Digi-Mantle – A Reaction Station with Interchangeable Mantles.

OMCA0250, OMCA0500, OMCA1000.

INSTRUCTION BOOK.

Page 1 of 28. Digi-Mantle M7754 issue 14.3

Please take your time to read this Instructions book in order to understand the safe and

Contents.

Section 1.

Page

3

Section 2.

Page

4

Section 3.

Page

5

Section 4.

Page

7

Section 5.

Page

8

Section 6.

Page

9

Section 7.

Page

10

Section

8.

Page

21

Section 9.

Page

23

Section 10.

Page

25

Section 11.

Page

26

Section 12.

Page

28

Appendix ‘A’

Page

27

Bibby Scientific Limited.

correct use of your new Bibby Scientific product.

It is recommended the Responsible Body for use of this equipment reads this

Instruction book and ensures the user(s) are suitably trained in its operation.

Introduction

Symbols and using this instruction book.

Safety Information.

Unpack and Contents.

Installation.

Environmental Protection.

Product Operation.

Technical Specification.

Maintenance

Parts and Accessories

Customer Support

EC Declaration of Conformity.

Decontamination Certificate

© The copyright of this instruction book is the property of Bibby Scientific Limited. This instruction book is supplied

by Bibby Scientific Limited on the express understanding that it is to be used solely for the purpose for which it is

supplied. It may not be copied, used or disclosed to others in whole or part for any purpose except as authorised

in writing by Bibby Scientific Limited. Bibby Scientific Limited reserves the right to alter, change or modify this

document without prior notification.

In the interest of continued development Bibby Scientific Limited reserve the right to alter or modify

the design and /or assembly process of their products without prior notification.

This product is manufactured in Great Britian by Electrothermal, part of the Bibby Scientific Group of

companies.

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

Page 2 of 28. Digi-Mantle M7754 issue 14.3

1. INTRODUCTION

1.1. Your Digi-Mantle has been designed to provide a comprehensive answer to heating and

stirring fluids in various vessel formats. This product is modular in design allowing for

complete interchange ability between mantles of various sizes. With its ‘easy to read / easy

to operate’ revolutionary CTC (Capacitance Touch Control) panel, setting the required

temperature and stir speed takes only seconds.

1.2. Heating is controlled by a modern ‘state of the art’ micro processor, which displays the

heat setting as a percentage of the total power. When the temperature probe is fitted, the

heating is controlled via the temperature feed back circuit and the actual temperature is

displayed. All new dry blocks come with an inbuilt temperature sensor. This allows the true

block temperature to be viewed at all times. When using a probe and dry block with in built

sensor, the temperature displayed is that as measured by the probe.

1.3. An ‘all new’ digital controller and motor arrangement allow for accurate, low speed stirring

control. Uniform stirring is provided via a motorised rotating magnet assembly positioned to

provide maximum magnetic flux linkage to rotate the stirrer bars in each reaction vessel.

