Electrolux ZHTAROW, EHTAROW60, ZHTAROW60, EHTAROW, OHTAROW60 User Manual

...

ENGLISH

GB CONTENTS

A GENERAL RECOMMENDATIONS.......................................................... Page 4

A1 HANDLING......................................................................................................................Page 4

A2 UNPACKING....................................................................................................................Page 4

A3 DISPOSAL.......................................................................................................................Page 4

A4 TECHNICAL DATA ..........................................................................................................Page 5

B INSTRUCTIONS FOR THE INSTALLER/MAINTENANCE PERSON..... Page 7

B1 WATER CONNECTION...................................................................................................Page 7

B2 ELECTRICAL CONNECTION .........................................................................................Page 7

B3 WARNING MESSAGES DISPLAYED ON THE CONTROL PANEL................................Page 8

B4 DETERGENT/RINSE-AID DISPENSERS AND SETTINGS............................................Page 9

B5 SETTING THE DISPENSERS.........................................................................................Page 10

B6 MAINTENANCE...............................................................................................................Page12

C INSTRUCTIONS FOR THE USER........................................................... Page 13

C1 STARTING.......................................................................................................................Page 14

C2 WASH CYCLES...............................................................................................................Page14

C3 OPERATION....................................................................................................................Page 14

C4 END OF WORK AND DAILY CLEANING.......... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... .......Page 15

C5 WARNING MESSAGES DISPLAYED ON THE CONTROL PANEL................................Page 16

C6 RESIDUAL RISKS...........................................................................................................Page 16

