Page 1

Fridge-Freezer

Instruction Book

P/N 241631700 (0105)

Page 2

Welcome & Congratulations

Welcome 2

Safety Instructions

Installation -- Includes Connecting

Ice Maker To Water Supply

Door Removal

Instructions

Features at a Glance

Temperature Controls

3 - 4

5 - 6

7

8

9 - 10

Congratulations on your purchase of a new fridge-freezer!

We here at Electrolux Home Products are very proud of

our product and we are completely committed to providing

you with the best service possible.

Please read this Instruction Book very carefully. It

contains valuable information on how to properly

maintain and use your new fridge-freezer.

We know you’ll enjoy your new fridge-freezer and Thank

You for choosing our product. We hope you consider us for

future purchases.

PLEASE READ AND SAVE THESE INSTRUCTIONS

This Use & Care Manual provides specific operating

instructions for your model. Use your fridge-freezer only as

instructed in this manual. These instructions are not meant

to cover every possible condition and situation that may

occur. Common sense and caution must be practiced when

installing, operating and maintaining any appliance.

Please record your model and serial numbers below for

future reference. This information is found on the serial

plate located inside the refrigerator compartment.

Looking Inside

11 - 13

Automatic Ice and Water

Dispenser

14 - 18

Food Storage

& Energy Saving Tips

Normal Operating Sounds

Care & Cleaning

21 - 22

Warranty

Something Not

NOTE: Use only water to clean serial plate.

Model Number:

Serial Number:

Purchase Date:

19

20

23

Working

24 - 27

Please complete and mail in the

Registration Card

included with your

fridge-freezer.

2

Product

Page 3

Important Safety Instructions

It is most important that this instruction book should

be retained with the appliance for future reference.

Should the appliance be sold or transferred to another

owner, or should you move house and leave the

appliance, always ensure that the book is left with the

appliance in order that the new owner can get to know

the functioning of the appliance and the relevant safety

information.

This information has been provided in the interest of

safety. You MUST read it carefully before installing or

using the appliance.

If you are unsure about any of this information please

contact our customer services department on 08705 950

950.

Installation

• This appliance is heavy. Care should be taken when

moving it.

• It is dangerous to alter the specifications or attempt

to modify this product in any way.

• Care must be taken to ensure that the appliance does

not stand on the electrical supply cable.

Important: if the supply cable is damaged, it must be

replaced by a special cable available from your local

Service Force Centre.

• Any electrical work required to install this appliance

should be carried out by a qualified electrician or

competent person.

• Parts which heat up should not be exposed.

Whenever possible, the back of the appliance should

be close to a wall but leaving the required distance for

ventilation as stated in the installation instructions.

• The appliance should be left for 2 hours after

installation before it is turned on, in order to allow the

refrigerant to settle.

• Ice lollies can cause frost/freezer burns if consumed

straight from the freezer.

• Manufacturers storage recommendations should be

strictly adhered to. Refer to relevant instructions.

Maintenance and Cleaning

• Switch off and unplug the appliance before carrying

out any cleaning or maintenance work.

Servicing

• This product should be serviced by an authorised

engineer and only genuine spare parts should be

used.

• Under no circumstances should you attempt to repair

the machine yourself. Repairs carried out by

inexperienced persons may cause injury or serious

malfunctioning. Refer to your local Electrolux Service

Force Centre and always insist on genuine spare

parts.

At the end of the Appliance Life

• When disposing of your appliance, use an authorised

disposal site.

• Remove the plug and doors to prevent young children

being trapped inside.

Child Safety

• Do not allow children to tamper with the controls or

play with the product.

• Keep all packaging well away from children.

During Use

• This appliance is designed for domestic use only,

specifically for the storage of edible foodstuffs only.

• Frozen food must NOT be re-frozen once it has

thawed out.

• Do not place carbonated or fizzy drinks in the freezer.

• Do not remove items from the freezer if your hands are

damp/wet, as this could cause skin abrasions or frost/

freezer burns.

3

Page 4

Important Safety Instructions

Electrical connections

Any electrical work required to install this appliance should

be carried out by a qualified electrician or competent person.

THIS APPLIANCE MUST BE EARTHED.

The manufacturer declines any liability should this

safety measure not be observed.

If the plug that is fitted to your appliance is not suitable for

your socket outlet, it must be cut off and the appropriate

plug fitted.

Remove the fuse from the cut off plug. The cut off plug should

then be disposed of to prevent the hazard of shocks in case

it should be plugged into a 13amp socket in another part of

your home.

IMPORTANT

The wires in the mains lead are coloured in accordance with

the following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

If you fit your own plug, the colours of the wires in the mains

lead of your appliance may not correspond with the markings

identifying the terminals in your plug, proceed as follows:

For replacement, use a 13amp BSI362 fuse. Only ASTA or

BSI approved fuses should be used.

The plug must not be used if the fuse cover/carrier is lost.

The cover/carrier is indicated by the coloured insert at the

base of the plug.

A replacement cover/carrier must be obtained from your local

Service Force Centre.

This appliance complies with the E.E.C. Directive No.

87/308 of 2.6.87 relative to radio interference

suppression.

This appliance complies with the following E.E.C.

Directives:

- 73/23 EEC of 19.2.73 (Low Voltage Directive) and

subsequent modifications;

- 89/336 EEC of 3.5.89 (Electromagnetic Compatibility

Directive) and subsequent modifications.

Please ensure that when the appliance is installed it

is easily accessible for the engineer in the event of a

breakdown.

*5((1<(//2:

%/8(

'

$03)86(

$03

%52:1

&25'&/$03

Connect the Green and Yellow (earth) wire to the terminal in

the plug which is marked with the letter <<E>> or the earth

symbol or coloured green and yellow.

Connect the blue (neutral) wire to the terminal in the plug

which is marked with the letter ÇNÈ or coloured black.

Connect the brown (live) wire to the terminal in the plug

which is marked with the letter ÇLÈ or coloured red.

The plug moulded onto the lead incorporates a fuse.

4

Page 5

Installation

This Owner’s Guide provides specific operating instructions

for your model. Use the fridge-freezer only as instructed in

this Use & Care Manual. Before starting the fridge-freezer

follow these important first steps.

LOCATION

• Choose a place that is near an earthed 13A socket. Do

Not use an extension cord or an adapter plug.

• If possible, place the fridge-freezer out of direct sunlight

and away from the cooker, dishwasher or other heat

sources.

• The fridge-freezer must be installed on a floor that is

level and strong enough to support a fully loaded

fridge-freezer.

• Consider water supply availability for models equipped

with an automatic ice maker.

INSTALLATION

Do Not install the fridge-freezer

where the temperature will drop below 55°F (13°C)

or rise above 110°F (43°C). The compressor will not

be able to maintain proper temperatures inside the

fridge-freezer.

Do Not block the toe grille on the

lower front of your fridge-freezer. Sufficient air

circulation is essential for the proper operation of your

fridge-freezer.

Installation Clearances

• Allow the following clearances for ease of installation,

proper air circulation, and plumbing and electrical

connections:

Sides & Top --------------- 3/8” (1 cm)

Back ------------------------ 1” (2.5 cm)

DOOR OPENING

NOTE: If your fridge-freezer is placed with the door hinge

side against a wall, you may have to allow additional

space so the door can be opened wider.

Your fridge-freezer should be positioned to allow easy access

to a counter when removing food. For best use of drawers and

freezer baskets, the fridge-freezer should be in a position where

both the refrigerator and freezer doors can be fully opened.

