Page 1

Features and benefits

• Clarus Control® – programmable microprocessor with

9 fixed and up to 192 programs to allow free programming

• High extraction for efficient dewatering

• Frequency-controlled motor for optimal washing

• Supplied with 8 + 5 signals for liquid detergents

• Eight connections for liquid detergents

• Large door opening for easy loading and unloading

• All critical parts made from stainless steel to provide a

high level of corrosion resistance

• Powder painted galvanised steel side panels

• Bearing seals lubricated with oil to ensure a long service

life. Empty container alarm

• Electric or direct steam heating

• Low noise level for pleasant working environment

• Designed for easy servicing and maintenance

PROFESSIONAL LAUNDRY

Washer extractor

W4600H

Main options

• Front mounted loading hopper

• Forward or forward/backward tilting with full reversing

function

• Noise/heat insulation

• Test tap with level tube

• Two drain valves for recovering water/wash solution

• Five-compartment injector for powder detergent

(located at the front or on the right hand side of the machine)

• Third water valve

• Large water valves

• Integrated weighing system (IWS)

• Connection for intelligent detergent system (DMIS)

• Connection to CMIS

Main specifications

Max. capacity kg/lb

Drum, volume litre/ft3

diameter ø mm/inch

Extraction rpm

G-factor

Heating alternatives electricity kW

steam

hot water

Consumption data ”Normal 60°C” * (7G01)

Total time (cold+hot/cold) min

Water consumption (cold/hot) litre

gallon

Energy consumption (motor/heating) kWh

Steam consumption (cold/hot) kg/lbs

Steam consumption (cold) kg/lbs

* Water temperature 59°F cold water and 149°F hot water.

** Steam at 44-58 psi.

Certified in accordance with ISO 9001 and ISO 14001 and approved IP 24D. Certified in accordance with UL/ETL standards.

