Page 1

(/(&752/8;+20(352'8&76125

7+$0(5,&$

SERVICE MANUAL

TOP LOAD WASHERS

2.7 & 3.0 Cu. Ft.

Tubs

5995377099 November 2002

:KLWH : HVWLQJKRXVH

1

Page 2

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe

Servicing Practices be observed. The following are some limited examples of

safe practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

Remove the power cord from the electrical outlet, trip the circuit breaker to

the OFF position, or remove the fuse.

Turn off the gas supply.

Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN,

or GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a hazard.

6. Prior to returning the product to service, ensure that:

All electrical connections are correct and secure

All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts

All non-insulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels

All safety grounds (both internal and external) are correctly and securely

connected

All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechanical

training and a level of knowledge of these subjects generally considered acceptable in

the appliance repair trade. Electrolux Home Products cannot be responsible, nor assume

any liability, for injury or damage of any kind arising from the use of this manual.

© 2001 White Consolidated Industries

2

Page 3

SAFE SERVICING PRACTICES 2

QUICK REFERENCE SHEET 7 - 9

Serial nameplate location 7

Serial number breakdown 7

Tech sheet location 7

Specification 8

Connecting drive motor for bench check 9

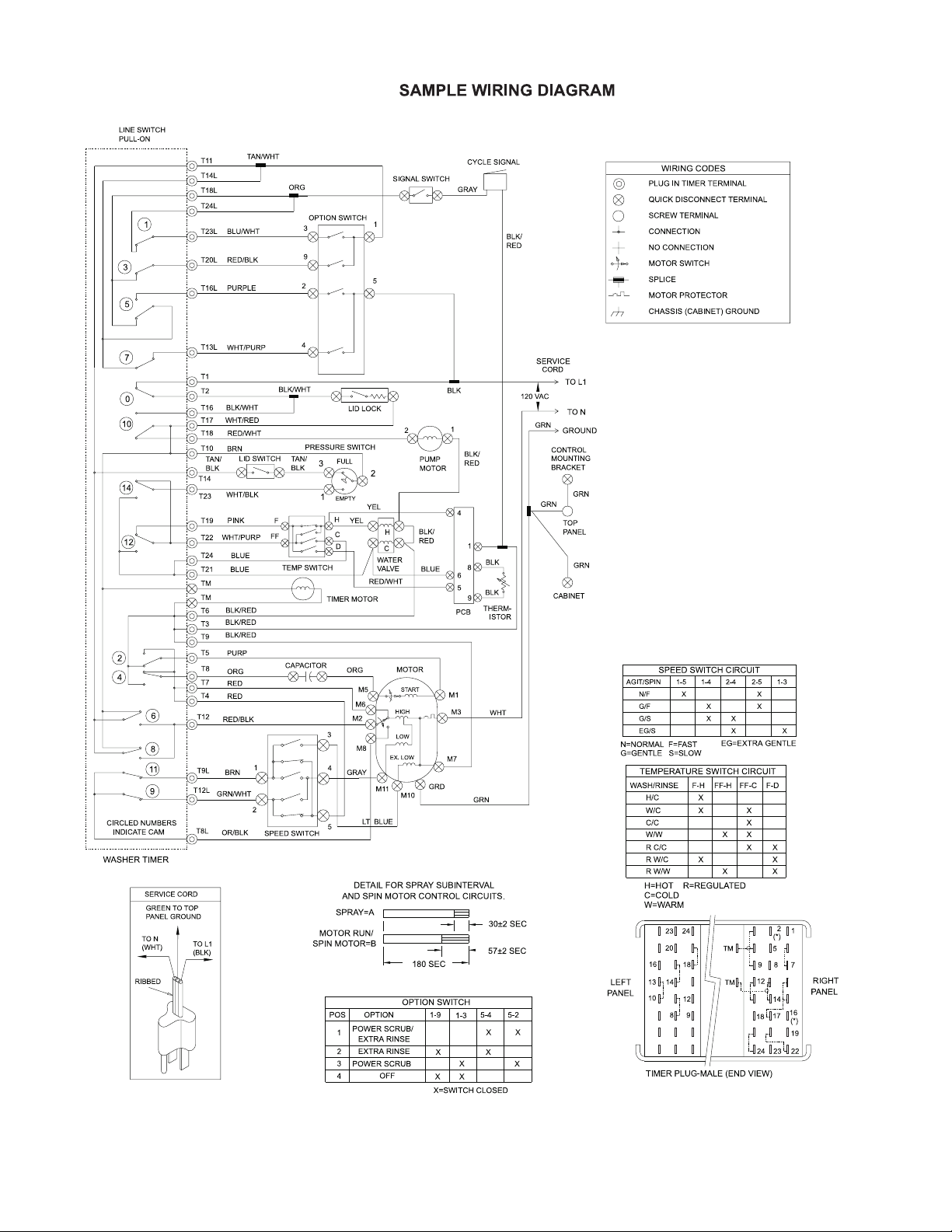

SAMPLE WIRING DIAGRAM 10

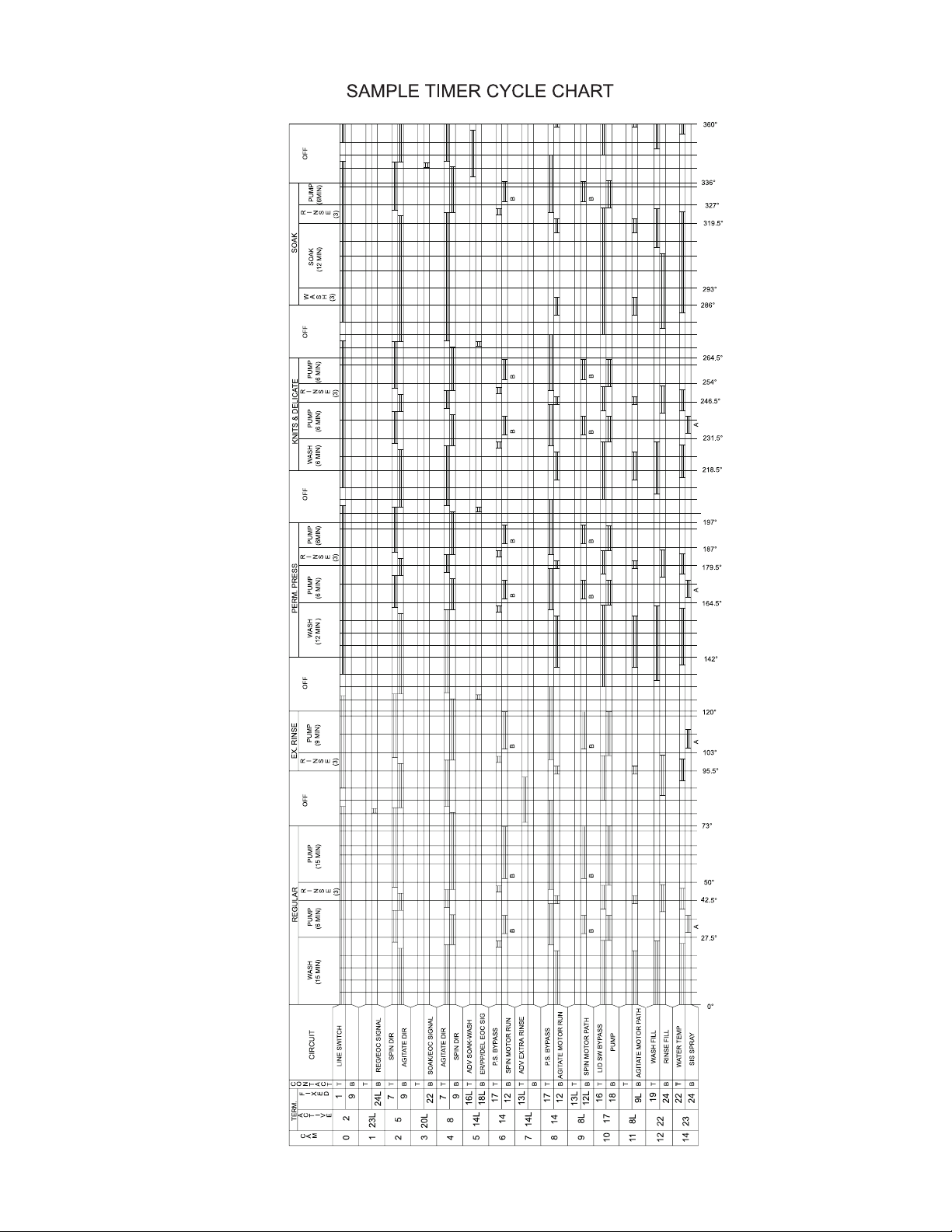

SAMPLE TIMER CHART 11

SECTION A - OPERATING INSTRUCTIONS 12 - 14

Before operating your washer 12

Operating steps 12

Cycle selection 12

Whites cycle 12

Extra rinse cycle 12

Colors cycle 12

Knits & delicates cycle 13

Soak & prewash cycle 13

Soak 13

Prewash 13

Power scrub option 13

Automatic extra rinse option 13 - 14

Controls 13

Agitate/spin speeds 14

Wash/rinse temperature 14

Precision temp control 14

Load size 14

Energy saving tips 14

SECTION B - OWNERS GUIDE 15 - 29

Safety information 15 - 16

For your safety 15

Product registration 15

Important safety instructions 15

Prevent fire 15

Protect children 15

Prevent injury 16

Washing procedures 17 - 19

Sorting laundry 17

Prepare items for washing 17

Pretreat stains and heavy soil 17

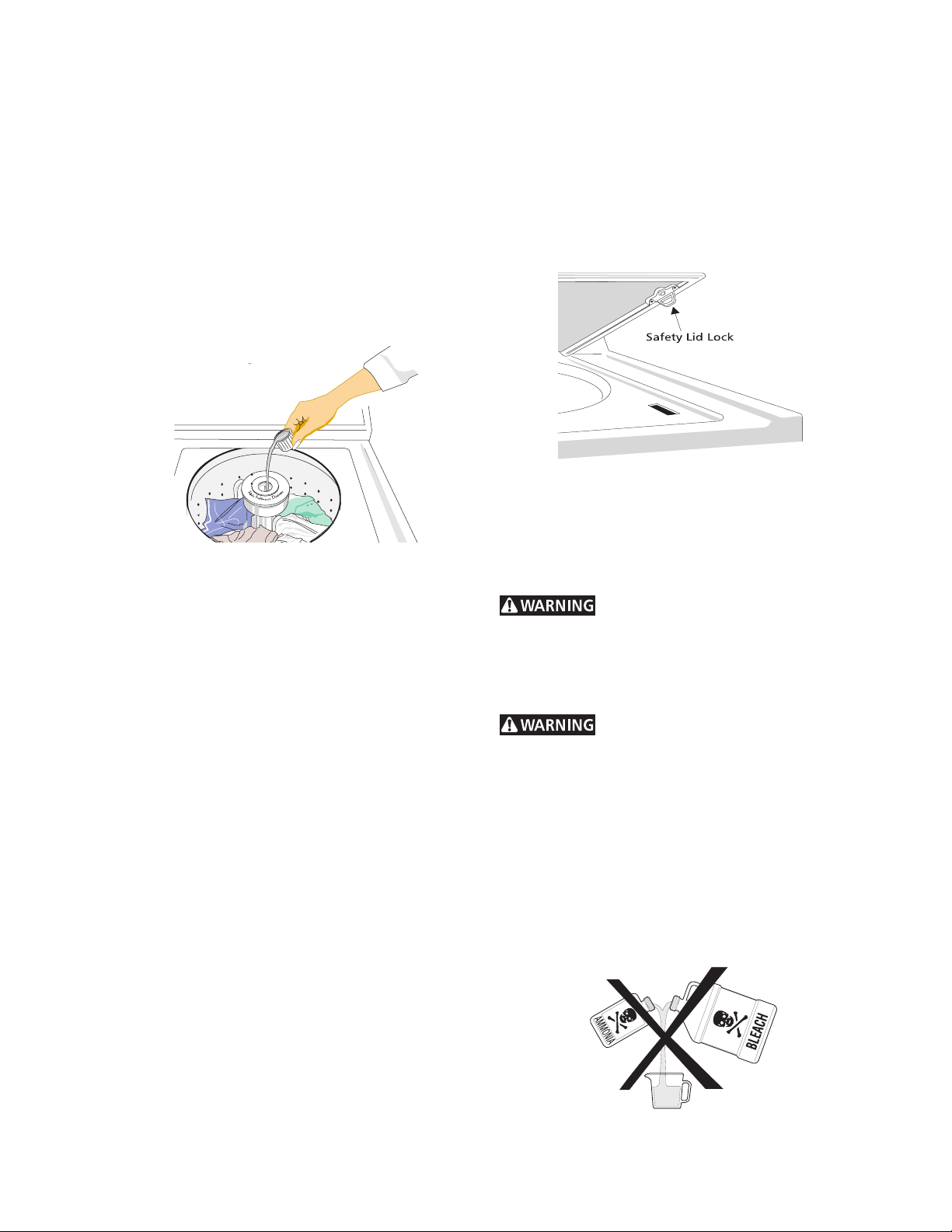

Adding detergent 18

Adding liquid bleach 18

Adding laundry 18

Adding liquid fabric softener 18

For models with a removable dispenser 19

For models without a fabric softener dispenser 19

Set cycle selector knob and washer controls 19

Start the washer 19

Remove items when the cycle is completed 19

Stain removal 19 - 21

Safe stain removal procedures 19

For successful stain removal 20

Stain removal chart 20 - 21

Common washing problems 22 - 23

Care and cleaning 24

3

Page 4

Inside 24

Outside 24

Winterizing instructions 24

Avoid service checklist 25 - 26

Sample warranty USA 27

Service information (Canada) 28

Sample warranty Canada 29

SECTION C - INSTALLATION INSTRUCTIONS 30 - 33

Full size automatic washer 30

Pre-installation requirements 30

Tools required for installation 30

Electrical reqirement 30

Circuit 30

Power supply 30

Outlet receptacle 30

Grounding requirements 30

Water supply requirements 30

Drain requirements 31

Rough-in dimensions 31

Location of your washer 31

Do not install your washer 31

Unpacking 31

Installation 32

Replacement parts 33

United States 33

Canada 33

SECTION D - PARTS LOCATION AND THEIR FUNCTION 34 - 42

Timer 34

Speed combination switch 34

Sample timer cycle chart 35

Pressure switch assembly 36

Wash cycle options switch 36

Wash/rinse temperature switch 36

Auto temp system 37

The end of cycle signal switch 37

The end of cycle signal 37

Lid lock assembly 38

Softener dispenser 38

Agitator 38

Bleach dispenser 38

Water inlet valve 39

Valve operation 39

Drain pump 40

The motor 40

Transmission 40

Spin basket or inner tub 41

Splash tub cover 42

Outer tub 42

Leg and dome assembly 42

Snubber 42

Base 42

SECTION E - ELECTRICAL OPERATION 43 - 46

Option switch circuits 43

Line switch circuit 44

