Elica EFG636SM Installation

User, Care and Installation Guide

Guide d’utilisation, d’entretien et d’installation

Guía de instalación, uso y mantenimiento

READ AND SAVE THESE INSTRUCTIONS

LISEZ CES INSTRUCTIONS ET CONSERVEZ-LES

LEA Y GUARDE ESTAS INSTRUCCIONES

English

Contents

page 2

French

Spanish

Sommaire

Contenido

page 15

página 44

English

Contents

Important Safety Notice ..................................................................................................................................................... 3

Electrical & Intallation Requirements ............................................................................................................................. 4

Electrical requirements ................................................................................................................................................... 4

Electrical Connection ......................................................................................................................................................... 5

List of Materials ................................................................................................................................................................. 6

Parts supplied ................................................................................................................................................................. 6

Parts not supplied ............................................................................................................................................................ 6

Dimensions and Clearances ............................................................................................................................................. 7

Ducting Options and Examples ....................................................................................................................................... 8

Venting methods .............................................................................................................................................................. 8

Preparation ....................................................................................................................................................................... 8

Installation ........................................................................................................................................................................... 9

Installation - Ducting version ................................................................................................................................................ 9

Descripcion of the Hood & Controls ................................................................................................................................. 11

Controls .............................................................................................................................................................................. 11

Maintenance ........................................................................................................................................................................ 12

Cleaning .............................................................................................................................................................................. 12

Grease Filter ....................................................................................................................................................................... 12

Replancing the light bulb .................................................................................................................................................... 13

Charcoal Filter .................................................................................................................................................................. 13

Warranty ............................................................................................................................................................................. 14

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions whit this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn off power circuit at service panel and lock out panel, before wiring the appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit.

READ AND SAVE THESE INSTRUCTIONS

Important Safety Notice

CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT USE

TO EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS

OR VAPOURS.

WARNING

TO REDUCE THE RISK OR FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you have questions, contac the manufacturer.

B. Before servicing or cleaning the unit, switch power off at

service panel and lock service panel disconneting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag,

to the service panel.

C. Installation Work and Electrical Wiring Must Be Done By

Qualied Person(s) In Accordance With All Applicable

Codes & Standards, Including Fire-rated Construction.

D. Sufcient air is needed for proper combustion and ex hausting of gases through the ue (Chimney) of fuel burnig

equipament to prevent back-drafting. Follow the standards

such as those published by the National Fire Protection

Association (NFPA), the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHARE),

and the local code authorities.

E. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

F. Ducted systems must always be vented to the outdoors.

CAUTION

To reduce risk of re and to properly exhaust air, be sure to

duct air outside - do not vent exhaust air into spaces within

wall, ceilings, attics, crawl spaces, or garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT

WORK.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

a) SMOTHER FLAMES with a clse-tting lid, cookie sheet,

or other metal tray, then turn off the gas burner or the

electric element. BE CAREFUL TO PREVENT BURNS.

If the ame do not go out immediately, EVACUATE AND

CALL THE FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - you may be burned.

c) DO NOT USE WATER, incluidiing wet dishcloths or towels

- a violent steam explosion will result.

d) Use an extinguisher explosion will result.

1) You know you have a class ABC extinguisher, and you

already know how to operate it.

2) The re is small and contained in the area where it

started.

3) The re department is being called.

4) You can ght the re with your back to an exit.

OPERATION

a. Always leave safety grills and lters in place. Without these

components, operating blowers could catch onto hair, ngers

and loose clothing.

The manufacturer declines all repsonsibility in the event of

failure to observe the instructions given here for installation,

maintenance and suitable use of the product. The manufacturer further declines all responsibility for injury due to negli-

gence and the warranty of the unit automatically expires due

to improper maintenance.

CAUTION

Automatically Operated Device - To reduce risk of injury disconnnect from power supply before servicing.

Install this hood in accordance with all requirements specied.

WARNING

To reduce risk of re or electical shock, do not use this hood with

any external solid state speed control device.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE.

a) Never leave surface units unattended at high settings.

