Page 1

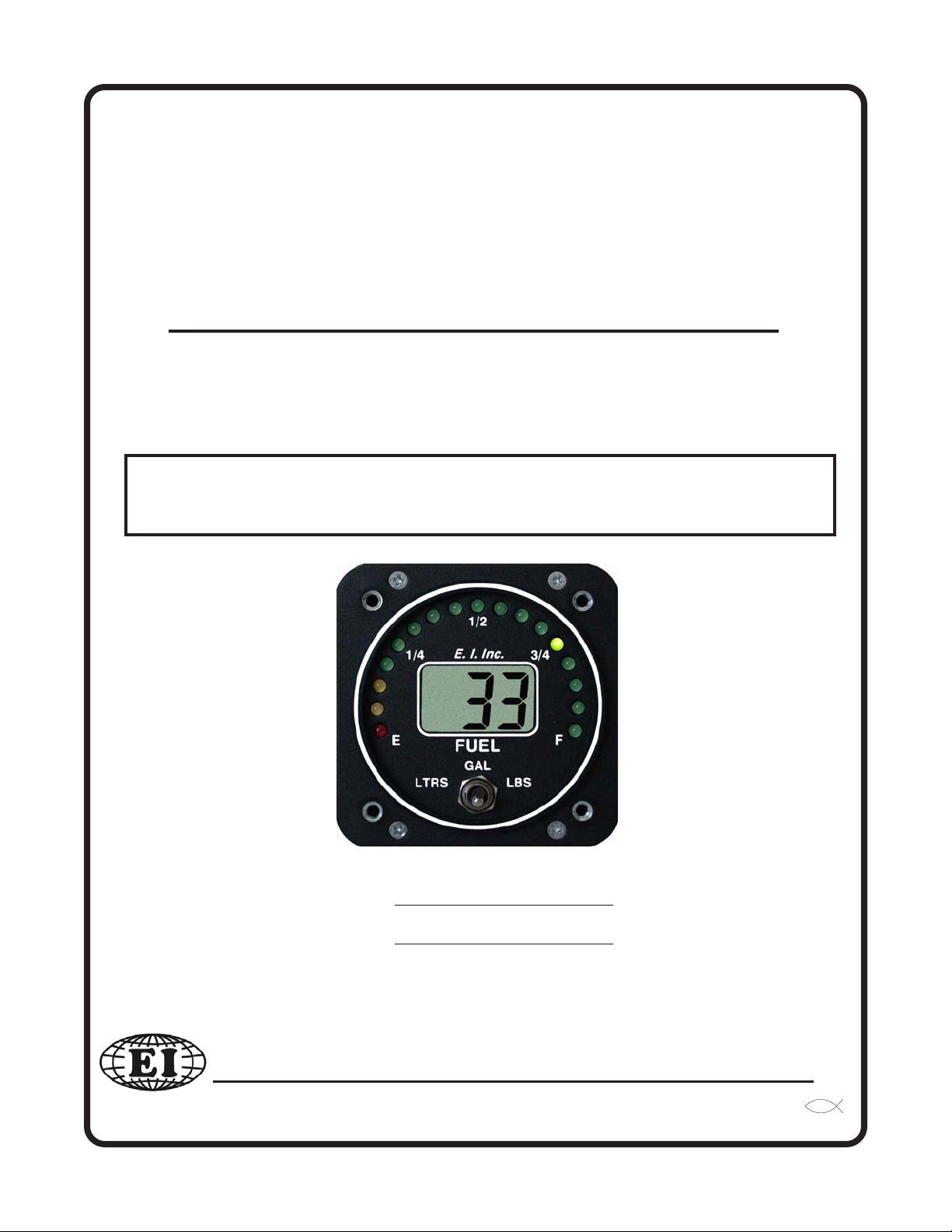

Fuel LevelFuel Level

Fuel Level

Fuel LevelFuel Level

(FL-1RA-12, FL-1RA-24 and FL-1CA)(FL-1RA-12, FL-1RA-24 and FL-1CA)

(FL-1RA-12, FL-1RA-24 and FL-1CA)

(FL-1RA-12, FL-1RA-24 and FL-1CA)(FL-1RA-12, FL-1RA-24 and FL-1CA)

(2nd Generation Instruments)(2nd Generation Instruments)

(2nd Generation Instruments)

(2nd Generation Instruments)(2nd Generation Instruments)

Operating and Installation InstructionsOperating and Installation Instructions

Operating and Installation Instructions

Operating and Installation InstructionsOperating and Installation Instructions

OI 1106011

11/6/01

You must read this manual before installing or operating the instrument. This

manual contains warranty and other information that may affect your decision

to install this product and/or the safety of your aircraft.

Model:Model:

Model:

Model:Model:

S/N:S/N:

S/N:

S/N:S/N:

Electronics International Inc.Electronics International Inc.

Electronics International Inc.

Electronics International Inc.Electronics International Inc.

63296 Powell Butte Hwy • Bend, OR 97701 • (541) 318-6060 • Buy-EI.com 63296 Powell Butte Hwy • Bend, OR 97701 • (541) 318-6060 • Buy-EI.com

63296 Powell Butte Hwy • Bend, OR 97701 • (541) 318-6060 • Buy-EI.com

63296 Powell Butte Hwy • Bend, OR 97701 • (541) 318-6060 • Buy-EI.com 63296 Powell Butte Hwy • Bend, OR 97701 • (541) 318-6060 • Buy-EI.com

®®

®

®®

Page 2

FL-1FL-1

FL-1

FL-1FL-1

Important NoticeImportant Notice

Important Notice

Important NoticeImportant Notice

***** Must Read ********** Must Read *****

***** Must Read *****

***** Must Read ********** Must Read *****

"DO NOT SOLELY RELY ON THE FL-1 TO DETERMINE THE FUEL LEVEL IN THE FUEL"DO NOT SOLELY RELY ON THE FL-1 TO DETERMINE THE FUEL LEVEL IN THE FUEL

"DO NOT SOLELY RELY ON THE FL-1 TO DETERMINE THE FUEL LEVEL IN THE FUEL

"DO NOT SOLELY RELY ON THE FL-1 TO DETERMINE THE FUEL LEVEL IN THE FUEL"DO NOT SOLELY RELY ON THE FL-1 TO DETERMINE THE FUEL LEVEL IN THE FUEL

TANKTANK

TANK

TANKTANK

planning, preflight and in-flight techniques for managing fuel.planning, preflight and in-flight techniques for managing fuel.

planning, preflight and in-flight techniques for managing fuel.

planning, preflight and in-flight techniques for managing fuel.planning, preflight and in-flight techniques for managing fuel.

." The use of the FL-1 does not eliminate or reduce the necessity for the pilot to use good flight." The use of the FL-1 does not eliminate or reduce the necessity for the pilot to use good flight

." The use of the FL-1 does not eliminate or reduce the necessity for the pilot to use good flight

." The use of the FL-1 does not eliminate or reduce the necessity for the pilot to use good flight." The use of the FL-1 does not eliminate or reduce the necessity for the pilot to use good flight

The following requirements must be met with before operating the aircraft with the FL-1:The following requirements must be met with before operating the aircraft with the FL-1:

The following requirements must be met with before operating the aircraft with the FL-1:

The following requirements must be met with before operating the aircraft with the FL-1:The following requirements must be met with before operating the aircraft with the FL-1:

1. All of the Operating Instructions must be read. There is important information in1. All of the Operating Instructions must be read. There is important information in

1. All of the Operating Instructions must be read. There is important information in

1. All of the Operating Instructions must be read. There is important information in1. All of the Operating Instructions must be read. There is important information in

this manual which the pilot must understand before flying the aircraft.this manual which the pilot must understand before flying the aircraft.

this manual which the pilot must understand before flying the aircraft.

this manual which the pilot must understand before flying the aircraft.this manual which the pilot must understand before flying the aircraft.

2. A copy of this operating manual must be in the aircraft at all times.2. A copy of this operating manual must be in the aircraft at all times.

2. A copy of this operating manual must be in the aircraft at all times.

2. A copy of this operating manual must be in the aircraft at all times.2. A copy of this operating manual must be in the aircraft at all times.

3. The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be3. The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be

3. The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be

3. The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be3. The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be

verified before flying the aircraft.verified before flying the aircraft.

verified before flying the aircraft.

verified before flying the aircraft.verified before flying the aircraft.

If you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of theIf you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of the

If you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of the

If you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of theIf you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of the

instrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the conditioninstrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the condition

instrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the condition

instrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the conditioninstrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the condition

of the FL-1.of the FL-1.

of the FL-1.

of the FL-1.of the FL-1.

Page 3

ContentsContents

Contents

ContentsContents

WW

arranty ...................................................................................arranty ...................................................................................

W

arranty ...................................................................................

WW

arranty ...................................................................................arranty ...................................................................................

22

2

22

Operating Instructions ............................................................Operating Instructions ............................................................

Operating Instructions ............................................................

Operating Instructions ............................................................Operating Instructions ............................................................

Instrument: ....................................................................................................... 3

Analog Display: ................................................................................................. 3

Digital Display: .................................................................................................. 4

Accuracy Limitations:

Important Considerations:

Installation Instructions ..........................................................Installation Instructions ..........................................................

