Electrolux AW 445, AW 465, AW 475, AW 455 T, Euroclean AW 445 Operating Instruction

...

AW 445

AW 445 T

AW 455 T

AW 465

AW 475

Graphic project

VISUAL DIVISION

Milan Italy

Operating instruction

MANUAL

Nilfisk-Advance Italia S.p.A

Località Novella Terza

26862 Guardamiglio (Lodi) Italia

Tel. +39 0377 451124

Fax +39 0377 51443

S31E47UKIN(1)99-01

S31E47UKIN(1)99-01

INDEX

INTRODUCTION AND WARNINGS.......................................1

UNPACKING ...................................................................... 2

TECHNICAL SPECIFICATIONS ............................................3-5

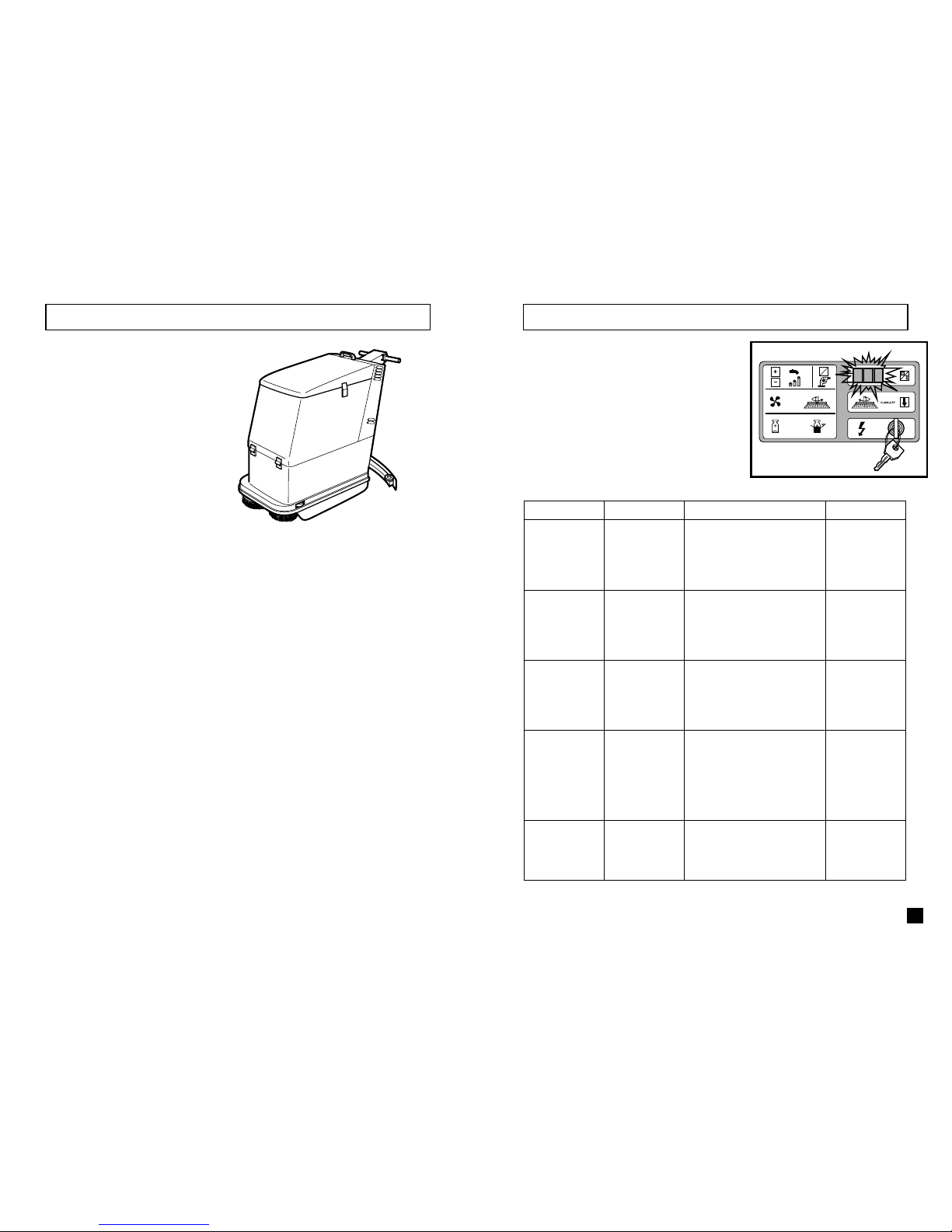

MACHINE CONTROLS AND MONITORS ...............................6

PREPARATION FOR USE .................................................7-11

SCRUBBING AND DRYING OPERATION ........................12-17

CLEANING OR REPLACING THE BRUSHES ..........................18

MAINTENANCE ...........................................................19-21

OPTIONALS.................................................................22-23

SAFETY FEATURES........................................................24-25

pag.

25

SAFETY FEATURES

SAFETY CODE-EVENT MACHINE BEHAVIOUR POSSIBLE INTERVENTION NOTES

302:

TROUBLE ON THE ELECTRONIC

CONTROL OF THE DRIVE

FUNCTION.

AUTOMATIC STOP OF THE

MACHINE.

BEFORE REPLACING THE POWER ELECTRONIC BOARD:

1-CHECK THE CONTINUITY OF THE CONNECTION CABLES

BETWEEN THE POWER ELECTRONIC BOARD AND THE

DRIVE MOTOR

2-CHECK THE OPERATION OF THE DRIVE MOTOR AND OF

ITS CARBON BRUSHES.