Boilovers couse smoking on low or medium settings.

b) Always turn hood ON when cooking at high heat or when

f lambeing food (I.e. Crepes, Suzette, Cherries Jubilee,

Peppercom Beef Flabe’).

c) Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or lter.

d) Use proper pan siza. Always use cookware appropriate for

the size of the surface element.

3

Electrical & Installation requirements

Electrical requirements

IMPORTANT

Observe all governing codes and ordinances.

It is the customer’s responsability:

To contact a qualied electrical installer.

To assure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA 70

- latest edition*, or CSA Standards C22.1-94 Canadian

Electrical Code, Part 1 and C22.2 No. 0-M91 - latest edition**

and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is rec-

ommended that a qualied electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualied electrician if you are not sure range

hood is properly grounded.

Do not have a fuse in the neutral or ground circuit.

IMPORTANT

Save Installation Instruction for electrical inspector’s use.

The range hood must be connected with copper wire only.

The range hood must be connected directly to the

fused disconnect (Or circuit breaker) box through metal electrical conduit.

Wire sizes must conform to the requirements of the National Electrical Code ANSI/NFPA 70 -- latest edition*, or CSA

Standards C22.1-94, CANADIAN ELECTRICAL CODE PART

1 AND C22.2 No. 0-M91 - latest edition** and all local codes

and ordinances.

Before installing the hood

For the most efcient air ow exhaust, use

1.

a straight run or as few elbows as possible.

CAUTION: Vent unit to outside of building, only.

At least two people are necessary for installation.

2.

Fittings material is provided to secure the hood to most

3.

types of walls/ceilings, consult a Qualied Installer,

check if they perfectly t with your cabinet/wall.

Do not use ex ducting.

4.

COLD WEATHER installations should have an addi-

5.

tional backdraft damper installed to minimize backward

cold air ow and a nonmetallic thermal break to minimize conductions of outside temperatures as part of the

ductwork. The damper should be on the cold air side of

the thermal break.

Make up air: Local building codes may require the use

6.

of Make-Up Air Systems whe using Ducted Ventilation

Systems greater than specied CFM of air movement.

The specied CFM varies from locale to locale. Consult

your HVAC professional specic requeriments in your

area.

Removing the packaging

CAUTION!

Remove carton carefully, Wear gloves to protect against

sharp edges.

WARNING:

Revome the protective lm convering the product before

putting into operation.

A U.L. - or C.S.A. - listed conduit connector must be provided

at each end of the ppower supply conduit (at the range hood

and at the junction box).

Copies of the standards listed may be obtained from:

* National Fire Protection Association Batterymarch Park Quincy.

** CSA International 8501 East Pleasant Vallery Road Cleveland, Ohio

44131-5575

4

Electrical connection

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extensión cord.

Failure to follow these instructions can result in death, re, or

electrical shock.

GROUNDING INSTRUCTIONS

For grounded, cord-connected range hood:

•

This range hood must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current.

This range hood is equipped with a cord having a grounding

wire with a grounding plug. The plug must be plugged into

an outlet that is properly installed and grounded.

WARNING: Improper grounding can result in a risk of electric shock.

This range hood is equipped with a power supply cord having a 3 prong grounding plug.

To minimize possible shock hazard, the cord must be plugged

into a matting, 3 prong, grounding-type outlet, grounded in accordance with local codes and ordinances. If a mating outlet

is not avaiable, it is the personal responsability and obligation of the customer to have the propely grounded outlet in-

talled by a qualied electrican.