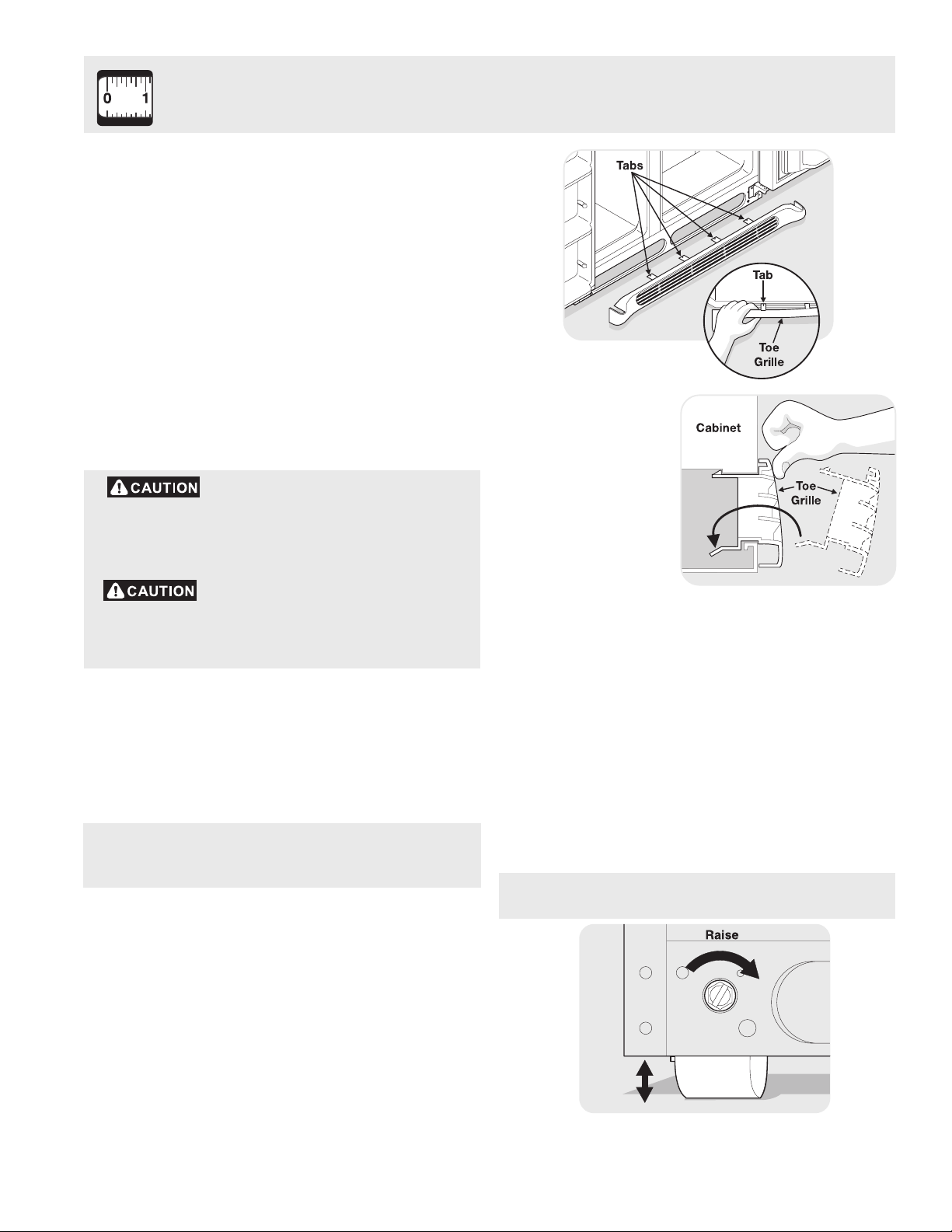

TOE GRILLE INSTALLATION / REMOVAL

To Remove Toe Grille:

1. Open freezer and fresh food compartment doors.

2. Working from left side of toe grille, slip your fingers

between top of toe grille and cabinet. Gently pull

forward until first set of tabs are free. Slide your hand

down past the free tabs and pull forward again until the

second set of tabs are free. Continue this process until

all tabs are free and the toe grille can be removed. (See

graphic at top of page in right column.)

To Install Toe Grille:

1. Open freezer and

fresh food

compartment doors.

2. Line up toe grille at

base of fridge-freezer,

making sure the four

bottom tabs are

resting through holes

at base of cabinet.

3. Starting from left side

of toe grille, press in on

first top tab using your thumb and push toe grille forward

until it snaps in place. Continue this process until all

tabs are snapped in place and toe grille is secured to

fridge-freezer.

LEVELING

All four corners of your fridge-freezer must rest firmly on a solid

floor. Your fridge-freezer is equipped with adjustable front rollers to

help level your unit. To ensure proper door seal and assist door

closing, the fridge-freezer should be tilted 1/4” (6 mm), front to

back.

To Level Your Fridge-Freezer:

1. Remove toe grille. (See

2. Use flat-blade screwdriver or 3/8” socket wrench to adjust

front rollers.

NOTE: The fridge-freezer doors are designed to shut by

themselves within a 20 degree opening.

3. Check both doors to be sure seals touch cabinet on all four

sides.

5

“To Remove Toe Grille”

.)

Page 6

Installation

To avoid electric shock, which can cause death or severe personal injury, disconnect the fridge-

freezer from electrical power before connecting a water supply line to the fridge-freezer.

To Avoid Property Damage:

• Copper tubing is recommended for the water supply line. Water supply tubing made of ¼” plastic is not

recommended since it greatly increases the potential for water leaks. Manufacturer will not be responsible

for any damage if plastic tubing is used for supply line.

• DO NOT install water supply tubing in areas where temperatures fall below freezing.

• Chemicals from a malfunctioning softener can damage the ice maker. If the ice maker is connected to soft

water, ensure that the softener is maintained and working properly.

IMPORTANT: Ensure that your water supply line connections comply with all local plumbing codes.

Before Installing The Water Supply Line, You Will Need

• Basic Tools: adjustable wrench, flat-blade screwdriver, and PhillipsTM screwdriver

• Access to a household cold water line with water pressure between 20 and 100 psi.

• A water supply line made of ¼ inch (6.4 mm) OD, copper tubing. To determine the length of copper tubing needed,

you will need to measure the distance from the ice maker inlet valve at the back of the fridge-freezer to your cold water

pipe. Then add approximately 7 feet (2.1 meters), so the fridge-freezer can be moved out for cleaning (as shown).

• A shutoff valve to connect the water supply line to your household water system. DO NOT use a self-piercing type

shutoff valve.

• A compression nut and ferrule (sleeve) for connecting the water supply line to the ice maker inlet valve.

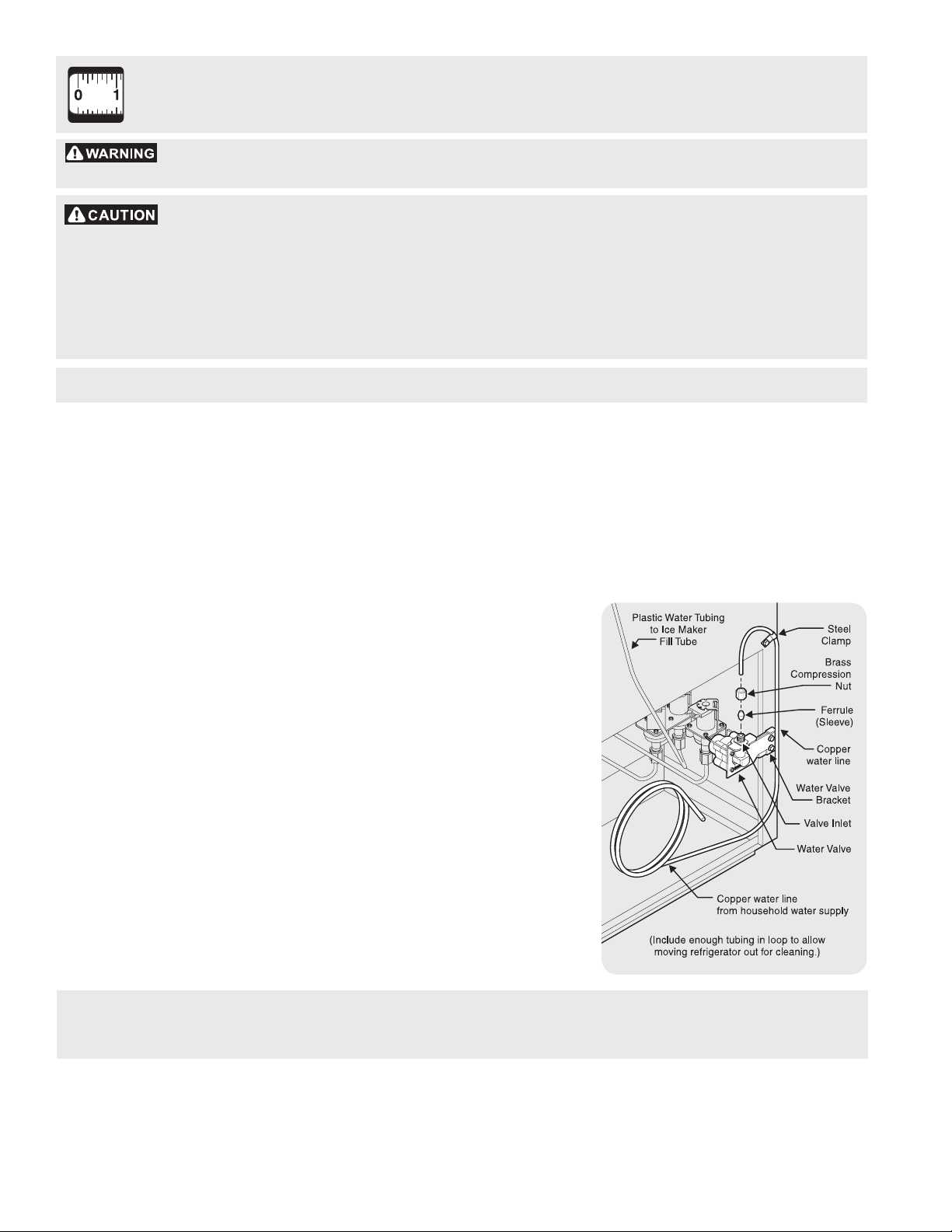

- Connecting Ice Maker To Water Supply

To Connect Water Supply Line To Ice Maker Inlet Valve

1. Disconnect fridge-freezer from electric power source.

2. Place end of water supply line into sink or bucket. Turn ON water supply

and flush supply line until water is clear. Turn OFF water supply at shut

off valve.

3. Unscrew plastic cap from water valve inlet and discard cap.

4. Slide brass compression nut, then ferrule (sleeve) onto water supply line,

as shown.

5. Push water supply line into water valve inlet as far as it will go (¼ inch).

Slide ferrule (sleeve) into valve inlet and finger tighten compression nut

onto valve. Tighten another half turn with a wrench; DO NOT over tighten.

6. With steel clamp and screw, secure water supply line to rear panel of

fridge-freezer as shown.

7. Coil excess water supply line (about 2½ turns) behind fridge-freezer as shown

and arrange coils so they do not vibrate or wear against any other surface.

8. Turn ON water supply at shutoff valve and tighten any connections that

leak.

9. Reconnect fridge-freezer to electrical power source.

10. Make sure ice maker power switch is turned On (See page 14 for location of

power switch).

IMPORTANT: It takes approximately 24 hours for the ice maker to begin producing ice. Air in new plumbing lines may

cause ice maker to cycle two or three times before making a full tray of ice. New plumbing may cause ice to be

discolored or have poor flavor. Discard ice made during the first 24 hours.

