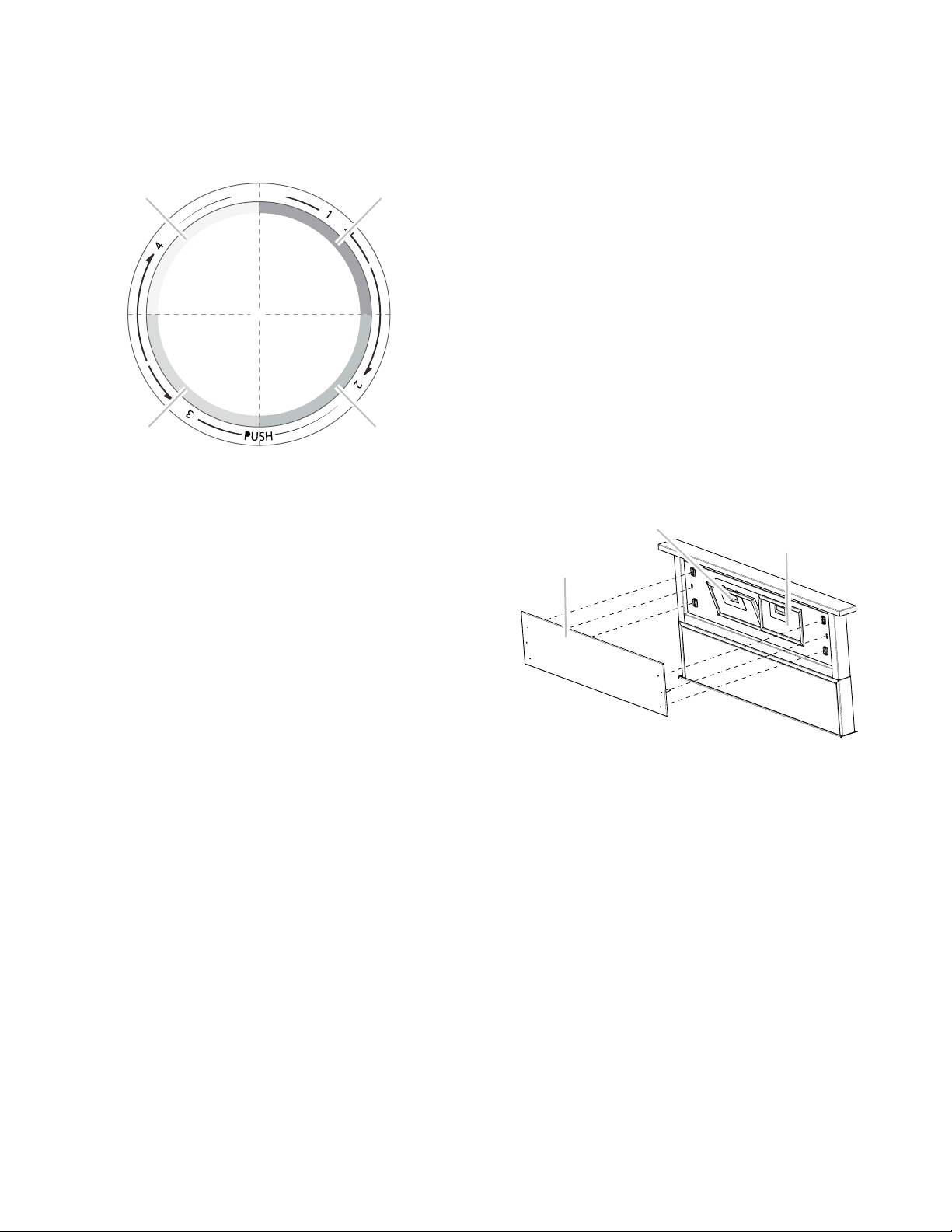

The control panel consists of a backlit rotating disk.

D

E

C

To raise the downdraft vent system:

Press on the disk (E) aprox 2 seconds to raise the downdraft vent

system.

Press on the disk (E) aprox 2 seconds to hide the downdraft vent

system.

NOTE: If you press the disk to hide the downdraft system while it is

working, the appliance will automatically turn off.

To select the available suction speeds:

Turn the disk (E) clockwise to turn on and increase the suction speed

and counter-clockwise to decrease it, and to turn off the hood.

The crown lights to indicate the selected suction speed:

A lit

speed 1 (minimum).

A + B lit

speed 2 (medium).

A + B + C lit

Speed 3 (maximum).

A + B + C + D lit

Speed 4 (intensive), lasting for 5 minutes, then the hood is placed

automatically at speed 2.

A off:

Suction motor off.

A + B + C + D lit in ashing mode

The light crown will ash after 40 hrs. of work. This indicates that the

grease lters must be removed and cleaned.

This function must be reset by pressing the button for 5 seconds.

A

B

Vent System Care

Surface of Downdraft Vent

To avoid damaging the nish, clean downdraft vent with soap

and water. Do not use scouring powder or abrasive solutions.

Exterior Surfaces:

To avoid damage to the exterior surface, do not use steel wool or

soap-lled scouring pads.

Always wipe dry to avoid water marks.

Cleaning Method:

• Liquid detergent soap and water, or all-purpose cleanser

Wipe with damp soft cloth or nonabrasive sponge, then rinse with

clean water and wipe dry.

To Clean:

1. Remove the aspiration plate and the lter(s) and clean them in a

dishwasher or in a hot detergent solution. The downdraft vent will

not operate when the lters are not in place.

2. Dry the clean lter(s) and reinstall, making sure that they lock into

place.