Fill circuit 44 - 45

During the wash cycle 44

4

Page 5

Spray rinse during the first pump cycle 45

During the rinse cycle 46

Drive motor circuit 47 - 50

Motor in agitation cycle 47 - 48

Motor in spin cycle 49 - 50

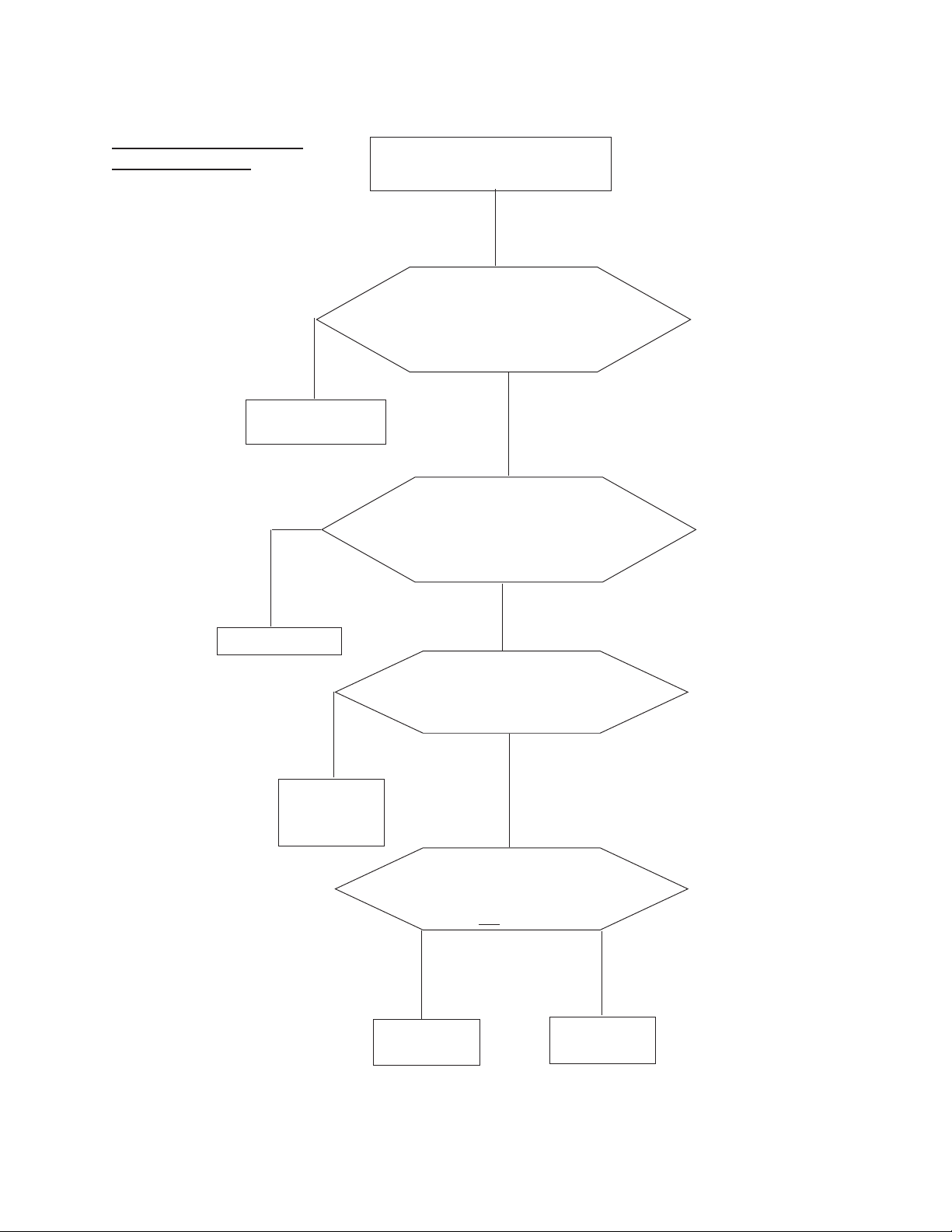

SECTION F - TROUBLESHOOTING FLOW CHARTS 51 - 61

Washer completely inoperative 52

Timer does not advance 52

Washer does not drain 53

Drive motor operates in spin but not in agitation 53

Drive motor does not turn 54

Drive motor operates in agitation but not in spin 55

Slow water fill 55

Drive motor cycles off and on rapidly when the speed switch set to normal 56

Drive motor cycles off and on rapidly when the speed switch set to gentle 56

Drive motor cycles off and on rapidly when the speed switch set to ex. gentle 57

Auto temp control does not control the wash water temperature

within specifications 57

Water fill does not turn off 58

Incorrect water level 58

Washer will not fill in any setting of the temperature selector sw 59

Washer will not fill in wash cycle, but will fill in rinse with

the temp switch set to cold/cold 60

Washer will only fill with cold water in the wash cycle, with the

temp switch set to warm/cold 60

Water temperature is too hot or too cold in the wash cycle

with the temp sw. set to warm/warm 61

Washer will only fill with hot water in the wash cycle, with the temp

switch set to warm/cold but does fill with cold water in the rinse cycle 61

SECTION G - TEARDOWN 62 - 79

Removing the knobs 62

Timer knob (some models) 62

Timer knob (some models) 62

Timer skirt (some models) 62

Timer skirt (some models) 63

All other knobs 63

Raising the top 63

Removing the rear panel from console 63

Removing the timer (some models) 64

Removing the timer (some models) 64

Removing the speed switch, option switch or temp switch 64

Removing the end of cycle signal 65

Removing the end of cycle signal switch 65

Removing the pressure switch assembly 66

Removing the electronic moisture sensor control 66

Removing the front closure 66

Removing the console 67

Removing the end caps 67

Removing the consoles front panel 68

Removing the lid lock assembly 68

Removing the lid hinges 68

Removing the lid spring 69

Removing the lid 69

Removing the water inlet nozzle assembly 69

Removing the bleach dispenser 69

Replacing the top 70

5

Page 6

Removing the top hinges 70

Removing the water inlet valve 70

Alternate water valve attachment 70

Removing the ATC sensor 71

Removing the front panel 71

Removing the drain pump 71

Disassembling the drain pump 72

Removing the softener dispenser 72

Removing the mechanism cap 72

Reinstalling the mechanism cap 73

Removing the agitator 73

Removing the drive hub 73

Removing the splash tub cover 74

Removing the spin basket 74

Removing the trunnion 74

Removing the top half of the tub seal 75

Removing the bottom half of the tub seal 75

Removing the outer tub 75

Removing the tub bearing 75

Removing the drive belt 76

Removing the transmission pulley 76

Removing the transmission 76

Replacing the vertical springs 76

Removing the idler pulley assembly 77

Removing the snubber 77

Removing the drive motor shield 77

Removing the start capacitor 78

Removing the drive motor 78

Removing the leg and dome assembly 79

Removing the base 79

6

Page 7

QUICK REFERENCE SHEET

1. Serial nameplate location:

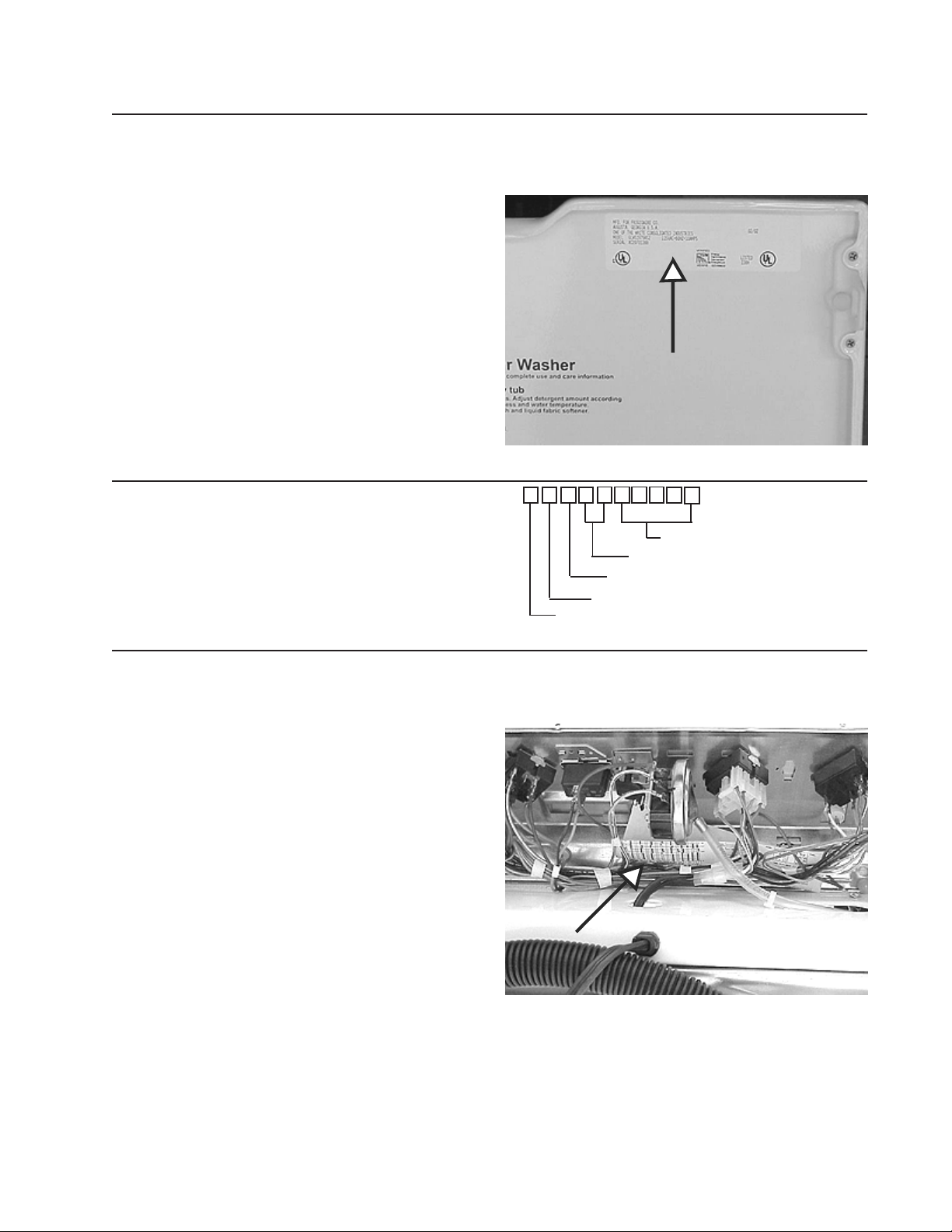

2. Serial number breakdown.

On the under side of the lid, in the top right-hand

corner.

X C 2 0 7 0 1 3 8 8

Incremented unit number

Production week

Last digit of production year

Product identification

Manufacturing facility

3. Tech sheet location

Inside the console

7

Page 8

Specifications

Washer 2.7 Cu. Ft. tub 3.0 Cu. Ft. tub

Transmission

Agitate Speed Oscillations Per Minute (High) 71 - 77 71 - 77

Agitate Speed Oscillations Per Minute (Low) 47 - 51 47 - 51

Agitate Speed Oscillations Per Minute (Gentle) 33 - 37 33 - 37

Spin Speed R.P.M. (High Speed) 600 - 640 600 - 640

Spin Speed R.P.M. (Low Speed) 390 - 420 390 - 420

Oil Capacity (Ounces) 32 32

Motor

Motor HP @ 120V, 60Hz. (Min OP - 100V Internal Thermal 1/2 & 3/4 1/2 & 3/4

Overload Protection, Capacitor Start (189 - 210 Mfd., 135 Volt)