6

Page 7

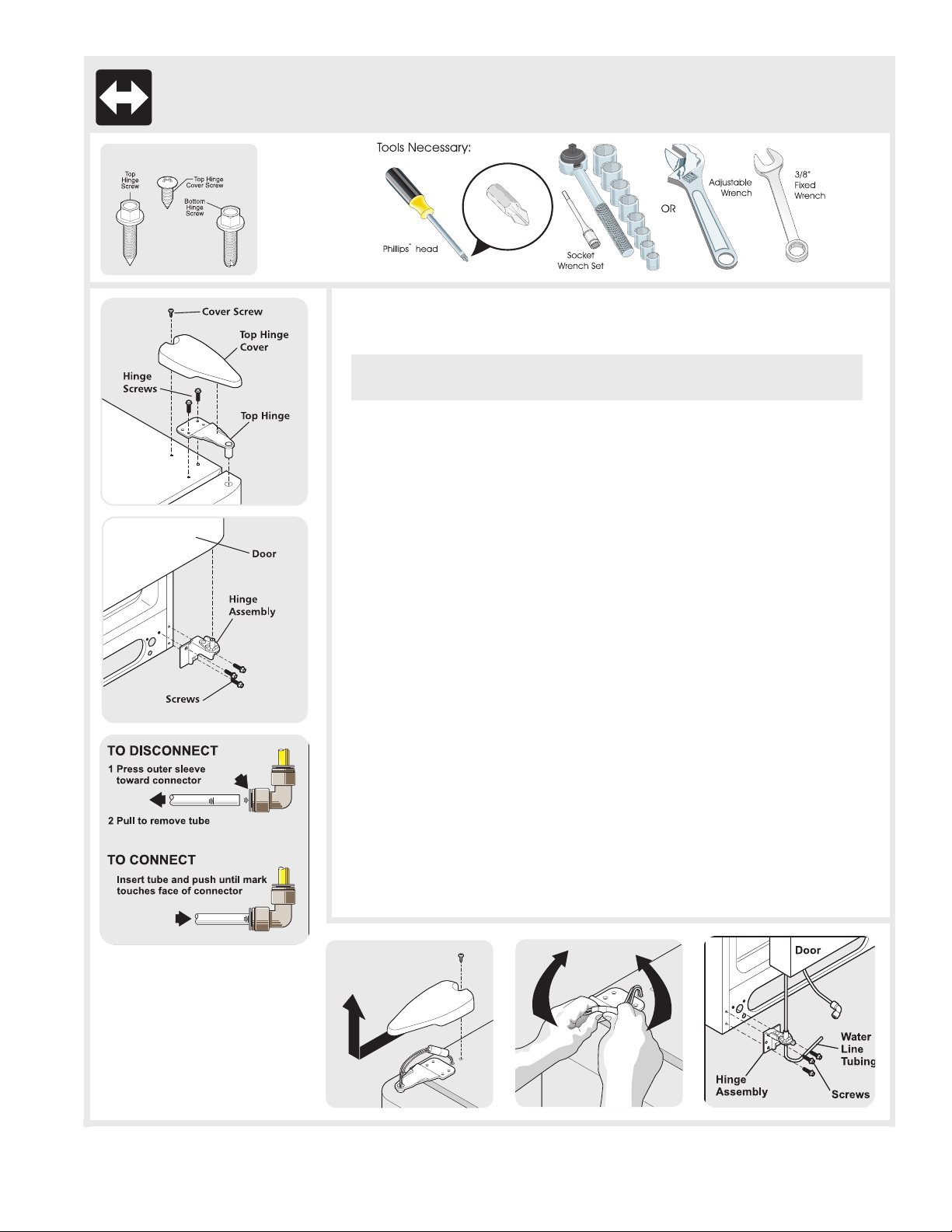

Door Removal Instructions

DOOR REMOVAL INSTRUCTIONS:

If it is necessary to move the fridge-freezer through narrow doorways,

follow these steps to remove the doors.

IMPORTANT: Before you begin, remove electrical power cord from wall

outlet. Remove any food from door shelves.

1. Disconnect electrical supply.

2. Open both doors, then remove toe grille (see page 4 to learn how).

3. Close doors.

To Remove Refrigerator Door:

1. Remove top hinge cover screw on refrigerator door and remove cover.

2. Trace around hinge with soft lead pencil. This will make it easier to realign

doors when they are replaced.

3. Remove top hinge and lift refrigerator door off bottom hinge pin. Set door

aside.

4. Remove bottom hinge, if necessary.

5. Reverse this procedure to reinstall refrigerator door.

To Remove Freezer Door:

1. Disconnect water line coming from lower hinge of freezer door at connection

located under front of freezer: Press outer ring against face of fitting, then pull

to remove tube.

2. Remove top hinge cover screw on freezer door and remove cover.

3. Disconnect wiring harness connector plug at top hinge: place your thumbs on

flat sides of each connector and bend both parts back and forth, then with

firm grasp, pull both pieces apart.

4. Trace around hinge with soft lead pencil. This will make it easier to realign

doors when they are replaced.

5. Remove top hinge, allowing wiring harness to pull through hinge and lift freezer

door off of bottom hinge pin. Lay door down flat to avoid kinking water line.

6. Remove bottom hinge, if necessary.

7. Reverse this procedure to reinstall freezer door.

When both doors have been reinstalled, connect water line by inserting tube and

pushing until mark touches face of fitting, replace toe grille and plug in electrical

power cord.

