Copyright 2013 ELECTROLUX HOME PRODUCTS PTY LTD Technical Services

ELECTROLUX HOME PRODUCTS PTY LTD

ABN 51 004 762 341

KELVINATOR

SPLIT SYSTEM

AIR-CONDITIONER

MODEL:

KSV26HRC

PNC: 950132910

KSV35HRC

PNC: 950132911

Issue: 2

Technical Publication Nº KSSSI113 Date: 01/13

DIAGNOSTIC MANUAL

Release Date: September 2011

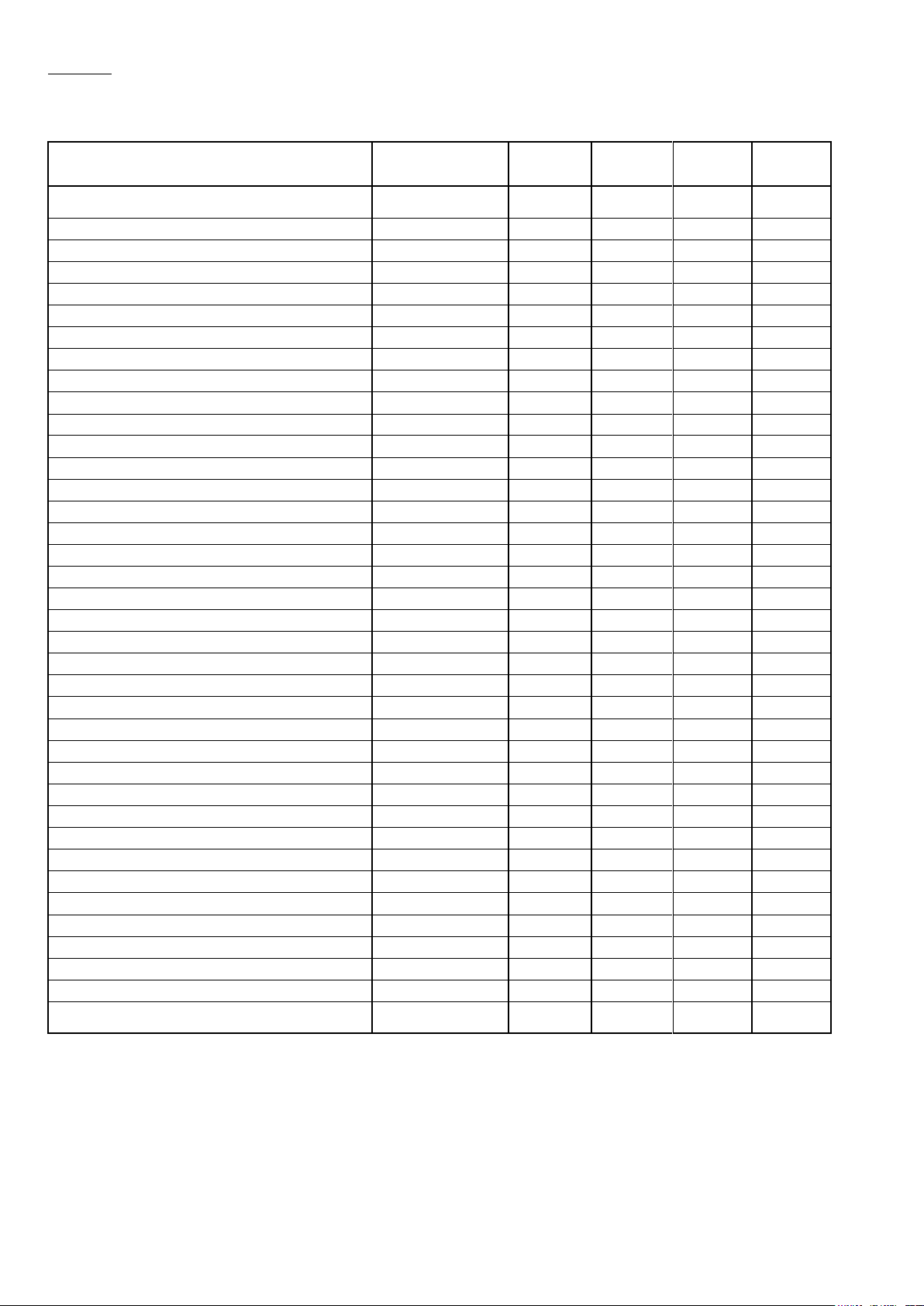

Index:

Description – (Indoor)