FOR FURTHER DETAILS SEE THE

WORKSHOP MANUAL OR CALL

THE SERVICE PERSONNEL.

304:

OVERTEMPERATURE ON THE

POWER ELECTRONIC BOARD.

THE MULTIFUNCTION DISPLAY

ON THE CONTROL PANEL IS

FLASHING AND THE MACHINE

IS STILL WORKING.

IF THE AMBIENT TEMPERATURE IS HIGH (OVER 35°C)

THIS COULD BE A NORMAL CONDITION.

OTHERWISE CHECK THAT THE ROTATION OF THE DRIVE

MOTOR AND/OR OF THE BRUSH MOTOR(S) IS FREE.

IT COULD BE USEFULL TO REDUCE THE PRESSURE OF THE

BRUSH(ES) ON THE FLOOR.

306:

OVERTEMPERATURE ON THE

POWER ELECTRONIC BOARD.

AUTOMATIC STOP OF ALL THE

FUNCTIONS OF THE MACHINE.

TURN-OFF THE KEY AND WAIT FOR THE SELF COOLING OF

THE ELECTRONIC BOARD (AT LEAST 20 MINUTES). THEN

CHECK THAT THE ROTATION OF THE DRIVE MOTOR AND/

OR OF THE BRUSH MOTOR(S) IS FREE.

IT COULD BE USEFULL TO REDUCE THE PRESSURE OF THE

BRUSH(ES) ON THE FLOOR.

IF THE 306 CODE OCCURS

FREQUENTLY CALL THE SERVICE

PERSONNEL.

307:

WRONG SWITCH-ON

SEQUENCE: THE ACCELERATOR

THUMB WHEELS WERE OUT OF

THE NEUTRAL POSITION WHEN

TURNING ON THE KEY.

THE MACHINE IS NOT ABLE TO

WORK.

PUT THE ACCELERATOR THUMB WHEELS IN THE NEUTRAL

POSITION.

IN THE EVENT THAT THE 307 CODE IS STILL FLASHING A

CHECK OF THE TWO MICROSWITCHES DEDICATED TO THE

FORWARD/REVERSE DRIVE CONTROL MUST BE DONE

(CALL THE SERVICE PERSONNEL).

CHECK THAT NO INTERFERENCE OCCURS BETWEEN THE

HAND GRIPS AND THE THUMB WHEELS.

308:

THE WIRES OF THE

POTENTIOMETER ARE CUT.

THE MACHINE IS NOT ABLE TO

WORK.

1-CHECK THE CONNECTION CABLES OF THE

POTENTIOMETER DEDICATED TO THE SPEED CONTROL.