Page 3 of 28 Digi-Mantle M7754 issue 14.4

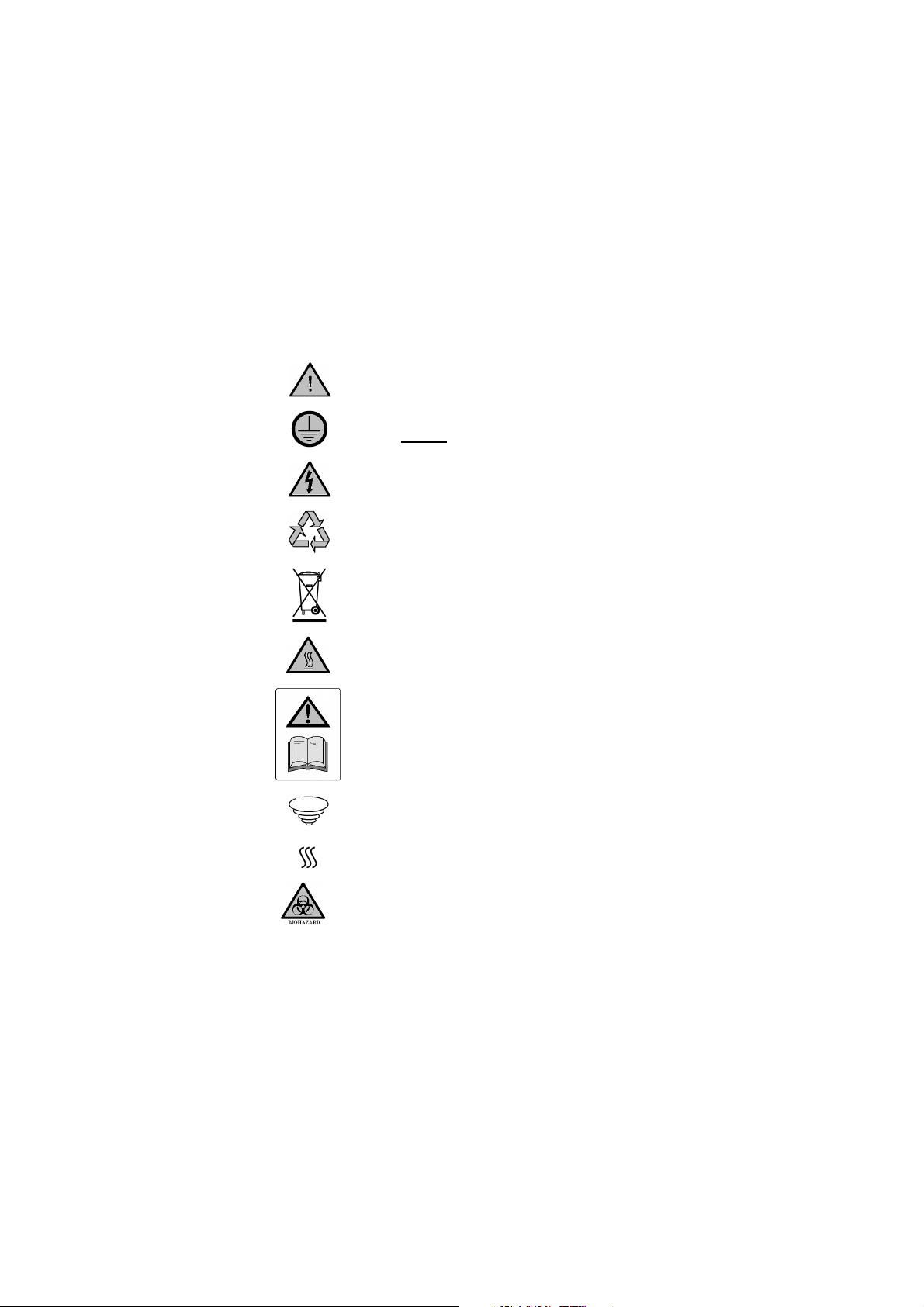

2. SYMBOLS AND USING THIS INSTRUCTION BOOK.

2.1. Throughout this Instruction book the following symbols are shown to identify conditions

which pose a hazard to the user, or to identify actions that should be observed. These

symbols are also shown on the product, or its packaging. When a symbol is shown next to

a paragraph or statement it is recommended the user takes particular note of that

instruction in order to prevent damage to the equipment or to prevent injury to one’s self or

other people.

To prevent injury or equipment damage it is the manufacturer’s recommendation

that all persons using this equipment are suitably trained before use.

2.2. Symbols Defined.

Caution, risk of danger. See note or adjacent

symbol.

Protective conductor terminal to be earthed.

Do Not loosen or disconnect.

Caution / risk of electric shock

Recyclable Packing Material

Do not dispose of product in normal domestic

waste.

Caution. Hot surface.

Refer to Operator Instructions book.

Stirring Facility On / Off

Heating Facility On / Off

Bio Chemical Hazard. Caution required. Will require

decontamination.

Page 4 of 28 Digi-Mantle M7754 issue 14.3

DO NOT

Never

Do not

Do not

Do not

Do not

Do not

Do not

Do not

Do not

3. SAFETY INFORMATION.

This product has been designed for safe operation when used as detailed in accordance

with the Manufactures instructions.

NOTE: Failure to use this equipment in accordance with the manufactures operating

instructions may compromise your basic safety protection afforded by the equipment and

may invalidate the warranty / guarantee. The warranty / guarantee dose not cover damaged

caused by faulty installation or misuse of the equipment.

3.1. Prevention of Fire and Electric Shock.

To prevent a risk of fire or electric shock,

product case without authorisation. Only qualified Service personnel

3.2. General Safe Operating Practice.

should attempt to repair this product

Replace fuses only with the type as listed in section, Parts and

Accessories (See fuse type and rating)

Ensure the Mains Power Supply conforms to rating found on the

data plate located on the underside of each item of this equipment.

Operate this equipment with out connection to earth /

ground. Ensure the mains supply voltage is correctly earthed /

grounded in accordance with current area legislation.

Always follow good laboratory practice when using this

equipment. Give due recognition to your company’s safety and

legislative health & safety procedures and all associated legislation

applicable to your areas of operation. Check laboratory procedures

for substances being heated and ensure all hazards (e.g. explosion,

implosion or the release of toxic or flammable gases) that might

arise have been suitably addressed before proceeding. When

heating certain substances the liberation of hazardous gases may

require the use of a fume cupboard or other means of extraction.

Ensure equipment is used on a clean, dry, non-combustible, solid

work surface with at least 300mm suitable clearance all around

from other equipment.

position the product so that it is difficult to disconnect from

the mains supply.

touch the heating element or any glass vessel whilst in use.

immerse unit in water or fluids.

spill substances onto the mantle. If spillage does occur,

disconnect unit from mains supply and follow instructions as

detailed in Section ‘Maintenance’.

cover the mantle whilst in use.

leave equipment switched on without a charged flask(s).

install or remove the mantle from the control unit whilst

power is applied to the controller.

thermally insulate the exposed upper section of the

vessel(s), as the insulation used may obstruct the convection

cooling airways around the rim of the cartridge enclosure and cause

the mantle to overheat.

open your

Page 5 of 28 Digi-Mantle M7754 issue 14.4

It is not recommended to leave any heating apparatus unattended

Do not

during operation.

Only use Original Equipment manufactures spares and

accessories. Ref Section 10.

This equipment employs the use of rotating magnets. Keep all

metal objects and magnetic data devises (credit cards, door /

security passes) away from the stirrer unit.

The equipment is not spark, flame or explosion proof and has not

been designed for use in hazardous areas in terms of BSEN 6007914:1997. Keep flammable, low flash point substances away from

the apparatus.

operate or handle any part of this product with wet hands.

Keep the Mains cord and moulded IEC plug and lead set cable

away from the heating surface.