Installation Instructions ..........................................................

Installation Instructions ..........................................................Installation Instructions ..........................................................

Important Information and Initial Check Out: .................................................... 6

Route The Circular Connector: .......................................................................... 7

Route the Power and Ground Wires: .................................................................. 7

Route the Backlight Wires: ................................................................................ 7

Route the External Warning Control Line: ......................................................... 8

Route the Fuel Tank Sensor Wire (FL-1RA-12 and -24 Only): .......................... 8

Install the Instrument in the Panel: ..................................................................... 8

Connect the Circular Connector to the Instrument: ............................................. 8

Mount the Placard on the Instrument Panel: ....................................................... 8

Selecting the Proper Filter: ................................................................................ 9

Selecting the Proper Operating Mode: ............................................................... 9

Selecting the Resolution: ................................................................................... 9

Programming the Filter, Operating Mode and Resolution: ................................. 10

Calibration Issues: ............................................................................................. 11

Calibrate the Fuel Tank: ..................................................................................... 12

Provide the Operating and Installation Manual to the Pilot: ............................... 15

(MUST READ) (MUST READ)

(MUST READ) .............................................................. 4

(MUST READ) (MUST READ)

(MUST READ) (MUST READ)

(MUST READ) ........................................................

(MUST READ) (MUST READ)

33

3

33

5

66

6

66

FLFL

-1RA-12 and FL-1RA-12 and FL

FL

-1RA-12 and FL

FLFL

-1RA-12 and FL-1RA-12 and FL

FLFL

-1RA-12 and FL-1RA-12 and FL

FL

-1RA-12 and FL

FLFL

-1RA-12 and FL-1RA-12 and FL

FLFL

-1CA Wiring Diagram ...........................................................-1CA Wiring Diagram ...........................................................

FL

-1CA Wiring Diagram ...........................................................

FLFL

-1CA Wiring Diagram ...........................................................-1CA Wiring Diagram ...........................................................

FLFL

-1CA Circular Connector .....................................................-1CA Circular Connector .....................................................

FL

-1CA Circular Connector .....................................................

FLFL

-1CA Circular Connector .....................................................-1CA Circular Connector .....................................................

Specifications and Operating FSpecifications and Operating F

Specifications and Operating F

Specifications and Operating FSpecifications and Operating F

TT

echnical Notes .........................................................................echnical Notes .........................................................................

T

echnical Notes .........................................................................

TT

echnical Notes .........................................................................echnical Notes .........................................................................

-1RA-24 Wiring Diagram .............................-1RA-24 Wiring Diagram .............................

-1RA-24 Wiring Diagram .............................

-1RA-24 Wiring Diagram .............................-1RA-24 Wiring Diagram .............................

-1RA-24 Circular Connector .......................-1RA-24 Circular Connector .......................

-1RA-24 Circular Connector .......................

-1RA-24 Circular Connector .......................-1RA-24 Circular Connector .......................

eatures ..................................eatures ..................................

eatures ..................................

eatures ..................................eatures ..................................

1

1616

16

1616

1717

17

1717

1818

18

1818

1919

19

1919

2020

20

2020

2121

21

2121

Page 4

Warranty

1209921

Electronics International Inc. warrants this instrument and system components to be free from defects in

materials and workmanship for a period of one year from the user invoice date. Electronics International

Inc. will repair or replace any item under the terms of this Warranty provided the item is returned to the

factory prepaid.

l. This Warranty shall not apply to any product that has been repaired or altered by any person other than

Electronics International Inc., or that has been subjected to misuse, accident, incorrect wiring, negligence,

improper or unprofessional assembly or improper installation by any person.

any reimbursement for any person’s time for installation, removal, assembly or repair.any reimbursement for any person’s time for installation, removal, assembly or repair.

any reimbursement for any person’s time for installation, removal, assembly or repair. Electronics

any reimbursement for any person’s time for installation, removal, assembly or repair.any reimbursement for any person’s time for installation, removal, assembly or repair.

International retains the right to determine the reason or cause for warranty repair.

2. This warranty does not extend to any machine, vehicle, boat, aircraft or any other device to which the

Electronics International Inc. product may be connected, attached, interconnected or used in conjunction

with in any way.

3. The obligation assumed by Electronics International Inc. under this warranty is limited to repair, replacement or refund of the product, at the sole discretion of Electronics International Inc.

4. Electronics International Inc. is not responsible for shipping charges or damages incurred under this

Warranty.

This warranty does not coverThis warranty does not cover

This warranty does not cover

This warranty does not coverThis warranty does not cover

5. No representative is authorized to assume any other liability for Electronics International Inc. in connection with the sale of Electronics International Inc. products.

If you do not agree to and accept the terms of this warranty, you may return the product in newIf you do not agree to and accept the terms of this warranty, you may return the product in new

6.

If you do not agree to and accept the terms of this warranty, you may return the product in new

If you do not agree to and accept the terms of this warranty, you may return the product in newIf you do not agree to and accept the terms of this warranty, you may return the product in new

condition, with receipt, within thirty (30) days for a refund.condition, with receipt, within thirty (30) days for a refund.

condition, with receipt, within thirty (30) days for a refund.

condition, with receipt, within thirty (30) days for a refund.condition, with receipt, within thirty (30) days for a refund.

This Warranty is made only to the original user.

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLYWARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

WARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLYWARRANTIES OR OBLIGATIONS: EXPRESS OR IMPLIED. MANUFACTURER EXPRESSLY

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR-DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR-

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR-

DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PAR-DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BETICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BE

TICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BE

TICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BETICULAR PURPOSE. PURCHASER AGREES THAT IN NO EVENT SHALL MANUFACTURER BE

LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOSTLIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOST

LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOST

LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOSTLIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING LOST

PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS EXPRESSLY PROVIDEDPROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS EXPRESSLY PROVIDED

PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS EXPRESSLY PROVIDED

PROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS EXPRESSLY PROVIDEDPROFITS OR LOSS OF USE OR OTHER ECONOMIC LOSS. EXCEPT AS EXPRESSLY PROVIDED

HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY TO PURCHASER OR ANYHEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY TO PURCHASER OR ANY

HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY TO PURCHASER OR ANY

HEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY TO PURCHASER OR ANYHEREIN, MANUFACTURER DISCLAIMS ALL OTHER LIABILITY TO PURCHASER OR ANY

OTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURER’SOTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURER’S

OTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURER’S

OTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURER’SOTHER PERSON IN CONNECTION WITH THE USE OR PERFORMANCE OF MANUFACTURER’S

PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN TORT.PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN TORT.

PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN TORT.

PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN TORT.PRODUCTS, INCLUDING SPECIFICALLY LIABILITY IN TORT.

.

THIS WARRANTY IS IN LIEU OF ALL OTHERTHIS WARRANTY IS IN LIEU OF ALL OTHER

THIS WARRANTY IS IN LIEU OF ALL OTHER

THIS WARRANTY IS IN LIEU OF ALL OTHERTHIS WARRANTY IS IN LIEU OF ALL OTHER

2

Page 5

Operating InstructionsOperating Instructions

Operating Instructions

Operating InstructionsOperating Instructions

FL-1RA & FL-1CAFL-1RA & FL-1CA

FL-1RA & FL-1CA

FL-1RA & FL-1CAFL-1RA & FL-1CA

Instrument:Instrument:

Instrument:

Instrument:Instrument:

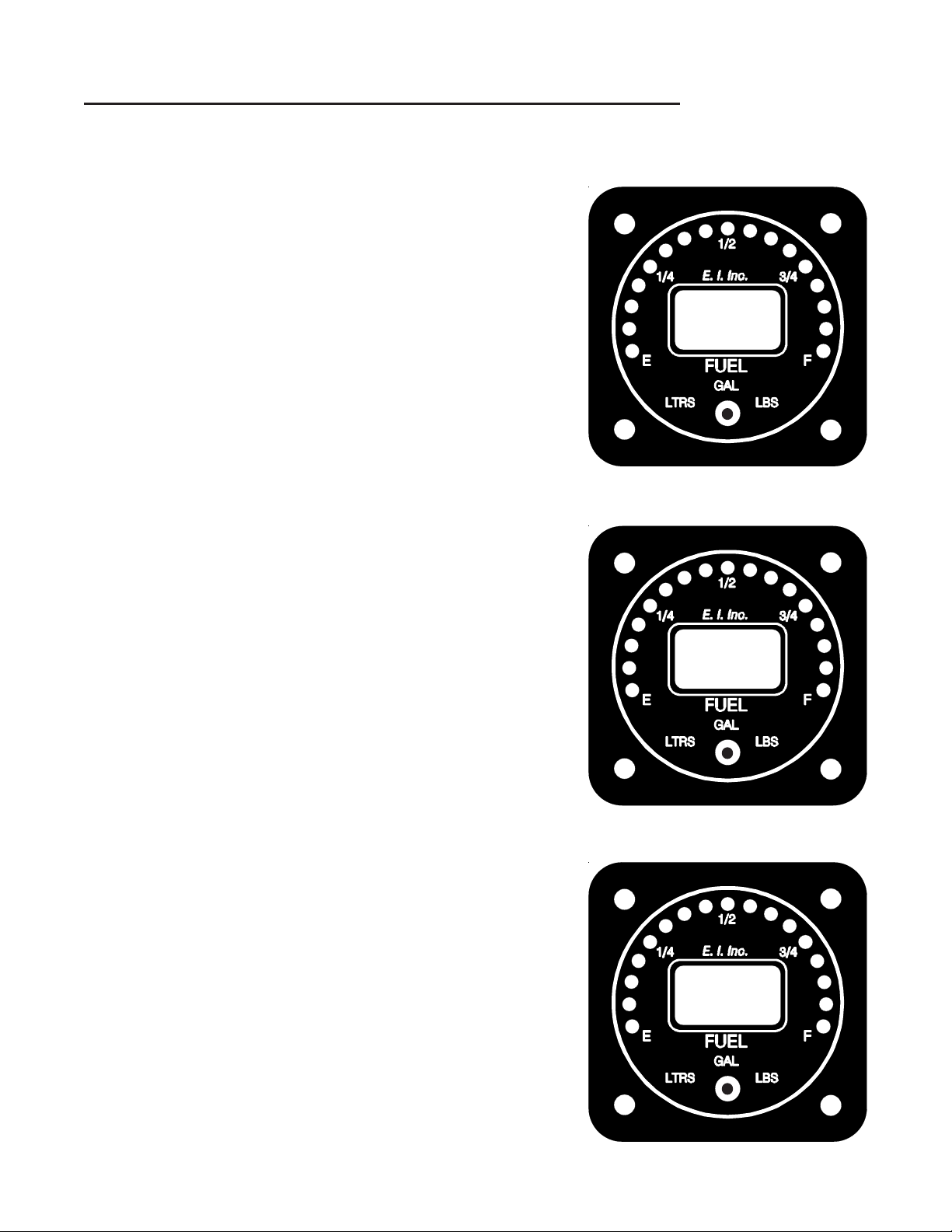

The FL-1 is a fuel level instrument featuring a 210 degree analog display and a digital display. These

two displays provide the primary indication of the fuel level for the tanks and offer many advantages over

conventional analog gauges, as described below. The FL-1 must be calibrated in gallons and it can display

in pounds or liters. When displaying in pounds the FL-1 uses a "6 x Gal" conversion factor and when

displaying liters it uses a "3.75 x Gal" conversion factor. When displaying gallons the FL-1 may be programmed to display in one or 1/2 gallon increments. For fuel levels above 99 gallons the FL-1 will display

in one gallon increments only. Since the FL-1 does not incorporate any moving parts (needles, bearings,

springs, etc.) there is little to go wrong or wear out.

The FL-1 has a programmed filter that effects how the instrument responds to changes in fuel level.

The filter may be set to 8, 16, 32, 64 or 128 seconds response. In the installation section of this manual is a

discussion of the advantages and disadvantages of the different filter settings.

The FL-1 connects to a fuel level sensors mounted in the fuel tank. The FL-1RA-12 and FL-1RA-24

was designed to be used with a resistive fuel level sensor that decrease or increases in resistance as fuel is

added to the tank. The -12 is for a 12 volt system and the -24 is for a 24 volt system. The FL-1CA was

designed to be used with E.I.'s capacitive fuel level sensor and it will operate on a 12 or 24 volt system.

Once the FL-1 is installed in the aircraft it must be calibrated to the aircraft fuel tank and sensor by

filling the tanks to predetermined fuel levels. You may use as few as two calibration points or as many as 9

points. This mapping of the tank removes any non-linearity in the tank and sensor.

Analog Display:Analog Display:

Analog Display:

Analog Display:Analog Display:

The 210 degree analog displays provide a quick reference of the fuel level. More precise information

is provided in the digital display. An advantage of the analog display is its ability to emit a green, yellow or

red light. With a quick glance you can determine if your fuel level is in the green, yellow, or red operating

range. In addition the FL-1 provides the following warnings:

1/17 Tank Warning -1/17 Tank Warning -

1.

1/17 Tank Warning - If the tank level reaches 1/17 of a tank, the appropriate yellow LED will

1/17 Tank Warning -1/17 Tank Warning blink. This is intended to alert you that the fuel level is getting low.

Low Fuel -Low Fuel -

3.

Low Fuel - If the tank level reaches 1/17 or 2 gallons (whichever is greater), the red LED will

Low Fuel -Low Fuel blink. This is intended to alert you that the fuel level is getting very low.

"OPEN" - "OPEN" -

4.

"OPEN" - If the wire to the fuel tank sensor becomes open, the analog display will show an empty

"OPEN" - "OPEN" and the digital display will show "OPEN." This warning is intended to alert you when the FL-1 has

lost the signal from the fuel sensor.

3

Page 6

Note:Note:

Note: To acknowledge a blinking LED (i.e., to stop the blinking), change the position of the Selector

Note:Note:

Switch. Once a blinking warning is acknowledged it will not occur again until the FL-1's power has

been turned off and back on. Although these blinking warnings are valuable, they can be annoying.

For this reason we provide a way of shutting them off.

During night operation the analog LED's may be too bright. If so, turn the panel light rheostat up and

the analog lights (LED's) will dim. If you wish to control the intensity of the LED's independent of the

panel light rheostat, a LED Intensity Control Pot is available from Electronics International. The red LED

will always be displayed at full intensity.

Digital Display:Digital Display:

Digital Display:

Digital Display:Digital Display:

With the Selector Switch in the left position the digital display will show the fuel level in liters. With

the Selector Switch in the right position the digital display will show the fuel level in pounds and in the

middle position the digital display will show the fuel level in gallons. Fuel levels below 2 gallons will be

displayed as "0."

If the digital display backlight has been permanently powered up (as recommended), the digital display

will be easier to see during low ambient light conditions and at night.

On power-up the FL-1 performs the following tests in sequence:

1. The fuel tank calibration data is check for errors. A table of error codes is provided in the calibration section of this manual. If an error is found, the appropriate error code is displayed and the FL-1

operation is stopped.

2. A self test is performed, all the LED's are sequenced and "8888" is shown on the digital display.

***** MUST READ ********** MUST READ *****

***** MUST READ *****

***** MUST READ ********** MUST READ *****

Accuracy Limitations:Accuracy Limitations:

Accuracy Limitations:

Accuracy Limitations:Accuracy Limitations:

The accuracy limitations of the FL-1 are listed below.

anyone flying the aircraft aware of these limitations.anyone flying the aircraft aware of these limitations.

anyone flying the aircraft aware of these limitations.

anyone flying the aircraft aware of these limitations.anyone flying the aircraft aware of these limitations.

1. Angle of Attack -1. Angle of Attack -

1. Angle of Attack - The FL-1 must be calibrated with the aircraft in a cruise angle of attack. If the

1. Angle of Attack -1. Angle of Attack aircraft is in a condition other than cruise, depending on the mounting location and type of sensor

used, the FL-1 may display inaccurate fuel levels. If your aircraft does not sit at a cruise angle of

attack when on the ground, it may not display accurate fuel levels.

angles of attack and see what the effects are on the fuel level readings for the FL-1.angles of attack and see what the effects are on the fuel level readings for the FL-1.

angles of attack and see what the effects are on the fuel level readings for the FL-1.

angles of attack and see what the effects are on the fuel level readings for the FL-1.angles of attack and see what the effects are on the fuel level readings for the FL-1.

Full Fuel Readings -Full Fuel Readings -

2.

Full Fuel Readings - As a tank is filled the fuel sensor may not be able to detect the fuel entering

Full Fuel Readings -Full Fuel Readings the upper corners of the fuel tank. If this is the case with your sensor, the FL-1 will display lower

fuel levels than the actual fuel in the tanks when the tanks are full. When the fuel level drops to a

point where the fuel sensors start to detect a change, the displayed fuel level should be accurate.

It is the pilot/owner's obligation to makeIt is the pilot/owner's obligation to make

It is the pilot/owner's obligation to make

It is the pilot/owner's obligation to makeIt is the pilot/owner's obligation to make

Test your aircraft at differentTest your aircraft at different

Test your aircraft at different

Test your aircraft at differentTest your aircraft at different

4

Page 7

Check your system by comparing the displayed fuel level on the FL-1 to the fuel level listed inCheck your system by comparing the displayed fuel level on the FL-1 to the fuel level listed in

Check your system by comparing the displayed fuel level on the FL-1 to the fuel level listed in

Check your system by comparing the displayed fuel level on the FL-1 to the fuel level listed inCheck your system by comparing the displayed fuel level on the FL-1 to the fuel level listed in

the flight manual at each fill up.the flight manual at each fill up.

the flight manual at each fill up.

the flight manual at each fill up.the flight manual at each fill up.

3. Low Fuel Readings -3. Low Fuel Readings -

3. Low Fuel Readings -

3. Low Fuel Readings -3. Low Fuel Readings levels below 1/8levels below 1/8

levels below 1/8. You should always fly the aircraft in such a manner as to at least maintain the

levels below 1/8levels below 1/8

FAA minimum fuel requirements in the aircraft at all times.

and type of sensor used, the FL-1 may not be able to accurately measure the last few gallons ofand type of sensor used, the FL-1 may not be able to accurately measure the last few gallons of

and type of sensor used, the FL-1 may not be able to accurately measure the last few gallons of

and type of sensor used, the FL-1 may not be able to accurately measure the last few gallons ofand type of sensor used, the FL-1 may not be able to accurately measure the last few gallons of

fuel in the tank.fuel in the tank.

fuel in the tank.

fuel in the tank.fuel in the tank.

