Page 1

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

GAS RANGES WITH MODULAR OVEN CONTROLS

LATCH MOTOR

DOOR SWITCH

CONVECTION ELEMENT

NOTICE: This service data sheet is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects generally considered acceptable in the appliance repair trade. The manufacturer cannot be responsible, nor assume

any liability, for injury or damage of any kind arising from the use of this data sheet.

IMPORTANT NOTE: This unit includes an EOC (electronic oven control). This board is

not eld-repairable.

Safe Servicing Practices

To avoid the possibility of personal injury and/or property damage, it is important that safe

servicing practices be observed. The following are some, but not all, examples of safe

practices.

1. Do not attempt a product repair if you have any doubts as to your ability to complete

it in a safe and satisfactory manner.

2. Before servicing or moving an appliance, remove power cord from electric outlet,

trip circuit breaker to Off, or remove fuse.

3. Never interfere with the proper installation of any safety device.

4. Use only replacement parts specied for this appliance. Substitutions may not

comply with safety standards set for home appliances.

5. Grounding: The standard color coding for safety ground wires is green or green with

yellow stripes. Ground leads are not to be used as current carrying conductors. It is

extremely important that the service technician reestablish all safety grounds prior to

completion of service. Failure to do so will create a potential hazard.

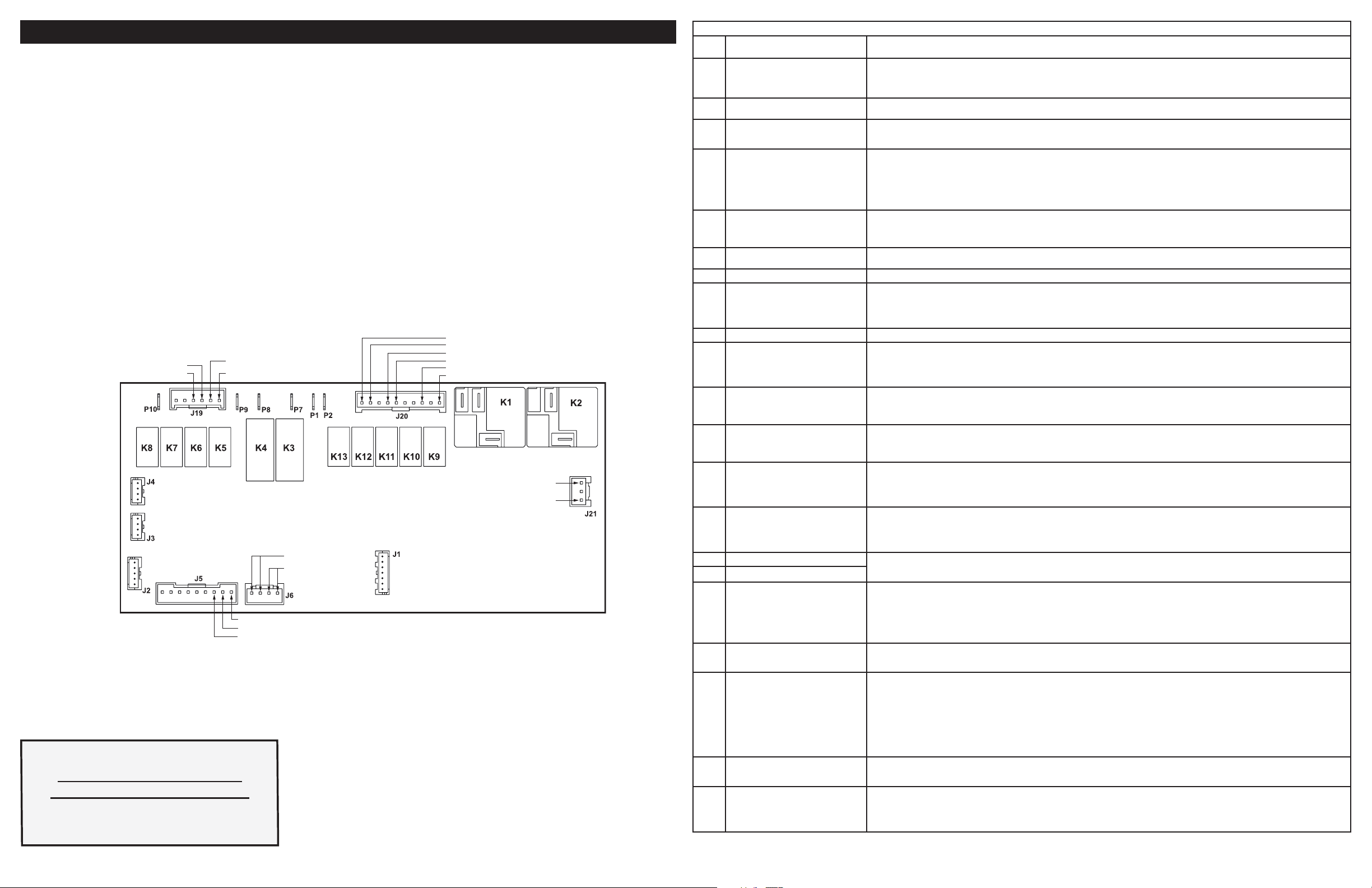

BROIL IGNITER

L1 & THERMAL

CIRCUIT BREAKER

1 1

BROIL

1

MOTOR DOOR LATCH SWITCH

COMMON

BAKE IGNITER

BAKECONV

1

J3 OR J4

TO USER INTERFACE BOARD

MARS BOARD

1

1

1

p/n A00980640 Rev B (1710)

SERVICE DATA SHEET

6. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges,

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately

• All safety grounds (both internal and external) are correctly and securely reas-

• All panels are properly and securely reassembled.

Temperature Adjustment

1. While in a non-cooking mode, press and hold the Bake key for 3 seconds until UPO

appears in the display.

2. Use the number keys (0-9) to enter the desired adjustments (-35° to 35° F).

3. Press the Self Clean key to change the sign of the adjustment to a (-), if necessary. A

positive adjustment will not display a sign.

4. Once the desired adjustment (-35° to 35° F) has been entered, press START to accept

the change or the STOP key to reject the change.