7

Page 8

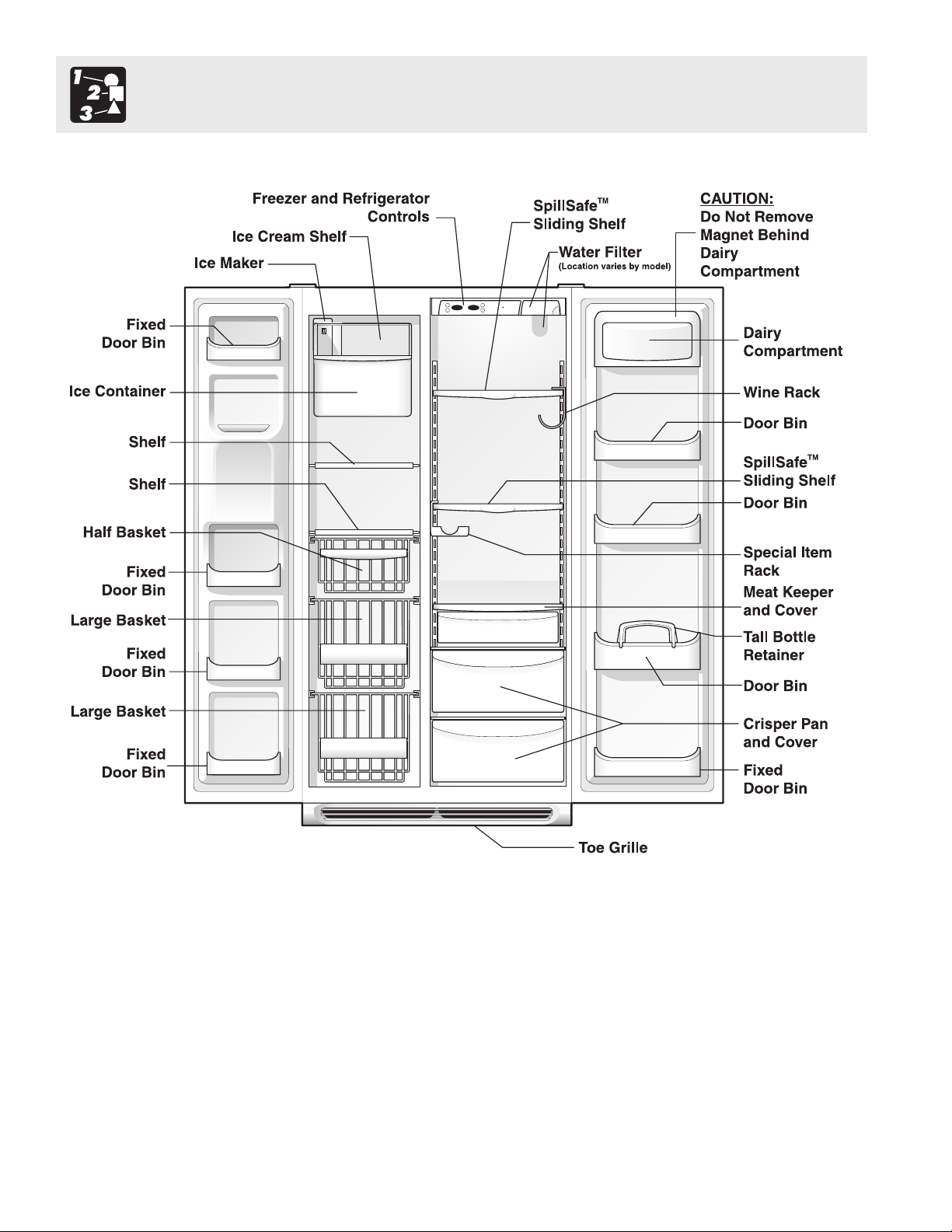

Features At A Glance

Features may vary according to model

8

Page 9

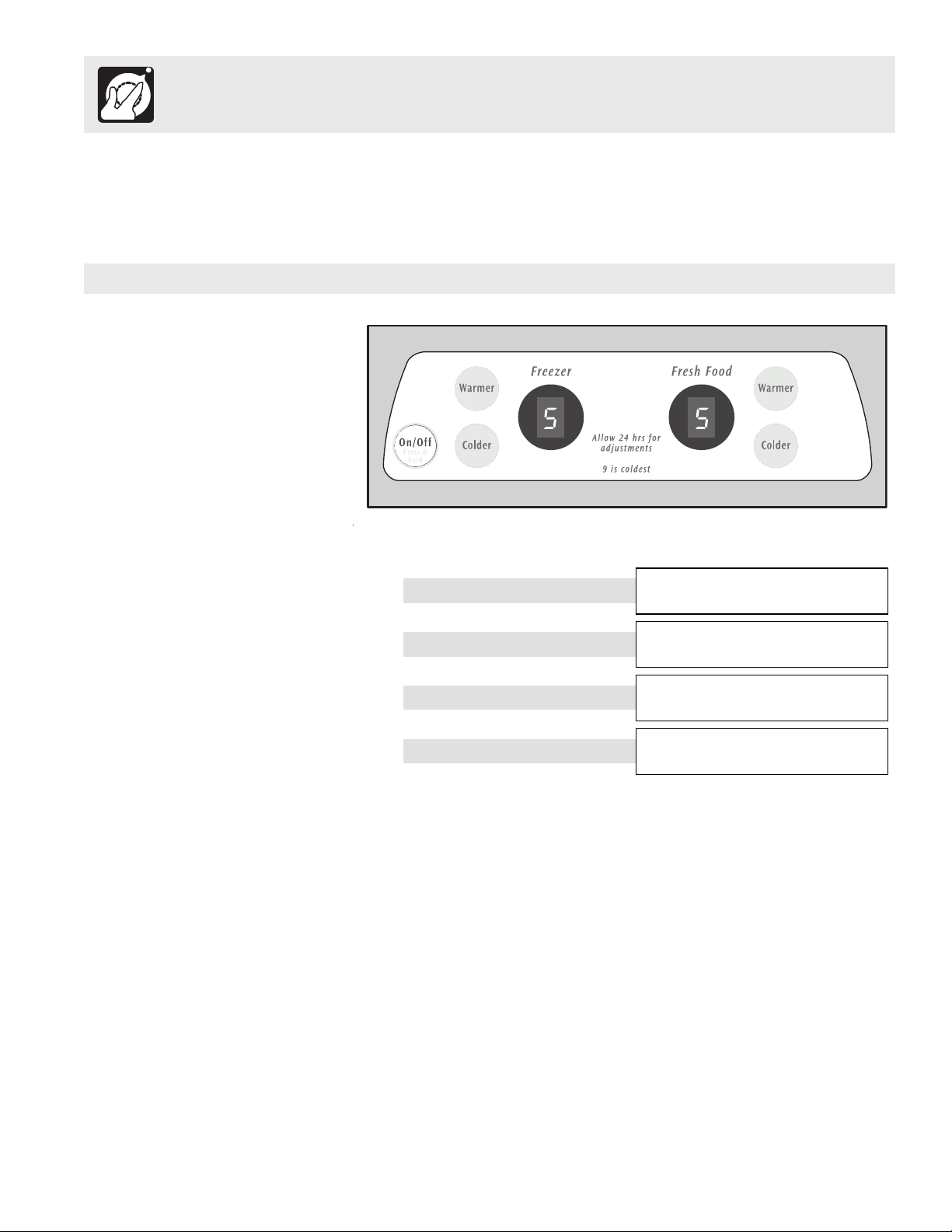

Temperature Controls

COOL DOWN PERIOD

To ensure safe food storage, allow the fridge-freezer to operate with the doors closed for at least 6 hours before loading

it with food.

REFRIGERATOR & FREEZER CONTROLS

NOTE: When changing control settings, wait 24 hours before making additional adjustments.

After 24 hours, adjust the controls as

needed. Make your adjustments small

and gradual; allowing time for

temperatures to change and stabilize.

Refer to the adjacent guidelines for

temperature settings.

The range of possible settings is 1

through 9, with 9 being the coldest.

Both the Freezer and Fresh Food

compartments are preset at the factory

to 5, the midpoint temperature setting.

To adjust the temperature to a higher or

lower setting, press the Warmer or

Colder button closest to the display. The

first time you press the button, the

display shows the last setting you

entered. Each press of the button after

that increments the setting by one.

The display shows your new setting

momentarily, then changes back to the

current temperature.

IF THE TEMPERATURE

DISPLAYS FLASH...

If ever you see both temperature displays

continously flashing, it may indicate that

the control system has detetcted a

performance problem. Call your local

Service Force Centre who can interpret

the flashing message.

Temperature Adjustment Guide

If Fresh Food compartment is too warm

If Fresh Food compartment is too cold

If Freezer compartment is too warm

If Freezer compartment is too cold

Adjust Fresh Food control one number

higher by pressing the Colder button.

Adjust Fresh Food control one number

lower by pressing the Warmer button.

Adjust Freezer control one number higher

by pressing the Colder button.

Adjust Freezer control one number lower

by pressing the Warmer button.

To maintain temperatures, a fan

circulates air in the refrigerator and

freezer compartments. For good

circulation, do not block cold air vents

with food items.

9

Page 10

Temperature Controls

OTHER CONTROL FEATURES

Cooling System On/Off Button

TURNING THE COOLING SYSTEM ON AND OFF

You can disable the cooling system in your fridge-freezer

by pressing the On/Off button located on the left side of

the temperature control panel.

NOTE: Each time you make

settings on the control panel,

a single audible tone

acknowledges your input.

To ensure that you do not accidentally turn off the cooling

system, the button does not work unless you press

hold

it for three seconds.

Once you disable the cooling system, all refrigeration to

the freezer and fresh food compartments stops.

To turn the cooling system back on, you must again press

and hold

the On/Off button for three more seconds.

and

IMPORTANT: Pressing the On/Off button on the control

panel disables your fridge-freezer’s cooling system but

does not disconnect power to lights and other electrical

components. To turn off power to your fridge-freezer you

must unplug the power cord from the wall outlet.

10

Page 11

Looking Inside

ICE CREAM SHELF (SOME MODELS)

This shelf attaches to the top of the ice dispenser container. It allows storage

of both round and rectangular cartons of your favorite ice cream.

To avoid personal injury or property damage, handle

tempered glass shelves carefully. Shelves may break suddenly if

nicked, scratched, or exposed to sudden temperature change.

CANTILEVER SHELF ADJUSTMENT

Fridge-freezer shelves are easily adjusted to suit individual needs. Before

adjusting the shelves, remove all food. Cantilever shelves are supported at

the back of the fridge-freezer.

Ice Cream Shelf

1

To adjust cantilever shelves:

1 Lift front edge up.

2 Pull shelf out.

Replace the shelf by inserting the hooks at rear of the shelf into the wall

bracket. Lower the shelf into the desired slots and lock into position.

* SpillSafeTM

In some models, the

food and for fast cleaning. The shelves slide out independently of their

mounting brackets. Just pull the front of the shelf forward. Shelves can be

extended as far as the stopper will allow but are not removable from their

mounting brackets.

glass shelves (some models) catch and hold accidental spills.

* SpillSafe

TM

shelves slide out for easy access to

2

Cantilever Glass Shelf

1

2

11

Cantilever Sliding Glass Shelf

Page 12

Looking Inside

(continued)

DOOR STORAGE

Door bins and shelves are provided for convenient storage

of jars, bottles, and cans. Frequently used items can be

quickly selected.

Some models have door bins that can accommodate 4.45 ltr

sized plastic drink containers and economy-sized jars and

containers. Some bins are adjustable for maximum storage

capacity.

The dairy compartment, which is warmer than the general

food storage section, is intended for short term storage of

cheese, spreads, or butter.

ADJUSTABLE DOOR BINS

Some models have adjustable door bins that can be moved

to suit individual needs.

To move door bins

1. Lift bin straight up.

2. Remove bin.

3. Place bin in desired position.

4. Lower bin onto supports until locked in place.

TALL BOTTLE RETAINER (SOME MODELS)

The Tall Bottle Retainer keeps tall containers in the bin from

falling forward when opening or closing the fridge-freezer

door. To install, hold the retainer at the top, and slide it over

the outside wall of the bin, as shown in the diagram.

Tall Bottle Retainer

SPECIAL ITEM RACK (SOME MODELS)

The innovative design of the Special Item Rack allows you

to store a six-pack of 330ml drink cans, a bottle of wine, a

two-litre soft drink bottle, or a carton of eggs. The Special

Item Rack mounts on the left side of your fridge-freezer. To

install, just slide the Special Item Rack onto any shelf as

shown in the drawing.

Adjustable Door Bin

Special Item Rack

12

Page 13

Looking Inside -

Special Storage Areas

CRISPERS (SOME MODELS)

The crispers, located under the bottom refrigerator shelf,

are designed for storing fruits, vegetables, and other fresh

produce. Wash items in clear water and remove excess water

before placing them in the crispers. Items with strong odors

or high moisture content should be wrapped before storing.

Crisper Drawer

MEAT KEEPER

Some models are equipped with a Meat Keeper. Meat Keeper

temperatures can be adjusted by sliding the Meat Keeper

Temperature Control in either direction. Use this pan for short

term storage of bulk meat items. If meats are to be kept

longer than one or two days, they should be frozen. The

Meat Keeper is fixed and cannot be moved up or down. If

fruits or vegetables are to be stored in the Meat Keeper, set

the Meat Keeper Temperature Control to a warmer setting to

prevent freezing.

HUMIDITY CONTROL (SOME MODELS)

The Humidity Control, present on some models with crisper

drawers, allows you to adjust the humidity within the crisper.

This can extend the life of fresh vegetables that keep best

in high humidity.

NOTE: Leafy vegetables keep best when stored with

the Humidity Control set on Higher Humidity, or in a

drawer without a Humidity Control. This keeps incoming

air to a minimum and maintains maximum moisture

content.

Crisper Humidity Control

Meat Keeper with Temperature Control

WINE RACK (SOME MODELS)

The wine rack stores bottles of wine, or single two-liter plastic

bottles of juice or soda pop. To install, slide the Wine Rack

onto the shelf with the curve facing in. To remove, slide the

Wine Rack out. Install on either side of shelf.

