Electrolux GU1EOEOOOO Service Manual

Thermetic

TILTING BOILING PANS, ROUND, GAS

(GU........)

(KU........)

US SERVICE MANUAL

Gas heated

TILTING BOILING PANS

Doc. 62.9693.03

Edition 1

09.2006

CONTENTS

1. CONSTRUCTION/ FUNCTIONS......................................................................................... 3

2. TECHNICAL DATA ............................................................................................................. 3

3. ELECTRIC DIAGRAMS ...................................................................................................... 4

4. MAINTENANCE CHECK LIST............................................................................................ 6

5. ACCESS TO INSIDE........................................................................................................... 7

6. FUNCTIONAL COMPONENTS.............. .... ... ... ... ... .... ... ... ... .... ............................................ 7

6.1 OPERATING FOIL ........................................................................... ..................................................7

6.2 UNIVERSAL CONTROL ............................................... .....................................................................8

6.2.1 PARAMETER PROGRAMMING .........................................................................................................................8

6.2.2 MANUAL PARAMETER INPUT ..........................................................................................................................8

6.2.3 PROGRAMMING SPECIFIC APPLIANCE AND USER DATA .......................................................................... 9

6.2.4 ADJUSTING OF TEMPERATURE MEASURING .............................................................................................11

6.2.5 TEST FUNCTIONS FOR SERVICE APPLICATION .........................................................................................11

6.2.6 TROUBLESHOOTING DISPLAY ......................................................................................................................12

6.2.7 OPERATING BOARD (UP) ...............................................................................................................................12

6.2.8 CONTROL BOARD (SP) ...................................................................................................... .............................13

6.2.9 CONTROL SWITCH (S) ........................................ ..................... ..................... ..................................................13

6.2.10 SAFETY THERMOSTAT (F1) ...........................................................................................................................13

6.2.11 FOOD SENSOR (B1) ........................................................................................................................................14

6.2.12 JACKET SENSOR (B2) ....................................................................................................................................14

6.2.13 DEAERATION SENSOR (B3) ...........................................................................................................................14

6.2.14 END SWITCH (ES) ............................................................................................................................................14

6.2.15 TERMINALS ......................................................................................................................................................15

6.2.16 CONTROL FUSE (X4) .......................................................................................................................................15

6.2.17 RELAY (K1) .......................................................................................................................................................15

6.2.18 HEATING RESISTOR (E11) .............................................................................................................................15

6.3 MOTOR TILTING ............................................................................................................................16

6.3.1 CONTROL SYSTEM (KS) .................................................................................................................................16

6.3.2 TILTING MOTOR (AN) ......................................................................................................................................16

6.3.3 SWITCH (CK) ....................................................................................................................................................16

6.4 BURNER SYSTEM ..........................................................................................................................17

6.4.1 FLAME ..............................................................................................................................................................17

6.4.2 AUTOMATIC GAS IGNITOR (A3) ....................................................................................................................17

62.9694.03 Page 1

6.4.3 BURNER ....................................................... ....................................................................................................18

6.4.4 SCREEN (BU) ............................................... ..................... ..................... ..........................................................18

6.4.5 GAS CONNECTION PRESSURE .....................................................................................................................18

6.4.6 THERMAL LOAD ..............................................................................................................................................19

6.4.7 DIFFUSOR (VU) and NOZZLE (DU) ................................................................................................................19

6.4.8 ELECTRODES (ED) (EM) .................................................................................................................................20

6.4.9 SEALANTS ................................................... ....................................................................................................20

6.4.10 CONVERSION TO ANOTHER TYPE OF GAS ................................................................................................20

6.4.11 GAS DATA TABLE ...........................................................................................................................................21

6.5 JACKET ..........................................................................................................................................22

6.5.1 SAFETY VALVE (SV) .......................................................................................................................................22

6.5.2 LEAKS / LACK OF WATER .............................................................................................................................23

6.5.3 DEAERATION SYSTEM ...................................................................................................................................24

6.5.4 DEAERATION VALVE (EV) .............................................................................................................................24

6.5.5 CHECK VALVE (RV) ........................................................................................................................................24

6.5.6 SIPHON (SP) ....................................................................................................................................................24

6.5.7 DATA PLATE, vessel (TY) ..............................................................................................................................25

6.5.8 INSULATION (see figure "Jacket") ................................................................................................................25

6.5.9 PAINT FINISH ...................................................................................................................................................25

6.5.10 JACKET PRESSURE TEST .............................................................................................................................25

6.6 ROTATION LINK (DK) ....................................................................................................................25

6.7 FAUCET ..........................................................................................................................................27

6.8 LID (D), ............................................................................................................................................28

6.8.1 LID HINGE (DG) ...............................................................................................................................................28

6.9 PAN .................................................................................................................................................29

6.9.1 BEARINGS, PIVOTS ........................................................................................................................................29

6.9.2 CASING (MN) ...................................................................................................................................................29

6.9.3 WASTE GAS FLUE (KI) ...................................................................................................................................29

6.10 APPENDIX

UNIVERSAL CONTROL DESCRIPTION OF PARAMETERS .....................................................30

Page 2 62.9694.03

VALIDITY

This document refers to the following tilting boiling pan program:

Gas heated tilting

boiling pan heated

.U.C......

080 E

.U.E......

100 E

.U.H......

150 E

.U.J......

200 E

.U.K......

300 E

ADDITIONAL DOCUMENTS

Operating instructions 76.9693.01delivered with the appliance

Installation instructions76.9699 delivered with the appliance

Spare parts list 76.9693.02distributed by the service

department

Electrical diagrams 91.4018, 91.4020

delivered with the appliance

SERIAL NUMBER YWWXXXXX

The serial number of the appliance is marked on the type

plate. The 8 digits give following information:

Y last digit of the year of production

WW week of production

XXXXX running number

SAFETY MEASURES

• Maintenance work, adjustments, conversions and repairs

may only be carried out by an authorized technician. These

technicians must be instructed by the manufacturer and

carry out the work in accordance with specific national and

local regulations. Parts requiring replacement are only to

be replaced by original spares.

• Strictly follow the attention and warning label indications on

the appliances.

• Servicing work on the gas supply may only be carried out

by gas company personnel or by an authorized installation

contractor.

• Cleaning and maintenance may only be carried out when

the appliance is cold.

• In case a connection with a seal is opened, always a new

seal should be used when installing the connection.

• The manager is responsible for ensuring that all compo-

nents relevant for safety (jacket safety valve, drain valve,

pressure gauge, thermostat, excess-temperature thermostat) are in perfect working order at all times. The operating

condition of these components must be examined by an

authorized technician at least once a year and any defects

remedied if required.

• Before beginning any servicing, all appliances must be dis-

connected from the power supply; the steam, condensate,

hot water and drinking water pipes must also be turned off

or closed. Disconnection from the power supply is effected

by switching off at the main switch or removing the fuses

fitted to the power supply.

• The internal wiring in the appliance as well as the earth

connections must be carried out in accordance with the

complete electrical schematic. Basically, all metal parts on

which electrical connections are located must be earthed.

• In case a connection with a sealing is o pened, always a

new sealing should be used when installing the connection.

• Boiling pans of this design and operating function do not

require special acceptance tests. They are subjected to a

pressure and operating test which meets the regulations on

the manufacturer's premises. Recurrent pressure testing is

not compulsory. To ensure the complete operating efficiency and safety of appliances, however, owners should

arrange for personnel authorized by the manufacturer to

check on all safety equipment and to conduct pressure

tests at regular intervals.