Indoor Display

Code

Standby

LED

Heating

LED

Cooling

LED

Page Nº

Safe Electrical Working Practices

4

Positive Lock Terminals

4

Capacitor Discharge

5

Led Flash Code Sequence Description

6 & 7

Not Operating

8 & 9

Diagnostic Display Mode Description

10

Wiring Diagram (Indoor & Outdoor)

29 to 31

Jumper Cap Malfunction

C5

Flash-15

27

DRED (Compressor Off)

D1

12

DRED (Output Capacity-50%)

D2

12

DRED (Output Capacity-75%)

D3

12

Anti-Freeze Protection

E2

Flash-2

12

Refrigeration System Blocked/Gas Leak

E3

Flash-3

28

Compressor High Temp Protection

E4

Flash-4

10

AC-Over Current Protection

E5

Flash-5

10

Communications Fault

E6

Flash-6

15 to 18

Anti-High Temperature Protection

E8

Flash-8

11

Loading EEPROM Malfunction

EE

Flash-15

14

Sensor, Room Temperature (Indoor)

F1

Flash-1

23

Sensor, Tube Temperature (Indoor)

F2

Flash-2

23

Sensor, Ambient (Outdoor)

F3

Flash-3

22

Sensor, Coil (Outdoor)

F4

Flash-4

22

Sensor, Compressor Discharge (Outdoor)