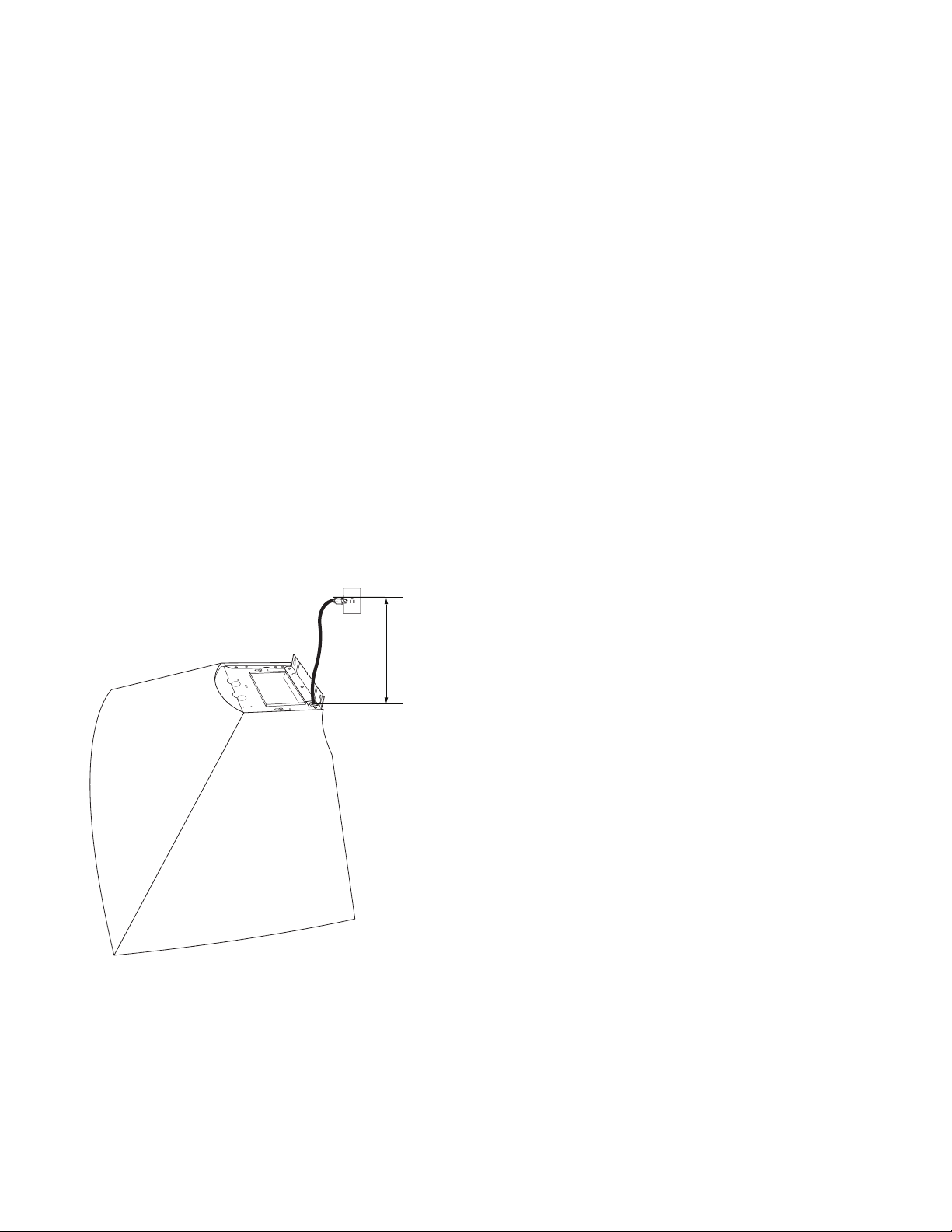

The grounded 3 prong outlet is to be located above the range

hood at a maximum distance of 33-7/18” (85.0 cm) from

where the power cord exits the hood. See Ilustration.

33-7/16”

(85 cm)

Consult a qualied electrical if the grounding instructions are

not completely understood, or if doubt exists as to whether

the range hood is propely grounded.

Do not use an extension cord.If the power supply cord is

too short, have a qualied electrician install an outlet near

the range hood.

5

List of Materials

Parts supplied

Removing the packaging

CAUTION!

Remove carton carefully, Wear gloves to proctect against

sharp edges.

WARNING:

Remove the protective film convering the product before put-

ting it into operation.

Hood canopy assembly with blower, transition.

•

Lamp already installed.