Steam El

555/92 555/92

147/24

1.2/– 1.2/4.7

7/15.4 –

14/30.9 –

44/49 48/–

W4600H

65/135

600/21.2

980 / 38 9/16

800

350

38.4

x

-

147/24

Page 2

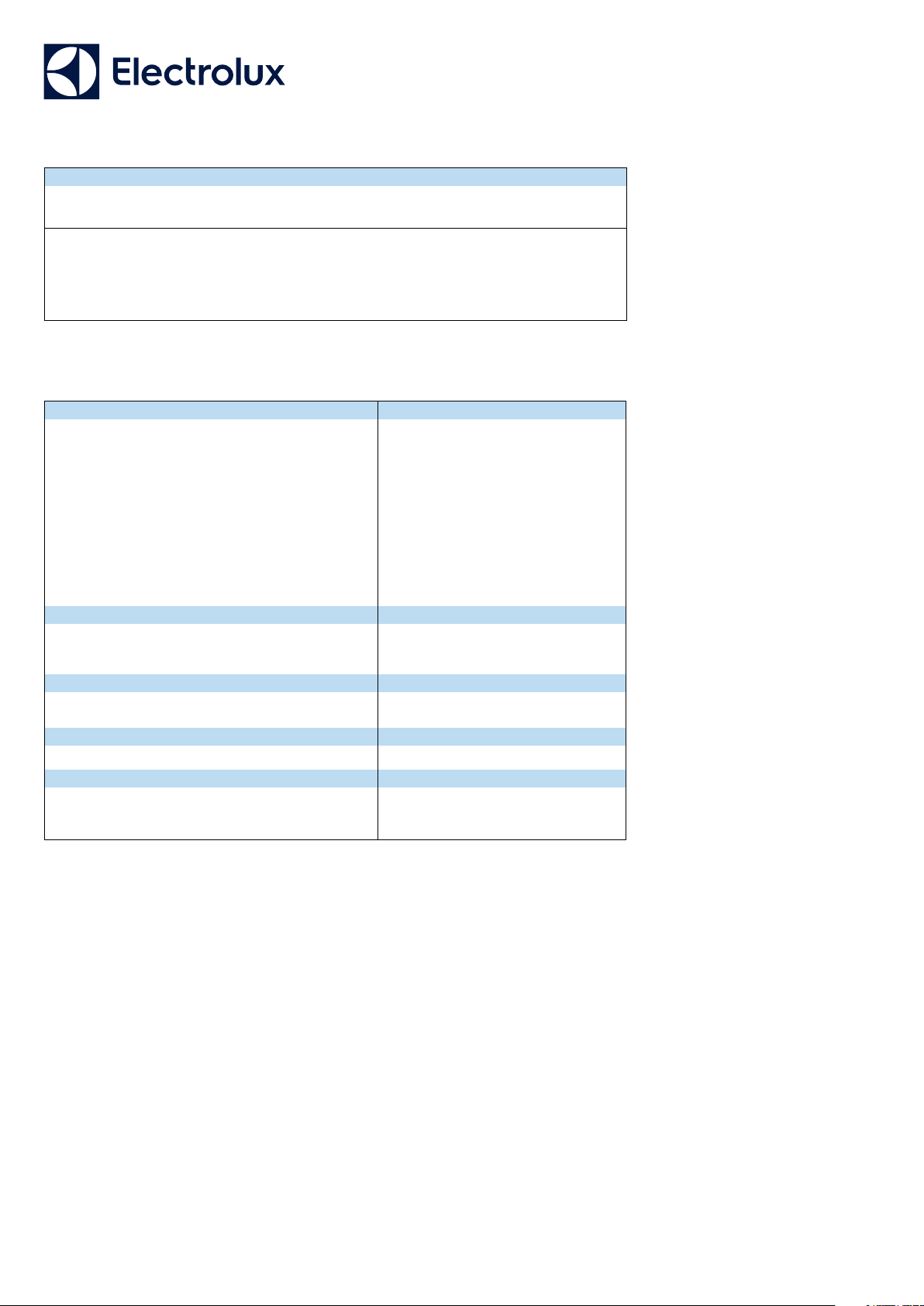

Electrical connections

Heating Main voltage Heating Total Recommended

alternative power power ITCB

Hz kW kW A

208-240V 3 ~ 60 38.4 41.0 125

Electric heated

440/480V 3 ~ 60 38.4 41.0 80/70

208-240V 3 ~ 60 - 4.5 25

Steam or

440/480V 3 ~ 60 - 4.5 15

Non heated

Water, steam and air connection

Water valves inch

Rec. water pressure psi

Functioning limits for water valve psi

Capacity at 300 kPa l/min / gallon/min

Drain valve ø mm/inch

Draining capacity l/min / gallon/min

Steam valve inch

Rec. steam pressure psi

Functioning limits for steam valve psi

Compressed air inch

Air pressure psi

Air consumption l/h / gallon/h

Five-compartment detergent injector inch

Floor requirements

Frequency of the dynamic force Hz

Floor load at max extraction kN

lbs force

Sound levels

Sound pressure level* dB(A)

With insulation dB(A)

Heat emission

% of installed power, max

Shipping data**

net, kg/lbs

crated, kg/lbs

Shipping volume m

* A-weighted emmission sound pressure level at workingstations.

** Average data. Crated weight/shipping volume depends on configuration.

Please contact logistics for exact measures.

3

3

/ft

W4600H

1

30-90

10-145

110/29

110 / 4 5/6

400/100

3/4

7-40

8-120

1/8

30-60

20/5

3/4

13.3

16.9 ± 1.4

3800 ± 310

76

< 70

6

1380/3042

1500/3307

5.7/201

Page 3

N

F

BEa

3a

6711B

1

6712B

P

6713

T

6714

Dimensions in mm/inch

A Width

B Depth

C Height std/tilt+IWS

C Height, low foot

D std/tilt+IWS

Ea

Eb

F std/tilt+IWS

G

H std/tilt+IWS

I std/tilt+IWS

K

L

M

N

O

P

R

S

T

U

V

A

W4600H

1390 / 54 3/4

1585 / 62 3/8

1975/2015

77 3/4 / 79 5/16

-

870/910

34 1/4 / 35 13/16

300 / 11 13/16

210 / 8 1/4

1815/1865

71 7/16 / 73 7/16

270 / 10 5/8

780/820

30 11/16 / 32 5/16

380/420

14 15/16 / 16 9/16

435 / 17 1/8

425 / 16 3/4

525 / 20 11/16

660 / 26

2225 / 87 5/8

935 / 36 13/16

815 / 32 1/16

325 / 12 13/16

2200 / 86 5/8

1120 / 44 1/8

300 / 11 13/16

Eb

1 Control panel

2 Door opening ø 535 mm / 21 1/16 inch

3a Five-compartment detergent injector for powder

detergent, front (optional)

3b Five-compartment detergent injector for powder

detergent, right hand side (optional)

4 Cold water connection

5 Hot water connection

6 Third water connection (optional)

7 Steam connection

8 Drain

9 Electrical connection

10 Compressed air connection

11 External liquid detergent connections, 6 pcs ø

10 mm, 1 pc ø 16 mm and 1 pc ø 20 mm

12 Water connection, liquid detergent injector

(optional) 3/4”

M

L

4

5

6

10

3b

3a

2

C

D

Front

R

Right side

O

U

12

11

7

H

G

I

K

Rear side

9

8

6710B

S

Tilt forward Tilt backward

11,5°

11,5°

V

Page 4

Options

• Front mounted loading hopper - easy loading from ”sling-bag” system. Manually operated.

• Backwards and forwards tilting – backwards tilting can be used in conjunction with input wheel or other loading

system.

• Forward tilting with drum reversal – makes unloading into a trolley easy.

• Noise/heat insulation – reduces airborne noise to less than 70 dB(A).

• Test tap with level tube – allows you to take samples from the wash solution.

• Water/wash solution recovery system – two drain valves allow you to recover rinse water and re-use it in the

wash.

• Five-compartment detergent injector – for powder detergent. (5 x 1 litre) on right hand side or front.

• Water inlet via pump – additional water inlet for water via pump from recovery system.

• Third water valve – electrically-controlled water valve for hard water.

• Steam connection components.

• Connection components for 2 water connections.

• Connection components for 3 water connections.

• Pump inlet connection components. Recovery

• Integrated weighing system (IWS).

• Combined steam and electrical heating - allows you to switch between electricity and steam.

• Connection to intelligent detergent system (DMIS)

• Large water valves (DN 32 / 1 1/4” BSP)

• Kit for connection to CMIS (Certus Management Information Systems) network. CMIS provides vital statistics,

error codes, maintenance intervals, process receipt, etc.

Accessory

• WPM PC program. Allows the creation of wash programs on a PC and their transference to the machine via a

memory card.

CMIS can be fitted to washer extractors with Clarus Control, tumble dryers with Selecta Control and ironers with electronic control system.

All you need to access and view the statistical feedback is a normal PC.

www.electrolux.com/laundrysystems

Share more of our thinking at www.electrolux.com

Art. No. 438919565US/2016.02.25

We reserve the right to alter specifications without notice.

Loading...

Loading...