4. Improper Calibration -4. Improper Calibration -

4. Improper Calibration - If the FL-1 has not been properly calibrated, it will not display accurate

4. Improper Calibration -4. Improper Calibration fuel levels in the tanks. It is important you verify the accuracy of the FL-1.

your measured fuel levels in the tanks with the readings on the FL-1 before each flight.your measured fuel levels in the tanks with the readings on the FL-1 before each flight.

your measured fuel levels in the tanks with the readings on the FL-1 before each flight.

your measured fuel levels in the tanks with the readings on the FL-1 before each flight.your measured fuel levels in the tanks with the readings on the FL-1 before each flight.

5. Poor Connections -5. Poor Connections -

5. Poor Connections - Poor connections in the wires leading from the FL-1 to the fuel sensor can

5. Poor Connections -5. Poor Connections become intermittent with age. An intermittent connection will most likely show up as wandering or

inaccurate readings on the FL-1.

the readings on the FL-1 before each flight.the readings on the FL-1 before each flight.

the readings on the FL-1 before each flight.

the readings on the FL-1 before each flight.the readings on the FL-1 before each flight.

6. Defective Fuel Level Sensor -6. Defective Fuel Level Sensor -

6. Defective Fuel Level Sensor - A fuel sensor can become intermittent or change resistance with

6. Defective Fuel Level Sensor -6. Defective Fuel Level Sensor age. It is not uncommon to find intermittent problems even in new sensors. We recommend

Stewart Warner F-385-CP05 resistive sensors be used with the FL-1RA. An intermittent problem

with a fuel sensor will most likely show up as wandering or inaccurate readings on the FL-1.

ways cross check the measured fuel levels in the tank with the readings on the FL-1 at each fillways cross check the measured fuel levels in the tank with the readings on the FL-1 at each fill

ways cross check the measured fuel levels in the tank with the readings on the FL-1 at each fill

ways cross check the measured fuel levels in the tank with the readings on the FL-1 at each fillways cross check the measured fuel levels in the tank with the readings on the FL-1 at each fill

up.up.

up.

up.up.

Do not rely on the FL-1 to determine the fuel in the tank for indicated tankDo not rely on the FL-1 to determine the fuel in the tank for indicated tank

Do not rely on the FL-1 to determine the fuel in the tank for indicated tank

Do not rely on the FL-1 to determine the fuel in the tank for indicated tankDo not rely on the FL-1 to determine the fuel in the tank for indicated tank

Depending on the mounting locationDepending on the mounting location

Depending on the mounting location

Depending on the mounting locationDepending on the mounting location

Always cross checkAlways cross check

Always cross check

Always cross checkAlways cross check

Always cross check your measured fuel levels in the tanks withAlways cross check your measured fuel levels in the tanks with

Always cross check your measured fuel levels in the tanks with

Always cross check your measured fuel levels in the tanks withAlways cross check your measured fuel levels in the tanks with

Al-Al-

Al-

Al-Al-

If you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of theIf you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of the

If you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of the

If you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of theIf you ever find an inaccuracy issue or any other problem with the FL-1, cover the face of the

instrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the conditioninstrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the condition

instrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the condition

instrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the conditioninstrument with a note saying "DEFECTIVE". This will alert anyone flying the aircraft to the condition

of the FL-1.of the FL-1.

of the FL-1.

of the FL-1.of the FL-1.

***** MUST READ ********** MUST READ *****

***** MUST READ *****

***** MUST READ ********** MUST READ *****

Important Considerations:Important Considerations:

Important Considerations:

Important Considerations:Important Considerations:

""

DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT (FL-1) TO DETERMINE THEDO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT (FL-1) TO DETERMINE THE

"

DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT (FL-1) TO DETERMINE THE

""

DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT (FL-1) TO DETERMINE THEDO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT (FL-1) TO DETERMINE THE

FUEL LEVELS IN THE AIRCRAFTFUEL LEVELS IN THE AIRCRAFT

FUEL LEVELS IN THE AIRCRAFT

FUEL LEVELS IN THE AIRCRAFTFUEL LEVELS IN THE AIRCRAFT

for the pilot to use good flight planning, preflight and in-flight techniques for managing fuel.for the pilot to use good flight planning, preflight and in-flight techniques for managing fuel.

for the pilot to use good flight planning, preflight and in-flight techniques for managing fuel. It is

for the pilot to use good flight planning, preflight and in-flight techniques for managing fuel.for the pilot to use good flight planning, preflight and in-flight techniques for managing fuel.

important the pilot adopt the practices listed below. If you are not familiar with these techniques, contact

the FAA to acquire proper training.

1. 1.

A copy of this operating manual must be in the aircraft at all times.A copy of this operating manual must be in the aircraft at all times.

1.

A copy of this operating manual must be in the aircraft at all times.

1. 1.

A copy of this operating manual must be in the aircraft at all times.A copy of this operating manual must be in the aircraft at all times.

2. Flight Planning -2. Flight Planning -

2. Flight Planning - Always calculate the fuel requirement for each leg of the flight including any

2. Flight Planning -2. Flight Planning alternate plans for bad weather. Keep this information available in the aircraft during the flight.

Keep a chart of the published fuel flows for various flight/engine conditions in the aircraft. Keep a

chart of the measured fuel flows for various flights in the aircraft. Measured fuel flows can be

considerably different from published figures. This is usually due to old inaccurate engine instruments.

""

..

The use of the FL-1 does not eliminate or reduce the necessity The use of the FL-1 does not eliminate or reduce the necessity

"

.

The use of the FL-1 does not eliminate or reduce the necessity

""

..

The use of the FL-1 does not eliminate or reduce the necessity The use of the FL-1 does not eliminate or reduce the necessity

5

Page 8

3. Preflight - Do not rely on the FL-1 to determine the fuel level in the fuel tank. The pilot must3. Preflight - Do not rely on the FL-1 to determine the fuel level in the fuel tank. The pilot must

3. Preflight - Do not rely on the FL-1 to determine the fuel level in the fuel tank. The pilot must

3. Preflight - Do not rely on the FL-1 to determine the fuel level in the fuel tank. The pilot must3. Preflight - Do not rely on the FL-1 to determine the fuel level in the fuel tank. The pilot must

visually check/measure the fuel level in the tank before every takeoff.visually check/measure the fuel level in the tank before every takeoff.

visually check/measure the fuel level in the tank before every takeoff. Cross-check the measured

visually check/measure the fuel level in the tank before every takeoff.visually check/measure the fuel level in the tank before every takeoff.

fuel level with the displayed level on the FL-1. Also, crosscheck these levels with the fuel requirements for the flight listed in your flight plan.

4. In Flight -4. In Flight -

4. In Flight - Make the FL-1 part of your normal instrument scan.

4. In Flight -4. In Flight played on FL-1 with your flight plan at each leg of the flight or every 30 minutesplayed on FL-1 with your flight plan at each leg of the flight or every 30 minutes

played on FL-1 with your flight plan at each leg of the flight or every 30 minutes (if a leg is

played on FL-1 with your flight plan at each leg of the flight or every 30 minutesplayed on FL-1 with your flight plan at each leg of the flight or every 30 minutes

longer than 30 minutes). Calculate the fuel flows from the FL-1 displayed fuel level and compare

them with your charts of measured and published fuel flows for the aircraft. If there is a discrepancy, land the aircraft at the nearest airport and verify the fuel level.

seriously.

5. New Pilot or Owner of the Aircraft -5. New Pilot or Owner of the Aircraft -

5. New Pilot or Owner of the Aircraft -

5. New Pilot or Owner of the Aircraft -5. New Pilot or Owner of the Aircraft previous aircraft pilot/owner's responsibility to insure the new pilot has read this manual and isprevious aircraft pilot/owner's responsibility to insure the new pilot has read this manual and is

previous aircraft pilot/owner's responsibility to insure the new pilot has read this manual and is

previous aircraft pilot/owner's responsibility to insure the new pilot has read this manual and isprevious aircraft pilot/owner's responsibility to insure the new pilot has read this manual and is

aware of the accuracy limitations and other important considerations. All limitations and operat-aware of the accuracy limitations and other important considerations. All limitations and operat-

aware of the accuracy limitations and other important considerations. All limitations and operat-

aware of the accuracy limitations and other important considerations. All limitations and operat-aware of the accuracy limitations and other important considerations. All limitations and operating characteristics learned from operating the FL-1 must be passed on to the new pilot/owner.ing characteristics learned from operating the FL-1 must be passed on to the new pilot/owner.

ing characteristics learned from operating the FL-1 must be passed on to the new pilot/owner.

ing characteristics learned from operating the FL-1 must be passed on to the new pilot/owner.ing characteristics learned from operating the FL-1 must be passed on to the new pilot/owner.