Page 6 of 28 Digi-Mantle M7754 issue 14.3

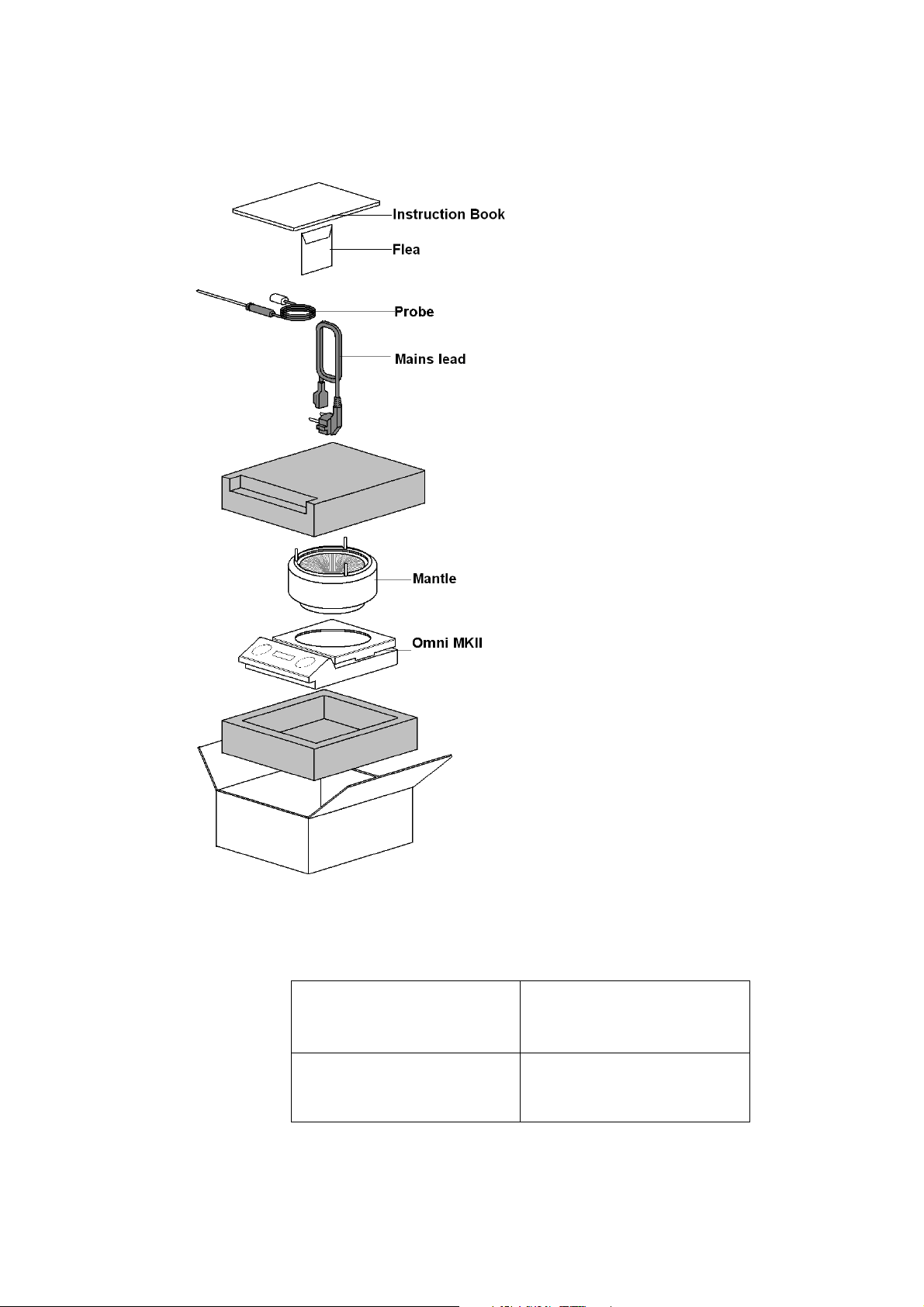

1x Digi controller with inbuilt stir

4. UNPACK AND CONTENTS.

4.1. OMCA0250, OMCA0250X1, OMCA0500, OMCA0500X1, OMCA1000, OMCA1000X1,

1x Instruction Book

1 x Flea Stir bar

(0250 mantle). OR

(0500 mantle). OR

(1000 mantle).

1x Probe

1x Mains lead and moulded IEC

plug and lead set (UK)

1x Mains lead and moulded IEC

plug and lead set (Europe)

1x Mains lead and moulded IEC

plug and lead set (USA)

1x Mantle

(0250ml). OR

(0500ml). OR

(1000ml).

Page 7 of 28 Digi-Mantle M7754 issue 14.4

For your future reference

Controller Serial Number

please record your products

Serial and Model numbers.

Mantle Serial Number

=

Blue

or

White

=

Neutral

Brown

or

Black

=

Live / line hot.

5. INSTALLATION.

5.1. Electrical safety and installation.

5.1.1. This equipment is designed for safe use under the following conditions:-

• Indoor use.

• Altitude up to 2000 meters.

• Temperatures between 5°C and 40°C.

• Maximum relative humidity 80% for temperatures up to 31°C decreasing

linearly to 50% relative humidity at 40°C.

• Mains input supply voltage fluctuations up to ± 10% of the nominal voltage.

• Transient over-voltages typically present on the mains supply.

• Applicable rated pollution degree 2.

5.1.2.

This equipment must be earthed / grounded to a fixed earth / grounded mains

socket outlet. The mains supply is to be earthed / grounded in accordance with

current legislation.

5.1.3. Ensure only the correct rated mains input fuses are fitted. (Where applicable

ensure the correct Mains cord and moulded IEC plug and lead set cable fuse if fitted).

See Technical Information Section 8 of this document.

5.1.4. Check the input voltage on the product data label of each Digi-Mantle item. Ensure

the rating conforms to your local supply.

5.1.5. This product should be connected to a mains supply source which incorporates an

RCD or GFCI device that has a tripping current of 30mA or less. The RCD or GFCI

residual Current Device cuts off power to the equipment immediately it detects a

current leakage fault. For example, cutting off the power when there is an accidental

liquid spillage in a mantle protected with an earth (ground) screen.