One Speed (RPM) 1725 1725

Two Speed (RPM) 1150/1725 1150/1725

Three Speed (RPM) 840/1150/1725 840/1150/1725

Agitate

Agitate Wattage - Full Load (High Speed) Max. 750 950

Agitate Wattage - Full Load (Low Speed) Max. 450 475

Agitate Wattage - Full Load (Ex. Low Speed) Max. 475

Spin

Full Spin Wattage - No Load (High Speed) 300 - 660 300 - 660

Full Spin Wattage - No Load (Low Speed) 250 - 575 250 - 575

Spin Wattage - No Load (High Speed) Max. After 10 Sec. 800 800

Spin Wattage - No Load (High Speed) Max. After 10 Sec. 700 700

Full Spin Wattage - Full Load (High Speed) 300 - 660 300 - 660

Full Spin Wattage - Full Load (Low Speed) 250 - 575 250 - 575

Spin Wattage - Full Load (High Speed) Max. After 10 Sec. 900 900

Spin Wattage - Full Load (High Speed) Max. After 10 Sec. 700 700

Tub Capacity / Water Usage

Capacity (Cu. Ft.) 2.7 3.0

Water Level (Inches) Measured from tub bottom

Large 10.8 - 13.0 13.5 - 15.2

Small 4.3 - 6.6 5.5 - 7.8

Water Supply

Pressure (P.S.I.) Minimum/Maximum 30/120 30/120

Water Flow Rate (G.P.M.) 3 - 14.6 3 - 14.6

Drain Pumpout

G.P.M. @ 36 (Min.) 12 12

G.P.M. @ 96 (Min.) 7 7

Agitator Clearance

Agitator Bottom to Tub .050 - .300 .050 - .300

Component resistance - Ohms +/- 10% @ 77°F

Motor

4 Pole Main Winding (High Speed) 2.4 2.4

6 Pole Main Winding (Low Speed) If 2 Speed Motor 1.5 1.5

Fill Valve

Hot Water Solenoid 880 880

Cold Water Solenoid 880 880

Timer Motor 2322 2322

Pump Motor - Ohms +/- 7% @ 68°F 12 12

ATC - Ohms +/- 2% @ 77°F 50000 50000

8

Page 9

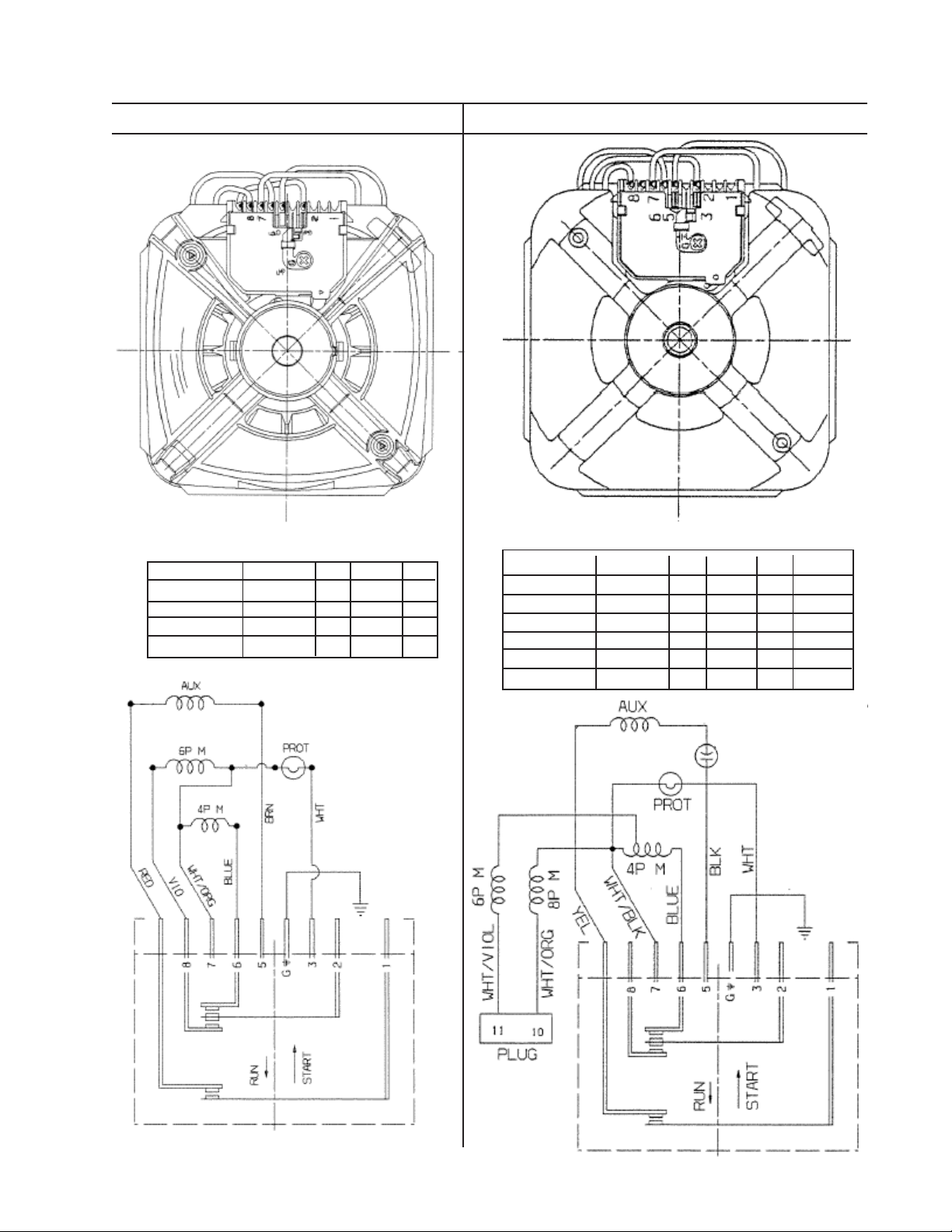

Connecting drive motor for bench check

Two Speed

ROTATION GIVEN VIEWING LEAD END

ROTATION SPEED L1 L2 7

CCW HI 3 6,1 5

CCW LO 3 2,1 5

CW HI 3 6,5 1

CW LO 3 2,5 1

Three Speed

ROTATION GIVEN VIEWING LEAD END

ROTATION SPEED L1 L2 7 8

CCW HI 3 6,1 5 - CCW LO 3 2,1 5 W/OR

CCW EX. LO 3 2,1 5 W/V

CW HI 3 6,5 1 - CW LO 3 2,5 1 W/OR

CW EX. LO 3 2,5 1 W/V

9

Page 10

Caution: Disconnect Electrical Current Before Servicing

10

Page 11

11

Page 12

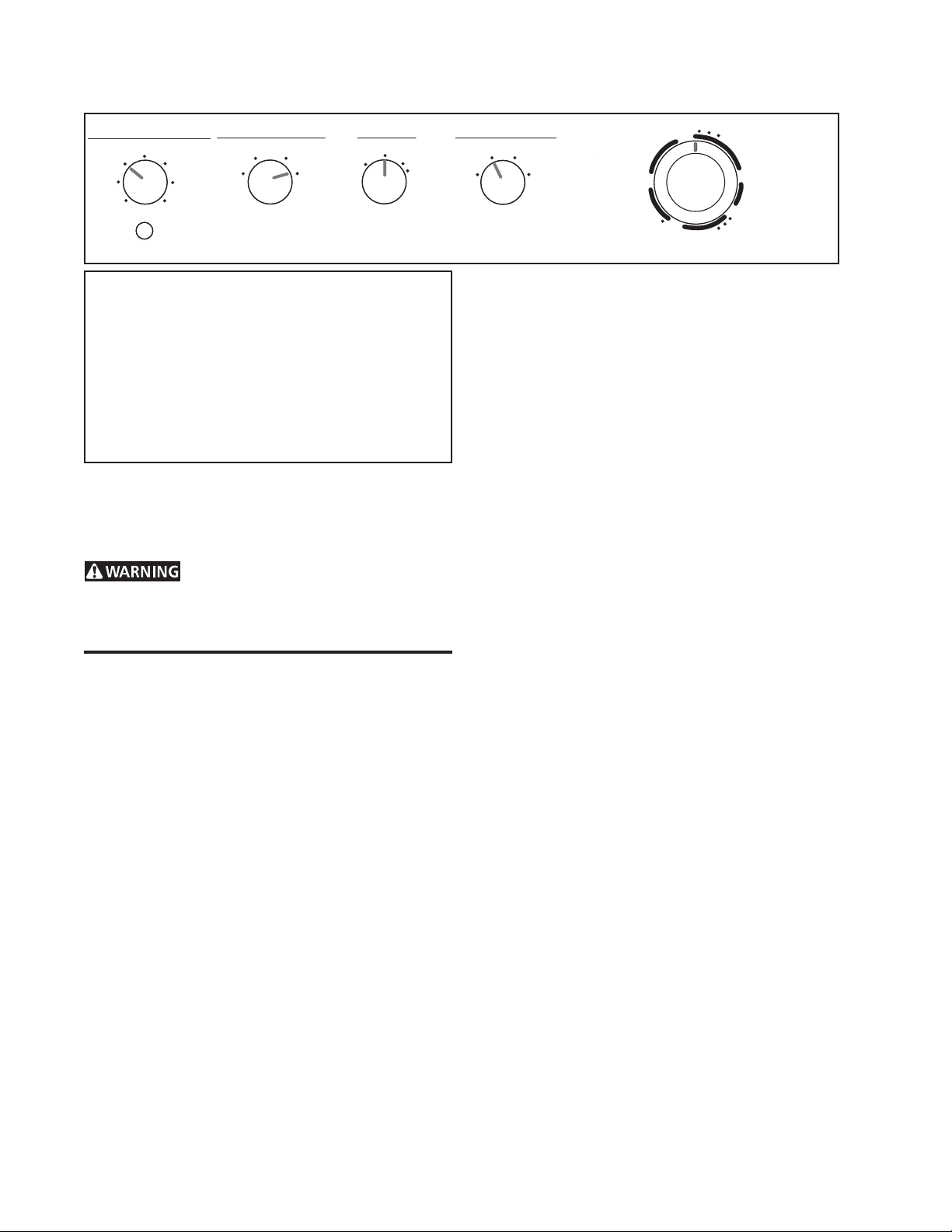

SECTION A - OPERATING INSTRUCTIONS

WASH/RINSE TEMPERATURE

WARM

WARM

WARM

COLD

COLD

COLD

HOT

COLD

ON

CYCLE SIGNAL

COLD

COLD

WARM

COLD

WARM

WARM

OFF

WASH CYCLE OPTIONS

EXTRA RINSE

*

POWER SCRUB /

EXTRA

RINSE

*

*

PRECISION TEMP CONTROL

*

POWER SCRUB

OFF

SMALL

LOAD SIZE

MEDIUM

SUPER

RESET

WASH / SPIN SPEEDS

GENTLE

NORMAL

NORMAL

NORMAL

GENTLE

GENTLE

EXTRA GENTLE

GENTLE

SOAK &

PREWASH

POWER

SCRUB

/SOAK

KNITS/DELICATES

HAND WASH

PULL TO START

PREWASH

SPIN

RINSE

15

12

6

PERM

PRESS

PREWAS

8

8

4

RINSE

POWER SPIN

EXTRA RINSE

12

PUSH TO STOP

REGULAR /

WHITES

PERM PRESS /

COLORS

Versión en español

Si desea obtener una copia en español de

estas Instrucciones de Funcionamiento, sírvase

escribir a la dirección que se incluye a continuación.

Solicite la P/N 134108600.

Spanish Owner's Guides

Electrolux Home Products

P. O. Box 212378

Augusta, GA 30917

Before Operating Your Washer

Read your washer Owner's Guide. It has important

safety and warranty information. It also has many

suggestions for best washing results.

To reduce the risk of fire, electric shock,

or injury to persons, read the IMPORTANT SAFETY

INSTRUCTIONS in your washer Owner's Guide before

operating this appliance.

Operating Steps

Read Washing Procedures in your Owner's Guide.

It explains these operating steps in detail.

1. Sort laundry into loads that can be washed

together.

9. Close lid and pull cycle selector knob to start

washer.

10. Remove items at end of cycle. A signal will sound

at the end of the cycle when the End of Cycle

Signal is turned on. Wait about 1 minute for safety

lid lock to release.

Cycle Selection

Always follow instructions on fabric care labels.

The Whites, Colors, and Knits & Delicates cycles

provide a spray rinse during the first spin, followed by

a deep rinse and final spin.

Whites Cycle

Provides up to 15 minutes of wash agitation for most

fabrics. Power Spin provides 12 minutes of spin at a

selected speed for maximum removal of water. This

conserves energy by reducing drying time.

Extra Rinse Cycle

Use Extra Rinse to remove excess dirt and

detergent from heavily soiled loads. Extra Rinse

provides 3 minutes of rinse agitation, then a 9

minute spin.

2. Prepare items for washing.

3. Pretreat stains and heavy soil.

4. Add the measured amount of detergent to wash

tub.

5. If desired, add liquid bleach to Bleach Dispenser.

6. Add laundry load to wash tub.

7. If desired, add liquid fabric softener to Fabric

Softener Dispenser.

8. Set cycle selector and washer controls according

to type, size, and soil level of each load.

Select Automatic Extra Rinse under Wash Cycle

Options to automatically advance to Extra Rinse

after the Whites cycle is completed.

Select Automatic Power Scrub/Extra Rinse

under Wash Cycle Options to automatically

advance to Extra Rinse after the Soak & Prewash

and Whites cycles are completed.

Colors Cycle

Provides 12 minutes of wash agitation for light weight

cottons, 8 minutes of wash agitation for items with a noiron finish or 4 minutes of wash agitation for knits.

12

Page 13

Knits & Delicates Cycle

Provides 6 minutes of wash agitation for delicate items

or 3 minutes of wash agitation for hand washables.

Soak & Prewash Cycle

Soak

from the Soak or Prewash setting into the Whites wash

and Extra Rinse cycles.

1. Add the measured amount of detergent to wash

tub, then add wash load.

2. Select appropriate Wash/Rinse Temperature,

Load Size, and Agitate/Spin Speed.

Use Soak to treat heavily soiled or stained items.

Soak provides 3 minutes of agitation and 12 minutes

of soaking time. The load then advances into the

Prewash portion of the cycle.

Use the amount of detergent recommended for a

normal wash cycle. If desired, use bleach or a

soaking agent for colorfast items.

The Soak water temperature is the same as the

rinse water temperature selected.

Select the Agitate/Spin Speed appropriate for the

items being soaked.

Select Wash Cycle Option OFF if advancing into

the Whites cycle is not desired.

Follow Soak with a complete wash cycle using the

normal amount of detergent.

Prewash

Use Prewash when soaking is not necessary.

Prewash helps remove protein-based stains such

as milk, grass and blood. It also helps loosen soils

before washing. Prewash provides 3 minutes of

wash agitation.

Use the amount of detergent recommended for a

normal wash cycle.

The Prewash water temperature is the same as the

wash water temperature selected. To avoid setting

protein stains, select cold water.

Select the Agitate/Spin Speed appropriate for the

items being prewashed.

Select Wash Cycle Option OFF if advancing into

the Whites cycle is not desired.

3. Select Power Scrub under Wash Cycle Options.

To use a cycle other than Whites after the Soak

or Prewash settings, select OFF and manually

advance cycle selector to cycle desired.

