Electrothermal EM0050/CE, EM0100/CE, EM0250/CE, EM0500/CE, EM1000/CE Instruction Manual

...

EM , SERIES ELECTROMANTLES.

INSTRUCTION BOOK

Page 1 of 28 M6873 Issue 12.7

Please take your time to read this Instruction book in order to understand the

Contents.

Section 1.

Page 3

Section 2.

Page 4

Section 3.

Page

5

Section 4.

Page

7

Section 5.

Page

9

Section 6.

Page

10

Section 7.

Page

11

Section 8.

Page

14

Section 9.

Page

19

Section 10.

Page

22

Section 11.

Page

25

Section 12.

Page 26

Section 13.

Page 28

Appendix ‘A’

Page

24

Bibby Scientific Limited.

safe and correct use of your new Bibby Scientific product.

It is recommended the Responsible Body for use of this equipment reads this

Instruction book and ensures the user(s) are suitably trained in its operation.

Introduction

Symbols and using this instructions book.

Safety Information.

Unpack and Contents.

Installation.

Environmental Protection.

Product Operation.

Technical Specification.

Maintenance

Replaceable Parts and Accessories

Customer Support

Notes

EC Declaration of Conformity.

Decontamination Certificate

© The copyright of this instruction book is the property of Bibby Scientific Limited. This instruction book is

supplied by Bibby Scientific Limited on the express understanding that it is to be used solely for the

purpose for which it is supplied. It may not be copied, used or disclosed to others in whole or part for any

purpose except as authorised in writing by Bibby Scientific Limited. Bibby Scientific Limited reserves the

right to alter, change or modify this document without prior notification.

In the interest of continued development Bibby Scientific Limited reserve the right to alter or

modify the design and /or assembly process of their products without prior notification.

This product is manufactured in Great Britian by Electrothermal, part of the Bibby Scientific Group

of companies.

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

Page 2 of 28 M6873 Issue 12.7

1. INTRODUCTION.

1.1. The Bibby Scientific series of heating mantles has been specifically designed to

provide a comprehensive answer to heating fluids in round bottomed glassware in

the modern laboratory. It combines the traditional Electrothermal heating element

with many new features thus providing the user with several options to meet different

applications.

1.2. Heating control is provided by a built-in solid state energy regulator. Non stirring

mantles can be used with an external controller. (Please contact distributor /

manufacturer for details).

1.3. The enclosures of individual heating mantles EM’s are manufactured from chemical

resistant Polypropylene.

1.4. The products are provided with ventilation slots underneath and around the rim to

ensure a low enclosure surface temperature. The heating element is retained in

thermal Rockwool to create a heating cartridge that facilitates very easy replacement

in the event of any damage. On all EM sizes up to 1 litre a single support clamp is

provided at the rear of the unit. On the 2, 3 and 5 litre models there are three rod

support clamps. The EMV’s and EMX’s have a hole in the base to enable funnels or

bottom outlet flasks to be heated. All EM’s are supplied with support rods and

clamps.

1.5. Bibby Scientific offers a comprehensive range of Mantles, and Controllers. The

Mantles range from the Standard cool-to-touch vented case EM, with element

temperatures between ambient and 450 deg C. The Standard EM Mantle has

Controlled /C, Spill-Proof EMX, V-Shaped EMV, Heating and Stirring EMA with

single or bi-directional stirring options. Capacities for round-bottomed glassware

ranging from 50ml up to 5,000ml, plus funnel options. Replacement heater cartridges

are available.