5.1.6. The unit is supplied with a Mains cord and moulded plug set cable wired as follows.

Green / Yellow

or

Green

Earth / Ground

When using with a new mantle:

Observation: the surface of the heating element of a mantle cartridge will upon receipt look

slightly discoloured. This discolouration is normal and occurs at the factory during testing

when the mantle is first heated up.

Page 8 of 28 Digi-Mantle M7754 issue 14.3

6. ENVIRONMENTAL PROTECTION.

6.1. Maximum consideration has been given to environmental issues within the design and

manufacturing process without compromising end product performance and value.

6.2. Packaging materials have been selected such that they may be sorted for

recycling.

6.3. At the end of your product and accessories life, it must not be discarded as domestic

waste. Ref: EU Directive 2002/96/EC on Waste Electrical and Electronic Equipment

Directive (WEEE). Please contact your distributor / supplier for further information. For end

users outside of the EU consult applicable regulations.

6.4. This product should only be dismantled for recycling by an authorised recycling company.

This product and accessories must be accompanied by a completed

Decontamination Certificate prior to any disposal. Copies of the Certificate are

available from your distributor of Bibby Scientific products, or you may copy and

enlarge from ‘Appendix A’ of this instruction book.

Bibby Scientific’s Electrothermal branded product range is registered with the Environment Agency under the name of as Electrothermal

Engineering Limited as being a producer of WEEE (Waste Electronic and Electrical Equipment) through b2b Compliance, an authorised

waste collection compliance scheme.

Page 9 of 28 Digi-Mantle M7754 issue 14.4

7. PRODUCT OPERATION.

7.1. Overview.

Your Digi-Mantle has been designed for easy operation. The illustrations show a

detailed layout of your Digi-Mantle control unit.

Figure 7 – 1

1 Magnetic Stir Hub.

2 Stir activation key

3 Heater activation key

4 LCD Display

5 Menu selection keys

Figure 7 - 2

6 On / Off power switch

Page 10 of 28 Digi-Mantle M7754 issue 14.3

Figure 7 - 3

7 External probe socket.

8 Data plate label.

9 Mantle cartridge control plug

10 Mantle cartridge power supply socket

11 Vertical Rod clamp fastening bracket

12 Mains Input IEC socket.

13 Earth test point

14 Fuses.

Figure 7 - 4

Typical front screen display.

7.2. Support Rod. (optional).

The Digi-Mantle incorporates a vertical rod support bracket. The rod is to be fastened

into the bracket. Glass arrangements are to be secured in conjunction with

appropriate clamp and flask support when using a Mantle.

7.3. Fitting a Mantle

7.3.1. Fitting a Mantle cartridge is achieved by aligning the 9 pin plug of the Mantle

cartridge with the 9 pin socket.

Page 11 of 28 Digi-Mantle M7754 issue 14.4

7.3.2. Carefully lower the Mantle cartridge into the control unit ensuring the tabs on the

controller align with the grooves in the base of the dry block or mantel ensuring

positive engagement.

7.3.3. If required, insert the external sample temperature probe plug into the external

probe socket.

WARNING.

Care should be exercised when handling a Mantle.

WARNING.

Ensure the mains electricity supply is turned off and disconnected before fitting

a Mantle.

7.4. Power on and Front Screen menu.

7.4.1. Connect the Mains cord and moulded IEC plug and lead set cable supplied with the

Digi-Mantle into the mains power inlet socket (see figure 7-3, item12). Press the On /

Off switch (see figure 7-2 item 6) to the on position.

7.4.2. The LCD display will go through a warm and self check routine that will take a few

seconds during which the Digi-Mantle Software revision will be displayed for 5

seconds before conformation. Upon completion of the routine the Digi-Mantle LCD will

then display the type of heating apparatus being used. (See figure 7-4).

Note: All function selections and settings are made using the menu keys. The keys

are indicated using

Press the right hand menu key

<^>

symbols in the LCD display.

>

to confirm correct module.

Figure 7-5

Note: The profile for 500ml is the same as the 1000ml. When using the 500ml

mantle 1000ml will be shown on the display. Please note this is not a fault of

the unit or the mantle. The 250ml mantle will display 250ml Mantle.

If the Error message ‘Module Missing’ is displayed (see figure 7-6) turn off the

Digi-Mantle unit. Insert a Mantle cartridge or ensure the existing module is correctly

seated.

Figure 7-6

• the main screen menu will look like the illustration seen in Figure 7-7.

Note: The e character next to the temperature display when external probe is

connected.

Figure 7-7.

Page 12 of 28 Digi-Mantle M7754 issue 14.3

7.5. Stir speed setting and activation.

From the main display screen menu press the > key to enter the ‘Stir speed’ setting

screen. (See figure 7-8).

Note: the Stir speed displayed is that of the last setting made by the user.

Press the > key to enter the stir speed selection screen. (See figure 7-9).

Press the ^ key to make the 100’s value selection. Press the v key if you wish to

reduce the selected stir speed value.

Press the > key to go into the 10’s selection screen (See figure 7-10).

Figure 7-8.

Figure 7-9.

Figure 7-10.

Press the ^ key to make the 10’s value selection. Press the v key if you wish to

reduce the selected stir speed value.

Press the > key to return to the front screen menu.

OR…….

If 10 seconds elapse without a key being pressed the display is to return to the

main display menu.

Note: There is no facility for setting the units stir speed value.

To start the stirring process press the stir key marked with the symbol

To stop the stirring process press the stir key once more.

Note. To show stirring is in operation the stir symbol will remain illuminated. The

stir speed shown on the LCD is the true speed of stir. Not the setting.

