Electrolux EGWSICGBMS, EGWSICGMS, ZGWSICGMS User Manual

ENGLISH

EN CONTENTS

A SAFETY INSTRUCTIONS ................................................................................ Page 5

B GENERAL INFORMATION .............................................................................. Page 6

B1 Introduction ...................................................................................................................... Page 6

B2 Definitions ........................................................................................................................ Page 6

B3 Typographical conventions .............................................................................................. Page 6

B4 Machine and Manufacturer's identification data .............................................................. Page 7

B5 Equipment identification .................................................................................................. Page 7

B5.1 How to identify the technical data........................................................................ Page 7

B5.2 How to interpret the factory description ............................................................... Page 7

B6 Copyright ......................................................................................................................... Page 7

B7 Liability............................................................................................................................. Page 8

B8 Personal Protection Equipment ....................................................................................... Page 8

B9 Keeping the manual......................................................................................................... Page 8

B10 Users of the manual ........................................................................................................ Page 8

C GENERAL SAFETY RULES ............................................................................ Page 9

C1 Introduction...................................................................................................................... Page 9

C1.1 Protection devices installed on the machine ....................................................... Page 9

C1.1.1 Guards .............................................................................................. Page 9

C1.2 Safety signs to be placed on the machine or near the work area........................ Page 9

C2 Decommissioning ............................................................................................................ Page 9

C3 Instructions regarding use and maintenance................................................................... Page 9

C4 Foreseeable improper use............................................................................................... Page 10

C5 Residual risks .................................................................................................................. Page 10

D GENERAL DESCRIPTION OF MACHINE ....................................................... Page 11

D1 General description ......................................................................................................... Page 11

E TECHNICAL DATA ........................................................................................... Page 11

E1 Main technical characteristics.......................................................................................... Page 11

E2 Power supply characteristics ........................................................................................... Page 12

F TRANSPORT, HANDLING AND STORAGE.................................................... Page 13

F1 Introduction...................................................................................................................... Page 13

F1.1 Transport: Instructions for the carrier................................................................... Page 13

F2 Handling .......................................................................................................................... Page 13

F2.1 Procedures for handling operations..................................................................... Page 13

F2.2 Shifting ................................................................................................................ Page 13

F2.3 Placing the load................................................................................................... Page 13

F3 Storage ............................................................................................................................ Page 13

G INSTALLATION AND ASSEMBLY ................................................................... Page 14

G1 Customer responsibilities ................................................................................................ Page 14

G2 Characteristics of the place of installation ....................................................................... Page 14

G3 Positioning ....................................................................................................................... Page 14

G4 Disposal of packaging ..................................................................................................... Page 15

G5 Plumbing connections ..................................................................................................... Page 15

3

G6 Electrical connections ...................................................................................................... Page 15

G6.1 Safety devices ..................................................................................................... Page 16

G7 Installation diagram.......................................................................................................... Page 16

H DESCRIPTION OF CONTROL PANEL ............................................................ Page 17

H1 Basic controls .................................................................................................................. Page 17

I COMMISSIONING............................................................................................. Page 18

I1 Preliminary checks, adjustments and operational tests ................................................... Page 18

I1.1 Electrical and plumbing checks ........................................................................... Page 18

I1.2 Fitting of filters, overflow and wash arms check .................................................. Page 18

I2 Commissioning ................................................................................................................ Page 18

I3 Detergent/rinse aid dispensers and prearrangements..................................................... Page 18

I3.1 Dishwasher with incorporated rinse aid dispenser (Figure 11)............................ Page 18

I3.2 Dishwasher with incorporated detergent dispenser............................................. Page 18

I3.2.1 Detergent dispenser manual activation ............................................. Page 19

I3.2.2 Setting the dispenser ........................................................................ Page 19

J NORMAL MACHINE USE................................................................................. Page 20

J1 Foreseen use ................................................................................................................... Page 20

J2 Characteristics of personnel enabled to operate on the machine.................................... Page 20

J3 Suggestions ..................................................................................................................... Page 20

J4 Daily activation of the machine ........................................................................................ Page 20

J5 Wash cycles..................................................................................................................... Page 20