D TROUBLESHOOTING............................................................................. Page 18

3

WARNING

A GENERAL RECOMMENDATIONS

PE

PP

PS

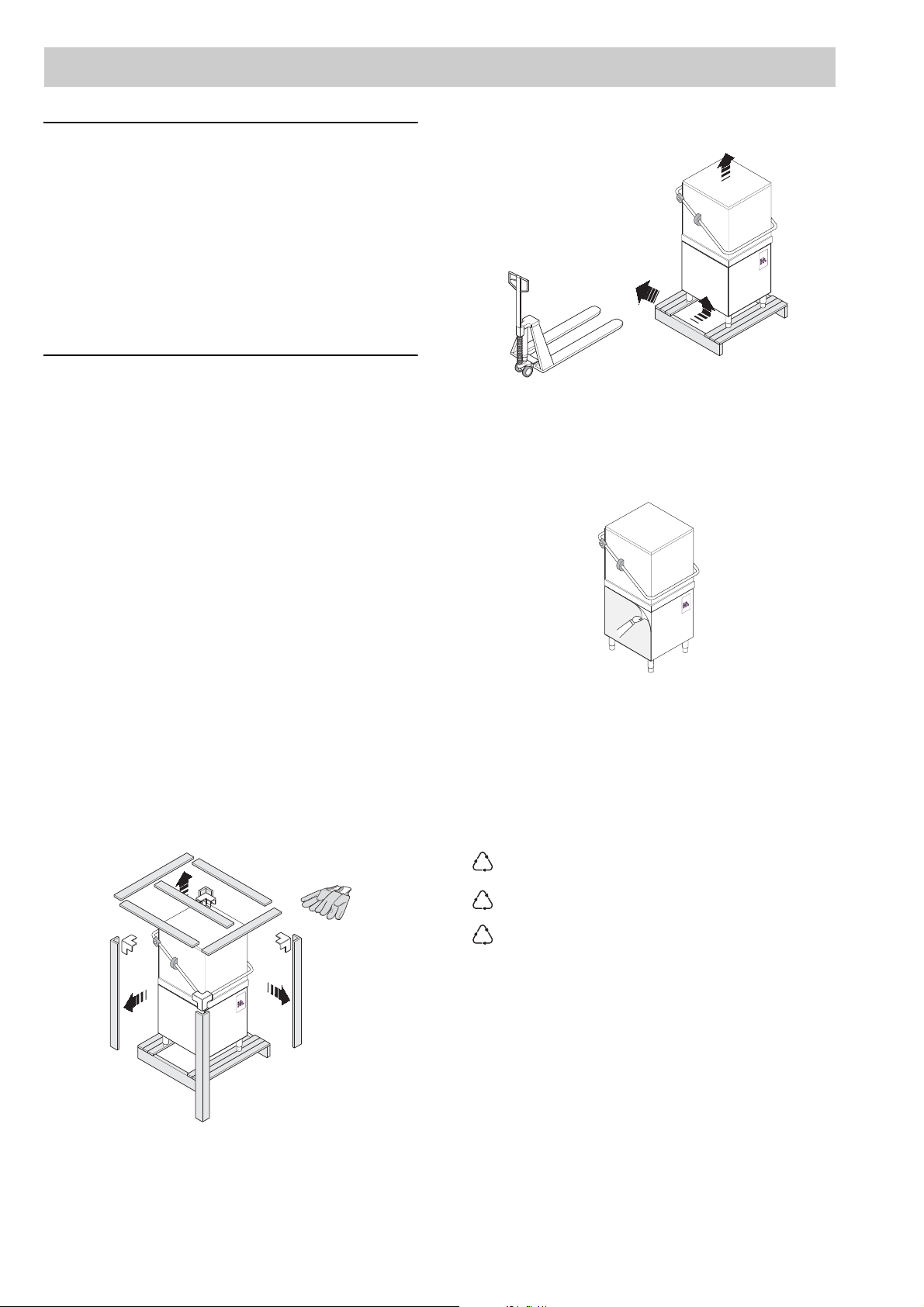

Lift the appliance using a lift truck, remove the base

CAREFULLY READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS BEFORE

INSTALLING THIS APPLIANCE. INCORRECT

INSTALLATIONS, ADAPTATIONS OR ALTERATIONS COULD CAUSE DAMAGE TO PROPERTY

OR INJURY TO PERSONS. MALICIOUS DAMAGE,

DAMAGE DUE TO NEGLIGENCE, OR TO FAILURE

TO COMPLY WITH INS TRUCTIONS AND REGULATIONS, OR TO INCORRECT CONNECTIONS OR

UNAUTHORISED TAMPERING INVALIDATE ANY

WARRANTY AND RELIEVE THE MANUFACTURER

OF ALL LIABILITY.

and position the appliance where it is to be installed.

1. Carefully read this instructions booklet, as it contains important advice for safe installation, operation and maintenance.

Keep this booklet to hand in a safe place for future

reference by other operators.

2. Installation should be carried out by qualified

engineers, in accordance with current regulations and with the manufacturerís instructions.

3. The appliance should only be used by persons specifically trained in this operation.

4. Switch off the appliance in the event of failure or

malfunctioning.

Only have the appliance repaired by a service centre

authorised by the manufacturer and ask for original

spare parts.

A1 HANDLING

Use suitable means to move the appliance: a lift truck

or fork pallet trucks (the forks should reach more than

halfway beneath the appliance).

A2 UNPACKING

Wear protective gloves to unpack.

Figure 2

Remove the protective film and ensure that the packaging material is disposed of correctly in compliance

with the regulations in force in the country wh ere the

product is to be used.

Figure 3

A3 DISPOSAL

All the packaging materials are environment friendly.

They may be kept without danger, recycled or burned

in a special waste incineration plant. Recyclable plastic

components are marked as follows:

4

polyethylene external wrapping film,

instruction bag.

polypropylene top packaging panels,

straps.

polystyrene foam protective

surround elements.

Wood and cardboard components may be disposed of

according to local regulations in force. Appliances that

have reached the end of their service life should be suitably disposed of. The appliance should be dismantled

according to regulations in force. All metal parts are in

stainless steel (AISI 304) and are removable. Plastic

parts are marked with the symbol of the material.