Note: Changing calibration affects all baking modes. The adjustments made will not change

the self-cleaning temperature.

MEAT PROBE

TEMPERATURE PROBE

PROGRAMMING HEADER

1

high-temperature components, and moving parts.

spaced away from all metal parts and panels.

sembled.

CONVECTION FAN

COOLING FAN

OVEN LIGHT

L1

NEUTRAL

L1

NEUTRAL

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Fault

Description of Error Code Suggested Corrective Action

Code

F001

Touch panel failure Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up replace the touch panel.

F002

F004

F005

F003 The oven user interface board is incorrectly

congured.

F010 Oven temperature runaway: the cavity

temperature has been detected in excess

of the maximum safe operating temperature.

F011 Stuck key: a key has been detected has

pressed continuously for 30 seconds or

more.

F012 Keyboard conguration alarm: the oven

user interface board received from the touch

panel a key code that does not match the

key map.

F013 Data written to non-volatile memory has

failed verication

F015 Keyboard error Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up replace the touch panel.

F017 The oven user interface board is unable to

congure the touch panel.

F018 Oven relay board failure (wiggler) Replace the oven relay board.

F019 The oven user interface board is unable to

congure the oven relay board

F022 Communication failure between the oven

user interface board and the oven relay

board

F023 Communication failure between the oven

user interface board and the glass touch

panel

F025

1

The communication between the over user

F027

interface and the oven relay board cannot

be initiated.

F028

The communication between the over user

F029

interface and the touch panel cannot be

initiated.

F030 Open oven temperature sensor (RTD) 1. Check probe circuit wiring for possible open or short condition.

F031 Shorted oven temperature probe (RTD)

F033 Meat probe temperature sensor shorted

or too hot

F050 A/D Out of Range: the oven relay board is

unable to read the status of the switches

(door, MDL)

F090 Motor Door Lock mechanism failure. The

oven control does not see the Motor Door

Lock running.

F095 Motor Door Lock mechanism failure. The

Motor Door Lock does not stop running or

the Lock Switch sends an invalid signal.

F096 The oven door has been detected open

during a Self Clean cycle.

Replace the oven user interface board. Make sure you install the latest revision available for this model.

1. If oven is overheating, disconnect power. Check oven temperature probe (RTD) and replace if necessary.

2. If the oven temperature probe is good and if oven continues to overheat when power is reapplied, replace the oven relay board.

1. If a key was pressed inadvertently for a long time this error code will be displayed. Make sure there is nothing (water, utensils) in contact with the

keyboard. The fault code should go away once the key is released and the Stop key is pressed. If the F011 error comes back when a key is pressed it

means the error condition is still there. If the F011 error does not come back it means the error condition is gone and the oven can be used.

2. If the fault code cannot be cleared, test the wiring harness between oven user interface board (connector I2C1 or I2C2) and touch panel (connector I2C1

or I2C2).

3. If the fault code cannot be cleared and the wiring is good, the touch panel is most likely defective: replace the touch panel.

4. If changing the touch panel did not x the problem replace the oven user interface board.

1. Verify the unit has the proper oven user interface board and touch panel, based on the model number and parts catalog.

2. Replace the oven user interface board.

3. If the problem persists replace the touch panel.

Disconnect power, wait 30 seconds and reapply power. If fault returns upon power-up replace the oven user interface.

1. Disconnect power to the unit, wait 30 seconds, then reapply power.

2. If fault returns, verify harness going to I2C1 or I2C2 connector of the touch panel.

3. Verify the unit has the proper oven user interface board and touch panel, based on the model number and parts catalog.

4. If fault persists, replace the oven user interface.

5. If fault persists, replace the touch panel.

1. Disconnect power to the unit, wait 30 seconds, then reapply power.

2. If fault returns, verify connection between the oven user interface board (MACS1 or MACS2 connector) and the oven relay board (connector J3 or J4).

3. Verify the unit has the proper oven user interface board and oven relay board, based on the model number and parts catalog.

4. If fault persists, replace oven user interface board.

5. If fault persists, replace the relay board.

1. Disconnect power, wait 30 seconds and reapply power. Check if error condition is still there.

2. Test wiring harness between oven user interface board (connector MACS1 or MACS2) and oven relay board (connector J3 or J4).

3. If wiring harness is good replace oven relay board.

4. If the problem persists replace the oven user interface.

1. Disconnect power, wait 30 seconds and reapply power. Check if error condition is still there.

2. Test wiring harness between oven user interface board (connector I2C1 or I2C2) and touch panel (connector I2C1 or I2C2).

3. If wiring harness is good replace touch panel.

4. If the problem persists replace the oven user interface.

1. Disconnect power to the unit, wait 30 seconds, then reapply power.

2. If fault returns, verify connection between the oven user interface board (MACS1 or MACS2 connector) and the oven relay board (connector J3 or J4).

3. Verify the unit has the proper oven user interface board and oven relay board, based on the model number and parts catalog.

4. If fault persists, replace relay board.

5. If fault persists, replace the oven user interface board.

1. Disconnect power to the unit, wait 30 seconds, then reapply power.

2. If fault returns, verify touch panel is connected (verify harness going to I2C1 or I2C2 connector) and is getting power from the oven user interface.

3. Verify the unit has the proper oven user interface board and touch panel, based on the model number and parts catalog.

4. If fault persists, replace the touch panel.

5. If fault persists, replace the oven user interface.

2. Verify RTD resistance at room temperature (compare to probe resistance chart). If resistance does not match the chart, replace the RTD probe.

3. If the problem persists replace the oven relay board.

1. The error is triggered if the meat probe sees a temperature in excess of 392°F. Make sure the meat probe was not used in such way that it could have

seen such temperature. If the tip of the probe is not inserted in the meat it will see the cavity temperature, which can be higher than 392°F (depending on

the setpoint) and trigger the alarm.

2. When the meat probe is connected to the socket inside the oven cavity, if the meat probe is not fully inserted into the socket it may short the contacts and

cause the error. Make sure the probe is inserted as much as it can.