J6 Operation ......................................................................................................................... Page 21

J6.1 Basket loading ..................................................................................................... Page 21

J7 Regeneration cycle .......................................................................................................... Page 21

J8 Machine cleaning............................................................................................................. Page 23

J8.1 End of service and daily internal cleaning ........................................................... Page 23

J8.1.1 Water drain and cleaning of the washing tank................................... Page 23

J8.1.2 Cleaning the tank filter: ..................................................................... Page 23

J8.1.3 Cleaning the washer and rinse arms................................................. Page 23

J8.2 Long idle periods ............................................................................................................. Page 24

J8.3 Cleaning exterior surfaces ................................................................................... Page 24

J9 Maintenance .................................................................................................................... Page 24

J10 Alarms ............................................................................................................................. Page 24

J11 Troubleshooting ............................................................................................................... Page 25

J12 Machine disposal ............................................................................................................. Page 25

4

ENGLISH

Foreword

The instruction manual (hereinafter Manual) provides the operator with useful information for working cor-

rectly and safely, facilitating him in using the machine (hereinafter “machine”, “dishwasher” or “equipment”).

The following must not be considered a long and exacting list of warnings, but rather a set of instructions suitable

for improving machine performance in every respect and, above all, preventing injury to persons and animals and

damage to property due to improper operating procedures.

All persons involved in machine transport, installation, commissioning, use and maintenance, repair and disassembly must consult and carefully read this manual before carrying out the various operations, in order to avoid

wrong and improper actions that could compromise the machine's integrity or endanger people.

The manual must be available to operators and carefully kept in the place where the machine is used so that it is

always at hand for consultation in case of doubts or whenever required.

If, after reading this manual, there are still doubts regarding machine use, do not hesitate to contact the Manufacturer or the authorised after-sales service centre to receive prompt and precise assistance for better operation

and maximum efficiency of the machine.

During all stages of machine use, always respect the current regulations on safety, work hygiene and environmental protection. It is the user's responsibility to make sure the machine is started and operated only in optimum conditions of safety for people, animals and property.

A SAFETY INSTRUCTIONS

• This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or instruction concerning use

of the appliance in a safe way and understand the hazards involved.

• Do not let children play with the appliance.

• Cleaning and user maintenance shall not be made by children without supervision.

ATTENTION!

Do not wash the appliance with direct or high pressure jets of water.

ATT ENT ION !

If the power cable is damaged it must be replaced by the After-Sales

Service or in any case by qualified personnel, in order prevent any

risk.

5

B GENERAL INFORMATION

B1 Introduction

This section describes the symbols used (that mark and

identify the type of warning), the definitions of terms

used in the manual, responsibilities and copyright.

B2 Definitions

Listed below are the definitions of the main terms used

in the Manual. Careful reading of the manual is recommended before use.

Operator

machine installation, adjustment, use, maintenance,

cleaning, repair and transport personnel.

Manufacturer

Electrolux Professional S.p.A. or any other assistance

centre authorised by Electrolux Professional S.p.A.

Operator for normal machine use

an operator who has been informed and trained

regarding the tasks and hazards involved in normal

machine use.

Technical assistance or specialised technician

an operator instructed/trained by the Manufacturer and

who, based on his professional and specific training,

experience and knowledge of the accident-prevention

regulations, is able to appraise the operations to be

carried out on the machine and recognise and prevent

any risks. His professionalism covers the mechanical,

electrotechnical and electronics fields.

Danger

source of possible injury or harm to health.

Hazardous situation

any situation where an operator is exposed to one or

more hazards.

Risk

a combination of probabilities and risks of injury or

harm to health in a hazardous situation.

Protection devices

safety measures consisting of the use of specific technical means (guards and safety devices) for protecting

operators against risks.

Guard

an element of a machine used in a specific way to provide protection by means of a physical barrier.

Safety device

a device (other than a guard) that eliminates or

reduces the risk; it can be used alone or in combination with a guard.

Customer

the person who purchased the machine and/or who

manages and uses it (e.g. company, entrepreneur,

firm).

Emergency stop device

a set of components intended for the emergency stop

function; the device is activated with a single action

and prevents or reduces damage to persons/

machines/property/animals.