To Replace Filters:

1. Place lters into the retractable section of the downdraft vent.

2. Place ngertips into the embossment at the top of the lters and

push down and back to allow the top tabs to snap in place.

B

C

A

A. Aspiration plate

B. Grease lter handle

B. Grease lters

NOTE: Downdraft vent will not operate if the aspiration plate are not

in its proper position. If the aspiration plates’ top tabs are not locked

behind the top ange, the vent may retract but not raise back up. If

retractable downdraft vent does not operate after clean aspiration

plate have been installed:

Push the aspiration plate in as far as it will go. When the plate is

removed, the microswitch behind the lter is inactivated. This feature

will not allow the vent system to operate until the aspiration plate is

properly installed.

13

Page 14

Troubleshooting

PROBLEM POSSIBLE CAUSES AND/OR SOLUTIONS

Nothing will operate Has a household fuse been blown or has a circuit breaker tripped? Replace the fuse or reset the

circuit breaker. If the problem continues, call an electrician.

Is the aspiration plate in its proper position? Check that aspiration plate is pressed in as far as they will

go.

Has the Control button been pressed for at least 2 seconds? Push and hold the control button for at

least 2 seconds to complete the cycle needed to start retracting.

Vent does not retract Is the aspiration plate in place? When the plate is removed, the microswitch behind the lter is inactivat-

ed. This feature will not allow the vent system to operate until the aspiration plate is properly installed.

Is the aspiration plate installed correctly? Push the lter in as far as it will go to activate the microswitch

behind the lter.

Has the Control button been pressed for at least 2 seconds? Push and hold the control button for at

least 2 seconds to complete the cycle needed to start retracting.

Is the downdraft correctly secured? Make sure that the vent hood is level and upright. Check it is se-

curely fastened to the oor and the counter top.

Vent partially raises Has an obstruction been interfering with the vent movement? Ensure the cooktop is not interfering

with the downdraft vent movement.

Is the vent leveled? Level the vent. See the “Complete the Installation” section.

Blower does

not operate

Downdraft not level on

countertop

Vent making noises Was the vent recently installed and making grinding noises? Use stainless steel cleaner to remove

Is the vent fully raised? Check that the vent is totally in the up position.

Is the aspiration plate installed correctly? Push the lter in as far as it will go to activate the microswitch

behind the lter.

Has the control button been activated? Turn the disk clockwise to turn on and increase the suction

speed and counter-clockwise to decrease it, and to turn off the hood.

Is the blower installed correctly? See the “Rear mounting (reversible mode)” section.

Is the vent leveled? Level the vent. See the “Complete the Installation” section.

Is the vent raising more in one side? Make sure both of the support legs have the same height from the

bottom of the vent box to the bottom of the support legs. See the “Installing the vent System” section.

any residue left by the white protective lm. Ensure nothing is blocking path of vent.

Is there noise due to moving air? Ensure the installation of the product is fully into the cutout and no gap

in the middle of it.

14

Page 15

Register your product in

elica.com

ELICA North America

TWO-YEAR LIMITED WARRANTY

and earn a 3

warranty, covering all parts

rd

year of factory

plus in-home labor.

TO OBTAIN SERVICE UNDER WARRANTY

Owner must present proof of original purchase date. Please keep a copy of your dated proof of purchase (sales slip) in

order to obtain service under warranty.

PARTS AND SERVICE WARRANTY

For the period of two (2) years from the date of the original purchase, Elica will provide free of charge, non consumable

parts or components that failed due to manufacturing defects. During these two (2) years limited warranty, Elica will also

provide free of charge, all labor and in-home service to replace any defective parts.

WHAT IS NOT COVERED

• Damage or failure to the product caused by accident or act of God, such as, flood, fire or earthquake.

• Damage or failure caused by modification of the product or use of non-genuine parts.

• Damage or failure to the product caused during delivery, handling or installation.

• Damage or failure to the product caused by operator abuse.

• Damage or failure to the product caused by dwelling fuse replacement or resetting of circuit breakers.

• Damage or failure caused by use of product in a commercial application.

• Service trips to dwelling to provide use or installation guidance.

• Light bulbs, metal or carbon filters and any other consumable part.

• Normal wear of finish.

• Wear to finish due to operator abuse, improper maintenance, use of corrosive or abrasive cleaning products/pads and

oven cleaner products.

WHO IS COVERED

This warranty is extended to the original purchaser for products purchased for ordinary residential use in North America

(Including the United States, Guam, Puerto Rico, US Virgin Islands & Canada).

This warranty is non-transferable and applies only to the original purchaser and does not extend to subsequent owners of

the product. This warranty is made expressly in lieu of all other warranties, expressed or implied, including, but not limited

to any implied warranty of merchantability or fitness for a particular purpose and all other obligations on the part of Elica

North America, provided, however, that if the disclaimer of implied warranties is ineective under applicable law, the dura

tion of any implied warranty arising by operation of law shall be limited to two (2) years from the date of original purchase

at retail or such longer period as may be required by applicable law.

Th

is warranty does not cover any special, incidental and/or consequential damages, nor loss of profits, suered by the

original purchaser, its customers and/or the users of the Products.