F5

Flash-5

22

Anti-High Temperature Protection

F6

Flash-6

12

Anti-Freeze Limit, Frequency Drop

FH

Flash-2

Flash-2

12

Defrosting

H1

Flash-1

11

Compressor Overload Protection

H3

Flash-3

26

IPM Protection

H5

Flash-5

19 to 21

Fan Stall, Indoor Unit

H6

Flash-11

24

PFC Protection

HC

Flash-6

11

Outdoor DC Fan Motor Malfunction

L3

Flash-23

25

Indoor & Outdoor Units Don’t Match

LP

Flash-23

27

Compressor Rated Frequency-Test State

P1

13

Compressor Maximum Frequency-Test State

P2

13

Compressor Medium Frequency-Test State

P3

13

High Voltage Protection

PH

11

Low Voltage Protection

PL

11

Compressor Minimum Frequency-Test State

PO

13

Page 2 KSSSI113

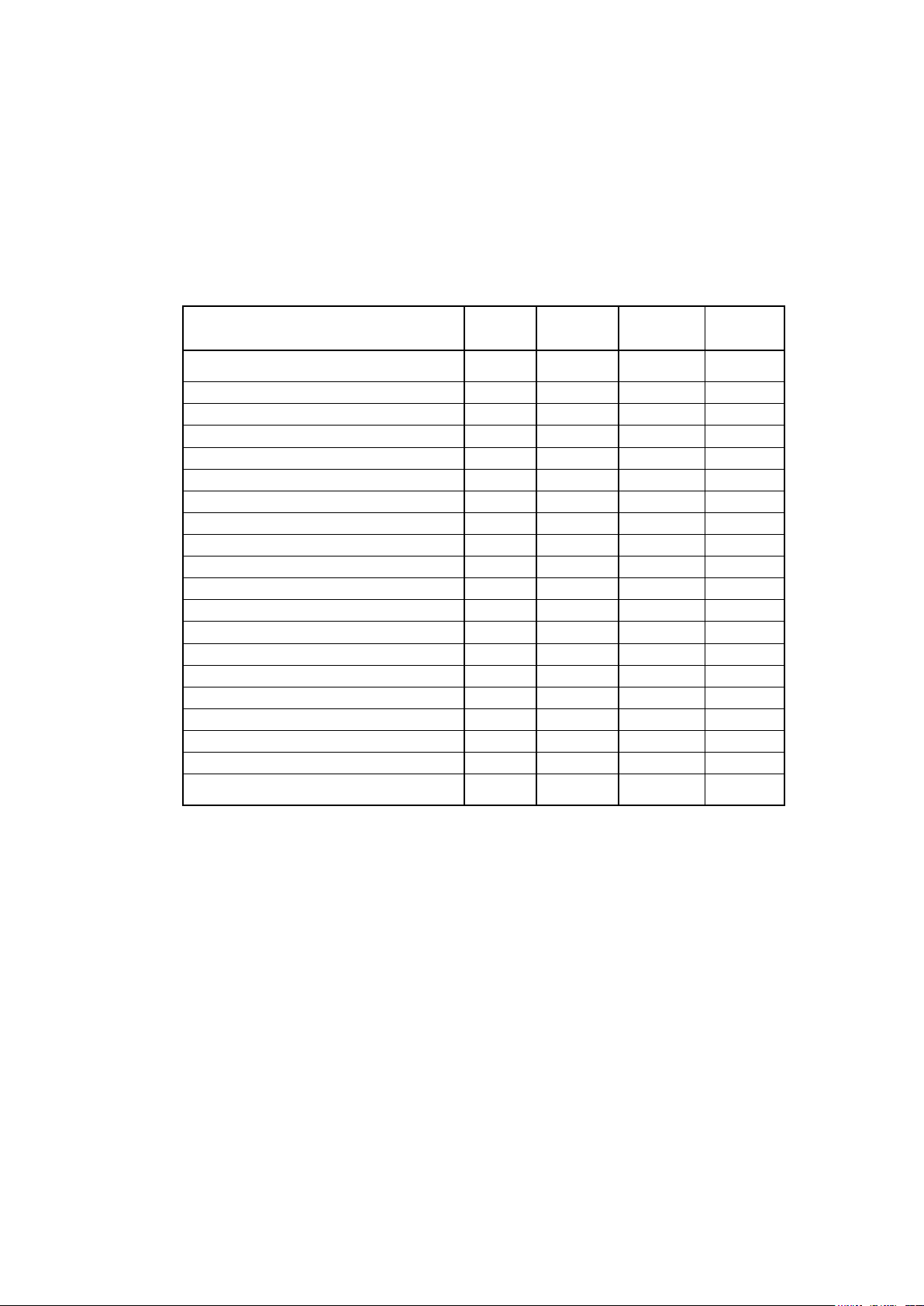

Description – (Outdoor)

Green

LED

Red

LED

Yellow

LED

Page Nº

Normal Communication

Flash-1

7

Normal Operation

Flash-8

7 Normal Operation

Flash-0.5

7

Defrosting

Flash-2

11

Frequency Limit

Flash-1

10

Anti-High Temperature Protection

Flash-3

11

Low Voltage Protection

Flash-12

11

High Voltage Protection

Flash-13

11

Anti-Freeze Protection

Flash-3

12

Anti-Freeze Limit, Frequency Drop

Flash-4

12

Anti-High Temperature Protection

Flash-4

12

Communications Fault

Off

15 to 18

IPM Protection

Flash-4

19 to 21

Loading EEPROM Malfunction

Flash-11

14

Sensor, Ambient (Outdoor)

Flash-5

22

Sensor, Coil (Outdoor)

Flash-6

22

Sensor, Comp Discharge (Outdoor)

Flash-7

22

High Temperature Prevention

Flash-3

Flash-6

24

Outdoor DC Fan Motor Malfunction

Flash-14

25

Compressor Overload Protection

Flash-8

26

Page 3 KSSSI113

Positive Lock Terminal arrangement.

Safe Electrical Working Practices

Remove Power cord, Fuse or Switch off the circuit breaker.

Always check appliance with multimeter to ensure the supply power is disconnected.

Use only insulated tools & equipment.

Wear insulated shoes.

No water on the floor or working space.

Reduce the amount of exposed skin, by covering your arms and legs.

Remove jewellery (Rings, Watches etc).

It is essential that you conform to all “Working Live” and “Risk Management” statutory

requirements.

Positive Lock Terminals

The indoor & outdoor PCB’s are fitted with “Positive Lock Terminals”.

To remove Positive Lock Terminals: Push the lever forward & lightly pull down on the terminal.

Note: When reconnecting the Positive Lock Terminal, connect it so that the lever faces towards the front

of the unit.