• All gas appliances are tested according to the standards

ANSI/NSF 4 - 2002 of Commercial Cooking, Rethermalization, and Powered Hot Food Holding and Transport Equipment and ANSI Z83.11-2002 and CSA 1.8-2002 of Gas

Food Service Equipment.

• After the appliance has been connected, the service age nt

must carry out a test of all functions in the course of which

all the programs and operating states of all operating ele-

ments as laid down in the operating instructions are

checked.

• The conclusion of a maintenance agreement should be

recommended to the user.

MAINTENANCE INTERVAL

An obligatory service check is required annually.

1. CONSTRUCTION/ FUNCTIONS

The food is uniformly heated by steam b y an external jacket.

The following sources of energy are used: electricity, saturated

steam and hot water. The pans are equipped with an electronic comfort control unit with regulation of the food temperature, with programming of the cooking time and with optional

programming of the starting time. The control system is operated via a membrane keyboard. The boiling pan has a variable-speed tilting facility powered by an electric motor. All

models can be optionally equipped with a mixer unit.

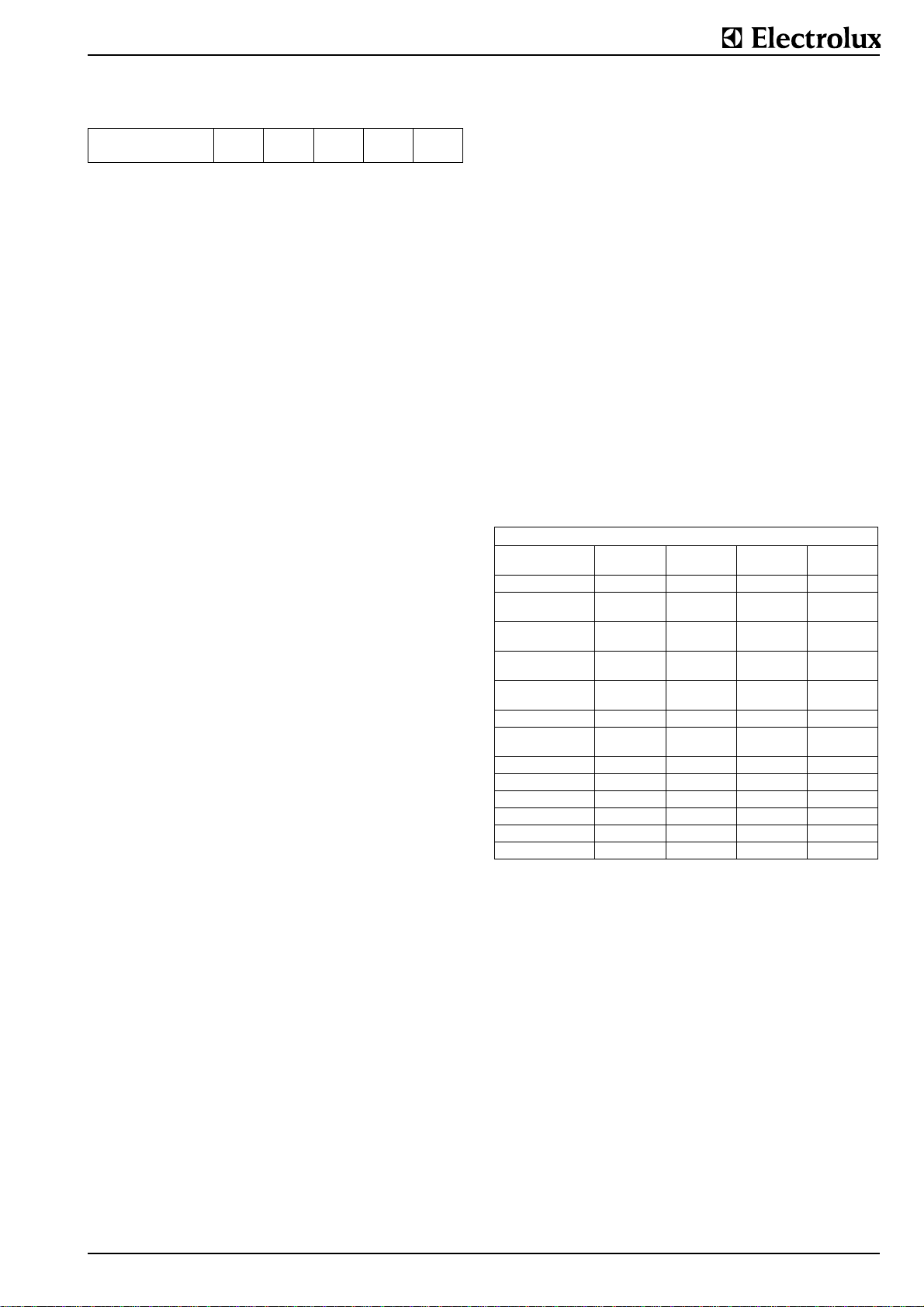

2. TECHNICAL DATA

Tilting boiling pan with jacket heating system.

Electrically heated tilting boiling pans models have water-filled

jackets. Max. working conditions in the jacket: pressure 0.8 bar

(5.8 psi), temperature 244°F (118°C).

Heating-up time: time taken to heat th e pan 100% full o f water

from 68°F (20°C) to 194°F (90°C).

Gas heated tilting boiling pans

.U.C......

080

vessel capacity gal 21.1 26.4 39.4 79.3

Gas heating capacity kW18 21 27 43

Gas heating capacity

btu/h

Natural gas

consumption ft/min

Propan

consumption ft/min

El. power kW 0.2 0.2 0.2 0.2

Voltage ) 120V/1~N,

Amperage A 0.7 0.7 0.7 0.7

Jacket volume dm3 32 38 50 64

Jacket volume gal 8.5 10 13.2 16.9

Water filling lt 17 17 22 30

Water filling gal 3.7 3.7 5.8 7.9

Heating-up time min. 40 45 50 64

61420 71650 92130 146720

1.15 1.34 1.66 2.87

0.44 0.51 0.64 1.1

60Hz

.U.E......

100

120V/1~N,

60Hz

) Voltage for control unit and tilting 230V/1~N*, 50/60 Hz

.U.H......

150

120V/1~N,

60Hz

.U.K......