Installation InstructionsInstallation Instructions

Installation Instructions

Installation InstructionsInstallation Instructions

Important Information and Initial Check Out:Important Information and Initial Check Out:

Important Information and Initial Check Out:

Important Information and Initial Check Out:Important Information and Initial Check Out:

If there is a new pilot or owner of the aircraft, it is theIf there is a new pilot or owner of the aircraft, it is the

If there is a new pilot or owner of the aircraft, it is the

If there is a new pilot or owner of the aircraft, it is theIf there is a new pilot or owner of the aircraft, it is the

FL-1FL-1

FL-1

FL-1FL-1

Cross-check the fuel leves dis-Cross-check the fuel leves dis-

Cross-check the fuel leves dis-

Cross-check the fuel leves dis-Cross-check the fuel leves dis-

Discrepancies should be taken

The installer and aircraft owner must read the Warranty before starting the installationThe installer and aircraft owner must read the Warranty before starting the installation

1.

The installer and aircraft owner must read the Warranty before starting the installation. There is

The installer and aircraft owner must read the Warranty before starting the installationThe installer and aircraft owner must read the Warranty before starting the installation

information in the Warranty that may alter your decision to install this instrument.

accept the terms of the Warranty, do not install this instrument.accept the terms of the Warranty, do not install this instrument.

accept the terms of the Warranty, do not install this instrument.

accept the terms of the Warranty, do not install this instrument.accept the terms of the Warranty, do not install this instrument.

2. If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft2. If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft

2. If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft

2. If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft2. If you are not an FAA Certified Aircraft Mechanic familiar with the issues of installing aircraft

fuel level instruments, fuel level instruments,

fuel level instruments,

fuel level instruments, fuel level instruments,

3. Read the entire Installation Instructions and resolve any issues you may have before starting the

installation. This may eliminate any delays once the installation is started.

THIS INSTALLATION MAY REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFTTHIS INSTALLATION MAY REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFT

4.

THIS INSTALLATION MAY REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFT

THIS INSTALLATION MAY REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFTTHIS INSTALLATION MAY REQUIRE SOME PARTS UNIQUE TO YOUR AIRCRAFT

THAT ARE NOT SUPPLIED IN THE KIT.THAT ARE NOT SUPPLIED IN THE KIT.

THAT ARE NOT SUPPLIED IN THE KIT. Acquire all the parts necessary to install this instru-

THAT ARE NOT SUPPLIED IN THE KIT.THAT ARE NOT SUPPLIED IN THE KIT.

ment before starting the installation.

5. Check that the instrument make and model are correct before starting the installation. The FL-1RA12 is for a 12 volt system and a resistive probe, the FL-1RA-24 is for a 24 volt system and a resistive probe and the FL-1CA is for E.I.'s capacitive probe.

6. Before starting the installation make sure the unit will fit in the location you intend to install it

without obstructing the operation of any controls.

Do Not attempt to install this instrument.Do Not attempt to install this instrument.

Do Not attempt to install this instrument.

Do Not attempt to install this instrument.Do Not attempt to install this instrument.

6

If you do notIf you do not

If you do not

If you do notIf you do not

Page 9

The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be verified beforeThe FL-1 must be calibrated to the aircraft fuel system and its accuracy must be verified before

7.

The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be verified before

The FL-1 must be calibrated to the aircraft fuel system and its accuracy must be verified beforeThe FL-1 must be calibrated to the aircraft fuel system and its accuracy must be verified before

flying the aircraft.flying the aircraft.

flying the aircraft.

flying the aircraft.flying the aircraft.

8. The FL-1 should only be installed in experimental aircraft or a certified aircraft by a T.C. or8. The FL-1 should only be installed in experimental aircraft or a certified aircraft by a T.C. or

8. The FL-1 should only be installed in experimental aircraft or a certified aircraft by a T.C. or

8. The FL-1 should only be installed in experimental aircraft or a certified aircraft by a T.C. or8. The FL-1 should only be installed in experimental aircraft or a certified aircraft by a T.C. or

S.T.C. holder.S.T.C. holder.

S.T.C. holder.

S.T.C. holder.S.T.C. holder.

A copy of this manual must be presented to the pilot/owner.A copy of this manual must be presented to the pilot/owner.

A copy of this manual must be presented to the pilot/owner.

9.

A copy of this manual must be presented to the pilot/owner.A copy of this manual must be presented to the pilot/owner.

they must read.

Route The Circular Connector:Route The Circular Connector:

Route The Circular Connector:

Route The Circular Connector:Route The Circular Connector:

Starting from under the instrument panel, route the circular connector wire harness up to the instrument

mounting location. (See the wiring diagram at the back of this manual). Place the circular connector about

2 inches back from the panel. Tie wrap the harness in place approximately 1 foot back from the circular

connector. This will allow the FL-1 to be connected outside the instrument for calibration.

wires do not obstruct the freedom of travel of any controls.wires do not obstruct the freedom of travel of any controls.

wires do not obstruct the freedom of travel of any controls.

wires do not obstruct the freedom of travel of any controls.wires do not obstruct the freedom of travel of any controls.

Route the PRoute the P

Route the P

Route the PRoute the P

In the wire harness are 3 foot red and black wires used for instrument power and ground. Route the 3

foot red wire in the harness to the aircraft’s 12 or 24 volt main or emergency bus as applicable via an

independent circuit breaker (five amps or less). An alternate method would be to route the red lead to the

bus via a one amp in-line fuse. With this method a spare fuse should be kept in the aircraft.

Route the 3 foot black wire in the harness to a good ground .

obstruct the freedom of travel of any controls.obstruct the freedom of travel of any controls.

obstruct the freedom of travel of any controls.

obstruct the freedom of travel of any controls.obstruct the freedom of travel of any controls.

ower and Ground Wires:ower and Ground Wires:

ower and Ground Wires:

ower and Ground Wires:ower and Ground Wires:

It contains important information

Be sure theseBe sure these

Be sure these

Be sure theseBe sure these

Tie wrap these wires so they do notTie wrap these wires so they do not

Tie wrap these wires so they do not

Tie wrap these wires so they do notTie wrap these wires so they do not

Route the Backlight Wires:Route the Backlight Wires:

Route the Backlight Wires:

Route the Backlight Wires:Route the Backlight Wires:

Connect the backlight wires as follows:

1. It is recommended to permanently power up the digital display backlight.

a) For a 12-volt system connect the white/brown wire to the bus (via the same fuse used to

power the unit) and connect the white/red wire to ground (see Wiring Diagram).

b) For a 24-volt system leave the white/brown open and connect the white/red wire to the

bus (via the same fuse used to power the unit) (see Wiring Diagram).

2. Connect the white/orange wire to the panel light rheostat. This wire will dim the analog LED’s

for night operation when the panel lights are turned on. If this line is left open, the analog LED's

will remain at full intensity at all times.

of travel of any controls.of travel of any controls.

of travel of any controls.

of travel of any controls.of travel of any controls.

Tie wrap all wires so they do not obstruct the freedomTie wrap all wires so they do not obstruct the freedom

Tie wrap all wires so they do not obstruct the freedom

Tie wrap all wires so they do not obstruct the freedomTie wrap all wires so they do not obstruct the freedom

7

Page 10

Route the External WRoute the External W

Route the External W

Route the External WRoute the External W

The white/yellow wire can be connected to a relay to control an external light, buzzer, etc. This wire

grounds when the red warning light is on. The current in this line must be limited to 1/10 of an amp maximum. Exceeding this limit will damage the unit. If this feature is not used leave this line open.

this wire so it does not obstruct the freedom of travel of any controls.this wire so it does not obstruct the freedom of travel of any controls.

this wire so it does not obstruct the freedom of travel of any controls.

this wire so it does not obstruct the freedom of travel of any controls.this wire so it does not obstruct the freedom of travel of any controls.

arning Control Line:arning Control Line:

arning Control Line:

arning Control Line:arning Control Line:

Tie wrapTie wrap

Tie wrap

Tie wrapTie wrap

Route the FRoute the F

Route the F

Route the FRoute the F

Only):Only):

Only):

Only):Only):

In the wire harness is a 6 foot brown wire. Route and connect the brown wire to the fuel tank resistive

sensor. These wires may be spliced for extra wire length.

freedom of travel of any controls.freedom of travel of any controls.

freedom of travel of any controls. Note: The maximum resistance of you sensor must be between 90 and

freedom of travel of any controls.freedom of travel of any controls.

300 ohms.

Route the Three FRoute the Three F

Route the Three F

Route the Three FRoute the Three F

Route and connect the group of three wires (red, black and white) to the fuel tank sensor. These wires

maybe spliced for extra wire length.

any controls.any controls.

any controls.

any controls.any controls.