WHO TO CONTACT

To obtain service under warranty or for any service related question:

• Elica North America Service, call at 1 888 732 8018

• For Eastern Canada, call AGI Services at 1 888 651 2534 Ask for the service department

• elica@servicepower.com

-

Page 16

Français

Sommaire

Avis de sécurité important............................................................................. 17

Exigences électriques et d’installation.......................................................... 18

Outils et piéces.............................................................................................. 19

Pièces fournies ............................................................................................. 19

Pièces non fournies....................................................................................... 19

Dimensions du produit ................................................................................. 19

Dimensions des ouvertures à découper....................................................... 20

Exigences concernant l’évacuation............................................................. 20

Instructions d’installation............................................................................... 21

Déterminer la meilleure orientation de l’évacuation pour l’installation.......... 22

Montage arriére (mode réversible) ............................................................... 23

Achever l’installation .................................................................................... 24

Installation de commande............................................................................. 25

Raccordement électrique.............................................................................. 25

Contrôle du fonctionnement.......................................................................... 26

Utilisation du système d’extraction par le bas............................................... 27

Entretien du système d’évacuation............................................................... 27

Dépannage ................................................................................................... 28

Garantie ....................................................................................................... 29

APPROUVÉ COMME APPAREIL DOMESTIQUE

POUR UNE UTILISATION RÉSIDENTIELLE SEULEMENT

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

VEUILLEZ LIRE CES INSTRUCTIONS AU COMPLET AVANT

DE COMMENCER.

L’INSTALLATION DE L’APPAREIL DOIT RESPECTER TOUS

LES CODES EN VIGUEUR.

IMPORTANT: Conservez ces instructions an de pouvoir les

remettre à l’inspecteur-électricien de votre région.

INSTALLATEUR: Veuillez laisser ces instructions avec

l’appareil pour le propriétaire.

PROPRIÉTAIRE: Veuillez conserver ces instructions pour

pouvoir vous y référer plus tard.

Avertissement de sécurité: Coupez l’alimentation du circuit

dans le panneau électrique et verrouillez le panneau avant de

raccorder les ls de cet appareil.

Exigence: 120 V c.a., 60 Hz circuit de dérivation de 15 V c.a.,

20 Hz, de 15 ou 20 A.

16

Page 17

LIRE ET CONSERVER CES INSTRUCTIONS

Avis de sécurité important

ATTENTION

UTILISER CET APPAREIL À DES FINS DE VENTILATION

GÉNÉRALE SEULEMENT. NE PAS UTILISER CET APPAREIL

POUR ÉVACUER DES MATÉRIAUX OU DES VAPEURS

DANGEREUX OU EXPLOSIFS.

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE ET DE BLESSURE, RESPECTER LES DIRECTIVES

SUIVANTES :

A. Utiliser cet appareil uniquement aux ns prévues par le fabricant.

Si vous avez des questions à propos de l’appareil, communiquez

avec le fabricant.

B. Avant de faire l’entretien de l’appareil ou de le nettoyer, coupez

l’alimentation dans le panneau électrique et verrouillez le

panneau en bloquant le dispositif permettant d’empêcher

d’activer l’alimentation accidentellement.

S’il n’est pas possible de verrouiller l’accès au panneau, xez

une étiquette très voyante au panneau électrique.

C. Une personne qualiée doit effectuer l’installation et le câblage

des ls électriques en conformité avec tous les codes et toutes

les normes, y compris la cote de résistance au feu.

D. Il est important de prévoir sufsamment d’air pour assurer

une bonne combustion de l’équipement de chauffe et

l’évacuation adéquates des gaz par le conduit de cheminé an

de prévenir les refoulements d’air. Respectez les directives et

les normes de sécurité des fabricants de l’équipement de

chauffage, comme celles publiées par la National Fire Protection

Association (NFPA), la American Society for Heating, Refri

eration and Air Conditioning Engineers (ASHRAE) et le code des

autorités de votre région.

E. Au moment de couper ou de percer un mur ou un plafond,

assurez-vous de ne pas endommager la lerie électrique ou tout

autre accès à un service publique.

F. Il faut toujours évacuer à l’extérieur les systèmes à conduit.

ATTENTION

Pour réduire les risques d’incendie et évacuer l’air correctement,

assurez-vous que le conduit mène à l’extérieur; il ne faut pas

évacuer l’air dans l’espace entre les murs, dans les plafonds,

dans les greniers, les vides sanitaires ou les garages.

AVERTISSEMENT

POUR RÉDUIRE DES RISQUES D’INCENDIE, UTILISEZ

UNIQUEMENT DES CONDUITS EN MÉTAL.

AVERTISSEMENT

POUR RÉDUIRE LES RISQUES D’INCENDIE DE GRAISSE SUR

LES CUISINIÈRES.

a) Ne laissez jamais la cuisinière sans surveillance lorsqu’elle est

réglée à une haute température. Les débordements par

bouillonnement causent de la fumée et des débordements de

gras qui peuvent s’enammer. Faites chauffer l’huile lentement, à

une température basse ou moyenne.

b) Faites toujours fonctionner la hotte lorsque vous utilisez la

cuisinière à une haute température ou que vous faites amber des

aliments (P. ex. : crêpes Suzette, cerises jubilées, boeuf au poivre

ambé).

c) Nettoyez les hélices de ventilation fréquemment. Il ne faut pas

que la graisse s’accumule sur les lres ou les hélices.

d) Utilisez le bon format de casserole. Utilisez toujours un] chaudron

de taille approprié à l’élément de la cuisinière.

AVERTISSEMENT

POUR ÉVITER DE BLESSER QUELQU’UN LORS D’UN INCENDIE

DE GRAISSE SUR LA CUISINIÈRE, SUIVRE LES CONSEILS SUIV-

a

ANTS:

a) ÉTOUFFER LES FLAMMES avec un couvercle aux dimensions

de la taque de cuisson, une tôle à biscuit ou tout autre plateau

métallique, puis couper le gaz ou l’alimentation électrique de

la cuisinière. FAIRE ATTENTION A NE PAS SE BRÛLER. Si les

ammes ne s’éteignent pas immédiatement, QUITTER LA PIÈCE

ET APPELER LES POMPIERS.

b) NE JAMAIS PRENDRE EN MAIN UNE CASSEROLE EN FEU,

vous pourriez vous blesser.

c) NE PAS UTILISER D’EAU, y compris les essuies de vaisselle

ou les serviettes humides – une violente explosion due à la

vapeur formée pourrait survenir.

d) Utiliser un extincteur SEULEMENT si:

1) Vous êtes sûr d’avoir un extincteur de classe ABC que vous

savez utiliser.