•

Grease filter.

•

Duct cover.

•

Hardware bag with:

•

Template

•

Duct cover support bracket (1 piece)

•

Use, care and installation guide

•

Wood screws (6 piece - 3/16” x 1”3/4)

•

Hood attachment anchors screw (6 pieces - 1/8”

•

x 3/8”)

Assembly screw (4 pieces)

•

Parts not supplied

Optional Accessories

Ductless Recirculating Kit

•

To be used only in the Ductless (Recirculating) version

Includes: charcoal filter, charcoal filter support and

fixing bracket, deflector.

Tools/Materials required

Wire nuts

•

Tape to mount template

•

8” rounded metal duct legth to suit installation

•

Measuring tape

•

Pliers

•

Gloves

•

Knife

•

Safety glasses

•

Electric drill with 5/6” and 3/8” Bits

•

Strain relief

•

Spirit level

•

Duct tape

•

Screwdrive:

•

Phillips (Posidrive) #2

Torx # 2

Wire cutter/stripper

•

Masking tape

•

Hammer

•

Saw, jig saw or reciprocating saw

•

6

Dimensions and Clearances

30” - 36”

*Ductless (Recirculating) version only

**Ducting version only

8 -1/16”

8 -1/8”

14 -1/8”

20”

24”

10 -1/8”

* 28-15/16 min.

42-3/16 max.

**28-7/8 min.

38-7/16 max.

7

Ducting Options and Examples

Closely follow the instructions set out in this manual.

All responsability for any eventual inconveniences, damages or res caused by not complying with the instructions in this

manual, is declined.

Venting methods

The hood is equipped with a transition B discharge of fumes to the outside (Ducting version).

Should it not be possible to discharge cooking fumes and vapour to the outside, the hood can be used in the Ductless

(Recirculating) version. Attach a charcoal lter and the deector F on the duct cover support bracket G. Fumes and vapours

are recycled through the top grille H by means of a duct connected to the transition B and the transtion mounted on the

deector F.

NOTE: For the ductless (Recirculating) version only: purchase the ductless recirculating Kit.

Minimum duct size (Ducting/Ductless version): 6” Round Pipe.

Roof pitch/w

Flashing and cap

Defector (F)

Top grille (H)

Support bracket (G)

Pipe

Pipe

Transition (B)

Pipe

Transition (B)

sidewall cap

with gravity

damper

Transition (B)

Vertical Discharge

Recirculating

Preparation

Do not cut a joist or stud only if absolutely necessary. If a joist or stud must be cut, then a supporting frame must be constructed.

Fitting material is provided to secure the hood to most types of walls/ceilings.

However, a qualied technician must verify suitability of the materials in accordance with the type of wall/ceiling.

Before marking cutots, make sure there is proper clearance within the ceiling or wall for exhaust vent.

Hood installation height above cooktop is the users preferecne. The lower the hood is adove the cooktop, the more efcient

the capturingof cooking odors, grease and smoke.

CAUTION: FOR 8’ CEILING : MOUNT THIS HOOD SO THAT THE BOTTOM EDGE IS AT 30” (76,2 CM) MINIMUM ABOVE

THE COOKING SURFACE.

FOR 9’ CEILING: MOUNT THIS HOOD SO THAT THE BOTTOM EDGE IS AT 36” (91,4 CM) MINIMUM ABOVE THE

COOKING SURFACE.

CHECK YOUR CEILING HEIGHT AND THE HOOD HEIGHT MAXIMUM BEFORE YOU SELECT YOUR HOOD.

8

Installation

Installation - Ducting version

It is recommended that the vent system be installed be-

•

fore the hood is installed.

Before making cutouts, make sure there is proper clear-

•

ance within the ceiling or wall for exhaust vent.

Check your ceiling height and the hood maximum height

•

before you select your hood.

Disconnect power.

•

Determine which venting method to use: roof, wall, or

•

non-vented.

Select a at surface for assembling the range hood.

•

Place covering over that surface.

Using 2 or more people, lift range hood onto covered

•

surface.