4. Fill fabric softener dispenser with the

recommended amount of LIQUID detergent.

Add water to bring liquid level to fill line on dispenser

cap.

When selecting Power Scrub, the fabric softener

dispenser must be filled with diluted liquid

detergent at the beginning of the Soak or Prewash

setting. The detergent for the Whites cycle will

then be dispensed after the spin in Prewash.

DO NOT use powdered detergent in the dispenser.

Clean the fabric softener dispenser thoroughly

after each use. Fabric softener and liquid detergent

should not be mixed.

5. Set the cycle selector at Soak or Prewash and

pull knob to start. The washer will provide Soak

or Prewash as selected. It then automatically

advances to the full Whites and Extra Rinse cycles.

Automatic Extra Rinse Option

Select Automatic Extra Rinse or Power Scrub/Extra

Rinse to provide an extra rinse at the end of the Whites

cycle.

Controls

Always follow instructions on fabric care labels.

AGITATE/SPIN SPEEDS offers three agitation speeds

and four combinations of agitation and spin speeds for

any cycle. The following chart suggests agitate/spin

speeds for basic fabric types.

Follow Prewash with a complete wash cycle using

the normal amount of detergent.

Power Scrub Option

Select Power Scrub to automatically advance a load

Fabric Type Agitate/Spin Speed

Regular Normal/Normal

Perm Press Normal/Normal

Knits Gentle/Normal

Delicates / Washable woolens Gentle/Gentle

Hand washables Extra Gentle/Gentle

13

Page 14

WASH/RINSE TEMPERATURE sets water temperatures

for washing and rinsing. Select wash water temperature

according to fiber content, soil level and type of detergent.

A cold water rinse saves energy and reduces wrinkling.

Precision Temp Control

The normal temperature of warm and cold wash water

can be affected by the hot water heater setting and

seasonally low ground water temperatures in some

geographic areas. Since detergents work best in wash

water at a minimum of 65° F, select a Precision Temp

to regulate the temperature of the warm and cold wash

water in any cycle.

When small wash loads cannot be avoided, use lower

water levels.

Select the appropriate cycle and time for each load.

Shorten wash times for lightly soiled loads.

To reduce drying time, select a fast spin speed to

remove more water from heavy items such as towels

and jeans.

Use warm water to wash most loads. Limit hot water

washes to heavily soiled and white loads. Use cold

water for lightly soiled items and rinsing.

Wash water in the Precision Temp Warm/Cold and

Precision Temp Warm/Warm settings is regulated to

approximately 90° F. and the wash water in the Precision

Temp Cold/Cold setting is regulated to approximately

70° F. Rinse water temperatures are not regulated.

The following chart suggests wash/rinse temperatures

for some typical wash loads.

Wash/Rinse

Fabric Type Temperature

Heavily soiled white/colorfast Hot/Cold

cotton, perm press

Lightly soiled white/colorfast Warm/Cold *

cotton, perm press

Noncolorfast fabrics, knits,

delicates, hand washables Cold/Cold *

Washable woolens Warm/Warm *

* unregulated or Precision Temp Control

Operate the washer in early morning and late evening

when utility demands are low.

Follow proper laundry procedures to avoid rewashing.

LOAD SIZE sets the amount of wash and rinse water for

the wash load. Select a water level appropriate for the

load size. There should be enough water for items to

move freely.

To increase water level after the wash cycle begins,

turn the Load Size control to Reset and hold. When

water begins to enter the tub, turn the control to the

desired setting.

Energy Saving Tips

Wash full loads. Oversize loads use extra energy.

Undersize loads waste energy.

14

Page 15

SECTION B - OWNERS GUIDE

Product Registration

waxes, etc. Do not store these items on or near the

washer. These substances give off vapors or chemical

reactions that could ignite or explode.

Thank you for choosing this washer. This owner's

guide will explain proper operation and care.

Record Your Model and Serial Numbers

Record below the model and serial numbers found on

the washer serial plate located on the underside of the

washer lid. Keep these numbers for future reference.

Model Number ________________

Serial Number _________________

Date of Purchase ________________

Register Your Product

The self-addressed PRODUCT REGISTRATION

CARD should be filled in completely, signed and

returned.

This Owner's Guide provides general operating

instructions for your washer. It also contains information

about features for several other models. Your washer

may not have every feature included here.

Do not put oily or greasy rags or clothing

on top of the washer. These substances give off

vapors that could ignite the materials.

Do not add gasoline, cleaning solvents,

or other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Under certain conditions, hydrogen gas

may be produced in a hot water system that has not

been used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washer, turn on

all hot water faucets and let the water flow from each

for several minutes. This will release any accumulated

hydrogen gas. Hydrogen gas is flammable; do not

smoke or use an open flame during this time.

Failure to comply with these warnings could result

in fire, explosion, serious bodily injury and/or damage

to the rubber or plastic parts of the washer.

Use the washer only as instructed in this Owner's

Guide and the Operating Instructions card included

with your washer.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

Important Safety Instructions

Read all instructions before using this washer.

To reduce the risk of fire, electrical

shock, or injury to persons when using this washer,

comply with the basic warnings listed below.

Failure to comply with these warnings could result

in serious personal injuries.

Prevent Fire

Do not wash items that have been

previously cleaned in, soaked in, or spotted with

gasoline, cleaning solvents, kerosene, cooking oils,

Protect Children

Do not allow children to play on or in the

washer. Close supervision of children is necessary

when the washer is used near children. As children

grow, teach them the proper, safe use of all appliances.

Destroy the carton, plastic bag and

other packing materials after the washer is unpacked.

Children might use them for play. Cartons covered with

rugs, bedspreads or plastic sheets can become airtight

chambers.

Keep laundry products out of children's

reach. To prevent personal injury, observe all warnings

on product labels.

Before the washer is removed from

service or discarded, remove the washer lid to prevent

accidental entrapment.

Failure to comply with these warnings could result

in serious personal injuries.

Avoid fire hazard or electrical shock.

Do not use an adaptor plug or extension cord or

15

Page 16

remove grounding prong from electrical power

cord. Failure to follow this warning can cause

serious injury, fire or death.

must be plugged into a properly grounded and polarized

3-prong outlet. The third grounding prong must

never be removed. Never ground the washer to a

gas pipe. Do not use an extension cord or an

adaptor plug.

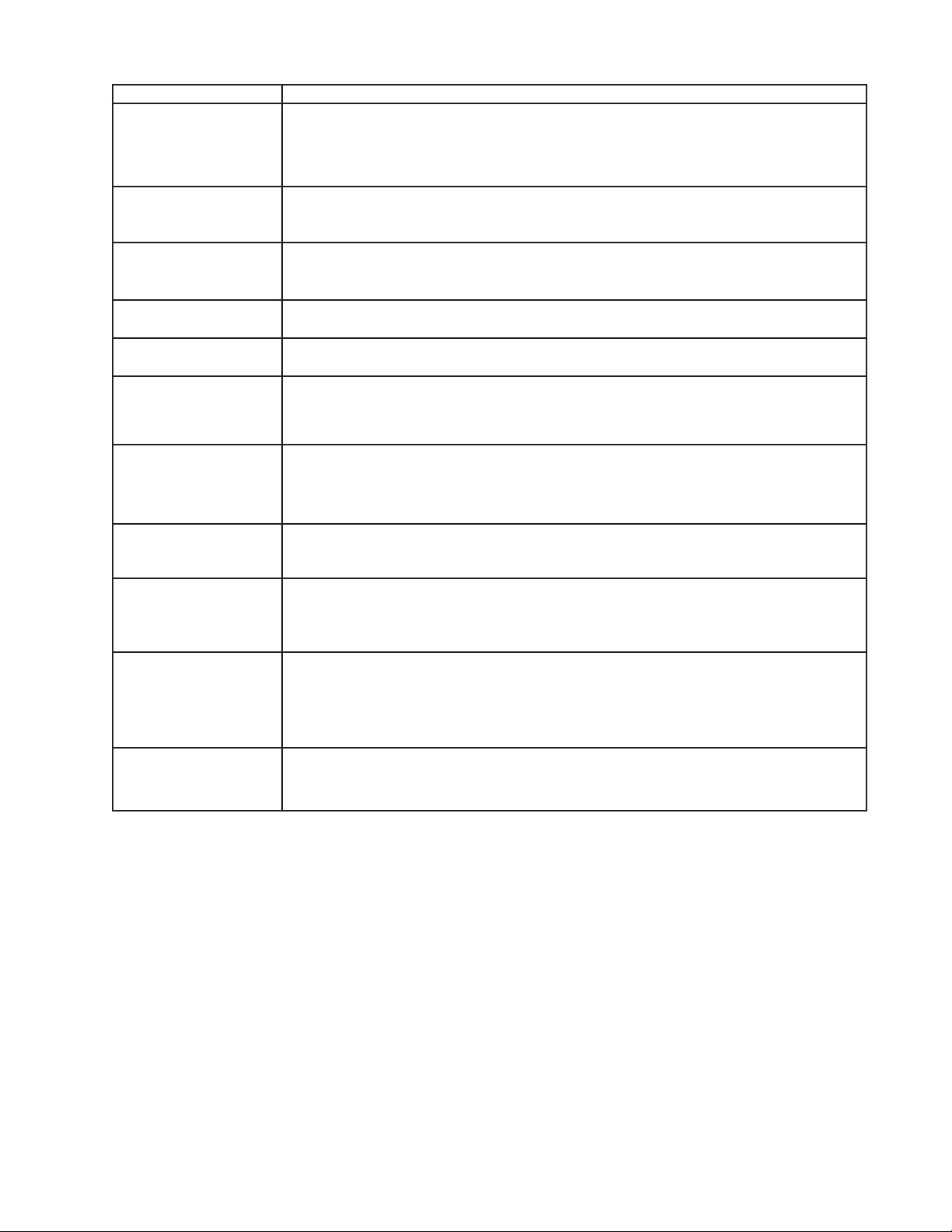

Follow package directions when using

laundry products. Incorrect usage can produce

poisonous gas--resulting in serious injury or death.

Do not combine laundry products for use in 1 load

unless specified on the label.

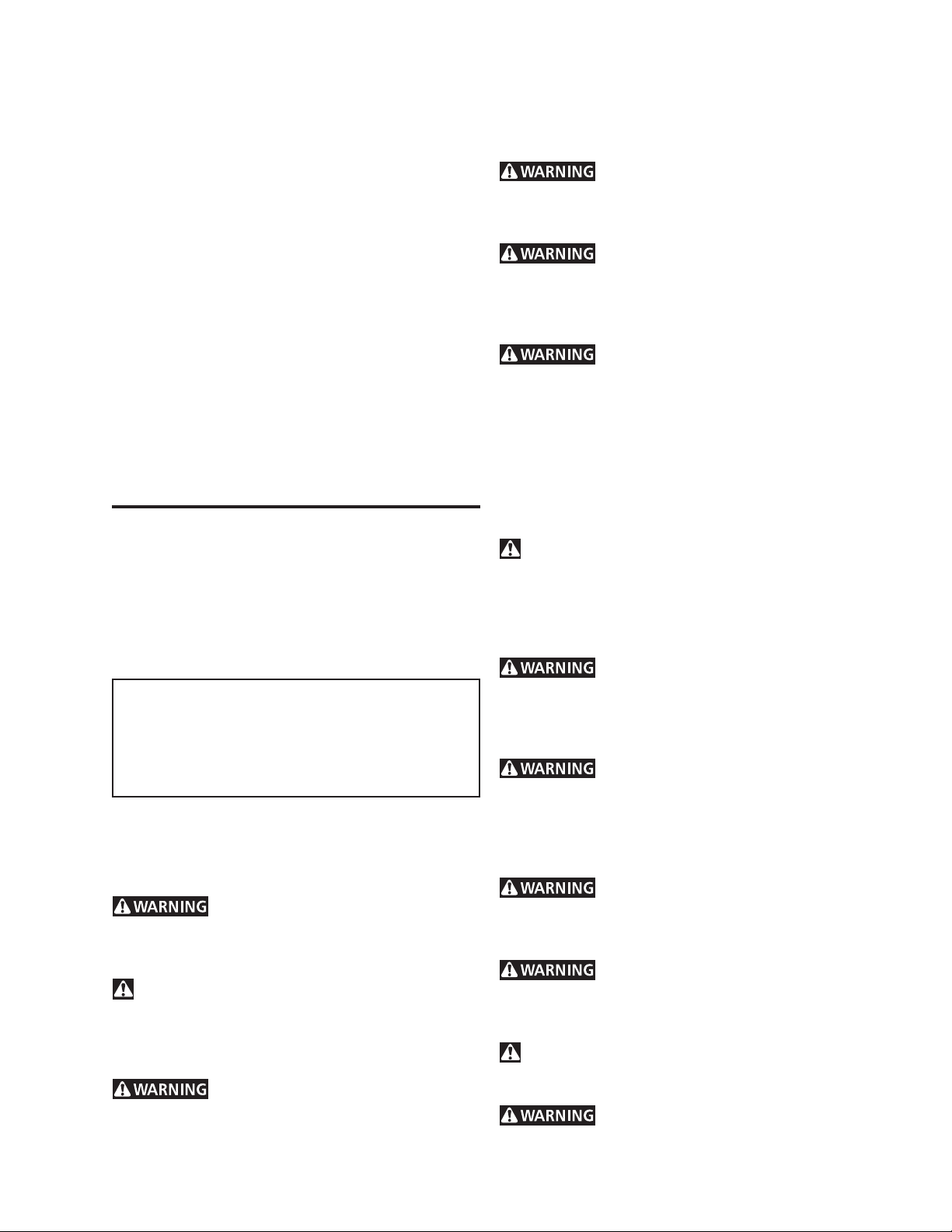

Do not mix chlorine bleach with ammonia or acids

such as vinegar.

CORRECT

Use this way ONLY

Do not use or mix liquid chlorine

bleach with other household chemicals such as

toilet cleaners, rust removers, acid or products

containing ammonia. These mixtures can produce

dangerous fumes which can cause serious injury

or death.