Wine Rack

13

Page 14

Automatic Ice and Water Dispenser

AUTOMATIC ICE & WATER DISPENSER OPERATING INSTRUCTIONS

dehsurC

debuC

thg

iL

nO

thgiL

ffO

RETAWresnepsidret

sserP ffOthgiL .daPhcuoTehtevobaraeppalliwrotacidniderA.thgilresnepsidffonrutotdaPhcuoT

2

1

5

43

6

Features may vary according to model.

ehtsserP dehsurC sserP.daPhcuoTehtevobaraeppalliwrotacidniderA.ecidehsurctegotdaPhcuoT

ehtsserP debuC ssalgsserP.daPhcuoTehtevobaraep

ehtsserP nOthgiL .daPhcuoTehtevobaraeppalliwrotacidniderA.thgilresnepsidnonrutotdaPhcuoT

eht

awehtetarepooT gnisnepsidpotsoT.elddapgnisnepsidRETAWehttsniagassalgasserp,

tmehtswolladnasllips dnaretawruoptonoD.

aerasihtniecissecxe .niardonsierehtesuaceb

1

5

2

5

3

4

6

acotelbissopsapurafsaelddapgnisnepsidECItsniagassalg

palliwrotacidniderA.ecidebuctegotdaPhcuoT

.ecillahct

.ecillahctacotelbissopsapurafsaelddapgnisnepsidECItsniaga

6

iretawdesnepsiD.elddapgnisnepsidehtmorfyawassalgehtllup,retaw

efasrehsawhsiddnaelbavomersiyartpirdsihT.etaropaveo

dda,retawredlocroF.dloctons

llamssehctacresnepsidehtfoesabehttadetacolyartpirdA.retawgnisnepsiderofebsebucroecidehsurc

14

Page 15

Automatic Ice and Water Dispenser

ICE AND WATER DISPENSER FEATURES

The ice and water dispenser conveniently dispenses chilled water, and ice cubes or crushed ice, depending on the model.

To operate the ice dispenser, select the ice option desired using the touchpad. Press a glass against the dispensing paddle

as far up as possible to catch all ice. To stop dispensing ice, pull glass away from dispensing paddle. Do not remove the

glass until the ice has completely dispensed. (Complete instructions for the dispenser operation are attached to the inside

of the freezer door.)

How the Water Dispenser Works

The water tank, located behind the refrigerator compartment, automatically fills as water is dispensed. For proper dispenser

operation, the recommended supply water pressure should fall between 20 psi and 100 psi.

Water pressure must not exceed 100 psi. Excessive pressure may cause water filter to malfunction.

After the fridge-freezer is connected to the water supply, fill the water tank by drawing one glass of water. It may take

about 1½ minutes after activating the dispenser paddle before water begins to fill this first glass. Continue flushing the

system for 3 minutes to rid the tank and plumbing connections of any impurities. The water dispenser has a built in shutoff

device that will stop the water flow after 3 minutes of continuous use. Simply release the dispenser paddle to reset the

shutoff mechanism.

Chemicals from a malfunctioning softener can damage the ice maker. If the ice maker is connected

to soft water, ensure that the softener is maintained and working properly.

How the Ice Dispenser Works

The ice maker and container are located in the top of the freezer compartment. After the

fridge-freezer is installed properly and has cooled for several hours, the ice maker can begin

making ice within 24 hours. Air in new plumbing lines may cause the ice maker to cycle two

or three times before making a full tray of ice. Ice production is controlled by the ice maker’s

On/Off power switch. Press the switch to the “O” position to turn it Off and press it to the “I”

position to turn it On. With no usage it will take approximately 2 days to fill the ice container.

The ice maker also has a built-in wire signal arm,which automatically stops ice production

when the ice bin is full. This signal arm should not be used to manually stop the ice maker.

The ice maker produces 4 to 6 pounds of ice every 24 hours depending on usage conditions.

Ice is produced at a rate of 8 cubes every 75 to 90 minutes.

Because of new plumbing connections, the first production of ice cubes may be discoloured or have an odd flavour. These

should be discarded until the cubes made are free of discoloration and taste.

ICE DISPENSER TIPS

• Ice cubes stored too long may develop an odd flavor. Empty the ice container and ensure that the ice maker’s On/Off

power switch is turned On (set to the “I” position). The ice maker will then produce more ice.

• Occasionally shake the ice container to keep ice separated.

• Keep the ice maker’s On/Off power switch turned Off (set to the “O” position) until the fridge-freezer is connected to the

water supply or whenever the water supply is turned off.

IMPORTANT: The ice maker is turned On at the factory so it can work as soon as you install your fridge-freezer. If

you cannot connect a water supply, turn the On/Off switch to the Off (“O”) position. Otherwise, the ice maker’s valve

may be noisy when it attempts to operate without water.

If the dispensing paddle is pushed for more than 4 minutes, the dispenser motor may overload

and stop. The overload protector will reset automatically after 3 or 4 minutes.

• If a large quantity of ice is needed at one time, it is best to remove cubes directly from the ice container.

• The following sounds are normal when the ice maker is operating:

• Motor running

• Ice dropping into ice container

• Water valve opening or closing

• Turn Off the ice maker when cleaning the freezer and during vacations.

• If the ice maker will be turned off for a long period of time, you should also turn off the water supply valve.

• Ice loosening from tray

• Running water

15

Page 16

Automatic Ice and Water Dispenser

Do not use the ice chute as a handle when

removing or replacing the ice storage bin.

Surfaces there may be sharp.

Do not put fingers up ice chute. Surfaces

there may be sharp.

CLEANING THE ICE DISPENSER

Clean the dispenser and ice container at regular intervals, particularly

before you take a vacation or move, or if the ice dispenser sticks.

1. Turn off ice production by pressing the ice maker’s On/Off switch.

2. Remove ice container by lifting up and out. Empty and carefully clean

the container with mild detergent. Rinse with clear water. Do not use

harsh or abrasive cleaners. Allow ice container to dry completely before

replacing in the freezer.

3. Remove ice chips and clean the shelf and chute that supports the ice

container.

4. Replace the ice container. Press the ice maker’s On/Off switch to

resume ice production.

IMPORTANT: When removing or replacing the ice bin, do not

rotate the auger in the ice bin. If the auger is accidentally turned,

you must realign the auger by turning it in 90° turns until the ice bin

fits into place with the drive mechanism.

Remove and empty the ice storage bin if:

1. An extended power failure (one hour or longer) causes ice cubes in

the ice storage bin to melt and freeze together and jam the dispenser

mechanism.

2. The ice dispenser is not used frequently. Ice cubes will freeze together

in the bin and jam the dispenser mechanism. Remove the ice storage

bin and shake to loosen the cubes.

NEVER use an ice pick or similar sharp instrument to break up the ice.

This could damage the ice storage bin and dispenser mechanism.

16

Page 17

Automatic Ice and Water Dispenser

PureSource TM * Ice and Water Filter (some models)

NOTE: If you purchased a fridge-freezer with a

use and care information.

This ice and water filter system filters water to your ice maker and water dispenser. It is

PureSource

located in the upper right back corner of the fresh food compartment.

System Startup:

Water supply does not need to be turned off, however, do not use ice and water dispenser while installing filter. The filter

cartridge has already been installed in the filter housing at the factory. Refer to the

to properly fill the system with water.

Changing the Filter:

Water conditions vary throughout the world, but changing the water filter every

6 - 9 months normally will ensure the highest possible water quality. The Filter

Status light will turn red after 400 gallons of water has flowed through the ice

and water dispenser (some models). Also, if the filter has been in a fridgefreezer that has not been in use for awhile (during moving for example), change

the filter before reinstalling the fridge-freezer. The dispenser system will also

operate without filtration (with filter cartridge removed).

To change filter:

It is not necessary to turn the water supply off to change the filter.

1. Open freezer door and leave open until filter change is complete.

2. Turn the ice maker’s power switch to the Off (“O”) position (See illustration

on page 14).

3. Hold filter cup firmly, and unscrew towards left (Some water could

leak out as you remove cup. This is normal.). Filter cartridge should come

down with cup. If cartridge remains in housing, pull down gently, while

twisting filter back and forth.

4. Rinse out cup under running water.

5. The large o-ring that seals the filter system sets in the o-ring groove

down inside the cup. Should the o-ring fall out during filter cartridge

Order new filter cartridges through the

dealer where you bought the fridgefreezer, contact your local Service Force

Centre on 08705 929 929, or go to our

web site at

might be good to order some filter

cartridges when you first install your

fridge-freezer. Be sure to ask for

100

cartridge.

the nationally recognized and respected,

not for profit, certification organization for

public health safety. The

system is tested and certified to ANSI/NSF

Standard 42. See performance data sheet

for specifications. This system should not

be used on water that is microbiologically

unsafe or with water of unknown quality

unless the water has been adequately

disinfected before or after traveling through

the filtration system.

• Rated Capacity - 400 gallons

• Rated service flow - .5 GPM

• Maximum Rated Pressure - 100 PSI

• Maximum Operating Temp. - 100° F

www.serviceforce.co.uk. It

PureSource™*

The

2000 Ice and Water Filter

System with the RG-100

cartridge is tested and

certified by NSF International,

replacement

PureSource™

PureSource™*

the

RG-

* NGRG-

replacement, simply place it back in the groove prior to screwing the cup

back in place. If the o-ring becomes damaged, you will need to order one

from your

local Service Force Centre

6. Discard old filter cartridge.

7. Remove new filter cartridge from packaging and place in cup. The end

with the small o-ring should be up, out of the cup.

8. Screw cup, with filter, back onto housing. Do Not Use Wrench To Reinstall

Cup. Filter cartridge will self-align as cup is tightened. Be sure cup is

completely tightened with

Tighten Past Stop.