2- IF THE POTENTIOMETER CONNECTION CABLES ARE

GOOD REPLACE THE POTENTIOMETER (CALL THE SERVICE

PERSONNEL).

The multifunction display on the control panel can

show some code numbers when the safety devices

of the machine are operated.

The list of the safety code numbers is shown

below:

ON

OFF

INTRODUCTION AND WARNINGS

1

INTRODUCTION

This manual is a guide to the efficient use of the machine and also contains practical information concerning the

functioning, adjustments and user maintenance of your new scrubber/drier. Your machine has been designed and

constructed to ensure maximum performarnce and ease of operation in a wide variety of applications. Before delivery, the

machine has been tested in our factory and by our distributor to ensure that it is delivered to you in perfect condition. To

maintain the machine in this condition and guarantee functioning without problems, it is essential that the periodic

maintenance operations indicated in this manual are properly carried out. Before using the machine, carefully read this

manual and keep it within easy reach for your future reference. Indications of “LEFT” and “RIGHT” are as seen from the

operator position. If you should need any further information concerning the machine, please do not hesitate to contact

either Electrolux Euroclean or our local distributor.

MODIFICATIONS AND IMPROVEMENTS

Electrolux Euroclean aim toward continuous improvement of its machines and reserves the right to carry out modifications

and improvements whenever necessary without being obliged to update machines which have been sold previously.

SAFETY

You too can avoid accidents.

No accident prevention programme is effective without the total co-operation of the person directly responsible for the

functioning of the machine. The majority of accidents which may occur either during work or transferring the machine from

site to site are caused by the non-observance of the most elementary safety rules. An alert and cautious operator is the best

guarantee against accidents and is more effective than any other part of an accident prevention programme.

The machine must be switched off and disconnected from either its battery or mains supply before any servicing or

adjustment of operational parts be carried out. Ensure that any assistant is clear of the machine and that covers are closed

before switching on.

GENERAL SAFETY RULES

The rules below have to be followed carefully in order to

avoid damages to the operator and to the machine.

- Read the labels carefully on the machine; Do not cover

them for any reason and replace them immediately if

damaged.

- The socket for the power supply must be fitted with a

standard earthing (ground) system.

- With the brushes in working position, avoid touching or

passing over the mains cable. Avoid damaging by

squashing, bending or stressing.

- Where there is damage to the mains cable, stop the

machine, take off the plug from the mains system, and

replace the damaged cable immediately by calling the

Electrolux Service department.

- Do not mix different detergents, avoiding harmful odours.

- Do not place any liquid containers onto the machine.

- The storage temperature has to be between +15°C and +

55°C.

- The perfect operating temperature should be between 0°

C and 40° C.

- The humidity should be between 30 and 95%.

- Do not use the machine in explosive atmosphere.

- Do not use the machine as a means of transport.

- Do not use acid solutions which could damage the

machine.

- Avoid working with the brushes when the machine stands

still, in order to prevent floor damages.

- Do not vacuum iflammable liquids.

- In case of fire, use a powder extinguisher. Do not use

water.

- Do not strike shelvings or scaffoldings, where there is

danger of falling objects.

- Adapt the utilization speed to the adhesion conditions.

- Do not exceed over the limit gradient stated, to avoid

conditions of instability (2% max).

- The machine has to carry out simultaneously the

operations of washing and drying. Different operations

have to be carried out in areas which are not permitted

for the passage of non employed staff. Signal the areas

of moist floors with suitable signs.

- If the machine does not work properly, check by

conducting simple maintenance procedures. Otherwise,

it is better to ask for technical service.

-Where parts are required, ask for ORIGINAL spare parts

to an agent and/or to an authorized dealer.

- For any maintenance operation take off the power supply

from the machine.

- Do not take off the pieces which require the use of tools

to be removed.

- Do not wash the machine with direct water jets or with

high water pressure not with corrosive material.

- Every 200 working hours have a machine check through

a service department.

- The machine should not be abandoned, because of the

presence of toxic-harmful materials (batteries, oil etc.).