Page 3 of 28 M6873 Issue 12.7

2. SYMBOLS AND USING THIS INSTRUCTION BOOK

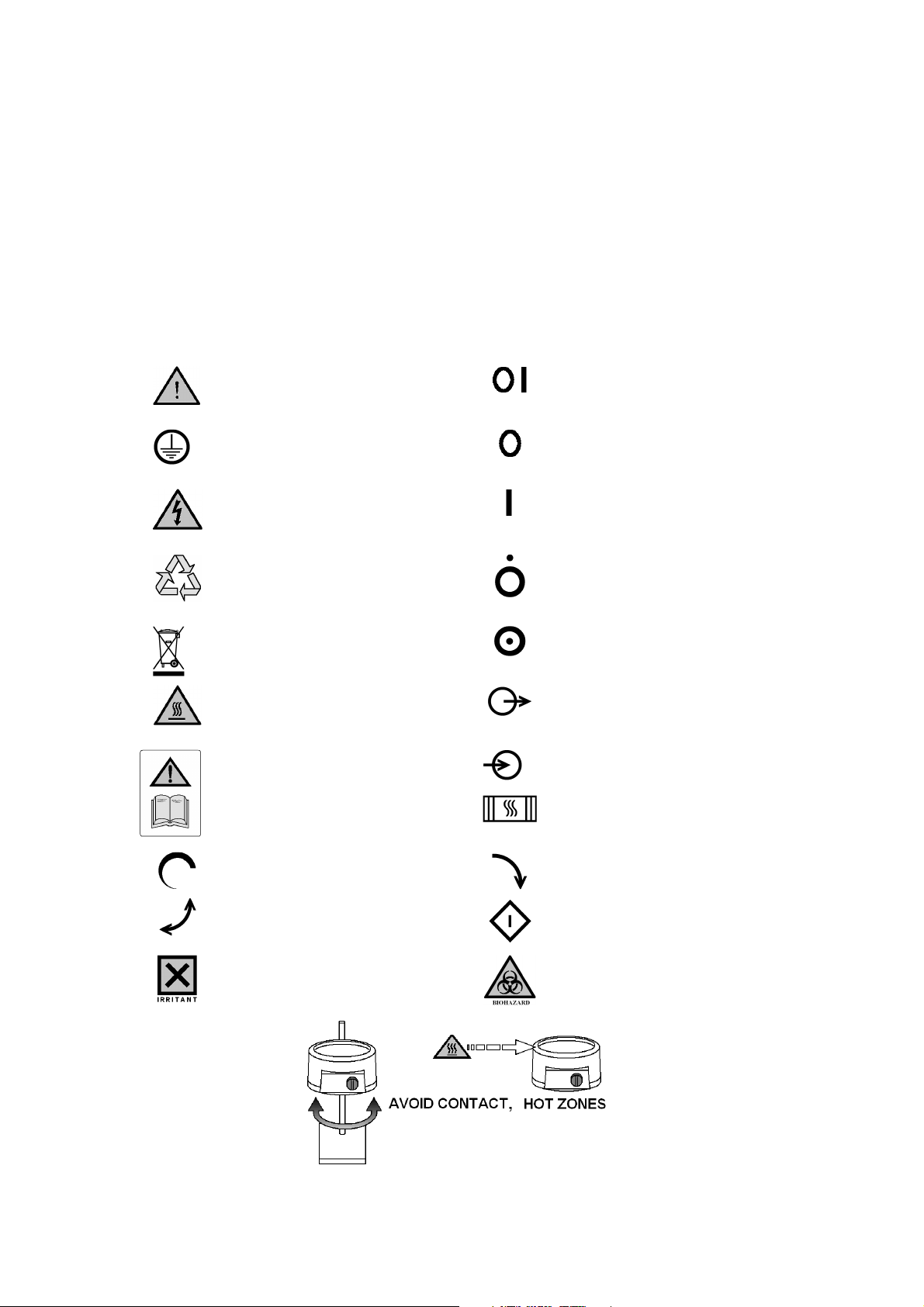

2.1. Throughout this Instruction book the following symbols are shown

to identify conditions which pose a hazard to the user, or to identify actions that

should be observed. These symbols are also shown on the product, or its

packaging. When a symbol is shown next to a paragraph or statement it is

recommended the user takes particular note of that instruction in order to prevent

damage to the equipment or to prevent injury to one’s self or other people.

The Responsible Body and the Operator should read and be familiar with this

Instruction book in order preserve the protection afforded by the equipment.

To prevent injury or equipment damage it is the manufacturers

recommendation that all persons using this equipment are suitably trained

before use.

2.2. Symbols defined.

Caution, risk of danger. See note or

adjacent symbol.

Protective conductor terminal to be

earthed.

(Do not loosen or disconnect).

Caution / risk of electric shock

Recyclable Packing Material.

Do not dispose of product in normal

domestic waste.

This symbol adjacent to an indication lamp

means mains power Off/On when lamp nonilluminated / illuminated

This symbol adjacent to a switch denotes the Off

condition for mains power.

This symbol adjacent to a switch denotes the ON

condition for mains power.

This symbol adjacent to a switch denotes the Off

condition for the Heater or Stirrer.

This symbol adjacent to a switch denotes the On

condition for a Heater or Stirrer.

Caution. Hot surface.

Refer to Instructions book.

This symbol denotes stirrer speed

control.

This symbol adjacent to the stirrer

switch denotes the bi-directional stir

condition with auto-reverse.

Material irritant to skin. When handling

wear face mask to BS/EN 149 and

protective gloves

This symbol indicates an output terminal for the

equipment.

This symbol indicates an input terminal for the

equipment.

This symbol adjacent to an indication lamp

means the heater power Off / On when lamp

non-illuminated / illuminated.

This symbol adjacent to the stirrer switch

denotes the uni-directional stir condition.

This symbol adjacent to the stirrer switch

denotes the stirrer manual capture condition or

stirrer off.

Bio Chemical Hazard. Caution required. Will

require decontamination.

Hot Zone on product

EM, EM/E, EMV,

EMX.