Electrocution

an accidental discharge of electric current on a human

body.

B3 Typographical conventions

For best use of the manual, and therefore the machine,

it is advisable to know all the terms and typographical

conventions used in the documentation.

The following symbols are used in the manual to indicate and identify the various types of hazards:

ATTENTION!

DANGER FOR THE HEALTH

AND SAFETY OF OPERATORS.

ATTENTION!

DANGER OF ELECTROCUTION

- DANGEROUS VOLTAGE.

Machine guards and protection devices marked with

this symbol must only be opened by qualified personnel, after disconnecting the machine's power supply.

AT TE N TI ON !

RISK OF DAMAGE TO THE MACHINE.

Words further explaining the type of hazard are placed

next to the symbols in the text. The warnings are

intended to ensure the safety of personnel and prevent

damage to the machine or the product being worked.

The drawings and diagrams given in the manual are

not in scale. They supplement the written information

with an outline, but are not intended to be a detailed

representation of the machine supplied.

The numerical values given in the machine installation

diagrams refer to measurements expressed in mm (see

par. G7 “Installation diagram”).

6

ENGLISH

B4 Machine and Manufacturer's identification

2016

F.Mod. EGWSSIC Comm. Model EGWSSIC

PNC 9CG 402125 00 Ser.Nr. 60210001

EL AC 230V 1N 50 Hz Max 3.3 kW

Electrolux Professional spa - Viale Treviso, 15 - 33170 Pordenone (Italy)

IPX4

IPX4

2016

F.Mod. EGWSSIC Comm. Model EGWSSIC

PNC 9CGX 402125 00 Ser.Nr. 60210001

EL AC 230V 1N 50 Hz Max 3.3 kW

Electrolux Professional spa - Viale Treviso, 15 - 33170 Pordenone (Italy)

F.Mod. EGWSSIC

Electrolux Professional spa - Viale Treviso, 15

E1 “Main technical characteristics”

