Page 1

Instruction Manual

Low Profile MagnaValves

Electronics Inc.

56790 Magnetic Drive

Mishawaka, Indiana 46545

1-800-832-5653 (Toll Free)

Phone: 1-574-256-5001

Fax: 1-574-256-5222

E-mail: sales@electronics-inc.com

Website: www.electronics-inc.com

Model LP-24 and Model VLP-24

IM:0083 Revision: B Date: 11/1/2012

Made in the USA

Page 2

y

(

)

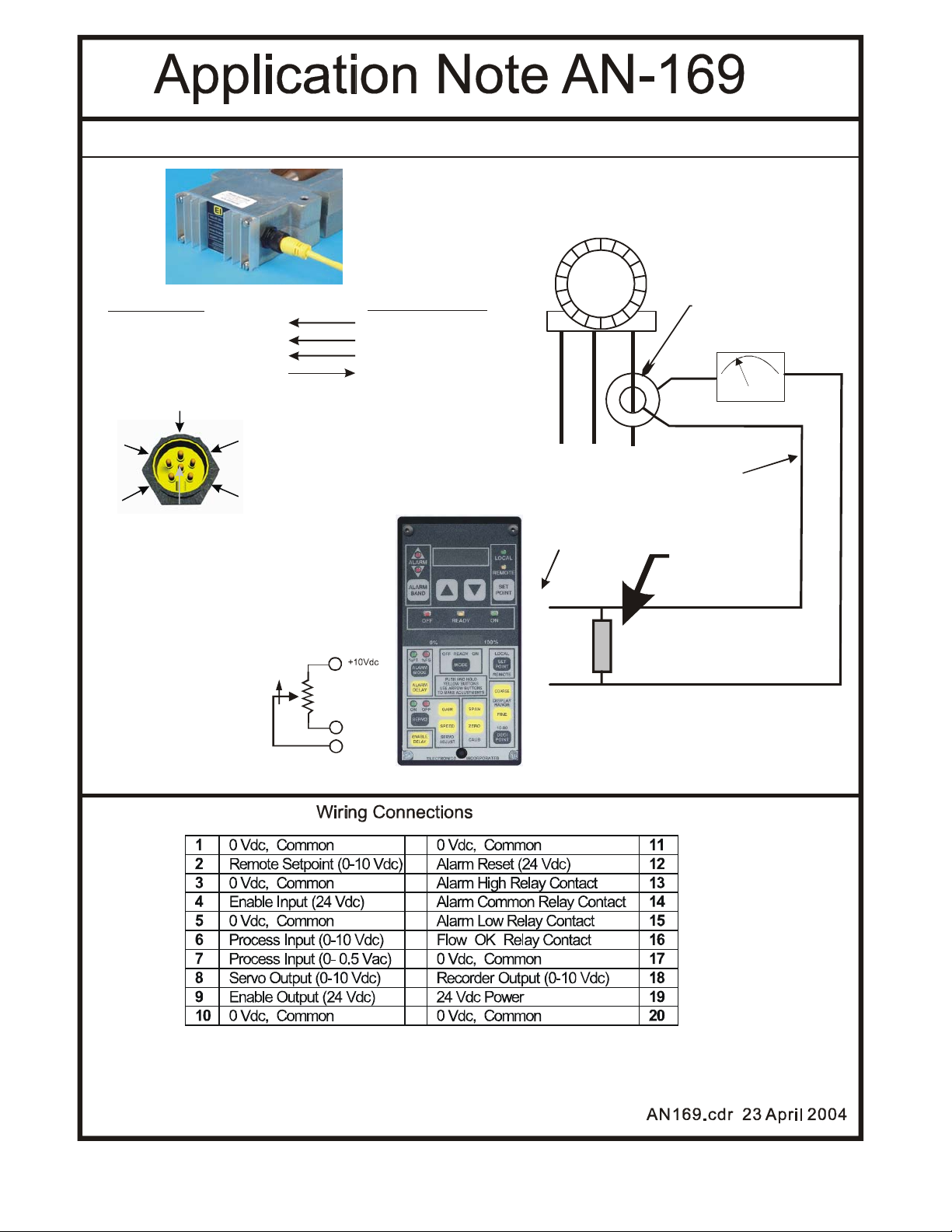

WIRE CONNECTIONS FOR VLP-24 OR LP-24 TO AN AC-24 A MPERA GE CONTR OLLER

NOTE : The valve must be loc ate d as close to the wheel

as possible for bes t servo cont r ol stabili t

5 feet or close r

Customer CT

100:5 etc.