300

120V/1~N,

60Hz

62.9693.03 Seite 3

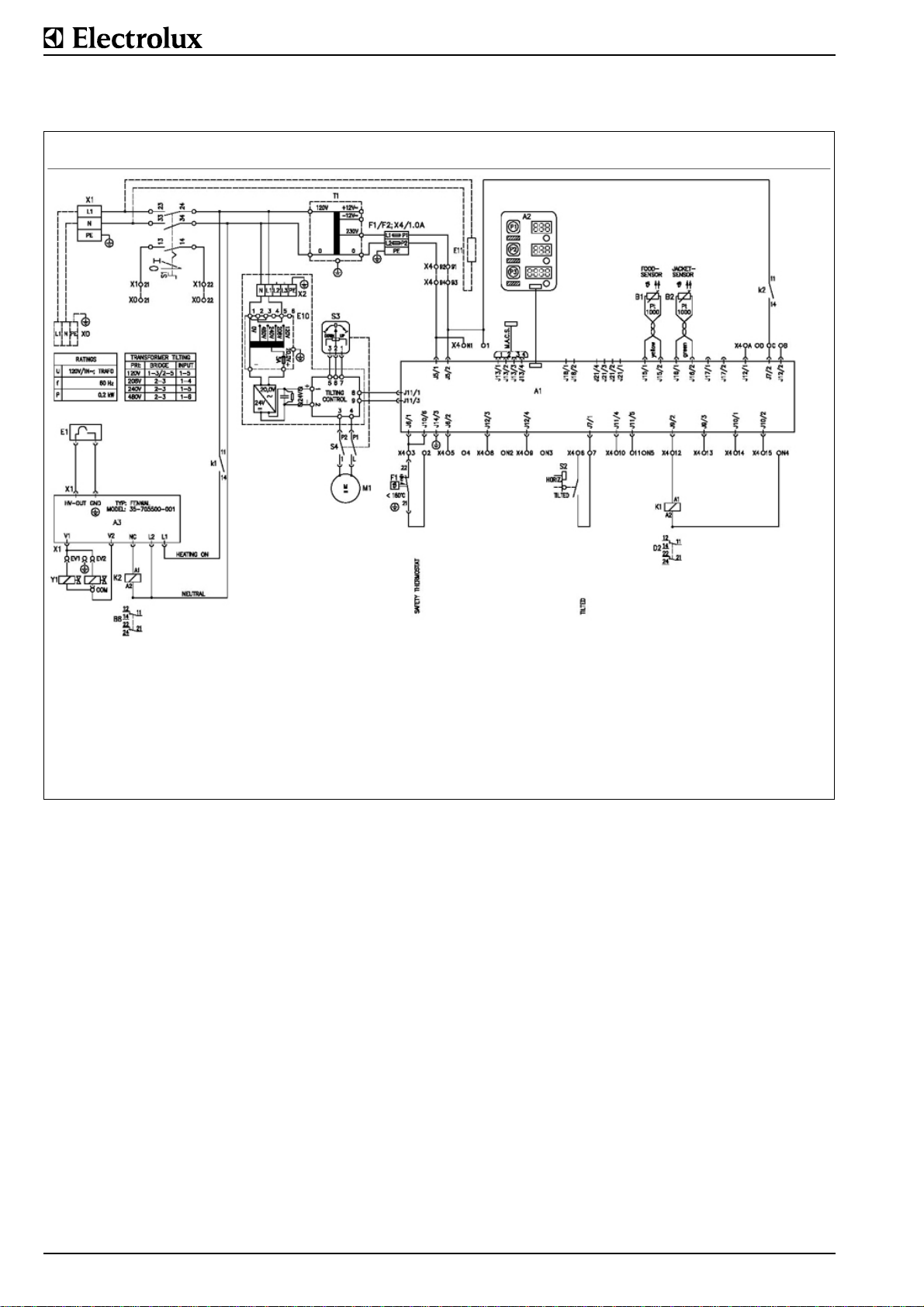

3. ELECTRIC DIAGRAMS

Gas heated tilting boiling pans 80 LT - 150 LT (21.1 gal - 39.4 g al),

120 V:

91.4020

A1 Control board

A2 Operating board

A3 Dungs gas ignitor

B1 Food temperature sensor

B2 Jacket temperature sensor

E1 Electrodes)

E10 Tilting control

E11 Heating resistor

Fig.1 Electric diagram, gas heated tilting boiling pans 80 LT - 150 LT (21.1 gal - 39.4 gal), 120 V

F1 Safety thermostat against lack of

water

K1 Contactor

K2 Contactor

M1 Tilting motor

S1 Control switch

S2 End switch for horizontal position of

the pan

S3 Potentiometer for tilting

X1 Terminals

X4 Control fuse

T1 Single- phase transformer (only for

Y1 Gas valve (SIT 080832 Tandem)

The precise specifications of the individual electric components are given in the corresponding parts list. These must be

used in conjunction with the electrical schematic valid for the

appliance.

voltage unequal 230V)

Seite 4 62.9693.03

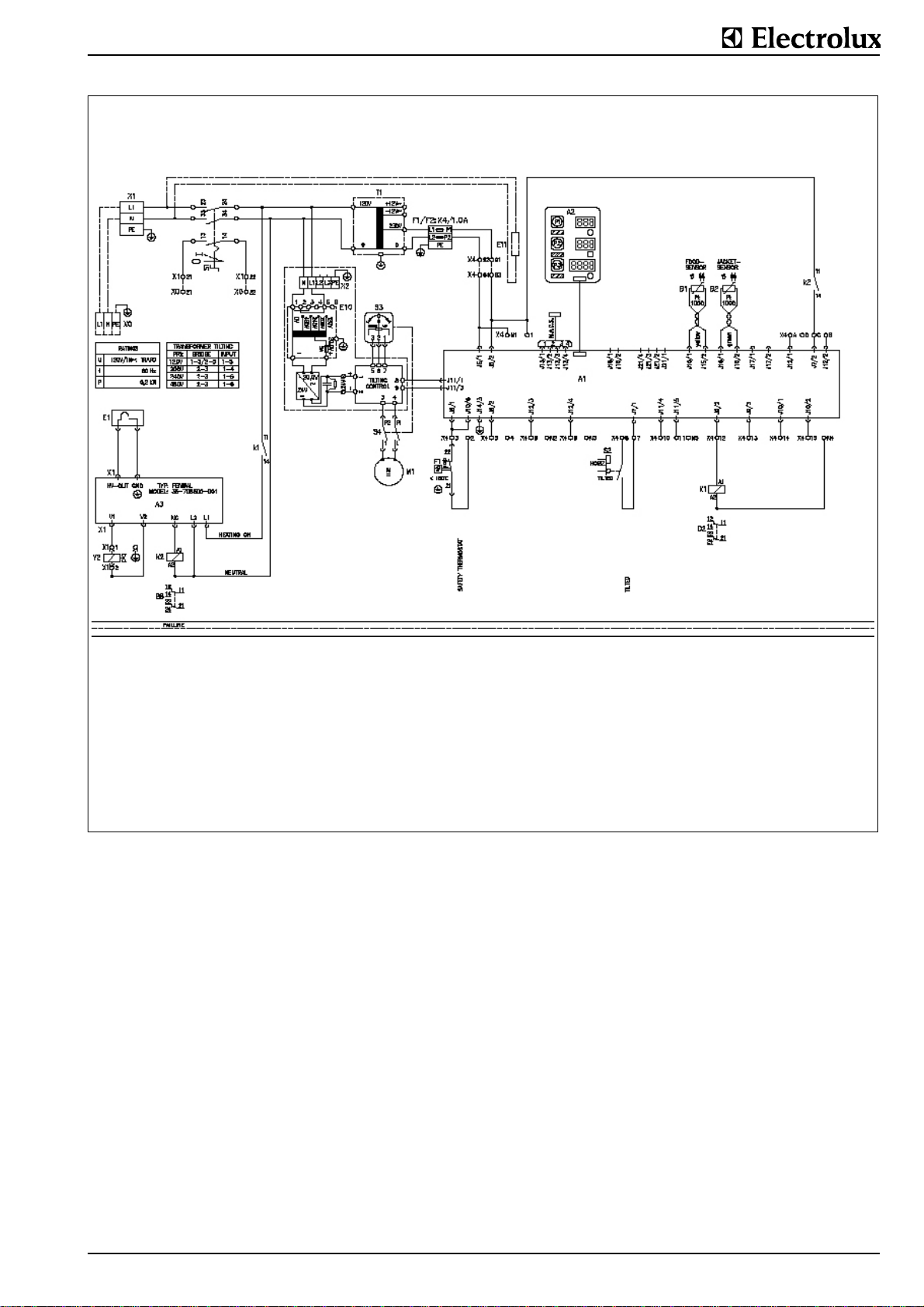

Gas heated tilting boiling pans 300 LT (79.3 gal), 120 V:

91.4018

A1 Control board

A2 Operating board

A3 Dungs gas ignitor

B1 Food temperature sensor

B2 Jacket temperature sensor

E1 Electrodes)

E10 Tilting control

E11 Heating resistor

Fig.2 Electric diagram, gas heated tilting boiling pans 300 LT (79.3 gal), 120 V

F1 Safety thermostat against lack of

water

K1 Contactor

K2 Contactor

M1 Tilting motor

S1 Control switch

S2 End switch for horizontal position of

the pan

The precise specifications of the individual electric components are given in the corresponding parts list. The se must be

used in conjunction with the electrical schematic valid for the

appliance.