2) Le feu est petit et conné à la zone où il s’est formé.

3) Les pompiers ont été appelés.

4) Vous pouvez lutter contre le feu avec une sortie derrière vous.

a

Recommandations tirées des conseils de sécurité en cas d’incendie

de cuisine publiés par la NFPA.

MODE OPÉRATOIRE

a. Toujours laisser les grilles de sécurité et les ltres à leur place.

Sans la présence de ces derniers, les parties aspirantes pourraient

attirer les cheveux, les doigts ou les vêtements.

Installez cette hotte en respectant toutes les exigences mentionnées.

AVERTISSEMENT

Pour réduire les risques d’incendie et de choc électrique,

n’utilisez pas cette hotte avec un contrôleur de vitesse à semi-

conducteurs.

Le fabricant décline toute responsabilité si les informations détaillées

dans ce manuel pour l’installation, l’entretien et l’utilisation adéquate

du produit ne sont pas observées. Le fabriquant décline en outre toute

responsabilité pour d’éventuelles blessures dues à des négligences;

en outre, la garantie de l’appareil sera annulée suite à des conditions

d’entretien inappropriées. Cet appareil est fabriqué pour un

usage interne. Ne pas utiliser cet appareil à l’extérieur.

17

Page 18

Exigences électriques et d’installation

Spécications électriques

IMPORTANT

Respectez tous les codes et les ordonnances en vigueur.

Le client a la responsabilité de:

Contacter un électricien-installateur.

Vérier que l’installation électrique est adéquate et conforme avec le

Code national de l’électricité, ANSI/NFPA 70 (la plus récente édition*),

ou les normes C22.1-94, Code canadien de l’électricité, Partie 1 et

C22.2 No.0-M91 (La plus récente édition**) de la CSA, ainsi que tous

les codes et les ordonnances de votre région.

Si le code le permet et que vous utilisez un l de mise à la terre

distinct, il est recommandé de faire vérier le chemin du l par un

électricien.

Ne pas mettre l’appareil à la terre sur une conduite de gaz.

Consultez un électricien qualié si vous n’êtes pas certain que la

hotte est mise à la terre correctement.

N’installez pas un fusible dans le circuit neutre ou le circuit de mise à

la terre.

IMPORTANT

Conservez ces instructions an de pouvoir les remettre à l’inspecteur-

électricien.

La hotte doit être câblée uniquement à l’aide de ls de cuivre.

Il faut raccorder la hotte directement à une boîte à fusible ou à un

disjoncteur par l’entremise d’une canalisation électrique en métal.

Le calibre de l doit être conforme aux exigences du Code national de

l’électricité, ANSI/NFPA 70 (La plus récente édition*), ou les normes

C22.1-94, Code canadien de l’électricité, Partie 1 et C22.2 0-M91 (La

plus récente édition**) de la CSA, ainsi que tous les codes et les

ordonnances de votre région.

Il faut prévoir un connecteur de canalisation approuvé par

l’UL ou la CSA à chaque extrémité de la canalisation

d’alimentation (À la hotte et à la boîte de jonction).

Vous pouvez obtenir un exemplaire des normes indiquées en vous adressant

à :

* La National Fire Protection Association, Batterymarch Park

Quincy, Massachusetts, 02269

** La CSA International, 8501 East Pleasant Valley Road,

Cleveland, Ohio, 44131-5575

Exigences d’emplacement

REMARQUE: Le système d’extraction par le bas est installé

directement derrière la table de cuisson. Installer d’abord le système

d’extraction par le bas, puis la table de cuisson.

IMPORTANT: Observer les dispositions de tous les codes et

règlements en vigueur.

• Demander à un technicien qualié d’installer le système

d’extraction par le bas. C’est à l’installateur qu’incombe la

responsabilité de respecter les distances de séparation exigées,

spéciées sur la plaque signalétique de l’appareil. La plaque

signalétique est située à l’avant de l’appareil, audessus du

couvercle du boîtier de connexion.

• Le système d’extraction par le bas doit être installé à l’écart des

zones de forts courants d’air, telles que fenêtres, portes et évents

ou ventilateurs de chauffage.

• Respecter les dimensions indiquées pour les ouvertures à

découper dans les placards. Ces dimensions tiennent compte des

valeurs minimales des dégagements de séparation.

• Avant d’effectuer des découpes, consulter les instructions

d’installation fournies par le fabricant de la table de cuisson.

Vérier qu’à l’emplacement d’installation le système d’extraction

par le bas et la table de cuisson ne produiront pas d’interférence

avec les parois des placards, panneaux anti-éclaboussure, et

poteaux du colombage mural à l’arrière.

Vérier le respect de la distance minimale entre le bord avant du

plan de travail et le bord avant de la table de cuisson. La distance

minimale de séparation horizontale entre les placards muraux est

identique à la largeur du système d’extraction installé.

• Assurer l’étanchéité au niveau de chaque ouverture découpée

dans le plafond ou le mur pour l’installation du système

d’extraction par le bas.

• On doit disposer d’une prise de courant électrique reliée à la terre.

Voir la section “Spécications électriques”.