Page 4 KSSSI113

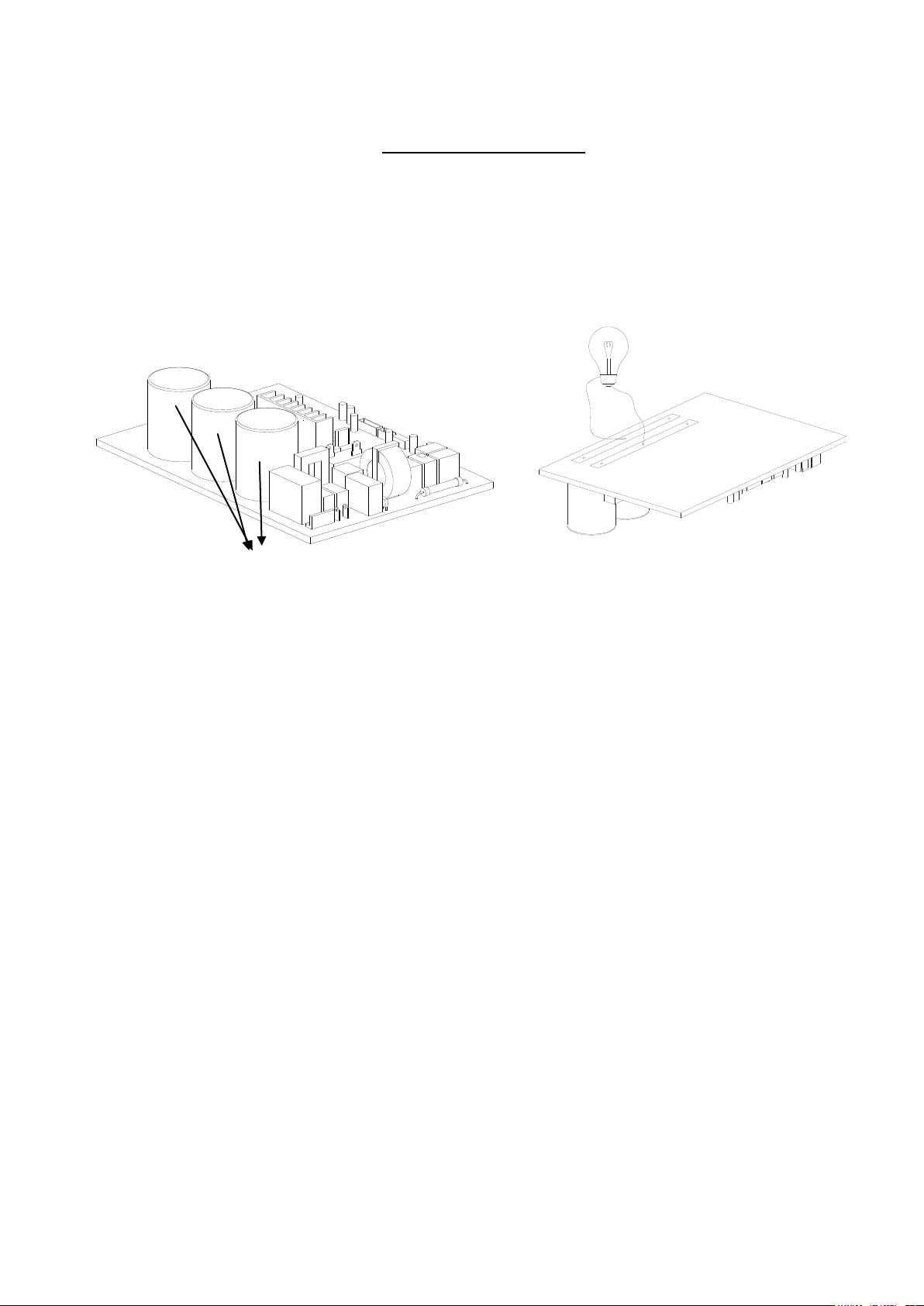

Capacitor Discharge

Discharge the capacitors located on the outdoor main PCB assembly.

Note: Even if the power supply has been disconnected, high voltage power can be stored in these

capacitors.

Discharge the capacitors with the use of a 25 or 40-Watt incandescent globe. As illustrated below.

Electrolytic Capacitors Bulb (25-40W)