Page 13 of 28 Digi-Mantle M7754 issue 14.4

7.6. Heat setting and activation.

7.6.1. Setting the temperature when using a Mantle cartridge without internal

sensor.

From the main display menu screen press the < key to go into the ‘Heat setting’

screen. (See figure 7-11).

Note: The default setting will always display 00%. Previous power settings are not

retained.

Press the > key to go into set power selection screen. (See figure 6-12).

Press the ^ key to make the % power selection. Press the v key if you wish to

reduce the power selection.

Note: The power settings are made in increments of 5°C. The power selection

range is from 0 to 100%.

Figure 7-11.

Figure 7-12.

Press the > key to return to the front screen menu.

OR…….

If 10 seconds elapse without a key being pressed the display is to return to the

main display menu.

To start the heating process press the heating key marked with the symbol .

To stop the heating process, press the heating key once more.

Note. To show heating is in operation the heat symbol will remain illuminated. The

power percentage shown on the LCD is that of the setting.

7.6.2. Setting the temperature when using Mantle cartridge using the external

probe.

Note: With the external probe attached an e symbol will appear in the LCD next to

the temperature reading indicating the connection of the external probe (See Figure

7-9). The Temperature reading displayed is that read by the probe.

The external probe is to be placed in the sample solution. Heating your sample is

now controlled via the external probe.

From the main display menu screen press the < key to go into the ‘Temperature

setting’ screen. (See figure 7-13).

Figure 7-13.

Note: the Stir temperature displayed is that of the last setting made by the user.

Page 14 of 28 Digi-Mantle M7754 issue 14.3

Press the > key to go into temperature selection screen. (See figure 7-14).

Figure 7-14.

Press the ^ key to make the 100’s temperature value selection. Press the v key if

you wish to reduce the selected temperature value.

Press the > key to go into the 10’s temperature selection screen (See figure 7-15).

Figure 7-15.

Press the ^ key to make the 10’s temperature value selection. Press the v key if

you wish to reduce the selected temperature value.

Press the > key to go into the units temperature selection screen (See figure 7-16).

Figure 7-16.

Press the ^ key to make the units temperature value selection. Press the v key if

you wish to reduce the selected temperature value.

Press the > key to return to the front screen menu.

OR…….

If 10 seconds elapse without a key being pressed the display is to return to the

main display menu.

To start the heating process press the heating key marked with the symbol .

To stop the heating process press the heating key once more.

Note: To show heating is in operation the heat symbol will remain illuminated. The

actual temperature shown on the LCD is that seen by the internal dry block sensor.

Note: During the heat up process the will flash to indicate the set temperature

has not been reached. Once the set temperature has been reached the flashing

symbol will remain constantly illuminated. To accommodate over / under

temperature oscillation the symbol will not recommence flashing until the

temperature is ± 5°C off of the set temperature.

Note: (When used with external probe) the temperature range setting for a ambient

+5°C to 220°C settable in increments of 1 °C

Page 15 of 28 Digi-Mantle M7754 issue 14.4

7.7. Timer Operation.

Your Digi-Mantle has the facility to set a countdown timer which will switch off the

heaters after a per-set time period. The timer can be set for up to 99hours 59

minutes.

Set the required heating temperature as described in section 7.6.

From the main display screen press the ^ key to enter ‘time set’ mode.

(See figure 7-17).

Press the ^ to make the 10’s hours selection. Pressing the v will reduce the

selection.

Note: Once a time digit has been set all the remaining time set digits will default to

zero until they are set.

Press the > key to go into the unit hours selection. (See figure 7-18).

Figure 7-17.

Figure 7-18.

Press the ^ to make the unit hours selection. Pressing the v will reduce the

selection.

Press the > key to go into the 10’s minutes selection. (See figure 7-19).

Figure 7-19.

Press the ^ to make the 10’s minutes selection. Pressing the v will reduce the

selection.

Press the > key to return to the front screen menu.

OR…….

If 10 seconds elapse without a key being pressed the display is to return to the

main display menu.

Note: There is no setting facility of setting unit minutes.

To start the heating process press the heating key marked with the symbol .

The timer will not commence count down until the heaters are activated.

With the timer set the front screen will display count down hours indicated with an

h

symbol next to the time display. (See figure 7-20).

Figure 7-20.

When only minutes remain on the time counter the display will switch over to a

minutes count and the

m

symbol will be displayed next to the time display. (See

figure 7-21).

Page 16 of 28 Digi-Mantle M7754 issue 14.3

When the timer counter reaches zero the heaters are turned off. The key

illumination is extinguished ant the main display screen reverts to

second ‘beep’ is sounded when the heaters are turned off in timer mode.

Note: At any time during the use of the timer facility the heaters may be turned off

manually using the key.

7.8. Keypad Lock / Unlock.

To prevent accidental switching of functions or the disturbance of run settings

the Digi-Mantle has a ‘Keypad lock facility.

7.8.1. To lock the keypad.

Press the down arrow v key. The display will now instruct you to press the left arrow

menu key. (See figure 7-22).

Press the left arrow < key. The display will now instruct you to press the up arrow

menu key. (See figure 7-23).

Figure 7-21.

Figure 7-22.

^

t

. A one

Figure 7-23.

Press the up arrow ^ key. The display will now instruct you to press the right arrow

menu key. (See figure 7-24).

Figure 7-24.

Press the right arrow > key. The display will confirm the keypad is locked.

(See figure 7-25).

Figure 7-25.

Note: To lock the keypad you have selected all of the arrow menu keys in a

clockwise rotation.

Page 17 of 28 Digi-Mantle M7754 issue 14.4

7.8.2. To unlock the keypad.

Press the up arrow ^ key. The display will now instruct you to press the right arrow

menu key. (See figure 7-26).

