Electrolux EFMC417SIW0, EFMC517SIW0, EFMC517STT0, EFMC617SIW0, EFMC617STT0 Installation Guide

...Page 1

EN FRONT LOAD DRYER

FR SÉCHEUSE Á CHARGEMENT FRONTAL

ES SECADORA DE CARGA FRONTAL

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACIÓN

A07020302 July 2017

Page 2

2

2

Important Safety Instructions

WARNING

For your safety the information in this manual must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury or loss of life. Do not store or use

gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

Recognize safety symbols, words

and labels

Safety items throughout this manual are

labeled with a WARNING or CAUTION

based on the risk type as described:

WARNING RISK OF FIRE

Read all of the following instructions before installing and using this appliance:

• Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play.

Cartons covered with rugs, bedspreads, or plastic sheets can become airtight chambers causing

suffocation. Place all materials in a garbage container or make materials inaccessible to children.

• Clothes dryer installation and service must be performed by a qualified installer, service agency or

the gas supplier.

• Install the clothes dryer according to the manufacturer’s instructions and local codes.

• The electrical service to the dryer must conform with local codes and ordinances and the latest

edition of the National Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical

code C22.1 part 1.

• The gas service to the dryer must conform with local codes and ordinances and the latest edition

of the National Fuel Gas Code ANSI Z223.1/NFPA 54, or in Canada, the Natural Gas and Propane Installation Code, CSA B149.1. An individual manual shutoff valve must be installed within 6

ft (1.83 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• The dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE only. This dryer is not recommended for commercial applications such as

restaurants, beauty salons, etc.

• Do not install a clothes dryer with flexible plastic or flexible foil venting material. Flexible venting

materials are known to collapse, be easily crushed and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

• Do not stack a dryer on top of washer already installed on pedestal. Do not stack washer on top

of dryer. Do not stack washer on top of another washer.

• The instructions in this manual and all other literature included with this dryer are not meant to

cover every possible condition and situation that may occur. Good safe practice and caution

MUST be applied when installing, operating and maintaining any appliance.

This symbol alerts you to situations that may

cause serious body harm, death or property

damage.

This symbol alerts you to situations that may

cause bodily injury or property damage.

Save these instructions for future reference.

Table of contents

Important Safety Instructions ....................................2

Installation Requirements ........................................3-9

Installation Instructions ......................................... 10-17

©2016 Electrolux Major Appliances All rights reserved.

Reversing Door .........................................................18-19

Options .............................................................................20

Page 3

Installation Requirements

(not duct tape)

(gas dryer)

(gas dryer)

clamp

3

Please read and save this

guide

Thank you for choosing Electrolux, the premium

brand in home appliances. These Installation

Instructions are part of our commitment to

customer satisfaction and product quality

throughout the life of your new appliance.

Installation Checklist

Exhaust Venting

Free-flowing, clear of lint buildup

4 inch (102 mm) rigid or semi-rigid ducting

of minimal length and turns

NO foil or plastic venting material

Approved vent hood exhausted to

outdoors

Leveling

Dryer is level, side-to-side and front-toback

Cabinet is sitting solid on all corners

Gas Supply (Gas Dryer)

Manual shutoff valve present in supply

All connections sealed with approved

sealer and wrench tight

Conversion kit for LP system

Gas supply turned on

No leaks present at all connections -

check with soapy water, NEVER check with

flame

Questions?

For toll-free telephone support in the U.S.:

1-877-4ELECTROLUX (1-877-435-3287) and in

Canada: 1-800-265-8352.

For online support and product information visit

www.electroluxappliances.com.

240v Electric Supply (Electric Dryer)

Approved NEMA 10-30 or 14-30 service

cord with all screws tight on terminal

block

Approved strain relief installed

Terminal access cover installed before

initial operation

Door Reversal

Follow detailed instructions in this guide

Test hinge and latch for function

Electrical Power

House power turned on

Dryer plugged in

Final Checks

Installation Instructions and Use and

Care Guide read thoroughly

Door latches and drum tumbles when

cycle starts

Registration card sent in

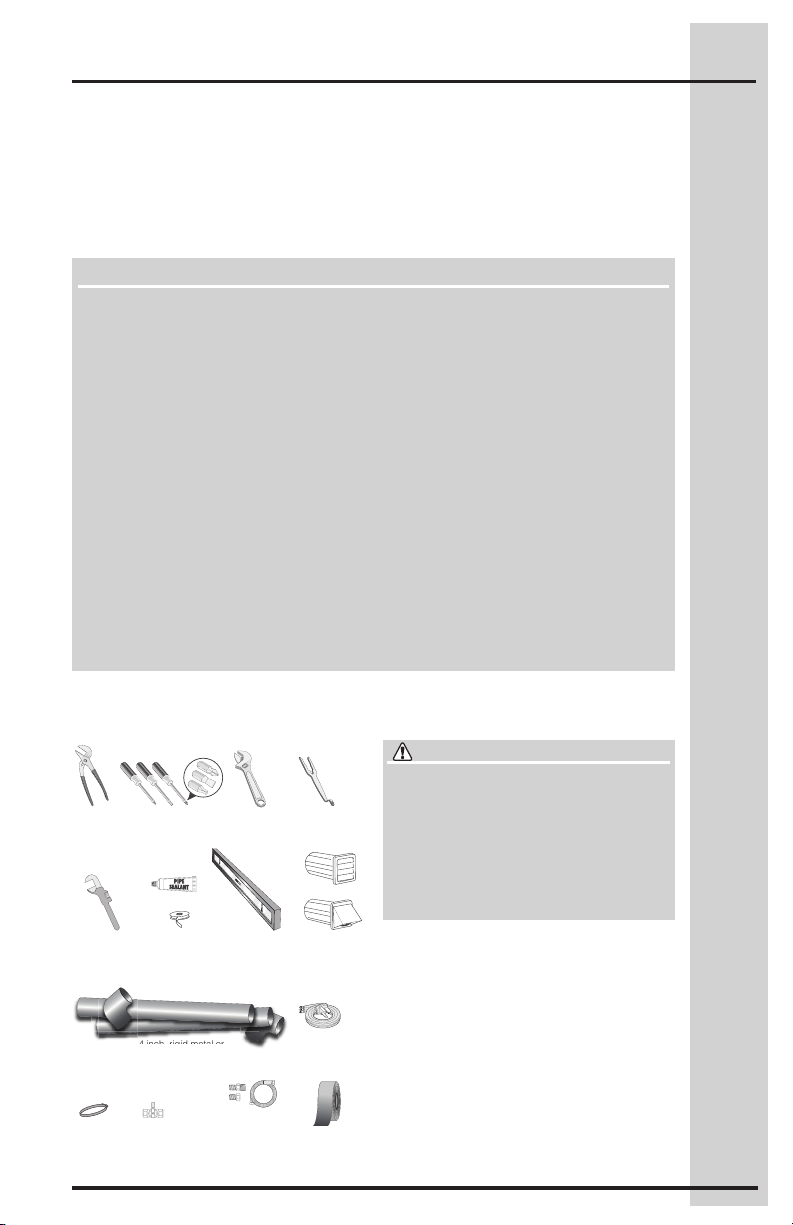

Tools and materials needed for installation:

Adjustable

(10.2 cm)

Phillips, straight, &

square bit screwdrivers

pliers

or

Pipe wrench

4 in.

LP-resistant

for gas

thread tape

supply

(for natural gas

or LP supply)

4 inch, rigid metal or

semi-rigid metal exhaust duct work

gas line

shutoff valve

flexible gas supply line

Adjustable

wrench

Carpenter’s level

½” NPT union flare

adapters (x2) and

Optional universal

3-wire or 4-wire

240 volt cord kit

(electric dryer)

Metal foil tape

accessory

wrench

or

External

vent hood

WARNING

FIRE HAZARD

● Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

● Do not install a booster fan in dryer exhaust

duct.

● Install all clothes dryers in accordance with

the installation instructions in this manual.

Page 4

4

Installation Requirements

Electrical system requirements

NOTE

Because of potentially inconsistent voltage

capabilities, the use of this dryer with power

created by gas powered generators, solar

powered generators, wind powered generators

or any other generator other than the local utility

company is not recommended.

ELECTRICAL REQUIREMENTS FOR ELECTRIC

DRYER:

CIRCUIT - Individual 30 amp. branch circuit

fused with 30 amp. time delay fuses or circuit

breakers. Use separately fused circuits for

washer and dryer. DO NOT operate a washer

and a dryer on the same circuit.

POWER SUPPLY - 3-wire or 4-wire, 120/240 volt,

single phase, 60 Hz, Alternating Current.

NOTE

A 120/208 volt, single phase, 60 Hz, Alternating

Current supply may be used on dryers marked

for use on the rating plate.

IMPORTANT

This dryer is internally grounded to neutral unless it was manufactured for sale in Canada.

Only a 4-conductor cord shall be used when

the appliance is installed in a location where

grounding through the neutral conductor is

prohibited. Grounding through the neutral link

is prohibited for: (1) new branch circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes do not

permit grounding through the neutral.

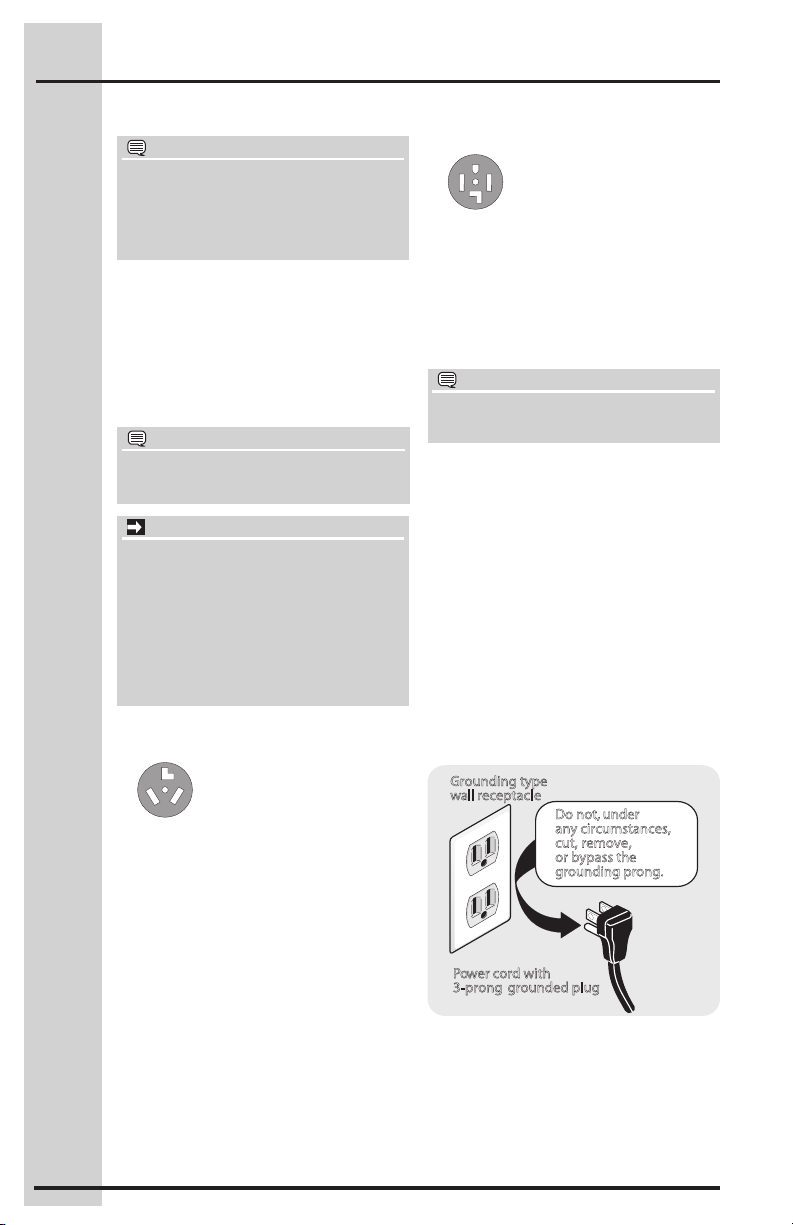

3-WIRE POWER SUPPLY CORD (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3-conductor power

supply cord NEMA 10-30 type SRDT rated at

240 volt AC minimum, 30 amp, with 3 open

end spade lug connectors with upturned

ends or closed loop connectors and marked

for use with clothes dryers. For 3-wire cord

connection instructions see ELECTRICAL

CONNECTIONS FOR A 3-WIRE SYSTEM.

OUTLET RECEPTACLE - NEMA 10-30R

receptacle to be located so the power supply

cord is accessible when the dryer is in the

installed position.

GROUNDING CONNECTION - See “Grounding

requirements” in Electrical Installation section.