S3 Potentiometer for tilting

X1 Terminals

X4 Control fuse

T1 Single-phase transformer (only for

voltage unequal 230V)

Y2 Gas valve (GS-4521-9993)

62.9693.03 Seite 5

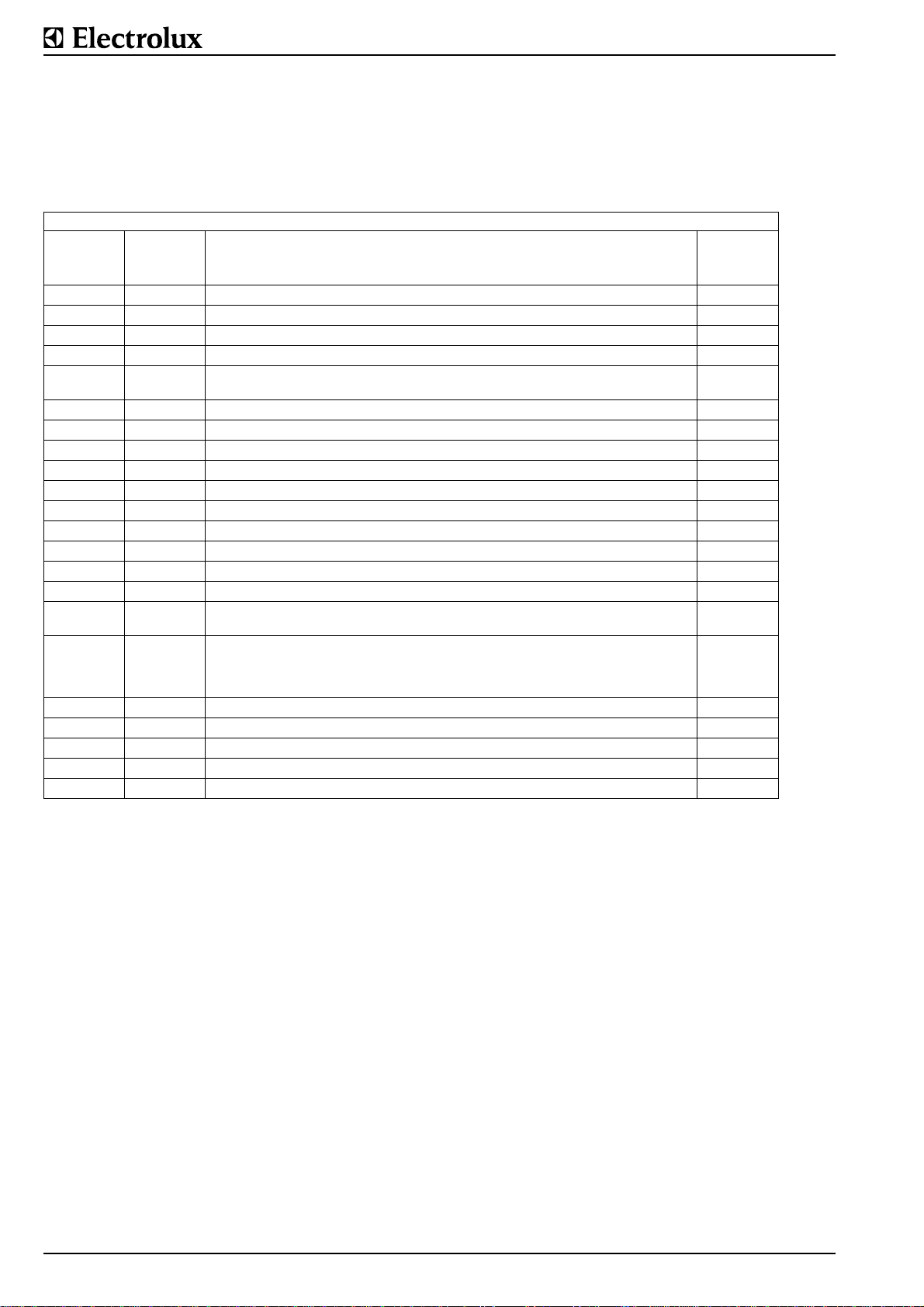

4. MAINTENANCE CHECK LIST

Check Fault D Remedy

Connections for protective

conductors

Connections for equipoten-

tiality

Check that all electric con-

nections and contacts to

terminals, coils, switches

and junctions are tight.

Check relays.

The contacts must move

freely without sticking or

jamming.

Check the burner output,

i.e. measure the preset heating-up time and compare

this with the nominal value.

Clean the diffusor on the

burner. Check its position

and attachment.

Check that the nozzle

(number) is correct. Clean

the area around the nozzle.

Check the distance between the burner and the

pan base.

Visual check of the flame

with a mirror.

Check the condition, the

gap and the attachment

point of the ignition elec-

trode and the earthing

(grounding) electrode.

Check that the gas valve is

not leaking and that it is set

correctly.

Measure the ionization current at the electrodes when

the appliance is at full

power.

Check the high-tension

cable for cracks or brittleness.

Check the plug on the ignition electrode.

Measure the gas pressure

when the appliance is at full

power.

Check condition and leakage of rotation link.

Check that the internal gas

pipes are not leaking.

Ensure that the main gas

tap (if fitted) operates

smoothly and correctly.

In case of loose contacts

D tighten contacts.

In case of defects or faults

D replace contactor or relay.

If this comparison reveals a

deviation of more than 10%

D Clean and check the gas

system.

If its position has changed

D Set the diffusor correctly.

If the nozzle is not the appropriate size ∅, fit the correct

nozzle. If the nozzle is damaged D Fit a new one.

If the actual measurement

deviates more than ± 1mm

from the nominal measurement

D Set the burner distance

exactly.

Flame tips yellow, flame

corona transparent, flames

lift off, flame strikes back

D Clean and set the diffusor

exactly.

If scaling is found, the gap is

not right or the shape has

changed

D Replace.

S If it is leaking

D Replace the valve.

If it is functioning incorrectly

D Readjust it.

If this is outside the recognized tolerance

D Set the electrodes more

accurately.

If any faults are found

D Replace the cables.

If any faults or oxidation are

found

D Replace the high-tension

cables.

In the case of deviations that

are higher than the permissible tolerance

D Send a report to the user

and have the gas pressure

corrected on-site or adapt the

nozzle to the new pressure.

If any faults are found

D replace the parts concerned.

If a leak is found

D Seal the leak.

If the tap is hard to turn

D Regrease the tap or

replace it.

Check Fault D Remedy

Inspect internal wiring. In case of defect cables

Check condition of all ope-

rating foils.

Optical inspection of the

whole control unit.

Test all operating functions

and check that the control

unit works correctly.

Check switches for easy

movement and correct

function.

Compare the food tempe-

rature display with the

actual value.

Inspect fixation and condition of all temperature sen-

sors (jacket, food,

deaeration, excess temperature) and check electrical

connections.

Check the function of the

heating resistance.

Check all elements of the

display on the control panel

with service test 1.