Figure 7-26.

Press the right arrow < key. The display will now instruct you to press the down

arrow menu key. (See figure 7-27).

Figure 7-27.

Press the down arrow v key. The display will now instruct you to press the left arrow

menu key. (See figure 7-28).

Figure 7-28.

Press the left arrow > key. The display will return to standard operational mode.(See

figure 7-4).

Note: To unlock the keypad you have selected all of the arrow menus keys in

an anti-clockwise rotation.

7.9. Errors and Warnings.

7.9.1. Warning – External Probe unplugged during operation.

If during use the external probe becomes detached from the Digi-Mantle the following

error message will be displayed (See figure 7-29).

Figure 7-29.

The unit will ‘beep’ rapidly for 10 seconds.

The heaters will be turned off.

If the unit was stirring a sample it will continue to do so.

The Warning will remain on the LCD until the > key is pressed.

The unit will return to the main display screen for use without the external probe

unless the connection is re-established. The heaters must then be turned back on

manually by pressing the key.

Page 18 of 28 Digi-Mantle M7754 issue 14.3

7.9.2. Warning – External probe plugged in but inadvertently left out of the sample.

When an external probe is plugged in and the heaters turned on your Digi-Mantle will

expect to see a rise in temperature of no less than 6°C within the first 10 minutes.

Should the external probe be accidentally left out of the sample solution the following

will be displayed (See Figure 7-30).

Figure 7-30.

The unit will ‘beep’ rapidly for 10 seconds.

The heaters will be turned off.

If the unit was stirring a sample it will continue to do so.

The Warning will remain on the LCD until the > key is pressed.

Rectify the fault

The unit will return to the main display screen for use without the external probe

unless the connection is re-established. The heaters must then be turned back on

manually by pressing the key.

7.9.3. Warning – Probe has fallen out of the sample

If during the heating cycle the external temperature probe falls out of the sample the

following condition will arise (See figure 7-31).

Figure 7-31.

Should the external probe fall of the sample the unit will see a decrease in

temperature. Once the probe temperature has dropped more than 6°C in 60 seconds

the heaters will be turned off.

The unit will ‘beep’ rapidly for 10 seconds.

If the unit was stirring a sample it will continue to do so.

The Warning will remain on the LCD until the > key is pressed.

Rectify the fault

The unit will return to the main display screen for use without the external probe

unless the connection is re-established. The heaters must then be turned back on

manually by pressing the key.

Page 19 of 28 Digi-Mantle M7754 issue 14.4

7.9.4. Warning – Heating module remover during operation.

If a Mantle is removed from the Digi-Mantle when the unit is powered up the Module

missing screen will be displayed (see Figure 7-6). Stirring and heating will stop.

This message will disappear when a Mantle is reinstated. The module type will be

displayed in the LCD. Press > key to return to the main display screen. Stirring and

Heating must then be manually turned back on.

Page 20 of 28 Digi-Mantle M7754 issue 14.3

8. TECHNICAL SPECIFICATIONS.

230v

115v

Description

Controller with

Stirrer & Mantle

8.1. Specifications.

Mains Input Supply Power. 230V-AC or 115/100V-AC @ 50/60Hz

Fuse rating (115V) 7 Amp Quick Blow 1 ¼”

Fuse rating (230V) 5 Amp Quick Blow 1 ¼”

Mains cord and moulded IEC

plug and lead set cable (UK) 13A

BS1362

Mains cord and moulded IEC

plug and lead set cable (Europe)

Mains cord and moulded IEC

plug and lead set cable (USA)

Lead set plug fuse (UK – only) 13A

OMCA250 (230V) 5Amp – 200 Watts

OMCA0250x1 (115V) 7Amp – 200 Watts

OMCA0500 (230V) 5Amp – 200 Watts

OMCA0500x1 (115V) 7Amp – 200 Watts

OMCA1000 (230V) 5 Amp – 300 Watts

OMCA1000x1 (115V) 7 Amp – 300 Watts

Stir speed, 250, 500 & 1000 Min 100 RPM. Max 2000RPM

The Ingress Protection rating for the controller has been classified as IPX1.

The Mantle has been classified as IPX0

8.2. Product configuration details.

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord H05 V

V-F- Replace only with equivalent cable.

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord H05 V

V-F- Replace only with equivalent cable.

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord SJT VW

1- Replace only with equivalent cable.

OMCA250 OMCA0250X1

(250ml size).

OMCA0500 OMCA0500x1 Controller with Sitter &

mantle (500ml size).

OMCA1000 OMCA1000x1 Controller with Stirrer &

Mantle (1000ml size).

Page 21 of 28 Digi-Mantle M7754 issue 14.4

8.3. Dimensions & Weight (unpacked). –Controller.

Dimension & Weight (unpacked) – Controller and Mantle.

D 330mm. W 235mm. H190mm

Weight 3.1Kg.

Page 22 of 28 Digi-Mantle M7754 issue 14.3

9. MAINTENANCE

"DUE TO THE MASS OF THE CARTRIDGE, NEVER SHIP A UNIT WITH THE CARTRIDGE

IN PLACE ON THE DIGI-MANTLE. ALWAYS PACK THE CARTRIDGE AND DIGI-MANTLE

SEPARATELY BEFORE TRANSPORTATION. "

9.1. General Information.

Unplug the unit from the mains voltage supply and allow it to cool before

undertaking any maintenance tasks.

Maintenance should only be carried out under the direction of the Responsible Body,

by a competent electrician. Failure to do so may result in damage to the product and in

extreme cases be a danger to the end user.