Install the Instrument in the PInstall the Instrument in the P

Install the Instrument in the P

Install the Instrument in the PInstall the Instrument in the P

Install the instrument from behind the instrument panel using 6 x 32 screws. These screws should not

be any longer than 1/2".

uel Sensor Wireuel Sensor Wire

uel Sensor Wire

uel Sensor Wireuel Sensor Wire

uel Tuel T

uel T

uel Tuel T

ank Sensor Wires (FLank Sensor Wires (FL

ank Sensor Wires (FL

ank Sensor Wires (FLank Sensor Wires (FL

Tie wrap these wires so they do not obstruct the freedom of travel ofTie wrap these wires so they do not obstruct the freedom of travel of

Tie wrap these wires so they do not obstruct the freedom of travel of

Tie wrap these wires so they do not obstruct the freedom of travel ofTie wrap these wires so they do not obstruct the freedom of travel of

(may use the power fuse)(may use the power fuse)

(may use the power fuse)

(may use the power fuse)(may use the power fuse)

Tie wrap these wires so they do not obstruct theTie wrap these wires so they do not obstruct the

Tie wrap these wires so they do not obstruct the

Tie wrap these wires so they do not obstruct theTie wrap these wires so they do not obstruct the

-1CA Only):-1CA Only):

-1CA Only):

-1CA Only):-1CA Only):

anel:anel:

anel:

anel:anel:

(FL (FL

-1RA-12 and -24-1RA-12 and -24

(FL

-1RA-12 and -24

(FL (FL

-1RA-12 and -24-1RA-12 and -24

Note: If you cannot get to the Enter Button on the back of the unit for calibration, you may want to

mount the instrument in the panel after you have calibrated the tanks.

Connect the Circular Connector to the Instrument:Connect the Circular Connector to the Instrument:

Connect the Circular Connector to the Instrument:

Connect the Circular Connector to the Instrument:Connect the Circular Connector to the Instrument:

1) Push the two mating connectors together and twist them until they snap into position.

2) Turn the locking ring on the instrument connector clockwise (1 1/2 turns) until it locks into position.

3) Tie wrap any loose wires as needed.

Mount the Placard on the Instrument PMount the Placard on the Instrument P

Mount the Placard on the Instrument P

Mount the Placard on the Instrument PMount the Placard on the Instrument P

Mount the placard reading Mount the placard reading

Mount the placard reading

Mount the placard reading Mount the placard reading

DETERMINE THE FUEL LEVELS IN THE AIRCRAFTDETERMINE THE FUEL LEVELS IN THE AIRCRAFT

DETERMINE THE FUEL LEVELS IN THE AIRCRAFT

DETERMINE THE FUEL LEVELS IN THE AIRCRAFTDETERMINE THE FUEL LEVELS IN THE AIRCRAFT

FL-1.FL-1.

FL-1.

FL-1.FL-1.

"DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT TO"DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT TO

"DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT TO

"DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT TO"DO NOT SOLELY RELY ON THE FUEL LEVEL INSTRUMENT TO

anel:anel:

anel:

anel:anel:

" on the aircraft instrument panel near the" on the aircraft instrument panel near the

" on the aircraft instrument panel near the

" on the aircraft instrument panel near the" on the aircraft instrument panel near the

8

Page 11

Selecting the Proper Filter:Selecting the Proper Filter:

Selecting the Proper Filter:

Selecting the Proper Filter:Selecting the Proper Filter:

The filter may be programmed for a response time of 8, 16, 32, 64 or 128 seconds (time to 100%

respond to a change in the fuel level). The advantage and disadvantage of a fast and slow filter setting is

discussed below.

Advantages of a faster filter setting (8 to 16 seconds) - A fast response time may show some fluctuations in the fuel level during sloshing or turns. This can give you a good feeling the instrument is working,

and there is fuel in the tank. If you ever fly with low fuel levels, this can be very comforting. Once you

reach level flight and the fuel has leveled out, accurate fuel levels will be displayed in 8 to 16 seconds

depending on the filter setting.

Disadvantages of a faster filter setting (8 to 16 seconds) - With the fuel sensor mounted in a wing tank,

a fast response time could show excessive fluctuation in the fuel level that could be annoying. This is

especially true for thin wet long wing tanks with little dihedral. Fluctuation can cause the FL-1 to read from

near empty to near full.

Advantages of a slower filter setting (32 to 128 seconds): - A slower filter can stabilize the display and

remove all short term fluctuations.

Disadvantages of a slower filter setting (32 to 128 seconds): - With the fuel sensor mounted in a wing

tank and if you stay in a turn for a long period of time, aircraft with thin wet long wings tanks and little

dihedral can have a significant shift in fuel. Eventually this will effect the fuel level readings. Once you

establish level flight and the fuel has leveled out, it will take 32 to 128 seconds for an accurate fuel level

reading to be displayed on the FL-1, depending on the filter setting.

How your aircraft will react to different filter settings depends on your tank's shape, size, baffles,

baffle hole sizes, and probe placement. You may need to experiment with the filter setting to get the results

you like best. The filter setting has no effect on calibration or the response time during calibration.

Selecting the Proper Operating Mode:Selecting the Proper Operating Mode:

Selecting the Proper Operating Mode:

Selecting the Proper Operating Mode:Selecting the Proper Operating Mode:

If you have an FL-1CA Instrument (used with and Electronics International capacitive probe) set the

operating mode to “FL C” the “FLrH” mode will cause the instrument to read improperly.

If you have an FL-1RA-12 or -24 and a resistive fuel probe that

the operation mode to “FL r”.

If you have an FL-1RA-12 or -24 and a resistive fuel probe that

the operation mode to “FLrH”.

Selecting the Resolution:Selecting the Resolution:

Selecting the Resolution:

Selecting the Resolution:Selecting the Resolution:

When displaying your fuel level in gallons, the resolution of the digital display may be set for one

gallon (shown as “GAL1”) or ½ gallon (shown as “GAL.5”). Fuel levels above 99 gallons will always show

in one gallon increments.

decreasedecrease

decrease resistance as you add fuel, set

decreasedecrease

increaseincrease

increase resistance as you add fuel, set

increaseincrease

9

Page 12

Programming the FilterProgramming the Filter

Programming the Filter

Programming the FilterProgramming the Filter

To program the Filter, Operating Mode and Resolution perform the following steps:

Note: You will need access to the back of the FL-1 to program

the instrument. This may be difficult with the instrument mounted

in the panel. You may want to remove the FL-1 from the panel and

reconnect it on the outside of the instrument panel with the wires

routed through the instrument mounting hole. Tape a clean rag

around the FL-1 case to protect it.

, Operating Mode and Resolution:, Operating Mode and Resolution:

, Operating Mode and Resolution:

, Operating Mode and Resolution:, Operating Mode and Resolution:

1. Turn the power to the FL-1 off.

2. Set the tank Selector Switch to the center position ("GAL").

3. Push and hold the Enter Button on the back of the unit.

Turn on the power, wait 3 seconds and release the Enter

Button. The FL-1 will display the current filter setting (F

08, 16, 32, 64 or 128). The programmable numbers will be

blinking ("08", "16", "32", "64" or "128").

4. Toggling the Selector Switch from the center position to

the left or right will change the filter setting (F 08, 16, 32,

64 or 128).

5. Once you have selected the filter setting, tap the Enter

Button on the back of the FL-1 to display the current

operating mode. The programmable letters will be blinking ("C", "r", or "rH").

6. Toggling the Selector Switch from the center position to

the left or right will change the operating mode (“FL r”,

“FLrH” or “FL C”).

F 08

FL C

7. Once you have selected the operation mode, tap the Enter

Button on the back of the FL-1 to display the current

resolution. The programmable numbers will be blinking

("1" or ".5").

8. Toggling the Selector Switch from the center position to

the left or right will change the resolution (“GAL1” or

GAL.5”).

9. To exit this program mode, push and hold the Enter Button

on the back of the FL-1 for 3 seconds, then release the

button. All programmed data is stored in memory for 100

years with or without aircraft power connected to the

instrument.

10

GAL.5

Page 13

Calibration Issues:Calibration Issues:

Calibration Issues:

Calibration Issues:Calibration Issues:

The FL-1 must be calibrated in gallons. Liters are calculated from gallons using a x3.75 factor. Pounds

are calculated from gallon using a x6.0 factor. The FL-1 can be calibrated for a 4 gallon tank or as large as

999 gallon tank.

The FL-1 can be calibrated with as few as two points (full and empty) or as many as 9 points. The

calibration points provide the FL-1 with a fuel sensor output for a specific fuel level. The output of a fuel

sensor will be resistance for a resistive fuel probe or a frequency for the Electronics International capacitive

probe. In either case, the output of the fuel probe is converted to an arbitrary count we call “Sensor

Counts."

As the fuel level in the fuel tank increase, the Sensor Counts displayed on the FL-1 will increase

(provided you have programmed the FL-1 with the proper operating mode). Some common problems with

fuel tanks are listed below:

1. As you add fuel to an empty tank, it will take a certain amount of fuel before the resistive float starts

to move off the bottom of the tank or off the bottom end stop. For a capacitive system, it takes a

certain amount of fuel to reach the center electrode. Fuel levels below this point cannot be measured.

2. As you add fuel and the fuel level nears the top of the tank, the float on a resistive sensor will hit the

top of the tank or the top end stop. For a capacitive system, the fuel level will exceed the center

electrode. The fuel above this point cannot be measured. Therefore the FL-1 may not read a full

tank.

These problems can cause accuracy issues for any system. To improve the accuracy of the FL-1, we

recommend you set 5 calibration points, empty, ¼, ½ , ¾, and full. By doing this, any issues at the full or

empty fuel levels will not effect the accuracy between the ¼ and ¾ fuel levels.