PANEL METER

(IF USED)

0

VLP-24/LP-24

4) Orange 0-10 Vdc input

6) Blue 24 Vdc Enable

2) Red 24 Vdc Supply

5) Black 0 Vdc Common

WHEEL

MOTOR

AC-24 Controll er

8) Servo Out

9) Valve Enable

19) 24 Vdc Supply

20) 0 Vdc Common

3

1. WHITE

4

5

6

NOTE: The Controller's Full Scale display (typical

100.0) must match the customer's current

transformer rating (typical 100:5 ratio). Adjust the

control display range to match the actual

transform er ratio. See instru ction manual.

2

2. RED

3. GREEN

4. ORANGE

5. BLACK

1

6. BLUE

0-5 amps

L3

L2

L1

Use 12 AWG wire for current loop. Use

10 AWG or larger for runs over 15 ft.

AC-24 Rear Terminal

Current Shunt

.05 ohm 5 watt.

P/N 999200

Included with

controller.

7

.

100

(0-5A)

*

Remote setpoint can come

from customer potentiometer

or 0-10 Vdc signal. Also see

model Pot-24 rem ote pot.

.05 Ohm shunt

.05 Ohm shunt

VLP-24 Or ange

VLP-24 Blu e +24Vdc to VLP-24 RED

Note: Connect power supply directly to the MagnaValve first and then run power back to the control using minimum 16 AWG

wire size t o prevent (high curr ent ) voltage drops. Pow er supply should be re gulated and rated at 50VA per valve.

CW

2

0 Vdc

common

5

Alternate: Long length of curren t loop may cause

inaccuracy. To keep the 0-5 Amp current loop sh ort

you may place the .05 ohm shunt at the transformer

termina ls and run 18 AWG shielded ca bl e f rom shunt

to control.

0Vdc to VLP-24 BLACK

www.magnavalve.com

2

Page 3

Diagnostic LED’s

VALVE ON – When this LED is on or blinking, the electromagnet is receiving power. When the LED

is off, the permanent magnets will hold or block the shot flow. When the LED is on, but not blinking,

the valve flow rate is at full capacity. When the LED is blinking, the electromagnet is regulating the

shot flow.

Vin > 0.25 Vdc- This LED indicates that the valve is receiving an analog signal input greater than

0.25 Vdc. When this LED is off there is no media flow allowed. The input signal range is 0-10 Vdc. At

10 Vdc the valve will “open” to full capacity, which is usually 10% to 50% higher than the calibrated

range. The relationship between the 0-10 Vdc input signal and actual flow rate is nonlinear. The output signal 0-10 Vdc signal is linear and this makes accurate regulation by the AC-24 control possible.

24Vdc ENABLE – This LED indicates that the valve is receiving a 24 Vdc Enable signal. When this

LED is off, the valve is inhibited, and no shot will flow. This feature is an on-off action so there is no

need to disable or remove the 0-10 Vdc input signal.

24 Vdc Power – This LED indicates that 24 Vdc is available to operate the electromagnets for media flow. It should always be available and able to supply 2 Amps. If the LED is blinking, the supply

is above the recommended operating range +/- 2VDC (22-26VDC). If the LED is OFF, then the supply is below the recommended range. If that condition occurs, please call for technical support.

All of the LED’s must be on in order to have media flow.

3

Page 4

This manual will explain how to replace the mechanical media (grit) valve on a wheel type blast

cleaning machine with the new MagnaValve automatic media regulator. The two most prominent

reasons for this type of upgrade are:

a) to eliminate maintenance required for the air cylinder that operates the mechanical valve

b) to provide an automatic alarm to alert the operator to replenish the shot/grit supply

The machine used for illustration in this manual is a RotoPeen system from Pangborn Corporation

modified to shot blast clean 20 foot lengths of round pipe. It is a single wheel, 20 horsepower, passthru cabinet design as shown in Fig. 1 below.