Figure 1

ENGLISH

A4 TECHNICAL DATA

MODEL EHTAROW / ZHTAROW /

OHTAROW

Supply voltage:

• three-phase version V 400...415- 3N~ 220...240- 3~ N~

- convertible to V 220...240- 3~ 400...415- 3

- convertible to V 220...240- 1N~ (**) 220...240- 1N~ (**)

Frequency Hz 50 60

Max. power input (three-phase version) kW 15,9 15,9

Max. power input (single-phase version) kW 9,9 9,9

Boiler heating elements kW 6,0 + 6,0 (**) 6,0 + 6,0 (**)

Tank heating elements kW 3,0 3,0

Water supply pressure kPa [bar] 50...700 [0,5...7] 50...700 [0,5...7]

Water supply temperature °C 10 ... 60 10 ... 60

Water supply hardness °fH [°dH ] 14 [8] max 14 [8] max

Rinse cycle water consumption l 3,0 3,0

Boiler capacity l 12 12

Tank capacity l 42 42

Standard cycle time:

- Thermal label mode sec. 77-90-150 77-90-150

- High productivity mode sec. 54-90-150 54-90-150

Legal noise level dB(A) <68 <68

Protection rating IPX4 IPX4

Net weight kg 98 98

Power supply cable H07RN-F H07RN-F

Supply cord diameter (min - max value) mm 18-25 18-25

EHTAROW60 / ZHTAROW60 /

OHTAROW60

(**) = Reduce the power of the boiler from 12 kW to 6kW as shown in the circuit diagram.

Table 1

400..415 V 3N 220...240 V 3 220…240 V 1N

CSCSCS

9,9 kW - - - - 3X10 60 A 1P+N

15,9 kW 5X6 40 A 3P+N 4X10 60 A 3P - -

C = Power supply cable

S = On/Off switch

Table 2

Standard cycle time may vary should the inlet water temperature be differen t from that indicated above.

