Page 1

SOI 01.05 FV 599 36 78-06

SERVICE MANUAL

MICROWAVE OVENS

ELECTROLUX HOME PRODUCTS

Corso Lino Zanussi,30

Publication No.

I - 33080 PORCIA /PN (ITALY)

599 36 78-06

Tel +39 0434 394850

Fax +39 0434 394096

SOI

Edition: 01.2005

EN/SERVICE/FV

Microwave Oven

(Compact Solo)

MC1751E/MC1761E (EU)

MC1751E/MC1761E (UK)

EMS1750X/EM1760X (UK)

QN4025/QN4026

(SCANDINAVIA)

JMW1051/JMW1061 (A,D)

MOA4217 (D,K)

Page 2

SOI 01.05 FV 2/33 599 36 78-06

Page 3

SOI 01.05 FV 3/33 599 36 78-06

TABLE OF CONTENTS

CAUTION, MICROWAVE RADIATION / GENERAL INFORMATION .............................................4

SERVICING......................................................................................................................................3

PRODUCT SPECIFICATIONS.........................................................................................................6

APPEARANCE VIEW.......................................................................................................................7

OPERATING SEQUENCE .............................................................................................................10

FUNCTION OF IMPORTANT COMPONENTS.............................................................................. 12

TROUBLESHOOTING CHART......................................................................................................13

TEST PROCEDURE ......................................................................................................................14

CONTROL PANEL ASSEMBLY.....................................................................................................22

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE..........................................24

MICROWAVE MEASUREMENT....................................................................................................30

TEST DATA A GLANCE / WIRING / RE-WIRING .........................................................................31

SCHEMATIC DIAGRAMS ..............................................................................................................32

PICTORIAL DIAGRAM................................................................................................................... 33

Page 4

SOI 01.05 FV 4/33 599 36 78-06

CAUTION

CAUTION

MICROWAVE RADIATION

Personnel should not be exposed to the microwave energy which may radiate from the

magnetron or other microwave generating devices if it is improperly used or connected. All

input and output microwave connections, waveguides, flanges and gaskets must be secured.

Never operate the device without a microwave energy absorbing load attached.

Never look into an open waveguide or antenna while the device is energized.

GENERAL IMPORTANT INFORMATIONS

This Manual has been prepared to provide Service Engineers with Operation and Service Information.

It is recommended that service engineers carefully study the entire text of this manual, so they will be

qualified to render satisfactory customer service.

WARNING

Note: The parts marked "*" are used at voltage

more than 250V. (Schematic Diagrams).

WARNING

Never operate the oven until the following points are ensured.

(A) The door is tightly closed.

(B) The door and oven hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by trained

Service Engineers.

All the parts marked ”*” on schematic diagrams are used at

voltages more

than 250V.

Removal of the outer wrap gives access to potentials above

250V.

All the parts marked "*" on the schematic diagrams may cause

undue microwave exposure, by themselves, or when they are

damaged, loosened or removed.

Page 5

SOI 01.05 FV 5/33 599 36 78-06

SERVICING

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current.

Contact with the following parts will result in electrocution

High voltage capacitor, High Voltage transformer, Magnetron, High voltage rectifier assembly,

High voltage wires.

REMEMBER TO CHECK 3D

1) Disconnect the supply.

2) Door opened, and wedged open.

3) Discharge high voltage capacitor.

WARNING AGAINST THE CHARGE OF THE

HIGH VOLTAGE CAPACITOR

The high-voltage capacitor remains charged about

60seconds after the oven has been switched off.

Wait for 60 seconds and then short-circuit the

connection of the high-voltage capacitor (that is, of

the connecting lead of the high-voltage rectifier)

against the chassis with the use of an insulated

screwdriver.

It is recommended that wherever possible faultfinding is carried out with the supply disconnected. It

may in, some cases, be necessary to connect the

supply after the outer case has been removed, in this

event carry out 3D checks and then disconnect the

leads to the primary of the power transformer. Ensure

that these leads remain isolated from other

components and the oven chassis. (Use insulation

tape if necessary.) When the testing is completed

carry out 3D checks and reconnect the leads to the

primary of the power transformer.

REMEMBER TO CHECK 4R

1) Reconnect all leads removed from components

during testing.

2) Replace the outer case (cabinet).

3) Reconnect the supply.

4) Run the oven. Check all functions.

Microwave ovens should not be run empty. To test

for the presence of microwave energy within a cavity,

place a cup of cold water on the oven turntable, close

the door and set the power to HIGH and set the

microwave timer for two (2) minutes. When the two

minutes has elapsed (timer at zero) carefully check

that the water is now hot. If the water remains cold

carry out 3D checks and re-examine the connections

to the component being tested.

When all service work is completed, and the oven is

fully assembled, the microwave power output should

be checked and a microwave leakage test carried

out.

When troubleshooting the microwave oven, it is

helpful to follow the Sequence of Operation in

performing the checks.

Many of the possible causes of trouble will require

that a specific test be performed. These tests are

given a procedure letter which will be found in the

"Test Procedure" section.

IMPORTANT:

If the oven becomes inoperative

because of a blown fuse F1 in the

monitored latch switch - monitor

switch - circuit, check the

monitored latch switch and monitor

switch and before replacing the

fuse F1.

GENERAL INFORMATION

WARNING

THIS APPLIANCE MUST BE EARTHED

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING

CODE:

GREEN-AND-YELLOW : EARTH

BLUE : NEUTRAL

BROWN : LIVE

As part of our policy of continuous improvement, we reserve the right to

alter design and specifications without notice

Page 6

SOI 01.05 FV 6/33 599 36 78-06

PRODUCT SPECIFICATIONS

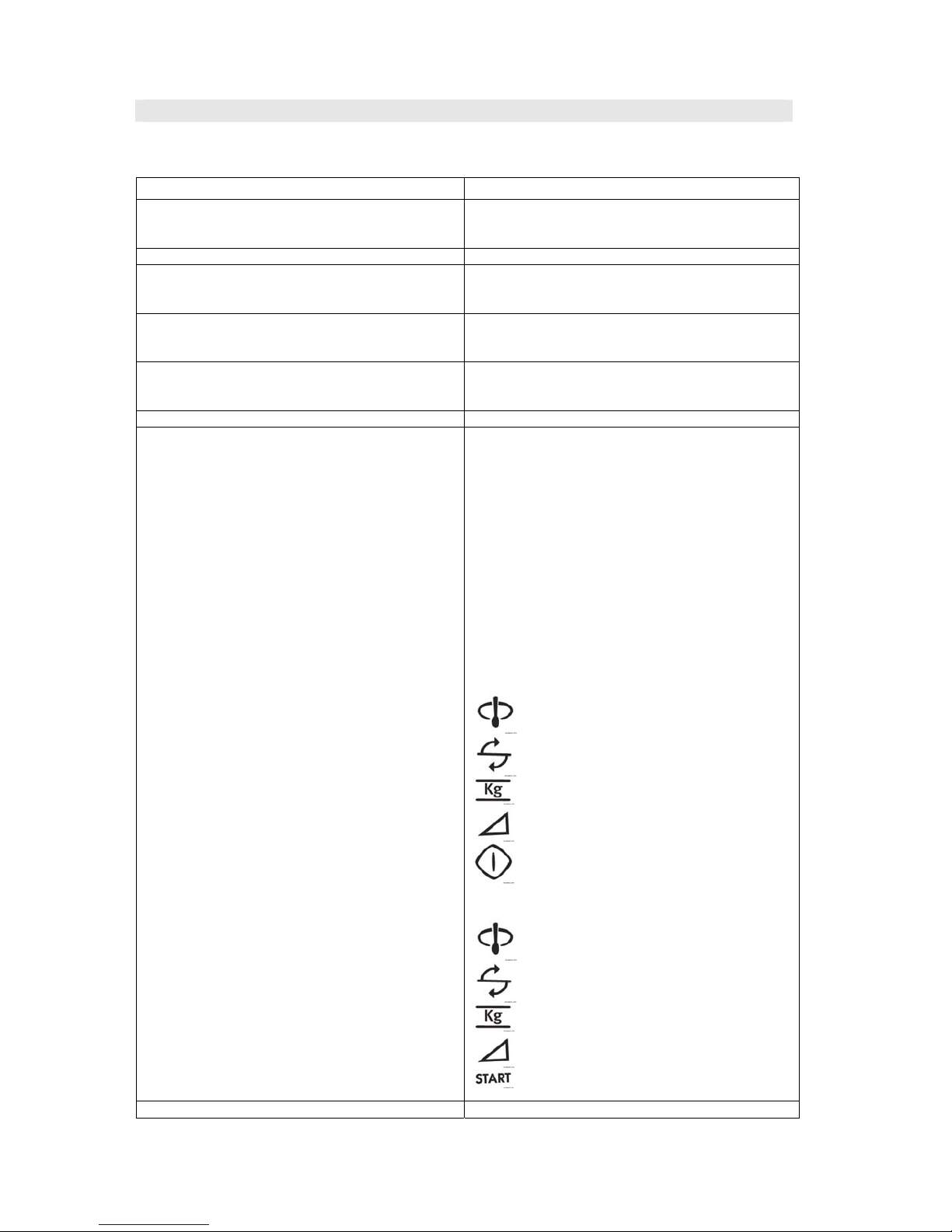

SPECIFICATION

ITEM DESCRIPTION

Power Requirements 230 Volts(EU)/230-240 Volts(UK)

50 Hertz

Single phase, 3 wire earthed

Power Consumption 1.2 kW

Power Output

800W watts nominal of RF microwave energy

(measured by way of IEC 60705)

Operating frequency of 2450 MHz

Case Dimensions

Width 454mm(including screws)

Height 357mm (including foot)

Depth 320mm

Cooking Cavity Dimensions

Width 285mm

Height 202mm

Depth 298mm

Turntable diameter 272mm

Jog/Touch Control System

Clock (1.00-12.59 or 0.00-23.59) - 12HR or 24HR

setting

Microwave Power for Variable Cooking

Repetition Rate;

HIGH .......................... Full power throughout

the cooking time

MEDIUM HIGH .......... approx. 70% of Full

Power

MEDIUM .................... approx. 50% of Full

Power

MEDIUM LOW............ approx. 30% of Full

Power

LOW .........................