Page 5 KSSSI113

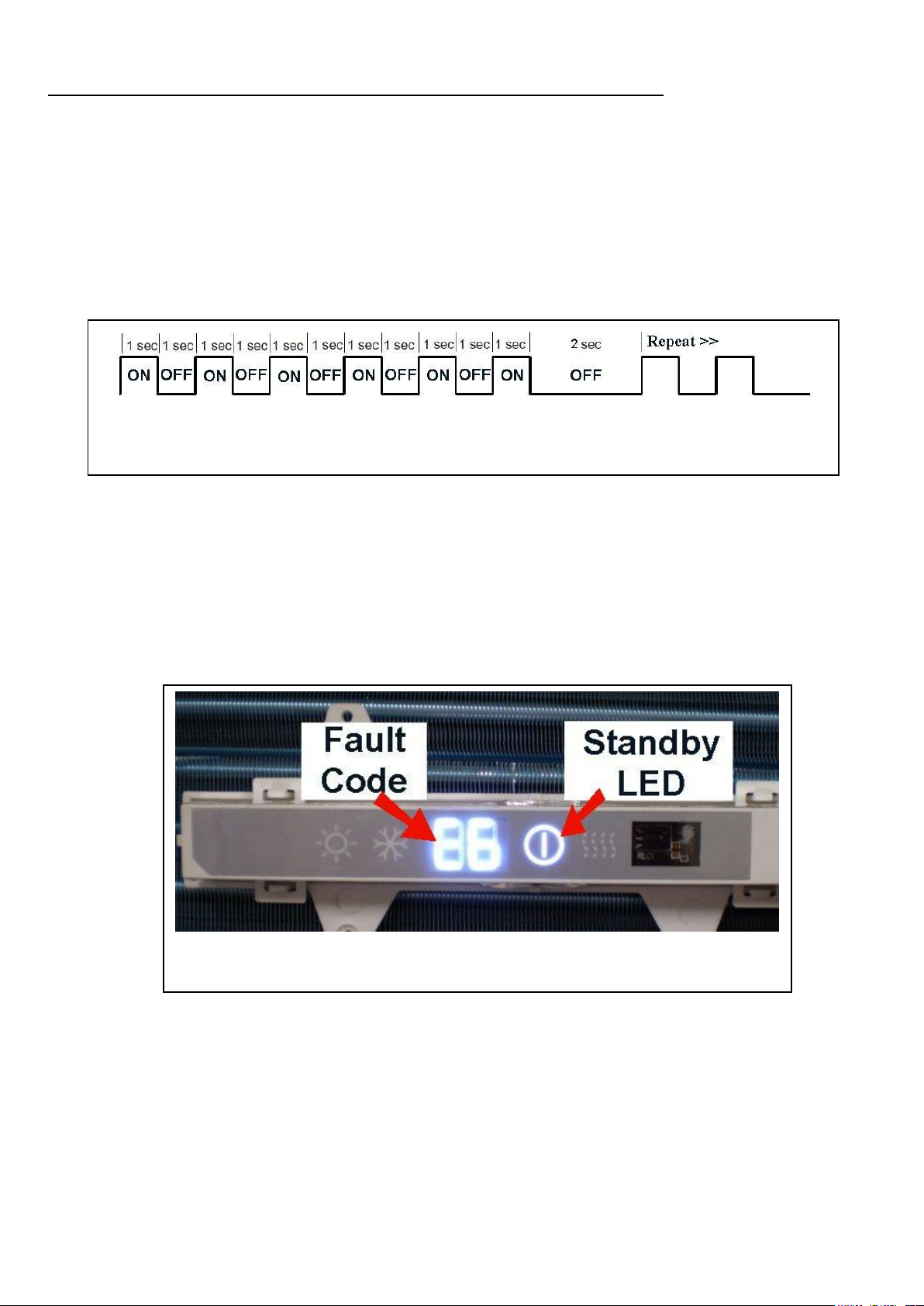

Fault Code (E6-Communication) & Standby LED indicating fault type.

(Communication Fault – Standby LED)

LED Flash Code Sequence Description (Indoor Display PCB)

# In the event of a complete shutdown or an operational control adjustment the Standby, Heating or

Cooling LED’s on the indoor display PCB flash to indicate this sequence.

Note: The LED’s flash at a 1 second rate for the required number of flashes, and then a 2 second pause

before repeating the 1 second rate sequence.