4-WIRE POWER SUPPLY CORD (not supplied)

The dryer MUST employ a 4-conductor

power supply cord NEMA 14-30 type SRDT

or DRT (as required) rated at 240 volt AC

minimum, 30 amp, with 4 open end spade

lug connectors with upturned ends or closed

loop connectors and marked for use with

clothes dryers. For 4-wire cord connection

instructions see ELECTRICAL CONNECTIONS

FOR A 4-WIRE SYSTEM.

NOTE

Dryers manufactured for sale in Canada have

factory-installed, 4-wire power supply cord

(NEMA 14-30).

OUTLET RECEPTACLE - NEMA 14-30R

receptacle to be located so the power supply

cord is accessible when the dryer is in the

installed position.

GROUNDING CONNECTION - See “Grounding

requirements” in Electrical Installation section.

ELECTRICAL REQUIREMENTS FOR GAS DRYER:

CIRCUIT - Individual, properly polarized and

grounded 15 amp. branch circuit fused with 15

amp. time delay fuse or circuit breaker.

POWER SUPPLY - 2-wire, with ground, 120 volt,

single phase, 60 Hz, Alternating Current.

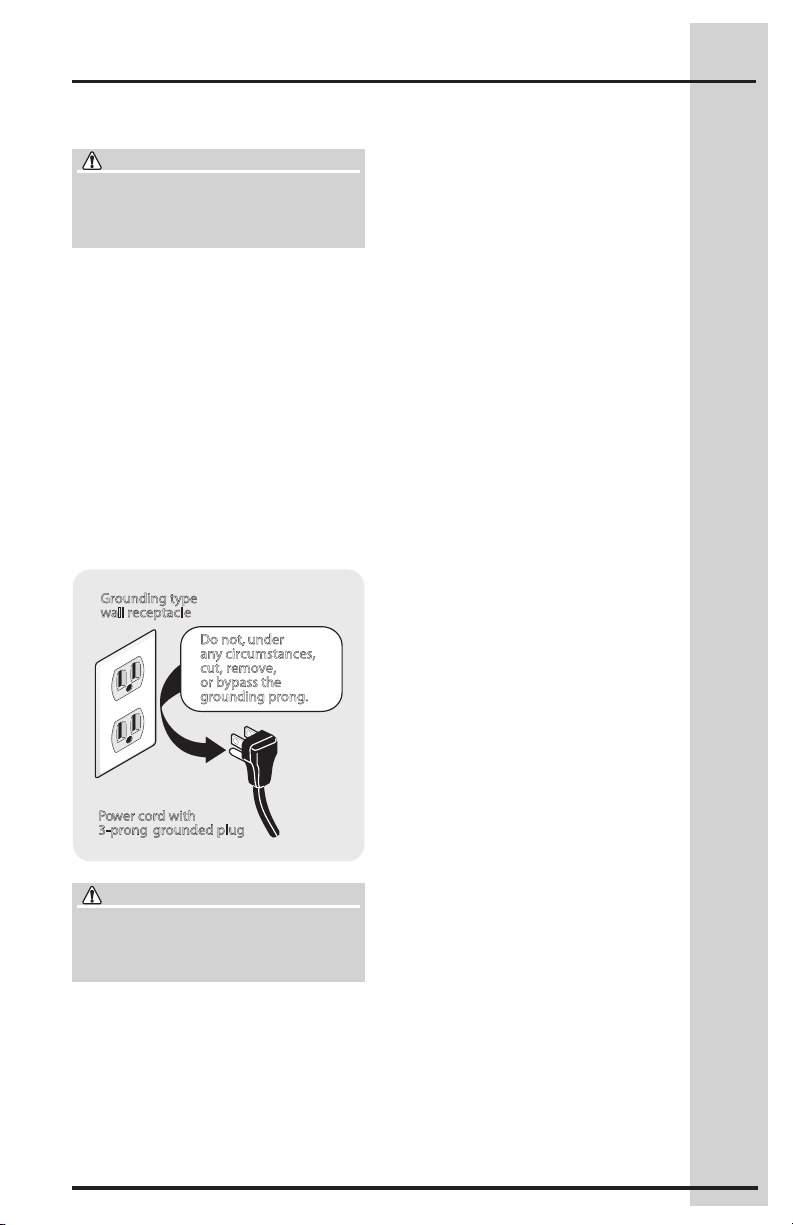

POWER SUPPLY CORD - The dryer is equipped

with a 120 volt 3-wire power cord.

GROUNDING CONNECTION - See “Grounding

requirements” in Electrical Installation section.

Grounding type

wall receptacle

Power cord with

3-prong grounded plug

4-wire receptacle

(NEMA type 14-30R)

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Page 5

Installation Requirements

Gas supply requirements

WARNING

Uncoated copper tubing will corrode when

subjected to natural gas, causing gas leaks.

Use ONLY black iron, stainless steel, or plasticcoated brass piping for gas supply.

1. Installation MUST conform with local codes,

or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (latest

edition).

2. The gas supply line should be 1/2 inch (1.27

cm) pipe.

3. If codes allow, flexible metal tubing may be

used to connect your dryer to the gas supply

line. The tubing MUST be constructed of

stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual

shutoff valve installed in accordance with the

B149.1, Natural Gas and Propane Installation

Code.

Exhaust system requirements

Use only 4 inch (102 mm) diameter (minimum)

rigid or flexible metal duct and approved vent

hood which has a swing-out damper(s) that

open when the dryer is in operation. When the

dryer stops, the dampers automatically close to

prevent drafts and the entrance of insects and

rodents. To avoid restricting the outlet, maintain

a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any

other obstruction.

WARNING

Failure to follow these instructions can create

excessive drying times and fire hazards.

The following are specific requirements

for proper and safe operation of your

dryer.

EXPLOSION HAZARD

FIRE HAZARD

5. A 1/8 inch (0.32 cm) N.P.T. plugged tapping,

accessible for test gauge connection, MUST

be installed immediately upstream of the gas

supply connection to the dryer.

6. The dryer MUST be disconnected from the

gas supply piping system during any pressure

testing of the gas supply piping system at test

pressures in excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the gas

supply piping system during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.45

kPa).

8. Connections for the gas supply must comply

with the Standard for Connectors for Gas

Appliances, ANSI Z21.24/CSA 6.10.

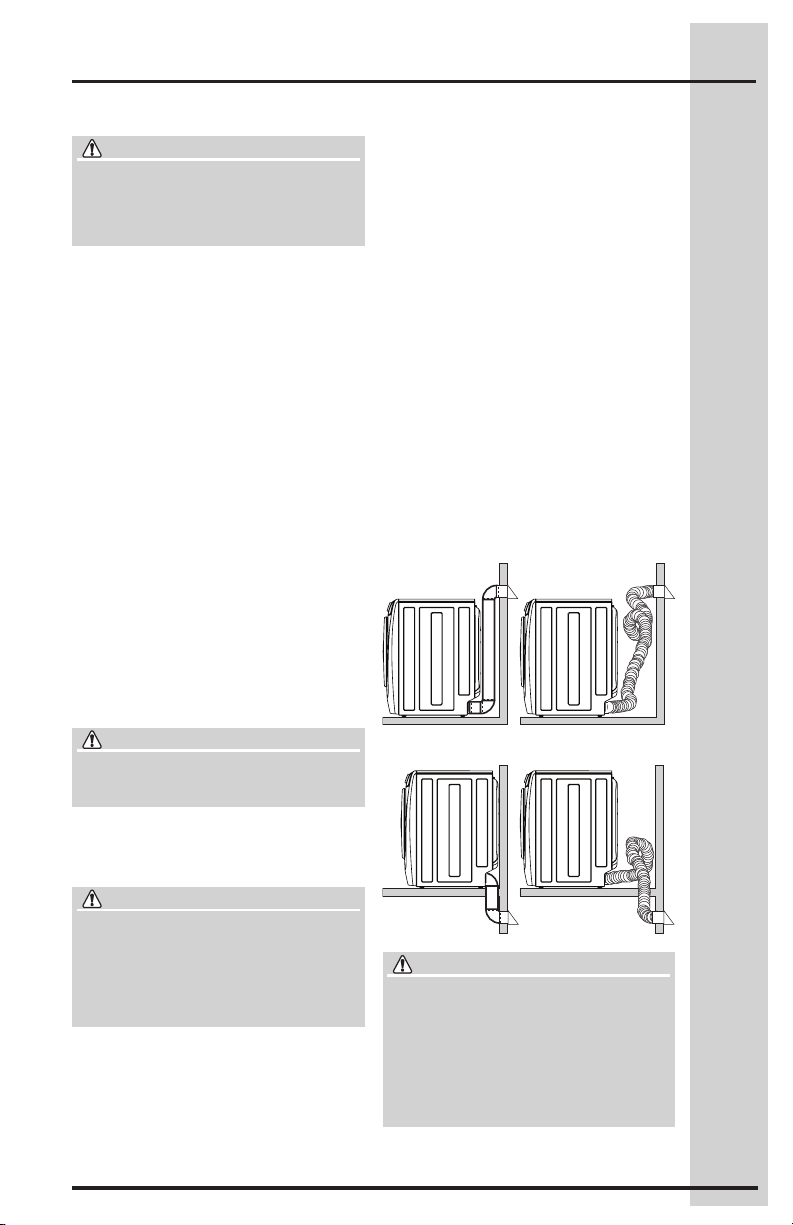

CORRECT

INCORRECT

5

WARNING

Do not install a clothes dryer with flexible

plastic or metal foil venting materials. Flexible

venting materials are known to collapse, be

easily crushed and trap lint. These conditions

will obstruct clothes dryer airflow and increase

the risk of fire.

If your present system is made up of plastic duct

or metal foil duct, replace it with a rigid or semirigid metal duct. Also, ensure the present duct is

free of any lint prior to installing dryer duct.

FIRE HAZARD

CORRECT

INCORRECT

WARNING

● Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

● Do not install a booster fan in dryer exhaust

duct.

● Install all clothes dryers in accordance with

the installation instructions in this manual.

FIRE HAZARD

Page 6

6

Installation Requirements

Exhaust system requirements, continued

WARNING

A clothes dryer must be exhausted outdoors.

Do not exhaust dryer into a chimney, a wall,

a ceiling, an attic, a crawl space or any

concealed space of a building. A clothes

dryer produces combustible lint. If the dryer

is not exhausted outdoors, some fine lint

will be expelled into the laundry area. An

accumulation of lint in any area of the home

can create a health and fire hazard.

The dryer must be connected to an exhaust

outdoors. Regularly inspect the outdoor exhaust

opening and remove any accumulation of lint

around the outdoor exhaust opening and in the

surrounding area.

FIRE HAZARD

WARNING

● Do not allow combustible materials (for

example: clothing, draperies/curtains, paper)

to come in contact with exhaust system.

The dryer MUST NOT be exhausted into a

chimney, a wall, a ceiling, or any concealed

space of a building which can accumulate

lint, resulting in a fire hazard.

● Do not screen the exhaust ends of the

vent system, or use any screws, rivets or

other fasteners that extend into the duct

to assemble the exhaust system. Lint can

become caught in the screen, on the

screws or rivets, clogging the duct work and

creating a fire hazard as well as increasing

drying times. Use an approved vent hood

to terminate the duct outdoors, and seal all

joints with metal foil tape. All male duct pipe

fittings MUST be installed downstream with

the flow of air.