• Pour l’installation du conduit d’aspiration par le bas, il sera

nécessaire d’enlever le tiroir du placard et d’installer à demeure

une façade de tiroir sur le placard.

Conguration du placard:

Le système d’extraction par le bas est conçu pour une utilisation

dans un placard de profondeur 24” (61 cm). Certaines installations

nécessitent un plan de travail de largeur supérieure à 25” (63,5 cm).

Voir le tableau de dimensions de découpage pour plan de travail.

La profondeur maximale du placard mural est de 13” (33 cm). Les

placards muraux installés à coté du système d’extraction par le

bas doivent se trouver à 18” (45,7 cm) au-dessus de la surface de

cuisson.

Installation dans une résidence mobile

L’installation de ce système d’extraction par le bas doit satisfaire

aux exigences de la norme Manufactured Home Construction

Safety Standards, Titre 24 CFR, partie 328 (anciennement Federal

Standard for Mobile Home Construction and Safety, titre 24, HUD,

partie 280); lorsque cette norme n’est pas applicable, l’installation doit

satisfaire aux critères de la plus récente édition

tured Home Installation 1982 (Manufactured Home Sites, Communities and Setups) ANSI A225.1/NFPA 501A, ou des codes locaux.

de la norme Manufac-

18

Page 19

Outils et piéces

Enlever l’emballage

ATTENTION

Enlever délicatement le carton, Porter des gants pour se protéger des

bords coupants.

AVERTISSEMENT

Enlever le lm de protection recouvrant le produit avant de commenc-

er l’opération.

Pièces fournies

• Système de ventilation rétractable avec moteur déjà installé

• Filtres a graise

• 2 - Pieds de soutien inférieurs

• 2 - Embouts

• Raccord de transition 6” de diamètre, avec clapet

• Clapet anti-reux rectangulaire de 3

• Metalic garniture supérieure

• Ensemble de commande

• Sac de matériel avec:

• Guide et l’utilisation d’installation

• 1 - Tube de l rétractable

• 2 - Attaches en plastique

• 2 - Brides de montage

• 4 - Clips en plastique

• 7 - Clips adhésifs

• 8 - 4 x 8 mm vis de installation

• 11 - 4.5 x 13 mm vis de installation

• 3 - 3.5 x 9.5 mm vis de installation

1

⁄4”x10”

Pièces nécessaires

• Câble d’alimentation électrique du domicile

• Connecteur de conduit (homologation UL ou CSA) de ½” (12,7 mm)

• 3 connecteurs de ls homologués UL

• Bouche de décharge murale ou à travers le toit avec clapet

correspondant au système d’évacuation

• Conduit d’évacuation de 6” ou rectangulaire 3

1

⁄4”x10”

Outillage nécessaire

• Niveau

• Perceuse et forets de1¼” (3.2 cm),⅛” (3.2 mm), et

pour avant trous

• Crayon

• Pince à dénuder ou couteau utilitaire

• Mètre-ruban ou règle

• Pince

• Pistolet à calfeutrage et composé de calfeutrage résistant

aux intempéries

• Cisaille de ferblantier

• Scie sauteuse ou scie à guichet

• Tournevis à lame plate

• Tournevis Phillips

5

⁄16” (7.9 mm)

131⁄2” (34.3 cm)

Hauteur de l’évacuation

rétractable

27” (68.6 cm) pour modèle 30”

33” (83.8 cm) pour modèle 36”

131⁄8”

(33.4 cm)

161⁄2”

(42 cm)

Largeurs de la

garniture

supérieure:

30” (76.2 cm)

36” (91.4 cm)

10”

(25.4 cm)

Dimensions du produit

Dimensions du placard

1

⁄2” (1.27 cm)

minimale

19

⁄32”

(1.5 cm)

215⁄16”

11⁄2”

(3.8 cm)

(72.6 cm)

51⁄4” (13.3 cm)

pour modèle 30”

1

⁄4” (21 cm)

8

pour modèle 36”

21⁄8”

(5.4 cm)

281⁄2”

Les découpes

correspondent

à un circuit

d’évacuation

rectangulaire

de 31⁄4” x 10”

(8.3 x 25.4 cm)

ou rond de 6”

(15.2 cm).

REMARQUES:

• Pour les dimensions de l’ouverture recevant la table de

cuisson, voir les instructions du fabricant de la table de cuisson

(profondeur et largeur).

• Pour les ouvertures découpées pour le circuit d’évacuation,

utiliser les dimensions applicables à la situation d’installation.

• Circuits d’évacuation avec ventilateur monté à l’intérieur et

raccordé au conduit d’évacuation rectangulaire de 3¼” x 10”

(8,3 x 25,4 cm) ou circulaire de 6” (15,2 cm). Pour cette co

guration, l’emplacement des ouvertures à découper dépend

de la conguration d’installation spécique.

(54.1 cm)

Placer le boîtier de

raccordement

électrique dans

l’angle arrière/gauche

au bas du placard.

91⁄2”

(24.4 cm)

Axe central

de l’ouverture

recevant la table

de cuisson

215⁄16”

(54.1 cm)

19

Page 20

Dimensions des ouvertures à découper

IMPORTANT: Les plans de travail avec rebord avant arrondi ne sont

pas recommandés pour ces installations.

Certains modèles nécessitent un plan de travail de plus de 25” (63,5

cm); voir le tableau des dimensions de l’ouverture du plan de

travail. Pour éviter une erreur, avant de découper une ouverture, tracer le périmètre de la table de cuisson et des ouvertures à découper

sur le plan de travail.

Pour les dimensions des ouvertures, la position des ouvertures et le

détail des installations, voir les instructions d’installation de la table

de cuisson.