approx. 10% of Full

Power

Stir

AUTOMATIC button

Turn over

MICROWAVE POWER

LEVEL button

Weight

STOP button

Microwave

power level

START/QUICK button

Cooking in

progress

TIMER/WEIGHT knob

Stir

AUTOMATIC button

Turn over

MICROWAVE POWER

LEVEL button

Weight

STOP button

Microwave

power level

START/ QUICK button

Control Complement

Cooking in

progress

TIMER/WEIGHT knob

Net weight Approx, 16kg

Page 7

SOI 01.05 FV 7/33 599 36 78-06

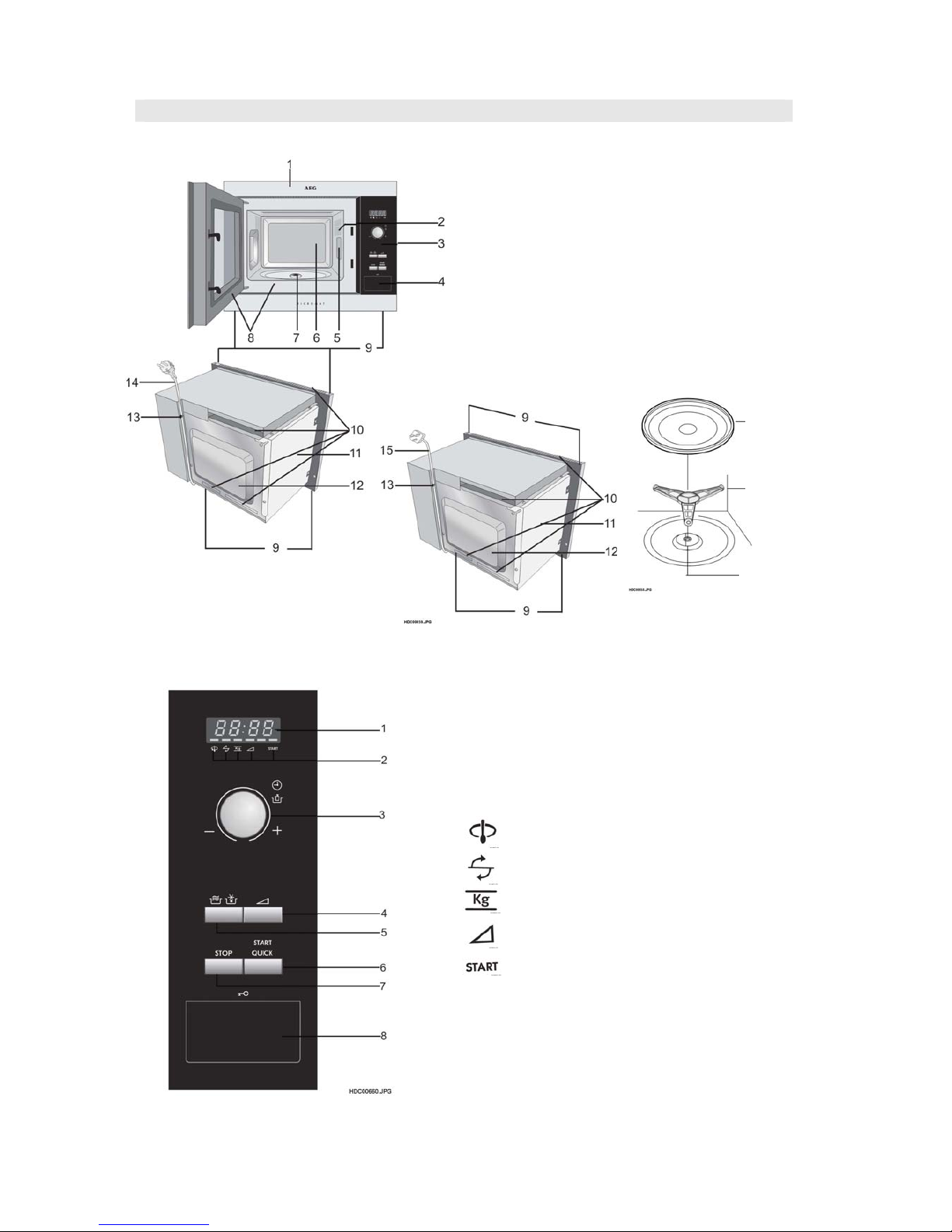

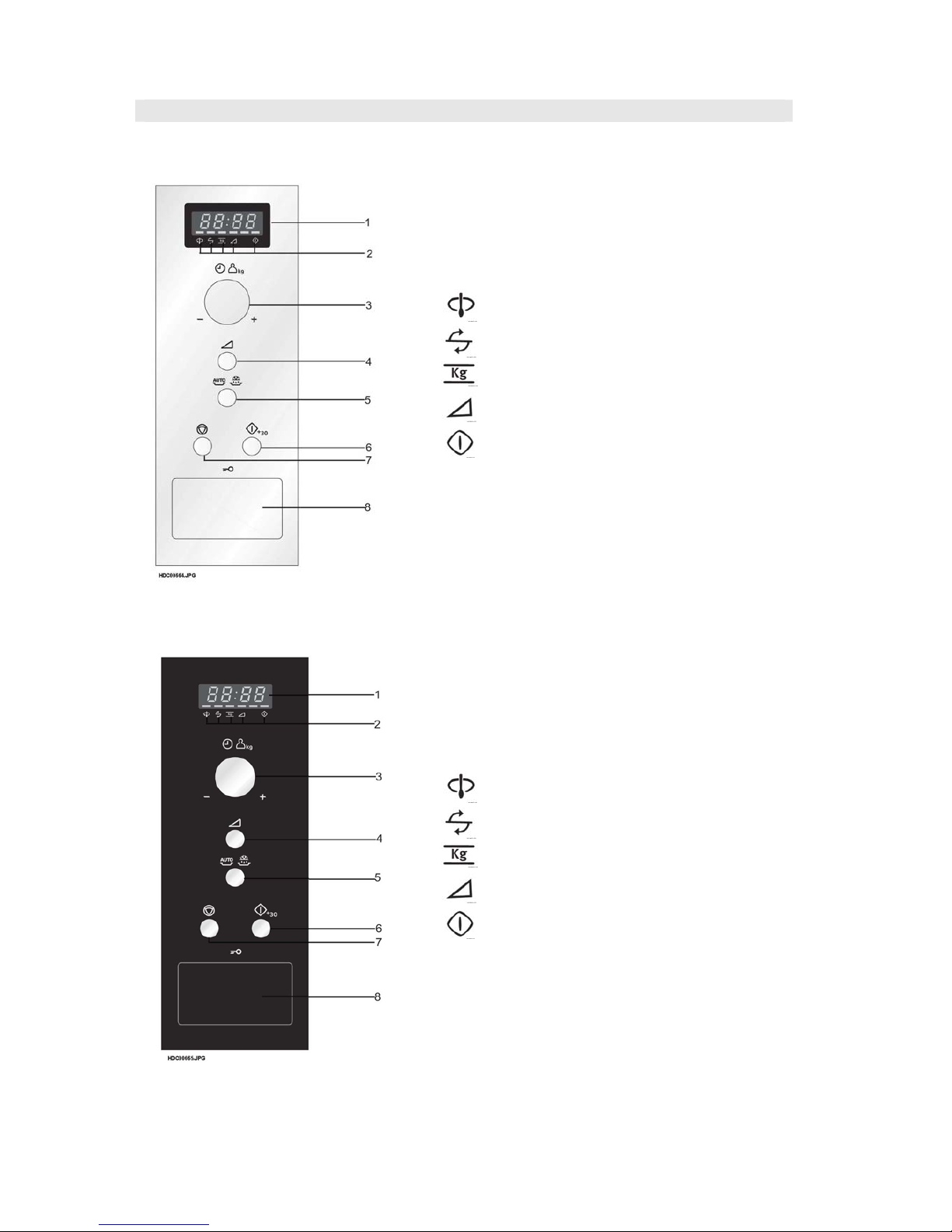

APPEARANCE VIEW

OVEN

1. Place the roller stay on the floor of

the oven cavity, engaging shaft into

turntable motor shaft.

2. Then place the turntable on roller

stay.

1 Digital Display

2 Indicators

The appropriate indicator will flash or light up,

just above each symbol according to the

instruction. When an indicator is flashing, press

the appropriate button (having the same symbol)

or carry out the necessary operation.

Stir

Turn oven

Weight

Microwave power level

Cooking in progress

3 TIMER/WEIGHT knob

4 MICROWAVE POWER LEVEL button

5 AUTOMATIC PROGRAMMES button

Press to select one of the 12 automatic programmes.