Fig. 1

The following text will describe each of the remaining photos in three sections, before, during and

after the installation of the MagnaValve. The entire project required less than one day for the conversion.

Note: To operate properly and prevent damage to the MagnaValve, always supply the full flow capacity of the valve. For example, a VLP will flow 1000lbs/min. While only 400lbs maximum is required for the application, the MagnaValve must be supplied the full 1000lbs to operate correctly. If

an amount less than 1000lbs is supplied, the shot travels through the valve at a high velocity, and

can damage the valve.

4

Page 5

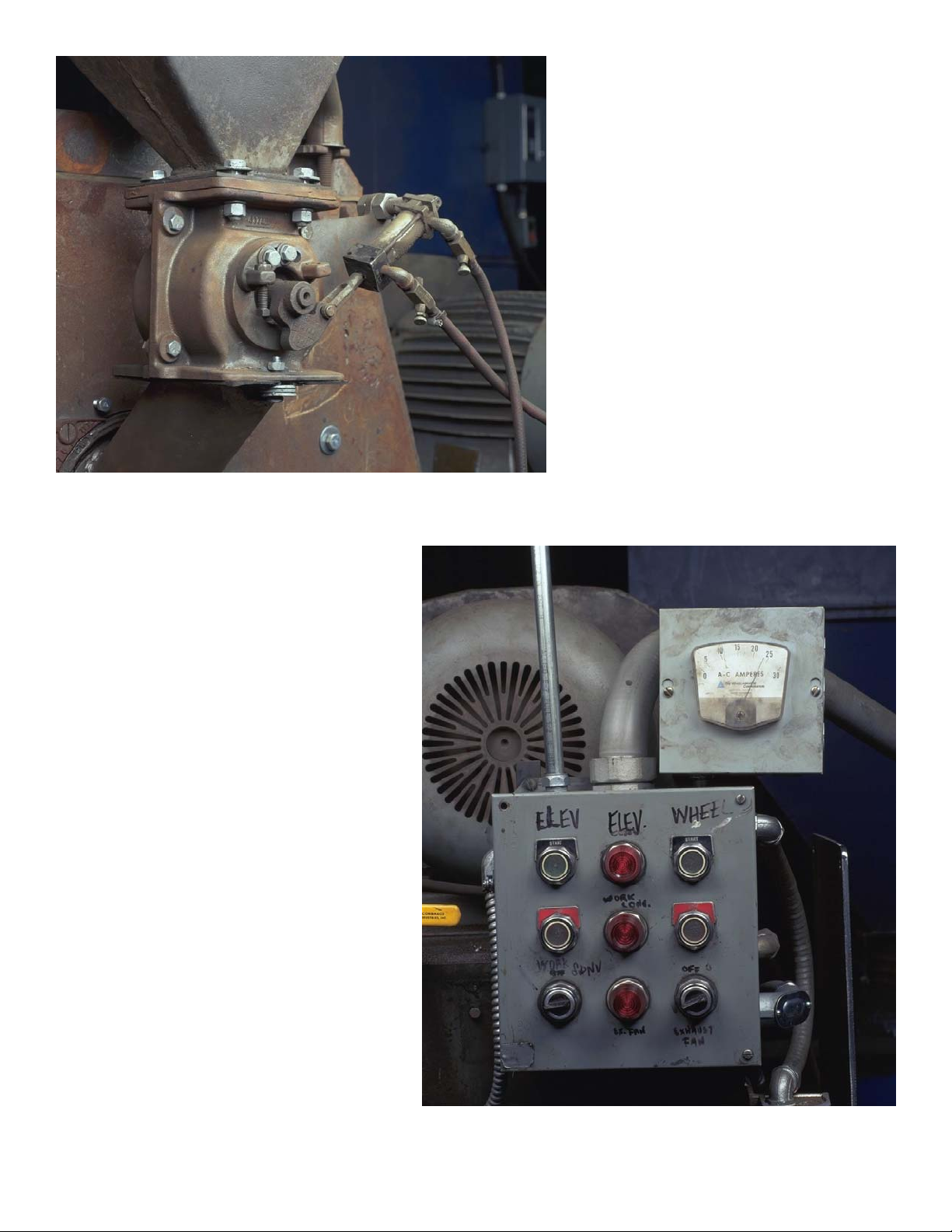

Fig. 2 An air cylinder was used to

open and close the original mechanical

valve as shown. This air cylinder was

controlled by a manually operated 2way air valve. The air cylinder moves

the mechanical valve from its closed to

open position. The amount of opening

was pre-set by the operator by adjusting a nut on the linkage of the air cylinder to limit the stroke.