3. Verify meat probe resistance at room temperature. Compare to meat probe resistance chart. If the meat probe does not match the chart, replace it.

4. If the above steps failed to correct the problem, replace the oven relay board.

1. Check to ensure that the connections between the door switch, MDL and temp probes are properly connected. This includes all splices and junctions.

2. If the above step failed to correct the problem, replace the oven relay board.

1. Disconnect power to the unit, wait 30 seconds, then reapply power. Try again to make the door lock or unlock (ex: initiate a Lockout or a Clean cycle).

2. Check if the Lock Motor is running or not. If it is not running, test the wiring between the Lock Motor and the oven relay board. If the wiring is good, check

if there is 120VAC at the motor when it is expected to run to see if the failure originates from a bad motor (120VAC present but not turning) or a problem

with the relay board (J20 pin 10 on the oven relay board is the output to the Lock Motor). The Lock Motor can also be tested by applying 120VAC directly

to the motor (unplug it from the relay board rst). If the Lock Motor does not run when 120VAC is applied replace the Lock Motor Assembly. If it is the

relay board that does not provide 120VAC to the Lock Motor replace the oven relay board.

3. If the Lock Motor is running but the oven control cannot nd the locked or unlocked position (ex: motor turns continuously until F90 fault code is gener-

ated) the Lock Switch needs to be veried. Check wiring between Lock Switch and oven relay board. Verify with ohmmeter if the switch makes contact

properly (verify continuity with ohmmeter when the switch is pressed). If the Lock Switch is defective replace the Motor Lock Assembly.

4. If all above steps failed to correct the situation, replace the oven relay board.

1. The problem can be caused by a faulty Lock Switch or by a defective oven relay board. If the Motor Door Lock is always running (as if the relay controlling it is stuck closed) replace the oven relay board.

2. If the motor is not always running replace the Motor Lock Assembly.

1. This error occurs if the door switch has lost its contact during a Self Clean cycle. Make sure the oven door closes well and fully presses on the door

switch plunger when the door is locked, and no one attempted to pull on the oven door during the Self Clean cycle.

2. Test continuity of wiring between the door switch and the oven relay board, make sure the door switch is well connected. With an ohmmeter, verify the

switch is closed when the plunger is pressed. If the door switch is found to be defective replace the door switch.

3. If the switch and wiring are good and the problem persists, replace the oven relay board.

Page 2

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

1453 ± 8.9

1654 ± 10.8

1852 ± 13.5

2047 ± 15.8

2237 ± 18.5

2697 ± 24.4

Open circuit/infinite resistance

RTD SCALE

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

75 ± 2.5 (24 ± 1.3)

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

650 ± 9.6 (343 ± 5.3)

900 ± 13.6 (482 ±7.5)

Probe circuit to case ground

GAS RANGES WITH MODULAR OVEN CONTROLS

MOTEUR VERROU

INTERRUPTEUR DE PORTE

ÉLÉMENT DE CONVECTION

SERVICE DATA SHEET

CUISINIÈRE GAZ AVEC RÉGULATEUR ÉLECTRONIQUE DE FOUR MODULAR

FICHE DE RÉPARATION

ELECTRONIC OVEN CONTROL (EOC) FAULT CODE DESCRIPTIONS

Fault Code Description of Error Code Suggested Corrective Action

SPr This device detects voltage from spark ignitor

harness. If voltage is detected at the AC detect

board this will signal to the oven control that

the spark module is trying to light a burner.

The oven control will only look for the signal

from the AC detect board when self-clean cycle

is started or running. Detection of the signal

will cause clean to be cancelled and “SPR”

(which means spark detected) will appear in

the display. The cooktop should not be used

during a self-clean cycle. On some models,

turning on any cooktop surface burner will

cause the clean cycle to cancel. If the clean

cycle is canceled, the oven control display will

show “SPr" for 5 seconds. The oven door will

remain locked until the oven has cooled down

below cleaning temperature. If the oven is

below cleaning temperature, the user can start

another clean cycle immediately. If the oven is

in cleaning temperature range, another selfclean cycle can be set once the door unlocks

(up to 4 hours).

If SPr continues:

1. Start a self-clean.

2. Turn any burner ignitor to the LITE position.

3. Verify that the self-clean cycle has been cancelled and “Spr” is displayed in the oven display.

If this does not happen, proceed with the following troubleshooting steps.

1. Verify the AC harness is connected to J1 of the AC detect board.

2. Verify the DC harness is connected to J2 of the AC detect board.

3. Multi-meter set to AC volts.

4. Verify 0 VAC at J1 pins 1 and 3 of the AC detect board, when the spark ignitor is turned OFF.

5. Verify 120 VAC at J1 pins 1 and 3 of the AC detect board, when the spark ignitor is turned ON.

6. Multi-meter set to DC volts.

7. Verify 4 - 5 VDC at J3 pins 2 and 3 of the AC detect board or J5 pins 5 and 6 of the OVC board, when the spark

ignitor is turned OFF. (Pin 3 is GND on the AC detect board and GND is pin 6 on the OVC board)

8. Verify 0 – 1 VDC at J3 pins 2 and 3 of the AC detect board or J5 pins 5 and 6 of the OVC board, when the spark

ignitor is turned ON. (Pin 3 is GND on the AC detect board and GND is pin 6 on the OVC board)

9. If steps 7 and 8 check, replace OVC board

CIRCUIT

ANALYSIS

MATRIX

Bake

J19-3

Broil

J19-2

Conv.

J19-4

Door

Motor

J20-10

Light

J20-6

Conv.

Fan

J20-9

Bake X X X X

Broil X X

Conv. Bake X X X X

Conv. Roast X X X X

Clean X X

Locking X

Unlocking X

Light X

Door Open X

Door Closed X

Door

Switch

J5-7,

J5-8

Cooling

Fan

J20-7

MEAT PROBE TEMPERATURE VS RESISTANCE

Temperature °F (°C) Resistance (Kohm)

77 (25) 50.0 ± 7%

122 (50) 18.0 ± 4.9%

176 (80) 6.3 ± 3.3%

212 (100) 3.4 ± 4.6%

AVIS: Cette feuille de données d’entretien est destinée aux personnes ayant reçu une

formation en électricité et en mécanique, et qui possèdent un niveau de connaissance jugé

acceptable dans l’industrie de réparation des appareils électroménagers. Le fabricant ne peut

être tenu responsable, ni assumer aucune responsabilité, pour toute blessure ou dommage

de quelque nature que ce soit pouvant résulter de l’utilisation de cette feuille de données.