Range hood mounting screws installation

Determine and mark centerline on the wall the canopy

•

hood will be installed.

Tape template in place, aligning the template centerline

•

and bottom of template with hood bottom line and with

the centerline marked on the wall.

A

TROPPUSLLAWRAERROSDUTSHGUORHTSELOHTOLIP"61/3)OWT(2LLIRD

Vertical Centerline

LLAWRAER

ETALPMETGNITNUOM

C

L

eniLlatnoziroH

thgieHnoitallatsnI

EGDEMOTTOBNGILA

ENILLICNEPHTIW

MOTTOBGNITACIDNI

DOOHEHTFO

Secure the bracket to the wall:

Position vent cover bracket on wall about 1/8” (3.0mm)

•

away from the ceiling.

Mark the hole locations.

•

Drill 3/8” (9.5mm) holes for wall anchors and insert an-

•

chors ush with the wall.

A

B

C

D

A. 8 x 40 mm drywall anchors

B. Centerline on wall

C. Vent cover support bracket

D. 5 X 45 mm screws

Attach vent cover support bracket to wall.

•

Mounting the hood

Using 2 or more people, hang range hood on 2 mount-

•

ing screws though the mounting slots on back of hood.

A

B

B

C

A. Centerline

B. Fastener locations

C. Mounting height reference

Marck centers of the fastener locations through the tem-

•

plate to the wall.

IMPORTANT: All screws must be installed into wood. If there

is no wood to screw into, additional wall framing supports

may be required.

Remove the template.

Drill 3/16” (4.8 mm) pilot holes at all locations where

•

screws are being installed into wood.

Install the 2 - 5 X 45 mm mounting screws. Leave a 1/4”

•

(6.4 mm) gap between the wall and the back of the screw

head to slide range hood into place.

1/4”

(6.4 mm)

C

A. Mounting screws

B. Mounting slots

C. Lower mounting screws

Remove the grease lter andmount the hood onto the upper

•

screws.

Level the range hood and tighten upper mounting screws.

•

Install 2 - 5 X 45 mm lower mounting screws and tighten.

•

9

Install transition on top of hood (if removed for shipping)

•

with 2 - 3.5 X 6.5 mm sheet metal screws.

A

B

A. Vent transition

B. 3.5 X 6.5 mm screw

For vented installations only:

Fit vent system transition place

•

Seal connetion with clamps.

•

Check tha brackdraft dampers work propely.

•

For non vented (reciculating) intallation only:

Assemble the air deector with the duct cover bracket

•

with 2 - assembly screws provided with the Recirculatin

Kit.

B

A

Cut the duct to the measured size (X)

•

Remove the iar deector

•

Slide the duct onto the bottom of the air deector

•

Place the assembled air deector and duct over the ex-

•

haust outlet from the hood.

Reassemble the air deector to the duct cover bracket

•

with 2 assembly screws.

Seal connetions with vent clamps.

•

WARNING: Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result

in death re, or electrical shock.

Mounting the duct cover

When using both upper and lower vent covers, push lower

cover down onot hood and lift upper cover to ceiling and

install with two 2.9 X 6.5 mm screws.

NOTE: For vent installations, the upper vent cover may be

reversed to hide slots.

D

C

C

A

B

C

A. Vent cover bracket

B. 2.9 X 6.5 mm screw

C. Deector

Measure from the bottom of the air deector to the bottom of

the hood outlet.

A

B

C

D

E

X

B

A. Upper ducto cover

B. Lower vent cover

C. 2.9 X 6.5 mm screws

D. Bracket

Complete Installation

For non-vented (recirculating) installation only, install charcoal lters over grille on blower housing. Install metal l-

ters.

Check the operation of the range hood blower and light.

A. Air deector

B. Vent clamp

C. X = length to cut duct cover

D. Duct cover

E. Exhaust outlet

10

Description of the hood & Control

6

1

5

2. Timer Button

The default timer setting is 10 minutes, and

•

it can be adjusted between 60 minutes and 1

minute.