Inspect fixation and condition of all switches (power

isolator, control, tilting, stirrer) and check electrical

connections.

Check function of acoustic

signals.

Check the number of deaerations and thus the water

level in the jacket with parameter PNo. 1.6.5.

Check max. jacket pres-

sure (except on pans with

direct steam heating).

Carry out a leak test of the

jacket (except on pans with

direct steam heating).

Check function of deaera-

tion valve.

Inspect safety valve for

corrosion, damage and leakage. Make function test

and maintenance.

Check the lid for correct

shape or damage.

Check the lid hinges for

correct function.

Check function of mixing

unit for function. Check for

leaks of water connections.

S = Part is relevant for safety

If, during servicing, an increased number of failures is

noted for a part that is relevant for safety, a written report

must be sent to the „Aftersales“ office responsible without

delay

D replace cables.

Defective foils D replace.

S

Defective foils D replace.

S If problems are encountered

D find reason and repair

failure.

If the switch is hard to turn or

makes a noise

D replace.

If the deviation is

D Adjust the display again.

S If sensors, fixation, electrical

connections are found to be

faulty

D replace the parts concerned.

If it is not warm D replace it.

If any element of the display

fails D exchange the whole

operating print.

If defects to any fixation or

electrical connections are

discovered

D replace the parts concerned.

If the sound is off key or no

sound is heard

D exchange the whole control board.

If the number of deaerations

is very high or there is too

little water in the jacket

D refill with demineralized

water and reset the value of

PNo. 1.6.5. to 0.

If it deviates from the max.

reference value

D reset the max. value with

PNo. 1.0.3.

If there is a leak and high

water loss

D locate the leak and seal.

If it is not tight during operation

D clean or replace the valve.

S Clean the valve. If any inad-

missible properties are

encountered

D replace the whole valve.

If irreparably damaged

D replace the lid.

If defective

D disassemble, clean,

grease, adjust the hinge.

If the tap drips or if any pipes

leak

D replace seals.

1°

Seite 6 62.9693.03

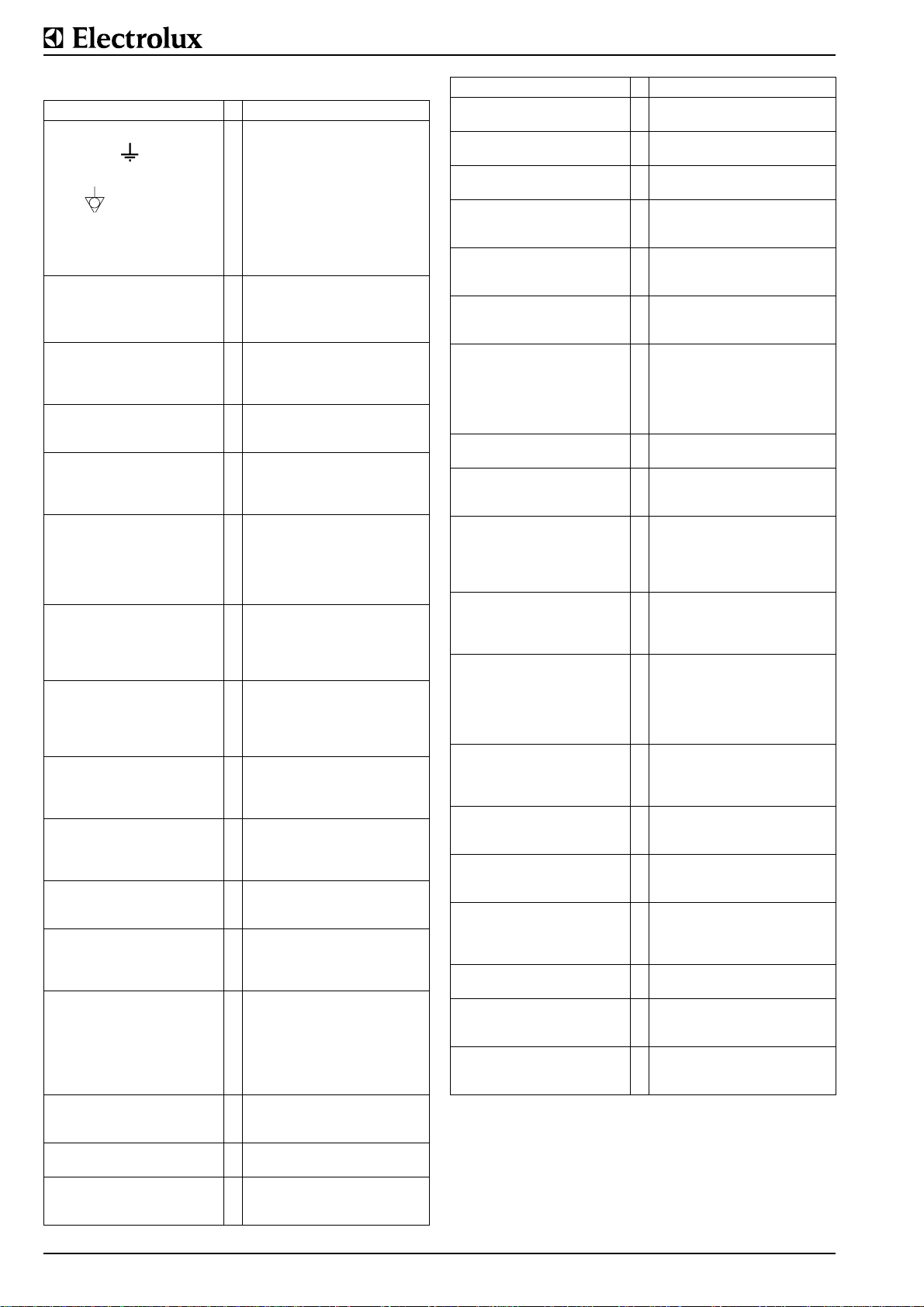

5. ACCESS TO INSIDE

Sheeting of console, support, pan

Remove the connecting rail

(VS)

Loosen the front nuts M6 from

underneath. Bend the rail up

slightly at the front. Pull the rail

out of the appliance.

Switch panel (F) removal:

Unscrew the two screws at

location (1) underneath the

switch panel and the nuts (MH)

at location (2) on the top, pull

out the switch panel at the bottom and then lift up and out of

the fixation. The panel is turned up 90° like a door and

hung at the top on the console.

Cover (A) removal:

If there is a connecting rail

installed to the cover it has to

be removed first. (see 5.3.1.).

Remove the nuts (MU) (two on

a single console, four on a twin

console) at the relevant location (2). Lift the cover at the

front and pull it out of its clip

attachment at the back (3). If a

mixing unit is fitted, this does

not need to be removed from

the cover.

Service panel (V) removal:

Remove the two external nuts

(6) at the front and pull the

panel from its rear attachment

points (5).

Side wall (S) removal:

To remove this, the switch

panel (F) must be removed

first. Remove the nuts (4) and

(5) inside. The upper internal

wall (W) cannot be disassembled. It must be removed and

refitted together with the pan.

The panels are refitted in the

reverse order to that described

above.

Cover (A). The height of the

cover can be levelled by fitting

more or fewer shims (BE) and

tightening the nuts (MH).

Floor mounting on plinth

Hanging the operating panel

(F) on the console

Removing the pan base (BD).

Set the pan in the horizontal

position. Remove the screws

(SB) from underneath and take

out the base (BD) from underneath.

Fitting the base (BD).

Carefully clean any remains of

the old seal from the edge of

the base. Stick a new sealing

strip (DB) on the edge of the

base. Carefully position the

threaded clip (SM) on the jakket (MK). Tighten the screws

(SB).