This disposal must be subject to the rules which provide

for its scrapping in appropiate centres.

- The machine does not cause any harmful vibrations.

24

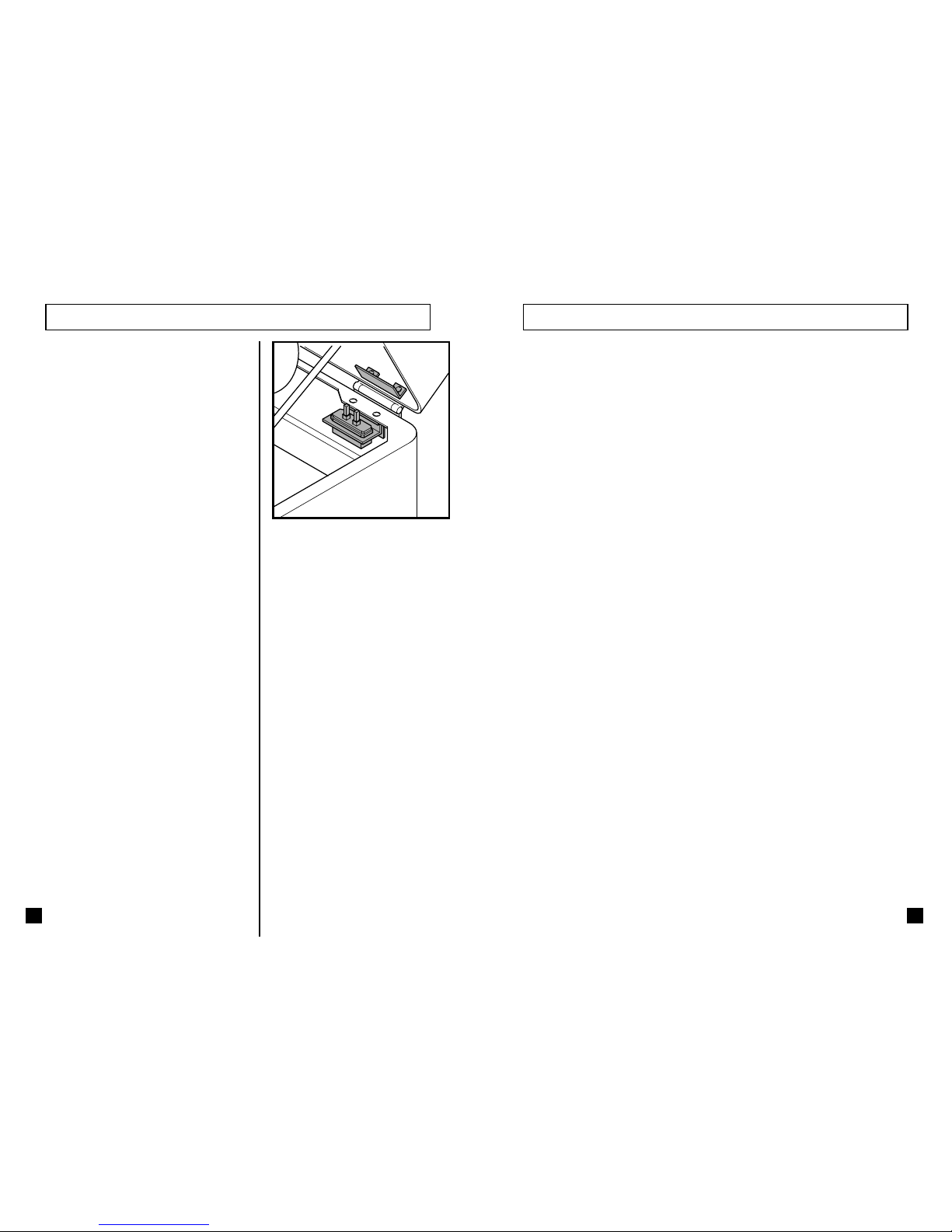

SAFETY FEATURES

For all models:

Safety micro switch:

Micro switch to shut off all the functions when the

tank unit is in the upright position. (SEMKO

APPROVAL).