Page 4 of 28 M6873 Issue 12.7

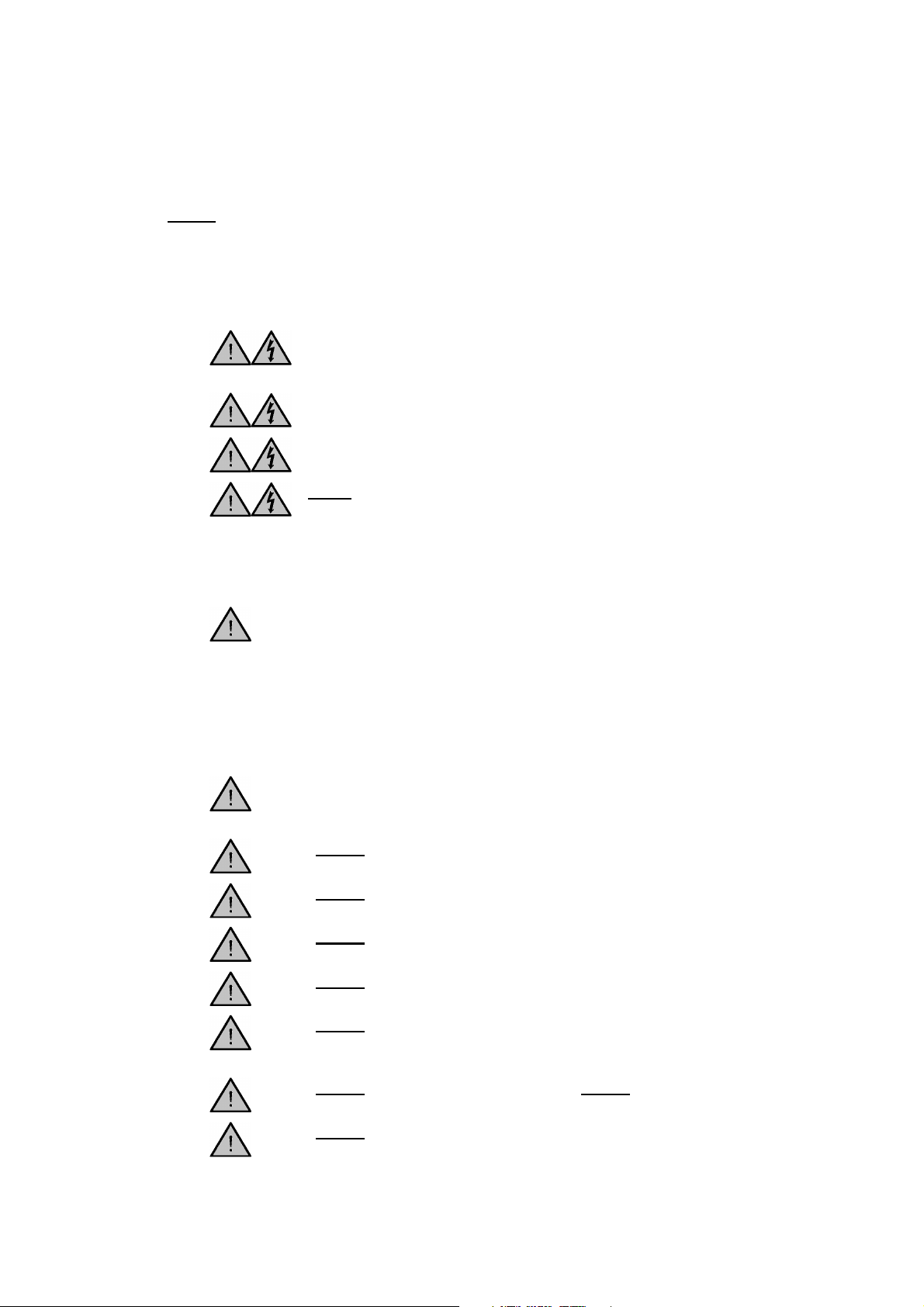

DO NOT

Never

Do not

Do not

Do not

Do not

Do not

Do not

Do not

Do not

3. SAFETY INFORMATION.

This product has been designed for safe operation when used as detailed in accordance with

the Manufacturers instructions.

NOTE: Failure to use this equipment in accordance with the manufactures instruction book

may compromise your basic safety protection afforded by the equipment and may invalidate

the warranty / guarantee. The warranty / guarantee does not cover damaged caused by faulty

installation or misuse of the equipment

3.1. Prevention of Fire and Electric Shock.

To prevent a risk of fire or electric shock,

case without authorisation. Only qualified Service personnel should

attempt to repair this product.

Replace fuses only with the type as listed in section, ‘Technical

Specifications and Parts and Accessories’ (See fuse type and rating).

Ensure the Mains Power Supply conforms to rating found on the data

plate located on the back of this product.

Operate this equipment without connection to earth / ground.

Ensure the mains supply voltage is correctly earthed / grounded in

accordance with current area legislation.

3.2. General Safe Operating Practice.

Always follow good laboratory practice when using this

equipment. Give due recognition to your company’s safety and

legislative health & safety procedures and all associated legislation

applicable to your areas of operation. Check laboratory procedures for

substances being heated and ensure all hazards (e.g. explosion,

implosion or the release of toxic or flammable gases) that might arise

have been suitably addressed before proceeding. When heating

certain substances the liberation of hazardous gases may require the

use of a fume cupboard or other means of extraction.

Ensure equipment is used on a clean, dry, non-combustible, solid work

surface with at least 300mm suitable clearance all around from other

equipment.

position the product so that it is difficult to disconnect from the

mains supply.

touch the heating element or any glass vessel whilst in use.

open your product

lean or stretch over equipment, glassware and fixings when in

use.

immerse unit in water or fluids.

spill substances onto the mantle. If spillage does occur,

disconnect unit from mains supply and follow instructions as detailed

in Maintenance. (Section 9).

cover the mantle whilst in use.

block or obstruct

ventilation slots / airways.

leave equipment switched on without a charged flask(s).

Page 5 of 28 M6873 Issue 12.7

Do not

Do not

ATTENTION:

-

as the insulation used may obstruct the convection

cooling airways around the rim of the cartridge enclosure and cause

the mantle to overheat.

It is not recommended to leave any heating apparatus unattended

during operation.

Only use Original Equipment manufactures spares and accessories.

Ref Section 10.

Stirring versions of this equipment generate magnet fields. Keep all

metal objects and magnetic data devices (e.g. credit cards) away from

the stirrer unit.

The equipment is not spark, flame or explosion proof and has not been

designed for use in hazardous areas in terms of BSEN 6007914:1997. Keep flammable, low flash point substances away from the

apparatus.

Keep the Mains cord and moulded IEC plug and lead set away

from the heating surface.

thermally insulate the exposed upper section of the vessel(s),

operate or handle any part of the product with wet hands.

With high energy input and certain configurations of glassware in

EMV & EMX products, where the heating contact of the glassware is

relatively small, localised heating and subsequent ‘bumping’ of the fluid

being heated may occur. Application advice should be sought from the

manufacturer.

Page 6 of 28 M6873 Issue 12.7

‘A’

‘V’

‘X’

3 or 6 =

‘S’

‘C’

‘E’