# Example of LED sequence:

# Example of fault code & LED sequence:

Page 6 KSSSI113

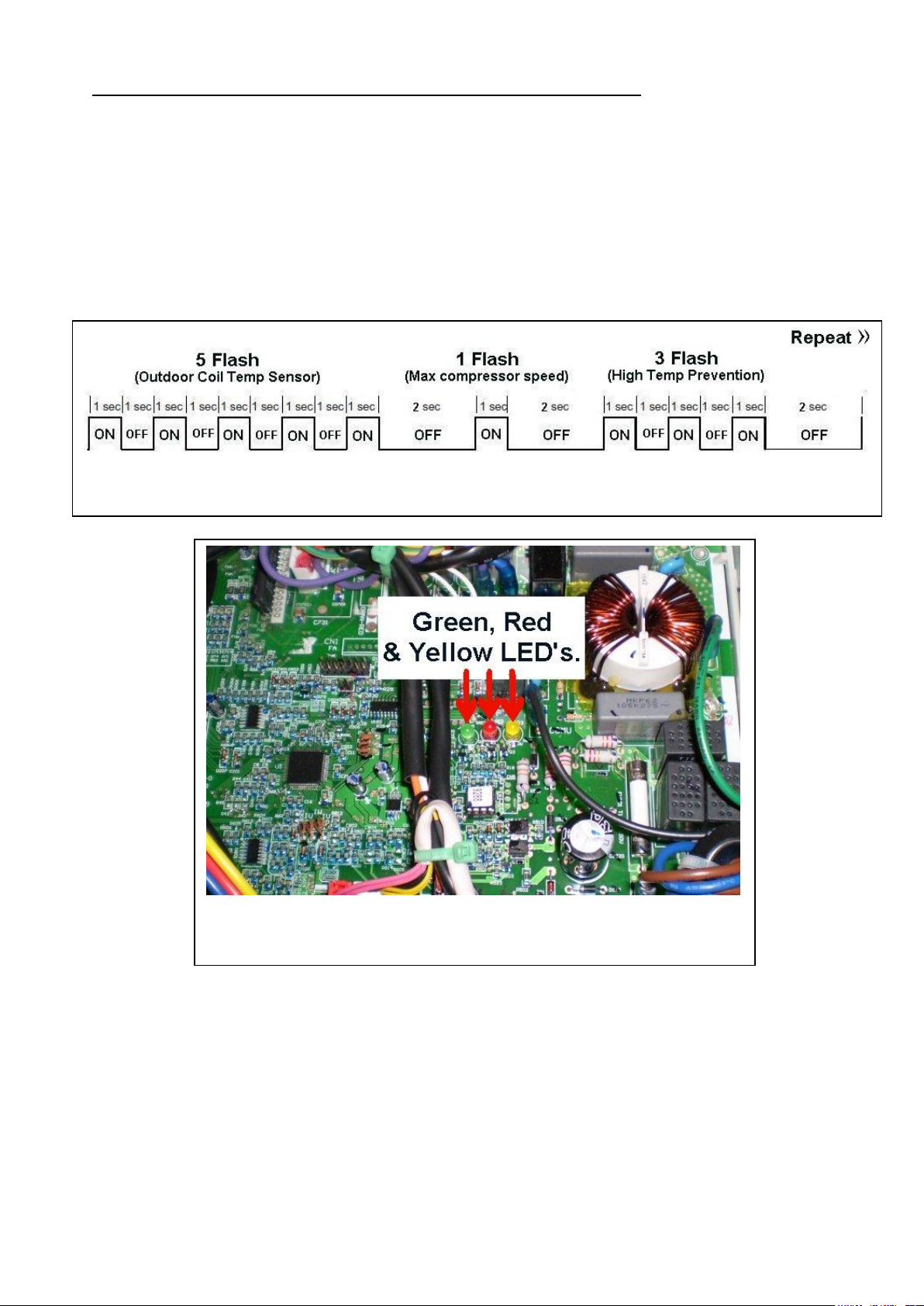

LED locations on outdoor PCB

Mutable fault code sequence.

LED Flash Code Sequence Description (Outdoor PCB)

# In the event of a complete shutdown or an operational control adjustment the outdoor PCB Green,

Yellow & Red LED’s flash to indicate this sequence.

Note: The LED’s flash at a 1 second rate for the required number of flashes, then a 2 second pause

before repeating the 1 second rate sequence.

Note: Two or more faults can appear in the one LED fault sequence.

# Example of LED sequence:

Green LED: Outdoor unit, flashing at 1 hertz.

# Normal communication.

Red LED: Outdoor unit, flashing at 8 times.

# Normal operation.

Yellow LED: Outdoor unit, flashing once every two seconds.