FIRE HAZARD

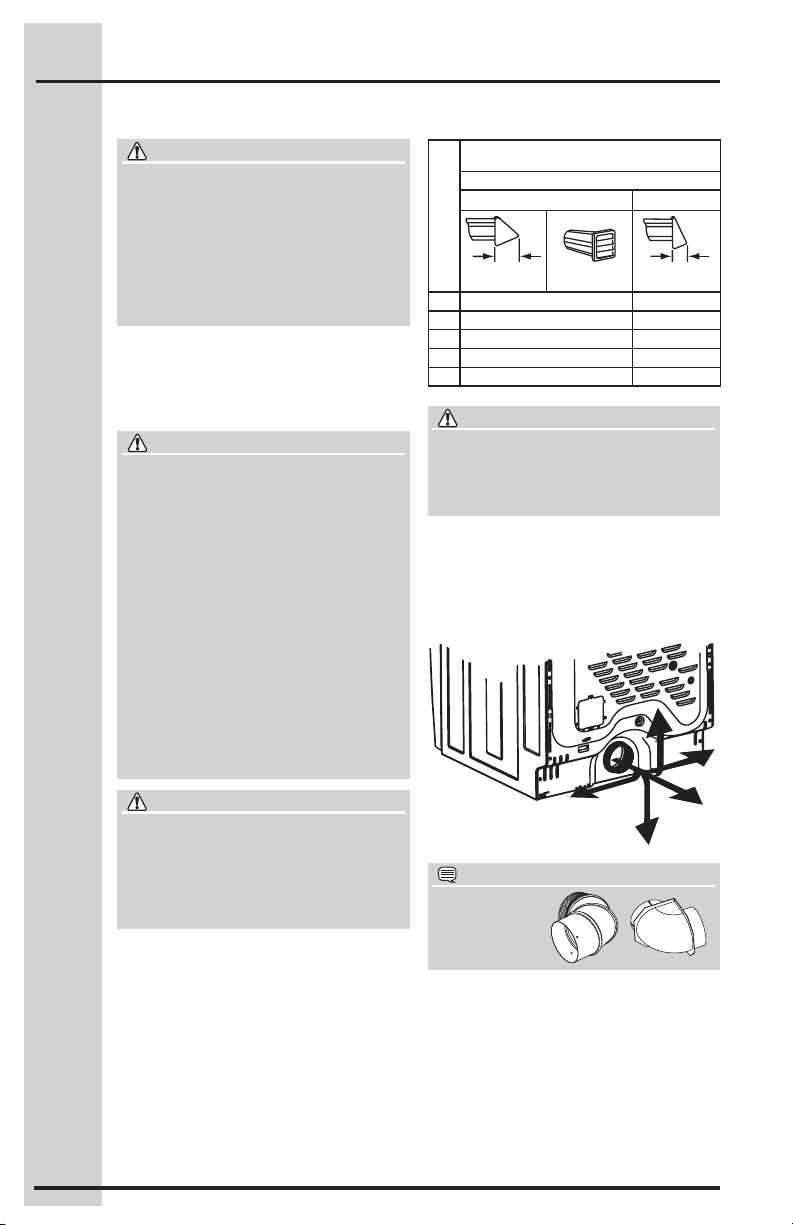

Number of 90° turns

0 125 ft. (38 m) 110 ft. (33.5 m)

1 115 ft. (35 m) 100 ft. (30.5 m)

2 105 ft. (32 m) 90 ft. (27.5 m)

3 95 ft. (29 m) 80 ft. (24.5 m)

4 85 ft. (26 m) 70 ft. (21.5 m)

MAXIMUM LENGTH

of 4” (102 mm) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

4”

(10.2 cm) louvered

2.5”

(6.35 cm)

WARNING

● Do not install flexible plastic or flexible foil

venting material.

● If installing semi-rigid venting, do not exceed

8 ft. (2.4 m) duct length.

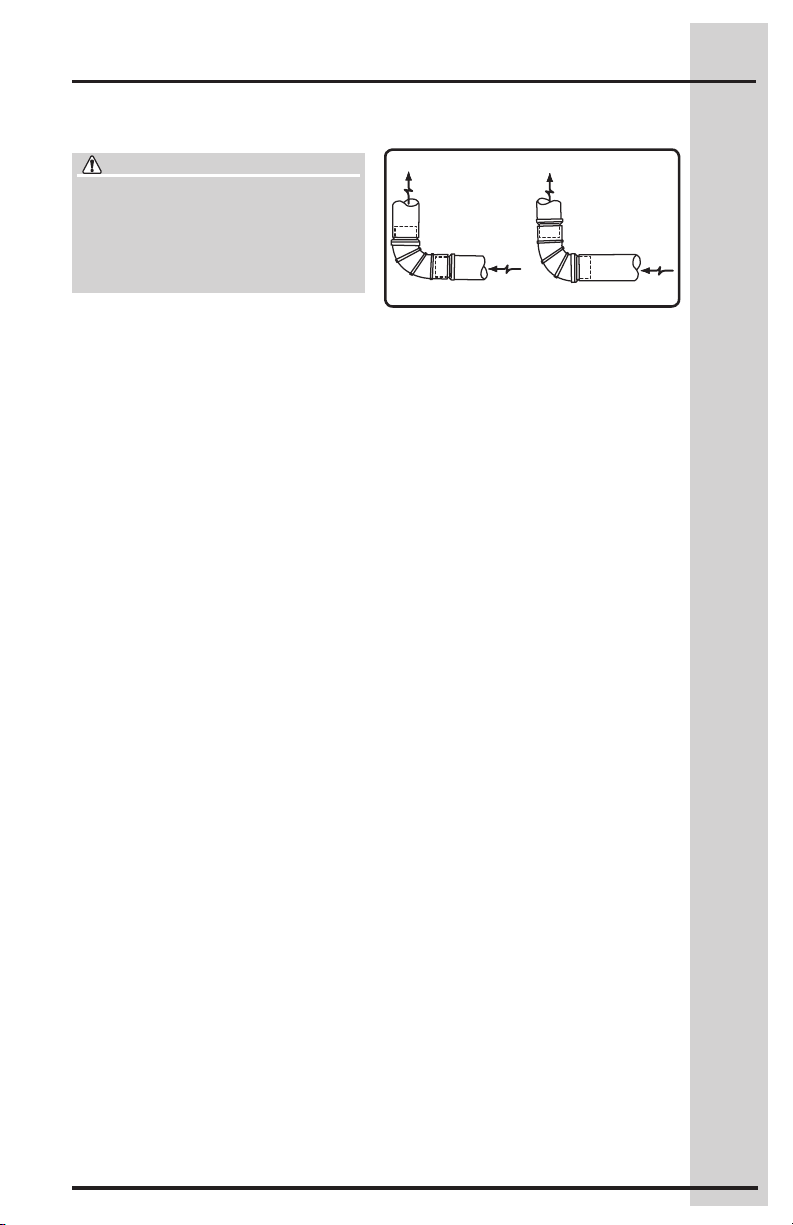

EXHAUST DIRECTION

Directional exhausting can be accomplished

by installing a quick-turn 90° dryer vent elbow

directly to exhaust outlet of dryer. Dryer vent

elbows are available through your local parts

distributor or hardware store.

FIRE HAZARD

WARNING

Exceeding the length of duct pipe or number

of elbows allowed in the “MAXIMUM LENGTH”

charts can cause an accumulation of lint in

the exhaust system. Plugging the system could

create a fire hazard, as well as increase drying

times.

FIRE HAZARD

See also CLEARANCE

REQUIREMENTS on the

next page.

NOTE

Use of 90° quickturn elbow required

to meet minimum

installation depth.

Page 7

Installation Requirements

INCORRECT

Exhaust system requirements, continued

7

WARNING

Do not install the dryer where gasoline or

other flammables are kept or stored. If the

dryer is installed in a garage, it must be a

minimum of 18 inches (45.7 cm) above the floor.

Failure to do so can result in death, explosion,

fire or burns.

In installations where the exhaust system is not

described in the charts, the following method

must be used to determine if the exhaust system

is acceptable:

1. Connect an inclined or digital manometer

between the dryer and the point the exhaust

connects to the dryer.

2. Set the dryer timer and temperature to air fluff

(cool down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be

higher than 1.0 inch of water column. If the

system back pressure is less than 1.0 inch of

water column, the system is acceptable. If

the manometer reading is higher than 1.0 inch

of water column, the system is too restrictive

and the installation is unacceptable.

FIRE HAZARD

Install male fittings in correct direction:

CORRECT

Although vertical orientation of the exhaust

system is acceptable, certain extenuating

circumstances could affect the performance of

the dryer:

● Only the rigid metal duct work should be

used.

● Venting vertically through a roof may expose

the exhaust system to down drafts causing

an increase in vent restriction.

● Running the exhaust system through an

uninsulated area may cause condensation

and faster accumulation of lint.

● Compression or crimping of the exhaust

system will cause an increase in vent

restriction.

● The exhaust system should be inspected and

cleaned a minimum of every 18 months with

normal usage. The more the dryer is used,

the more often you should check the exhaust

system and vent hood for proper operation.

Manufactured or mobile home installation

1. Installation MUST conform to current

Manufactured Home Construction & Safety

Standard, Title 24 CFR, Part 32-80 (formerly

the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part

280) or Standard CAN/CSAZ240 MH.

2. Dryer MUST be exhausted outside (outdoors,

not beneath the mobile home) using metal

ducting that will not support combustion.

Metal ducting must be 4 inches (10.16 cm) in

diameter with no obstructions. Rigid metal duct

is preferred.

3. If dryer is exhausted through the floor and

area beneath the mobile home is enclosed,

the exhaust system MUST terminate outside

the enclosure with the termination securely

fastened to a non-combustible portion of the

mobile home structure.

4. Refer to previous sections in this guide for

other important exhaust venting system

requirements.

5. When installing a gas dryer into a mobile

home, a provision must be made for outside

make up air. This provision is to be not less

than twice the area of the dryer exhaust

outlet.

6. Installer MUST anchor this (1) dryer or (2)

dryer mounted on pedestal to the floor with

approved Mobile Home Installation Kit - P/N

137067200.

Page 8

8

60 sq. in.

(387.1cm²)

3”

(7.6cm)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

(0

1”

(2.5

0”

Installation Requirements

Clearance requirements

IMPORTANT

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or

outside weather conditions.

2. In an area where it will come in contact with

curtains, drapes, or anything that will obstruct

the flow of combustion and ventilation air.

3. On carpet. Floor MUST be solid with a maximum slope of 1 inch (2.5 cm).

INSTALLATION IN A RECESS OR CLOSET

1. A dryer installed in a bedroom, bathroom,

recess or closet, MUST be exhausted

outdoors.

2. No other fuel burning appliance shall be

installed in the same closet as the gas dryer.

3. Your dryer needs the space around it for

proper ventilation.

DO NOT install your dryer in a closet with a

solid door.

4. Closet door ventilation required: A minimum

of 120 square inches (774.2 cm²) of opening,

equally divided at the top and bottom of

the door, is required. Openings should be

located 3 inches (7.6 cm) from bottom and

top of door. Openings are required to be

unobstructed when a door is installed. A

louvered door with equivalent air openings

for the full length of the door is acceptable.

MIN INSTALLATION CLEARANCES - Inches (cm)

Alcove 0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

Under-

Counter

Closet 0” (0 cm) 0” (0 cm)* 0” (0 cm) 1” (2.5 cm)

* F

SIDES REAR TOP FRONT

0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

or other than straight back venting, a quick-turn

90° dryer vent elbow must be installed to achieve

0” (0 cm) installation.

0”

cm)

0”

(0

cm)

cm)

(0 cm)

closet door

NOTE

To achieve an installation with 0” (0 cm)

clearance for the back of the dryer (for other

than straight back venting), a quick-turn 90°

dryer vent elbow must be installed as described

previously in this manual.