Note: The instructions appearing in this Owner's Guide

are not meant to cover every possible condition and

situation that may occur. Common sense and caution

must be practiced when installing, operating and

maintaining any appliance.

Prevent Injury

To prevent serious personal injury and

damage to the washer:

All repairs and servicing must be performed by

an authorized servicer unless specifically

recommended in this Owner's Guide. Use only

authorized factory parts.

Do not tamper with controls.

Do not install or store the washer where it will be

exposed to the weather.

ALWAYS disconnect the washer from

the electrical supply before attempting any service or

cleaning. Failure to do so can result in electrical shock

or injury.

To prevent injury, do not reach into the

washer while parts are moving. Before loading,

unloading or adding items, push in the cycle selector

knob and allow the tub to coast to a complete stop

before reaching inside.

Failure to comply with these warnings could result

in serious personal injuries.

To prevent shock hazard and assure

stability during operation, the washer must be installed

and electrically grounded by a qualified service person

in accordance with local codes. Installation instructions

are packed in the washer for installer's reference.

Refer to INSTALLATION INSTRUCTIONS for detailed

grounding procedures. If the washer is moved to a new

location, have it checked and reinstalled by a qualified

service person.

To prevent personal injury or damage to

the washer, the electrical power cord of the washer

This washer is equipped with an electrical overload

protector. The motor will stop if it becomes overheated.

The washer will automatically restart after a cool down

period of up to 30 minutes, if the washer has not been

manually turned off during this time.

SAVE THESE INSTRUCTIONS

16

Page 17

Washing Procedures

2. Prepare items for washing.

Follow the guidelines below for preparing the wash

load.

Read the Operating Instructions card for

operating your specific model.

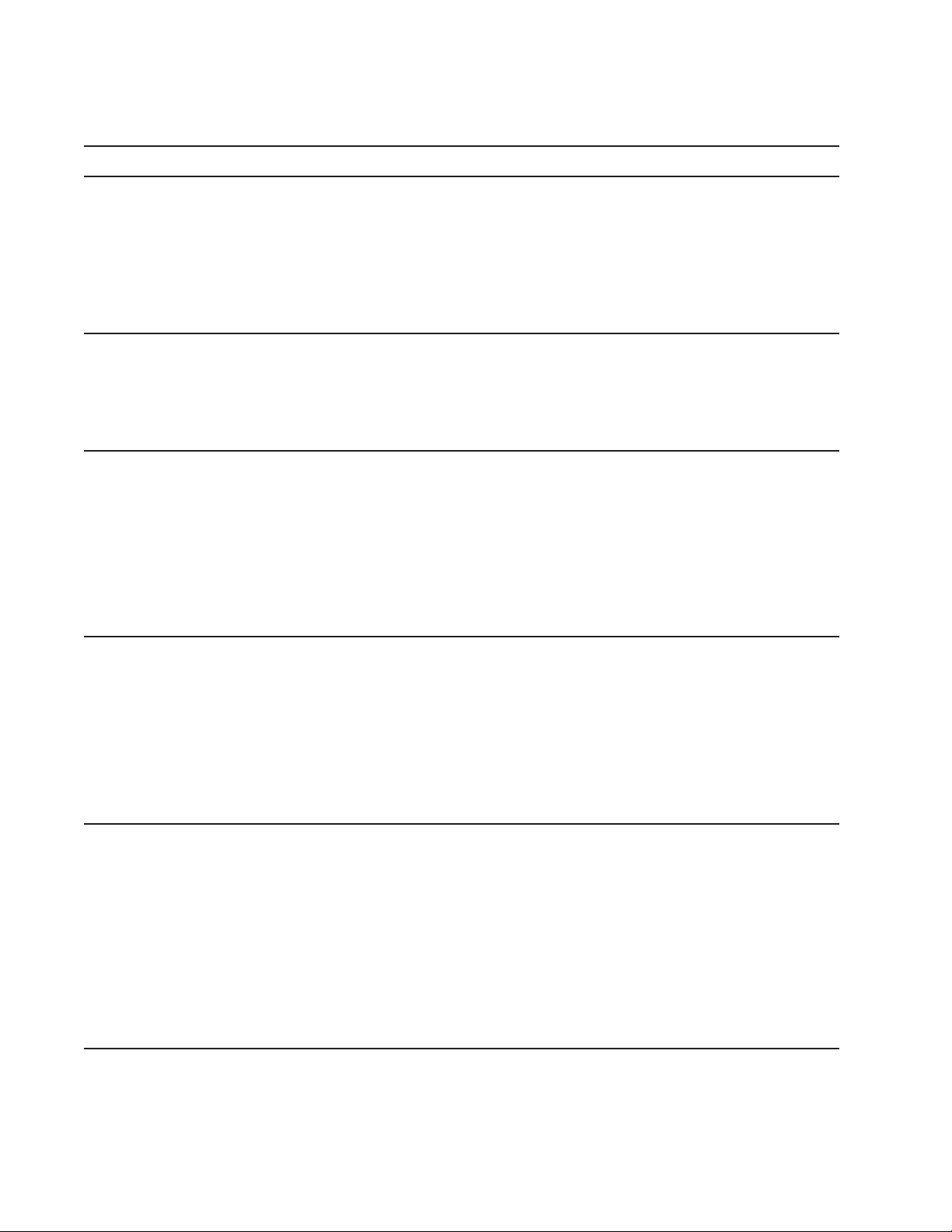

Always read and follow fabric care and laundry

product labels.

To reduce the risk of fire, electrical

shock, or injury to persons, read Important Safety

Instructions, before operating this washer.

1. Sort laundry into loads that can be washed

together.

Sort items by recommended water temperatures,

wash time, and agitate/spin speeds.

Separate white, light, and colorfast items from

dark and noncolorfast items.

Separate items which shed lint from items

which attract lint. Permanent press, synthetic,

knit and corduroy items will pick up lint from

towels, rugs and chenille bedspreads.

Empty pockets.

Empty pockets.

Brush off lint and dirt. Shake out rugs and

beach towels.

Close zippers, fasten hooks, tie strings and

sashes, and remove nonwashable trims and

ornaments.

Remove pins, decorative buttons, belt buckles,

and other objects which could be damaged.

This also helps protect other items in the wash

load.

Separate heavily soiled items from lightly

soiled items.

Separate lacy, sheer and loosely knit items

from sturdy items.

Sort laundry into loads that can be washed together.

Mend rips and tears to prevent further damage

during washing.

Place delicate items such as bras, shoulder

pads, hosiery, and belts in a mesh bag to

prevent tangling during the wash cycle.

Place delicate items in a mesh bag.

Turn knit items inside out to prevent pilling.

3. Pretreat stains and heavy soil.

See Stain Removal.

4. Add a measured amount of detergent to the

wash tub before adding the laundry load.

Follow detergent manufacturer's directions. The

17

Page 18

amount required depends on type of detergent, load

size and soil level, and water hardness.

5. If desired, add liquid bleach to Bleach Dispenser

(some models).

Before adding the wash load, add liquid bleach

to bleach dispenser located in left front corner

under the lid:

3/4 cup (180 ml) for small loads

1 cup (240 ml) for large loads

1-1/4 cups (300 ml) for extra-large loads.

Then add 1 cup (240 ml) water to flush the

dispenser.

Combine large and small items in a load. Load

large items first. Large items should not be

more than half the total wash load.

When washing a single heavy item, add 1 or 2

towels to balance the load.

7. If desired, add liquid fabric softener to Fabric

Softener Dispenser (some models).

For models with a built-in dispenser

Bleach Dispenser (some models)

Do not use powdered bleach in the bleach

dispenser.

For models without a bleach dispenser, dilute

the recommended amount of liquid chlorine bleach

in 1 quart (.95 L) water. Add it to wash water after

a few minutes of agitation. Do not pour bleach

directly on wash load.

6. Add laundry load to washer.

Dry load level should not be higher than top row

of holes in wash tub.

Built-In Fabric Softener Dispenser

(some models)

1. Add liquid softener to the dispenser, following

fabric softener label directions.

2. Add water to bring liquid level to fill line on

dispenser cap.

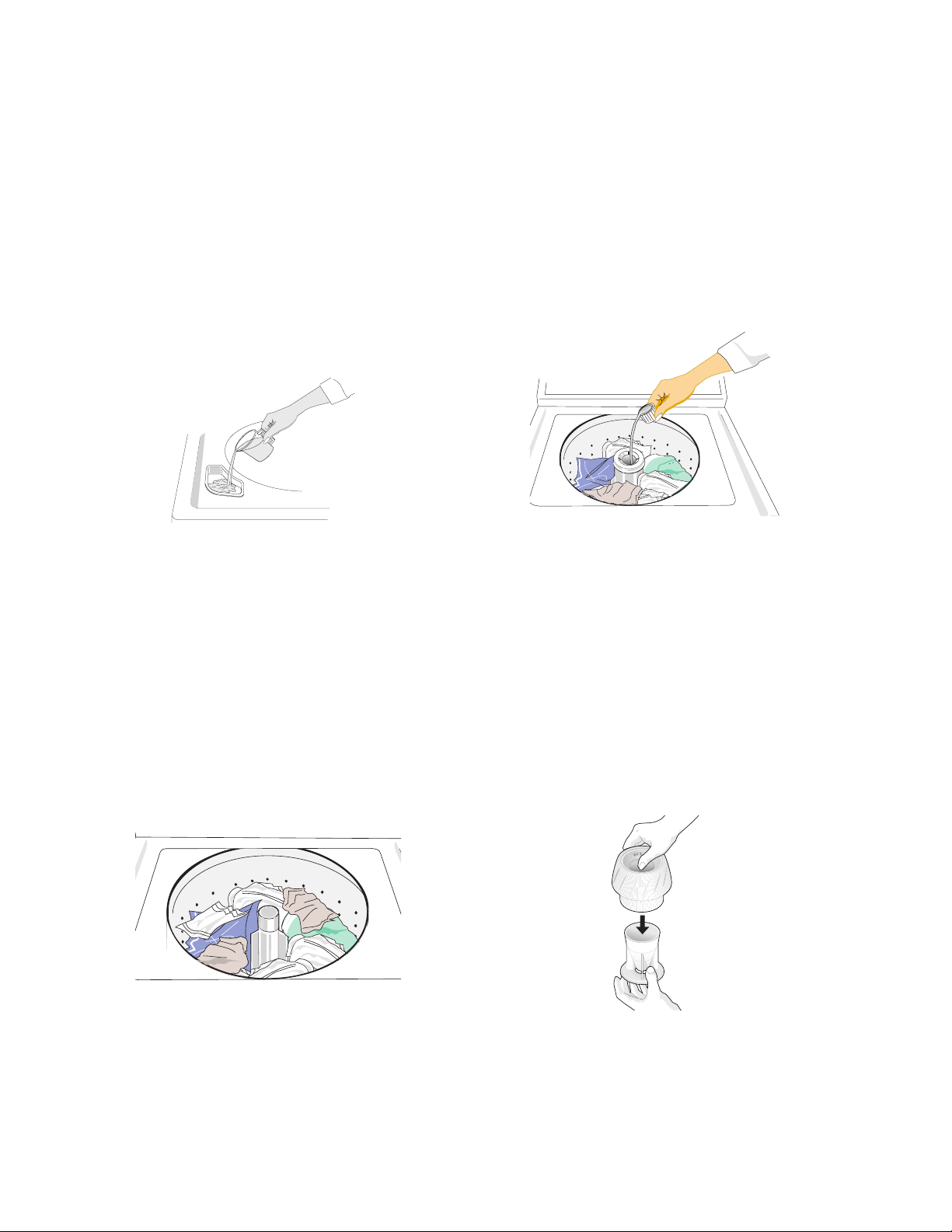

3. Remove the dispenser from the agitator after

each use. Rinse both cap and cup with warm

water. Replace dispenser in the agitator.

NOTE: To separate cap from cup, put thumb into

dispenser and push against side of cup.

Do not load items above

top row of holes in wash tub.

Do not overload washer.

Do not put items on top of agitator or wrap them

around it. Load items evenly.

Built-In Fabric Softener Dispenser(some models)

After cleaning, push cap and cup firmly together.

Replace dispenser by lining up the ribs and grooves

and snapping it into position.

18

Page 19

Fabric softener will be flushed from area under the

built-in fabric softener dispenser when Large Load

Water Level is selected. If a build-up of fabric

softener occurs, clean with hot water. DO NOT

REMOVE SERVICE CAP.

For models with a removable dispenser:

1. Attach fabric softener dispenser to top of agitator

by pressing down gently.

2. Add softener to the dispenser, following fabric

softener label directions.

Removable Fabric Softener Dispenser

(some models)

3. Add water to bring liquid level to top of the peg

in the center of the cup.