6 START/QUICK button

7 STOP button

8 DOOR OPEN button

Turntable

Roller stay

Seal packing

1 Front trim

2 Oven lamp

3 Control panel

4 Door opening button

5 Waveguide cover

6 Oven cavity

7 Seal packing

8 Door seals and sealing surfaces

9 Fixing points (4 points)

10 Ventilation openings

11 Outer cover

12 Rear cabinet

13 Power supply cord support clip

14 Power supply cord (EU)

15 Power supply cord (UK)

CONTROL PANEL

MC1751E/MC1761E/MOA4117

Page 8

SOI 01.05 FV 8/33 599 36 78-06

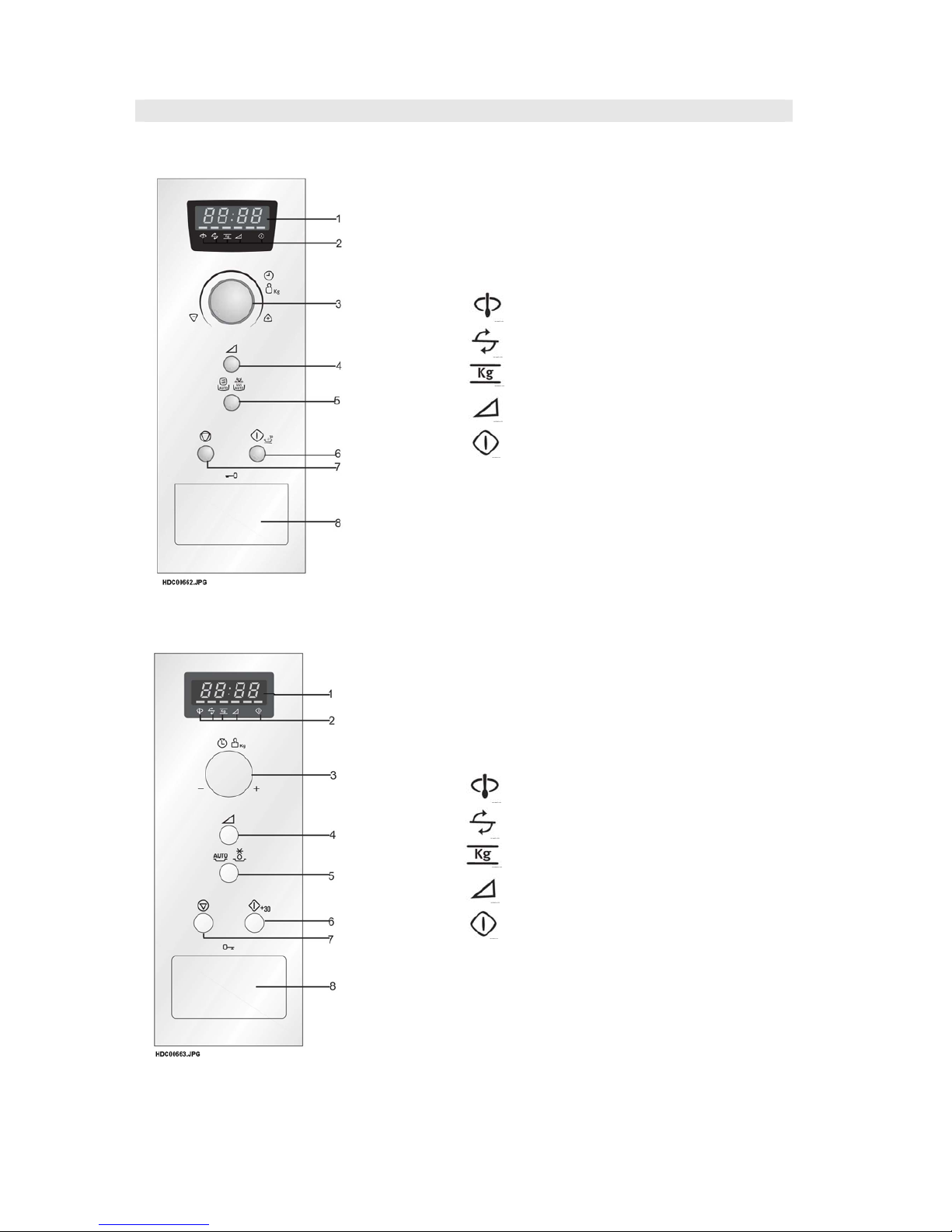

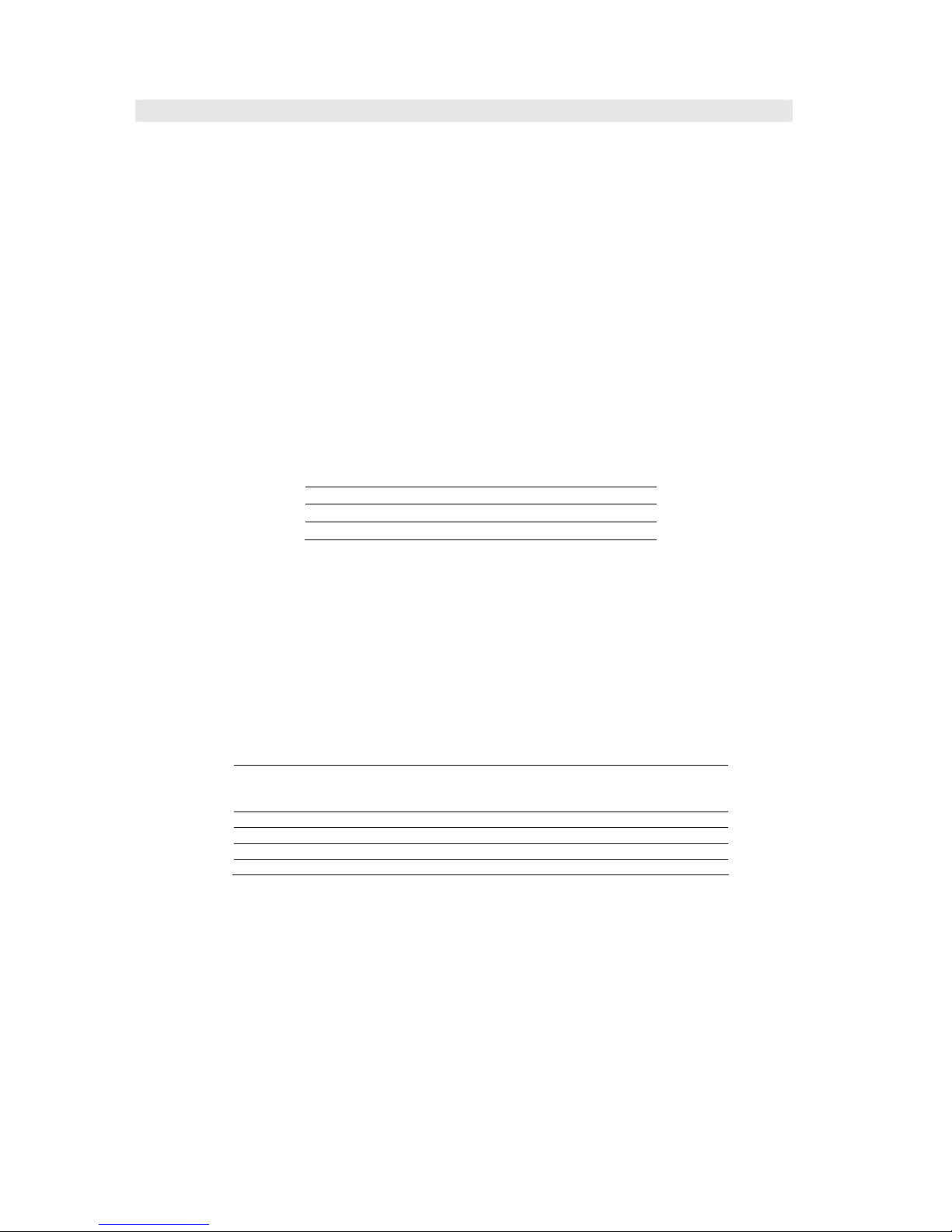

APPEARANCE VIEW

CONTROL PANEL

EMS1750X/EMS1760X

ZM175ST/ZM176ST

1 Digital Display

2 Indicators

The appropriate indicator will flash or light up,

just above each symbol according to the

instruction. When an indicator is flashing, press

the appropriate button (having the same symbol)

or carry out the necessary operation.

Stir

Turn oven

Weight

Microwave power level

Cooking in progress

3 TIMER/WEIGHT knob

4 MICROWAVE POWER LEVEL button

5 AUTOMATIC PROGRAMMES button

Press to select one of the 12 automatic programmes.

6 START/QUICK button

7 STOP button

8 DOOR OPEN button

1 Digital Display

2 Indicators

The appropriate indicator will flash or light up,

just above each symbol according to the

instruction. When an indicator is flashing, press

the appropriate button (having the same symbol)

or carry out the necessary operation.

Stir

Turn oven

Weight

Microwave power level

Cooking in progress

3 TIMER/WEIGHT knob

4 MICROWAVE POWER LEVEL button

5 AUTOMATIC PROGRAMMES button

Press to select one of the 12 automatic programmes.

6 START/QUICK button

7 STOP button

8 DOOR OPEN button

Page 9

SOI 01.05 FV 9/33 599 36 78-06

APPEARANCE VIEW

QN4025/QN4026

JMW1051/JMW1061

1 Digital Display

2 Indicators

The appropriate indicator will flash or light up,

just above each symbol according to the

instruction. When an indicator is flashing, press

the appropriate button (having the same symbol)

or carry out the necessary operation.

Stir

Turn oven

Weight

Microwave power level

Cooking in progress

3 TIMER/WEIGHT knob

4 MICROWAVE POWER LEVEL button

5 AUTOMATIC PROGRAMMES button

Press to select one of the 12 automatic programmes.

6 START/QUICK button

7 STOP button

8 DOOR OPEN button

1 Digital Display

2 Indicators

The appropriate indicator will flash or light up,

just above each symbol according to the

instruction. When an indicator is flashing, press

the appropriate button (having the same symbol)

or carry out the necessary operation.

Stir

Turn oven

Weight

Microwave power level

Cooking in progress

3 TIMER/WEIGHT knob

4 MICROWAVE POWER LEVEL button

5 AUTOMATIC PROGRAMMES button

Press to select one of the 12 automatic programmes.

6 START/QUICK button

7 STOP button

8 DOOR OPEN button

Page 10

SOI 01.05 FV 10/33 599 36 78-06

OPERATION SEQUENCE

MICROWAVE OFF CONDITION

Closing the door activates the door interlock switch (monitored latch switch).

IMPORTANT

When the oven door is closed, the monitor switch contacts COM - NC must be open.

When the microwave oven is plugged in a wall outlet (230V/ 230-240v 50Hz), the noise filter is energized.

Figure 0-1 on page 32

NOTE: When the oven door is opened, the oven lamp comes on at this time.

MICROWAVE COOKING CONDITION

HIGH COOKING

Enter a desired cooking time by rotating the time/weight knob

and start the oven by touching START pad.

Figure 0-2 on page 32

CONNECTED COMPONENTS RELAY

Oven lamp, Turntable motor RY1

Power transformer RY3

Fan motor RY4

1. The line voltage is supplied to the primary winding of the power transformer. The voltage is converted

to about 3.3 volts A.C. output on the filament winding and high voltage of approximately 2000 volts A.C.

on the secondary winding.

2. The filament winding voltage (3.3 volts) heats the magnetron filament and the high voltage (2000 volts)

is sent to the voltage doubling circuit, where it is doubled to negative voltage of approximately 4000 volts

D.C..

3. The 2450 MHz microwave energy produced in the magnetron generates a wave length of 12.24 cm.

This energy is channelled through the waveguide (transport channel) into the oven cavity, where the

food is placed to be cooked.