NOTEs IMPORTANTES: Cet appareil inclut un contrôleur de four électronique. Le tableau de

contrôle n’est pas réparable sur place.

Pratiques d’entretien Sécuritaires

Pour éviter tout risque de blessure et/ou dommage matériel, il est important que des

pratiques d’entretien sécuritaires soient suivies. Voici quelques exemples de pratiques

sécuritaires.

1. N’essayez jamais de réparer un appareil si vous ne croyez pas avoir les compétences

nécessaires pour le faire de manière satisfaisante et sécuritaire.

2. Avant de procéder au service d’entretien ou de déplacer tout appareil ménager, débranchez le cordon d’alimentation de la prise électrique, réglez le disjoncteur de circuit à

OFF, ou enlevez le fusible et fermez le robinet d’alimentation en gaz.

3. N’entravez jamais l’installation adéquate de tout dispositif de sécurité.

4. Utilisez que les pièces de remplacement énumérées dans le catalogue pour cet appareil. La moindre substitution risque de ne pas être conforme aux normes de sécurité

établies pour les appareils électroménagers.

5. Mise à la Terre: La couleur de codage standard des conducteurs de mise à la terre

de sécurité est verte ou verte à barres jaunes. Les conducteurs de mise à la terre

ne doivent pas être utilisés comme conducteurs de courant. Il est d’une importance

ALLUMEUR DU

BRÛLEUR DE CUISSON

CONV

1

J3 OU J4

À PLAQUETTE D'INTERFACE DE UTILISATEUR

“MARS BOARD”

1

1

1

CUISSON

ALLUMEUR DU

BRÛLEUR DE GRILLAGE

L1 & DISJONCTEUR THERMIQUE

1 1

GRIL

SONDE À VIANDE

SONDE À TEMPÉRATURE

1

INTERRUPTEUR DU MOTEUR VERROU DE LA PORTE

COMMUNE

capitale que le technicien d’entretien complète toutes les mises à la terre de sécurité

avant de terminer le service. Si cette recommandation n’est pas suivie à la lettre, il en

résultera des risques pour les personnes et les biens.

6. Avant de retourner le produit au service de réparation ou d’entretien, assurez-vous que:

• Toutes les connexions électriques sont correctes et sécuritaires.

• Tous les conducteurs électriques sont correctement préparés et à l’abri des bords

tranchants, des composants à température élevée, et des parties mobiles.

• Toutes les bornes électriques, connecteurs, réchauffeurs, etc. dénudés sont

espacés convenablement loin de toute pièce en métal et des panneaux.

• Toutes les mises à la terre de sécurité (interne et externe) sont correctement

ré-assemblées de façon sécuritaire.

• Tous les panneaux sont correctement et fermement remontés.

Réglage de la Température

1. Assurez-vous de ne sélectionner aucun mode de cuisson, puis appuyez sur la touche

BAKE (cuisson au four) et maintenez-la enfoncée pendant 3 secondes.

2. Utilisez les touches numériques (0 à 9) pour entrer l’ajustement désiré (jusqu’à 35 ºF/19

ºC).

3. Appuyez sur la touche SELF CLEAN (autonettoyage) pour ajouter le symbole à (-) à

l’ajustement, si nécessaire. Aucun signe n’apparaît si l’ajustement est positif.

4. Lorsque vous avez fait le réglage désiré (-35 à 35 ºF / -18 à 18 ºC), appuyez sur la touche Start (mise en marche) pour conrmer le choix ou STOP (annuler) pour l’annuler.

Remarque: La modication de la calibration affecte tous les modes de cuisson. Les ajustements n’inuent pas sur la température du cycle d’autonettoyage.

VENTILATEUR DE CONVECTION

VENTILATEUR DE REFROIDISSEMENT

LAMPE HALOGÈNE

L1

NEUTRE

1

L1

NEUTRE

TÊTE DE PROGRAMMATION

1

A00980640 Rev B (1710) FR

Page 3

Résistance (ohms)

1 000 ± 4,0

1 091 ± 5,3

1 453 ± 8,9

1 654 ± 10,8

1 852 ± 13,5

2 047 ± 15,8

2 237 ± 18,5

2 697 ± 24,4

Circuit ouvert/résistance infinie

ÉCHELLE DU DÉTECTEUR DE TEMPÉRATURE

À RÉSISTANCE

Température °F (°C)

32 ± 1,9 (0 ± 1,0)

75 ± 2,5 (24 ± 1,3)

250 ± 4,4 (121 ± 2,4)

350 ± 5,4 (177 ± 3,0)

450 ± 6,9 (232 ± 3,8)

550 ± 8,2 (288 ± 4,5)

650 ± 9,6 (343 ± 5,3)

900 ± 13,6 (482 ±7,5)

Circuit de la sonde mise à la

terre à la caisse

CODES D’ERREUR POUR LA FICHE TECHNIQUE DE LA CUISINIÈRE AVEC BOUTONS DE COMMANDE À L’AVANT

Code Description de l’erreur Actions correctives suggérées

F001

Panneau tactile en échec. Débranchez l’alimentation, attendez 30 secondes et rebranchez. Si le problème réapparaît lorsque l’appareil est rebranché, remplacez le panneau tactile.

F002

F004

F005

F003 La carte interface usager n’est pas congurée

correctement.

F010 Emballement de la température du four: La

température du four a été détectée comme

étant supérieure à la température maximale

sécuritaire.

F011 Touche engagée: Une touche a été rapportée

appuyée pendant 30 secondes ou plus.

F012 Alarme de conguration de clavier: La carte

interface usager a reçu du panneau tactile un

code qui ne se retrouve pas dans le registre.

F013 Échec lors de la vérication des données écrites

à la mémoire permanente.