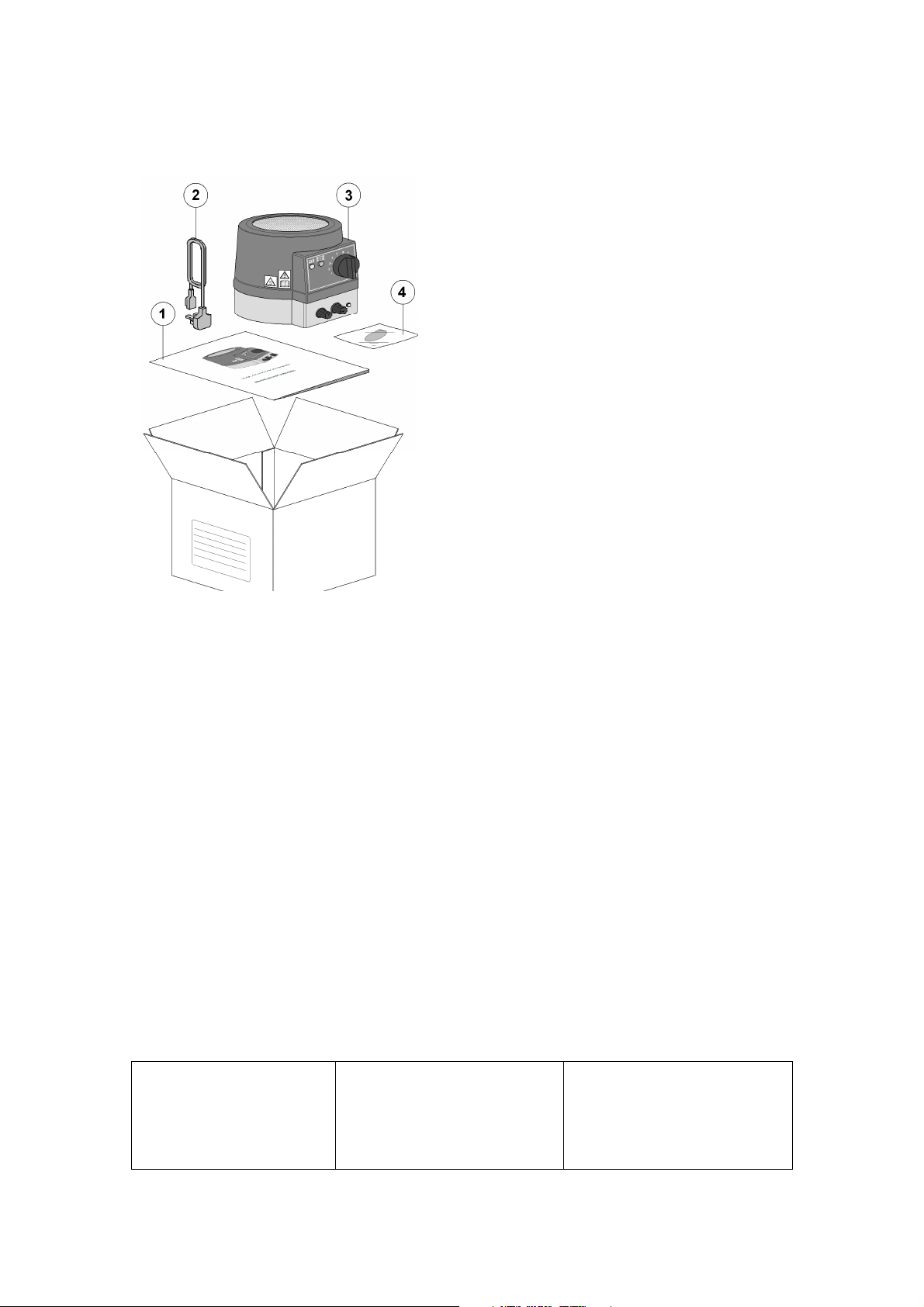

4. UNPACKING AND CONTENTS.

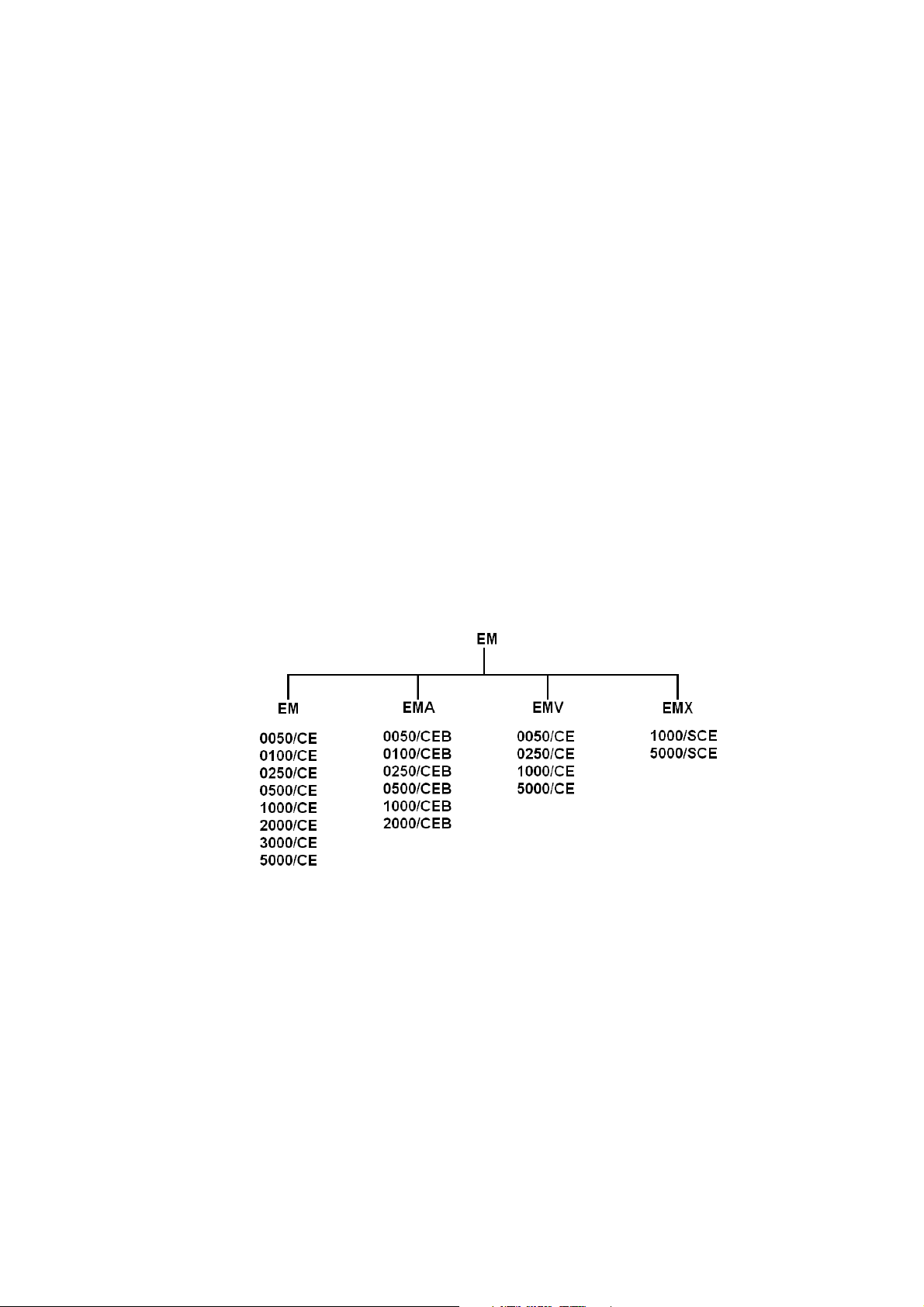

4.1. Product Identification:

A Catalogue number allocated to each type of mantle is descriptive. The method of coding is

detailed below.