Pan jacket. The pan jacket is

not removed during normal

servicing work.

6. FUNCTIONAL COMPONENTS

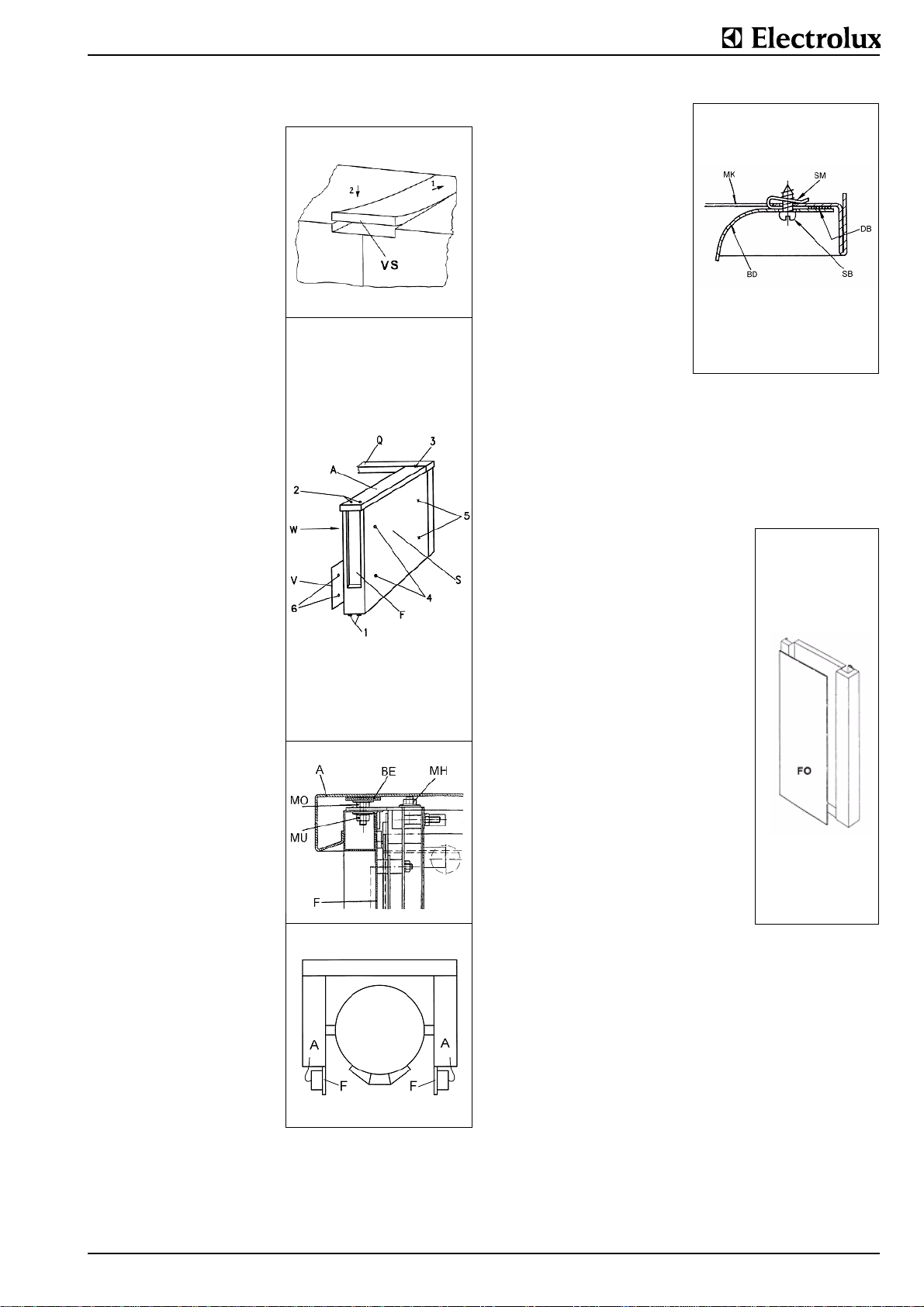

6.1 OPERATING FOIL EXCHANGE Removal

Operating foils (FO) are bonded to the sheet metal surfaces

(cover plates) with self-adhesive coatings. They are removed

with a spatula, a screwdriver or a knife.

Cleaning

The surfaces to which the foil is to be

applied must be clean and dry, i.e., free

from dust, grease, rust, paint, etc. Suitable for cleaning: toluol or 3M article S152 stick remover.

Procedure: shake the can thoroughly and

spray evenly on the surface to be cleaned. (Distance about 5.9 - 7.9“ / 15 - 20

cm.) Rub over with a clean lint-free cloth.

If surfaces are heavily soiled, repeat the

process.

Sticking on the foil

Remove the protective backing, taking

care not to touch the adhesive. After

positioning press down well. It is

important to apply firm, even pressure.

The ideal working temper ature is approxi mately 77°F (25°C). Temperatures below

50°F (10°C) should be avoided since the

adhesive becomes too hard and instantaneous adhesion is reduced. Following

application, the foil has a working temperature range from -40 to +248°F (-40° to

+ 120°C) continuous temperature load

and 356°F (180°C) short-time temperature load.