Fig. 2

Fig. 3 This figure shows an ammeter

reading of approximately 8 amps, the

no-load or no shot flow condition. A

conventional panel ammeter (0-30

Amps) was used to indicate motor

amps and relative shot flow rate. It is

not uncommon for these meters to be

inaccurate because metallic dust collects inside the meter movement mechanism. This prevents the meter from

displaying the proper amperage.

Fig. 3

5

Page 6

Fig. 4 This figure shows the original

operating amperage level, in this case

approximately 24 amps. Tests indicated a 4 amp error.

Fig. 4

Fig. 5 The first step in removing the

old mechanical valve is to remove the

feed spout going to the wheel inlet.

First, remove the four bolts attaching

the feed spout to the bottom of the mechanical valve.

Caution: Be sure the machine is

properly locked out. Follow all safety

precautions and instructions shown on

the machine or in the owner’s manual.

Fig. 5

6

Page 7

Fig. 6 Some machines will have a slide gate

or maintenance gate located above the mechanical valve. This should be closed to allow

removal of the mechanical valve without

draining the shot from the hopper. If the machine does not have a slide gate (this machine did not), you must drain the hopper.

Drain the shot from the hopper using a hose

or chute to guide the shot into a drum or receptacle.

Fig. 6

Fig. 7 Next, remove air hoses

from air cylinder and terminate

the air supply line coming from

the air compressor. With the

slide gate closed (if available) or

with the hopper empty, loosen

the bolts from the top of the mechanical.

Fig. 7

7

Page 8

Fig. 8 Once the bolts are removed,

remove the valve from the machine.

Be careful. The valve is heavy and

may contain some shot that may spill

upon removal.

Fig. 8

Fig. 9 Special adapter plates can be

fabricated that will compensate for the

bolt hole locations and vertical spacing

needed by the MagnaValve.

Fig. 9

8

Page 9

Fig. 10 The adapter plates should be

installed onto the MagnaValve and the

assembly installed as a single unit. The

entire MagnaValve assembly can be

temporarily positioned and held into

place by using vise-grip or similar pliers

and then the bolts can be installed and

tightened.

Note: Adding a nonmetallic 1” spacer

above and below the MagnaValve will

improve MagnaValve performance.

Fig. 10

Fig. 11 The feed spout can now be rein-

stalled easily, since it bolts directly to the

adapter plate. Be sure to use a rubber gasket between the adaptor plate and the feed

spout. Do not use silicon or any other adhesive that will make it difficult to remove the

valve for inspection.

Fig. 11

9

Page 10

Fig. 12

Fig. 13 A new electrical panel was

used in this installation and was

mounted to a rigid plate prior to performing the wiring. Some installations

have adequate room in the existing

electrical panel, however, be sure that

the electrical panel is suitable (dust

tight, proper location for operator viewing, and well ventilated to prevent temperatures above 140 degrees F) for the

enviroment.

Fig. 12 The cable fastens to the mating connector. The cable should be routed in either

flexible or rigid conduit. In some installations

where the conduit for the air cylinder control

solenoid is nearby it is possible to reuse the

conduit for the MagnaValve cable.

Fig. 14

Fig. 13

Fig. 14 This is a rear view of the panel amme-

ter showing the connections to the meter lugs

coming from the current transformer secondary. Remove one of the meter wires to allow

installation of a wiring loop to the current shunt

mounted on the rear of the AC-24 Controller.

10

Page 11

Fig. 15 Attach the loose current transformer wire to one of the AC-24 controller shunt wires and attach the other

AC-24 controller shunt wire to the meter lug. This procedure allows the AC24 controller shunt to be in series with

the existing panel meter so that both of

them receive the (transformed) motor

current (0-5 Amps). If the panel meter

is to be eliminated then connect the

two current transformer output wires

directly to the AC-24 controller shunt.