F015 Erreur du clavier. Débranchez l’alimentation, attendez 30 secondes et rebranchez. Si le problème réapparaît lorsque l’appareil est rebranché, remplacez le panneau tactile.

F017 La carte interface usager du four est incapable

de congurer le panneau tactile.

F018 Échec du panneau de relais du four (onduleur) Remplacez le panneau de relais du four.

F019 La carte interface usager du four est incapable

de congurer le panneau de relais du four.

F022 Échec de communication entre la carte d’inter-

face usager et le panneau de relais du four.

F023 Échec de communication entre la carte d’inter-

face usager et le panneau tactile.

F025

La communication entre la carte interface

usager et le panneau de relais du four ne peut

F027

être démarrée.

F028

La communication entre la carte interface usag-

er et le panneau tactile ne peut être démarrée.

F029

F030 Le circuit de la sonde de température du four

est ouvert (RTD)

F031 La sonde de température du four (RTD) est en

court-circuit.

F033 Le capteur de la sonde à viande est en court-cir-

cuit ou trop chaud.

F050 A/D hors limite: Le panneau relais du four ne

peut connaître le statut des interrupteurs (porte,

moteur verrou)

F090 Échec du mécanisme du moteur verrou de la

porte du four: La commande du four ne détecte

pas que le moteur verrou de la porte du four est

en marche.

F095 Échec du mécanisme du moteur verrou de

la porte du four. Le moteur verrou tourne

continuellement ou l’interrupteur envoie un

mauvais signal.

F096 La porte du four a été détectée ouverte lors d’un

cycle autonettoyant.

Remplacez la carte interface usager. Assurez-vous d’installer la dernière version disponible pour ce modèle.

1. 1- Si le four surchauffe, débranchez l’alimentation. Vériez la sonde de température (RTD) et remplacez-la si nécessaire.

2. 2- Si la sonde de température est correcte et que le four continue de surchauffer une fois l’appareil rebranché, remplacez le panneau de relais du four.

1. Ce code s’afche si une touche est appuyée par inadvertance pendant une longue période. Assurez-vous qu’il n’y a rien en contact avec le panneau tactile (eau,

ustensiles). Le code d’erreur disparaît lorsque la touche est relâchée et que la touche STOP est appuyée. Si le code F011 réapparaît lorsqu’une touche est appuyée,

ceci indique que les conditions de l’erreur sont toujours présentes. Si le code F011 ne réapparaît pas, ceci indique que les conditions de l’erreur ont disparu et que le

four peut être utilisé.

2. Si le code d’erreur ne disparaît pas, vériez le l entre la carte interface usager (connecteur I2C1 ou I2C2) et le panneau tactile (connecteur I2C1 ou I2C2).

3. Si le code d’erreur ne disparaît pas et que le l est bon, le panneau tactile est probablement défectueux: remplacez le panneau tactile.

4. Si le problème n’est toujours pas réglé après avoir changé le panneau tactile, changez la carte interface usager.

1. À l’aide du numéro de modèle et du catalogue de service, vériez si l’appareil a la bonne carte interface usager et le bon panneau tactile.

2. Remplacez la carte interface usager du four.

3. Si le problème persiste, remplacez le panneau tactile.

Débranchez l’alimentation, attendez 30 secondes et rebranchez. Si le problème réapparaît lorsque l’appareil est rebranché, remplacez la carte interface usager du four.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez.

2. Si l’erreur réapparaît, vériez le l allant au connecteur I2C1 ou I2C2 du panneau tactile.

3. À l’aide du numéro de modèle et du catalogue de service, vériez si l’appareil a la bonne carte interface usager et le bon panneau tactile.

4. Si le problème persiste, remplacez la carte interface usager.

5. Si le problème persiste, remplacez le panneau tactile.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez.

2. Si l’erreur réapparaît, vériez le connexion entre la carte interface usager du four (connecteur MACS1 ou MACS2) et le panneau de relais du four (connecteur J3 ou

J4).

3. À l’aide du numéro de modèle et du catalogue de service, vériez si l’appareil a la bonne carte interface usager et le bon panneau de relais du four.

4. Si le problème persiste, remplacez la carte interface usager.

5. Si le problème persiste, remplacez le panneau de relais du four.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez. Vériez si l’erreur est encore présente.

2. Vériez le faisceau de ls entre la carte interface usager (connecteur MACS1 ou MACS2) et le panneau de relais du four (connecteur J3 ou J4).

3. Si le faisceau de ls est bon, remplacez le panneau de relais du four.

4. Si le problème persiste, remplacez la carte interface usager du four.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez. Vériez si les conditions d’erreur sont encore présentes.

2. Vériez le l entre la carte interface usager (connecteur I2C1 ou I2C2) et le panneau tactile (connecteur I2C1 ou I2C2).

3. Si le l est bon, remplacez le panneau tactile.

4. Si le problème persiste, remplacez la carte interface usager du four.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez.

2. Si l’erreur réapparaît, vériez la connexion entre la carte interface usager du four (connecteur MACS1 ou MACS2) et le panneau de relais du four (connecteur J3 ou

J4).

3. À l’aide du numéro de modèle et du catalogue de service, vériez si l’appareil a la bonne carte interface usager et le bon panneau de relais du four.

4. Si le problème persiste, remplacez le panneau relais du four.

5. Si le problème persiste, remplacez la carte interface usager.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez.

2. Si l’erreur réapparaît, vériez si le panneau tactile est branché (vériez le faisceau de ls allant au connecteur I2C1 ou I2C2) et s’il reçoit de l’alimentation de la carte

interface usager.

3. À l’aide du numéro de modèle et du catalogue de service, vériez si l’appareil a la bonne carte interface usager et le bon panneau tactile.

4. Si le problème persiste, remplacez le panneau tactile.

5. Si le problème persiste, remplacez la carte interface usager du four.

1. Vériez si le circuit de la sonde ne serait pas ouvert ou en condition de court-circuit.

2. Vériez la résistance RTD à la température ambiante (comparez la valeur obtenue dans la charte de résistance). Si la valeur obtenue ne correspond pas à la valeur de

la charte, remplacez la sonde RTD.