4. When the cooking time is up, a single tone is heard and the relays RY1 + RY3 + RY4 go back to their

home position. The circuits to the oven lamp, power transformer, fan motor and turntable motor are cut off.

5. When the door is opened during a cook cycle, the switches come to the following condition.

CONDITION

SWITCH

CONTACT

DURING

COOKING

DOOR OPEN

(NO COOKING)

Monitor switch COM-NC Open Closed

COM-NO Closed Open

Monitored latch switch COM-NO Closed Open

Stop switch COM-NO Closed Open

The circuits to the power transformer, fan motor and turntable motor are cut off when the monitored latch

switch is opened. The oven lamp remains on even if the oven door is opened after the cooking cycle has

been interrupted, because the relay RY1 stays closed. Shown in the display is the remaining time.

6. MONITOR SWITCH CIRCUIT

The monitor switch (SW2) is mechanically controlled by oven door, and monitors the operation of the

monitored latch switch (SW1)

6-1 When the oven door is opened during or after the cycle of a cooking program, the monitored latch

switch (SW1)and stop switch (SW3) must open their contacts(COM-NO) first. After that the contacts

(COM - NC) of the monitor switch (SW2) can be closed.

6-2 When the oven door is closed, the contacts (COM - NC) of the monitor switch (SW2) must be

opened first. The contacts (COM - NO) of the monitored latch switch (SW1) and stop switch (SW3)

are closed after.

6-3 When the oven door is opened and the contacts of the monitored latch switch (SW1) remain

closed, the fuse F1 will blow, because the monitor switch is closed and a short circuit is caused.

Page 11

SOI 01.05 FV 11/33 599 36 78-06

OPERATION SEQUENCE

HIGH, MEDIUM HIGH, MEDIUM, MEDIUM LOW, LOW COOKING

When the microwave oven is preset for variable cooking power, the line voltage is supplied to the power

transformer intermittently within a 32-second time base through the vary contact. The following levels of

microwave power are given.

SETTING

NOTE: The ON/OFF time ratio does not exactly correspond to the percentage of microwave power,

because approx. 3 seconds are needed for heating up the magnetron filament.

HIGH

MEDIUM HIGH

MEDIUM

MEDIUM LOW

LOW

Approx.

Approx.

Approx.

Approx.

Page 12

SOI 01.05 FV 12/33 599 36 78-06

FUNCTION OF IMPORTANT COMPONENTS

DOOR OPEN MECHANISM

The door can be opened by pushing the door open button.

MONITORED LATCH SWITCH (SW1)

1. When the oven door is closed, the contacts

(COM - NO) must be closed.

2. When the oven door is opened, the contacts

(COM - NO) must be opened.

MONITOR SWITCH (SW2)

1. When the oven door is closed, the contacts

(COM - NC) must be opened.

2. When the oven door is opened, the contacts

(COM - NC) must be closed.

3. If the oven door is opened and the contacts

(COM - NO) of the monitored latch switch

(SW1) fail to open, fuse F8A blows

simultaneously with closing the contacts

(COM - NC) of the monitor switch (SW2).

STOP SWITCH (SW3)

1. When the oven door is closed, the contacts

(COM - NO)must be closed.

Figure D-1. Door Open Mechanism

2. When the oven door is opened, the contacts (COM - NO) must be opened.

CAUTION: BEFORE REPLACING A BLOWN FUSE (F1) TEST THE MONITORED LATCH SWITCH

(SW1) AND MONITOR SWITCH (SW2) FOR PROPER OPERATION. (REFER TO

CHAPTER "TEST PROCEDURE".)

FUSE F1

1. The fuse F1 also blows when the H.V. rectifier, H.V. wire harness, H.V. capacitor, magnetron or

secondary winding of power transformer is shorted.

2. If the wire harness or electrical components are short-circuited, the fuse F1 blows to prevent an electric

shock or fire hazard.

THERMAL CUT-OUT 125°C TC01 (OVEN)

The thermal cut-out located on the top of the oven cavity is designed to prevent damage to the oven if the

foods in the oven catch fire due to over heating produced by improper setting of cook time or failure of control

unit. Under normal operation, the oven thermal cut-out remains closed. However, when abnormally high

temperatures are reached within the oven cavity, the oven thermal cut-out will open at

125°C, causing the oven to shut down. The defective thermal cut-out must be replaced with a new one.

THERMAL CUT-OUT 125°C TC02 (MG)

This thermal cut-out protects the magnetron against overheat.

If the temperature goes up higher than 125

°C because the fan motor is interrupted or the ventilation

openings are blocked, the thermal cut-out TC02 will open and line voltage to the high voltage transformer T

will cut off and operation of the magnetron MG will be stopped. The defective thermal cut-out must be

replaced with a new one.

TURNTABLE MOTOR

The turntable motor drives the turntable roller assembly to rotate the turntable.

FAN MOTOR

The fan motor drives a blade which draws external cool air.

This cool air is directed through the air vanes surrounding the magnetron and cools the magnetron. This air

flows through the oven cavity to remove steam and vapours given off from the heating foods. It is then vented

through the exhaust air vents at the rear of oven cavity.

NOISE FILTER

The noise filter prevents the radio frequency interference that might flow back in the power circuit.

Door

Latch hook

SW3: Stop switch

SW2: Monitor switch

SW1: Monitored latch switch

Latch heads

Page 13

SOI 01.05 FV 13/33 599 36 78-06

TROUBLESHOOTING CHART

When troubleshooting the microwave oven, it is helpful to follow the Sequence of Operation in performing the

checks. Many of the possible causes of trouble will require that a specific test be performed. These tests are

given a procedure letter which will be found in the “Test Procedure” section.

IMPORTANT: If the oven becomes inoperative because of a blown fuse F1. Check the monitored latch

switch and monitor switch before replacing the F8A fuse.

TEST PROCEDURE

A

B C

D E E E F F G H I I J J K L M

CONDITION

PROBLEM

MAGNETRON

HIGH VOLTAGE TRANSFORMER

H.V. RECTIFIER ASSY

H.V. HARNESS

HIGH VOLTAGE CAPACITOR

MONITORED LATCH SWITCH

STOP SWITCH

MONITOR SWITCH

MAG THERMAL CUT-OUT 125°C

THERMAL CUT-OUT 125°C (OVEN)

FUSE F1

NOISE FILTER

TURNTABLE MOTOR

FAN MOTOR

TC TRANSFORMER

CONTROL UNIT

SWITCH UNIT

RELAY RY1,3,4

FOIL PATTERN ON P.W.B.

POWER SUPPLY CORD

SHORTED WIRE HARNESS

OPENED WIRE HARNESS

OVEN LAMP

BLOCKED VENTILATION OPENINGS

WRONG OPERATION

MIS-ADJUSTMENT OF SWITCHES

HOME FUSE OR BREAKER

NO POWER AT WALL OUTLET

BLOKED COOLING FAN

Home fuse blows when power cord is

plugged into wall outlet.

● ●

●

"88:88"does not operate in display

when power cord is plugged into wall

outlet.

● ● ●

● ●

● ● ●

● ●

Display does not operate properly

when STOP button is touched.

●

● ●

●

Oven lamp does not light, when door

is opened. (Display operates).

●

● ●

● ● ●

OFF

CONDITION

Oven does not start when START

button is touched.(Display operates).

●

● ● ●

●

●

Fan motor does not operate (Oven

lamp lights).

● ● ●

●

●

Turntable motor assembly does not

operate (Oven lamp lights).

●

● ●

●

Oven or electrical parts does not stop

when timer knob is at "0" or STOP

button is touched.

●

● ●

●

●

Display operates properly but all

electrical parts do not operate.

● ●

●

Oven goes into cook cycle but shuts

down before end of cooking cycle.

●

● ●

● ●

●

● ●

Oven seems to be operating but little

or no heat is produced in oven load

(Microwave power control is set at

HIGH).

● ● ● ● ● ● ● ● ●

● ●

●

●

Oven does not seem to be operating

properly during variable cooking

condition(Oven operates properly at

HIGH).

● ●

COOKING

CONDITION

Fuse F8A blows (F1)

● ● ● ● ●

● ● ●

●

●

Page 14

SOI 01.05 FV 14/33 599 36 78-06

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

A

MAGNETRON TEST

NEVER TOUCH ANY PART IN THE CIRCUIT WITH YOUR HAND OR AN INSULATED

TOOL WHILE THE OVEN IS IN OPERATION.

CARRY OUT 3D CHECK

Isolate the magnetron from high voltage circuit by removing all leads connected to the

filament terminal.

To test for an open circuit filament use an ohmmeter to make a continuity test between

the magnetron filament terminals, the meter should show a reading of less than 1 ohm.

To test for a short circuit filament to anode condition, connect ohmmeter between one

of the filament terminals and the case of the magnetron (ground). This test should be

indicated an infinite resistance.

If a low or zero resistance reading is obtained then the magnetron should be replaced.

MICROWAVE OUTPUT POWER (IEC-60705-1988)

The following test procedure should be carried out with the microwave oven in a fully

assembled condition (outer case fitted). Microwave output power from the magnetron

can be measured by way of IEC 60705. To measure the microwave output power in the

microwave oven, the relation of calorie and

watt is used. When P(W) heating works for t(second), approximately

P x t/4.187 calorie is generated. On the other hand, if the temperature of the water with

V(ml) rises ∆T (°C) during this microwave heating period, the calorie of the water is V x

∆T.

The formula is as follows;

P x t / 4.187 = V x ∆ T P (W) = 4.187 x V x ∆T / t

Our condition for water load is as follows:

Room temperature..............around 20°C

Power supply Voltage.........Rated voltage

Water load.........1000 g

Initial temperature...........10 ± 2°C

Heating time....52 + 3 = 55 sec.

P = 80 x ∆T

Measuring condition:

1. Container

The water container must be a cylindrical borosilicate glass vessel having a

maximum material thickness of 3 mm and an outside diameter of approximately 190

mm.

2. Temperature of the oven and vessel

The oven and the empty vessel are at ambient temperature prior to the start of

the test.

3. Temperature of the water

The initial temperature of the water is (10 ± 2)°C.