9. Turn the ice maker’s power switch to the On (“I”) position.

10. Check for leaks. Open refrigerator door. Wipe any water droplets from the

filter cup. Fill a glass with water. If there is a leak, unscrew filter cup, and

reinsert the filter cartridge. Check placement of large O-ring. Reinstall

filter cup, making certain it is tightened completely.

11. To condition filter system and purge air from water line, fill a glass with

water. Continue flushing the system for approximately 3 minutes to assure

that the purest water possible is stored in the water tank.

IMPORTANT: Resetting The Filter Status Light (some models)

After replacing the filter cartridge, it will be necessary to press the

Status

reset button located on the ice and water dispenser. This will reset

the Filter Status light. Push the reset button until the green, red and amber

lights flash (10-15 seconds). Please refer to the complete dispenser

operating instructions attached to the inside of the freezer door.

On models without a

Reminder Stickers included in the envelope that the Use & Care Manual

came in. Choose a dated sticker that indicates 6 - 9 months (depending

on your water quality and usage) from the date of installation. Place the

sticker on the front of the filter cup to remind you when it is time to

change the filter.

TM

* Ice and Water filter, please read the following

How The Water Dispenser Works

.

PureSource™

Filter Status

logo facing outward. Do Not

reset button, there is a set of

section

Filter

17

Page 18

Automatic Ice and Water Dispenser

PureSource2

NOTE: If you purchased a fridge-freezer with a

TM

* Ice and Water Front Filter (some models)

PureSource2

TM *

Ice and Water front filter, please read the

following use and care information. This ice and water filter system filters water to your ice maker and water

dispenser. It is located in the upper right front corner of the fresh food compartment.

System Startup:

Water supply does not need to be turned off, however, do not use ice and water dispenser while installing filter.

The filter cartridge has already been installed in the filter housing at the factory. Refer to the

Works

section to properly fill the system with water.

How The Water Dispenser

Changing the Filter:

Water conditions vary throughout the world, but changing the water filter every

6 - 9 months normally will ensure the highest possible water quality. The Filter

Status light will turn red after approximately 400 gallons of water has flowed

through the ice and water dispenser. Also, if the filter has been in a fridgefreezer that has not been in use for awhile (during moving for example), change

the filter before reinstalling the fridge-freezer. The dispenser system will also

operate without filtration (with filter cartridge removed and bypass installed).

To change filter:

It is not necessary to turn the water supply off to change the filter.

Turn the ice maker’s power switch to the Off (“O”) position (See illustration

1.

on page 14).

Order new filter cartridges through the

dealer where you bought the fridgefreezer, contact your local Service Force

Centre on 08705 929 929, or go to our

web site at

might be good to order some filter

cartridges when you first install your

fridge-freezer. Be sure to ask for

100

cartridge.

the nationally recognized and respected,

not for profit, certification organization for

public health safety. The

Filter system is tested and certified to ANSI/

NSF Standards 42 and 53. See

performance data sheet for specifications.

This system should not be used on water

that is microbiologically unsafe or with water

of unknown quality unless the water has

been adequately disinfected before or after

traveling through the filtration system.

• Rated Capacity - 400 gallons

• Rated service flow - .5 GPM

• Maximum Rated Pressure - 100 PSI

• Maximum Operating Temp. - 100° F

www.serviceforce.co.uk. It

PureSource™*

The

Water Filter System NGFC

2000 with the

cartridge FC 100 is tested and

certified by NSF International,

replacement

PureSource2

PureSource2

PureSource2

TM*

the

FC-

Ice and

TM*

TM*

2. Push the

to release the filter from the housing. To minimize the possibility of the

filter falling out of the housing during removal, it would be best to hold the

filter as it moves out toward you.

NOTE: A small amount of water may be released during this operation.

You should have a paper towel or dish cloth handy to wipe up any water

that may drip out of the filter or housing. Two small holes near the back of

the housing have been added for any excess water to escape. It would be

best to clear away any food near this area on the top shelf in advance of

removing the filter.

3. Pull the old filter cartridge straight out of the housing.

4. Discard the old filter.

5. Remove the new filter cartridge from the packaging and insert into the

filter housing the same way the old one came out.

6. When the cartridge is almost in, you will feel it stop against the clip assembly

in the back of the housing. The clip assembly holds the filter cartridge

firmly in place. At this point, you will need to push firmly until the cartridge

snaps fully in place. When completely in place, the front of the filter cartridge

will be flush with the front of the housing.

Turn the ice maker’s power switch to the On (“I”) position.

7.

8. Fill a glass with water. As you are doing this, check for leaks at the filter

housing. There will be noticeable spurts and sputters as the system pushes

the air out through the system and out the dispenser nozzle. This is normal.

9. After you have run one glass of water, continue to flush the system for

approximately 3 minutes to assure that the purest water possible is stored

in the water storage tank.

IMPORTANT: Resetting The Filter Status Light (some models)

After replacing the filter cartridge, it will be necessary to press the

Reset

Filter Status light. Push the reset button until the green, red and amber

lights flash (10-15 seconds). Please refer to the complete dispenser

operating instructions attached to the inside of the freezer door.

Filter Release Button

, located to the right of the filter cartridge,

button located on the ice and water dispenser. This will reset the

Filter

18

Page 19

Food Storage & Energy Saving Ideas

FOOD STORAGE IDEAS

Fresh Food Storage

• The fresh food compartment should be kept between 1.1° C and 4.4° C with an optimum temperature of 2.8° C.

• Avoid overcrowding the fridge-freezer shelves. This reduces the circulation of air around the food and results in uneven

cooling.

Fruits and Vegetables

• Storage in the crisper drawers traps moisture to help preserve the fruit and vegetable quality for longer time periods.

Meat

• Raw meat and poultry should be wrapped securely so leakage and contamination of other foods or surfaces does not

occur.

Frozen Food Storage

• The freezer compartment should be kept at 0° F or lower.

• A freezer operates most efficiently when it is at least 2/3 full.

Packaging Foods for Freezing

• To minimize dehydration and quality deterioration, use aluminum foil, freezer wrap, freezer bags or airtight containers.

Force as much air out of the packages as possible and seal them tightly. Trapped air can cause food to dry out,

change color, and develop an off-flavor (freezer burn).

• Wrap fresh meats and poultry with suitable freezer wrap prior to freezing.

• Do not refreeze meat that has completely thawed.

Loading the Freezer

• Avoid adding too much warm food to the freezer at one time. This overloads the freezer, slows the rate of freezing,

and can raise the temperature of frozen foods.

• Leave a space between the packages, so cold air can circulate freely, allowing food to freeze as quickly as possible.

• Avoid storing hard-to-freeze foods such as ice cream and orange juice on the freezer door shelves. These foods are

best stored in the freezer interior where the temperature varies less.

ENERGY SAVING IDEAS

• Locate the fridge-freezer in the coolest part of the room, out of direct

sunlight, and away from heating ducts or registers. Do not place the fridgefreezer next to heat-producing appliances such as a cooker, range, oven,

or dishwasher. If this is not possible, a section of cabinetry or an added

layer of insulation between the two appliances will help the fridge-freezer

operate more efficiently.

• Level the fridge-freezer so that the doors close tightly.

• Refer to this Use & Care Manual for the suggested temperature control

settings.

• Do not overcrowd the fridge-freezer or block cold air vents. Doing so

causes the fridge-freezer to run longer and use more energy.

• Cover foods and wipe containers dry before placing them in the

fridge-freezer. This cuts down on moisture build-up inside the unit.

• Organize the fridge-freezer to reduce door openings. Remove as many

items as needed at one time and close the door as soon as possible.

19

Page 20

Normal Operating Sounds & Sights

UNDERSTANDING THE SOUNDS YOU MAY HEAR

Your new high-efficiency fridge-freezer may make unfamiliar

sounds. Most often, these are all normal sounds that soon

become familiar to you. They indicate your fridge-freezer is

operating as designed. Hard surfaces, such as vinyl or wood

floors, walls, and kitchen cabinets may make sounds more

noticeable. The following list describes some of the most

common sounds you may hear, and what is causing them.

NOTE: Rigid foam insulation is very energy efficient,

but is not a sound insulator.

A. Evaporator

The flow of refrigerant through the evaporator may

create a boiling or gurgling sound.

B. Evaporator Fan

You may hear air being forced through the fridge-freezer

by the evaporator fan.

C. Defrost Heater

During defrost cycles, water dripping onto the defrost

heater may cause a hissing or sizzling sound. After

defrosting, a popping sound may occur.

IMPORTANT: During the automatic defrost cycle, you

may notice a red glow in the vents on the back wall of

your freezer compartment. This is normal during the

defrost cycle.

D. Automatic Ice Maker

If your fridge-freezer is equipped with an automatic ice

maker, you will hear ice cubes falling into the ice bin.

E. Cold Control & Automatic Defrost Control

May create minimal mechanical sounds.

F. Condenser Fan

You may hear air being forced through the condenser

by the condenser fan.

G. Compressor

Modern, high-efficiency compressors operate much

faster than older models. The compressor may have a

high-pitched hum or pulsating sound.

H. Water Valve

If your fridge-freezer is equipped with an automatic ice

maker, you will hear a buzzing sound as the water

valve opens to fill the ice maker during each cycle.

IMPORTANT: Your ice maker is turned On at the factory

so it can work as soon as you install your fridge-freezer.

To ensure proper function of your ice maker, connect a

water supply immediately or turn the On/Off switch to

the Off (“O”) position.

I. Drain Pan

You may hear water running into the drain pan during

the defrost cycle.

(not removable)

J. Condenser

May create minimal sounds from forced air.

K. Motorised Damper

May produce a light humming or clicking during

operation.