3. Si le problème persiste, remplacez le panneau de relais.

1. L’erreur est déclenchée si la sonde à viande perçoit une température supérieure à 392°F. Assurez-vous que la sonde à viande ne puisse pas percevoir la température

provenant d’une autre source. Si le bout de la sonde n’est pas inséré dans la viande, celui-ci va capter la température de la cavité, laquelle peut être supérieure à

392°F (dépendant de la température réglée dans le four) et déclencher l’alarme.

2. Si la sonde à viande n’est pas complètement insérée dans le réceptacle situé à l’intérieur de la cavité du four ceci peut entrainer un court-circuit et causer un code

d’erreur. Assurez-vous que la sonde est correctement insérée dans le réceptacle.

3. Vériez la résistance de la sonde à viande à la température ambiante. Comparez cette valeur à celles dans la table de la résistance de la sonde à viande. Si elle ne

correspond pas aux valeurs du tableau, remplacez la sonde à viande.

4. Si toutes les étapes mentionnées ci-haut ont échoué, remplacez le panneau de relais du four.

1. Vériez que les branchements entre le commutateurs de la porte, le loquet de porte à moteur (LPM) et les sondes de température sont correctement établis. Ceux-ci

incluent toutes les épissures et les jonctions.

2. Remplacez la carte de relais de commande des relais du four.

1. Débranchez l’alimentation, attendez 30 secondes et rebranchez. Essayez à nouveau de verrouiller ou déverrouiller la porte (ex: activez le Lockout ou un cycle autonettoyant).

2. Vériez si le moteur tourne ou non. S’il ne tourne pas, vériez le faisceau de ls entre le moteur verrou et le panneau de relais. Si le faisceau de ls est bon, vériez si

il y a 120VAC au moteur lorsqu’il est sensé fonctionner pour voir si le problème est dû à un mauvais moteur (la lecture est de 120VAC mais le moteur ne tourne pas)

ou si le problème revient au panneau de relais (Tige 10 de J20 sur le panneau de relais est la sortie vers le moteur verrou). Le moteur verrou peut aussi être vérié

en appliquant 120VAC directement au moteur (Il faut commencer par le débrancher du panneau de relais). Si le moteur verrou ne tourne pas lorsque 120VAC est

appliqué, remplacez l’assemblé moteur verrou. Si c’est le panneau de relais qui ne fournit pas 120VAC au moteur verrou, remplacez le panneau de relais.

3. Si le moteur tourne mais la commande de four ne peut trouver la position verrouillée ou déverrouillée (ex: le moteur tourne continuellement lorsque le code F90 est

afché) l’interrupteur verrou doit être vérié. Vériez le faisceau de ls entre l’interrupteur verrou et le panneau de relais. Vériez avec un ohmmètre que le contact

de l’interrupteur est correct (vériez la continuité avec le ohmmètre lorsque l’interrupteur est appuyé). Si l’interrupteur est défectueux, remplacez l’assemblé moteur

verrou.

4. Si toutes les étapes mentionnées ci-haut ont échoué, remplacez le panneau de relais du four.

1. Le problème peut être causé par un interrupteur ou un panneau de relais défectueux. Si le moteur verrou fonctionne continuellement (ou comme si le relais demeure

fermé) remplacez le panneau de relais du four.

2. Si le moteur ne tourne pas continuellement remplacez l’assemblé moteur verrou.

1. Cette erreur survient si l’interrupteur de porte perd son contact lors d’un cycle autonettoyant. Assurez-vous que la porte du four ferme complètement et qu’elle presse

adéquatement le piston de l’interrupteur de porte lorsque cette dernière est verrouillée et assurez-vous que personne n’essaie d’ouvrir la porte lorsque le four est en

cycle autonettoyant.

2. Vériez le faisceau de ls entre l’interrupteur de porte et le panneau de relais, assurez-vous que l’interrupteur de porte est bien branché. À l’aide d’un ohmmètre,

vériez si l’interrupteur est fermé lorsque le piston est pressé. Si l’interrupteur est défectueux, remplacez-le.

3. Si l’interrupteur et le faisceau de ls sont bons, remplacez le panneau de relais.

CUISINIÈRE GAZ AVEC RÉGULATEUR ÉLECTRONIQUE DE FOUR MODULAR

FICHE DE RÉPARATION

CODES D’ERREUR POUR LA FICHE TECHNIQUE DE LA CUISINIÈRE AVEC BOUTONS DE COMMANDE À L’AVANT

Code Description de l’erreur Actions correctives suggérées

SPr Le dispositif recherche une tension venant du

faisceau de l’allumeur à étincelle. Si une tension

est détectée, le détecteur CA signale au contrôleur

de four que le module d’allumage tente d’allumer un brûleur. Le contrôleur de four recherche

le signal du détecteur CA uniquement lorsqu’un

cycle d’autonettoyage est lancé ou en fonction. La

détection du signal occasionne l’annulation du cycle

d’autonettoyage et le message < SPr > (étincelle

détectée) s’afche à l’écran Ne pas utiliser la sur-

face de cuisson durant un cycle d’autonettoyage.

Chez certains modèles, allumer l’un ou l’autre des

brûleurs occasionne l’annulation du cycle d’autonet-

toyage. Si le cycle d’autonettoyage est annulé,

l’écran du contrôleur de four afche le message

< SPr > pendant 5 secondes. La porte de four de-

meure verrouillée jusqu’au refroidissement du four

en dessous de la température de nettoyage. Une

fois le four en dessous de la température de nettoyage, il est possible de lancer immédiatement un

autre cycle d’autonettoyage. Si le four est toujours à

sa température d’autonettoyage, il faut attendre que

la porte soit déverrouillée avant de régler un autre

cycle d’autonettoyage (jusqu’à 4 heures).