4. Select the initial and final water temperature so that the maximum difference

between the final water temperature and the ambient temperature is 5K.

5. Select stirring devices and measuring instruments in order to minimize addition or

removal of heat.

6. The graduation of the thermometer must be scaled by 0.1°C at minimum and an

accurate thermometer.

7. The water load must be (1000 ± 5) g.

8. “t” is measured while the microwave generator is operating at full power.

Magnetron filament heat-up time is not included.

TEST PROCEDURES

Page 15

SOI 01.05 FV 15/33 599 36 78-06

PROCEDURE

LETTER

COMPONENT TEST

NOTE: The operation time of the microwave oven is “t + 3” sec. 3 seconds are

needed for magnetron filament heat-up time.

Measuring method:

1. Measure the initial temperature of the water before the water is added to the

vessel.

(Example: The initial temperature T1 = 11°C)

2. Add the 1 litre water to the vessel.

3. Place the load on the centre of the turntable.

4. Operate the microwave oven at HIGH for the temperature of the water rises

by a value ∆ T of (10 ± 2) K.

5. Stir the water to equalize temperature throughout the vessel.

6. Measure the final water temperature. (Example: The final temperature

T2 = 21°C)

7. Calculate the microwave power output P in watts from above formula.

Initial temperature T1 = 11°C

Temperature after (52+ 3) = 55 sec.................................................... T2 = 21°C

Temperature difference Cold-Warm................................................. ∆T1 = 10°C

Measured output power

The equation is “P = 80 x ∆T” ................................... P = 80 x 10°C = 800Watts

JUDGEMENT: The measured output power should be at least

± 15 % of

the rated output power.

CAUTION: 1°C CORRESPONDS TO 80 WATTS. REPEAT MEASUREMENT

IF THE POWER IS INSUFFICIENT.

B

POWER TRANSFORMER TEST

WARNING: High voltages and large currents are present at the

secondary winding and filament winding of the power

transformer. It is very dangerous to work near this part when

the oven is on. NEVER make any voltage measurements of

the high-voltage circuits, including the magnetron filament.

CARRY OUT 3D CHECKS

Disconnect the leads to the primary winding of the power transformer.

Disconnect the filament and secondary winding connections from the rest of

the HV circuitry. Using an ohmmeter, set on a low range, it is possible to check

the continuity of all three windings. The following readings should be

obtained:-

a. Primary winding ............ 2 ohms approximately

b. Secondary winding ....... 160 ohms approximately

c. Filament winding ........... less than 1 ohm

If the reading obtained are not as stated above, then the power transformer is

probably faulty and should be replaced.

CARRY OUT 4R CHECKS

TEST PROCEDURES

Heat up for 55 sec.

Page 16

SOI 01.05 FV 16/33 599 36 78-06

PROCEDURE

LETTER

COMPONENT TEST

C

HIGH VOLTAGE RECTIFIER ASSEMBLY TEST

CARRY OUT 3D CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The high voltage

rectifier can be tested using an ohmmeter set to its highest range. Connect the

ohmmeter across the terminal B+C of the high voltage rectifier and note the

reading obtained. Reverse the meter leads and note this second reading.

The normal resistance is infinite in one direction and more than 100 kΩ in the

other direction.

CARRY OUT 4R

CHECKS

ASYMMETRIC RECTIFIER TEST

CARRY OUT 3D

CHECKS.

Isolate the high voltage rectifier assembly from the HV circuit. The asymmetric

rectifier can be tested using an ohmmeter set to its highest range across the

terminals A+B of the asymmetric rectifier and note the reading obtained.

Reverse the meter leads and note this second reading. If an open circuit is

indicated in both direction then the asymmetric rectifier is good. If an

asymmetric rectifier is shorted in either direction, then the asymmetric rectifier

is probably faulty and must be replaced. When the asymmetric rectifier is

defective, check whether magnetron, high voltage rectifier, high voltage wire or

filament winding of the power transformer is shorted.

CARRY OUT 4R CHECKS

NOTE: FOR MEASUREMENT OF THE RESISTANCE OF THE RECTIFIER,

THE BATTERIES OF THE MEASURING INSTRUMENT MUST HAVE

A VOLTAGE OF AT LEAST 6 VOLTS, BECAUSE OTHERWISE AN

INFINITE RESISTANCE MIGHT BE SHOWN IN BOTH

DIRECTIONS.

D

HIGH VOLTAGE CAPACITOR TEST

CARRY OUT 3D CHECKS

A. Isolate the high voltage capacitor from the circuit.

B. Continuity check must be carried out with measuring instrument which is set

to the highest resistance range.

C. A normal capacitor shows continuity for a short time (kick) and then a

resistance of about 10 MΩ after it has been charged.

D. A short-circuited capacitor shows continuity all the time.

E. An open capacitor constantly shows a resistance about 10 MΩ because of

its internal 10 MΩ resistance.

F. When the internal wire is opened in the high voltage capacitor, the

capacitor shows an infinite resistance.

G. The resistance across all the terminals and the chassis must be infinite

when the capacitor is normal.

If incorrect reading are obtained, the high voltage capacitor must be replaced.

CARRY OUT 4R CHECKS

HIGH VOLTAGE

RECTIFIER

ASYMMETRIC

RECTIFIER

Page 17

SOI 01.05 FV 17/33 599 36 78-06

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

E

SWITCH TEST

CARRY OUT 3D CHECKS.

Isolate the switch to be tested and using an ohmmeter check between the

terminals as described in the following table.

Table: Terminal Connection of Switch

Plunger Operation COM to NO COM to NC COM; Common terminal

Released Open circuit Short circuit NO; Normally open terminal

Depressed Short circuit Open Circuit NC; Normally close terminal

If incorrect readings are obtained, replace the switch.

CARRY OUT 4R CHECKS.

F

THERMAL CUT OUT TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the terminals of the thermal cut-out. Then using an

ohmmeter, make a continuity test across the two terminals as described in the

below.

CARRY OUT 4R CHECKS

Table: Thermal Cut-out Test

Parts Name

Temperature of

"ON" condition

(closed circuit).

(°C)

Temperature of

"OFF" condition

(open circuit).

(°C)

Indication of

ohmmeter

(When room

temperature is

approx. 20°C.)

Thermal cut-out

125°C TC01

This is not

reset able type

Above 125°C Closed circuit

Thermal cut-out

125°C TC02

This is not

reset able type

Above 125°C Closed circuit

If incorrect readings are obtained, replace the thermal cut-out.

An open circuit thermal cut-out (MG) TC02 indicates that the magnetron has

overheated, this may be due to restricted ventilation, cooling fan failure.

An open circuit thermal cut-out (OVEN) TC01 indicates that the oven cavity

has overheated, this may be due to no load operation.

G

BLOWN FUSE F8A (F1)

CARRY OUT 3D CHECKS

If the fuse F8A (F1) is blown when the door is opened, check the primary

latch switch, monitor switch and monitor resistor.

If the fuse F8A (F1) is blown by incorrect door switching replace the

defective switch(es) and the fuse F8A (F1).

CARRY OUT 4R CHECKS

CAUTION: Only replace fuse with the correct value replacement.

Page 18

SOI 01.05 FV 18/33 599 36 78-06

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

H

NOISE FILTER TEST

CARRY OUT 3D CHECKS

Disconnect the leads from the

terminals of the noise filter.

Using an ohmmeter, check between

the terminals as described in the

following table.

MEASURING POINTS INDICATION OF OHMMETER

Between N and L Open circuit

Between terminal N and WHITE Short circuit

Between terminal L and RED Short circuit

If Incorrect readings are obtained, replace the noise filter unit.

CARRY OUT 4R CHECKS

I

MOTOR WINDING TEST

CARRY OUT 3D CHECKS.

Disconnect the leads from the motor. Using an ohmmeter, check the

resistance between the two terminals as described in the table below.

Table: Resistance of Motor

Motors Resistance

Fan motor

Approximately 290 Ω

Turntable motor

Approximately 12 - 15 kΩ

If incorrect readings are obtained, replace the motor.

CARRY OUT 4R CHECKS.

LIVE TEST FOR MOTOR WINDING

CAUTION: The following procedure requires the oven to be connected

to the supply and should only be used if the relevant "cold"

checks for the motor under test are inconclusive.

1. CARRY OUT 3D CHECKS.

2. Disconnect the leads from the primary of the high voltage transformer. Make

sure that the leads remain isolated from other oven components and

chassis (Use insulation tape if necessary) (See the pictorial diagram

page 33).

3. Connect the voltmeter, set to 250V AC, across the motor terminals. (Refer

to the relevant motor test procedure or pictorial diagram for the correct

terminal numbers.)

4. Arrange the meter in a position where it can be read during the test.

(Do not touch the meter, meter leads or oven circuitry while the oven is

active.)

5. Close the oven door.

6. Set the power level to 800W and set the relevant timer for about three (3)

minutes.

7. Note the reading on the meter and carefully observe the motor under test to

see if it is turning.

8. CARRY OUT 3D CHECKS.

9. Remove the test meter leads.

10.Reconnect the leads to the primary of the high voltage transformer.

Page 19

SOI 01.05 FV 19/33 599 36 78-06

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

If a reading of the line voltage was obtained (step 7) but the motor was not

turning then it is faulty and should be replaced. If the meter indicated that the

no supply was present then the winding to the motor should be checked for

continuity or other circuit checks should be made, i.e. relays, switches.

J

TOUCH CONTROL PANEL ASSEMBLY TEST

The touch control panel consists of circuits including semiconductors such as

LSI, ICs, etc. Therefore, unlike conventional microwave ovens, proper

maintenance can not be performed with only a voltmeter and ohmmeter.

In this service manual, the touch control panel assembly is in three units,

Control unit, Switch Unit, and LED Unit. Troubleshooting by unit replacement is

described according to the symptoms indicated.

Control Panel.

The following symptoms indicate a defective control unit.

1. Switch Unit. NOTE: Check switch unit lead wire harness connection

before replacement.

The following symptoms indicate a defective switch unit. Replace the

switch unit.

a) When touching the keys, a certain key produces no signal at all.

b) When touching a key, two figures or more are displayed.

c) When touching the keys, sometimes a key produces no signal.