Page 9

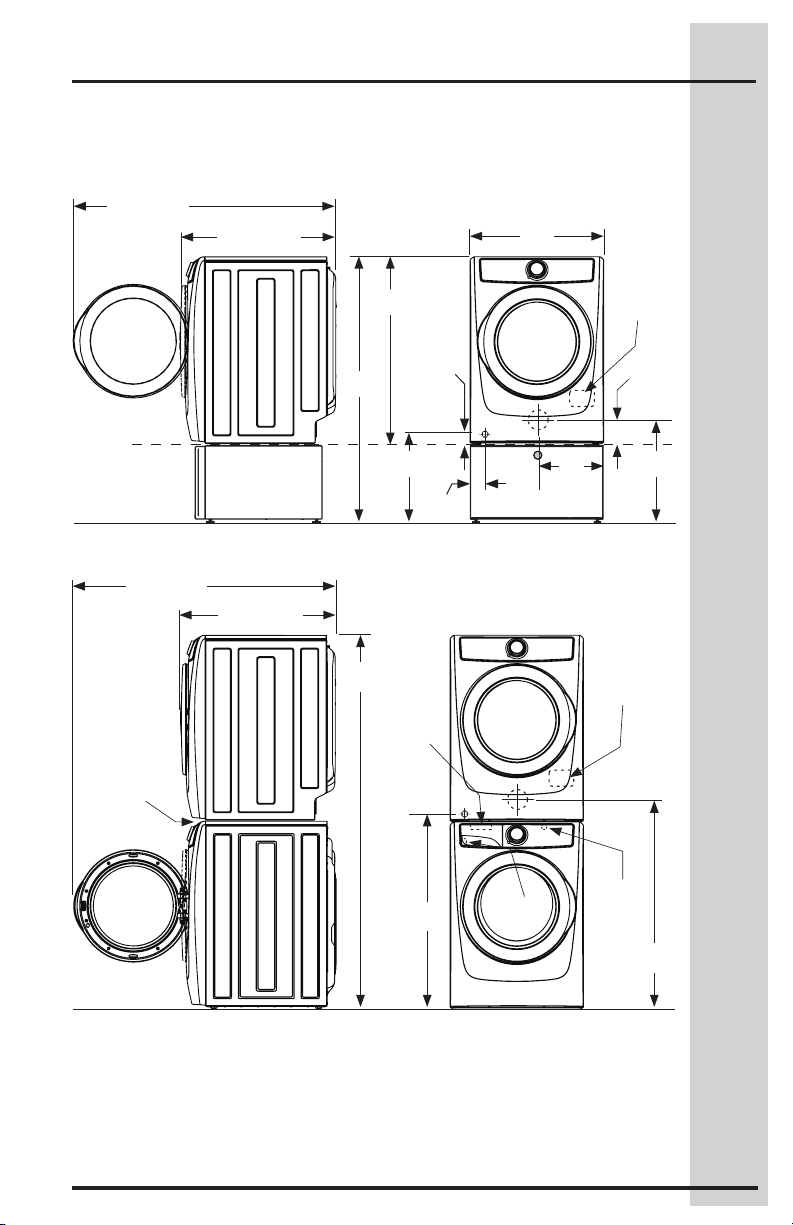

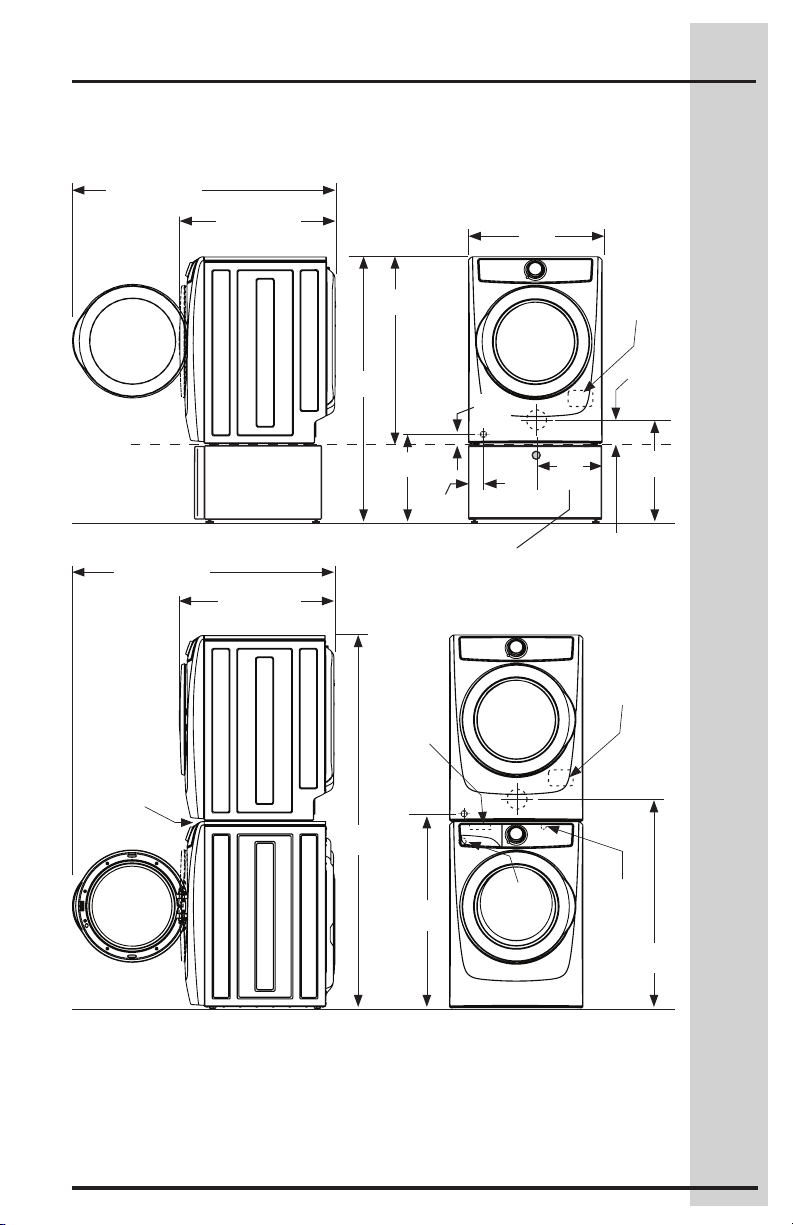

Dryer dimensions

53.2” (135 cm)*

to clear open door

to front of closed door

31.6” (80 cm)*

Installation Requirements

27.0”

(68.5 cm)

9

freestand dryer

on floor

floor line

dryer mounted on

optional pedestal

floor line

53.5” (136 cm)*

to clear open door

approved stacking

kit (STACKIT7X)

required for

stacked installation

32.0” (81.25 cm)*

to front of closed door

(96.5 cm)

53.25”

(135.5 cm)

75.75 ”

(192.5 cm)

38.0”

gas supply

pipe on rear

of gas unit

17. 0”

(43 cm)

(9.5 cm)

water supply

connection on

rear of unit

gas supply

pipe on rear

of gas unit

1.5”

(4 cm)

3.75”

13.5”

(34.5 cm)

to center of

rear vent

electrical

supply on

rear of unit

(9.5 cm)

centerline

height of

rear vent

electrical

supply on

rear of unit

centerline

height for

rear vent

3.7”

19. 0”

(48 cm)

1

1

39.0”

(99 cm)

floor line

*Connection of water inlet hose on steam dryer adds 3/4 in. (2 cm) to installation depth.

1

Power supply cord length on gas dryer or electric Canadian dryer approximately 60 inches (152.5 cm).

2

Drain hose length on washer approximately 59 inches (150 cm).

3

Power supply cord length on washer approximately 60 inches ( 152.5 cm).

drain hose on

2

rear of unit

power cord on

3

rear of unit

(105 cm)

41.0”

Page 10

10

Installation Instructions

Electrical installation

The following are specific requirements for

proper and safe electrical installation of your

dryer. Failure to follow these instructions can

create electrical shock and/or a fire hazard.

WARNING

ELECTRICAL SHOCK HAZARD

● This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not

properly grounded. Follow the instructions in

this manual for proper grounding.

● Do not use an extension cord with this dryer.

Some extension cords are not designed to

withstand the amounts of electrical current

this dryer utilizes and can melt, creating

electrical shock and/or fire hazard. Locate

the dryer within reach of the receptacle for

the length power cord to be purchased,

allowing some slack in the cord. Refer to the

pre-installation requirements in this manual

for the proper power cord to be purchased.

WARNING

ELECTRICAL SHOCK HAZARD

● A U.L.-approved strain relief must be

installed onto power cord. If the strain relief

is not attached, the cord can be pulled

out of the dryer and can be cut by any

movement of the cord, resulting in electrical

shock.

● Do not use an aluminum wired receptacle

with a copper wired power cord and plug

(or vice versa). A chemical reaction occurs

between copper and aluminum and can

cause electrical shorts. The proper wiring

and receptacle is a copper wired power

cord with a copper wired receptacle.

NOTE

Dryers operating on 208 volt power supply

will have longer drying times than dryers

operating on 240 volt power supply.

Grounding requirements - Electric dryer (USA)

WARNING

Improper grounding of the dryer may cause

serious injury or death. Check with a licensed

electrician if you are in doubt as to whether

the appliance is properly grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event

of a malfunction or breakdown, grounding

will reduce the risk of electrical shock by

providing a path of least resistance for

electrical current.

2. After you purchase and install a 3 wire or 4

wire power supply cord having an equipmentgrounding conductor and a grounding plug

that matches your wiring system, the plug

MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and

grounded in accordance with all local codes

and ordinances. If in doubt, call a licensed

electrician.

3. DO NOT modify the plug you’ve installed

on this appliance. If it will not fit the outlet,

have a proper outlet installed by a qualified

electrician.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded

metal, permanent wiring system; or an

equipment grounding conductor must be run

with the circuit conductors and connected to

the equipment-grounding terminal or lead on

the appliance.

Page 11

Installation Instructions

Grounding requirements - Electric dryer (Canada)

11

WARNING

Improper grounding of the dryer may cause

serious injury or death. Check with a licensed

electrician if you are in doubt as to whether

the appliance is properly grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event

of a malfunction or breakdown, grounding

will reduce the risk of electrical shock by

providing a path of least resistance for

electrical current.

2. Since your dryer is equipped with a power

supply cord having an equipment-grounding

conductor and a grounding plug, the plug

must be plugged into an appropriate outlet

that is properly installed and grounded

in accordance with all local codes and

ordinances. If in doubt, call a licensed

electrician.

3. DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have

a proper outlet installed by a qualified

electrician.

Grounding requirements - Gas dryer (USA and Canada)

1. The dryer is equipped with a three-prong

Grounding type

wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong

receptacle.

2. The plug must be plugged into an

appropriate outlet that is properly installed

and grounded in accordance with all local

codes and ordinances. If in doubt, call a

licensed electrician.

3. DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have

a proper outlet installed by a qualified

electrician.

WARNING

Improper grounding of the dryer may cause

serious injury or death. Check with a licensed

electrician if you are in doubt as to whether

the appliance is properly grounded.

Page 12

12

e

(BRASS terminal)

VER terminal)

(BRASS terminal)

e)

DO NOT remove

Installation Instructions

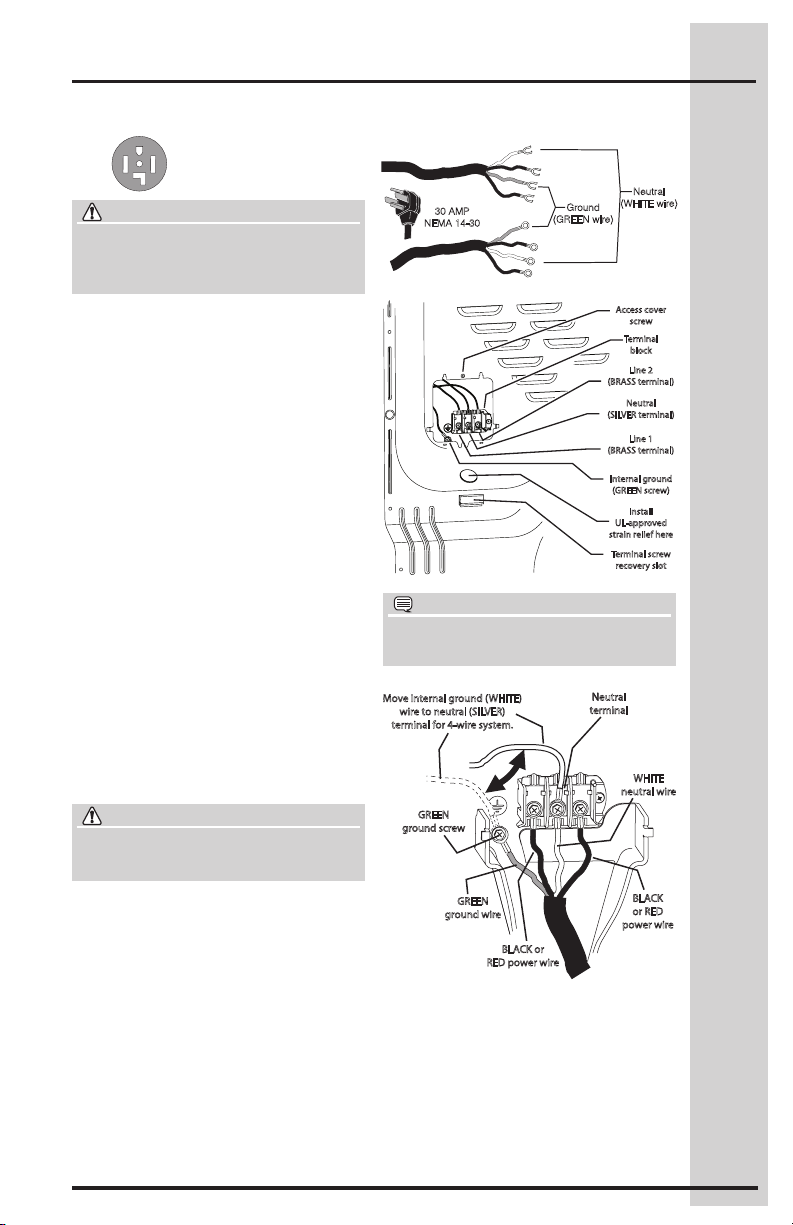

Electrical connection (non-Canada) - 3 wire cord

3-wire receptacle

(NEMA type 10-30R)

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before

servicing could result in personal injury or even

death.

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal

block access cover in the lower corner on

the back of the dryer.

3. Install a UL-approved strain relief

according to the power cord/strain relief

manufacturer’s instructions in the power

cord entry hole below the access panel. At

this time, the strain relief should be loosely

in place.

4. Thread an UNPLUGGED, UL-approved, 30

amp. power cord, NEMA 10-30 type SRDT,

through the strain relief.

5. Attach the power cord neutral (center wire)

conductor to the SILVER colored center

terminal on the terminal block. Tighten the

screw securely.

6. Attach the remaining two power cord outer

conductors to the outer, BRASS colored

terminals on the terminal block. Tighten both

screws securely.

WARNING

ELECTRICAL SHOCK HAZARD

Do not make a sharp bend or crimp wiring/

conductor at connections.

7. Follow manufacturer’s guidelines for firmly

securing the strain relief and power cord.