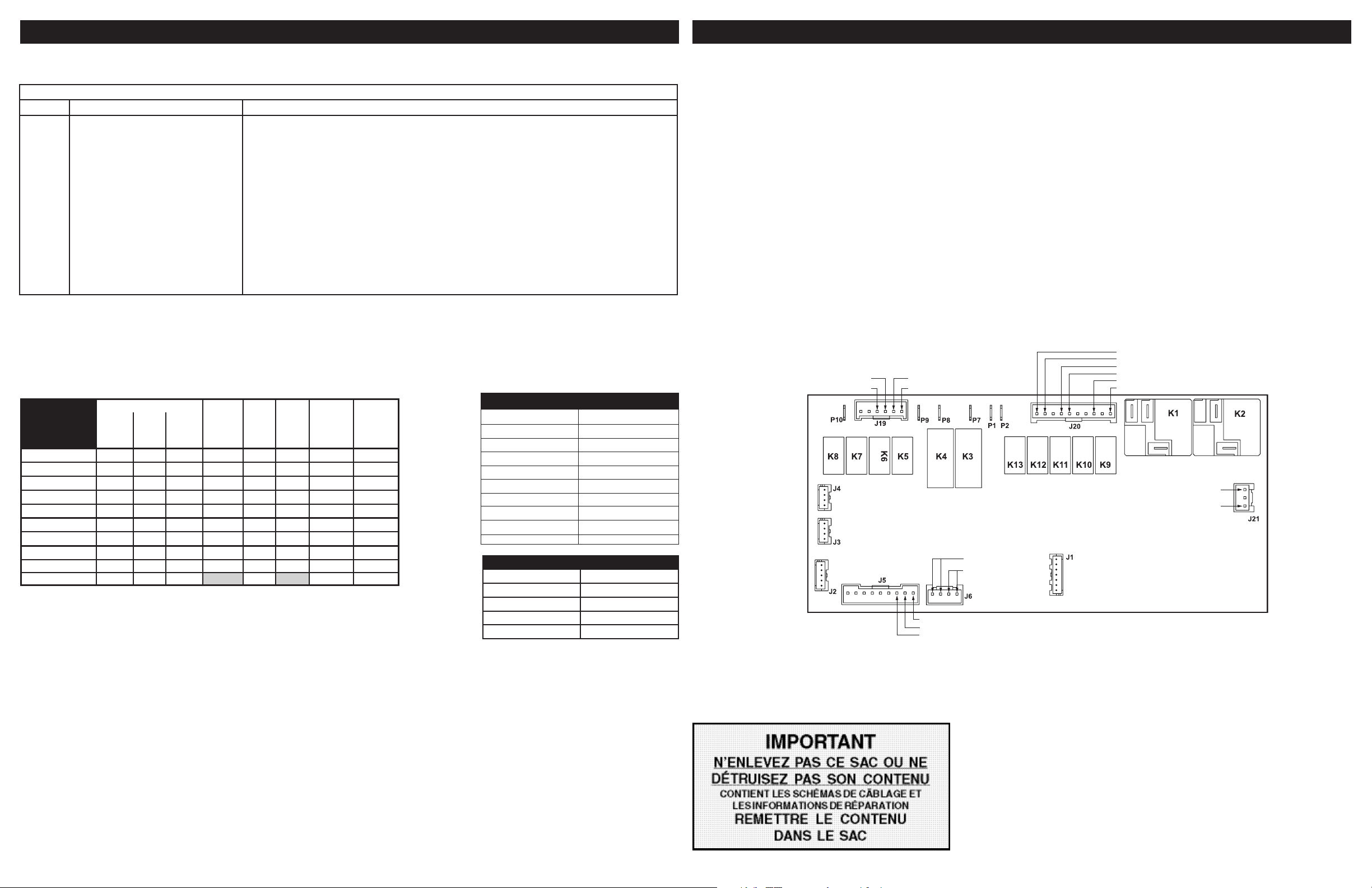

MATRICE

D’ANALYSE DU

CIRCUIT

Cuisson

J19-3

Gril

J19-2

Conv.

J19-4

Moteur

Verrou

J20-10

Cuisson X X X X

Gril X X

Cuisson Conv. X X X X

Rôtissage Conv. X X X X

Nettoyage X X

Verrouillage X

Déverrouillage X

Lampes X

Porte Ouverte X

Porte Fermée X

Si < SPr > persiste :

1. Lancer un cycle d’autonettoyage.

2. Tourner l’un ou l’autre des allumeurs de brûleur sur < LITE > (allumer)

3. Valider l’annulation du cycle d’autonettoyage et que le message < SPr > apparaît à l’écran du four.

Dans le cas contraire, effectuer les procédures de dépannage suivantes :

1. Valider que le faisceau CA est branché sur J1 du détecteur CA.

2. Valider que le faisceau CC est branché sur J2 du détecteur CA.

3. À l’aide d’un multimètre réglé sur Volts CA.

4. Valider 0 V CA aux broches 1 et 3 de J1 du détecteur CA lorsque l’allumeur à étincelle est sur < OFF > (FER-

MÉ).

5. Valider 120 V CA aux broches 1 et 3 de J1 du détecteur CA lorsque l’allumeur à étincelle est sur < ON > (AL-

LUMÉ).

6. À l’aide d’un multimètre réglé sur Volts CC.

7. Valider 4 à 5 V CC aux broches 2 et 3 de J3 du détecteur CA ou aux broches 5 et 6 de J5 du contrôleur OVC

lorsque l’allumeur à étincelle est sur < OFF > (FERMÉ). (La broche 3 est la mise à la terre du détecteur CA et la

broche 6 est la mise à la terre du contrôleur OVC.

8. Valider 0 à 1 V CC aux broches 2 et 3 de J3 du détecteur CA ou aux broches 5 et 6 de J5 du contrôleur OVC

lorsque l’allumeur à étincelle est sur < ON > (ALLUMÉ). (La broche 3 est la mise à la terre du détecteur CA et la

broche 6 est la mise à la terre du contrôleur OVC.