First and second Characters EM Series

Next Character

Next Character (if Multi bank)

Next four Characters Flask size in ml. 0050, 0100, 0500, 1000,

Next Character after the /

Next Character

Last Characters No Characters = 230V, X1 = 115V,

The following family tree outlines product variants.

unit with stir facility.

Bottom opening for funnel.

Spillproof (Stainless Steel liner) with

bottom opening for funnel.

3 way or 6 way.

2000, 3000, 5000.

Spillproof (Stainless steel liner).

Controlled.

Earthed screen.

X7 = 220V with Chinese mains lead

Page 7 of 28 M6873 Issue 12.7

Item

Description

Qty

1

1

2

A/R

3

1

4

1

Please check the contents of your carton against the relevant product diagram.

Applicable to all EM product.

No

Instruction book

Mains cord and moulded IEC plug

and lead set

(May differ from illustration depending on

destination).

EM product (Model shown EMA)

Stir bar (only on EMA)

For future reference

please record your

products Serial and

Model Numbers.

Serial Number Unit Model/Cat Number

Page 8 of 28 M6873 Issue 12.7

Blue

or

White

=

Neutral

Brown

or

Black

=

Live / line

hot.

5. INSTALLATION.

5.1. Electrical safety and installation.

5.1.1. This equipment is designed to be used safely under the following conditions:-

• Indoor use.

• Altitude up to 2000 meters.

• Temperatures between 5°C and 40°C.

• Maximum relative humidity 80% for temperatures up to 31°C decreasing linearly

to 50% relative humidity at 40°C.

• Mains supply voltage fluctuations up to ± 10% of the nominal voltage.

• Transient overvoltages typically present on the mains supply. Overvoltage

category II

• Applicable rated pollution degree 2.

5.1.2. This equipment must be earthed / grounded to a fixed earth / grounded

mains socket outlet. The mains supply is to earthed / grounded in accordance with

current legislation. See Technical Specification for recommended fuse ratings.

5.1.3. Ensure only the correct rated mains input fuses are fitted. (Where applicable

ensure the correct Mains cord and moulded IEC plug and lead set fuse if fitted).

See Technical Information Section 8 of this Instructions book.

5.1.4. Check the voltage on the product data label on this product unit and those of any

accompanying electrical accessory. Ensure the rating conforms to your local

supply.

5.1.5. This product should be connected to a mains supply source which incorporates a

RCD or GFCI device that has a tripping current of 30mA or less. The RCD or GFCI

residual Current Device cuts off power to the equipment immediately it detects a

current leakage fault. For example, cutting off the power when there is an

accidental liquid spillage in a mantle protected with an earth (ground) screen.

5.1.6. Do not install this product or accessories on a surface which may

become flooded.

5.1.7. The unit is supplied with a Mains cord and moulded IEC plug and lead set wired

as follows.

Green / Yellow

5.2. Observation: the surface of the heating element of a mantle cartridge will upon receipt

look slightly discoloured. This discolouration is normal and occurs at the factory during

test when the mantle is first heated up.

5.3. Bibby Scientific controllers, series MC227 / MC228 / MC242 / MC5 and MC810B, can

also be used for external control when the mantle is used in a fume cupboard. NOTE:

External controllers cannot be used for EMA or EMEA products.

Page 9 of 28 M6873 Issue 12.7

or

Green = Earth / Ground

USA Notification.

Warning ! Any modification or changes made to this device, unless explicitly approved by Bibby Scientific,

will invalidate the authorisation of this device. Operation of an unauthorised device is prohibited under

Section 302 of the Communications Act of 1934 as amended, and Subpart 1 of Part 2 of Chapter47 of the

code of Federal Regulations.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

•

Consult the dealer or an experienced radio/TV technician for help.

6. ENVIRONMENTAL PROTECTION.

6.1. Maximum consideration has been given to environmental issues within the design and

manufacturing process without compromising end product performance and value.

6.2. Packaging materials have been selected such that they may be sorted for

recycling.

6.3. At the end of your product and accessories life, it must not be discarded as

domestic waste. Ref: EU Directive 2002/96/EC on Waste Electrical and Electronic

Equipment Directive (WEEE). Please contact your distributor / supplier for further

information. For end users outside of the EU consult applicable regulations.

6.4. This product should only be dismantled for recycling by an authorised recycling

company.

This product and accessories must be accompanied by a completed

Decontamination Certificate prior to any disposal. Copies of the Certificate are

available from your distributor of Bibby Scientific products, or you may copy and

enlarge from ‘Appendix A’ of this instruction book.

Bibby Scientific’s Electrothermal branded product range is registered with the Environment Agency under the name of as

Electrothermal Engineering Limited as being a producer of WEEE (Waste Electronic and Electrical Equipment) through b2b

Compliance, an authorised waste collection compliance scheme.

Page 10 of 28 M6873 Issue 12.7

Item

Description.

1

6

2

7

3

8

4

9

5

7. PRODUCT OPERATION.

7.1. EM, EMV and EMX Mantle with controller.

7.1.1. Overview of EM Mantle with controller.

Note: Circuit selection switch (only for

mantles with two heating circuits).

Position I is for lower heating circuits only.

Position II is for both circuits on.

Note: If an external controller is to be used, always set the energy regulator control knob

to maximum setting 10.

Mains power on indicator

Heating element on

Energy regulator control

knob

Circuit selection switch (for mantles with two

heating circuits

Data Plate

Mains input IEC socket (Contains protective

fuses).

Support rod bracket. (Note for 2, 3 & 5 litre

Heating Element

Warning Labels.

variants 3 clamp positions are fitted).

(Hot surface and refer to

this Instructions book).

Note: The EMV and EMX series

mantles both have bottom

opening for use with a funnel.

EMX has a spill proof liner. Both

units may be raised up using a

retort rod stand allowing for

heated filtration of the sample.

Both mantles can be supported

using the rod clamp arrangement

as illustrated.

Page 11 of 28 M6873 Issue 12.7

7.1.2. When heating a funnel in an EMV or EMX the mantle should be

Item

Description.