62.9693.03 Seite 7

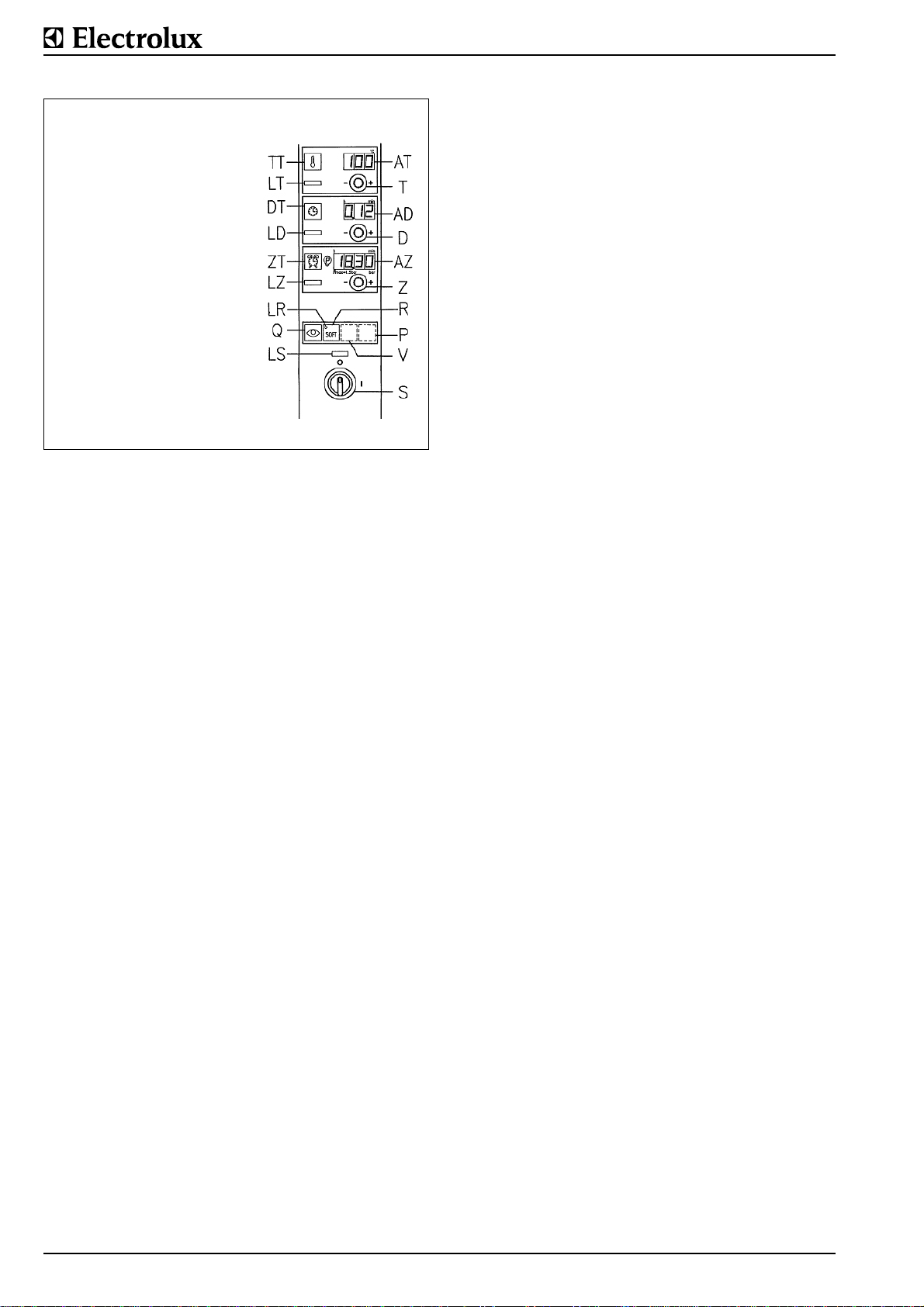

6.2 UNIVERSAL CONTROL

TT Button, activation of settings

LT Lamp, cooking temperature

DT Button, cooking time

LD Lamp, cooking time expires

ZT Button, starting time

LZ Lamp, starting time

LR Lamp, soft settings

Q Button, acoustic signal

R Button, soft

LS Lamp, temperature

pre-setting

AT Display, cooking tempera-

ture

T Temperature selection knob

AD Display, remaining cooking

time

D Cooking time knob

AZ Display, time

Z Starting time knob

S Control switch

The appliances are equipped with a precise state-of-the-art

electronic microprocessor control system with digital preselection of temperature, cooking time and starting time. The control

system can also be remotely controlled using a PC. For control-system operation, please refer to the Operating Instructions.

Temperature setting

If the nominal temperature set on the display (AT) is below the

boiling point of water 207 - 212°F (97 - 100 °C), this temperature will be reached during heating up and then maintained at

this value by the electronic control system and the careful supply of energy. The nominal temperature will not be exceeded

during this process.

When cooking certain products with poor heat conductivity

such as sugar solutions, nominal temperature settings

between 212 and 230°F (100° and 110°C) are required in

order to reach boiling point. The correct setting is largely a

matter of experience.

Setting Power Heating time during

(AT) (%) a period of 120 sec.

L1 12.5 15 sec

L2 12.5 15 sec

L3 25 30 sec

L4 37.5 45 sec

L5 50 60 sec

L6 62.5 75 sec

L7 75 90 sec

L8 87.5 105 sec

L9 100 120 sec

Displays

AT (3 di gits) Temperatures (if all 3 digits light up as well as

the point after the third digit, then this means

that 0.5°F must be added on after the point).

Power settings.

Hold levels.

Parameter number (PNo.).

Parameter value (if all 3 digits light up as well as

a decimal point, then the numeral must be multi-

plied by 1000. E.g. display = 3.99, value =

3990).

Excess pressure in the jacket (test function).

State of the heating system or the valves (if all 3

digits light up as well as a decimal point, then

the numeral must be multiplied by 1000. E.g.

display = 12.3, value = 12300)

Software version.

AD (3 digits) Cooking time

AZ (4 digits) Clock time.

Starting time.

Excess pressure in the jacket (normal function).

6.2.1 PARAMETER PROGRAMMING

General remarks

The same software is used for all appliances which are

equipped with this control system. To ensure that each a ppliance operates as desired, specific parameters must be

entered. The control systems which are installed in the appliances at the factory or are in stock, are equipped with the

microprocessors fitted including the software. The software

contains a default setting (GS) of the parameters (PNo.). The

default setting is selected in such a way that a minimum of

parameters have to be adjusted for the individual setting of the

different appliances. In principle, the corresponding parameters have to be entered for each appliance.

Software version

The microprocessor bears an adhesive label stating the software version and the date. Any change in the software usually

also involves a change in the parameters. Please always

ensure that the version of the parameter list used matches the

software version. The following general rule applies: if the software version has a different number, the parameter list with

the same version must also be used. If the software version

has a different additional letter in the version number (e.g. version 2.51A, version 2.51B, etc.), the parameter list does not

change. Only the number of the version without the additional

letter is important for the parameter list.

Microprocessor (MP)

2 IC insertion sockets are located on the control board. The

large insertion socket for 64 pins accepts the microprocessor.

The software program is located in the ROM (Read Only Memory) of the microprocessor chip. An OTP version (One Time

Programmable) microprocessor is used. This version can only

be written to once and cannot be erased. This mean s that any

program change also means the use of a ne w chip. The old

chip can no longer be used.

EEPROM (EP)

The small insertion socket for 8 pins is for the EEPROM (Electrically Erasable Programmable Read Only Memory). The

parameters are stored in this IC. Once stored, the parameters

remain in this IC even when disconnected from the power supply until they are changed by reprogramming or erased.

Before the parameters are changed for the first time to suit an

appliance, the values for the default setting must be loaded

into the EEPROM. The parameters can be entered in 2 different ways:

Manual input (the more frequent case) and PC input.