REMARQUE: Pour éviter d’éventuels problèmes de sifets pour la

ltration de l’air, il est recommandé de garder au minimum la distance

entre le table de cuisson et la hotte de ventilation (J).

Il est recommandé une application de scellant dans ce domaine.

D

E

B

C

F

G

Exigences concernant l’évacuation

IMPORTANT : Avant d’effectuer des découpes, s’assurer qu’il y

a un dégagement convenable dans le mur ou le plancher pour le

système d’extraction.

• Utiliser un conduit métallique rigide.

• Le système doit décharger l’air à l’extérieur.

• Ne pas terminer le système d’extraction dans un grenier ou dans

un autre espace fermé.

• Ne pas utiliser une bouche de décharge murale de 4” (10,2 cm)

normalement utilisée pour un équipement de buanderie.

• Ne pas connecter 2 coudes ensemble.

• Ne pas utiliser un conduit de plastique ou en métal exible.

• La longueur du système d’évacuation et le nombre de coudes

doivent être réduits au minimum pour l’obtention de la meilleure

performance.

• Ne pas utiliser plus de trois coudes à 90°.

• Veiller à incorporer une section de conduit rectiligne d’au moins

24” (61 cm) entre deux raccords coudés adjacents.

• Au niveau de chaque jointure du système d’extraction, assurer

l’étanchéité avec les brides de serrage pour conduit.

• Autour de la bouche de décharge murale ou par le plancher à

l’extérieur, assurer l’étanchéité avec un produit de calfeutrage.

• Ne pas couper une solive ou un poteau du colombage. Si le

point de passage d’un système d’extraction correspond à la

position d’un poteau du colombage ou d’une solive, on doit

réaliser une structure de support appropriée.

• On déconseille l’emploi d’un conduit en métal exible. Si un

conduit de ce type doit être utilisé, on doit tenir compte du fait

que chaque pied de conduit exible compte comme 2 pi (0,6 m)

de conduit rigide métallique.

• Un raccord coudé exible compte comme deux raccords coudé

standard.

I

A

A. Système d’extraction par le bas

B. Table de cuisson

C. Dimension du dépassement arrière de la

table de cuisson.

D. D = Dimension du dépassement arrière de la

table de cuisson (C) + 2

1

⁄2” [61 mm] (E)

E. 21⁄2” (61 mm)

F. ¼” (6.4 mm) minimum

G. Plan de travail et panneau anti-écla-

boussure

H. ½” (12.7 mm) minimum

I. Seal la table de cuisson / downdraft

conjointe

Tableau des dimensions de l’ouverture

B

D

C

A

A. ½” (12.7 mm) min. jusqu’au panneau

antiéclaboussure ou mur arrière

3

B.

⁄4” (19.1 mm) maximum pour la

profondeur du panneau anti-éclaboussure

C. 27½” (70cm) sur les modèles de 30”

(76.2cm)

33½” (86cm) sur les modèles de 36”

(91.4cm)

D. D = E + 21⁄2” (61 mm)

E. Dépassement arrière de la table de

E

cuisson

F. Ø 29⁄16” (6.5 cm). La commande peut être

installé dans les deux côtés gauche ou

à droite.

G. Distance a la table de cuisson:

Minimale 4” (10 cm)

Maximale 8” (20 cm)

Longueur recommandée pour le système d’extraction :

Pour une conguration avec ventilateur monté à l’intérieur ou monté

H

à l’extérieur, la longueur du système d’extraction ne doit pas être

supérieure à la valeur maximum indiquée au tableau Longueur maximum du système d’extraction. Voir “Calcul de la longueur du système

d’extraction” à la section “Méthodes d’extraction” des Instructions

d’installation.

Installations dans les régions au climat froid

On doit installer un clapet anti-retour supplémentaire à l’arrière pour

minimiser le reux d’air froid et incorporer un élément d’isolation ther-

mique pour minimiser la conduction de chaleur par l’intermédiaire du

conduit d’évacuation, de l’intérieur de la maison à l’extérieur. Le clapet

anti-retour doit être placé du côté air froid de la résistance thermique.

L’élément d’isolation thermique doit être aussi proche que possible de

l’endroit où le circuit d’évacuation s’introduit dans la partie chauffée

de la maison.

F

Air d’appoint

Le code du bâtiment local peut exiger l’emploi d’un système d’appoint

G

d’air lors de l’emploi d’un ventilateur d’extraction dont la capacité d’aspiration est supérieure à un débit (pieds cubes par minute) spécié.

Le débit spécié en pieds cubes par minute varie d’une juridiction à

l’autre. Consulter un professionnel des installations de chauffage ventilation/climatisation au sujet des exigences spéciques applicables

dans la juridiction locale.

20

Page 21

Instructions d’installation

Méthodes d’évacuation

Déterminer la méthode d’évacuation la plus appropriée. La sortie

à l’extérieur du circuit d’évacuation peut se faire à travers le

plancher ou à travers un mur.

Conguration en îlot

Ventilateur monté à l’avant

(standard)

Ventilateur monté à l’arrière

C

B

A

Conguration en îlot

Circuit d’évacuation installé sous une dalle de béton (utilisation de

conduit de PVC pour égout).

Ventilateur monté à l’avant (standard)

B

A

C

B

L

K J I

Ventilateur monté à l’arrière

A

B

D

CM

E

F

G

H

A. Évacuation vers le bas

B. Table de cuisson

C. Aspiration plate

Conguration en meuble intégré

B

A

A. Évacuation vers le bas B. Évacuation à gauche C. Évacuation à droit

C

Installation du système de

ventilation rétractable

AVERTISSEMENT

Risque du poids excessif. Utiliser deux ou plus de personnes

pour déplacer et installer le système d’extraction.