# Normal operation.

Page 7 KSSSI113

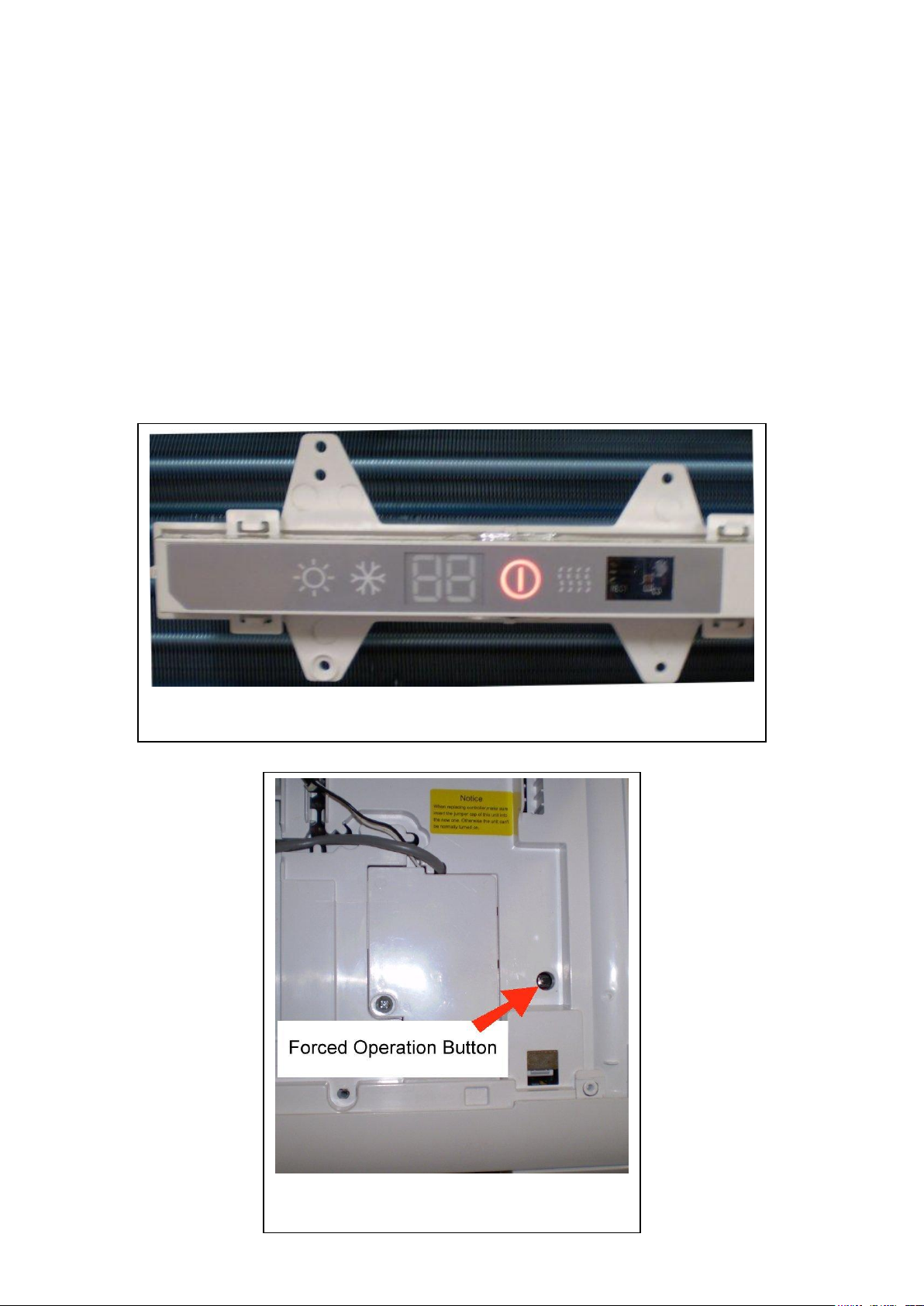

Standby indicator on Display PCB assembly.

Button located under indoor filter cover.

Not Operating:

# Check the wiring configuration from the outdoor unit to the indoor unit. Is it wired up correctly

in accordance to the wiring diagrams provided on both indoor & outdoor units? (Refer pages 29

to 31)

# While the unit is in “standby” mode, check if the red stand by light is on?

# Try operating the unit by the forced operations button: By pressing the button once, the unit

should activate in Auto mode. Pressing it twice will turn the unit off.

# If the unit can be operated by the forced operations button & the red stand by light was on,

check the remote controller.

# If the unit can be operated by the forced operations button & the red stand by light was off,

replace the display PCB assembly.

# If the unit cannot be operated by the use of the remote control or the forced operation button,

check for supply voltage at the following points, illustrated on the next page.