2. Control Unit

The following symptoms indicate a defective control unit. Replace the

control unit, perform the switch unit test(Procedure K) to determine if

control unit is faulty.

2-1 In connection with keys.

a) When touching a key, a certain group of keys do not produce a signal.

b) When touching a key, no keys produce a signal.

2-2.In connection with indicators.

a) At a certain digit, all or some dots do not light up.

b) At a certain digit, brightness is low.

c) Only one indicator does not light up.

d) The corresponding dots of all digits do not light up; or they continue to

light up.

e) Wrong figure appears.

f) A certain group of indicators do not light up.

g) The figure of all digits flicker.

h) When touching a tact switch, the control unit does not respond.

2-3.Other possible problems caused by defective control unit.

a) Buzzer does not sound or continues to sound.

b) Clock does not operate properly.

c) Cooking is not possible.

3. LED Unit

a) No backlight behind display.

b) Dull backlight behind display.

Page 20

SOI 01.05 FV 20/33 599 36 78-06

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

K

SWITCH UNIT TEST

If the display fails to clear when the STOP key is depressed, first verify the

lead wire harness is marking good contact, verify that the stop switch

operates properly; that is the contacts are closed when the door is closed and

open when the door is open. If the stop switch is good, disconnect the lead

wire harness that connects the switch unit to the control unit and make sure

the stop switch is closed (either close the door or short the stop switch

connecter). Use the switch unit matrix indicated on the switch unit circuit and

place a jumper wire between the pins that correspond to the STOP key

making momentary contact. If the control unit responds by clearing with a

beep the switch unit is faulty and must be replaced. If the control unit does not

respond, it is a faulty and must be replaced. If a specific key does not

respond, the above method may be used (after clearing the control unit) to

determine if the control unit or switch unit is at fault.

MC1751E/

Mc1761E/

MOA4117

EMS1750X/EMS1760X/

ZM175ST/ZM176ST/

QN4025/QN4026/

JMW1051/JMW1061

SW

USAGE USAGE

1

Start/Quick Start/Quick

2

Not Used Not Used

3

Stop Stop

4

Power Level Not Used

5

Not Used Auto Programs

6

Auto Programs Not Used

7

Not Used Not Used

8

Not Used Power Level

9

Not Used Not Used

L

RELAY TEST

Remove the outer case and check voltage between Pin No 1and Pin No 3 of the 3

pin connector (A) on the control unit with an A.C. voltmeter.

The meter should indicate rated voltage, if not check oven circuit.

RY1,RY3 and RY4 Relay Test

These relays are operated by D.C. voltage

Check voltage at the relay coil with a D.C. voltmeter during the microwave cooking

operation.

DC. voltage indicated ............. Defective relay.

DC. voltage not indicated ....... Check diode which is connected to the relay

coil. If diode is good, control unit is defective.

RELAY SYMBOL OPERATIONAL VOLTAGE CONNECTED COMPONENTS

RY1 Approx. 12.0V D.C. Oven lamp / Turntable motor

RY3 Approx. 12.0V D.C. High voltage transformer

RY4 Approx. 12.0V D.C. Fan motor

Page 21

SOI 01.05 FV 21/33 599 36 78-06

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

M

PROCEDURES TO BE TAKEN WHEN THE FOIL PATTERN ON THE

PRINTED

WIRING BOARD (PWB) IS OPEN

To protect the electronic circuits, this model is provided with a fine foil pattern

added to the input circuit on the PWB, this foil pattern acts as a fuse. If the foil

pattern is open, follow the troubleshooting guide given below for repair.

Problem: POWER ON, indicator does not light up.

STEPS OCCURRENCE CAUSE OR CORRECTION

1 The rated AC voltage is not

present between Pin No. 5-1 of the

3 pin connector (A)

Check supply voltage and oven power

cord.

2 The rated AC voltage is not

present at primary side of low

voltage transformer.

Low voltage transformer or secondary

circuit defective.

check and repair.

3 Pattern at "a" and "b" are broken. *Insert jumper wire J1 and solder.

(CARRY OUT 3D CHECKS BEFORE

REPAIR)

4 Pattern at "c" and "d" are broken. *Insert the coil code 5028 24 08-00/9

between "c" and "d

(CARRY OUT 3D CHECKS BEFORE

REPAIR)

NOTE: *At the time of making these

repairs, make a visual

inspection of the varistor.

Check for burned damage. If

any abnormal condition is

detected, replace the

defective parts.

CARRY OUT 4D CHECKS

Page 22

SOI 01.05 FV 22/33 599 36 78-06

CONTROL PANEL ASSEMBLY

OUTLINE OF CONTROL PANEL

The touch control section consists of the following units as shown in the touch control panel circuit.

(1) Switch Unit

(2) Control Unit

(3) LED Unit

The principal functions of these units and the signals communicated among them are explained below.

Switch Unit

The switch unit is composed of a matrix, signals generated in the LSI are sent to the switch unit

through P22, P23 and P24.

When a switch button is touched, a signal is completed through the switch unit and passed back to the

LSI through P50 and P51 to perform the function that was requested.

Control Unit

Control unit consists of LSI, power source circuit, relay circuit, back light circuit, synchronizing signal

circuit, reset circuit, buzzer circuit, and indicator circuit.

1) LSI

This LSI controls the tact switch strobe signal, relay driving signal, for oven function and

indicator signal.

2) Power Source Circuit

This circuit generates voltage necessary in the control unit.

Symbol Voltage Application

VC -5.0V LSI(IC1)

3) Synchronizing Signal Circuit

The power source synchronizing signal is available in order to compose a basic standard time in

the clock circuit. It accompanies a very small error because it works on commercial frequency.

4) ACL Circuit

A circuit to generate a signals which resets the LSI to the initial state when power is supplied.

5) Buzzer Circuit

The buzzer is responsive to signals from the LSI to emit audible sounds (tact switch touch sound

and completion sound).

6) Stop Switch

A switch to "tell" the LSI if the door is open or closed.

7) Relay Circuit

To drive the magnetron, fan motor, turntable motor, light the oven lamp.

8) Indicator Circuit

This circuit consists of 4-digits, 12-segments and 3-common electrodes using a Liquid Crystal

Display.

9) Encoder

The encoder converts the signal generated by LSI into the pulse signal, and the pulse signal is

returned to the LSI.

10) Back Light Circuit

A circuit to drive the back light (Light emitting diodes LD1 - LD3).

LED Unit

A circuit consisting of three light emitting diodes (LD1- LD3)which are driven by the control unit

and provide the backlight for the display.

Page 23

SOI 01.05 FV 23/33 599 36 78-06

SERVICING

1. Precautions for Handling Electronic

Components

This unit uses CMOS LSI in the integral part of the

circuits. When handling these parts, the following

precautions should be strictly followed. CMOS LSI

have extremely high impedance at its input and

output terminals. For this reason, it is easily

influenced by the surrounding high voltage power

source, static electricity charge in clothes,

etc. and sometimes it is not fully protected by the

built-in protection circuit.

In order to protect CMOS LSI.

1) When storing and transporting, thoroughly wrap

them in aluminium foil. Also wrap all PW boards

containing them in aluminium foil.

2) When soldering, ground the technician as

shown in the figure and use grounded soldering

iron and work table.

2. Servicing of Touch Control Panel

We describe the procedures to permit servicing

of the touch control panel of the microwave

oven and the precautions you must take when

doing so. To perform the servicing, power to the

touch control panel is available either from the

power line of the oven itself or from an external

power source.

(1) Servicing the touch control panel with

power line of the oven:

CAUTION:

THE HIGH VOLTAGE TRANSFORMER OF THE

MICROWAVE OVEN IS STILL LIVE DURING

SERVICING AND PRESENTS A HAZARD.

Therefore, before checking the performance of

the touch control panel,

1) Disconnect the power supply cord, and then

remove outer case.

2) Open the door and block it open.

3) Discharge high voltage capacitor.

4) Disconnect the leads to the primary of the

power transformer.

5) Ensure that these leads remain isolated from

other components and oven chassis by using

insulation tape.

6) After that procedure, re-connect the power

supply cord.

After checking the performance of the touch

control panel,

1) Disconnect the power supply cord.

2) Open the door and block it open.

3) Re-connect the leads to the primary of the

power transformer.

4) Re-install the outer case (cabinet).

5) Re-connect the power supply cord after the

outer case is installed.

6) Run the oven and check all functions.

A. On some models, the power supply cord

between the touch control panel and the oven

itself is so short that the two can’t be separated.

For those models, check and repair all the

controls (sensor-related ones included) of

the touch control panel while keeping it

connected to the oven.

B. On some models, the power supply cord

between the touch control panel and the oven is

long enough that they may be separated from

each other. For those models, it is possible to

check and repair the controls of the touch

control panel while keeping it apart from the

oven; in this case you must short both ends of

the door sensing switch (on PWB) of the touch

control panel with a jumper, which activates an

operational state that is equivalent to the oven

door being closed.

(2) Servicing the touch control panel with

power supply from an external power

source:

Disconnect the touch control panel completely

from the oven, and short both ends of the door

sensing switch (SW3: STOP SWITC on PWB)

of the touch control panel, which activates an

operational state that is equivalent to the oven

door being closed. Connect an external power

source to the power input terminal of the touch

control panel, then it is possible to check and

repair the controls of the touch control panel.

3. Servicing Tools

Tools required to service the touch control panel

assembly.

1) Soldering iron: 30W

(It is recommended to use a soldering iron with

a grounding terminal.)

2) Others: Hand tools

4. Other Precautions

1) Before turning on the power source of the

control unit, remove the aluminium foil applied

for preventing static electricity.

2) Connect the connectors of the key unit to the

control unit being sure that the lead wires are

not twisted.

3) After aluminium foil is removed, be careful that

abnormal voltage due to static electricity etc. is

not applied to the input or output terminals.

4) Attach connectors, electrolytic capacitors, etc.

to PWB, making sure that all connections are

tight.

5) Be sure to use specified components where

high precision is required.

approx. 1 M ohm

Page 24

SOI 01.05 FV 24/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

WARNING: Avoid possible exposure to microwave energy. Please follow the instructions

below before operating the oven.

1. CARRY OUT 3D CHECKS.

2. Make sure that a definite "click" can be heard

when the microwave oven door is unlatched.