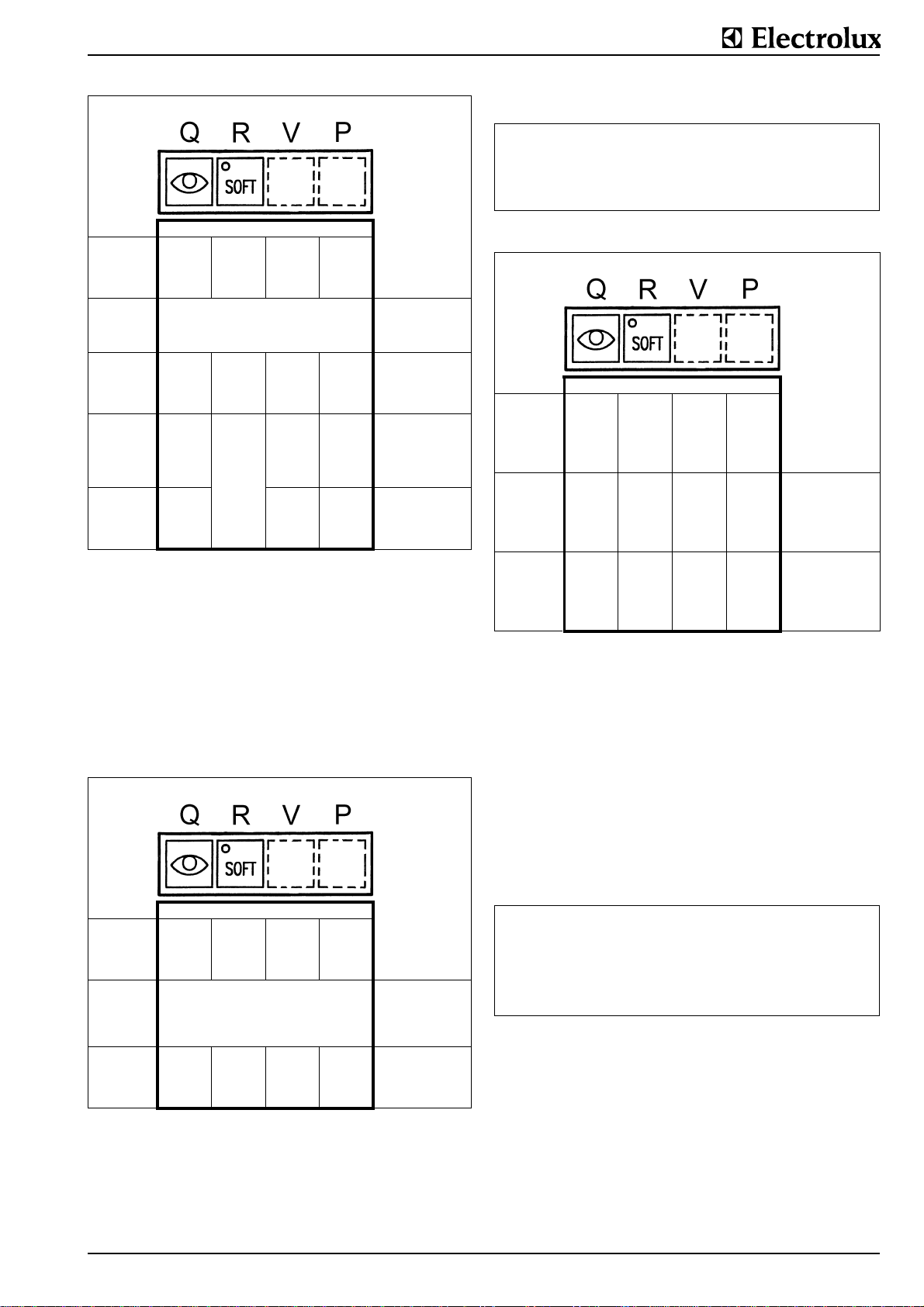

6.2.2 MANUAL PARAMETER INPUT

Default setting (GS) of the parameters

The default setting of the parameters is the same for all appliances which are equipped with this control system. Dependent

on the type of appliance, more or fewer parameters are

required with values that differ from each other to some

degree.

3 of the 4 buttons on the membrane keyboard (Q, R, V a nd P)

are used for the programming of parameters. The 3 buttons

are located in the bottom row on the operating panel. Buttons

V and P are located under the membrane and are not visibly

marked.

Seite 8 62.9693.03

)

Ð

As the same display is used to show the numbers (PNo.) and

the content (X) of the parameters, the following difference is

made between the two figures:

Kind of display (AT): Meaning of display:

with 3 decimal points (e.g.

1.0.3.)

without decimal points (e.g.

126)

Number of parameter PNo

Content (X) of parameter (e.g.

temperature)

Starting position: supply switched off (switch S at 0)

1st

combination

Press and hold

buttons

2nd

combination

Press buttons

3rd

combination

Press buttons

4th

hold

button R

* *

Supply to be switched on (turn switch S to I) Press buttons conti-

* *

*

*

⇓

⇓

*

Waiting time between

the different combinations is 3 seconds

maximum

nuously until the 2nd

beep, then press the

2nd combination

Press buttons continuously until the 2nd

beep, then press the

3rd combination

Hold button R pressed

until the 2nd beep,

then release.

(*)

(*) Display (AT): After "def" is displayed for approx. 2 seconds,

the actual value of the current food temperature will appear.

Display (AZ): Clock time appears (only with process com-

fort control).

The control system program now contains all the default settings for the software version of the microprocessor installed.

Important

which was already in operation is programmed for new, all

parameters which register running times are set to zero.

Parameter-setting (X) specific to each appliance

In order to change the numbers (PNo.) and the content (X) of

the parameters, the same buttons are used as those for entering the default setting.)

Starting position: supply switched off (switch S at 0)

1st

combination

Press and hold

buttons

2nd

Press button

* *

Supply to be switched on (turn switch S to I) Press buttons conti-

Waiting time between

the different combinations is 3 seconds

maximum

nuously until the 2nd

beep, then press 2nd

combination (for the

first time only 1 beep)

Hold button R pressed

until the 2nd beep,

then release.

*

Display (AT): Parameter PNo... 1 appears

Display (AZ): None

The parameter numbers (PNo.) and the values (X) which devi-

ate from the standard setting can now be entered alternately

on the display (AT).

Changing the parameter number (PNo.) and content (X))

Starting position: supply switched off (switch S at 0)

1st

Press button

2nd

Press button

3rd

Press button

*

*

*

Changing

(AT) from:

parameter number

(PNo.) to

parameter content (X)

or vice versa

Increasing the display

entered under 1.

parameter number

(PNo.)

Ï

or parameter content

(X)

Reducing the display

(AT):

parameter number

(PNo.)

or parameter content

(X)

the display

Rate of change of the displays

Increases (button P) or reductions (button Q) can be done at

three different speeds:

• Press the button briefly changes in single steps

• Press the button longer

• at least 1 second the display changes slowly

• press for at least 5 seconds the display changes fast

End of parameter programming

If the content (X) of a parameter (PNo.) is changed, the

changed value is stored when the display (AT) is changed

from parameter content to parameter number using the button

R. The following applies for the last parameter content

changed or if only a parameter content has been changed.

Parameter programming can be finished in 2 ways dependent

on whether the changed value is to be stored or not.:

Finishing: Procedure:

Changed value

to be stored

without decimal

points (e.g. 126)

• Display (AT) shows the parameter number

• Switch off control switch (S)

• Display (AT) shows the parameter value

(X)

• Switch off control switch (S)

6.2.3 PROGRAMMING SPECIFIC APPLIANCE AND

USER DATA

Appliance-specific parameters are only set on the basis of the

type of appliance. User-specific parameters are dependent on

user order, user requirements, siting terms an d are only appliance-dependent to a certain degree.

The parameters are programmed at the factory to the default

setting (GS) if no specific information is given.

New appliance installation

In the case of new appliances, the control system is programmed at the factory to the appliance-specific setting.

62.9693.03 Seite 9

When the appliance is installed at its intended site, the fitter in

charge of installation must set or check the following parameters on the control system. The parameter values are different

for each software version.

PARAMETER SETTINGS

SOFTWARE VERSION BPTH 5.06

PNr.

Parameter

number

GS

Default

setting

Designation

boiling pan,

1 0 Temperature display 1

24 0 Kind of heating 1

29 1 Deaeration sensor of the jacket 0

31 0 HOLD function 1

32 0 HACCP function

without:0

with: 1

54 4 Quantity of switching steps 1

59 2 Regulator hysteresis for double jacket sensor 0.5

63 2 Double jacket sensor lower temperature band 1 1

64 4 Double jacket sensor lower temperature band 2 2

65 6 Double jacket sensor lower temperature band 3 3

66 4 Double jacket sensor upper temperature band 1 2

67 6 Double jacket sensor upper temperature band 2 3

68 8 Double jacket sensor upper temperature band 3 4

78 30 Duration of periods of the power levels 120

79 25 Power level L1 12

83 50

Input of height above sea level of the installation site in 10 m (500 m above sea

level = 50).

X

Opening time of the deaeration valve

85 80

60 liter kettle:

80 - 150 liter kettle:

300 liter kettle:

60

80

120

99 170 Max. jacket pressure to release alarm 180

103 122 Double jacket sensor remappingy-high normal cooking 118

113 115 Double jacket sensor remappingy-high soft cooking 113

116 140 Max. pressure in double jacket 86

157 70 Maximum board temperature 80

Tilting

gas

Seite 10 62.9693.03

Loading...

Loading...