1

2

3

4

5

6

8

9

10

11

12

securely supported above the work surface using the support rod clamps.

7.1.3. With the mains electricity supply switched off, connect the Mains cord and

moulded IEC plug and lead set to the mains IEC socket.

7.1.4. Place a charged, clean, dry glass vessel of the size indicated on the mantle data

plate label. Wherever possible the glass vessel should be supported within the

mantle by means of the support rod and clamp.

7.1.5. Switch on the mains electrical supply. Adjust the controller regulator knob to the

required setting.

NOTE: The ‘mains power on’ indication neon will illuminate. The ‘amber

heating on’ neon will illuminate / pulsate when the heaters are in operation.

7.1.6. When the process is complete switch the regulator knob to the off position.

Disconnect the mains electricity supply.

7.1.7. Remove charged vessel. Handle hot charged vessel with care.

7.2. EMA Mantle (With controller and stir facility).

7.2.1. Overview of EMA Mantle with stir facility.

Mains power on indicator

Heating element on

Energy regulator control knob

Heating Element

Warning Labels.

(Hot surface and refer to this

Instructions book).

Stir speed adjustment.

Stir selection rotary switch.

Stir facility ‘on’ LED indicator.

Data Plate

Mains input IEC socket (Contains

protective fuses).

Support rod bracket. (Note for 2, 3

& 5 litre variants 3 clamp

positions are fitted).

Page 12 of 28 M6873 Issue 12.7

7.2.2. With the mains supply electricity switch off, Connect the Mains cord and moulded

IEC plug and leads set to the mains IEC socket. Ensure the stirrer rotary switch is in

the off position.

7.2.3. Place a charged, clean, dry glass vessel of the size indicated on the mantle data

plate. Wherever possible the glass vessel should be supported within the mantle by

means of the support rod and clamp.

7.2.4. Switch on the mains electrical supply. Adjust the Energy regulator control knob to

the required setting.

NOTE: The mains power on indication neon will illuminate. The amber heating

on neon will illuminated when the heaters are in operation.

7.2.5. On the EMA there are two stirring functions available.

a) Bi-directional with auto capture and auto reverse period of approximately 20 /

30 seconds.

b) Uni-directional up to 500RPM approximately.

c) Manual capture / reset is achieved with the rotary switch in the off position.

7.2.6. Carefully place the stirrer bar provided into the vessel and turn the rotational

speed control to its minimum position.

7.2.7. Select the required stir function on the stir selection rotary switch. The green LED

will now illuminate.

7.2.8. Adjust the rotational speed by means of the speed control knob. Should the

stirring action be lost by over rotation, then reduce the stir speed slightly and

recapture the stir bar by selecting the off position on the stir selection rotary switch

7.2.9. When the process is complete switch the stir speed and regulator knobs to there

off positions. Disconnect the mains electricity supply.

7.2.10.

Remove charged vessel. Handle hot charged vessel with care.

Page 13 of 28 M6873 Issue 12.7

Type

Size Total

Heating

Po

wer

Fuse rating (Amps)

EM

EMA

The power consumption of the stir facility is 20 Watts.

EMV

EMX

8. TECHNICAL SPECIFICATION.

8.1. Specifications EM range (General).

Mains cord and moulded IEC plug

and lead set cable (UK) 13A BS1362

AZ9165

Mains cord and moulded IEC plug

and lead set cable (Europe)

AZ6747

Mains cord and moulded IEC plug

and lead set cable (USA)

AZ6746

Fuse type 20mm x 5mm Glass Quickblow. (2 per unit) See below

Heating Element Construction. Thermal insulated element wire stitched into a cartridge

Maximum Element temperature.

EM Case construction. Polypropylene.

Thermal Insulation Ceramic Fibre.

8.1.1. Power Consumption and fuse ratings.

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord H05 V VF- Replace only with equivalent cable.

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord H05 V VF- Replace only with equivalent cable.

3 core earthed / ground. 2 meters long

Moulded IEC plug and Lead set – supply cord SJT VW

1- 105° Replace only with equivalent cable.

for rating.

construction.

450°C. Nominal Max.

(Watts).

220/240V∼∼∼∼ 115V∼∼∼∼ 220/240V∼∼∼∼ 115V∼∼∼∼

50ml 60 70 F0.5 F1.25

100ml 60 70 F0.5 F1.25

250ml 150 150 F1.25 F2.5

500ml 200 200 F1.25 F2.5

1000ml 300 300 F2.5 F3.15

2000ml 500 500 F2.5 F6.3

3000ml 500 500 F2.5 F6.3

5000ml 500+300 500+300 F6.3 F6.8

50ml 60+(20stir) 76+(20stir) F0.5 F1.25

100ml 60+(20stir) 76+(20stir) F0.5 F1.25

250ml 150+(20stir) 190+(20stir) F1.25 F2.5

500ml 200+(20stir) 250+(20stir) F1.25 F2.5

1000ml 300+(20stir) 380+(20stir) F2.5 F6.3

2000ml 500+(20stir) 650+(20stir) F2.5 F6.3

50ml 60 70 F0.5 F1.25

250ml 100+50 100+50 F1.25 F2.5

1000ml 200+100 200+100 F2.5 F3.15

5000ml 500+300 500+300 F6.3 F8

1000ml 165+80 160+80 F1.25 F2.5

5000ml 400+200 400+200 F6.3 F10

8.1.2. The Ingress protection rating for the EM, EME, EMV and EMA product range is IPX0.

For the EMX range the Ingress protection rating is IPX1.

8.1.3. Dimensions and Weight (unpacked).

Page 14 of 28 M6873 Issue 12.7

EM 50ml

EM 100ml

EM 250ml

EM1000

WEIGHT 0.78Kg

WEIGHT 0.78Kg

EM 500ml

WEIGHT 0.78Kg

WEIGHT 1.25Kg

Page 15 of 28 M6873 Issue 12.7

EM2000

EM3000

EM5000

EMV

0050/CE

. Glass sizes 10

– 50ml.

WEIGHT 1.25Kg

WEIGHT 2.58Kg

WEIGHT 2.58Kg

WEIGHT 2.58Kg

Page 16 of 28 M6873 Issue 12.7

WEIGHT 0.78Kg.