MODEL EGWXS

Supply Electric

Power supply voltage V 230 1N

Frequency Hz 50

data

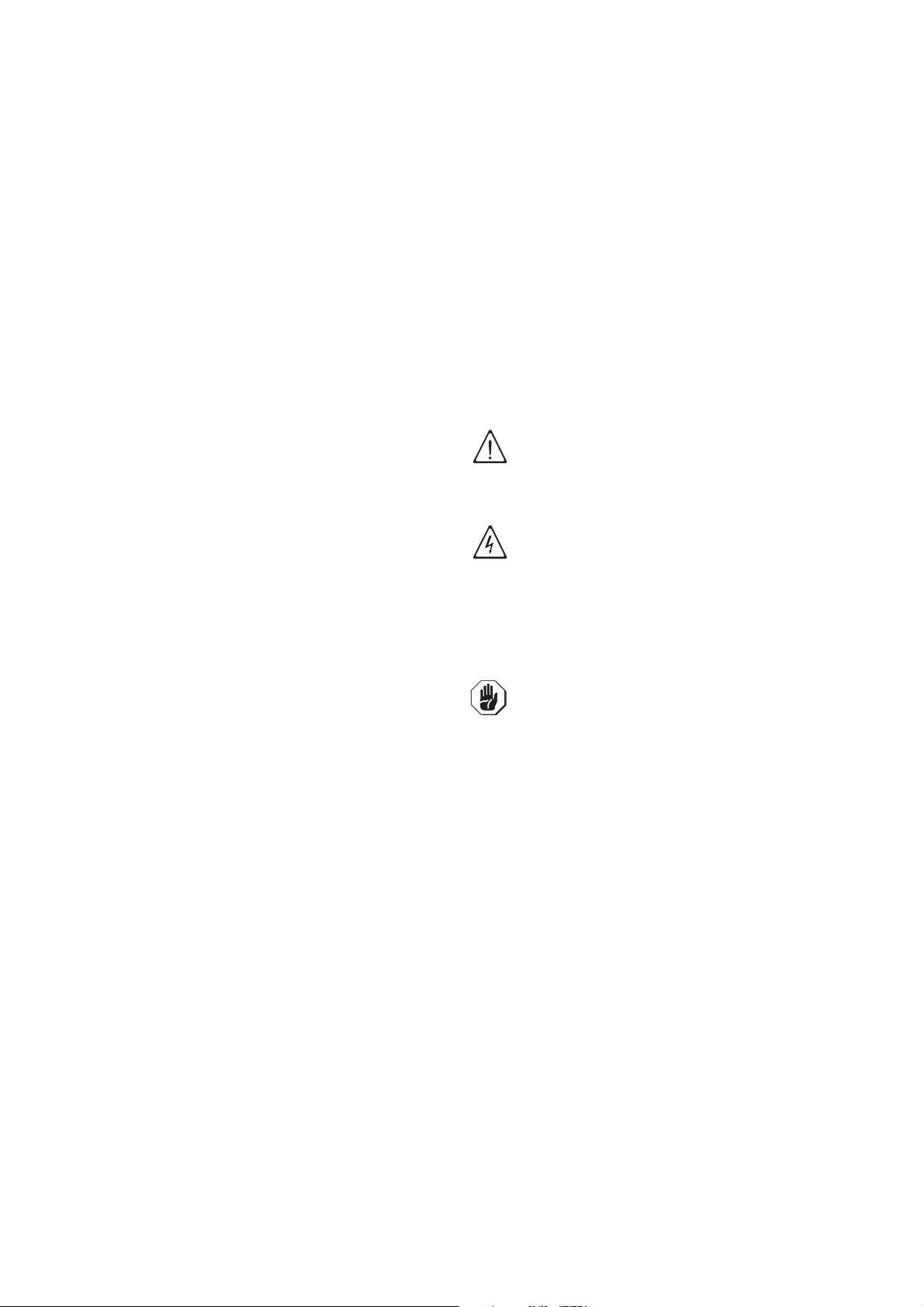

A reproduction of the marking or data plate on the

machine is given.

Figure 1 Reproduction of the marking/data plate on

the machine.

The data plate gives the product identification and

technical data; listed below is the meaning of the various information given on it.

B5 Equipment identification

B5.1 How to identify the technical data

To identify the technical data (Figure 3), read the factory description of the product (F. Mod.) on the data

plate, identify the main machine data and consult

Table 2 “Main technical characteristics, performance

and consumption”.

F.Mod .....................

factory description of product

Comm. Model......... commercial description

PNC........................ production number code

Ser. Nr. .................. serial number

AC 230V 1N .......... power supply voltage

50 Hz...................... power supply frequency

Max 3.3 kW ............ max. power input

2016 ....................... year of construction

CE .......................... CE marking

IPX4 ....................... protection rating

Electrolux Professional S.p.A. - Viale Treviso, 15 -33170

Pordenone (Italy)

..... Manufacturer

Figure 3 Technical data identification

B5.2 How to interpret the factory description

The factory description on the data plate has the following meaning (some examples are given below):

(1) (2) (3) (4) (5) (6) (7) (8) (9)

EGWS S I C W P B

ZGWS S I C W

NGWS I C W P U

XGWS I C W P

Descrizione variabili

(1) Brand Z = Zanussi, E = Electrolux, N = To Brand, X = KxT.

(2) Machine type GW = Glass washer

(3).. (9) S = standard version, SS = short version, I =

insulation, DI = double imsulation, C = cold rinse, W

= water softner, P = drain pump, D = detergent

pump, G = drain pump + detergent pump, U = UK

plug, 6 = 60Hz, B = booster pump, MS = multi rack

support, 3 = 400V 3N ~.

Figure 2 Position of marking

ATTENTION!

Do not remove, tamper with

or make the machine marking

illegible.

ATTENTION!

Refer to the data given on the machine

marking for relations with the Manufacturer (e.g. when ordering spare parts,

etc.).

B6 Copyright

This manual is intended for consultation exclusively by

the operator and can be given to third parties only with

the written permission of Electrolux Professional S.p.A.