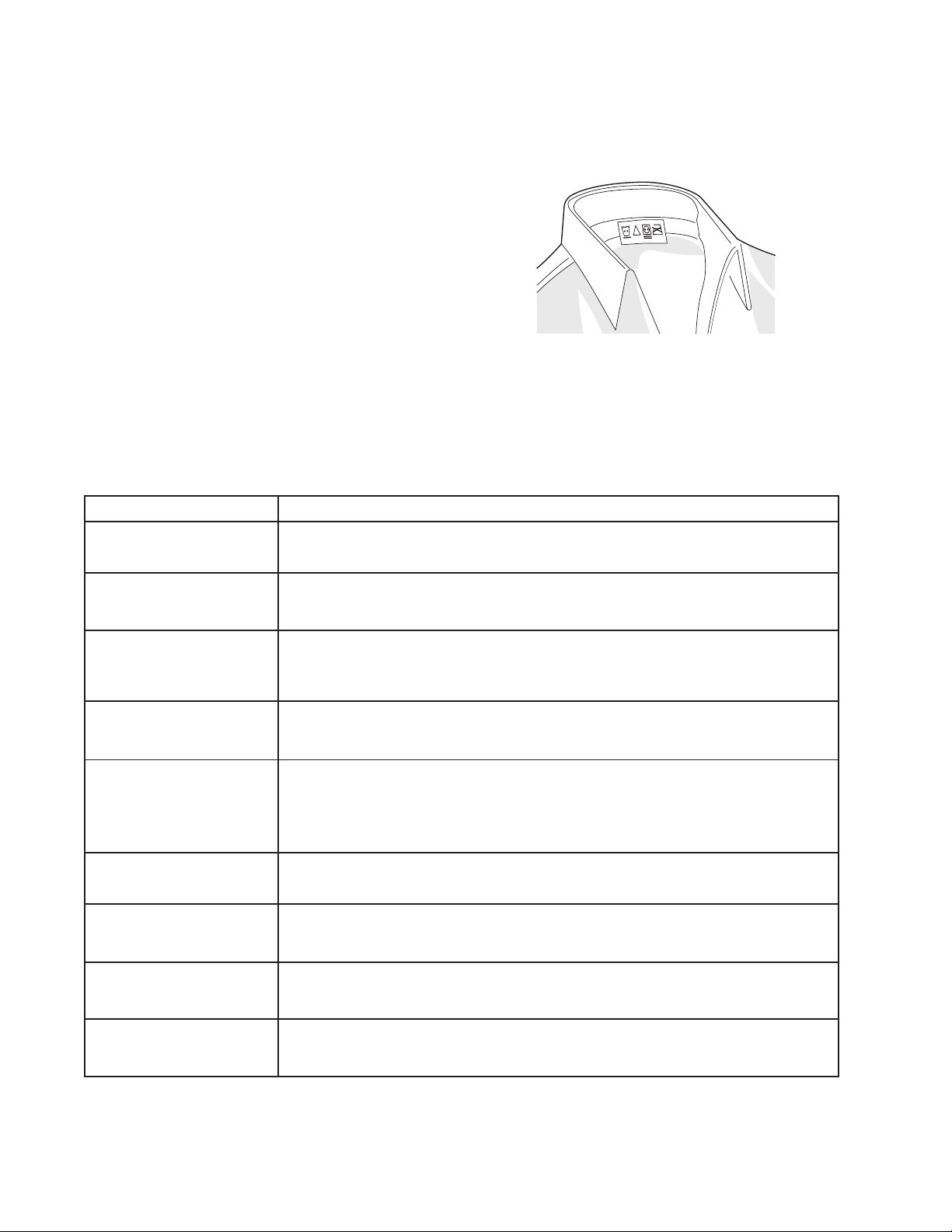

10. Remove items when the cycle is completed.

For your safety, the lid locks when the tub is

spinning. It will remain locked for about 1 minute

after the tub stops spinning.

To open the lid during a spin, push in the cycle

selector knob and wait about 1 minute for the lid

lock to release. Do not force open the locked

lid.

Place washed items in automatic dryer, line dry, or

dry flat as directed by fabric care label. Excess

wrinkling, color transfer or odors may develop in

items left in the washer after the cycle has ended.

To avoid serious personal injury, do not

operate washer if safety lid lock is missing or damaged.

4. Remove the dispenser from the agitator after

each use. Rinse both lid and bowl thoroughly

with warm water. Reassemble and place

dispenser on agitator or store it nearby.

For models without a fabric softener dispenser,

follow fabric softener label directions. Add diluted

fabric softener to the final rinse. Do not pour fabric

softener directly on the wash load

8. Set cycle selector knob and washer controls

according to type, size, and soil level of each

load, and detergent used.

9. Start the washer.

Close the washer lid and pull out the cycle selector

knob. Washer will fill with the lid open. The tub will

not agitate or spin unless the lid is closed.

To stop the washer, push in the cycle selector

knob.

Do not stop and restart washer during a spin

when using the fabric softener dispenser.

To change a cycle, push in the cycle selector

knob. Turn it clockwise to the desired setting.

Pull out the knob to restart the washer.

Stain Removal

Safe Stain Removal Procedures

To reduce the risk of fire or serious

injury to persons or property, comply with the basic

warnings listed below:

Read and comply with all instructions on stain

removal products.

Keep products in their original labeled containers

and out of children's reach.

Thoroughly wash any utensil used.

Do not combine stain removal products,

especially ammonia and chlorine bleach.

Dangerous fumes may result.

Do not combine stain removal products.

19

Page 20

Never wash items which have been previously

cleaned in, washed in, soaked in or spotted with

gasoline, dry cleaning solvents or other

flammable or explosive substances because they

give off vapors that could ignite or explode.

Never use highly flammable solvents, such as

gasoline, inside the home. Vapors can explode

on contact with flames or sparks.

For successful stain removal:

Remove stains promptly.

Determine the kind of stain, then follow

recommended treatment in the stain removal

chart on the next page.

To pretreat stains, use a prewash product, liquid

detergent, or a paste made from granular

detergent and water.

Stain Removal

Use cold water on unknown stains because hot

water can set stains.

Check care label instructions for treatments to

avoid on specific fabrics.

Follow fabric care label instructions.

Check for colorfastness by testing stain remover

on an inside seam.

Rinse and wash items after stain removal.

STAIN

Adhesive tape, chewing

gum, rubber cement.

Baby formula, dairy

products, egg.

Beverages (coffee, tea,

soda,juice, alcoholic

beverages).

Blood.

Candle wax, crayon.

Chocolate.

Collar or cuff soil,

cosmetics.

TREATMENT

Apply ice. Scrape off excess. Place stain face down on paper towels. Saturate

with prewash stain remover or nonflammable dry cleaning fluid.

Use product containing enzymes to pretreat or soak stains. Soak for 30

minutes or more. Wash.

Pretreat stain. Wash using cold water and bleach safe for fabric.

Rinse with cold water. Rub with bar soap. Or, pretreat or soak with product

containing enzymes. Wash using bleach safe for fabric.

Scrape off surface wax. Place stain face down between paper towels. Press

with warm iron until wax is absorbed. Replace paper towels frequently. Treat

remaining stain with prewash stain remover or nonflammable dry cleaning

fluid. Hand wash to remove solvent. Wash using bleach safe for fabric.

Pretreat or soak in warm water using product containing enzymes. Wash using

bleach safe for fabric.

Pretreat with prewash stain remover or rub with bar soap.

Dye transfer on white

fabric.

Grass.

Use packaged color remover. Wash using bleach safe for fabric.

Pretreat or soak in warm water using product containing enzymes. Wash using

bleach safe for fabric.

20

Page 21

STAIN

Grease, oil, tar (butter,

fats,salad dressing,

cooking oils, car grease,

motor oils).

TREATMENT

Scrape residue from fabric. Pretreat. Wash using hottest water safe for fabric. For

heavy stains and tar, apply nonflammable dry cleaning fluid to back of stain.

Replace towels under stain frequently. Rinse thoroughly. Wash using hottest water

safe for fabric.

Ink.

Mildew, scorch.

Mud.

Mustard, tomato.

Nail polish.

Paint, varnish.

Perspiration.

Rust, brown or yellow

discoloration.

Some inks may be impossible to remove. Washing may set some inks. Use

prewash stain remover, denatured alcohol or nonflammable dry cleaning fluid.

Wash with chlorine bleach if safe for fabric. Or, soak in oxygen bleach and hot water

before washing. Badly mildewed fabrics may be permanently damaged.

Brush off dry mud. Pretreat or soak with product containing enzymes.

Pretreat with prewash stain remover. Wash using bleach safe for fabric.

May be impossible to remove. Place stain face down on paper towels. Apply nail

polish remover to back of stain. Repeat, replacing paper towels frequently. Do not

use on acetate fabrics.

WATER BASED: Rinse fabric in cool water while stain is wet. Wash. Once paint is

dry, it cannot be removed. OIL BASED AND VARNISH: Use solvent recommended

on can label. Rinse thoroughly before washing.

Use prewash stain remover or rub with bar soap. Rinse. Wash using nonchlorine

bleach in hottest water safe for fabric.

For spots, use rust remover safe for fabric. For discoloration of an entire load, use

nonchlorine bleach. Do not use chlorine bleach because it may intensify

discoloration.

Shoe polish.

Urine, vomit, mucus,

feces.

LIQUID: Pretreat with a paste of granular detergent and water. PASTE: Scrape

residue from fabric. Pretreat with prewash stain remover or nonflammable dry

cleaning fluid. Rinse. Rub detergent into dampened area. Wash using bleach safe

for fabric.

Pretreat or soak in product containing enzymes. Wash using bleach safe for fabric.

21

Page 22

Common Washing Problems

Many washing problems involve poor soil and stain removal, residues of lint and scum, and fabric damage. For

satisfactory washing results, follow these suggestions provided by The Soap and Detergent Association.

PROBLEM POSSIBLE CAUSES SOLUTIONS PREVENTIVE MEASURES

Blue stains

Discoloration,

graying

Greasy, oily

stains

Detergent or liquid

fabric softener did not

dissolve or disperse.

Not enough detergent.

Wash water

temperature too low.

Incorrect sorting.

Not enough detergent.

Undiluted liquid fabric

softener poured

directly on fabric.

If caused by detergent, mix 1

cup (240 ml) white vinegar

with 1 quart (.95 L) water in a

plastic container. Soak item 1

hour. Rinse.

If caused by fabric softener,

rub stains with bar soap.

Wash.

Rewash with correct amount

of detergent and hottest water

safe for fabric. Add bleach

safe for fabric.

Treat with prewash stain

remover or liquid detergent.

Increase detergent and water

temperature. Rewash.

Rub fabric softener stains with

bar soap.

Add detergent before wash

load. Then start washer.

Dilute fabric softener with

water.

Sort items by soil level

and color.

Use correct amount of

detergent, hottest water

and bleach safe for fabric.

Use correct amount of

detergent and hottest

water safe for fabric.

Do not pour liquid fabric

softener directly on

fabric. See package

directions or Washing

Procedures for proper

diluting.

Holes, tears, or

snags

Lint

Incorrect use of

chlorine bleach.

Unfastened zippers,

hooks, buckles.

Rips, tears and

broken threads.

Overloading the

washer.

Degradation of fabric.

Incorrect sorting.

Tissues left in pocket.

Overloading the

washer.

Not enough

detergent.

Undissolved detergent

has left residue.

Static cling is

attracting lint.

Load washed too long.

May be irreversible if rips,

tears and seams cannot be

mended.

Reduce load size. Rewash

using correct water

temperature, water level, and

amount of detergent.

Add nonprecipitating water

conditioner to wash water.

Add liquid fabric softener to

final rinse.

Dry load in dryer.

Remove lint with lint brush or

roller.

Never pour chlorine bleach

directly on fabric.

Check condition of items

before washing. See

Washing Procedures for

preparing

and loading the wash load.

See Washing

Procedures for sorting

and preparing the wash

load.

Do not overload washer.

Use correct amount of

detergent, water

temperature and water

level.

22

Page 23

Common Washing Problems

Many washing problems involve poor soil and stain removal, residues of lint and scum, and fabric damage. For

satisfactory washing results, follow these suggestions provided by The Soap and Detergent Association.

PROBLEM POSSIBLE CAUSES SOLUTIONS PREVENTIVE MEASURES

Pilling

(Fibers break off,

ball up and cling to

fabric)

Pilling is normal with

synthetic and permanent

press fabrics. This is due

to abrasion from normal

wear.

Use a lint brush or shaver

to remove pills.

Use fabric softener in the

washer to lubricate fibers.

When ironing, use spray

starch or fabric finish on

collars and cuffs.

Turn items inside out to

reduce abrasion.

Residue or

powder on dark

items;

Stiff, harsh

fabrics.

Wrinkling

Yellow buildup of

body soil on

synthetic fabrics

Undissolved detergent.

Some nonphosphate

granular detergents can

combine with hard water

minerals to form a

residue.

Overloading the washer.

Agitation time too short.

Wash water temperature

too low.

Not enough detergent.

Reduce load size.

Add dissolved detergent

to tub . Rewash load.

Mix 1 cup (240 ml) white

vinegar to 1 gallon (3.8 L)

warm water in plastic

container. Soak item.

Rinse and rewash.

Reduce load size.

Rinse in cold water with

liquid fabric softener.

Soak in detergent booster

or product containing

enzymes.

Wash in hot water (120°F/

49°C) using full

permanent press cycle.

Increase detergent.

Add bleach safe for

fabric.

Or, treat with color

remover.

Increase water temperature

using hottest water safe for

fabric.

Do not overload washer.

Use liquid detergent or use

nonprecipitating water

conditioner with

nonphosphate granular

detergent.

Do not overload washer.

Remove items from washer

as soon as cycle is

completed.

Use liquid fabric softener.

Wash synthetics frequently

using water at least 100°F

(37°C ) and correct water

level.

Yellow or brown

rust stains

Iron or manganese in

water supply, water pipes,

or water heater.

To restore discolored load

of whites, use rust

remover safe for fabric.

Do not use chlorine

bleach to remove rust

stains. It may intensify

discoloration.

23

Use nonprecipitating water

softener.

Before washing, run hot

water for a few minutes to

clear lines.

Drain water heater

occasionally.

For an ongoing problem,

install an iron filter in your

water supply system.

Page 24

Care and Cleaning

Use care with laundry products. They

can damage finish on the washer.

Inside

Before moving the washer, place a strip of

cardboard or thin fiberboard under the front leveling

legs to prevent floor damage.

Follow Winterizing

Instructions for

cold weather care.

Remove items from the washer as soon as the

cycle ends. Excess wrinkling, color transfer, and

odors may develop in items left in the washer.

Dry the washer top, the area around the lid opening,

and the underside of the lid. These areas should

always be dry before the lid is closed.

Before cleaning the washer interior, unplug the

electrical power cord to avoid electrical shock

hazards.

When extremely soiled items have been washed,

a dirty residue may remain on the tub. Remove this

by wiping the tub with a nonabrasive household

cleanser. Rinse thoroughly with water.

The agitator or tub may become stained from fabric

dye. Clean these parts with a nonabrasive household

cleanser. This prevents dye transfer to future loads.