8. Reinstall the terminal block cover.

30 AMP

NEMA 10-30

Neutral

(center wir

Access cover

screw

Terminal

block

Line 2

Neutral

(SIL

Line 1

Internal ground

(GREEN screw)

Install

UL-approved

strain relief her

Terminal screw

recovery slot

NOTE

If a terminal screw falls during cord

installation, it can be retrieved in the terminal

screw recovery slot below the access panel.

internal ground in

a 3-wire system!!

Neutral

terminal

IMPORTANT

If moving dryer from a 4-wire system and installing it in a 3-wire system, move the internal

ground from the center terminal back to the

GREEN screw next to the terminal block.

Page 13

Electrical connection (non-Canada) - 4 wire cord

(BRASS terminal)

VER terminal)

(BRASS terminal)

e)

Move internal ground (WHITE)

Neutral

e

WARNING

Failure to disconnect power source before

servicing could result in personal injury or even

death.

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block

access cover in the lower corner on the back

of the dryer.

3. Install a UL-approved strain relief

according to the power cord/strain relief

manufacturer’s instructions in the power

cord entry hole below the access panel. At

this time, the strain relief should be loosely

in place.

4. Thread an UNPLUGGED, UL-approved, 30

amp. power cord, NEMA 14-30 type DRT or

SRDT, through the strain relief.

5. Disconnect the internal (WHITE) dryer

harness ground wire from the (GREEN)

ground screw next to the terminal block.

6. Attach the ground (GREEN) power cord

wire to the cabinet with the ground (GREEN)

screw. Tighten the screw securely.

7. Move the internal dryer harness ground

(WHITE) wire to the terminal block and

attach it along with the neutral (WHITE)

power cord wire conductor to the center,

SILVER colored terminal on the terminal

block. Tighten the screw securely.

8. Attach the RED and BLACK power cord

conductors to the outer, BRASS colored

terminals on the terminal block. Tighten both

screws securely.

WARNING

Do not make a sharp bend or crimp wiring/

conductor at connections.

9. Follow manufacturer’s guidelines for firmly

securing the strain relief and power cord.

10. Reinstall the terminal block cover.

4-wire receptacle

(NEMA type 14-30R)

ELECTRICAL SHOCK HAZARD

ELECTRICAL SHOCK HAZARD

Installation Instructions

Neutral

(WHITE wir

30 AMP

NEMA 14-30

NOTE

If a terminal screw falls during cord

installation, it can be retrieved in the terminal

screw recovery slot below the access panel.

wire to neutral (SILVER)

terminal for 4-wire system.

GREEN

ground screw

GREEN

ground wire

BLACK or

RED power wire

Ground

(GREEN wire)

terminal

Access cover

screw

Terminal

block

Line 2

Neutral

(SIL

Line 1

Internal ground

(GREEN screw)

Install

UL-approved

strain relief here

Terminal screw

recovery slot

WHITE

neutral wir

BLACK

or RED

power wire

13

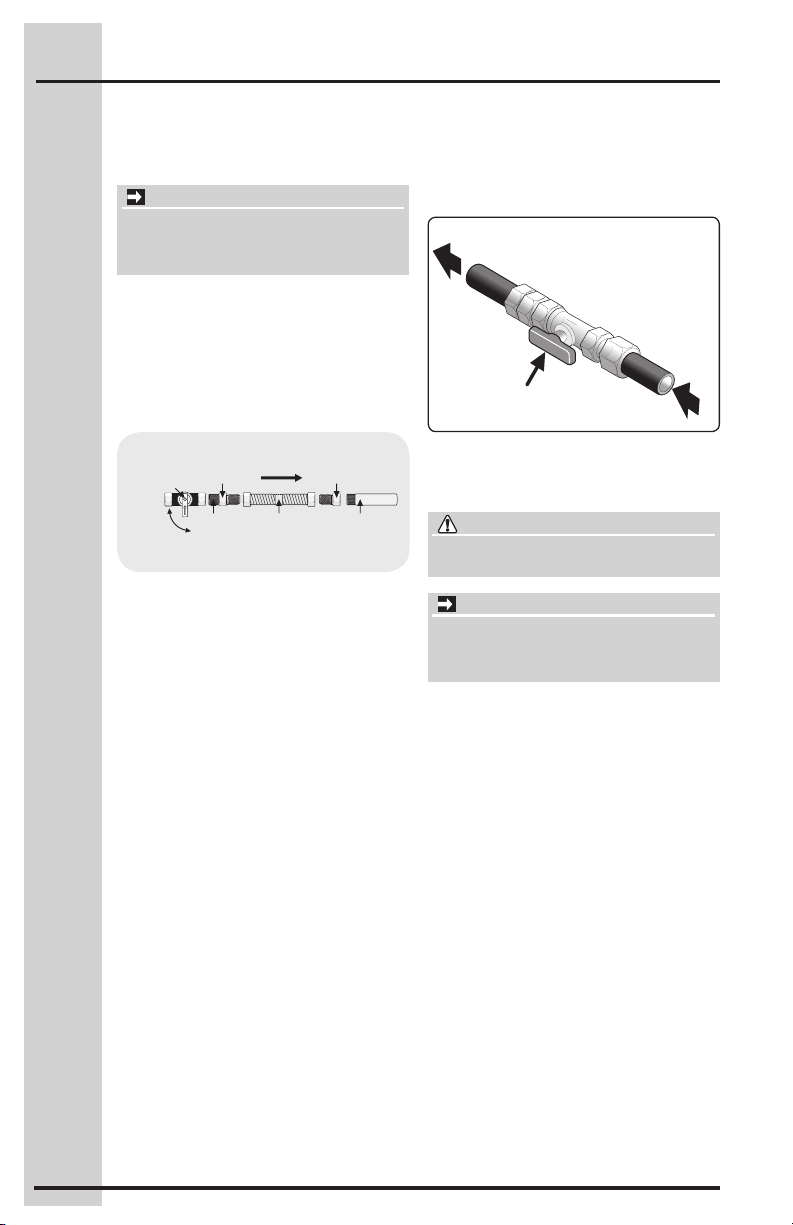

Page 14

14

All connections must be wrench-tightened

Flare

Union

Flare

Union

Manual

Shutoff

Valve

Closed

Open

Flexible

Connector

GAS FLOW

Inlet Pipe on

Back of Dryer

Nipple

to dr

y

Installation Instructions

Gas connection

1. Remove the shipping cap from gas pipe at

the rear of the dryer.

IMPORTANT

DO NOT connect the dryer to L.P. gas service

without converting the gas valve. An L.P. conversion kit must be installed by a qualified gas

technician.

2. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid

or approved pipe from gas supply line to the

3/8 inch (0.96 cm) pipe located on the back

of the dryer. Use a 1/2 inch to 3/8 inch (1.27

cm to 0.96 cm) reducer for the connection.

Apply an approved thread sealer that is

resistant to the corrosive action of liquefied

gases on all pipe connections.

3. Open the shutoff valve in the gas supply line

to allow gas to flow through the pipe. Wait

a few minutes for gas to move through the

gas line.

yer

from gas suppl

Shuto Valve Open position

4. Check for gas system leaks with a

manometer. If a manometer is not available,

test all connections by brushing on a soapy

water solution.

WARNING

NEVER test for gas leaks with an open flame.

EXPLOSION HAZARD

IMPORTANT

Installation to the gas service must follow local

codes and ordinances and the latest edition of

the National Fuel Gas Code ANSI Z223.1/NEPA

54 or in Canada, CSA B149.1.

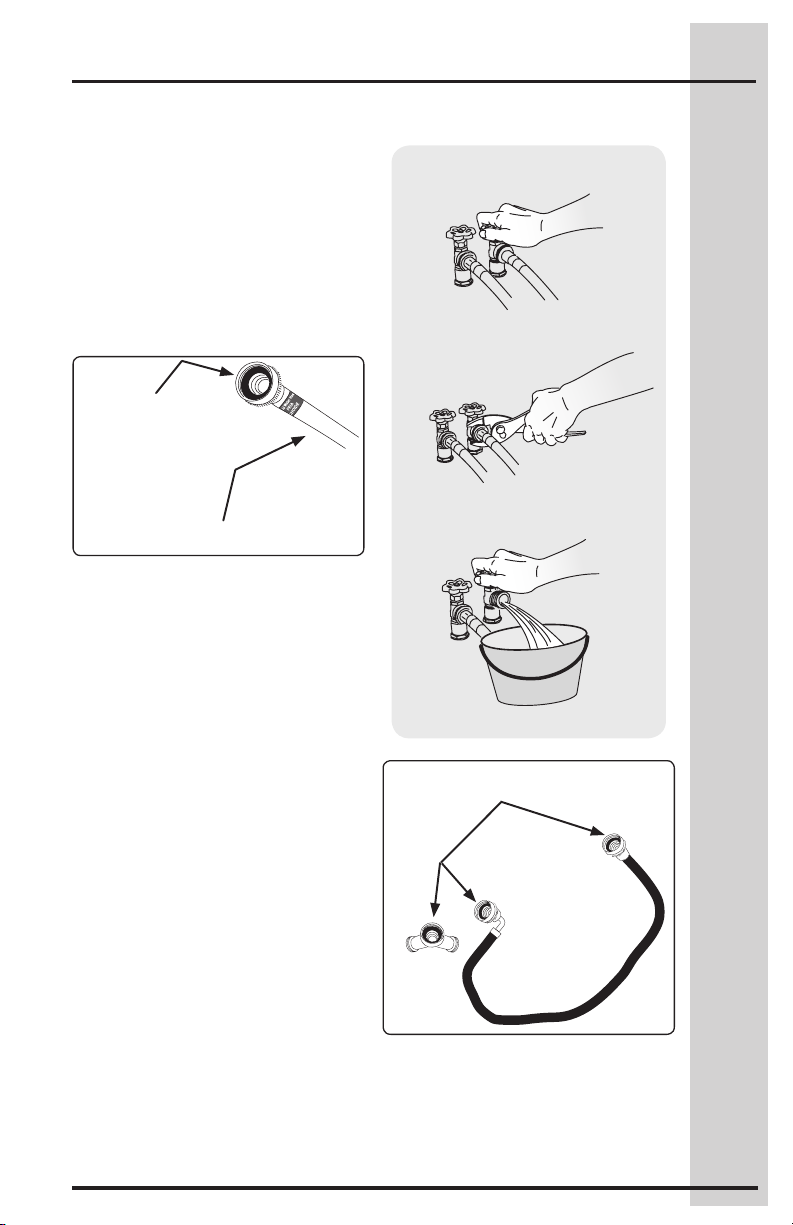

Page 15

Installation Instructions

Water connection (Steam Model only)

WATER SUPPLY REQUIREMENTS

Cold water faucet MUST be installed within 42

inches (107 cm) of your dryer’s water inlet. The

faucet MUST be 3/4 inch (1.9 cm) with threading for laundry hose connection. Water pressure

MUST be between 20 and 120 psi. Your water department can advise you of your water pressure.

1. Turn off COLD water supply to washer,

2. Remove COLD inlet hose from COLD water

supply and inspect for rubber washer.

Replace washer if it is torn or worn out.

RUBBER WASHER

MUST BE PRESENT

AND UNDAMAGED

COLD INLET HOSE

TO WASHER

3. Momentarily turn on COLD supply and run

some water into a bucket or container to

clear any contaminants in the line.

4. Remove hose kit from dryer drum and

inspect hose couplings for proper

placement of rubber washers.