Le non-respect de cette instruction peut causer une blessure au

dos ou d’autre blessure.

1. Placer une feuille de carton ou matériau similaire sur une surface

plane, où on pourra facilement assembler le système d’extraction

par le bas.

2. Déballer les ensembles de pièces, le système d’extraction par le

bas et le ventilateur.

3. Enlever tous les matériaux d’emballage, ruban adhésif et lm

protégeant l’appareil et le ventilateur.

4. Installer sur la caisse du système d’extraction les équerres droite

et gauche de montage sous le plan de travail. Insérer les

encoches en trou de serrure dans les languettes guides et

pousser les équerres vers le haut pour les xer.

A

B

A

M C

L

A. Bouche de décharge murale

B. Conduit métallique rond de dia. 6” (15.2 cm)

C.16” (40.6 cm) maximum

D. Conduit PVC dia. 6” (15.2 cm)

E. Raccord de transition métallique de dia. 6”

(15.2 cm) avec clapet (fourni)

F. Raccord PVC de dia. 6” (15.2 cm)

G. Dalle de béton

H. Conduit PVC pour égout de dia. 6” (15.2 cm)

D

E

F

G

H

IJK

I. Coude à 90° en PVC pour égout de

dia. 6” (15.2 cm)

J. Gravier ou sable compacté tout autour

du tuyau

K. Raccord coudé 90° PVC dia. 6” (15.2cm)

L. Raccord PVC de dia. 6” (15.2 cm)

M. 12” (30.5 cm) minimum

5. Fixer l’embout sur la caisse du système d’extraction, en fonction

de la position que vous choisissez: standard (A) OU réversible

(B). Placer la languette dans la rainure de montage à chaque

extrémité de la caisse du système d’extraction tel qu’illustré

ci-dessous et l’emboîter en la poussant vers le bas.

B

A

A. Caisse du système d’extraction

B. Équerre de montage sous le plan de travail

C

D

C. Encoches en trou de serrure

D. Languettes guides

21

A. Languette de l’embout standard

REMARQUE: Seulement une languette doit être instalée A ou B

B. Languette de l’embout réversible

Page 22

Mesurer la distance “X” entre le sol et le dessus du plan de

travail. Soustraire 28½” de la distance “X” pour déterminer la

distance “Y” (X - 28½ = Y).

Dessus du plan de travail

Système d’extraction

par le bas

281⁄2”

(73 cm)

“X”

Left or right venting:

1. À deux personnes ou plus, poser l’arrière du système d’extraction

par le bas face au sol.

2. Retirer les 4 vis du couvercle monté à l’avant de la caisse du

moteur et les mettre de côté.

B

C

“Y”

Plancher du placard

6. Fixer les pieds de soutien aux côtés de la caisse du système

d’extraction avec 4 vis de 4 x 8 mm pour chacun. Les régler à la

distance “Y” entre le bas de la caisse du système d’extraction et

le bas des pieds de soutien. Serrer les vis.

A

A. Caisse du moteur

B. Pied de soutien

C. Vis de 4 x 8 mm

C

B

dim. “Y”

Déterminer la meilleure

orientation de l’évacuation pour

l’installation.

Dans le cas d’une installation dans un meuble, l’évacuation du

système d’extraction peut se faire par le bas, par le côté gauche

ou par le côté droit du meuble.

IMPORTANT: En cas d’utilisation du raccord de transition de

6” (15,2 cm) fourni pour un conduit rond de 6”, seule une

évacuation par la gauche ou par la droite est recommandée.

G

F

E

D

A.Couvercle

C. Vis à épaulement pour encoches en trou de serrure du couvercle

B. Vis du couvercle

D.Vis de montage du moteur

E. Couvercle de l’évacuation

F. Caisse du moteur

G. Vis du couvercle de l’évacuation

A

3. Faire glisser le couvercle vers le haut et le sortir des vis à

épaulement pour encoches en trou de serrure. Mettre le

couvercle de côté.

4. Retirer les 4 vis du bas de la caisse du moteur qui maintiennent

le moteur à la caisse.

REMARQUE : Débrancher le câblage électrique du moteur si

nécessaire.

5. Retirer les 3 vis et le couvercle de l’évacuation à gauche ou à

droite de la caisse du moteur, en fonction de l’orientation à

utiliser pour l’évacuation.

6. Faire pivoter le moteur du ventilateur de 90° à droite ou à gauche

selon l’orientation d’évacuation choisie et le xer à la caisse du

moteur avec les vis de montage du moteur retirées précédemment.

Ne pas tordre ou plier le câblage.

7. Fixer le couvercle de l’évacuation sur l’ouverture rectangulaire au

bas de la caisse du moteur à l’aide des vis correspondantes.

REMARQUE: Rebrancher le câblage électrique du moteur s’il a

été retiré.

8. Remonter le couvercle de la caisse du moteur à l’aide des 4 vis

précédemment retirées.

9. Pour monter le ventilateur à l’arrière de la caisse du système

d’extraction, passer à la section “Montage du ventilateur à

l’arrière”. Sinon, passer à la section “Achever l’installation”.

Évacuation par le bas:

REMARQUE: Si le clapet anti-retour est monté vers le bas, une

bouche de décharge murale ou à travers le toit équipée d’un clapet

est nécessaire à l’extrémité du circuit d’évacuation.

• Le système d’extraction par le bas est livré avec le ventilateur

en position pour une évacuation par le bas; par conséquent

aucune modication n’est nécessaire.