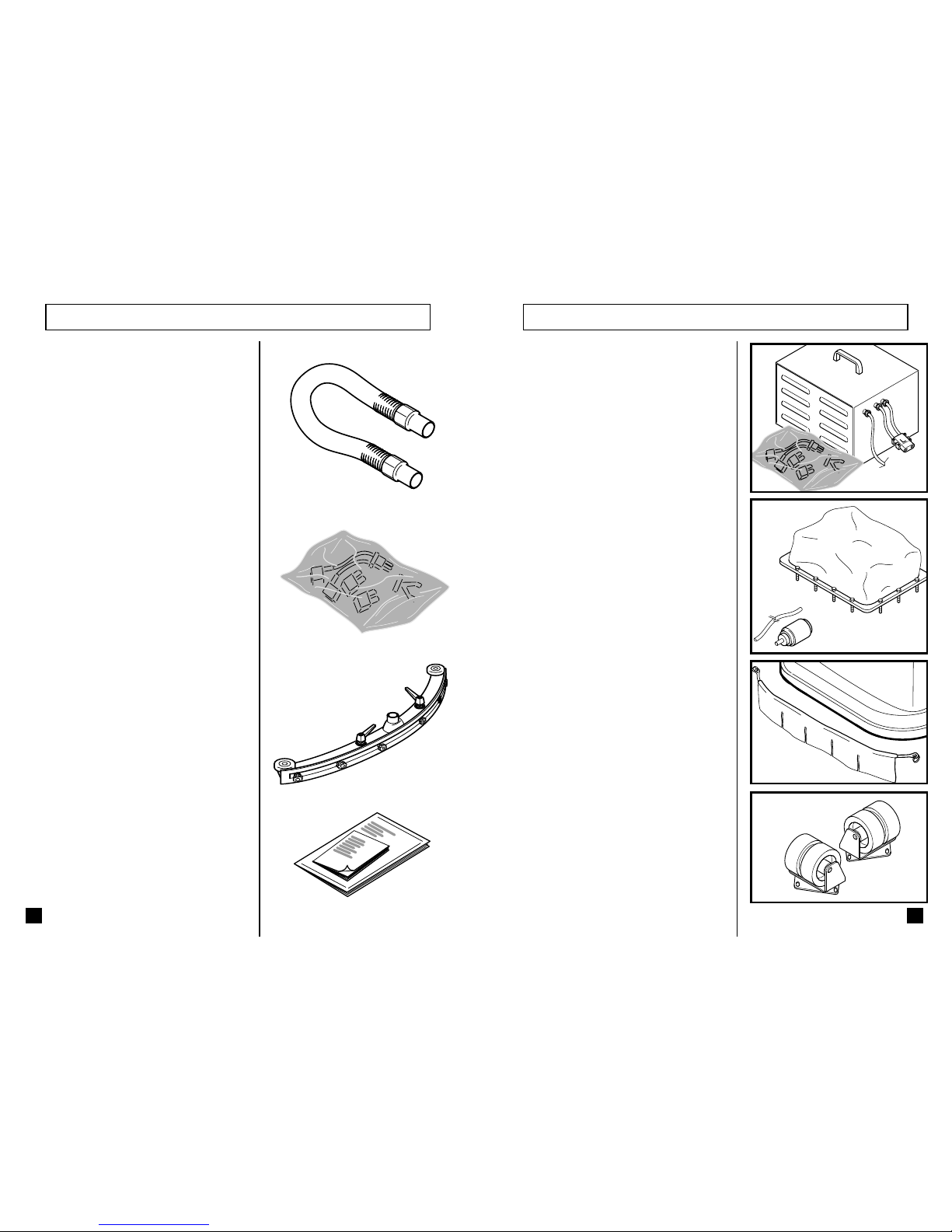

2

Check that you have received the following parts

together with the machine:

1

- Connecting hose for squeegee

2

- Plastic bag with cables for connection of

batteries

NOTE : Not supplied with mains cable versions of

models AW445 , AW445 T and AW455 T .