15

RUBBER WASHERS

MUST BE PRESENT

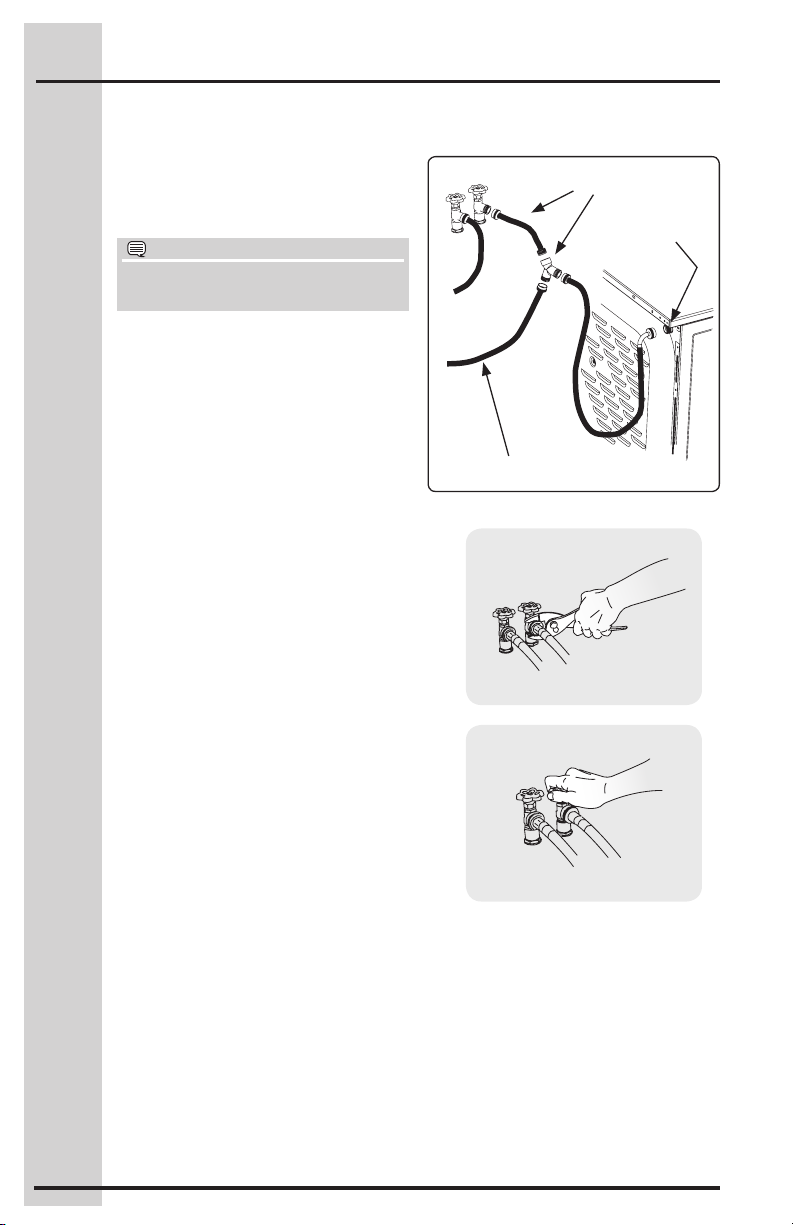

Page 16

16

Installation Instructions

Water connection, continued (Steam Model only)

5. If your installation has room for the COLD

water supply to accept the “Y” connector

directly, thread the “Y” connector to the

COLD water supply and snug it by hand;

then tighten it another 2/3 turn with pliers.

NOTE

If you were able to install the “Y” connector

directly to the COLD water supply, please skip

to step 8.

6. If there is not room to install the “Y”

connector directly, thread the short

extension hose on to the COLD water

supply and snug it by hand; then tighten it

another 2/3 turn with pliers.

7. Thread the “Y” connector to the short

extension hose and snug it by hand; then

tighten it another 2/3 turn with pliers.

8. Connect the COLD inlet hose for the washer

to the “Y” connector and snug it by hand;

then tighten it another 2/3 turn with pliers.

9. Connect the straight end of the long hose

from the kit to the other outlet on the “Y”

connector and snug it by hand. Connect

the hose’s 90° coupling to the brass water

inlet on the back of the dryer and snug it by

hand. Tighten each connection of the dryer

inlet hose another 2/3 turn with pliers.

10. Turn on the water and check for leaks at all

connections.

DIRECT CONNECTION

OR WITH EXTENSION

COLD WATER SUPPLY

HOSE TO WASHER

WATER INLET

ON DRYER

Page 17

Installation Instructions

General installation

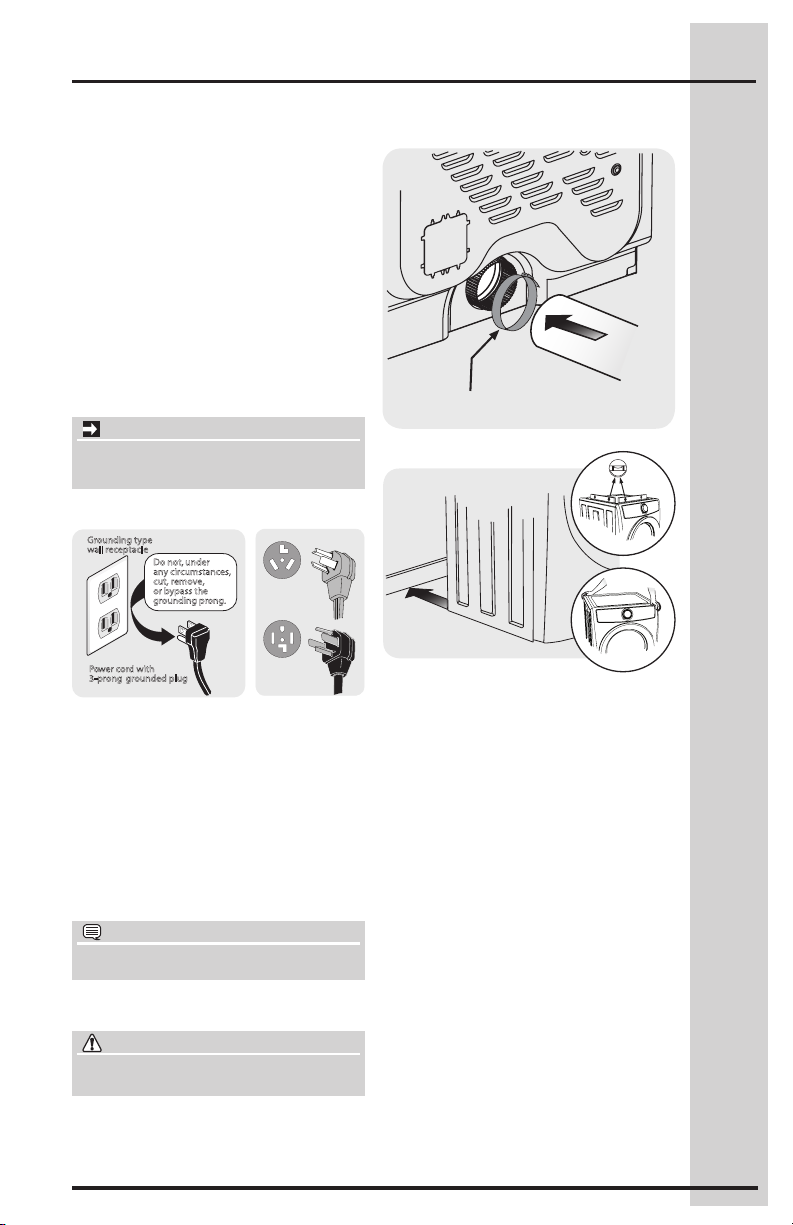

1. Connect the exhaust duct to the outside

exhaust system. Use of a 4” (102 mm) clamp

(item A) is recommended to connect the

dryer to the exhaust vent system. Use metal

foil tape to seal all other joints.

2. Use a carpenter’s level to level your dryer

front-to-back and side-to-side.

3. Use adjustable pliers to adjust the leveling

legs so the dryer is level front-to-rear and

side-to-side, and stable corner-to-corner.

4. Press down on alternate corners and sides

and feel for the slightest movement. Adjust

the appropriate leg(s) so the dryer sits

solidly on the floor on ALL four legs. Keep

the leveling leg extension at a minimum for

best performance of the dryer.

IMPORTANT

Be sure the power is off at a circuit breaker/

fuse box before plugging the power cord into

an outlet.

5. Plug the power cord into a grounded outlet.

Grounding type

wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

17

A

Power cord with

3-prong gr ounded plug

6. Turn on the power at the circuit breaker/fuse

box.

7. Read the Use & Care Guide provided with

the dryer. It contains valuable and helpful

information that will save you time and

money.

8. If you have any questions during initial

operation, please review the “Avoid Service

Checklist” in your Use & Care Guide before

calling for service.

9. Place these instructions in a location near

the dryer for future reference.

NOTE

A wiring diagram and technical data sheet are

located under the dryer top panel.

CAUTION

When discarding or storing your old dryer,

remove the door.

Page 18

18

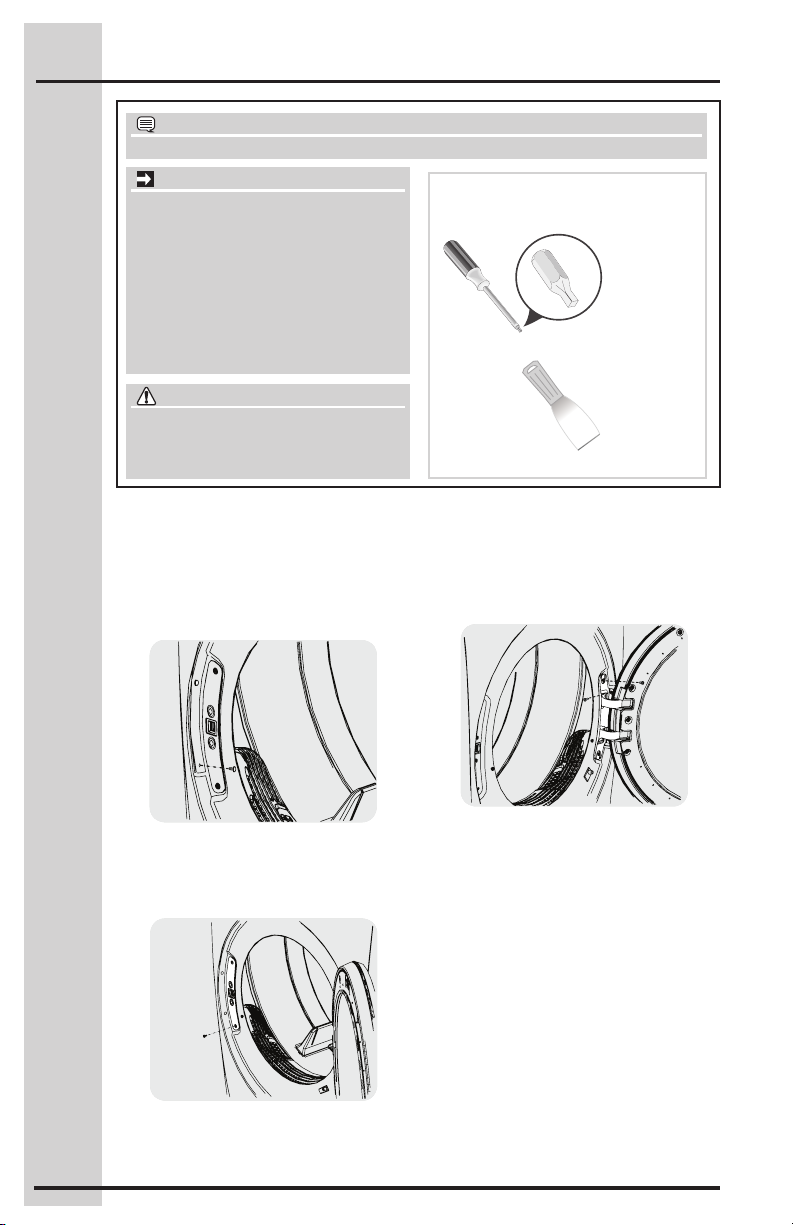

Reversing Door

NOTE

Door reversibility is availabel on the following dryer models: 300, 400, 500, or 600 series.

IMPORTANT

BEFORE YOU REVERSE YOUR DRYER

DOOR:

1. Be sure you have adequate swing area

before reversing door.

2. Gather your tools - including a screw

driver with a #2 square bit and plastic

knife (or small, flat prying tool that won’t

damage paint).

3. Be sure dryer is unplugged from power

source!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before

servicing could result in personal injury or

even death.

Tools needed for reversal:

Screwdriver

with #2

square bit

Plastic

knife

A) Removing Latch Cover and Hole Plugs

1. Open the door.

2. Remove plastic hole plugs and save to

reinstall later. You may have to use a nanscratching plastic knife if you are unable

to dislodge the plugs manually.

x 2

3. Remove both screws from door latch

cover. Save latch cover and screws for

reinstallation later.

x 2

B) Removing Door Assembly

1. Completely open the door to expose all

four hinge screws.

2. Remove all four hinge screws with #2

square bit driver. Save for reinstalling later.

x 4

3. Grasp the door with both hands and lift

slightly as you pull door and hinge away

from the front panel.