9. Si les étapes 7 et 8 sont valides, remplacer le contrôleur OVC.

Sur le Panneau Relais

Sur le

panneau

Lampe

J20-6

Ventilateur

Conv. - HI

J20-10

d’afchage

Interr. porte

J5-7/J5-8

Ventilateur

refroidissement

J20-7

SONDE À VIANDE TEMPÉRATURE VS

Température °F (°C) Résistance (Kohm)

77 (25) 50.0 ± 7%

122 (50) 18.0 ± 4.9%

176 (80) 6.3 ± 3.3%

212 (100) 3.4 ± 4.6%

RÉSISTANCE

Page 4

LAMPE HALOGÈNE

LAMPE HALOGÈNE

VENTILATEUR DE REFROIDISSEMENT

CIRCUIT DU FOUR

COMMANDE ÉLECTRONIQUE DU FOUR

SONDE À VIANDE

SONDE À TEMPÉRATURE

INTERRUPTEUR D'ALLUMAGE

DU BRÛLEUR AVANT GAUCHE

INTERRUPTEUR D'ALLUMAGE

DU BRÛLEUR ARRIÈRE GAUCHE

INTERRUPTEUR D'ALLUMAGE

DU BRÛLEUR AU CENTRE

BRÛLEUR DE SURFACE

PANNEAU DU MODULE D'ALLUMAGE

BRÛLEUR DE SURFACE

BRÛLEUR DE SURFACE

BRÛLEUR DE SURFACE

VENTILATEUR DE CONVECTION

INTERRUPTEUR

DE PORTE

MOTEUR VERROU

VALVE DU BRÛLEUR DE GRILLAGE

VALVE DU BRÛLEUR DE CUISSON

ÉLÉMENT DE CONVECTION

TIROIR RÉCHAUD THERMOSTAT

INTER. TIROIR RÉCHAUD

ALLUMEUR DU BRÛLEUR DE GRILLAGE

ALLUMEUR DU BRÛLEUR DE CUISSON

TIROIR RÉCHAUD

ÉLÉMENT DU TIROIR RÉCHAUD

DISJONCTEUR THERMIQUE

INTERRUPTEUR DE PORTE

D'INTERFACE

DE UTILISATEUR

CALIBRE

(PANNEAU DE

VERRE TACTILE)

INTERRUPTEUR D'ALLUMAGE

DU BRÛLEUR ARRIÈRE DROITE

INTERRUPTEUR D'ALLUMAGE

DU BRÛLEUR AVANT DROITE

L1 DU

HARNAIS

PRINCIPAL

NEUTRE DU

HARNAIS

PRINCIPAL

L1 À

PARTIR DU

HARNAIS

PRINCIPAL

BRÛLEUR DE SURFACE

CAUTION:

DISCONNECT POWER BEFORE SERVICING UNIT.LABEL

ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS.WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING

LEGEND / LÉGENDE

SW - SWITCH / INTERRUPTEUR

PL - PILOT LIGHT / PTÉMOIN LUMINEUX

RF - RIGHT FRONT / AVANT DROITE

RR - RIGHT REAR / ARRIÈRE DROITE

LF - LEFT FRONT / AVANT GAUCHE

LR - LEFT REAR / ARRIÈRE GAUCHE

HS - HOT SURFACE / SURFACE CHAUDE

LIM - LIMITER / LIMITEUR

WD - WARMER DRAWER / TIROIR RÉCHAUD

.

TÉMOIN LUMINUEUX TIROIR RÉCHAUD

ATTENTION:

DÉBRANCHEZ L'APPAREIL AVANT DE PROCÉDER À LA RÉPARATION.

IDENTIFIEZ TOUS LES FILS AVANT DE LES DÉBRANCHER LORSQUE

VOUS PROCÉDEZ À UNE RÉPARATION. UNE ERREUR DE FILAGE PEUT

CAUSER UN FONCTIONNEMENT INADÉQUAT ET/OU UNE SITUATION

DANGEREUSE. VÉRIFIEZ QUE L'APPAREIL FONCTIONNE

CORRECTEMENT APRÈS LA RÉPARATION.

CONNECTEUR

CONNECTEUR

CONNECTEUR

CONNECTEUR

CODE DE COULEURS

BK-BLACK/NOIR

G-GREEN/VERT

W-WHITE/BLANC

R-RED/ROUGE

O-ORANGE

Y-YELLOW/JAUNE

BR-BROWN/BRUN

BL-BLUE/BLEU

GY-GRAY/GRIS

V-VIOLET

T-TAN/OCRE

PR-PURPLE/POURPRE

P-PINK/ROSE

CAUTION:

DISCONNECT POWER BEFORE SERVICING UNIT.LABEL

ALL WIRES PRIOR TO DISCONNECTION WHEN

SERVICING CONTROLS.WIRING ERRORS CAN CAUSE

IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING

LEGEND / LÉGENDE

SW - SWITCH / INTERRUPTEUR

PL - PILOT LIGHT / PTÉMOIN LUMINEUX

RF - RIGHT FRONT / AVANT DROITE

RR - RIGHT REAR / ARRIÈRE DROITE

LF - LEFT FRONT / AVANT GAUCHE

LR - LEFT REAR / ARRIÈRE GAUCHE

HS - HOT SURFACE / SURFACE CHAUDE

LIM - LIMITER / LIMITEUR

WD - WARMER DRAWER / TIROIR RÉCHAUD

.

CONNECTEUR

ATTENTION:

DÉBRANCHEZ L'APPAREIL AVANT DE PROCÉDER À LA RÉPARATION.

IDENTIFIEZ TOUS LES FILS AVANT DE LES DÉBRANCHER LORSQUE

VOUS PROCÉDEZ À UNE RÉPARATION. UNE ERREUR DE FILAGE PEUT

CAUSER UN FONCTIONNEMENT INADÉQUAT ET/OU UNE SITUATION

DANGEREUSE. VÉRIFIEZ QUE L'APPAREIL FONCTIONNE

CORRECTEMENT APRÈS LA RÉPARATION.

CONNECTEUR CONNECTEUR CONNECTEUR

CODE DE COULEURS

BK-BLACK/NOIR

G-GREEN/VERT

W-WHITE/BLANC

R-RED/ROUGE

O-ORANGE

Y-YELLOW/JAUNE

BR-BROWN/BRUN

BL-BLUE/BLEU

GY-GRAY/GRIS

V-VIOLET

T-TAN/OCRE

PR-PURPLE/POURPRE

P-PINK/ROSE

Loading...

Loading...