3

- Squeegee

4

- Documents

UNPACKING

For models AW445 , AW445 T and

AW455 T :

Kit of cables to transform the machine from mains

version to battery operated version.

Mains unit (or transformer) to change the machine

from the battery operated version to the mains

version.

For all versions of models AW445 ,

AW445 T and AW455 T :

A kit is available to equip the machine with the

membrane; in this case also the water pump must

be mounted.

For all models:

A front splash guard is also available.

For all models:

In order to reduce the pressure of the machine on

the floor (according to norm DIN 18032) two rear

twin wheels can be mounted.

OPTIONALS

23

3

TECHNICAL SPECIFICATION

22

OPTIONALS

In addition to the normal accessories supplied

with the machine the following optionals are

available:

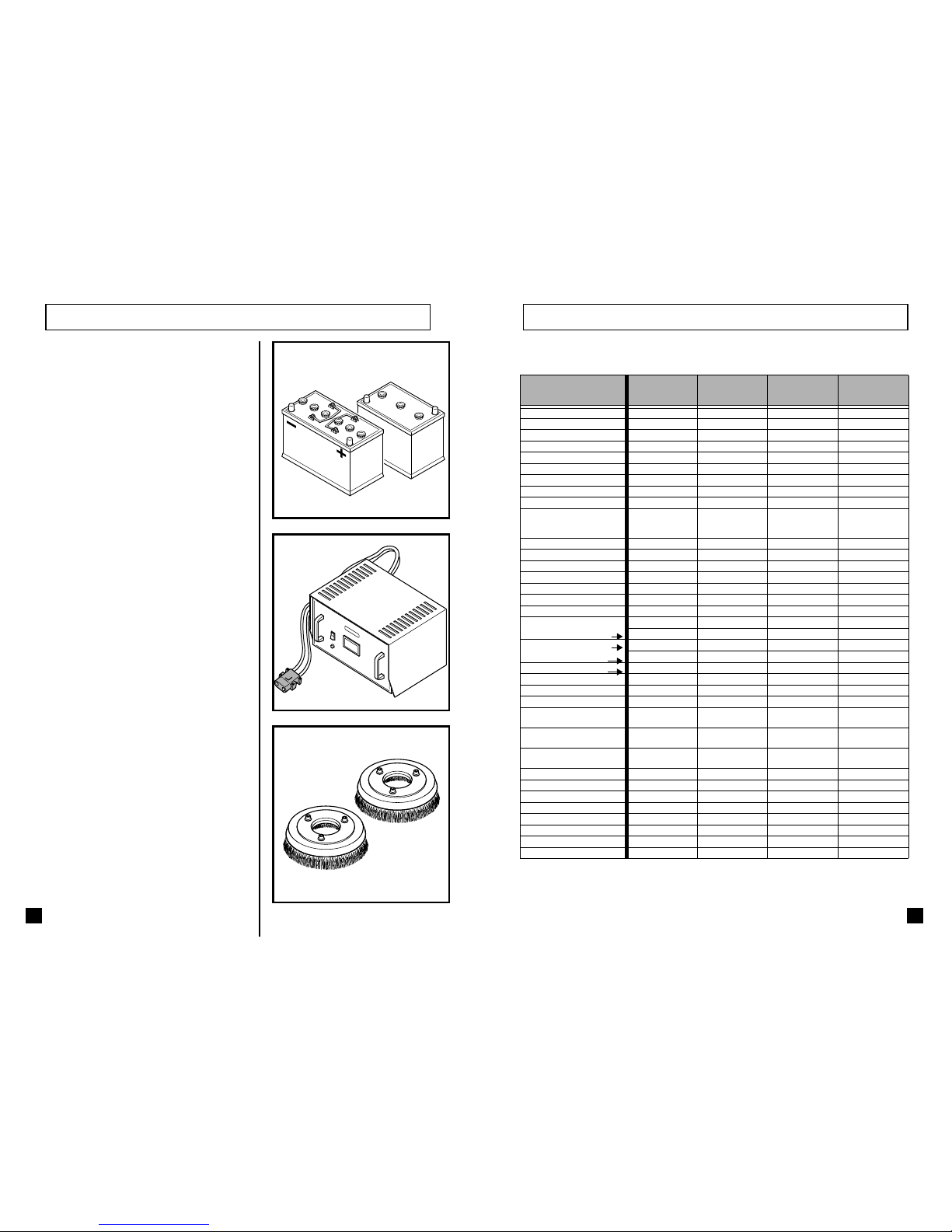

Batteries:

- For models AW465 and AW475: four 6 V

batteries 240 amp.h wet type.