Page 19

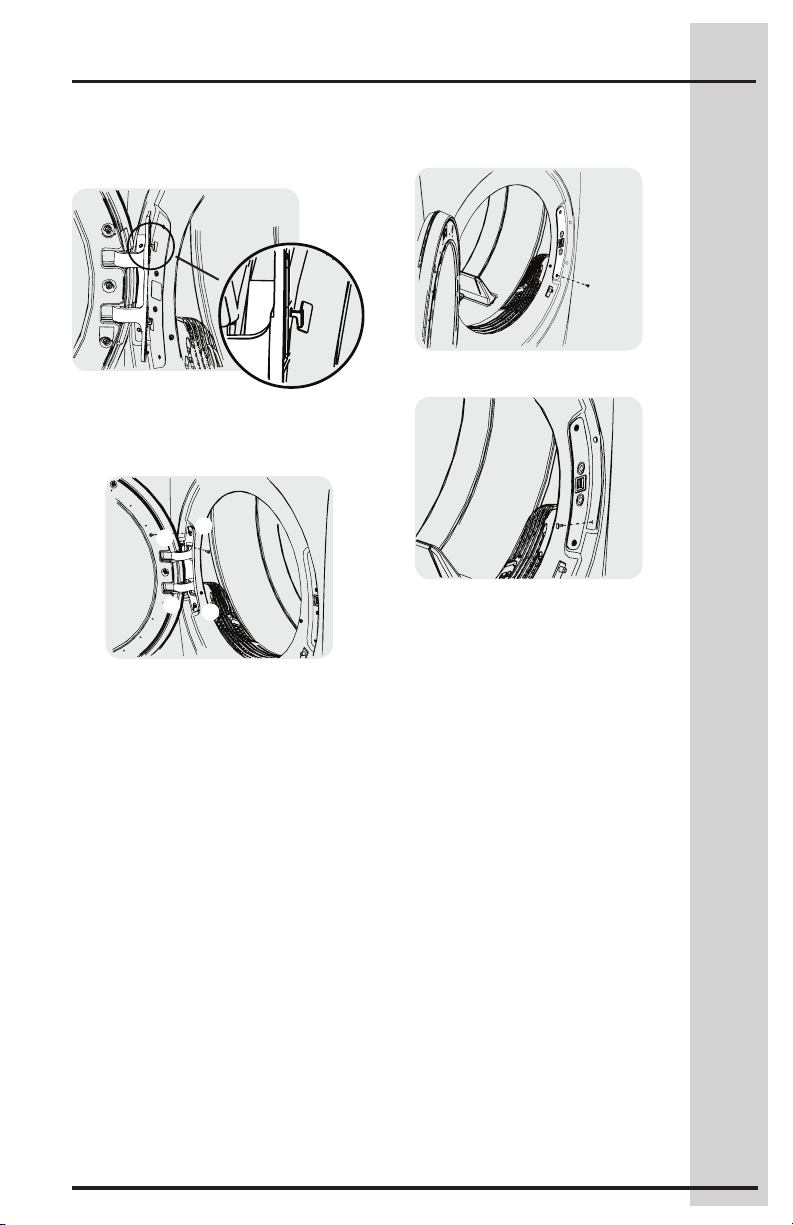

Reversing Door

19

C) Reinstalling Door Assembly

1. Rotate the door and hang the upper hook

on the back of the hinge in the upper hole

of the front panel.

2. Reinstall and tighten all four screws

removed earlier - two front screws first,

then two side screws.

1

3

x 4

4

2

D) Reinstalling Latch Cover and Hole Plugs

1. Install door latch cover with screws

removed earlier.

x 2

2. Insert plastic hole plugs removed earlier.

x 2

E) Verify Reversed Door Operation

1. Test door for free, smooth swinging

operation and secure latching when

closed.

2. Plug in dryer and close the door. Start

a test cycle: drum should tumble until

door is pulled open or cycle is paused or

canceled.

Page 20

20

(67 cm)

(38 cm)

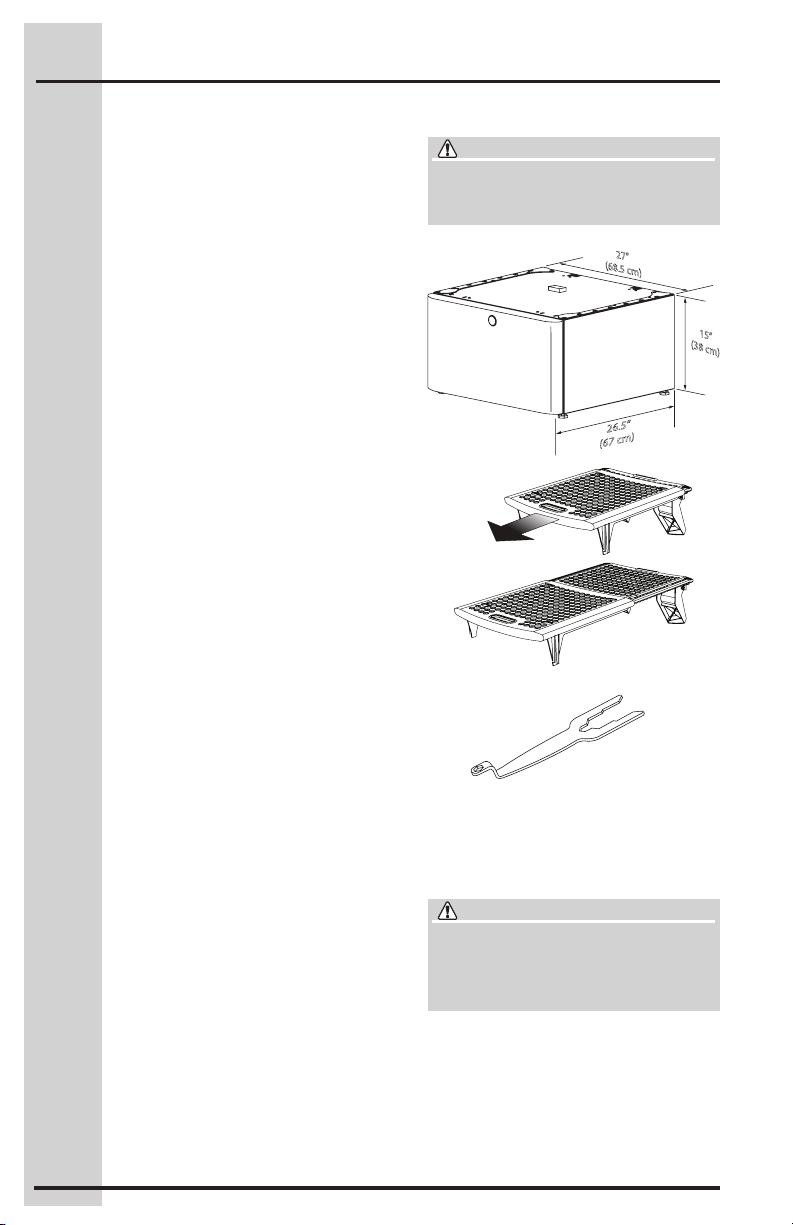

Options

Accessories

MATCHING STORAGE PEDESTAL*

White Pedestal - P/N EPWD157SIW

Titanium Pedestal - P/N EPWD157STT

A storage pedestal accessory, specifically

designed for this dryer may be used to elevate

the dryer for ease of use. This pedestal will add

about 15” (38 cm) to the height of your unit.

*Other colors may be available. Contact the source

where you purchased your dryer.

DRYER STACKING KIT

P/N STACKIT7X

Depending on the model you purchased, a kit for

stacking a matching dryer on top of this washer

may have been included in the initial purchase

of your dryer. If your model did not include a

stacking kit or you desire another stacking kit, you

may order one.

LP CONVERSION KIT

P/N PCK4200

Gas dryers intended for use in a location

supplied with LP must use a conversion kit prior

to installation.

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installations in mobile homes require use of

MOBILE HOME INSTALLATION KIT.

DRYING RACK

P/N A04840701

Depending on the model you purchased, a

drying rack may have been included in the

initial purchase of your dryer. If your model did

not include a drying rack or you desire another

drying rack, you may order one.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is

available to aid in dryer/washer/pedestal feet

adjustment.

TOUCH UP PAINT PENS

White - P/N 5304468812

Titanium - P/N 5304475700

*Other colors may be available. Contact the source

where you purchased your dryer.

CAUTION

Failure to use accessories manufactured by (or

approved by) the manufacturer could result in

personal injury, property damage or damage

to the dryer.

27”

(68.5 cm)

15”

26.5”

Replacement parts in U.S. and Canada:

If replacements parts are needed for your

dryer, you can contact the source where you

purchased your dryer, call 1-877-4ELECTROLUX

(1-877-435-3287) in the U.S. or 1-800265-8352 in Canada, or visit our website,

www.electroluxappliances.com, for the

Electrolux Authorized Parts Distributor nearest

you.

WARNING

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

ELECTRICAL HAZARD

Page 21

EN FRONT LOAD DRYER

FR SÉCHEUSE Á CHARGEMENT FRONTAL

ES SECADORA DE CARGA FRONTAL

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACIÓN

A07020302 Jullet 2017

Page 22

2

Mesures de Sécurité Importantes

AVERTISSEMENT

Pour votre sécurité, l’information contenue dans ces instructions doit être suivie afin de réduire

les risques d’incendie ou d’explosion ou pour prévenir les dommages matériels, les blessures

ou la mort. Vous ne devez ni entreposer, ni utiliser d’essence ou d’autres vapeurs ou liquides

inflammables à proximité de cet appareil ou de tout autre appareil électroménager.

Sachez reconnaître les symboles, les

avertissements et les étiquettes de

sécurité.

Les mesures de sécurité présentées dans ce guide

sont identifiées par le mot AVERTISSEMENT ou

ATTENTION selon le type de risque présenté.

AVERTISSEMENT

Ce symbole vous avertit à propos des situations

pouvant causer des dommages matériels, des

blessures graves ou même la mort.

ATTENTION

Ce symbole vous avertit à propos des situations

pouvant causer des dommages matériels ou

des blessures.

AVERTISSEMENT RISQUE D’INCENDIE

Lisez toutes les instructions de sécurité suivantes avant d’installer et d’utiliser votre appareil :

• Détruisez le carton d’emballage et les sacs en plastique après avoir déballé l’appareil. Les enfants

pourraient les utiliser pour jouer. Le carton recouvert de tapis, les couvertures et les feuilles de plastique peuvent être étanches à l’air et provoquer la suffocation. Déposez tous les matériaux d’emballage dans un conteneur à déchets ou faites en sorte que les enfants ne puissent y avoir accès.

• L’installation et l’entretien de cette sécheuse doivent être réalisés par un installateur qualifié, un

technicien de service ou le fournisseur de gaz.

• Installez l’appareil conformément aux instructions du fabricant et aux codes locaux.

• L’installation électrique de la sécheuse doit être conforme aux codes et aux règlements locaux

ainsi qu’à la toute dernière édition du National Electrical Code (ANSI/NFPA 70), ou au Canada,

au Code canadien de l’électricité (C22.1, article 1).

• L’installation de gaz de la sécheuse doit être conforme aux codes et aux règlements locaux ainsi

qu’à la toute dernière édition du Fuel Gas Code (ANSI Z223.1/NFPA 54), ou au Canada, au CSA

B149.1. Un robinet d’arrêt manuel distinct doit être installé à moins de 1,83 m (6 pi) de la sécheuse

conformément au National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• La sécheuse est classée, en vertu des règlements ANSI Z 21.5.1 ou ANSI/UL 2158 - CAN/CSA C22.2

Nº 112 (dernières versions), pour un USAGE DOMESTIQUE uniquement. Il n’est pas recommandé

d’utiliser cette sécheuse pour des usages commerciaux, comme des restaurants, des salons de

coiffure, etc.

• N’installez pas une sécheuse avec du matériel d’évacuation en plastique ou en feuille métallique

flexible. Le matériel de ventilation flexible peut s’écraser facilement et emprisonner la charpie. Ces

conditions nuiraient à l’écoulement d’air de votre sécheuse et pourraient accroître le risque d’incendie.

• Ne superposez pas une sécheuse sur une laveuse déjà installée sur un socle. Ne superposez pas

une laveuse sur une sécheuse. Ne superposez pas une laveuse sur une autre laveuse.

• Les instructions comprises dans ce guide et toute autre documentation fournie avec cet appareil

ne sont pas conçues pour couvrir toutes les éventualités ou situations qui pourraient survenir. Vous

DEVEZ faire preuve de bon sens et de prudence durant l’installation, l’utilisation et l’entretien de

tout appareil ménager.

Conservez ces instructions pour vous y reporter ultérieurement.

Table des matières

Mesures de Sécurité Importantes ............................2

Exigences d’Installation ...........................................3-9

Instructions d’Installation .....................................10-17

©2016 Electrolux Major Appliances Tous droits réservés.

Inversion de la Porte ..............................................18-19

Options .............................................................................20

Page 23

Exigences d’Installation

(sécheuse à gaz)

cordon d’alimentation

3

Veuillez lire et conserver ce

guide

Merci d’avoir choisi Electrolux, la marque de

qualité en matière d’électroménager. Ces

instructions d’installation font partie de notre

engagement à vous satisfaire et à vous fournir

un produit de qualité pendant toute la durée de

vie de votre nouvel appareil.

Liste de vérification d’installation

Conduit d’évacuation

L’air circule librement, il n’y a aucune

accumulation de charpie

Le conduit rigide ou semi-rigide de 102 mm (4

po) est le plus court et le plus direct possible

Il n’y a AUCUN matériel de ventilation en

papier d’aluminium ou en plastique

Le système d’échappement doit évacuer l’air

a l’extérieur a l’aide d’un évent approuve

Mise à niveau

La sécheuse est au niveau latéralement et de

l’avant vers l’arrière

Les quatre coins de la caisse reposent

fermement sur le plancher

Alimentation au gaz (sécheuse au gaz)

Le conduit d’alimentation comporte un

robinet d’arrêt manuel

Tous les raccords sont étanchéifiés à l’aide

de joints certifiés serrés avec une clé

Nécessaire de conversion pour système au GPL

L’alimentation en gaz est ouverte

Aucun raccord ne présente de fuite -

vérifiez à l’aide d’eau savonneuse, ne faites

JAMAIS cette vérification avec une flamme

Des questions?