7

B7 Liability

The Manufacturer declines any liability for damage and

malfunctioning caused by:

• non-compliance with the “Definitions” instructions

contained in this manual;

• repairs not carried out in a workmanlike fashion, and

replacements using spare parts different from those

specified in the spare parts catalogue (the fitting and

use of non-original spare parts and accessories can

negatively affect machine operation);

• operations by non-specialised technicians;

• unauthorised modifications or operations;

• inadequate maintenance;

• improper machine use;

• unforeseeable extraordinary events;

• use of the machine by uninformed and untrained

personnel;

• non-application of the current provisions in the

country of use, concerning safety, hygiene and

health in the workplace.

The Manufacturer declines any liability for damage

caused by arbitrary modifications and conversions carried out by the user or the Customer.

The employer or workplace manager is responsible for

identifying and choosing adequate and suitable personal protection equipment to be worn by operators, in

compliance with current regulations in the country of

use.

Electrolux Professional S.p.A. declines any liability for

any inaccuracies contained in the manual, if due to

printing or translation errors.

Any supplements to the instruction manual the Customer receives from the Manufacturer must be kept

together with the manual, of which they will form an

integral part.

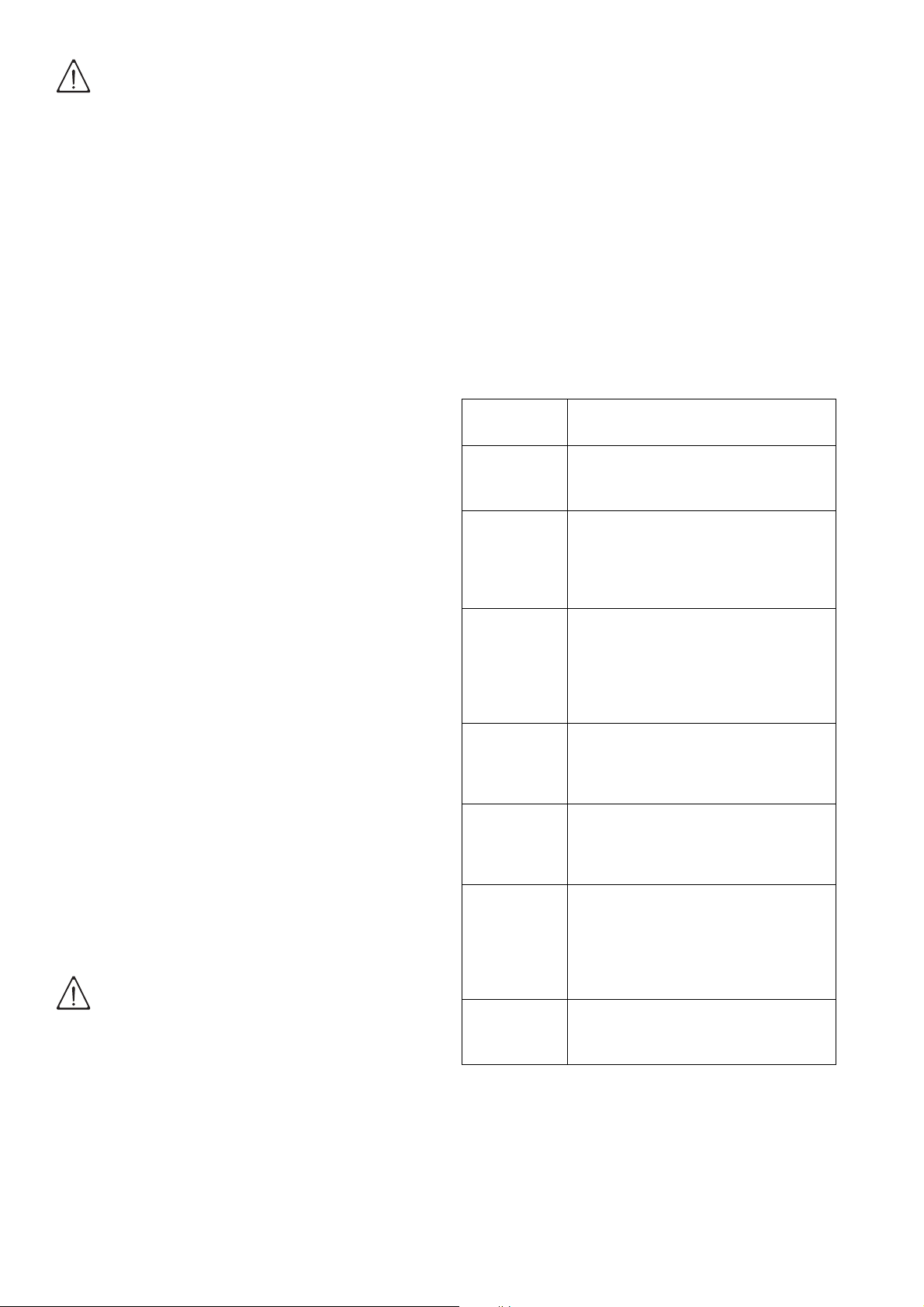

B8 Personal Protection Equipment

Given below is a summary table of the Personal Protection Equipment (PPE) to be used during the various

phases of the machine's service life.

Protection

garments

Phase

Transport

Handling

Unpacking

Installation

Normal use

Adjustments

Routine

cleaning

Extraordinary

cleaning

Maintenance

Dismantling

Scrapping

Legend:

M

F

C

(1)

Use heat resistant gloves suitable for contact with

C

M M

F

F

M M M (1)

F

F

F

F

F

F

PPE REQUIRED

PPE AVAILABLE OR TO BE USED IF NECESSARY

PPE NOT REQUIRED

Safety

footwear

M

M

M

M

M M (1)

M M (1)

M F

M

M