Outside

When washing is completed, wipe top and sides of

washer with a damp cloth. Turn water faucets off

to prevent pressure build-up in the hoses.

As needed, clean the cabinet with mild soap and

water. Never use harsh, gritty or abrasive

cleansers. If top or lid becomes stained, clean with

diluted chlorine bleach [1/2 cup (120 ml) in 1 quart

(.95 L) water]. Rinse several times with clear water.

Winterizing Instructions

If the washer is stored in an area where freezing can

occur or moved in freezing temperatures, follow these

winterizing instructions to prevent damage to the washer:

1. Turn off water supply faucets.

2. Disconnect hoses from water supply and drain

water from hoses.

3. Plug electrical cord into a properly grounded

electrical outlet.

4. Add 1 gallon nontoxic recreational vehicle (RV)

antifreeze to empty wash tub. Close lid.

5. Set cycle selector knob at a spin setting. Pull out

knob and let washer spin for 1 minute to drain out

all water. Not all of the RV antifreeze will be

expelled.

6. Push in knob, unplug electrical power cord, dry tub

interior, and close lid.

7. Store washer in an upright position.

8. To remove antifreeze from washer after storage,

run empty washer through a complete cycle using

detergent. Do not add wash load.

Remove glue residue from tape or labels with a

mixture of warm water and mild detergent. Or,

touch residue with the sticky side of the tape or

label.

24

Page 25

Avoid Service

Checklist

OCCURRENCE POSSIBLE CAUSE SOLUTION

NOISE

"Clunking" or gear

sounds.

Before calling for service, review this list. It may save both time and expense. The list includes

common concerns that are not the result of defective workmanship or materials in this washer.

A certain amount of "clunking" or gear

sounds are normal in a heavy-duty washer.

This is normal.

Rattling and clanking

noise.

Squealing sound or

hot rubber odor.

Thumping sound.

Vibrating noise.

Foreign objects such as coins or safety

pins may be in tub or pump.

Belt buckles and metal fasteners are

hitting wash tub.

Washer is overloaded.

Heavy wash loads may produce a

thumping sound.

Washer is not resting firmly on floor.

Shipping bolt and block have not been

removed during installation.

Wash load unevenly distributed in tub.

Stop washer and check tub. If noise

continues after washer is restarted,

objects may be in pump. Call your

authorized servicer.

To prevent unnecessary noise and

damage to tub, fasten fasteners and turn

items inside out.

Do not overload washer. Stop washer

and reduce load.

This is usually normal. If sound

continues, washer is probably out of

balance. Stop washer and redistribute

wash load.

Move washer so it rests firmly on floor.

Adjust leveling legs. See INSTALLATION

INSTRUCTIONS for details.

See INSTALLATION INSTRUCTIONS for

removing shipping bolt and block.

Stop washer and rearrange wash load.

OPERATING

Washer does not start.

Electrical power cord may not be plugged

in or connection may be loose.

House fuse blown, circuit breaker tripped,

or a power outage has occurred.

Water supply faucets are not turned on.

Cycle selector is not in correct position.

Motor is overheated.

25

Make sure plug fits tightly in wall outlet.

Reset circuit breaker or replace fuse. Do

not increase fuse capacity. If problem is

a circuit overload, have it corrected by a

qualified electrician. If problem is a

power outage, call local electric company.

Turn on water supply faucets.

Move indicator clockwise slightly. Pull

out knob.

Washer motor will stop if it becomes

overheated. It will automatically restart

after a cool down period of up to 30

minutes (if washer has not been manually

turned off).

Page 26

OCCURRENCE POSSIBLE CAUSE SOLUTION

Washer won't spin.

Lid is not completely closed.

Close lid completely.

Residue left in tub.

Wash load too wet

after spin.

Water does not enter

washer or it enters

slowly.

Water level does not

cover load.

Heavily soiled items.

Washer is overloaded.

Load is out of balance.

Drain hose is kinked.

Water supply is not adequate in

area.

Water supply faucets are not

completely open.

Water is being used elsewhere in

the house.

Water inlet hoses are kinked.

Improper water level selection (for

models with water level/load size

control).

Washer is overloaded.

Wipe tub with a nonabrasive household cleanser,

then rinse. Shake or brush excess dirt and sand

from items before washing.

Do not overload washer. See Washing

Procedures.

Rearrange load to allow proper spinning.

Straighten drain hose.

Check another faucet in the house. Wait until

water supply and pressure increase.

Fully open hot and cold faucets.

Water pressure must be at least 30 psi (260 kPa).

Avoid running water elsewhere while washer is

filling.

Straighten hoses.

Select higher water level/load size.

Do not overload washer. When control is set at

highest fill level, dry load level should not be higher

than top row of circular holes in wash tub.

Warm or hot water is

not hot enough.

Water in washer

does not drain or

drains slowly.

Water leaks.

Incorrect wash and

rinse temperatures.

Water is entering

washer but tub does

not fill.

Hot water heater is set too low or

is a distance from washer.

Hot water is being used elsewhere

in the house.

Drain hose is kinked or clogged.

Fill hose connection at faucet or

washer.

House drain pipes are clogged.

Oversudsing.

Hot and cold water hoses are

Measure hot water temperature at nearby faucet

with candy or meat thermometer. Water temperature

should be at least 130°F (70°C). Adjust water

heater as necessary.

Avoid using hot water elsewhere before or during

washer use. There may not be enough hot water

available for proper cleaning. If problem persists,

your hot water system may be unable to support

more than 1 use at a time.

Clean and straighten the drain hose.

Check and tighten hose connections. Install rubber

sealing washers provided.

Unclog drain pipes. Contact plumber if necessary.

Use less detergent.

Connect hot water hose to hot water faucet and

cold water hose to cold water faucet.

Standpipe must be a minimum of 33" (83.82 cm)

high to prevent siphoning. See INSTALLATION

INSTRUCTIONS.

26

Page 27

FRIGIDAIRE GALLERY TOP LOAD WASHER WARRANTY

(UNITED STATES)

Your Frigidaire product is protected by this warranty

SAMPLE WARRANTY ALWAYS USE THE WARRANTY

SUPPLIED WITH PRODUCTS

FULL ONE-YEAR

WARRANTY

LIMITED 2ND - 5TH

YEAR WARRANTY

FULL 25-YEAR

INNER WASH BASKET

WARRANTY

(Excluding Alaska)

LIMITED WARRANTY

(Applicable to the

State of Alaska)

WARRANTY

PERIOD

One year from original

purchase date.

Second through fifth

years from original

purchase date.

25 years from original

purchase date.

Time periods listed

above.

FRIGIDAIRE, THROUGH ITS AUTHORIZED

SERVICERS, WILL:

Pay all costs for repairing or replacing any parts of this

appliance which prove to be defective in materials or

workmanship.

Provide a replacement for a defective or malfunctioning

part found in the washer transmission (illustrated below).

Provide a replacement and in-home service labor, without

charge, for an inner wash basket (illustrated below) that

breaks due to defective materials or workmanship.

All of the provisions of the full and limited warranties

above and the exclusions listed below apply.

THE CONSUMER WILL BE

RESPONSIBLE FOR:

Costs of service calls that are listed under

NORMAL RESPONSIBILITIES OF THE

CONSUMER.*

Costs for labor and replacement parts other than

defective transmission parts.

Costs of service calls that are listed under

NORMAL RESPONSIBILITIES OF THE

CONSUMER.*

Costs of the technician's travel to the home and

any costs for pick up and delivery of the appliance

required because of service.

Your appliance is warranted by Frigidaire Home Products, a division of White Consolidated Industries, Inc. We authorize no person to change or

add to any of our obligations under this warranty. Our obligations for service and parts under this warranty must be performed by Frigidaire or an

authorized Frigidaire servicer.

*NORMAL

RESPONSIBILITIES

OF THE CONSUMER

This warranty applies only to products in ordinary household use, and the consumer is responsible for the

items listed below:

1. Proper use of the appliance in accordance with instructions provided with the product.

2. Proper installation by an authorized servicer in accordance with instructions provided with the appliance and in

accordance with all local plumbing, electrical and/or gas codes.

3. Proper connection to a grounded power supply of sufficient voltage, replacement of blown fuses, repair of loose

connections or defects in house wiring.

4. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards, shelves, etc.,

which are not a part of the appliance when it was shipped from the factory.

5. Damages to finish after installation.

6. Replacement of light bulbs and/or fluorescent tubes (on models with these features).

EXCLUSIONS

IF YOU NEED

SERVICE

This warranty does not cover the following:

1. CONSEQUENTIAL OR INCIDENTAL DAMAGES SUCH AS PROPERTY DAMAGE AND INCIDENTAL

EXPENSES RESULTING FROM ANY BREACH OF THIS WRITTEN OR ANY IMPLIED WARRANTY.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so this limitation

or exclusion may not apply to you.

2. Service calls which do not involve malfunction or defects in workmanship or material, or for appliances not in ordinary

household use. The consumer shall pay for such service calls.

3. Damages caused by services performed by servicers other than Frigidaire or its authorized servicers; use of parts

other than genuine Frigidaire Home Products parts; obtained from persons other than such servicers; or external

causes such as abuse, misuse, inadequate power supply or acts of God.

4. Products with original serial numbers that have been removed or altered and cannot be readily determined.

Keep your bill of sale, delivery slip, or some other appropriate payment record. The date on the bill establishes the

warranty period should service be required. If service is performed, it is in your best interest to obtain and keep all receipts.

This written warranty gives you specific legal rights. You may also have other rights that vary from state to state. Service

under this warranty must be obtained by contacting Frigidaire Home Products:

800 944 9044

Frigidaire Home Products

P.O. Box 212378

Augusta, GA 30917

27

Page 28

Service

Information

To avoid unnecessary cost and inconvenience, make a few simple checks before

calling for service. Common occurrences and their solutions can be found in the

Avoid Service Checklist. Be sure you have followed the instructions in this manual.

(Canada)

If you are unable to locate the cause of a problem, call for service. Insist on factory

service by an authorized FRIGIDAIRE HOME PRODUCTS PARTS AND SERVICE

depot.

FRIGIDAIRE HOME PRODUCTS PARTS AND SERVICE

All Frigidaire appliances are backed by FRIGIDAIRE HOME PRODUCTS PARTS

AND SERVICE, one of Canada's largest parts and service networks.

The Frigidaire reputation means you can enjoy complete professional service from

one of our hundreds of trained technicians across the country. Ask your Frigidaire

dealer for details about the Extended Service Plan offered by FRIGIDAIRE HOME

PRODUCTS PARTS AND SERVICE to all purchasers of Frigidaire appliances in

Canada.

FRIGIDAIRE HOME PRODUCTS PARTS AND SERVICE

7075 Ordan Drive

Mississauga, Ontario

L5T 1K6

Place the name, address and telephone number of your service depot in the

spaces below.

Product and feature specifications as described or illustrated are subject to

change without notice.

28

Page 29

WARRANTY (CANADA)

GALLERY AUTOMATIC WASHERS AND DRYERS

WARRANTOR:

Frigidaire Home Products

7075 Ordan Drive

Mississauga, Ontario

L5T 1K6

WARRANTY PERIOD:

For the first two years after purchase by the

original consumer/owner:

Lifetime washer, after purchase by the original

consumer/owner:

Top load automatic washers only: transmission

for the third through tenth year after purchase

by the original consumer/owner:

WARRANTY APPLIES TO:

a) Products purchased and installed in Canada for personal single family household use.

b) Defects resulting or arising out of the manufacturing process.

c) Products bearing legible manufacturer's model and serial numbers.

d) Replacement parts only for the remainder of the original warranty.

For service under this warranty, contact your local

dealer/retailer, authorized FRIGIDAIRE HOME PRODUCTS

PARTS AND SERVICE

FRIGIDAIRE HOME PRODUCTS PARTS & SERVICE

7075 Ordan Drive

Mississauga, Ontario

L5T 1K6

Tel.: (905) 565-9200

Fax: (905) 565-0937

WARRANTOR WILL THROUGH ITS AUTHORIZED

SERVICE DEPOT:

Pay all costs to repair or replace any defective parts.

Pay all costs (excluding labour to install) of a

polypropylene washer basket and/or polypropylene tub.

Pay all costs (excluding labour to install) to replace any

defective transmission.

depot, or:

WARRANTY DOES NOT APPLY TO:

a) Transportation damage.

b) Supply and replacement of porcelain, fuses, glass and light bulbs.

c) Parts and service supplied or obtained from other than FRIGIDAIRE HOME PRODUCTS PARTS AND

SERVICE or FRIGIDAIRE HOME PRODUCTS PARTS AND SERVICE authorized depots.

d) Damage or failure as the result of abuse, improper or commercial use.

CONSUMER/OWNER RESPONSIBILITY:

a) To provide proof of the original date of purchase by means of a bill of sale or payment record verifying purchase

date.

b) To pay all costs to make the appliance readily accessible for service.

c) To ensure proper power supply and connection of the appliance to same.

d) Proper installation, control setting and care of finish.

This warranty is in addition to any statutory warranties contained in any applicable legislation. The terms and

conditions of this warranty are not intended to exclude or limit your rights under those statutes. The warrantor

however reserves the right to charge transportation and travelling costs for distances in excess of 48 kilometres

(30 miles) from the nearest FRIGIDAIRE HOME PRODUCTS PARTS AND SERVICE authorized service depot.

This warranty plus the statutory warranties mentioned are the only warranties given to the consumer/owner for

this product.

29

Page 30

SECTION C - INSTALLATION

INSTRUCTIONS

Full Size Automatic Washer

Before beginning installation, carefully read these

instructions. This will simplify the installation and

ensure the washer is installed correctly and safely.

Leave these instructions near the washer after

installation for future reference.

NOTE: The electrical service to the washer must

conform with local codes and ordinances and the

latest edition of the National Electrical Code, ANSI/

NFPA 70, or in Canada, CSA 22.1 Canadian

Electrical Code Part 1.