20

Page 21

Care & Cleaning

Keep your fridge-freezer clean to prevent odour build-up. Wipe up any spills immediately and clean both sections at least

twice a year. Never use any type of scouring pads, brushes, abrasive cleaners or strong alkaline solutions on any surface.

Do not wash any removable parts in a dishwasher.

cleaning.

• When moving the fridge-freezer, pull straight out. Do not shift the fridge-freezer from side to side as this

may damage the floor. Be careful not to move the fridge-freezer beyond the plumbing connections.

• Damp objects stick to cold metal surfaces. Do not touch refrigerated surfaces with wet or damp hands.

• Never us e CHLORIDE to clean stainless steel.

NOTES:

• If you set your temperature controls to turn off cooling, power to lights and other electrical components continues

until you unplug the power cord from the wall outlet.

• Do not use razor blades or other sharp instruments which can scratch the appliance surface when removing

adhesive labels. Any glue left from tape or labels can be removed with a mixture of warm water and mild

detergent, or, touch the glue residue with the sticky side of tape you have already removed. Do not remove the

serial plate.

Always unplug the electrical power cord from the wall outlet before

Care & Cleaning Chart

Part Cleaning Agents Tips and Precautions

Interior/Door

Liner

Door Gaskets

Drawers/Bins

Glass

Shelves

Toe Grille

Exterior and

Handles

Exterior and

Handles

(Stainless

Steel Models

Only)

• Mild washing up liquid and water

• Mild washing up liquid and water

• Mild washing up liquid and water

• Mild washing up liquid and water

• Glass cleaner

• Mild liquid sprays

• Mild washing up liquid and water

• Mild liquid sprays

• Vacuum attachment

• Mild washing up liquid and water

• Non Abrasive Glass Cleaner

• Mild washing up liquid and water

Ammonia

• Stainless Steel Cleaners

Use 2 tablespoons of baking soda in 1 quart of warm water.

Be sure to wring excess water out of sponge or cloth

before cleaning around controls, light bulb or any

electrical part.

Wipe gaskets with a clean soft cloth.

Do not wash any removable items (bins, drawers, etc.) in

dishwasher.

Allow glass to warm to room temperature before immersing in

warm water.

Vacuum dust from front of toe grille. Remove toe grille (See

illustration on page 4). Vacuum backside and wipe with sudsy

cloth or sponge. Rinse and dry.

Do not use commercial household cleaners, ammonia, or

alcohol to clean handles. Use a soft cloth to clean smooth

handles. Do Not use a dry cloth to clean smooth doors.

Never use CHLORIDE to clean stainless

steel.

Clean stainless steel front and handles with non-abrasive

soapy water and a dishcloth. Rinse with clean water and a

soft cloth. Wipe stubborn spots with an ammonia-soaked

paper towel, and rinse. Use a non-abrasive stainless steel

cleaner. These cleaners can be purchased at most home

improvement or major department stores. Always follow

manufacturer's instruction. NOTE: Always, clean, wipe and

dry with the grain to prevent cross-grain scratching.

Wash the rest of the cabinet with warm water and mild liquid

detergent. Rinse well, and wipe dry with a clean soft cloth.

21

Page 22

Care & Cleaning

Wear gloves when replacing light

bulbs to avoid contact with any sharp edges.

REPLACING LIGHT BULBS

1. Unplug fridge-freezer.

2. Allow the bulb and glass to cool if your are replacing a

bulb which has only recently been illuminated.

3. Wear gloves as protection against possible broken

glass and heat.

4. Remove light cover, if necessary.

5. Unscrew and replace old bulb with an appliance bulb

of the same type and wattage.

6. Replace light cover, if necessary.

7. Remember to plug the fridge-freezer back in.

(continued)

Fridge-freezer Light Replacement

Short

Vacations

Long

Vacations

Moving

or

Freezer Light ReplacementCrisper Light Replacement (Models may vary)

Vacation and Moving Tips

• Leave refrigerator operating during vacations of 3 weeks or less.

• Use all perishable items from refrigerator compartment.

• Turn automatic ice maker off and empty ice bucket, even if you will only be

gone for a few days.

• Remove all food and ice if you will be gone one month or more.

• Turn the cooling system off ( see page 8 for On/Off button position) and

disconnect power.

• Turn off automatic ice maker and turn water supply valve to closed position.

• Clean interior thoroughly.

• Leave both doors open to prevent odours and mould build-up. Block doors open

if necessary.

• Remove all food and ice.

• If using handcart, load from side.

• Adjust rollers all the way up to protect them during sliding or moving.

• Pad cabinet to avoid scratching surface.

IMPORTANT: If the fridge-freezer is going to be stored or moved in freezing temperatures, the water in

the ice and water system must be drained completely. Failure to do so could result in water leaks when

the fridge-freezer is put back into service. Contact a service representative to perform this operation.

This will be a chargeable call.

22

Page 23

Guarantee Conditions

Standard guarantee conditions

We, Electrolux, undertake that if within 12 months of the date of the purchase this Electrolux appliance or any part

thereof is proved to be defective by reason only of faulty workmanship or materials, we will, at our option repair or

replace the same FREE OF CHARGE for labour, materials or carriage on condition that:

The appliance has been correctly installed and used only on the electricity supply stated on the rating plate.

The appliance has been used for normal domestic purposes only, and in accordance with the manufacturer’s

instructions.

The appliance has not been serviced, maintained, repaired, taken apart or tampered with by any person not authorised

by us.

All service work under this guarantee must be undertaken by an Electrolux Service Force Centre. Any appliance or

defective part replaced shall become the Company’s property.

This guarantee is in addition to your statutory and other legal rights.

Home visits are made between 8.30am and 5.30pm Monday to Friday. Visits may be available outside these hours in

which case a premium will be charged.

Exclusions

This guarantee does not cover:

Damage or calls resulting from transportation, improper use or neglect, the replacement of any light bulbs or removable

parts of glass or plastic.

Costs incurred for calls to put right an appliance which is improperly installed or calls to appliances outside the

European Community (EC) or European Free Trade Area.

Appliances found to be in use within a commercial environment, plus those which are subject to rental agreements.

Products of Electrolux manufacture which are not marketed by Electrolux.

European Guarantee

If you should move to another country within Europe then your guarantee moves with you to your new home subject to

the following qualifications:

The guarantee starts from the date you first purchased your product.

The guarantee is for the same period and to the same extent for labour and parts as exists in the new country of use for

this brand or range of products.

This guarantee relates to you and cannot be transferred to another user.

Your new home is within the European Community (EC) or European Free Trade Area.

The product is installed and used in accordance with our instructions and is only used domestically, i.e. a normal

household.

The product is installed taking into account regulations in your new country.

Before you move please contact your nearest Customer Care centre, listed below, to give them details of your new

home. They will then ensure that the local Service Organisation is aware of your move and able to look after you and

your appliances.

France Senlis +33 (0)3 44 62 20 13

Germany N.rnberg +49 (0)800 234 7378

Italy Pordenone +39 (0)800117511

Sweden Stockholm +46 (0)20 78 77 50

UK Slough +44 (0)1753 219898

23

Page 24

Something Not Working

IMPORTANT: If you call out an engineer to a fault listed below, or to repair a fault caused by incorrect use or

installation a charge will be made, even if the appliance is under guarantee. Before contacting your local Electrolux

Service Force Centre, check the following points:

PROBLEM CAUSE CORRECTION

RUNNING OF REFRIGERATOR

Compressor does not run.

Refrigerator runs too

much or too long.

Compressor goes off and

on frequently.

Digital temperature

displays are flashing.

• Cooling system is turned Off.

• Refrigerator is in defrost cycle.

• Plug at wall outlet is

• House fuse blown or tripped

• Power cut.

• Room or outside weather is

• Refrigerator has recently been

• Automatic ice maker is

• Doors are opened too

• Refrigerator/freezer door may

• Freezer control is set too cold

• Refrigerator/freezer gasket is

• Electronic control system

• Electronic control system has

disconnected.

circuit breaker.

hot.

disconnected for a period of

time.

operating.

frequently or too long.

be slightly open.

(control found in refrigerator

section).

dirty, worn, cracked, or poorly

fitted.

keeps the refrigerator at a

constant temperature.

detected a performance

problem.

• Turn cooling system On. See Temperature Controls

section.

• This is normal for a fully automatic defrost refrigerator.

The defrost cycle occurs periodically, lasting about 30

minutes.

• Ensure plug is tightly pushed into outlet.

• Check/replace fuse. Reset circuit breaker.

• Check house lights. Call local Electric Company.

• It’s normal for the refrigerator to work longer under

these conditions.

• It takes 8-12 hours for the refrigerator to cool down

completely.

• Ice maker operation causes refrigerator to run slightly

more.

• Warm air entering the refrigerator causes it to run

more. Open doors less often.

• Ensure refrigerator is level. Keep food and containers

from blocking door. See PROBLEM section

OPENING/CLOSING OF DOORS/DRAWERS.

• Set refrigerator control to warmer setting until

refrigerator temperature is satisfactory. Allow 24 hours

for temperature to stabilise.

• Clean or change gasket. Leaks in door seal will cause

refrigerator to run longer in order to maintain desired

temperatures.

• This is normal. Refrigerator goes on and off to keep

temperature constant.

• Call your local Service Force Centre, who can interpret

any messages or number codes flashing on the digital

displays.

TEMPERATURES ARE TOO COLD

Freezer temperature too

cold. Refrigerator

temperature is satisfactory.

Refrigerator temperature

too cold. Freezer

temperature is satisfactory.

Food stored in drawers

freezes.

Food stored in Meat

Keeper freezes (some

models).

• Freezer control is set too cold. • Set freezer control to a warmer setting. Allow 24 hours

• Refrigerator control is set too

cold.