After pressing the timer button, the control en-

•

ters to a timer setup mode, and user can adjust

the timer countdown time with the “+” and “-”

buttons within 5 seconds. The timer can be initiated immediately pressing the timer button. after

setting the timer duration or pressing the timer

button twicw ( default 10 minutes setting).

If no action occurs within 5 seconds, the count-

•

down will start.

During the timer setup the “+” and “-” buttons

•

are dedicated to the timer and no motor action

will occur.

Once the timer is initiated, it can be cancelled

•

by pressing the timer button again.

4

2

Blower and light controls

1.

Lamp housings

2.

Grease lter Handle

3.

Grease Filter

4.

Canopy

5.

Duct covers

6.

3

Controls

Use the high suction speed in case of concentrated kitchen

vapours. It is recommended that the cooker hood suction is

switched on for 5 minutes prior to cooking and to leave in operation during cooking and for another 15 minutes approximately after terminating cooking.

Note: Hood retains last speed setting when aspiration switch

is turned off.

Description of control panel

3. Display

Shows the hood settings.

•

The display will be lit at low intensity when the

•

hood is not operating.

Pressing and key the display will light up at

high intensity.

The display will be lit at high intensity when the

•

hood is operating.

If no key is pressed within a minute the display

•

will return to being at low intensity.

4. “-” Button. Speed Decrease / OFF

This button is used to decrease the fan speed,

•

or turn OFF the fan.

The fan will turn OFF if the “-” button is pressed

•

and the hood was in the rst speed.

If the fan is at second speed and the “-” button

•

is pressed, the fan will be set to rst speed.

If the fan is at third speed and the “-” key is

•

pressed, the fan will be set to second speed.

If the fan is at fourth speed and the “-” button is

•

pressed, tha fan will be set third speed.

If the fan is OFF and the “-” button is pressed,

•

the control backlight will light up.

1. Light Button

Press lamp button to turn ON the light on High

•

Intensity (Lamp state previously OFF).

Press lamp button to turn ON the light on Low

•

Intensity (Lamp state previously ON).

Press lamp button to turn OFF the light (Lamp

•

state previously ON).

5. “+” Button. Speed Increase / ON

This button is used to increase the fan speed,

•

or turn ON the fan.

The fan will turn On if the “+”button is press and

•

the hood was OFF.

If the fan is at rst speed and the “+” button is

•

pressed, the fan will be set to second speed.

If the fan is at second speed and the “+” button

•

is pressed, the fan will be set to third speed.

If the fan is att third speed and the “+” button is

•

pressed, the fan will be set to fourth speed.

If the fan is at fourth speed and the “+” button is

•

pressed, a beep will sound.

11

Clock programming

The clock can be reprogrammed at any time except dur-

•

ing an active timed fuction.

The clock can be displayed in a twelve hour format and

•

velid clock times are from 1:00 to 12:59.

The clock can be reprogrammed pressing the “Timer”

•

button for 3 seconds, and after, the clock can be adjust-

ed with the “+” and “-” buttons.

The user can have minute increments / decrements of 1

•

minute, but if the user keep pressing the “+” / “-” buttons

for more than 1 second, the increments 7 decrements

will be of 5 minutes.

During this option the control will round to the nearest 5

minutes.

The user can nish on reprogramming the clock pressing

•

the “Timer” button.

After 1 minute of no button pressed the control will ac-

•

cept the programmed clock time and will add one minute

to the se clock.

Grease lter saturation alarm (Optional)

After thirty fan functional hours, the display will show

•

“Grease Filter” if the fan is active.

When this icon is shown in the display, the grease lters

installed are required to be washed.

To reset the grease lter saturation alarm the user must

•

press the “+” button for 5 seconds, after this action the

icon “Grease Filter” is not displayed, and the hood has

normal display operation.

Charcoal lter saturation alarm (Optional)

After one hundred and twenty fuctional hours of the fan,

•

the display will show “Charcoal Filter” if the fan is active.

When this icon ashes on display, the charcoal lters

installed are required to be replaced or reactivated.