Another common problem with fuel gauges is they may not display a full tank after calibration. If the

FL-1 has this problem, slightly reduce the Sensor Counts for the full fuel level calibration point. To calculate how much to reduce the counts, divide the change in the Sensor Counts between two cal points (near 1/

2 tank) by the change in the fuel level between the same two cal points. The FL-1 allows you to change the

fuel level or the Sensor Counts for any calibration point without having to add or remove fuel from the tank.

You can also recalibrate any calibration point at any time.

11

Page 14

Calibrate the FCalibrate the F

Calibrate the F

Calibrate the FCalibrate the F

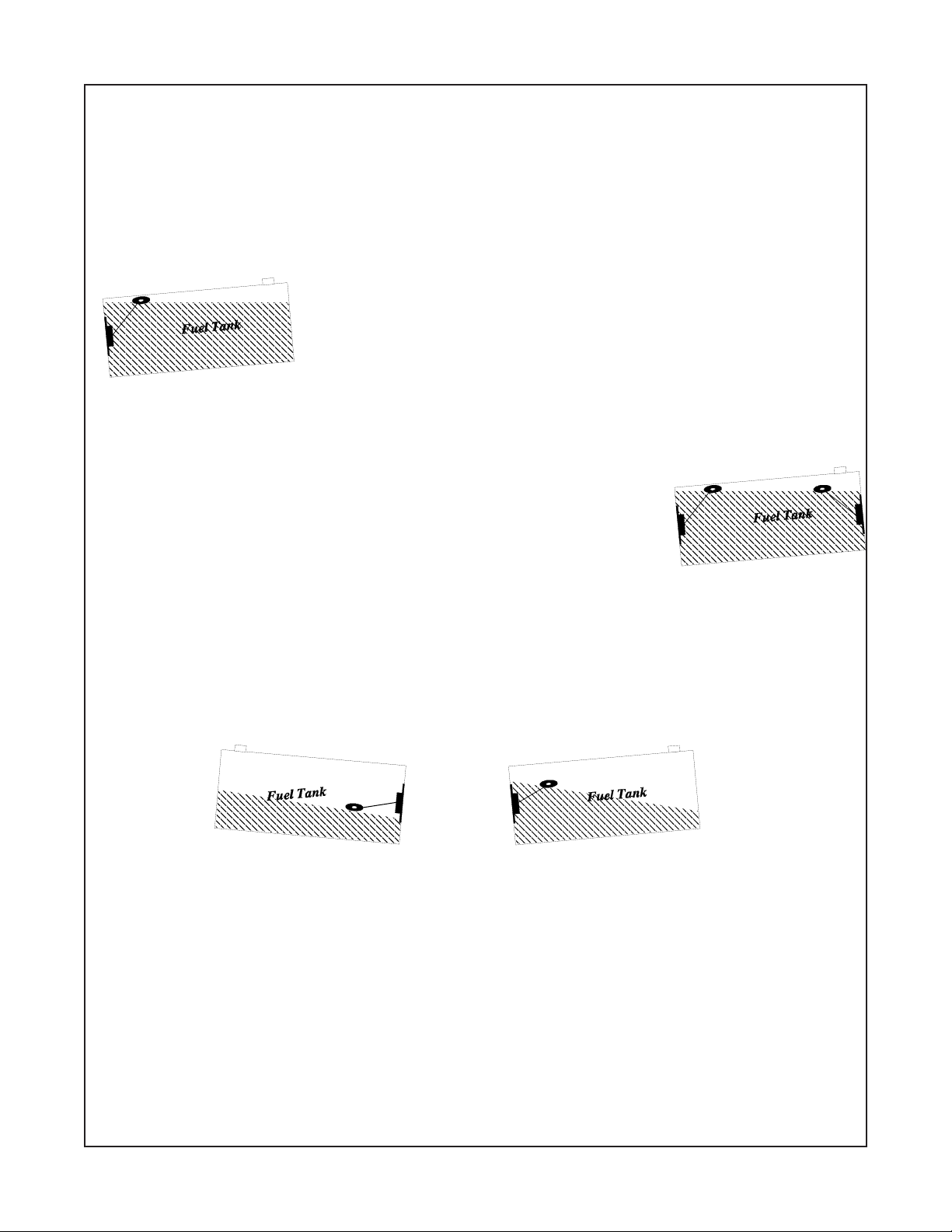

1. Use the chart at the back of this section and select the fuel levels for each calibration point. You

can use any number of cal points between 2 and 9. If you are not sure what the full fuel level will

be for your tank, you can record this level at the last step of this procedure when you have an

accurate measurement of the fuel required to fill the tank.

2. Drain the Left Tank with a normal aircraft angle of attack (nose up or down) such that the most

amount of fuel is left in the tank. This fuel in the tank is considered unusable and the FL-1 should

read “0” (Empty) for this fuel level.

uel Tuel T

uel T

uel Tuel T

ank:ank:

ank:

ank:ank:

Note: Note:

Note:

Note: Note:

lated hangar or outdoors. Keep it away from any flames, heat sources or electrical equipment.lated hangar or outdoors. Keep it away from any flames, heat sources or electrical equipment.

lated hangar or outdoors. Keep it away from any flames, heat sources or electrical equipment.

lated hangar or outdoors. Keep it away from any flames, heat sources or electrical equipment.lated hangar or outdoors. Keep it away from any flames, heat sources or electrical equipment.

Always store gasoline in a closed container. If you are not familiar with all of the issues ofAlways store gasoline in a closed container. If you are not familiar with all of the issues of

Always store gasoline in a closed container. If you are not familiar with all of the issues of

Always store gasoline in a closed container. If you are not familiar with all of the issues ofAlways store gasoline in a closed container. If you are not familiar with all of the issues of

working with gasoline, contact your local fire department for important safety advice.working with gasoline, contact your local fire department for important safety advice.

working with gasoline, contact your local fire department for important safety advice.

working with gasoline, contact your local fire department for important safety advice.working with gasoline, contact your local fire department for important safety advice.

3. Set the aircraft angle of attack for cruise flight.

4. Turn the power to the FL-1 off. Set the Tank Selector Switch to the left position.

5. Push and hold the Enter Button on the back of the unit. Turn on the

power. Wait 3 seconds and release the Enter Button. Only the

Empty LED should be lit and the digital display should read “Cal 1”.

This is your first calibration point.

Note: If you are recalibrating the FL-1 and wanted to advance to a

specific calibration point, push and hold the Enter Button on the

back of the FL-1 until you get to the calibration point of interest.

The calibration points will advance every 3 seconds. If you accidentally advance past the full fuel calibration point, the FL-1 will check for errors, go through the

power-up sequence and then into the normal operating mode. You

will have to start over.

Gasoline is explosive and can be very dangerous. It should be handled in a well venti-Gasoline is explosive and can be very dangerous. It should be handled in a well venti-

Gasoline is explosive and can be very dangerous. It should be handled in a well venti-

Gasoline is explosive and can be very dangerous. It should be handled in a well venti-Gasoline is explosive and can be very dangerous. It should be handled in a well venti-

CAL 1

6. Place the Selector Switch into the center position. The FL-1 will

display “E000”. The “E” indicates you are calibrating the Empty

Fuel Level. The “000” indicates the fuel level for this calibration

point is 0 gallons.

7. Place the Selector Switch into the right position. The FL-1 will

display the last programmed Sensor Counts for this cal point.

Tap the Enter Button on the back of the FL-1, the display will start

blinking and the Sensor Counts for the

will be displayed. Wait for the display to stabilize and tap the Enter

Button to lock the current Sensor Counts into the display and stop

the blinking.

8. Record the Sensor Counts for calibration point 1 in the calibration

chart at the back of this section.

current fuel level in the tank

12

E000

0297

Page 15

Note: If you want to manually program the Sensor Counts, push and hold the Enter Button at the

back of the FL-1 (with the Sensor Counts displayed and not blinking) until the thousands digits

starts to blink.

To increase the count of the blinking digit, move the Selector Switch from the center position to

the right.

To decrease the count of the blinking digit, move the Selector Switch from the center position to

the left.

To blink the next digit to the right, tap the Enter Button on the back of the FL-1.

To exit the manual programming of the Sensor Counts, lock the Sensor Counts into the display

and stop the blinking of a digit, push and hold the Enter Button for 3 seconds.

9. To advance to the next calibration point, move the selector switch to

the left position, push and hold the Enter Button on the back of the

unit until you see “CAL2” in the display. All of the calibration data

for calibration point 1 has been stored to permanent memory.

10. Fill the tank to the fuel level indicated on your calibration chart for

the next calibration point.

CAL 2

11. Place the Selector Switch to the center position. The FL-1 will

display the last programmed fuel level for this calibration point. The display will show something

like “P015” or maybe “F015”. A “P” would indicate this is a partial fuel level (not the full fuel

level). An “F” would indicate this is the full fuel level for the tank and the last cal point. The "015"

is the fuel level for this cal point.

12. To program (change) the fuel level for this calibration point, push

and hold the Enter Button on the back of the FL-1 for 3 seconds.

The far left letter (“P” or “F”) will be blinking. To change this

letter, move the selector switch to the left or right.

If this calibration point is for a partial fuel level (not the full fuel

level), select “P”. If this calibration point if for the full fuel level

(the last cal point) select “F”.