EMV0250/CE

. Glass size 100

– 250ml.

EMV1000/CE

. G

lass size 500

– 1000ml

EMV5000/CE

. Glass size 2000

– 5000ml.

WEIGHT 0.78Kg.

EMX1000/SCE Glass size 50 to 1000ml

WEIGHT 2.76Kg

EMX5000/SCE Glass size 500 to 5000ml

WEIGHT 5.69Kg

Page 17 of 28 M6873 Issue 12.7

EM

A050

/CEB

EMA

0250/CE

B

EMA0500/CE

B

EMA1000/CE

B

WEIGHT 1.73Kg

EMA2000/CEB

WEIGHT 1.73Kg.

WEIGHT 2.75Kg.

WEIGHT 2.75Kg

WEIGHT 5.68Kg

Page 18 of 28 M6873 Issue 12.7

9. MAINTENANCE.

9.1. General Information.

Unplug the unit from the mains voltage supply and allow it to cool before

undertaking any maintenance tasks.

Maintenance should only be carried out under the direction of the Responsible

Body, by a competent electrician. Failure to do so may result in damage to the product

and in extreme cases be a danger to the end user.

With proper care in operation this equipment has been designed to give many years of

reliable service. Contamination or general misuse will reduce the effective life of this

product and may cause a hazard.

Maintenance for the unit should include:

• Periodic electrical safety testing (an annual test is recommended as the minimum

requirement).

• Regular inspection for damage with particular attention to the mains lead and

plug set.

• Routine cleaning of the equipment should be undertaken using a clean cloth.

DO NOT USE SOLVENTS FOR CLEANING ANY PART OF THIS

EQUIPMENT.

9.2. Fuse Replacement.

The mains fuse holder is located at rear your product. Refer to Technical specification,

‘Fuse Rating’ for correct fuse type and rating. Turn your product off and disconnect it from

the mains supply.

9.2.1. Heater Cartridge replacement.

Page 19 of 28 M6873 Issue 12.7

Attention. The heater contains insulation material made from

Refractory Ceramic Fibres (RCF), classified as a category 2 carcinogenic

under EU Directive 67/548/EC. Follow the guidelines for working with RCF

as laid down under in the ECFIA Code of Practise. Wear suitable protective

clothing and gloves.

EM and EMA

9.2.1.1. Unplug or disconnect the mantle from the mains electricity supply.

9.2.1.2. The EM single heater mantles should be turned over and placed upside

9.2.1.3. Remove the plastic rivets from around the base of the mantle and remove

9.2.1.4. On 2,3 and 5 litre models remove the 3 cross-head screws and remove the

9.2.1.5. On EM product remove the 2 cross-head screws retaining the base bracket

9.2.1.6. Disconnect the two or four heater cold leads. (The number of leads is

9.2.1.7. Lift the heater cartridge out of the case without disconnecting the earth

9.2.1.8. The new heater cartridge is then fitted into the metal ring and the heater cold

9.2.1.9. On EM product replace the base bracket. On the 2,3, and 5 litre model EM’s

9.2.1.10. Replace the earth lead and base and refasten using the previously

9.2.1.11. The responsible body shall check the electrical safety of the product

In the event of a heater element becoming damaged or open circuit the

follow procedure should be adopted for its replacement.

down on a clean dry surface.

the base.

triangular base plate.

then hinge the bracket clear of the heater cartridge.

dependant on single / double element configuration).

connection to the metal ring.

leads reconnected.

replace the triangular base plate and refit the 3 screws.

removed plastic rivets.

before further use.

Page 20 of 28 M6873 Issue 12.7

9.3. Spillage and Decontamination.

Spillage:

In the event of spillage or glassware fracture, do not touch the mantle. Disconnect

the product from the mains electrical supply. Allow the product to cool. Wearing

suitable hand protection (giving due consideration to substances that were being

heated) carefully remove any pieces of broken glassware. If decontamination is

necessary, see section below. Otherwise wipe off all excess liquid from the mantle

and surrounding area using an absorbent soft cloth. Drain of any residual fluid

retained in the mantle. In the case of excessive spillage/ flask fracture, invert the

mantle and allow it to drain for minimum of one hour. Then proceed with the

following drying out procedure. Place the complete mantle, the correct way up, in a

heated oven at 50 °C for a minimum period of 40 hours

! Warning: The equipment cannot be assumed to meet all the safety requirements

of EN 61010-2-010: 2003 during the drying out process and until the drying out

process is completed.

If in doubt please consult Customer Support. Refer to section 11.” NB:

Replacement heater cartridges are obtainable from your Distributor/Manufacturer.

Before further use, the mantle must be subjected to electrical safety

testing by competent service personnel.

If in doubt please consult Customer Support. Refer to section 11.

If the equipment has been exposed to contamination, the Responsible

Body is responsible for carrying out appropriate decontamination. If hazardous

material has been spilt on or inside the equipment, decontamination should only

be undertaken under the control of the Responsible Body with due recognition of

possible hazards. Before using any cleaning or decontamination method, the

Responsible Body should check with the manufacturer the proposed method will

not damage the equipment.

Prior to further use, the Responsible Body shall check the electrical safety of the

unit. Only if all safety requirements are met can the unit be used again. The above

procedure is intended as a guide. Should spillage occur with a toxic or hazardous

fluid then special precautions may be necessary.

Decontamination Certificate.

Note: In the event of this equipment or any part of the unit becoming damaged, or

requiring service, the item(s) should be returned to the manufacturer for repair

accompanied by a decontamination certificate. Copies of the Certificate are available

from Distributor/Manufacturer. Appendix A of this instructions book may be

copied and enlarged.

At the end of life, this product must be accompanied by a Decontamination

Certificate. See section 6.3 and 6.4

Page 21 of 28 M6873 Issue 12.7

Mantle model type

Replacement heater Cartridge.

10. PARTS AND ACCESSORIES

10.1. Replacement Heater Cartridges. All Bibby Scienetific mantles are specified by

the letters RE and Flask size. Add x1 suffix when ordering for 115V

For all 220/240 volt product quote the Non x1 part number.