Fig. 15

Fig. 16 Apply control power to the circuit.

Caution: Be sure all wiring has been

properly completed and that no shock

hazard exists. The AC-24 controller is

factory set to display 100.0 Amps full

scale when connected to a 100:5 ratio

current transformer. The display range

can be verified by pressing Coarse Display Range.

100.0

Fig. 16

11

Page 12

30.0

Fig. 17 Since this application uses a 30:5 ratio current transformer the AC-24 controller must be adjusted to read 30.0 full scale. Press and hold the

Coarse Display Range and Down arrow until 30.0 is

displayed. For finer adjustment use the Fine Display Range.

Fig. 17

Fig. 18 Start the wheel motor and

place a clamp-on type ammeter on

the motor leads to confirm calibration

of both the panel ammeter and the

AC-24 controller display.

Note: The AC-24 controller zero and

span have been factory set. Minor

adjustments may be needed. Press

the Span button along with up/down

arrows to change value. Release the

Span Button to see new amperage

readings. Make the controller reading

match the clamp-on ammeter reading. Even though there is no shot

flow, ammeter readings will show the

no load or no flow rate values. Note

that the clamp-on ammeter and the

AC-24 Controller digital display show

the no load motor amperage to be

about 8.8 amps, while the panel meter shows over 9 amps.

Fig. 18

12

Page 13

The last step of the installation is to adjust the AC-24 controller to the same operating amperage noted before at the beginning of the installation, 24 amps. Push and hold the Setpoint and press the

Down arrow until the value 24.0 appears in the display. Release the keypad and notice that the display returns to show the no load amperage. Activate the MagnaValve, either by pressing the Mode

keypad to the on position or pressing the Mode keypad to the Ready position and activate the blast

machine automatic cycle. The green ON LED on the front of the AC-24 controller will come on and

the green VALVE ON LED on the valve will start to blink, indicating that the valve is receiving power

pulses to allow shot to flow. After a few seconds the motor current will rise to the setpoint value, in

this case 24.0 amps. It is normal for the digital display to vary by +/- 0.2 amps. If the variation is

greater than this refer to the installation manual for the AC-24 controller.

This installation also included an alarm horn and a highly visible pedestal mounted light stalk with

green indicator to indicate shot flow and a red blinking indicator to show an alarm condition (such as

low shot flow). The elapsed meter for “abrasive on” time was included to verify the increased

productivity and reduced downtime.

13

Page 14

Fig. 20 Once the final conveyor speed

and shot flow rate (motor amps) have

been determined, the standard Almen

strip (SAE specification J442) can be

used to check for proper operation.

The Almen strip, shown here, is mounted with four hold-down screws onto a

standard Almen holder that has been

welded into place on the pipe. This is

the industry standard test for the shot

peening and blast cleaning intensity.

Fig 20

The Almen test strip is blasted on one side only and then removed from the holder. Once released

from the hold-down screws the strip will curve.

Fig. 21 The amount of this curvature,

called arc height, is an indication of

the blast stream intensity and the value, as measured on a standard Almen gage, can be placed into a

standard SPC process control chart.

There are three strip thicknesses, low

intensity (N), medium intensity (A),

and high intensity (C). Most abrasive

blast cleaning is performed at high

intensity with the (C) strip.

An arc height of .005" to .007" was

found to be ideal for this blast cleaning application.

Fig 21

14

Page 15

The advantage of using the Almen strip method lies in the ability to detect the many changes that

can occur in a blast machine cleaning operation. Many quality departments are demanding real

time process control to satisfy customer requirements for documentation. Instead of relying upon

the operator’s judgment of cleanliness, the Almen strip method provides a scientific basis for qualifying the machine. The following are the changes that can be detected by the Almen method:

a. Wrong shot size added to machine (check the bag or drum for correct size)

b. Wrong shot size, dust collector not removing all small or broken shot

c. Wrong shot hardness (check the bag or drum for correct hardness)

d. Incomplete coverage, due to exposure time, shot flow rate adjustment, or improper targeting

e. Improper targeting caused by worn wheel blades or control cages out of adjustment

15

Loading...

Loading...