With proper care in operation this equipment has been designed to give many years of

reliable service. Contamination or general misuse will reduce the effective life of this

product and may cause a hazard.

Maintenance for the unit should include:

• Periodic electrical safety testing (an annual test is recommended as the minimum

requirement).

• Regular inspection for damage with particular attention to the mains lead and plug

set.

• Routine cleaning of the equipment should be undertaken using a clean cloth.

DO NOT USE SOLVENTS FOR CLEANING ANY PART OF THIS

EQUIPMENT.

9.2. Fuse Replacement.

The mains fuse holder is located at the rear of the Digi-Mantle. Refer to Technical

specification, ‘Fuse Rating’ for correct fuse type and rating. Turn your Digi-Mantle off

and remove it from the mains electricity supply. Unscrew both fuse holder caps

from the fuse housings and remove the fuses. Inspect fuse for damage. Fit

replacement fuses of suitable rating and value (See section 8.1 for correct type,

rating and value) and refit into fuse housing. See Figure 9-1:

Figure 9 -1

Page 23 of 28 Digi-Mantle M7754 issue 14.4

9.3. Spillage and Decontamination.

In the event of spillage switch off and unplug this product from the mains electrical supply.

Wipe off all excess liquid from the mantle and surrounding area using an absorbent soft

cloth. Do not use the mantle until a drying out period has been allowed and the mantle has

been subjected to electrical safety testing by competent service personal. To aid the drying

out process, the mantle may be placed in a vented oven at a maximum temperature of

50°C. The drying out period will be dependant on the nature and volume of spillage.

Before further use, the mantle must be subjected to electrical safety

testing by competent service personnel.

If in doubt please consult Customer Support. Refer to section 11.

If the equipment has been exposed to contamination, the Responsible Body

is responsible for carrying out appropriate decontamination. If hazardous material

has been spilt on or inside the equipment, decontamination should only be

undertaken under the control of the Responsible Body with due recognition of

possible hazards. Before using any cleaning or decontamination method, the

Responsible Body should check with the manufacturer the proposed method will

not damage the equipment.

Prior to further use, the Responsible Body shall check the electrical safety of the

unit. Only if all safety requirements are met can the unit be used again. The above

procedure is intended as a guide. Should spillage occur with a toxic or hazardous

fluid then special precautions may be necessary.

Decontamination Certificate.

Note: In the event of this equipment or any part of the unit becoming damaged, or

requiring service, the item(s) should be returned to the manufacturer for repair

accompanied by a decontamination certificate. Copies of the Certificate are available

from Distributor/Manufacturer. Appendix A of this instructions book may be copied

and enlarged.

At the end of life, this product must be accompanied by a Decontamination

Certificate. See section 6.3 and 6.4

Page 24 of 28 Digi-Mantle M7754 issue 14.3

10. PARTS & ACCESSORIES.

Cat No

Cat No

Cat No

Description.

- -

- -

10.1. Spares.

Order additional system items as follows:

230V

OM0250 OM0250x1 OM0250x3 250ml size mantle. (200W)

OM0500 OM0500x1 OM0500x3 500ml size mantle. (200W)

OM1000 OM1000x1 OM1000x3 1000ml mantle. (300W)

115V

100V

AZ9007 - - Fuse 5A 20 x 5mm Glass Quick-

blow (Pack 10)

(230V)

- AZ9035 AZ9035 Fuse 8A 20 x 5mm Glass Quickblow (Pack 10)

(115V)

AZ9165

Mains cord and moulded IEC

plug and lead set (UK) 230V ~

AZ6747

AC

Mains cord and moulded IEC

plug and lead set (Europe) 230V

~ AC

- AZ6746 AZ6746 Mains cord and moulded IEC

plug and lead set (USA) 115V ~

AC.

ATS10063 ATS10063 ATS10063 Temperature probe.

Page 25 of 28 Digi-Mantle M7754 issue 14.4

11. CUSTOMER SUPPORT.

Bibby Scientific Limited.

For the America’s and Canada, contact:

For help and support in using this product, please contact Customer Services at the following

address.

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

• General enquiries :

info@bibby-scientific.com

• Order enquiries :

sales@bibby-scientific.com

• Technical support :

electrothermalhelp@bibbyscientific.com

• www.electrothermal.com

Techne Incorporated, 3 Terri Lane,

Suite 10 Burlington, NJ 08016 USA.

Toll free:800-225-9243Tel: 609-589-2560

Fax: 609-589-2571

Email: labproducts@techneusa.com

Http www.techneusa.com

Page 26 of 28 Digi-Mantle M7754 issue 14.3

.