Gloves Glasses Protec-

F

F

F

F

tive head-

gear or

helmet

C

F

CC

CC

CC

F

C

CCC

F

F

C

C

CC

F

F

CC

CC

water and the substances used (see the safety data

sheet of the substances used to check other possible

PPE).

Failure to use the personal protection equipment by

operators, specialised technicians or users can involve

exposure to chemical risk and possible damage to

health.

B9 Keeping the manual

The manual must be kept intact for the entire life of the

machine, until scrapping of the machine. The manual

must stay with the machine in case of transfer, sale, hire,

granting of use or leasing.

B10 Users of the manual

This manual is intended for:

•

the carrier and handling personnel

;

• installation and commissioning personnel;

• the employer of machine users and the workplace

manager;

• operators for normal machine use;

• specialised technicians - technical assistance (see

wiring diagram and service manual).

8

ENGLISH

C GENERAL SAFETY RULES

C1 Introduction

The machines are provided with electric and/or

mechanical safety devices for protecting workers and

the machine itself. Therefore the user must not remove

or tamper with such devices.

The Manufacturer declines any liability for damage due

to tampering or their non-use.

C1.1 Protection devices installed on the machine

C1.1.1 Guards

The guards on the machine are:

- fixed guards (e.g. casings, covers, side panels,

etc.), fixed to the machine and/or frame with screws

or quick-release connectors that can only be

removed or opened with tools;

- interlocked movable guards (front panels) for

accessing inside the machine;

- machine electrical equipment access doors, made

from hinged panels openable with tools. The door

must not be opened when moving the machine, if

inside the door there is equipment which is dangerous when under tension or pressure.

ATTENTION!

Several illustrations in the manual show

the machine, or parts of it, without guards

or with guards removed. This is purely for

explanatory purposes. Do not use the

machine without the guards or with the

protection devices deactivated.