• Refrigerator control is set too

cold.

• Meat Keeper Temperature

Control set too cold.

for temperature to stabilise.

• Set refrigerator control to a warmer setting. Allow 24

hours for temperature to stabilise.

• See solution above.

• Adjust Meat Keeper Temperature Control to a lower

setting. (Meat should be stored at a temperature just

below the freezing point for maximum fresh storage

time. It is normal for ice crystals to form due to the

moisture content of meat.)

24

Page 25

Something Not Working

(continued)

PROBLEM CAUSE CORRECTION

TEMPERATURES ARE TOO WARM

Freezer/Refrigerator

temperature is too warm.

Freezer temperature is too

warm. Refrigerator

temperature is satisfactory.

Refrigerator temperature is

too warm. Freezer

temperature is satisfactory.

Temperature in the Meat

Keeper is too warm (some

models).

• Doors are opened too

• Door is slightly open.

• Freezer control is set too

• Refrigerator control is set too

• Meat Keeper Temperature

frequently or too long.

warm.

warm.

Control is set too warm.

WATER/MOISTURE/FROST INSIDE REFRIGERATOR

Moisture collects on inside

of refrigerator walls.

Water collects on bottom

side of drawer cover.

• Weather is hot and humid.

• Door is slightly open.

• Door is opened too often or too

long.

• Open containers.

• Vegetables contain and give

off moisture.

• Warm air enters the refrigerator whenever the door is

opened. Open the door less often.

• See PROBLEM section OPENING/CLOSING OF

DOORS/DRAWERS.

• Set freezer control to a colder setting. Allow 24 hours

for temperature to stabilise.

• Set refrigerator control to a colder setting. Allow 24

hours for temperature to stabilise.

• Adjust Meat Keeper Temperature Control to a colder

setting.

• The rate of frost buildup and internal sweating

increases.

• See PROBLEM section OPENING/CLOSING OF

DOORS/DRAWERS.

• Open door less often.

• Keep containers covered.

• It is not unusual to have moisture on the bottom side of

the cover.

• Move humidity control (some models) to lower setting.

Water collects in bottom of

drawer.

• Washed vegetables and fruit

drain while in the drawer.

WATER/MOISTURE/FROST OUTSIDE REFRIGERATOR

Moisture collects on

outside of refrigerator or

between doors.

AUTOMATIC ICE MAKER

Ice maker is not making

any ice.

• Weather is humid.

• Door is slightly open, causing

cold air from inside refrigerator

to meet warm air from outside.

• Ice maker power switch is Off.

• Household water line valve is

not open.

• Freezer is not cold enough.

• Saddle valve on cold water

pipe is clogged or restricted by

foreign material.

• Check to see if the water

dispenser is dispensing water.

• Water filter is not completely

seated (models with filter

beside temperature control

panel).

• Dry items before putting them in the drawer. Water

collecting in bottom of drawer is normal.

• This is normal in humid weather. When humidity is

lower, the moisture should disappear.

• See PROBLEM section OPENING/CLOSING OF

DOORS/DRAWERS.

• Turn power switch to On (“I”) position.

• Turn on household water line valve.

• See PROBLEM section TEMPERATURES ARE TOO

WARM.

• Turn off household water line valve. Remove valve.

Ensure that valve is not a self-piercing saddle valve.

Clean valve. Replace valve if necessary.

• If not, the ice & water filter cartridge is clogged or

restricted by foreign material, and must be replaced.

• Push firmly until the water filter snaps into place.

25

Page 26

Something Not Working (

continued)

PROBLEM CAUSE CORRECTION

AUTOMATIC ICE MAKER (CONTINUED)

Ice maker is not making

enough ice.

Ice maker will not stop

making ice.

Ice maker is not separating

the ice cubes.

Ice has bad odour and

taste.

ICE DISPENSER

• Ice maker is producing less ice

than you expect.

• Freezer is not cold enough.

• Household water line valve is

not completely open.

• Check to see if water

dispenser is dispensing slower

than normal.

• Ice maker wire signal arm is

being held down by some item

in the freezer.

• Ice cubes are not being used

frequently enough.

• Ice cubes are hollow or smaller

than normal.

• Ice has picked up odor or

flavor from strong food stored

in refrigerator or freezer.

• Water running to ice maker

has poor taste or odor.

• Ice not used frequently enough.

• Ice maker should produce approximately 4 – 5 pounds

of ice every 24 hours.

pounds of ice every 24 hours.

• See PROBLEM section TEMPERATURES ARE TOO

WARM.

• Turn on household water line valve.

• If it is, replace the ice & water filter cartridge.

• Move item and release wire signal arm. Remove any

ice cubes that are frozen together over the wire signal

arm.

• Remove and shake ice container to separate cubes.

• The ice & water filter cartridge may be clogged.

Replace filter cartridge.

• Cover foods tightly. Discard stale ice. Ice maker will

produce fresh supply.

• Add filter to water supply line. Consult a water

purifying company.

• Discard stale ice.

Extra Ice

should produce up to 6

Dispenser will not dispense

ice.

Ice dispenser is jammed.

• Ice storage container is empty.

• Freezer temperature is set too

warm.

• Household water line valve is

not open.

• Freezer door is not closed.

• Ice dispensing arm has been

held in for more than 4-5

minutes.

• Ice has melted and frozen

around auger due to infrequent

use, temperature fluctuations,

and/or power outages.

• Ice cubes are jammed

between ice maker and back

of ice container.

• Ice cubes are frozen together.

• Ice cubes are hollow or smaller

than normal.

• When the first supply of ice is dropped into the

container, the dispenser should operate.

• Turn freezer control to a higher setting so that ice

cubes will be made. When first supply of ice is made,

dispenser should operate.

• Open household water line valve. Allow sufficient time

for the ice to be made. When ice is made, the

dispenser should operate.

• Ensure freezer door is closed.

• Motor is overloaded. Motor overload protector will

reset in approximately 3 minutes. Ice can then be

dispensed.

• Remove ice container, thaw, and empty the contents.

Clean container, wipe dry, and replace in proper

position. When new ice is made, dispenser should

operate.

• Remove ice cubes that are jamming the dispenser.

• Use the dispenser often so that cubes do not freeze

together.

• The ice & water filter cartridge could be clogged.

Replace the filter cartridge. Dispensing system

operates best at 20 – 100 psi water pressure. Well

water pressures should fall within this range.

26

Page 27

Something Not Working

(continued)

PROBLEM CAUSE CORRECTION

WATER DISPENSER

Dispenser will not

dispense water.

Water has an odd taste

and/or odour.

Water pressure is

extremely low.

• Household water line valve is

not open.

• Freezer door is not closed.

• Ice & water filter cartridge is

clogged.

• Front filter not fully installed, if

equipped

• Water has been in the tank for

a period of time.

• Unit not properly connected to

cold water line.

• Tubing used in the household

water supply and installation

may affect water taste and

odor.

• Water has a high mineral

content.

• Cut-off and cut-on pressures

are too low (well systems

only).

• Household water softener

system is in regenerative

phase.

ODOURS IN REFRIGERATOR

Interior is dirty.

• Interior needs to be cleaned.

• Food with strong odours is in

refrigerator.

OPENING/CLOSING OF DOORS/DRAWERS

Door(s) will not close.

Drawers are difficult to

move.

• Door was closed too hard,

causing other door to open

slightly.

• Refrigerator is not leve l. It

rocks on the floor when moved

slightly.

• Refrigerator is touching a wall

or cabinet.

• Food is touching shelf on top

of drawer.

• Track that drawers slide on is

dirty.

LIGHT BULB IS NOT ON

Light bulb is not on.

• Light bulb is burned out.

• Light switch is stuck.

• No electric current is reaching

refrigerator.

• Control system has disabled

lights because magnet switch

trigger has been removed.

• Control system has disabled

lights because one or both

doors were left open too long.

• Open household water line valve. See PROBLEM

section ICE MAKER IS NOT MAKING ANY ICE.

• Ensure that freezer door is closed.

• Replace filter cartridge.

• Push filter in until you hear a “click”. Filter should be

flush with cabinet.

• Draw and discard 10 – 12 glasses of water to freshen

the supply and completely rinse out the tank.

• Connect unit to cold water line that supplies water to

the kitchen tap.

• For best results, use copper tubing for water

connections.

• Contact water treatment plant for help.

• Have someone turn up the cut-off and cut-on pressure

on the water pump system (well systems only).

• It is normal for a water softening system to be below

20 psi during the regenerative phase.

• See

• Cover food tightly.

• Close both doors gently.

• Ensure floor is level and solid, and can adequately

• Ensure floor is level and solid, and can adequately

• Keep less food in drawer.

• Clean drawer, rollers, and track. See

• See

• Release light switch located inside freezer

• See PROBLEM section RUNNING OF

• Reinstall magnet behind dairy compartment in fresh

• Close and reopen door(s) to enable lights.

Care & Cleaning Chart

section.

support the refrigerator. Contact a carpenter to correct

a sagging or sloping floor.

support the refrigerator. Contact a carpenter to correct

a sagging or sloping floor.

in Care and Cleaning section.

Chart

Replacing Light Bulbs

section.

compartment.

REFRIGERATOR.

food door.

in Care and Cleaning

Care & Cleaning

in Care and Cleaning

27

Page 28

Page 29

documentation manual, user maintenance, brochure, user reference, pdf manual

This file has been downloaded from:

User Manual and User Guide for many equipments like mobile phones, photo cameras, monther board, monitors, software, tv, dvd, and othes..

Manual users, user manuals, user guide manual, owners manual, instruction manual, manual owner, manual owner's, manual guide,

manual operation, operating manual, user's manual, operating instructions, manual operators, manual operator, manual product,

Loading...

Loading...