(Hold the door in a closed position, then

push the open button slowly. This causes

the latch heads to rise, it is then possible to

hear a "click" as the door switches operate.)

3. Visually check the door and cavity face plate

for damage (dents, cracks, signs of arcing

etc.).

Carry out any remedial work that is necessary

before operating the oven.

Do not operate the oven if any of the following

conditions exist;

1. Door does not close firmly.

2. Door hinges or latch hook is damaged.

3. The door seal is damaged.

4. The door is bent or warped.

5. There are defective parts in the door interlock

system.

6. There are defective parts in the microwave

generating and transmission assembly.

7. There is visible damage to the oven.

Do not operate the oven:

1. Without the RF gasket (Magnetron).

2. If the wave guide or oven cavity are not intact.

3. If the door is not closed.

4. If the outer case (cabinet) is not fitted.

Please refer to ‘OVEN PARTS, CABINET PARTS, DOOR PARTS’, when carrying out any of the

following removal procedures:

BUILT IN FRAME ASSEMBLY REMOVAL

To remove the built in frame assembly, proceed

as follows.

1. Remove the four screws securing the frame

assembly to the oven cavity, (two from the

top and two from the hinge side).

2. Remove the two screws securing the frame

assembly to the control panel frame

(accessed from the back of the frame).

3. Open the oven door fully.

4. Push down the built in frame assembly at

the bottom, where it meets the cavity face.

5. Pull the built in frame assembly away from the

cavity face

6. Now the built in frame assembly is free.

OUTER CASE REMOVAL

6. Slide the entire case back about 3cm to free it from

the retailing clips on the cavity face plate.

7. Lift the entire case from the oven.

8. Discharge the H.V capacitor before carrying any

further work.

9. Do not operate the oven with the outer case

removed.

To remove the outer case, proceed as follows.

1. Disconnect oven from power supply.

2. Open door and wedge open.

3. Remove the two screws from the rear

intake duct.

4. Slide the rear intake duct up and pull it

away from the oven cavity.

5. Remove the screws from the rear(4), along

the side edges(4 hinge side, 3 control panel

side) and from the top(2 control panel side).

CAUTION: DISCHARGE HIGH VOLTAGE

CAPACITOR BEFORE TOUCHING ANY

OVEN COMPONENTS OR WIRING.

TOP

SCREWS

C.P. SECURING

SCREWS

HINGE SEDE

SCREWS

PRESS

HERE

Page 25

SOI 01.05 FV 25/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

HIGH VOLTAGE COMPONENTS REMOVAL

(HIGH VOLTAGE CAPACITOR AND HIGH VOLTAGE RECTIFIER ASSEMBLY)

To remove the components, proceed as

follows.

1. CARRY OUT 3D CHECKS

2. Disconnect all the leads and terminal of high

voltage rectifier from high voltage capacitor.

3. Remove one (1) screw holding earth side

terminal of high voltage rectifier, and remove

capacitor holder from the base plate.

4. Remove the capacitor from the capacitor

holder.

5. Now the high voltage rectifier and capacitor

should be free.

CAUTION: WHEN REPLACING HIGH

VOLTAGE RECTIFIER ASSEMBLY,

ENSURE THAT THE CATHODE

(EARTH) CONNECTION IS

SECURELY FIXED TO THE

CAPACITOR HOLDER AND

BASEPLATE WITH AN EARTHING

SCREW.

HIGH VOLTAGE TRANSFORMER REMOVAL

1. CARRY OUT 3D CHECKS

2. Disconnect the filament leads of the power

transformer from high voltage capacitor and the

magnetron.

3. Disconnect the H.V. secondary wire from the

power transformer.

4. Remove the four (4) screws holding the

transformer to base plate (from the under side).

5. Remove the transformer from the baseplate by

sliding it away from the oven cavity and lifting it.

6. Now, the power transformer is free.

MAGNETRON REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the H.V. wire B and filament lead of

the transformer from the magnetron.

3. Move the air intake duct to left.

4. Carefully remove two (2) screws holding

magnetron to the waveguide.

5. Remove the magnetron from the waveguide with

care so the magnetron antenna is not hit by any

metal object around the antenna.

CAUTION: WHEN REPLACING THE MAGNETRON,

BE SURE THE R.F. GASKET IS IN

PLACE AND THE MAGNETRON

MOUNTING SCREWS ARE TIGHTENED

SECURELY. REINSTALL THE

MAGNETRON TO WAVE GUIDE

FLANGE WITH THE TWO (2) SCREWS

DIAGONALLY.

ENSURE THE MAGNETRON WIRING IS

REFITTED IN ACCORDANCE WITH

THE PICTORIAL DIAGRAM ON PAGE

33 (FA AND F).

CONTROL PANEL ASSEMBLY REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the main wire harness from the

control panel.

3. Remove the one (1) screw holding the control

panel to the oven cavity.

4. Lift the control panel assembly and pull it

forward. Now, the control panel assembly is

free.

TURNTABLE MOTOR REMOVAL

1. Disconnect the oven from the power supply.

2. Remove the turntable motor cover by snipping

off the material in four corners.

3. Where the corners have been snipped off bent

corner areas flat. No sharp edge must be

evident after removal of turntable motor cover.

4. Disconnect the wire leads from the turntable

motor and remove the one (1) screw holding the

turntable motor.

5. Turntable motor is now free.

6. After replacement use one (1) screw to fit the

turntable motor cover.(code 5028 05 76-00/5).

Page 26

SOI 01.05 FV 26/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

FAN MOTOR REPLACEMENT

REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire leads from the fan

motor.

3. Remove the two (2) screws holding the fan

motor to the oven cavity back plate. The fan

motor is now free.

4. Remove the fan blade from the fan motor

shaft according

to the following procedure.

1) Hold the edge of the rotor of the fan motor by

using a pair of groove joint pliers.

CAUTION:

• Make sure that any pieces do not enter the

gap between the rotor and the stator of

the fan motor.

Because the rotor is easy to be shaven by

pliers and metal pieces may be produced.

• Do not let the pliers touch the coil of the

fan motor because the coil may be cut or

damaged.

• Do not distort the bracket by touching with

the pliers.

2) Remove the fan blade from the shaft of the

fan motor by pulling and rotating the fan

blade with your hand.

3) Now, the fan blade will be free.

CAUTION:

• Do not use this removed fan blade again.

Because the hole (for shaft) of it may

become bigger than a standard one.

INSTALLATION

1. Install the fan blade to the fan motor shaft according

to the following procedure.

1) Hold the centre of the bracket which supports the

shaft of the fan motor on a flat table.

2) Install the fan blade to the shaft of fan motor by

pushing the fan blade with a small, light weight,

ball peen hammer or rubber mallet.

CAUTION:

• Do not hit the fan blade when installing

because the bracket may be deformed.

• Make sure that the fan blade rotates smoothly

after installation.

• Make sure that the axis of the shaft is not

slanted.

2. Install the fan motor to the oven cavity back plate

with the two (2) screws.

3. Re-connect the wire leads to the fan motor,

referring to the pictorial diagram.

Groove joint pliers

Coil

Stator

Gap

Bracket

Rotor

Rear view

Shaft

A

xis

Stator

Rotor

These are the position

that should be pinched

with pliers

Side view

Shaft

Table

Center o

f

bracket

Page 27

SOI 01.05 FV 27/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

OVEN LAMP REMUVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire lead from the oven lamp

3. Lift up the oven lamp from the clips of the air

intake duct.

4. Now, the oven lamp is free.

POWER SUPPLY CORD REPLACEMENT

Removal

1. CARRY OUT 3D CHECKS.

2. Remove the wiring of the main harness from the

noise filter.

3. Remove the two (2)screws securing the N.F.U.

holder to the baseplate.

4. Remove the one(1) screw holding the

green/yellow (earth wire) to the N.F.U. holder

assembly.

5. Release the power supply cord stopper from the

N.F.U. holder assembly by sliding it out.

6. Remove the wiring of the power cord from the

noise filter.

7. Now the power supply cord is free.

Re-install

1. Insert the moulding cord stopper of power

supply cord into the cut-out of the N.F.U. holder

assembly, referring to the Figure C-1(b).

Installation of Power supply cord.

2. Install the earth wire lead of power supply cord

to the N.F.U. holder assembly with one (1)

screw and tighten.

3. Connect the brown and blue wire leads of

power supply cord to the noise filter correctly,

referring to the Pictorial Diagram.C-1(a)

4. Re-fit the N.F.U. holder assembly to the base

plate with the two (2) screws.

5. Connect the main harness wiring to the noise

filter correctly, referring to the Pictorial

Diagram(figure C - 1(a)).

Figure C-1 (a) Replacement of Power Supply Cord

Figure C-1 (b). Installation of Power Supply

Cord

Socket

Bulb

Lock

Oven lamp

Noise filte

r

Power supply cord

Moulded

Cord

Stopper

Green / Yellow

Wire

Noise filter holder

Blue Wire

Brown Wire

POWER SUPPLY

CORD

MOULDING

CORD

STOPPER

GROMMET

MOULDING

Page 28

SOI 01.05 FV 28/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

MONITORED LATCH SWITCH, MONITOR SWITCH AND

STOP SWITCH REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire leads from the switches

and control panel.

3. Remove the control panel assembly from the

oven cavity front flange. Referring to chapter

"CONTROL PANEL ASSEMBLY

REMOVAL".

4. Remove the one (1) screw holding the latch

hook to the oven flange.

5. Remove the latch hook assembly from the

oven flange.

6. To remove the switch.

6-1. With pushing outward on the tab that is

holding the switch, turn the switch so that the

post is an axis.(Monitor Switch).

With pushing outward on the tab that is

holding the switch, slide the switch out of the

latch hook.(Stop Switch and Monitored Latch

switch).

6-2. Pull out the switch from the latch hook. Do

not break the post or tab of the latch hook.

6-3. Now the switch is free.

Re-install

1. Re-install each switch in its place. The

monitored latch switch is in the lower

position and the monitor switch is

in the middle position. The stop switch is in

the upper position.

2. Re-connect wire leads to each switch. Refer

to charter “Pictorial Diagram”.(page 32)

3. Secure latch hook (with one (1) mounting

screw) to oven.

flange.