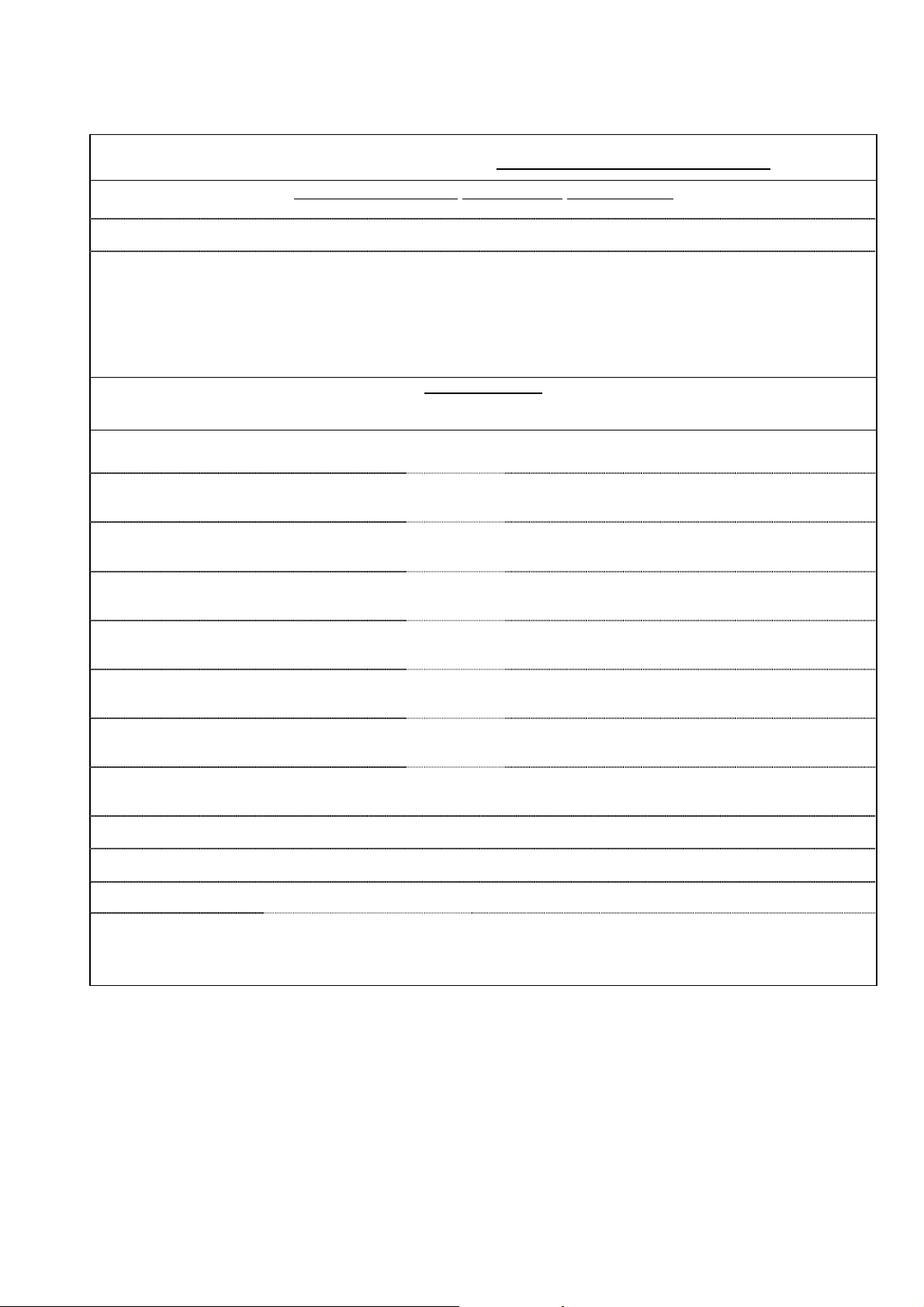

CUSTOMER DETAILS

APPENDIX ‘A’. DECONTAMINATION CERTIFICATE.

Bibby Scientific Limited

Tel: +44(0)1785 812121. Fax: +44(0)1785 810405

Prior to a Service Engineer working on equipment that has been in an environment where substances hazardous to health may have been

used, you are requested to provide the following information:

Beacon Road, Stone, Staffordshire ST15 0SA. Great Britain

E-mail:

electrothermalhelp@bibby-scientific.com

DECONTAMINATION CLEARANCE CERTIFICATE

For the Inspection, Repair or Return of Medical, Laboratory or Industrial Equipment.

Company:-

Department:-

Contact Name:-

Model No:-

Tel No:-

Fax No:-

Product Description

Address:-

Post Code:-

Serial No:-

Has the equipment been exposed to any of the following, Please answer all questions by deleting YES/NO as applicable and by providing

A. Blood, body fluids, Pathological

specimens

B. Biodegradable material that could

become a hazard

C. Other biohazard YES/NO Provide details if YES

D. Chemical or substances hazardous to

health

E. Radioactive substances State name(s)

and quantities of isotopes and checks

made for residual activity

F. Other hazards YES/NO Provide details if YES

2. Please provide details of any hazard present as indicated above. Include details of names and quantities of

agents as appropriate:-

3. Your method of decontamination (please describe):-

4. Are there likely to be any areas of residual contamination (please specify)

I declare that the above information is true and complete to the best of my knowledge and belief.

Authorised signature:- Name (please print):-

Title/Position:-

For and behalf of:- Date:-

details in section 2 below.

YES/NO Provide details if YES

YES/NO Provide details if YES

YES/NO Provide details if YES

YES/NO Provide details if YES

Page 27 of 28 Digi-Mantle M7754 issue 14.4

Bibby Scientific Limited.

For the America

’s and Canada, contact:

Distributors Stamp

12. EC DECLARATION OF CONFORMITY.

CE marked products and associated accessories covered by this Instruction book conform to the

essential requirements of the following directives:

EMC Directive.

Low Voltage Directive.

A full copy of the EC Declaration / Conformity document can be obtained from the manufacture at the

email address : info@bibby-scientific.com

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

• General enquiries :

info@bibby-scientific.com

• Order enquiries :

sales@bibby-scientific.com

• Technical support :

electrothermalhelp@bibbyscientific.com

• www.electrothermal.com

Part of the Bibby Scientific Group

Techne Incorporated, 3 Terri Lane,

Suite 10 Burlington, NJ 08016 USA.

Toll free:800-225-9243Tel: 609-589-2560

Fax: 609-589-2571

Email: labproducts@techneusa.com

Http www.techneusa.com

Page 28 of 28 Digi-Mantle M7754 issue 14.3

2013 Bibby Scientific Limited. All rights reserved.

Loading...

Loading...