• S’il n’est pas nécessaire que le ventilateur soit monté à l’arrière,

passer à la section “Achever l’installation”.

• Pour monter le ventilateur à l’arrière de la caisse du système

d’extraction, passer à la section “Montage du ventilateur à

l’arrière”.

22

Page 23

Montage arrière (mode réversible)

Il ya une position de montage optionnelle de la plaque d’aspiration

(côté opposé) pour les emplacements du île. L’ensemble d’aspiration

(plaque métallique, ltres), peut être déplacé vers le côté opposé

(arrière) de la hotte.

B

D

C

4. Débranchez le raccordement électrique de l’ensemble de

l’aspiration, et retirez le de la hotte.

REMARQUE: Une fois que vous avez débrancher le connecteur, cou-

vrir avec le tube de l rétractable et les attaches en plastique comme

le montre l’image ci-dessous. Découvrez le connecteur opposé.

A

A

A. Boîte de moteur

B. Aspiration orientation

C. Table de cuisson

D. Assemblez aspiration

1. Déplacer la plaque d’aspiration et les ltres à graisse et les

mettre de côté. (Voir la section de nettoyage).

2. Avec l’aide d’un tournevis à tête plate, prendre les clips en

plastique du plaque d’aspiration.

B

C

A. Clip plastique de l

B. Tube de l rétractable

C. Connexion d’assemblage d’aspiration

5. Retirer les vis de montage de la structure d’aspiration comme

indiqué l’image ci-dessous.

B

A. Structure d’aspiration

B. Vis d’installation

A

6. Soulevez la structure et tourner le de l’autre côté et xer le avecla

mêmes vis retirées précédemment.

REMARQUE: An d’aligner correctement la structure, commencer

l’installation les vis indiquées dans le dessin.

3. Une fois que les clips ont été retirés de l’ensemble de l’aspiration,

la retraite les vis et la rondelle comme indiqué l’image ci-dessous.

Mettez les vis de côté.

A

A. Vis d’installation

7. Branchez le conexion électrique et le mettre en place.

8. Remettre les vis et rondelles métalliques dens l’ensemble de

l’aspiration. Insérez les clips en plastique.

9. Relocaliser les ltres à graisse et la plaque d’aspiration.

23

Page 24

Achever l’installation

REMARQUE: Le système d’extraction par le bas est livré avec un

clapet anti-retour de 3¼” x 10” (8,3 x 25,4 cm) et un raccord de transition pour conduit rond de 6” (15,2 cm) avec clapet. Se reporter à la

section “Clapet anti-retour de 3¼” x 10” (8,3 x 25,4 cm)” ou “Raccord

de transition pour conduit rond de 6” (15,2 cm) avec clapet”, selon le

type de circuit d’évacuation utilisé.

Clapet anti-retour de 3¼” x 10” (8,3 x 25,4 cm)

1. Fixer le clapet anti-retour de 3¼” x 10” (8,3 x 25,4 cm) à

l’ouverture d’évacuation de la caisse du ventilateur à l’aide de

trois vis de 3,5 x 9,5 mm.

AB

A. Vis de 3.5 x 9.5 mm

B. Clapet anti-retour de 3¼” x 10”

(8.3 x 25.4 cm)

A

Raccord de transition rond de 6” (15,2

cm) avec clapet

2. Fixer le raccord de transition rond de

6” (15,2 cm) à l’ouverture d’évacuation

(seule une évacuation par le côté droit

ou gauche est recommandée) à l’aide

de deux vis de 3,5 x 9,5 mm.

A

B. Raccord de transition rond de 6” (15.2 cm) avec clapet

3. Ôter les 4 vis du couvercle du boîtier de connexion.

4. Déterminer par quel côté (avant ou arrière) le câble

d’alimentation domestique entre dans le boîtier de connexion.

Ôter l’opercule approprié du panneau avant ou arrière et installer

un connecteur de conduit de ½” (12,7 mm) homologué UL ou

CSA.

A. Vis de 3.5 x 9.5 mm

B

5. À 2 personnes ou plus, insérer le système d’extraction par le

bas dans l’ouverture découpée dans le plan de travail.

Centrer le système d’extraction par le bas dans la découpe, son

rebord arrière par-dessus l’arrête de la découpe et l’arrière contre

la tranche de la découpe.

A

G

F

A. Rebord arrière du système

d’extraction par le bas

B. Tranche de la découpe du plan de travail

C. Arrière du système d’extraction par le bas

B

C

D

E

D. Arrière du meuble

E. Pied de soutien

F. Plancher du meuble

G. Plan de travail

6. Percer 2 avant-trous à travers les équerres de xation sous le

plan de travail, dans la face inférieure du plan de travail. Avec 2

vis du 4.5 x 13 mm screws, mount the brackets to the countertop.

IMPORTANT: Choisir des vis d’une longueur adéquate pour ne pas

traverser le plan de travail au serrage.

B

C

A

A. Vis

B. Backsplash

C. Table de cuisson

Établir l’aplomb vertical de l’appareil. Desserrer les vis des pieds

de soutien et régler les pieds de soutien en appui sur le plancher

du meuble.

IMPORTANT: Vériez avec un niveau, la tour verticale de la hotte est

perpendiculaire au sol installé.

B

B

24

A

A

A. Downdraft

B. Level

Page 25

7. Fixer les pieds de soutien de l’appareil sur le plancher du meuble

avec des vis (non fournies).

8. Serrer les vis des pieds de soutien.

Installation de commande

• Avant l’installation de commande, assurez-vous que vous avez

fait le découpes de procéde.

• Placez la base de contrôle sur place et marquer les trous avec un

crayon.

• Percer sur les emplacements marqués.