5

1515

636

748

55

236

543

55

327

215

132

39

833

126

329

329

329

138

65

658

833

410

1970

152

56

404

559

167

200

875

140

S2

650

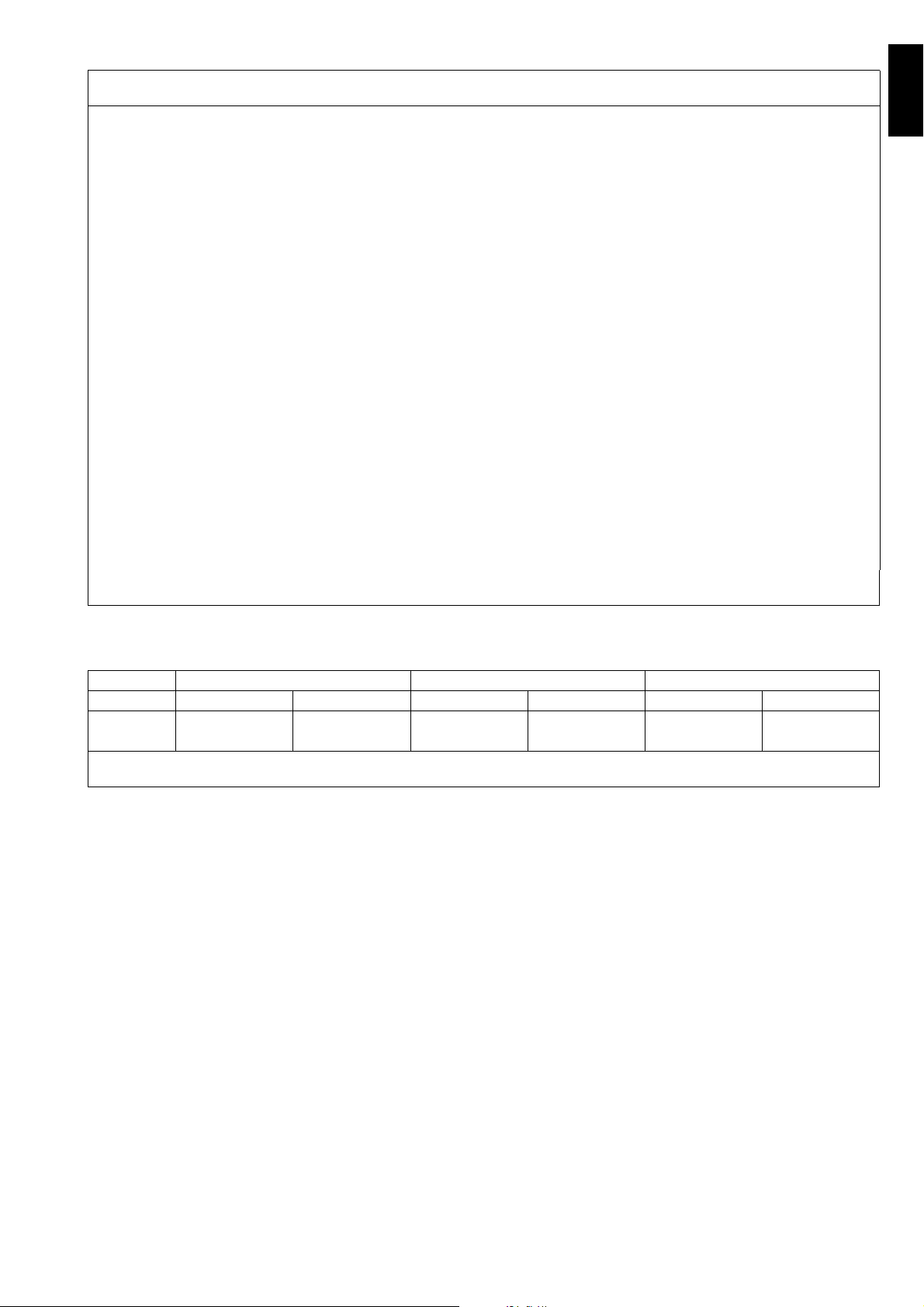

Figure 4

Legend Figure 4

A - Water inlet pipe with Ø 3/4” G fittings

C - Outlet pipe Øi 40 mm (^) – Øi 18 mm (*).

I - Power supply

S - Pipe inlet for detergents

S2 - Solid detergent injector (only ”OHTAROW / OHTAROW60” vers ions)

Q - Unipotential screw

(^) - Only for model with free-fall drainage

(*) - Only for model with drain pump

6

ENGLISH

ATTENTION

B

Model RT10 ED

PNC 9CGX 531300 05 Ser.N .123000001

AC 400V 3N 50Hz

Power Boiler 16500w

Power Tank 7500w

Power Max 26800w

Made in EEC

Model RT10 ED

PNC 9CGX531300 05

Ser.N .123000001

!

A

C 400....

1

11

10

9

8

7

6

5

4

3

2

12

!