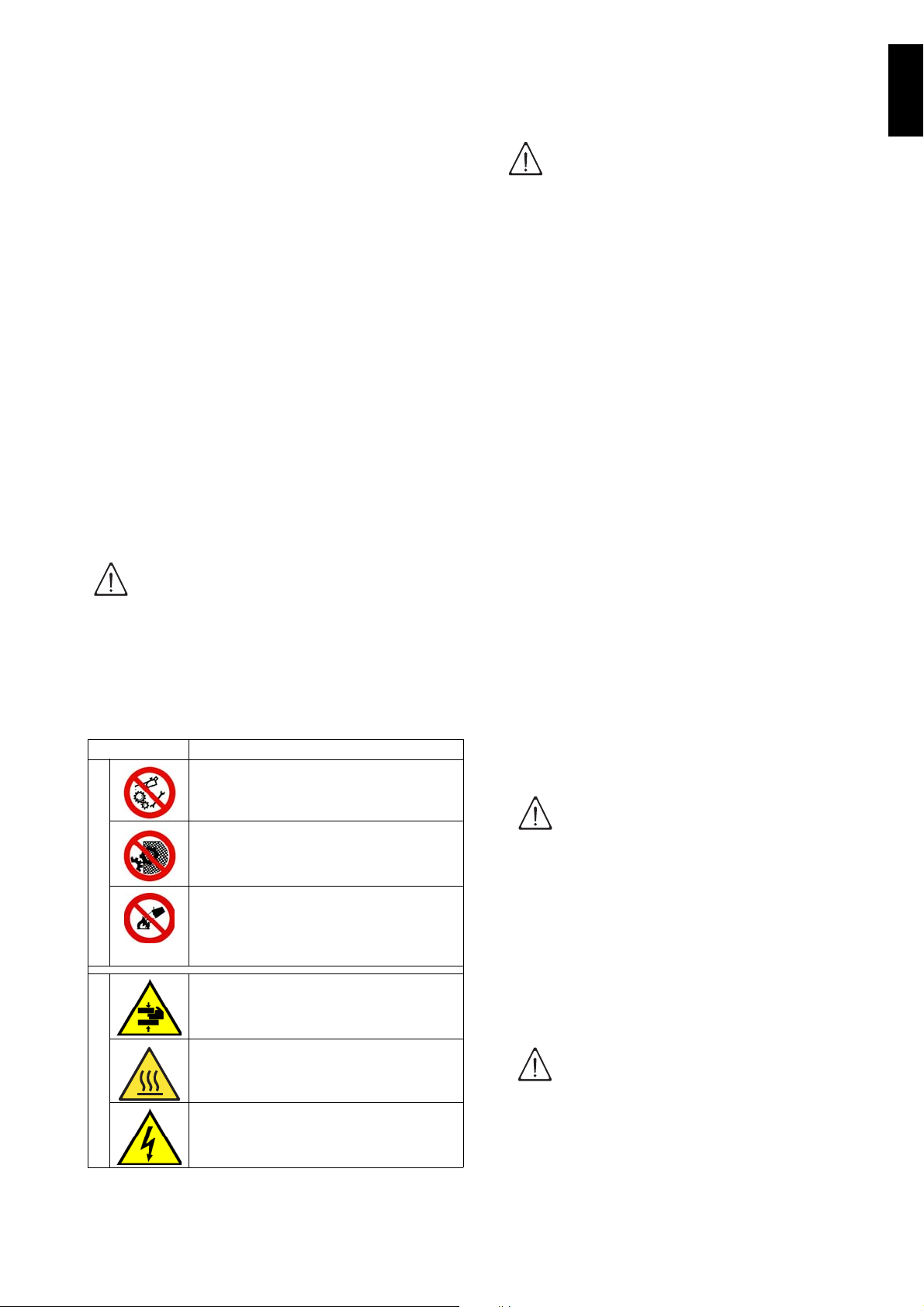

C1.2 Safety signs to be placed on the machine or

near the work area

MEANING

P

R

O

H

I

B

I

T

I

O

N

D

A

N

G

E

R

Do not oil, lubricate, repair and

adjust moving parts.

Do not remove the safety devices.

Do not use water to extinguish fires

(placed on electrical parts).

DANGER OF CRUSHING HANDS

DANGER OF BURNS

DANGER OF ELECTROCUTION

(placed on electrical parts with indi-

cation of voltage).

ATTENTION!

Do not remove, tamper with or

make the labels on the

machine illegible.

C2 Decommissioning

When the machine is no longer to be used, make it

unusable, removing the wiring from the power supply

and the water connections.

C3 Instructions regarding use and maintenance

Risks mainly of a mechanical, thermal and electrical

nature exist in the machine.

Where possible the risks have been neutralised:

• directly, by means of adequate design solutions,

• indirectly by using guards, protection and safety

devices.

Any anomalous situations are signalled on the control

panel display.

During maintenance several risks remain, as these

could not be eliminated, and must be neutralised by

adopting specific measures and precautions.