Note: The programmed fuel level must increase for each calibration point.Note: The programmed fuel level must increase for each calibration point.

Note: The programmed fuel level must increase for each calibration point.

Note: The programmed fuel level must increase for each calibration point.Note: The programmed fuel level must increase for each calibration point.

To increase the count of the blinking digit, move the Selector Switch from the center position to

the right.

To decrease the count of the blinking digit, move the Selector Switch from the center position to

the left.

P015

To blink the next digit to the right, tap the Enter Button on the back of the FL-1.

To exit the programming of the fuel level for this calibration point and stop the blinking of a digit,

push and hold the Enter Button on the back of the FL-1 for 3 seconds.

13

Page 16

13. Place the Selector Switch into the right position. The FL-1 will display the last programmed Sensor

Counts for this cal point.

Tap the Enter Button on the back of the FL-1, the display will start

blinking and the Sensor Counts for the current fuel level in the tank

will be displayed. Wait for the display to stabilize and tap the Enter

Button to lock the current sensor counts into the display, and stop

the blinking.

14. Record the Sensor Counts for this cal point on the calibration chart

at the back of this section.

15. Perform steps 10 trough 14 for each cal point. Once you have calibrated the full fuel level, the FL1 will evaluate the calibration data for any errors. The error codes are listed on the following table.

1056

Error Codes

Displayed

Code

The Sensor C ounts for C al Point 1 (Empty) is

Err1

Err2

Err3 Th e Full Fu el L ev el is le s s t h an 4 g allons .

Err4

Err5

too high (> 3072).

Th e Full Fu el Ca libration p oint is missin g . A ll 9

Cal Po ints are for pa r t ial fue l lev e ls.

The Sensor Counts between full and empty is

less than 200 counts.

The fuel level for each successive Cal Point

must be higher than the last. One or more is

not.

Comm ents

1107011

Note: On every power-up, the FL-1 checks the fuel tank calibration data for errors. If an error is

found, the FL-1 locks the FL-1 into a nonoperating mode with the first error code found shown in

the digital display.

14

Page 17

FL-1 Calibratio n Chart

Cal

Point

1

2

3

4

5

6

7

8

9

Fuel

Level

Tank

Se nsor Count Comme nts

The S ensor C o unts for Cal Point 1 (e mpty)

must not be > 3072 (Error Code 1).

The fuel level must increase for each

successive C al Point (Error Code 5).

The Sensor Counts between Full and Empty

must be 200 Sensor Counts or more (Error

Code 4).

The full fuel level must be 4 gallons or more

(Error Code 3).

Provide the Operating and Installation Manual to the Pilot:Provide the Operating and Installation Manual to the Pilot:

Provide the Operating and Installation Manual to the Pilot:

Provide the Operating and Installation Manual to the Pilot:Provide the Operating and Installation Manual to the Pilot:

A copy of this manual must be presented to the pilot/owner.A copy of this manual must be presented to the pilot/owner.

A copy of this manual must be presented to the pilot/owner.

A copy of this manual must be presented to the pilot/owner.A copy of this manual must be presented to the pilot/owner.

must be read. A copy of this manual must be kept in the aircraft at all times.

It contains important information which

1107012

15

Page 18

Do not use screwsDo not use screws

Do not use screws

Do not use screwsDo not use screws

longer than 1/2" (4 ea.).longer than 1/2" (4 ea.).

longer than 1/2" (4 ea.).

longer than 1/2" (4 ea.).longer than 1/2" (4 ea.).

Circular Connector

FLFL

-1RA-12 and FL-1RA-12 and FL

FL

-1RA-12 and FL

FLFL

-1RA-12 and FL-1RA-12 and FL

Wiring Diagram Wiring Diagram

Wiring Diagram

Wiring Diagram Wiring Diagram

23

-1RA-24-1RA-24

-1RA-24

-1RA-24-1RA-24

Red

Black

White/Brwn

White/Red

Wire Harness

White/Orng

White/Yel

Brn Wire

3' Power Lead, connects to 12 or 24 Volt Bus via 1 amp fuse or circuit

breaker.

3' Ground Lead, connects to Ground.

3' Backlight Control Line, connects to 12 Volt Bus via 1 amp fuse (may

use power fuse). 12 volts turns on the digital display backlight.

3' Backlight Control Line, connects to 24 Volt Bus via 1 amp fuse (may

use power fuse). Connect to ground for 12 Volt System.

3' Analog LED Lighting Control Line, connects to Panel Light Rheostat.

12/24 volts dims the analog LEDs.

3' External Warning Control Line. Can be connected to a relay to

control an external light, buzzer, etc. Grounds when Red Warning Light

is on. Current must be limited to 1/10 amp maximum.

6' Fuel Tank Input, connects to Fuel Tank Resistive Sensor.

16

Airframe Ground

Page 19

FL-1RA-12 and FL-1RA-24FL-1RA-12 and FL-1RA-24

FL-1RA-12 and FL-1RA-24

FL-1RA-12 and FL-1RA-24FL-1RA-12 and FL-1RA-24

Circular ConnectorCircular Connector

Circular Connector

Circular ConnectorCircular Connector

Connecting Cable Harness, Back View (wire side)

W/

3

Yel

W/

6

Org

9

Blk

W/

Red

Brwn

Red

W/

Brn

1

4

7

Note: See Wiring Diagram for

hook up information.

17

Page 20

Do not use screwsDo not use screws

Do not use screws

Do not use screwsDo not use screws

longer than 1/2" (4 ea.).longer than 1/2" (4 ea.).

longer than 1/2" (4 ea.).

longer than 1/2" (4 ea.).longer than 1/2" (4 ea.).

Circular Connector

FLFL

-1CA-1CA

FL

-1CA

FLFL

-1CA-1CA

Wiring Diagram Wiring Diagram

Wiring Diagram

Wiring Diagram Wiring Diagram

23

Red

Black

White/

Brwn

White/Red

White/Orng

Wire Harness

White/Yel

Red Wire

Black Wire

White Wire

3' Power Lead, connects to 12 or 24 Volt Bus via 1 amp fuse or circuit

breaker.

3' Ground Lead, connects to Ground.

3' Backlight Control Line, connects to 12 Volt Bus via 1 amp fuse (may

use power fuse). 12 volts turns on the digital display backlight.

3' Backlight Control Line, connects to 24 Volt Bus via 1 amp fuse (may

use power fuse). Connect to ground for 12 Volt System.

3' Analog LED Lighting Control Line, connects to Panel Light Rheostat.

12/24 volts dims the analog LEDs.

3' (Optional) External Warning Control Line. Can be connected to a

relay to control an external light, buzzer, etc. Grounds when Red

Warning Light is on. Current must be limited to 2/10 amp maximum.

6' Grouped wires, connects to Fuel Tank Capacitive Sensor.

18

Page 21

FL-1CAFL-1CA

FL-1CA

FL-1CAFL-1CA

Circular ConnectorCircular Connector

Circular Connector

Circular ConnectorCircular Connector

Connecting Cable Harness, Back View (wire side)

14

2

Blk

W/

6

Org

10

W/

Red

W/

Brn

Wht

Red

Blk

1

W/

Yel

Red

1516

Note: See Wiring Diagram for

hook up information.

3

7

11

7 to 9 (Fuel Level Input).

19

Page 22

Specifications and Operating FeaturesSpecifications and Operating Features

Specifications and Operating Features

Specifications and Operating FeaturesSpecifications and Operating Features

Model:

FL-1RA-12FL-1RA-12

FL-1RA-12 (Fuel Level Instrument to be used in a 12 Volt System and with resistive sensors .)

FL-1RA-12FL-1RA-12

FL-1RA-24FL-1RA-24

FL-1RA-24 (Fuel Level Instrument to be used in a 24 Volt System and with resistive sensors .)

FL-1RA-24FL-1RA-24

FL-1CAFL-1CA

FL-1CA (Fuel Level Instrument for use with E.I.'s capacitive sensors from 125Hz to 5KHz.)

FL-1CAFL-1CA

Case Size and Weight:

2.5" x 2.5" x 3.65" depth, 2 1/4" Bezel.

10 Oz. Unit Only.

Environmental:

Meets TSO-C55

Power Requirements:

7.5 to 35 Volts, 1/10 Amp.

Analog Display:

A sets of 17 High Intensity Light Emitting Diodes (LEDs) in 210 degree arc with Intensity Control

Line available for dimming. Sequential flash test on power up.

LED Warnings:

3/17 Tank Warning -3/17 Tank Warning -

1.

3/17 Tank Warning - If the fuel tank level reaches 3/17 of a tank, the appropriate yellow LED will

3/17 Tank Warning -3/17 Tank Warning blink.

Low Fuel -Low Fuel -

2.

Low Fuel - If the left or right tank reaches 1/17 of a tank, the red LED will blink.

Low Fuel -Low Fuel -

"OPEN" - "OPEN" -

4.

"OPEN" - If the wire to the fuel tank sensor becomes open, the analog display will show empty and

"OPEN" - "OPEN" the digital display will show "OPEN."

Note:Note:

Note: To acknowledge a blinking LED (i.e., to stop the blinking), change the position of the Selector

Note:Note:

Switch.