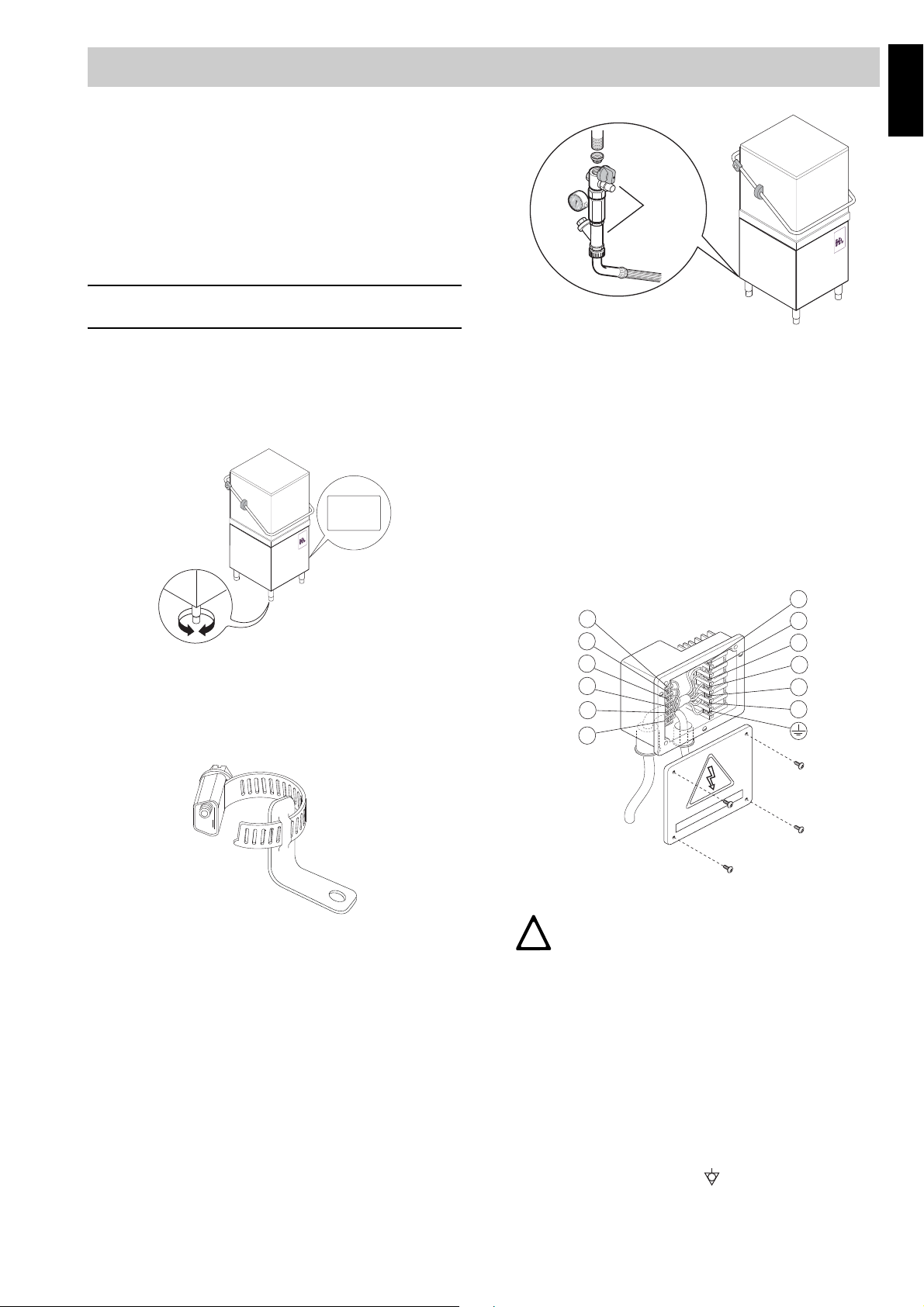

INSTRUCTIONS FOR THE INSTALLER/MAINTENANCE PERSON

Install a disconnecting switch with a capacity at

least equal to that given in the technical data table,

a 30mA residual current circuit breaker and an

overcurrent device (magnetothermal cut-out with

manual reset or fuse) between the appliance and

the mains power outlet.

The chosen device must be lockable in the open

position in case of maintenance.

Do not place the dishwas h er ne ar direct heat sources such as fryers, ovens, hot-plates, etc.