Do not carry out any checking, cleaning, repair or maintenance operations on moving parts.

Workers must be informed of this prohibition by means

of clearly visible signs.

To guarantee machine efficiency and correct operation, periodical maintenance must be carried out

according to the instructions given in this manual. In

particular, make sure to periodically check correct

operation of all the safety devices and the insulation of

electrical cables, which must be replaced if damaged.

ATTENTION!

Machine maintenance opera-

tions must only be carried out

by specialised Technicians

provided with all the appropriate personal protection equipment (safety shoes, gloves,

glasses, overalls, etc.), tools,

utensils and ancillary means.

ATTENTION!

Never operate the machine,

removing, modifying or tampering with the guards or protection and safety devices.

9

ATTENTION!

Before carrying out any opera-

tion on the machine, always

consult the manual, which

gives the correct procedures

and contains important information on safety.

C4 Foreseeable improper use

Improper use is any use different from that specified in

this manual. During machine operation, other types of

work or activities considered improper and that in general can involve risks for the safety of operators and

damage to the system are not allowed.

Foreseeable improper use includes:

• failure to disconnect the power supply (with main

switch in off position “O”) before carrying out adjustment, cleaning, resetting and maintenance operations;

• failure to disconnect the power supply (with main

switch in off position “O”) at the end of the day;

• lack of machine maintenance, cleaning and periodical checks;

• structural changes or modifications to the operating

logic;

• tampering with the guards or safety devices;

• failure to use personal protection equipment by

operators, specialized technicians and maintenance personnel;

• failure to use suitable accessories (e.g. the use of

equipment, ladders unsuitable for carrying out

maintenance to equipment inside the machine);

• keeping combustible or flammable materials, or in

any case materials not compatible with or pertinent

to the work, near the machine;

• incorrect machine installation (see section E “Installation and assembly”);

• placing in the machine any objects or things not

compatible with washing or that can obstruct/damage the machine or persons or pollute the environment;

• non-compliance with the requirements for correct

machine use;

• other actions that give rise to risks not eliminable by

the Manufacturer.

ATTENTION!

The previously described

actions are prohibited!

Nevertheless, through this manual the Manufacturer

has taken steps to inform operators of such risks, carefully indicating the personal protection equipment to be

used by them.

Sufficient spaces are provided for during the machine

installation stages in order to limit these risks.

To preserve these conditions, corridors and areas

around the machine must always be:

• kept free of obstacles (e.g. ladders, tools, containers, boxes, etc.);

• clean and dry;

• well lit.

For the Customer's complete information, the residual

risks remaining on the machine are given below: such

actions are deemed improper and therefore strictly forbidden.

APPLICATION PHASE: I=Installation, U=Normal use,

M=Maintenance, P=Cleaning.

RESIDUAL

RISK

Slipping or

falling

[ U - M ]

Burns

[ U - M - P ]

Electrocution

[ M ]

Falling from

above

[ I - U - M ]

Tipping of

loads

[ I - M ]

Chemical

[ I - U - M - P ]

Crushing or

shearing

[ I - U - M ]

DESCRIPTION OF HAZARDOUS

SITUATION

The operator can slip due to water or dirt

on the floor.

The operator deliberately or unintentionally touches some parts inside the

machine or dishes at the outfeed without

using gloves or without allowing them to

cool.

Contact with live parts during maintenance operations carried out with the

electrical panel powered. The operator

intervenes (with a power tool or without

disconnecting the power to the machine)

lying down on the wet floor.

The operator intervenes on the machine

using unsuitable systems to access the

upper part (e.g. rung ladders, or climbs

on it).

During maintenance on the machine, or

moving its packing, using unsuitable

accessories or lifting systems or with

load unbalanced.

Contact with chemical substances

(e.g. detergent, rinse aid, scale remover,

etc.) without taking adequate safety precautions. Therefore always refer to the

safety data sheets and labels on the

products used.

Possible risk of injury to upper limbs

during the hood closing operation.

C5 Residual risks

The machine has several risks that were not completely eliminated from a design standpoint or with the

installation of adequate protection devices.

10

Table 1 Residual risks

Loading...

Loading...