Page 8 KSSSI113

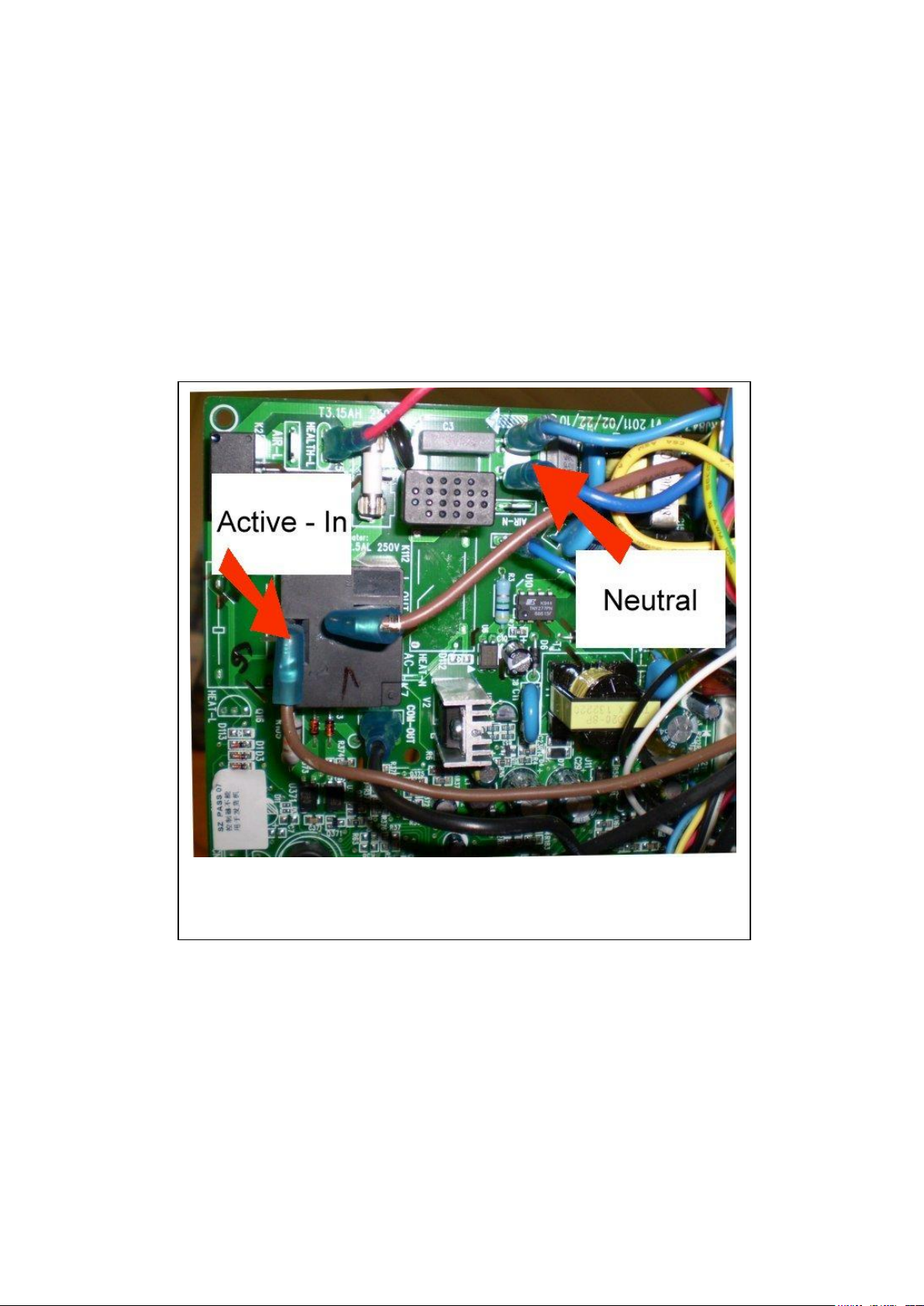

Active & Neutral Supply voltage points from service cord to indoor

PCB.

Not Operating Continues:

# Check for supply voltage at the following connection points:

From the isolation switch to the Active-In & Neutral connector points located on the indoor

PCB.

If supply power is available at the above connector points, yet the unit can still not be operated

by the remote control or the forced operation button, replace the indoor PCB.

Page 9 KSSSI113

Diagnostic Display Mode Description:

Built into the software for models: KSV26HRC & KSV35HRC are two different diagnostic methods:

(Fault Codes & Condition Codes) that can be used to help diagnose various faults.

These two diagnostic types are described in the following pages.

Note: Where there is referral to (Delayed)

# This indicates a time delay before the fault code in question is displayed.

Note: Where there is a referral to (Remote Control Access – 3)

# This indicates the need to use the remote controller to view the relevant fault code.

This is achieved by pressing the “Light” button 3 times within three seconds.

Note: Where there is a referral to (Remote Control Access – 5)

# This indicates the need to use the remote controller to initiate a selected “Test State”.

This is achieved by pressing the “Light” button 5 times within three seconds.

Note: Where there is a referral to (DRED)

# This indicates the unit in question is fitted with a “Demand Response Electrical Device” that enables

the compressor to operate at various capacities (75% of total capacity, 50% of total capacity &

compressor off).

Fault Code Descriptions:

Red LED: Outdoor unit, flashing at 1 hertz.

(Frequency Limit)

# This indicates the compressor has reached its maximum setting speed.

E4, Indoor Unit.

Indoor Standby LED, flash 4 times.

(Compressor Discharge High Temperature Protection)

# Check the outdoor coil for airflow obstructions.

# Check the outdoor fan motor for correct operation.

E5, Indoor Unit.

Indoor Standby LED, flash 5 times.

(AC Over-Current Protection)

# While the unit is in operation, check the maximum current draw. If it’s above the maximum current

rating illustrated on the outdoor rating plate, check operation of the compressor.

Page 10 KSSSI113

Loading...

Loading...