To reset the charcoal lter saturation indication the user

•

must press the “-” button for 5 seconds, after this time

the icon “Charcoal Filter” is not displayed and the hood

has the normal display operation.

Heat sensor

The control is equipped with a heat sensor that will turn

•

on the blower at third speed if excessive heat occurs

(over 149°F or 65°C) surrounding the control area.

If the blower is OFF or if it is operating at rst speed, the

•

blower will be set automatically to third speed, the dis-

play shows the word “CArE” to indicate that heat sensor

has detected an excessive heat.

During this state, the user may raise the blower speed to

•

fourth speed but can not decrease the speed.

When the temperature level on the hood droops to nor-

•

mal, the blower will operate in the setting dened by the

user before the alarm occured.

Maintenance

ATTENTION! Before performing any maintenance opera-

tion, isolate the hood from the electrical supply by switching

off at the connector and removing the connector fuse.

Or if the appliance has been connected through a plug and

socket, then the plug must be removed from the socket.

Cleaning

Do not spray cleaners directly to the control while cleaning

the Hood. The cooker hood should be cleaned regurarly

(at least with the same frequency with which you carry out

maintenance of the fat lters) internally and externally. Clean

using the cloth dampened with neutral liquid detergent. Do

not use abrasive products. DO NOT USE ALCOHOL!

WARNING:

Failure to carry out the basic cleaning recommendations of

the cooker hood and replacement of the lters may cause

re risks.

The refore, we recommend oserving these instructions.

The manufacturer declines all responsibility for any dam-

age to the motor or any re damage linked to inappropriate

maintenance or failure to observe the above safety recommendations.

Audible signal activation and deactivation

The audible signals can be activated or deactivated

•

pressing the “Light” button for 5 seconds.

If the audible signal is activated, a tone must sound and

•

the “Snd” symbol must appear on the display for 3

seconds.

If the audible signal is deactivated, the “Snd” symbol must

•

appear on the display for 3 seconds and no tone must

sound.

Charcoal lter inclusion and exclusion

(Recirculating accessories)

The charcoal lter inclusion or exclusion can be set by

•

pressing the “+” and “-” buttons at the same time for 5

seconds.

The inclusion or exclusion of chacoal lter must be

•

selected while the lamps and the motor are OFF.

When the carcoal lter has been excluded, the charcoal

•

lter alarm is disabled.

Grease Filter

Traps cooking grease particles.

This lters should be washed frequently using non aggressive detergents, either by hand or in the dishwasher, which

must be set to a low temperature and a short cylcle. When

washed in a dishwasher, the grease lter may discolour

slightly, but this does not affects its ltering capacity.

To remove the grease lter, pull the spring release handle.

12

Replacing the light bulb

CAUTION

Before replacing the lamps, switch power off at service panel

and lock service panel disconnecting means to prevent power from being switched on accidentally.

NOTE: Turn off the lights and fan. Allow the lights to cool

before handling. If new lights do not operate be sure

lights are inserted correctly before calling service.

Charcoal Filter

If the model is not vented to the outside, the air will be recir-

culated through disposable charcoal lters that help remove

smoke and odors.

The charcoal lters cannot be cleaned.

They must be replaced.

Cover the grill that protects the suction motor with the carbon

lter so that the slots on the lter correspond to the pins on

the sides of the motor protection grill.

Turn the carbon lter clockwise to block them (bayonet xing).

The charcoal lters should be replaced every 4-6 months

(depending on hood usage).

NOTE: DO NOT rinse, or put charcoal lters in an automatic

dishwasher.

NOTE: Charcoal lters are not included with the hood.

They must be ordered from your supplier.

Order the needed kit specifying your hood model and width

size.

Replace Lights

Remove the damaged light (twist counter clockwise) and

•

replace with a new 120 Volt, 50 Watt (maximum) 50°

halogen light made for a GU10 base, suitable for use in

open luminarie.

B

A

A. Charcoal lter

B. Slots

C.Blower motor

C

13

Loading...

Loading...