PRE-INSTALLATION REQUIREMENTS

the grounding prong on the power supply cord. In

situations where a two-slot receptacle is present, it

is the owners responsibility to have a licensed

electrician replace it with a properly grounded

three prong grounding type receptacle.

Tools Required for Installation:

1. 3/8 in. socket with ratchet.

2. Channel-lock adjustable pliers.

3. Carpenters level.

ELECTRICAL REQUIREMENTS

CIRCUIT - Individual, properly polarized and grounded

15 amp. branch circuit fused with 15 amp. time delay

fuse or circuit breaker.

POWER SUPPLY - 2 wire, with ground, 120 volt, single

phase, 60 Hz, Alternating Current.

OUTLET RECEPTACLE - Properly grounded 3-prong

receptacle to be located so the power supply cord is

accessible when the washer is in an installed position.

GROUNDING REQUIREMENTS

Improper connection of the equipment

grounding conductor can result in a risk of electrical

shock. Check with a licensed electrician if you are in

doubt as to whether the appliance is properly grounded.

1. The washer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electrical shock by a path of least

resistance for electrical current.

3. For added personal safety, connect a separate

ground wire (No. 18 minimum) from a top panel

hinge screw on the rear of the washer to a grounded

cold water pipe. DO NOT ground to a gas supply

pipe or hot water pipe.

4. Grounded cold water pipe MUST have metal

continuity to electrical ground and MUST register

no more than 25 ohms resistance. It MUST not be

interrupted by plastic, rubber, or other electrical

insulating connectors such as hoses, fittings,

washers, gaskets (including water meter or pump).

Any electrically insulated connector should be

jumped with a length of No. 4 copper wire securely

clamped to bare metal at both ends with a UL

approved ground clamp.

5. If a grounded water pipe is not available, a ground

rod MUST be used and register no more than 25

ohms resistance when in the ground. Drive the rod

into the ground outside the dwelling and connect a

grounding wire (12 AWG or heavier) between the

grounding screw and the grounding rod. It may take

more than one ground rod to not exceed 25 ohms

resistance to ground.

WATER SUPPLY REQUIREMENTS

2. Since your washer is equipped with a power supply

cord having an equipment-grounding conductor

and a grounding plug, the plug MUST be plugged

into an appropriate, copper wired receptacle that

is properly installed and grounded in accordance

with all local codes and ordinances or in the

absence of local codes, with the National Electrical

Codes, ANSI/NFPA 70 (latest edition). If in doubt,

call a licensed electrician. DO NOT cut off or alter

Hot and cold water faucets MUST be installed within

42 inches (107 cm) of your washers water inlet. The

faucets MUST be 3/4 inch (1.9 cm) garden hose type

so inlet hoses can be connected. Water pressure MUST

be between 10 and 120 pounds per square inch

(maximum unbalance pressure, hot vs. cold, 10 psi.)

Your water department can advise you of your water

pressure. The hot water temperature should be about

140 degrees F (60 degrees C).

30

Page 31

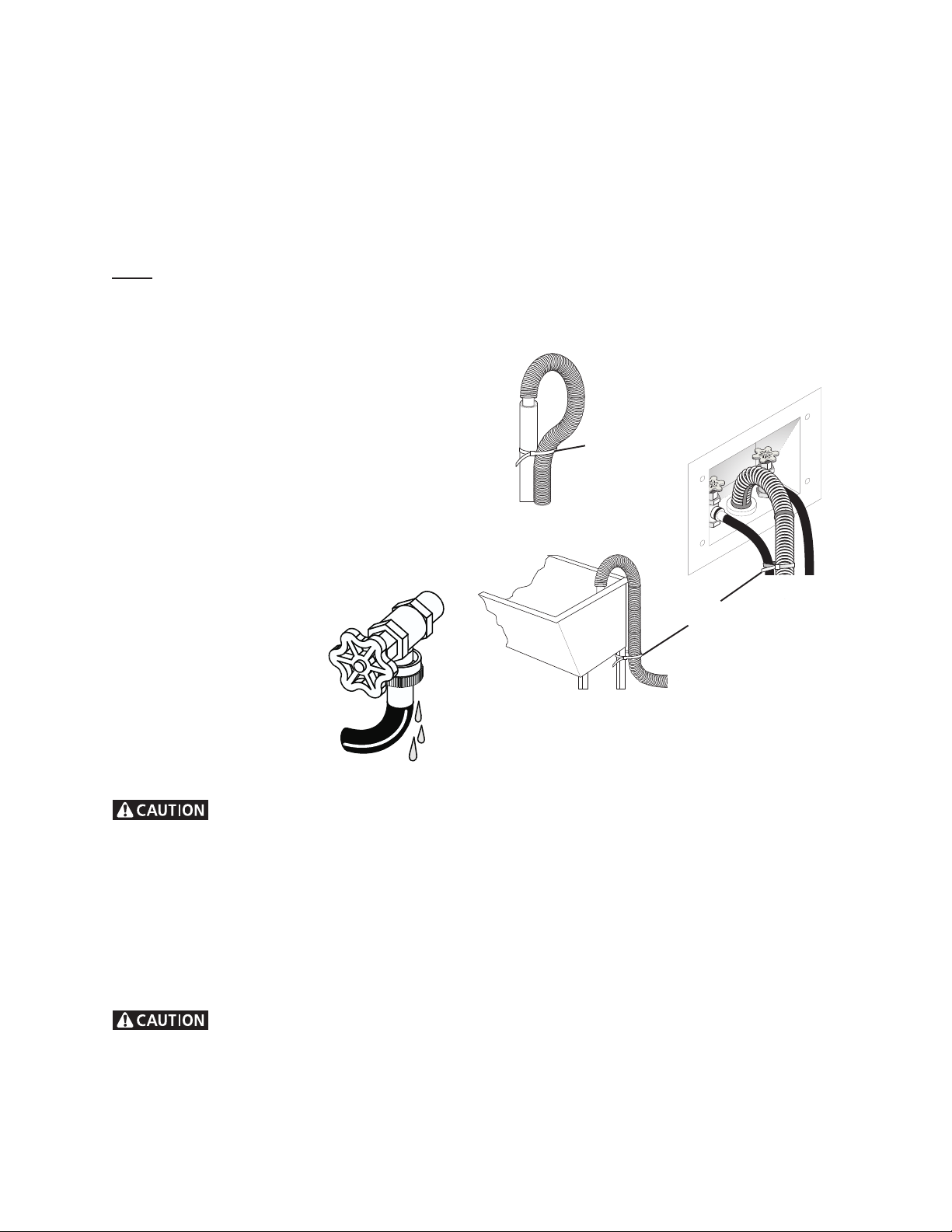

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gallons (64.3 L) per

minute.

2. A standpipe diameter of 1-1/4 in. (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum height: 33 in. (83.82 cm)

Maximum height: 96 in. (244 cm)

2. In an area where it will come in contact with curtains

or drapes.

3. In an area (garage or garage-type building) where

gasoline of other flammables are kept or stored

(including automobiles).

4. On carpet. Floor

MUST BE SOLID with a maximum

slope of 1 in. (2.54 cm). To ensure vibration or

movement does not occur, REINFORCEMENT of the

floor may be necessary.

↑

↑

33" Min.

(83.82 cm)

↓

NOTE: For installations requiring a longer drain hose,

have a qualified technician install a longer

drain hose, P/N 131461201, available from

an authorized parts distributor. For drain

systems in the floor, install a syphon break

kit, available from your local hardware store.

ROUGH-IN DIMENSIONS

WATER

INLETS

(REAR)

DRAIN

OUTLET

(REAR)

3-3/4"

(9.53 cm)

27"

(68.58 cm)

FRONT VIEW

(129.54

29-7/16"

(74.77 cm)

51"

cm)

44"

(111.76

cm )

96" Max.

(244 cm)

↓

LID OPEN 90°

(68.58 cm)

SIDE VIEW

DRAIN

OUTLET

27"

11-7/16"

(29.05 cm)

IMPORTANT MINIMUM INSTALLATION

CLEARANCES

When installed in alcove: Sides = 0" (0 cm),

Rear = 0" (0 cm), Top = 20" (50.8 cm).

When installed in closet: Sides = 0" (0 cm),

Rear = 0" (0 cm), Top = 20" (50.8 cm), Front = 1"

(2.54 cm).

Closet door ventilation required: 2 louvered openings

each 60 square inches (387 cm2) 3 inches (7.6 cm)

from bottom and top of door.

UNPACKING

1. Using the four shipping carton corner posts (two

on each side), carefully lay the washer on its left

side and remove foam shipping base.

2. Using a ratchet with 3/8" socket, remove the

mechanism shipping bolt and plastic spacer block

from the center of the base.

NOTE: If the washer is to be transported at a later

date, the tub blocking pad, shipping bolt,

and plastic spacer block should be

retained.

←

PLASTIC

SPACER

BLOCK

SHIPPING BLOCKS

LOCATION OF YOUR WASHER

DO NOT INSTALL YOUR WASHER:

1. In an area exposed to dripping water or outside

weather conditions. The ambient temperature

should never be below 60 degrees F (15.6

degrees C) for proper washer operation.

MECHANISM

SHIPPING

BOLT

FOAM

SHIPPING

PAD

31

SHIPPING CARTON

CORNER POSTS

POWER

CORD

DRAIN HOSE

Page 32

3. Return the washer to an upright position.

4. Remove the tape holding the lid shut and open the

lid.

5. Remove the foam tub blocking pad.

6. Remove the inlet hoses and enclosure package

from the tub.

7. From the back of the washer, remove only the

WIRE shipping clips that secure the drain hose to

the left side of the washer backsheet. DO NOT

REMOVE THE PLASTIC CLAMPS on the right

side of the washer. These clamps form a standpipe

to prevent water siphoning.

8. Carefully move the washer to within 4 feet of the

final location for the start of the installation.

6. To ensure the washer is level and solid on all four

legs, open the lid, grasp the top panel and tilt the

washer forward so the rear legs are off the ground.

Gently set the washer back down to allow the rear

legs to self adjust. Place a level on top of the

washer. Check it side to side, then front to back.

Screw the front leveling legs up or down to ensure

the washer is resting solid on all four legs (no

rocking of the washer should exist).

NOTE: Keep the leg extension at a minimum to

prevent excessive vibration. The farther

out the legs are extended the more the

washer will vibrate.

INSTALLATION

1. Run some water from the hot and cold faucets to

flush the water lines and remove particles that

might clog up the water valve screens.

2. Remove the inlet hoses and rubber washers from

the plastic bag and install the rubber washers in

each end of the inlet hoses.

3. Carefully connect the inlet

hose marked "HOT" to the

bottom outlet of the water

valve. Tighten by hand, then

tighten another 2/3 turn with

pliers. Carefully connect the

other inlet hose to the top

outlet of the water valve.

Tighten by hand, then

tighten another 2/3 turn with

pliers.

DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

4. Determine which water faucet is the HOT water

faucet and carefully connect the bottom inlet hose

to the HOT water faucet, tighten by hand, then

tighten another 2/3 turn with pliers. Carefully

connect the top inlet hose to the COLD water

faucet, tighten by hand, then tighten another 2/3

turn with pliers.

DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

Turn the water on and check for leaks at both

connections.

5. Carefully move the washer to its final location.

CABLE TIE

CABLE TIE

7. Form a "U" shape on the end of the drain hose

with the hose pointed toward the drain. Place the

formed end in a laundry tub or a standpipe and

secure with a cable tie provided in the enclosure

package.

NOTE: The standpipe inside diameter must be

1-1/4" (3.18 cm) minimum. There must

be an air gap around the drain hose in

the standpipe. A snug hose fit can cause

a siphoning action.

8.Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at a

circuit breaker/fuse box before plugging

the power cord into an outlet.

9. Turn on the power at a circuit breaker/fuse box.

10. Read the Operating Instructions and Owners Guide

provided with the washer. They contain valuable

and helpful information that will save you time and

money.

32

Page 33

11. Run the washer through a complete cycle. Check

for water leaks and proper operation.

12. If your washer does not operate, please review the

Avoid Service Checklist located in your Owners

Guide before calling for service.

13. Place these instructions in a location near the

washer for future reference.

NOTE: A wiring diagram is located inside the washer

console.

REPLACEMENT PARTS

UNITED STATES

If replacement parts are needed for your washer,

contact the source where you purchased your washer

or call

1-800-944-9044 for the Frigidaire Company Authorized

Parts Distributor nearest you.

CANADA

If replacement parts are needed for your washer,

contact your local dealer/retailer or call (905) 565-9200

for the authorized Frigidaire Parts and Service depot

nearest you.

Destroy the carton and plastic bags

after the washer is unpacked. Children might use them

for play. Cartons covered with rugs, bedspreads, or

plastic sheets can become airtight chambers causing

suffocation. Place all materials in a garbage container

or make materials inaccessible to children.

The instructions in this manual and all

other literature included with this washer are not meant

to cover every possible condition and situation that may

occur. Good safe practice and caution MUST be applied

when installing, operating and maintaining any

appliance.

Maximum benefits and enjoyment are achieved

when all the Safety and Operating instructions are

understood and practiced as a routine with your

laundering tasks.

33

Page 34

SECTION D - PARTS LOCATION AND

N=NORMAL F =FAST

G=GENTLE S=SLOW

SPEED SW ITCH CIRCUIT

G/F

G/S

EG/S

N/F

AGIT/SPIN

EG=EXTRA GENTLE

2-5

X

1-5X1-4

X

X

X

2-4

X

X

X

1-3

THEIR FUNCTION

Timer

The timer is located in the console and controls

electrical power to the components of the washer.

The timer is made up of a motor driven spool that

advances one increment a minute whenever electrical

power is applied to the motor.

power applied to them with the fixed terminals connected

to the components that power is being applied to. The

next column is titled CONTACT and identified as T for

the top contacts of the fixed terminals and B for the

bottom contacts of the fixed terminals. The next column

is titled CIRCUIT and indicates the circuit controlled by

the cam, terminals and contacts. For example, CAM

10, ACTIVE terminal 17, FIXED terminal 18, and