EM0050/CE, Order RE0050

EM0100/CE Order RE0100

EM0250/CE Order RE0250

EM0500/CE Order RE0500

EM1000/CE Order RE1000

EM2000/CE Order RE2000

EM3000/CE Oder RE3000

EM5000/CE Order RE5000

EMA0050/CE, EMA0050/CEB. Order REA0050

EMA0100/CE, EMA0100/CEB. Order REA0100

EMA0250/CE, EMA0250/CEB. Order REA0250

EMA0500/CE, EMA0500/CEB. Order REA0500

EMA1000/CE, EMA1000/CEB. Order REA1000

EMA2000/CE, EMA2000/CEB. Order REA2000

EMX1000/SCE Order REMX1000

EMX5000/SCE Order REMX5000

EMV0050/CE Order REMV0050

EMV0250/CE Order REMV0250

EMV1000/CE Order REMV1000

EMV5000/CE Order REMV5000

Page 22 of 28 M6873 Issue 12.7

Order Number

Description.

Quantity

AZ

9165

1

AZ

129409

1

AZ6746

1

AZ6747

1

AZ9021

1

AZ9034

10

AZ9035

10

AZ9036

10

AZ9038

10

AZ9040

10

AZ9041

10

AZ9130

10

CR

M5607

1

CR

M5608

1

CR

M5619

1

CR

M5620

1

CR

M5621

1

129320/3

1

129320/4

1

129320/5

1

129320/6

1

10.2. REPLACEABLE PARTS.

Mains cord and moulded IEC plug and lead set (UK) 230V-AC

Mains cord and moulded IEC plug and lead set (USA) 115V-AC

Mains cord and moulded IEC plug and lead set (USA) 115V-AC

Mains cord and moulded IEC plug and lead set (Europe) 230V-AC

Spares Pack Simmerstat Controller

Fuse: F10A

Fuse: F8A

Fuse: F6.3A

Fuse: F0.5A

Fuse:F2.5A

Fuse: F3.15A

Fuse; F3A

Neon: Clear (230V)

Neon: Amber (230V)

Neon: Clear (115V)

Neon: Amber (115V)

Switch, Element Selection (EMX, EMV).

Support rod (710mm / 28 “ long).

Support rod (1160mm / 45” long).

Support rod (1440mm / 55” long).

Support rod (590mm / 23” long).

APPENDIX ‘A’. DECONTAMINATION CERTIFICATE.

Page 23 of 28 M6873 Issue 12.7

.

Bibby Scientific Limited

Beacon Road, Stone, Staffordshire ST15 0SA. Great Britain

Tel: +44(0)1785 812121. Fax: +44(0)1785 810405

E-mail:

electrothermalhelp@bibby-scientific.com

DECONTAMINATION CLEARANCE CERTIFICATE

For the Inspection, Repair or Return of Medical, Laboratory or Industrial Equipment.

Prior to a Service Engineer working on equipment that has been in an environment where substances hazardous to health may have been

used, you are requested to provide the following information:

CUSTOMER DETAILS

Company:-

Department:-

Contact Name:-

Tel No:-

Fax No:-

Address:-

Post Code:-

Product Description

Model No:-

Has the equipment been exposed to any of the following, Please answer all questions by deleting YES/NO as applicable and by providing

A. Blood, body fluids, Pathological

specimens

B. Biodegradable material that could

become a hazard

C. Other biohazard YES/NO Provide details if YES

D. Chemical or substances hazardous to

health

E. Radioactive substances State name(s)

and quantities of isotopes and checks

made for residual activity

F. Other hazards YES/NO Provide details if YES

2. Please provide details of any hazard present as indicated above. Include details of names and quantities of

agents as appropriate:-

3. Your method of decontamination (please describe):-

4. Are there likely to be any areas of residual contamination (please specify)

I declare that the above information is true and complete to the best of my knowledge and belief.

Authorised signature:- Name (please print):-

Title/Position:-

For and behalf of:- Date:-

details in section 2 below.

YES/NO Provide details if YES

YES/NO Provide details if YES

YES/NO Provide details if YES

YES/NO Provide details if YES

Serial No:-

11. CUSTOMER SUPPORT.

Page 24 of 28 M6873 Issue 12.7

Bibby Scientific Limited.

For the America’s and Canada, contact:

For help and support in using this product, please contact Electrothermal at the following

address.

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

• General enquiries :

info@bibby-scientific.com

• Order enquiries :

sales@bibby-scientific.com

• Technical support :

electrothermalhelp@bibbyscientific.com

• www.electrothermal.com

12. NOTES

Techne Incorporated, 3 Terri Lane,

Suite 10 Burlington, NJ 08016 USA.

Toll free:800-225-9243Tel: 609-589-2560

Fax: 609-589-2571

Email: labproducts@techneusa.com

Http www.techneusa.com

Page 25 of 28 M6873 Issue 12.7

Page 26 of 28 M6873 Issue 12.7

13. EC DECLARATION OF CONFORMITY.

Page 27 of 28 M6873 Issue 12.7

Bibby Scientific Limited.

For the America’s and

Canada, contact:

Distributors Stamp

CE marked products and associated accessories covered by this Instruction book conform to the

essential requirements of the following directives:

EMC Directive.

Low Voltage Directive.

A full copy of the EC Declaration / Conformity document can be obtained from the manufacture at

the email address : info@bibby-scientific.com

Beacon Road,

Stone,

Staffordshire ST15 0SA,

Great Britain.

Tel: +44(0)1785 812121

Fax: +44(0)1785 810405

• General enquiries :

info@bibby-scientific.com

• Order enquiries :

sales@bibby-scientific.com

• Technical support :

electrothermalhelp@bibbyscientific.com

• www.electrothermal.com

Part of the Bibby Scientific Group

Techne Incorporated, 3 Terri Lane,

Suite 10 Burlington, NJ 08016 USA.

Toll free:800-225-9243Tel: 609-589-2560

Fax: 609-589-2571

Email: labproducts@techneusa.com

Http www.techneusa.com

Page 28 of 28 M6873 Issue 12.7

2013 Bibby Scientific Limited. All rights reserved.

Loading...

Loading...