- For models AW445 T and AW455 T: two 12

V batteries 140 amp.h wet type.

- For model AW445 : two 12 V batteries 115

amp.h wet type.

Battery chargers:

- For all models: charger for wet batteries

charger for dry batteries

Different types of brushes and pad holders are

available.

Union mix scrub brush

Polypropylene scrub brush

Silicon Carbide scrub brush

Pad holder

For sizes and codes consult the factory.

MODELS

AW 445

BATTERY

AW 445

CABLE

AW 445 T

BATTERY

AW 445 T

CABLE

Voltage

24V 220VAC-24VDC 24V 220VAC-24VDC

Drive motor

- - 24V-90W 24V-90W

Vacuum motor rating

420W-2 stages 420W-2 stages 420W-2 stages 420W-2 stages

Vacuum depression (mm H2O)

1150 1150 1150 1150

Brush motor

24V-250W 24V-250W 24V-250W 24V-250W

Brush

nr. 1x 430mm nr. 1x 430mm nr. 1x 430mm nr. 1x 430mm

Brush speed (scrubbing)

330 RPM 330 RPM 330 RPM 330 RPM

Brush pressure to floor (Kg)

from 9 to 21 from 9 to 21 from 9 to 24 from 9 to 24

Automatic Click OFF/Click ON

yes yes yes yes

Electrovalves

nr. 3 hole

diameters:

3.5-4.5-5.5mm

nr. 3 hole

diameters:

3.5-4.5-5.5mm

nr. 3 hole

diameters:

3.5-4.5-5.5mm

nr. 3 hole

diameters:

3.5-4.5-5.5mm

Water pump (optional)

12V-31W-0.9lt/1’ 12V-31W-0.9lt/1’ 12V-126W- 9lt/1’ 12V-126W- 9lt/1’

Water flow (lt/min)

1.3-2.6 1.3-2.6 1.3-2.6 1.3-2.6

Water flow + pump lt/min (opt)

1.9-3 1.9-3 2.8-4.5 2.8-4.5

Max slope

- - 2 % 2 %

Driving speed F/R (Km/h)

- - 3/2.25 3/2.25

Working width (mm)

430 430 430 430

Squeegee width (mm)

700 700 700 700

Solution tank capacity (lt)

with membrane (optional) (lt)

34 34 34 34

50 50 50 50

Recovery tank capacity (lt)

with membrane (optional) (lt)

35 35 35 35

51 51 51 51

Suggested batteries (wet)

nr.2 12V-115Ah - nr.2 12V-140Ah -

Suggested batteries (dry)

nr.2 12V-70Ah - - -

Running time (with wet batteries) about 2h - 2.8-3h Running time (with dry batteries) about 1h 30’ - - Suggested battery charger

(for wet battery)

CBN2 20A-24V - CBN2 25A-24V -

Suggested battery charger

(for dry battery)

CBS2 20A-24V - CBS2 25A-24V -

Feeder

-

220/240 VAC

50/60HZ

-

220/240 VAC

50/60HZ

Front wheels diameter (mm)

nr.2-150 nr.2-150 nr.2-150 nr.2-150

Rear wheels diameter (mm)

nr.2-80 nr.2-80 nr.2-80 nr.2-80

Middle drive wheel diameter

- - nr.1-150 nr.1-150

Width (mm)

460 460 460 460

Length (mm)

1235 1235 1235 1235

Height (mm)

1050 1050 1050 1050

Weigth without batteries (Kg)

81-91-

Total weigth with feeder (Kg)

- 115 - 125

Loading...

Loading...