Figure 7

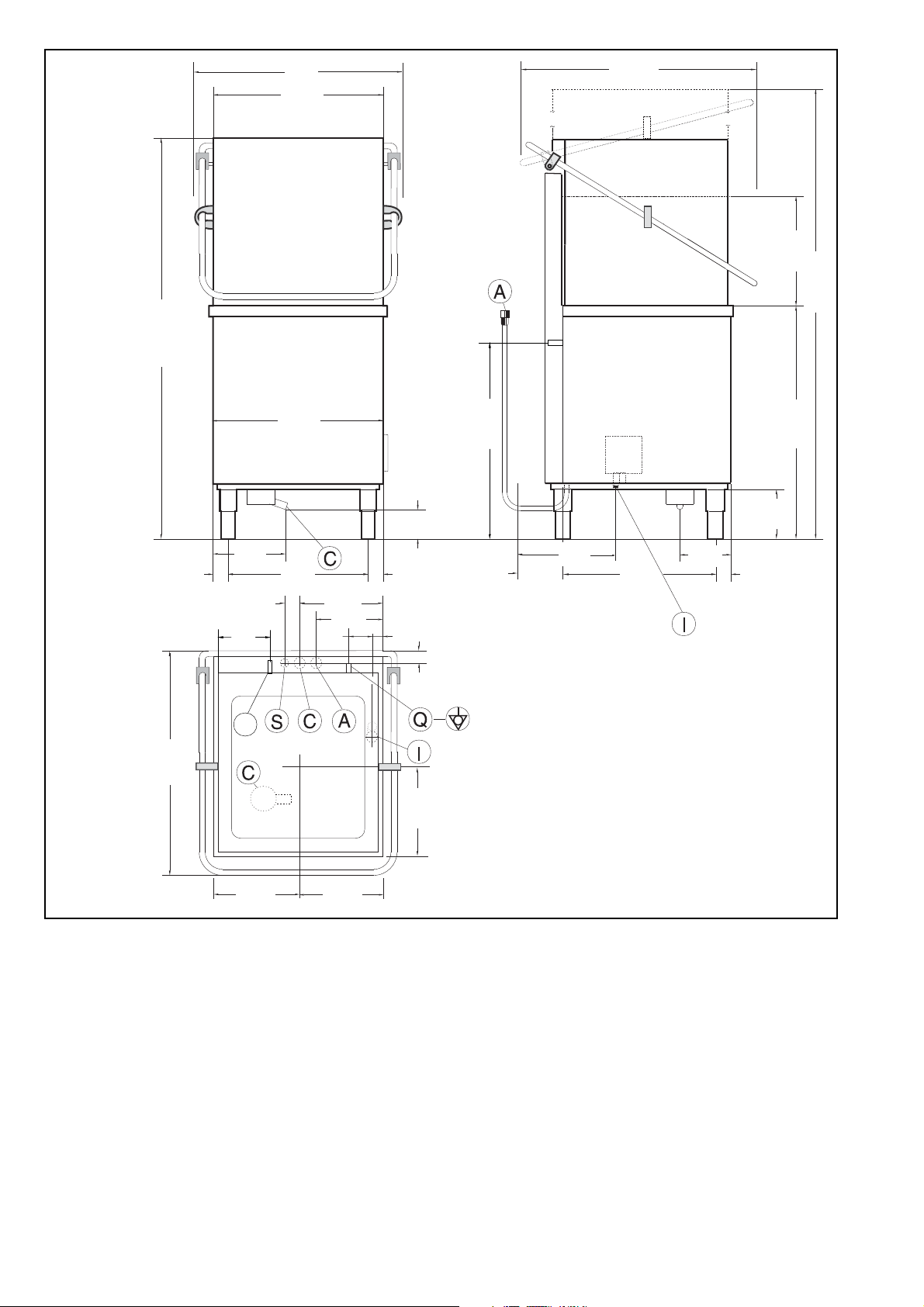

RATING PLATE

The rating plate contains identification and technical

data and is located on the right-hand side panel of the

appliance (Figure 5).

Figure 5

B1 WATER CONNECTION

• The appliance must be fixed to the ground using

the two clamps supplied (Figure 6).

• Check that the dynamic water supply pressure,

measured between the ap pliance and the main, is

between 50 and 700 kPa (test while dishwasher

tank or boiler is filling with water).

If the pressure is too high, fit a suitable pressure reducer on the inlet pipe.

Connect the waste outlet pipe “C” (Figure 4) to the

main drain pipe, fitting a trap, or place the outlet pipe

over an S trap set into the floor.

B2 ELECTRICAL CONNECTION

Figure 6

• Position the dishwasher and level the appliance by

turning the feet (Figure 5).

• Accessing the appliance bottom panel.

• Fit the clamps on feet as shown in supp lied technical sheet.

• Screw the appliance steadily to the ground using

hole clamps.

• Connect the appliance water supply pipe “A”

(Figure 4) to the mains, fitting a cut-off cock, the filter provided and a pressure gauge between the

appliance and the mains (Figure 7).

Figure 8

CAUTION

THE EARTH AND ELECTRICAL CONNECTIONS SHOULD BE IN COMPLIANCE

WITH NATIONAL REGULATIONS.

• Before carrying out the electrical connection, check that

the voltage and frequency on the appliance rating plate

correspond to those of the mains electricity supply.

• The earth wire at the terminal end must be longer

(max. 20 mm) than the phase wires.

• Connect the earth wire of the power supply cable to

an efficient earth clamp. The appliance must also

be included in a unipotential system, the connection being made through the screw “Q” (Figure 4)

marked with the symbol “ ”. The unipotential wire

must have a cross section of 10 mm

2

.

7

Loading...

Loading...