4. Re-install the control panel assembly to the oven

cavity front flange.

5. Re-connect wire leads to the control unit. Refer to

chapter “Pictorial Diagram”.(page 33).

6. Make sure that monitor switch is operating properly

and check continuity of the monitor circuit. Refer to

chapter “Test Procedure”, and Adjustment

Procedure below.

Figure C-2. Latch Switches Removal

MONITORED LATCH SWITCH, MONITOR SWITCH AND

STOP SWITCH ADJUSTMENT

1. CARRY OUT 3D CHECKS.

If the monitored latch switch, stop switch and

monitor switch do not operate properly due

to a misadjustment, the following adjustment

should be made.

2. Loosen the one (1) screw holding the latch

hook to the flange of the oven front face.

3. With the door closed, adjust latch hook by

moving it up and down. In and out play of

the door allowed by the upper and lower

position of the latch hook should be less

than 0.5mm. The vertical position of the

latch hook should be adjusted so that the

stop switch and the monitored latch switch

are activated with the door closed.

4. Secure the screws firmly.

5. Check the operation of all switches. If each

switch has not activated with the door

closed, loosen screw and ad just the latch

hook position.

After adjustment, make sure of the

following.

1. In and out play of the door remains less than

0.5mm when in the latched position.

2. The monitored latch switch and stop switch

interrupt the circuit before the door can be

opened.

3. The monitor switch contacts (COM-NC) close

when the door is opened.

4. Re-install outer case and check for microwave

leakage around the door with an approved

microwave survey meter. (Refer to Microwave

Measurement Procedure.)

Figure C-3. Latch Switch Adjustments

Latch hook

SW3:Stop switch

Tab

Tab

SW2:Monitor switch

SW1:Monitored latch switch

Tab

Door

Latch hook

SW3: Stop switch

SW2: Monitor switch

SW1: Monitored latch

switch

Latch heads

Page 29

SOI 01.05 FV 29/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

REMOVAL

1. Disconnect the power supply cord.

2. Open the door slightly and remove the built in

frame assembly(Ref: to chapter built in frame

assembly removal).

3. Remove the choke cover taking care not to

break clips by inserting an iron plate (thickness

of about 0.5mm) or flat type screw driver to the

gap between the choke cover and door panel

as shown Figure C-4 to free the engaged

parts.

4. Release choke cover from door panel.

5. Now choke cover is free.

Figure C-4. Door Disassembly

6. Release two (2) pins of door panel from two (2)

holes of upper and lower oven hinges by lifting

up.

7. Remove door assy by removing screws (4).

8. Release door panel from tabs of door frame and

remove door frame.

9. Now, door panel with inner sealer film is free.

10.Tear inner sealer film from door panel.

11.Now, door panel is free.

12.Slide latch head upward and remove it from

door frame with releasing latch spring from door

frame and latch head.

13.Now, latch head and latch spring are free.

RE-INSTALL

1. Re-install latch spring to the head. Re-install

latch spring to the door frame. Re-install latch

head to the door frame.

2. Re-install door panel to door frame by fitting tabs

of door frame to holes of door panel.

3. Put sealer film on door panel. Refer to “Inner

Sealer Film” and figure C-6, on how to handle

the new film.

4. Catch two (2) pins of door panel on two (2) hole

of upper and lower oven hinges.

5. Re-install choke cover to door panel by pushing.

Note: After any service to the door;

(A) Make sure that monitored latch switch, stop

switch and monitor switch are operating

properly. (Refer to chapter “Test

Procedures , Switch Test page 17”.).

(B) An approved microwave survey meter

should be used to assure compliance with

proper microwave radiation emission

limitation standards.

After any service, make sure of the following :

1. Door latch heads smoothly catch latch hook

through latch holes and that latch head goes

through center of latch hole.

2. Deviation of door alignment from horizontal line

of cavity face plate is to be less than 1.0mm.

3. Door is positioned with its face pressed toward

cavity face plate.

4. Check for microwave leakage around door with

an approved microwave survey meter. (Refer to

Microwave Measurement Procedure.)

Note: The door on a microwave oven is

designed to act as an electronic seal

preventing the leakage of microwave

energy from oven cavity during

cook cycle. This function does not require

the door be air-tight, moisture

(condensation)-tight or light-tight.

Therefore, occasional appearance

of moisture, light or sensing of gentle

warm air movement around oven door is

not abnormal and does not indicate

leakage of microwave energy from the

oven cavity.

Figure C-5. Door Replacement

NOTE: When carrying out any repair to the

door, do not bend or warp the slit

choke (tabs on the door panel

assembly) to prevent microwave

leakage.

Choke Cover

Putty Knife

Door Frame

PIN

UPPER

OVEN HINGE

DOOR SUB

ASSEMBLY

DOOR

PANEL

SLIT CHOCHE

CHOKE COVER

LOWER

OVEN

HINGE

LOWER

OVEN HINGE

Page 30

SOI 01.05 FV 30/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

INNER SEALER FILM

Installation

1. Tear away the backing film.

3. Put the pasted side of the inner sealer film

on the door panel.

Figure C-6. Inner Sealer Film

MICROWAVE MEASUREMENT

After adjustment of door latch switches, monitor

switch and door are completed individually or

collectively, the following leakage test must be

performed with a survey instrument and it must be

confirmed that the result meets the requirements

of the performance standard for microwave oven.

REQUIREMENT

The safety switch must prevent microwave

radiation emission in excess of 5mW/cm2 at any

point 5 cm or more from external surface of the

oven.

PREPARATION FOR TESTING:

Before beginning the actual test for leakage,

proceed as follows;

1. Make sure that the test instrument is operating

normally as specified in its instruction booklet.

Important:

Survey instruments that comply with the

requirement for instrumentations as prescribed

by the performance standard for microwave

ovens must be used for testing.

Recommended instruments are:

NARDA 8100

NARDA 8200

HOLADAY HI 1500

SIMPSON 380M

2. Place the oven tray into the oven cavity.

3. Place the load of 275 ± 15ml of water initially at

20 ± 5°C in the center of the oven tray. The

water container should be a low form of 600 ml

beaker with inside diameter of approx. 8.5cm

and made of an electrically non-conductive

material such as glass or plastic.

The placing of this standard load in the oven is

important not only to protect the oven, but also

to insure that any leakage is measured

accurately.

4. Close the door and turn the oven ON with the

timer set for several minutes. If the water begins

to boil before the survey is completed, replace it

with 275ml of cool water.

5. Move the probe slowly (not faster that

2.5cm/sec.) along the gap.

6. The microwave radiation emission should be

measured at any point of 5cm or more from the

external surface of the oven.

Finger tab

Door film

Backing film

Microwave leakage measurement at 5 cm distance

Page 31

SOI 01.05 FV 31/33 599 36 78-06

TEST DATA AT A GLANCE

Parts Symbol Value / Data

Thermal cut-out (OVEN) TC01 125°C

Oven lamp OL 240-250V 25W

High voltage capacitor C 0.91µF AC 2100V(EU)

0.88µF AC 2100V(UK)

Magnetron MG

Filament < 1

Ω

Filament – chassis

∞ ohm.

Power transformer T

Filament winding < 1

Ω

Secondary winding Approx. 160

Ω.

Primary winding Approx. 2

Ω.

Fuse F1 F8A 250V

thermal cut-out(Magnetron) TC02 125°C

WIRING/RE-WIRING

WARNING: WIRING / RE-WIRING.

Before carrying out any work; carry out 3D

checks.

1. Disconnect the supply

2. Door opened and wedge open.

3. Discharge the high voltage capacitor.

RE-WIRING.

Ensure the following:

1. Wires must not touch:

a) High voltage parts.

(Magnetron, high voltage transformer, high

voltage capacitor and high voltage rectifier).

b) Parts that become hot.

(Heating elements, oven lamp, oven cavity

magnetron and high voltage transformer).

c) Sharp edges.

(Bottom plates, oven cavity, waveguide

flange, chassis support and other metallic

parts).

d) Movable parts.

( Fan blade, any motor, switch).

2. Positive lock connectors are fitted correctly.

Ensure the locking pin is located correctly.

3. Wires are connected correctly as per pictorial

diagram.

4. No wire leads are trapped by the outer wrap.

Page 32

SOI 01.05 FV 32/33 599 36 78-06

SCHEMATIC DIAGRAMS

Figure 0-1 Oven Schematic-OFF Condition, Door Closed.

Figure 0-2 Oven Schematic-ON Condition, Door Closed.

* INDICATES COMPONENTS WITH

POTENTIAL ABOVE 250V

OVEN THERMAL

CUT- OUT 125°C

MAGNETRON

THERMAL

CUT- OUT 125°C

HIGH VOLTAGE

TRANSFORMER

CAPACITOR

RECTIFIER

MONITO

R

SWITCH

MONITORED

LATCH SWITCH

STOP SWITCH

OVEN LAMP

FAN MOTOR

TURNTABLE

MOTO

R

TRANSFORMER T/C

NOISE SUPRESSION COIL

NIOSE FILTER

OVEN THERMAL

CUT- OUT 125°C

MAGNETRON

THERMAL

CUT- OUT 125°C

HIGH VOLTAGE

TRANSFORMER

CAPACITOR

RECTIFIER

MONITO

R

SWITCH

MONITORED

LATCH SWITCH

STOP SWITCH

OVEN LAMP

FAN MOTOR

TURNTABLE

MOTO

R

TRANSFORMER T/C

NOISE SUPRESSION COIL

NIOSE FILTER

Page 33

SOI 01.05 FV 33/33 599 36 78-06

PICTORIAL DIAGRAMS

CONTROL UNIT

MONITORED LATCH SWITCH

MONITOR SWITCH

STOP SWITCH

MAG.

THERMAL

CUTOUT

OVEN

THERMAL

CUTOUT

NOISE FILTER UNIT

OVEN LAMP

HIGH VOLTAGE COMPONENTS

SHORT

PROCTETOR

HV CAPACITOR

HV

RECTIFIER

POWER TRANSFORMER

TURNTABLE MOTOR

SWITCH UNIT

LED BOARD

MAINS SUPPLY CORD

FAN MOTO

R

FA

Loading...

Loading...