Pour rejoindre le service aux États-Unis :

1-877-4ELECTROLUX (1-877-435-3287) et au

Canada : 1-800-265-8352.

Pour obtenir de l’aide et de l’information sur les

produits en ligne, visitez le site

www.electroluxappliances.com.

Alimentation électrique de 240 V (sécheuse

électrique)

Le cordon d’alimentation est certifié NEMA

10-30R ou 14-30R et il fixé solidement avec

toutes les vis dans le bornier

Un réducteur de tension certifié est installé

Le couvre-borne est installé avant la

première mise en marche

Inversion de la porte

Suivez les instructions détaillées contenues

dans ce guide

Vérifiez que la charnière et le loquet

fonctionnent correctement

Alimentation en électricité

Le système électrique de la maison est sous

tension

La sécheuse est branchée

Vérifications finales

Vous avez lu entièrement les instructions

d’installation et le Guide d’utilisation et

d’entretien

La porte se verrouille et le tambour tourne

lorsqu’un cycle démarre

La carte d’enregistrement est envoyée

Outils et matériel nécessaires à l’installation :

Tournevis Phillips

Pince

réglable

Clé à tuyau

l’alimentation

en gaz

Conduit d’évacuation de 102 mm (4 po)

Collier de

102 mm

(4 po)

à pointe plate

et à pointe carrée

ou

Ruban à filetage

résistant au GPL

pour

pour l’alimentation

en gaz naturel

ou en GPL)

en métal rigide ou semi-rigide

Robinet

d’arrêt pour

conduite de gaz

(sécheuse à gaz)

Deux raccords-unions

à évasement de 1/2 po

(1,3 cm) NPT et une

conduite flexible

d’alimentation en gaz

Clé à

molette

Niveau de

charpentier

Clé universelle

optionnel

ou

Évent

extérieur

Ensemble pour

de 240 V à 3 ou 4 fils

(sécheuse électrique)

Ruban métallique

(et non du ruban

à conduits)

AVERTISSEMENT

RISQUE D’INCENDIE

● Le non-respect des consignes de sécurité

peut causer des lésions corporelles graves,

voire la mort, ou provoquer des dégâts

matériels importants.

● Ne pas installer de ventilateur d’appoint

dans le conduit d’échappement de la

sécheuse.

● Installer toutes les sécheuses en conformité

avec les instructions d’installation figurant

dans ce manuel.

Page 24

4

avec mise à la terre

Exigences d’Installation

Exigences des systèmes électriques

REMARQUE

Étant donné les variations de tension possibles,

l’utilisation de cette sécheuse avec une source

d’alimentation produite par une génératrice à

essence, solaire ou éolienne ou par toute autre

source d’alimentation différente de celle fournie

par les services publics n’est pas recommandée.

EXIGENCES ÉLECTRIQUES DE LA SÉCHEUSE

ÉLECTRIQUE:

CIRCUIT - Circuit indépendant de 30 ampères

avec fusible temporisé ou disjoncteur de 30 A.

Utilisez des circuits indépendants pour la

laveuse et la sécheuse. NE BRANCHEZ PAS la

laveuse et la sécheuse sur le même circuit.

ALIMENTATION ÉLECTRIQUE - Câble

monophasé à trois ou quatre fils, 240 volts,

60 Hz; courant alternatif.

REMARQUE

Une alimentation secteur de 120/208 V CA,

monophasée, 60 Hz peut être utilisée pour les

sécheuses dont la plaque signalétique l’indique.

IMPORTANT

Cette sécheuse est mise à la terre par le fil

d’alimentation neutre, sauf si elle est destinée à

la vente au Canada.

Seul un cordon à 4 conducteurs doit être utilisé

lorsque l’appareil est installé dans les endroits

où la mise à la terre par conducteur neutre est

interdite. La mise à la terre par le fil d’alimentation neutre est interdit pour : (1) un nouveau

circuit de dérivation, (2) les maisons mobiles,

(3) les véhicules récréatifs, et (4) les régions où

les codes locaux ne permettent pas la mise à

la terre par le fil d’alimentation neutre.

TROUSSE DE CORDON D’ALIMENTATION À

TROIS FILS (non fournie)

Prise à 3 alvéoles

(NEMA type 10-30R)

La sécheuse DOIT utiliser un cordon

d’alimentation à trois fils NEMA 10-30 de type

SRDT d’une capacité de 240 volts (c.a.) et d’au

moins 30 ampères, avec trois connecteurs

ouverts embrochables avec extrémités

renversées, ou connecteurs à boucle fermée,

spécialement indiqués pour une utilisation

avec une sécheuse. Pour les instructions de

raccordement du cordon à 3 fils, consultez la

section CONNEXIONS ÉLECTRIQUES POUR

UN SYSTÈME À TROIS FILS.

PRISE - Prise NEMA 10-30R située de manière à

permettre l’accès au cordon d’alimentation

lorsque la sécheuse est à sa position de

fonctionnement.

CONNEXION DE MISE À LA TERRE - Consultez

la rubrique « Exigences de mise à la terre »

dans la section d’installation électrique.

TROUSSE DE CORDON D’ALIMENTATION À

QUATRE FILS (non fournie)

La sécheuse DOIT utiliser un cordon

d’alimentation à quatre fils NEMA 14-30 de

type SRDT d’une capacité de 240 volts (c.a.)

et d’au moins 30 ampères, avec quatre

connecteurs ouverts embrochables avec

extrémités renversées, ou connecteurs

à boucle fermée, spécialement indiqués

pour une utilisation avec une sécheuse.

Pour les instructions de raccordement du

cordon à quatre fils, consultez la section

CONNEXIONS ÉLECTRIQUES POUR UN

SYSTÈME À QUATRE FILS.

REMARQUE

Les sécheuses destinées à la vente au Canada

sont munies d’un cordon d’alimentation à 4 fils

(NEMA 14-30R).

PRISE - NEMA 14-30R située de manière à

permettre l’accès au cordon d’alimentation

lorsque la sécheuse est à sa position de

fonctionnement.

CONNEXION DE MISE À LA TERRE - Consultez

la rubrique « Exigences de mise à la terre »

dans la section d’installation électrique.

EXIGENCES ÉLECTRIQUES DE LA SÉCHEUSE

À GAZ :

CIRCUIT - Circuit indépendant de 15 ampères,

polarisé et mis à la terre, avec fusible

temporisé ou disjoncteur de 15 A.

ALIMENTATION ÉLECTRIQUE - Câble

monophasé à deux fils mis à la terre,

120 volts, 60 Hz; courant alternatif.

CORDON D’ALIMENTATION - La sécheuse est

dotée d’un cordon d’alimentation de 120 volts

à trois fils.

CONNEXION DE MISE À LA TERRE - Consultez

la rubrique « Exigences de mise à la terre »

dans la section d’installation électrique.

Prise murale avec

mise à la terre

Prise à 4 alvéoles

(NEMA type 14-30R)

Ne coupez pas, n'enlevez

pas et ne mettez pas hors

circuit la broche de mise

à la terre de cette che.

Cordon électrique muni

d’une che à trois broches

Page 25

Exigences d’Installation

Exigences relatives à l’alimentation en gaz

AVERTISSEMENT

Un tuyau en cuivre sans revêtement se corrode

lorsqu’il entre en contact avec le gaz naturel,

entraînant des fuites. Utilisez SEULEMENT des

tuyaux en fer noir, en acier inoxydable ou

encore en cuivre avec revêtement en plastique

pour l’alimentation en gaz.

1. L’installation DOIT être conforme aux

2. Le tuyau d’alimentation en gaz doit être d’un

3. Si les codes le permettent, un tuyau

RISQUE D’EXPLOSION

codes locaux ou au code national sur le

combustible, ANSI Z223.1 (dernière version),

s’il n’existe pas de codes locaux.

diamètre intérieur de 1,27 cm (1/2 po).

métallique flexible peut être utilisé pour

raccorder votre sécheuse au tuyau

d’alimentation en gaz. Le tuyau DOIT être

fabriqué en acier inoxydable ou en laiton

avec revêtement en plastique.

Exigences du système d’évacuation

Utilisez seulement des conduites métalliques

rigides ou flexibles d’au moins 102 mm (4 po)

de diamètre, et une bouche d’évacuation qui

possède un ou des volets qui s’ouvrent lorsque

l’appareil est en fonction. Lorsque la sécheuse

s’arrête, les volets se ferment automatiquement

pour empêcher les infiltrations d’air, d’insectes

et de rongeurs. Pour éviter de bloquer la sortie,

gardez un espace minimal de 30,5 cm (12 po)

entre le bas de la bouche d’évacuation et le sol

ou toute autre obstruction.

AVERTISSEMENT

Le non-respect de ces instructions pourrait

augmenter démesurément les temps de

séchage et entraîner des risques d’incendie.

Vous trouverez ci-dessous les exigences pour l’utilisation adéquate et

sécuritaire de votre appareil.

RISQUE D’INCENDIE

AVERTISSEMENT

N’installez pas une sécheuse avec du

matériel d’évacuation en plastique ou en

feuille métallique flexible. Le matériel de

ventilation flexible peut s’écraser facilement et

emprisonner la charpie. Ces conditions nuiraient

à l’écoulement d’air de votre sécheuse et

pourraient accroître le risque d’incendie.

Si votre système actuel utilise une conduite en

plastique ou en feuille métallique, remplacez-la

par une conduite métallique rigide ou semirigide. De plus, assurez-vous que la conduite

en place est libre de charpie avant d’installer la

conduite de sécheuse.

RISQUE D’INCENDIE

4. Le tuyau d’alimentation en gaz DOIT

être muni d’un robinet d’arrêt distinct

conformément à la norme B149.1, Code

d’installation du gaz naturel et du propane.

5. Un orifice taraudé de 0,32 cm (1/8 po)

bouché, accessible pour le branchement de

la jauge d’essai, DOIT être installé directement

en amont du branchement du tuyau

d’alimentation en gaz avec la sécheuse.

6. Cette sécheuse DOIT être débranchée de la

canalisation de gaz pendant toute vérification

de pression de la canalisation de gaz à des

pressions supérieures à 3,45 kPa (1/2 lb/po2).

7. Cette sécheuse DOIT être isolée de

la canalisation de gaz pendant toute

vérification de pression de la canalisation de

gaz à des pressions égales ou inférieures à

3,45 kPa (1/2 lb/po2).

8. Les branchements d’alimentation en

gaz doivent être conformes à la norme

Connectors for Gas Appliances (Raccords

pour appareils au gaz) ANSI Z21.24/CSA 6.10.

CORRECT

CORRECT

AVERTISSEMENT

● Le non-respect des consignes de sécurité

peut causer des lésions corporelles graves,

voire la mort, ou provoquer des dégâts

matériels importants.

● Ne pas installer de ventilateur d’appoint

dans le conduit d’échappement de la

sécheuse.

● Installer toutes les sécheuses en conformité

avec les instructions d’installation figurant

dans ce manuel.

5

INCORRECT

INCORRECT

RISQUE D’INCENDIE

Page 26

6

Exigences d’Installation

Exigences du système d’évacuation (suite)

AVERTISSEMENT

Une sécheuse doit être évacuée vers

l’extérieur. N’évacuez pas une sécheuse

dans une cheminée, un mur, un plafond, un

grenier, un vide sanitaire ou dans tout espace

clos d’un bâtiment. La sécheuse produit de

la charpie inflammable. Si la sécheuse n’est

pas évacuée vers l’extérieur, de la charpie

pourrait être évacuée dans l’aire de buanderie.

L’accumulation de charpie dans toute pièce de

la maison peut entraîner des risques pour la

santé et des risques d’incendie.

La sécheuse doit être branchée à une

évacuation extérieure. Inspectez régulièrement

l’ouverture de l’évacuation extérieure et

retirez toute accumulation de charpie près de

l’ouverture et de la région avoisinante.

RISQUE D’INCENDIE

AVERTISSEMENT

● Ne laissez pas de matière combustible (par

exemple : des vêtements, des rideaux, du

papier) entrer en contact avec le système

d’évacuation. La sécheuse NE DOIT PAS

être évacuée dans une cheminée, un mur, un

plafond, ou dans tout espace confiné d’un

bâtiment qui pourrait accumuler la charpie,

entraînant un risque d’incendie.

● Ne placez pas de grillage à l’extrémité du

système d’évacuation, ni de vis, de rivet

ou autre fixation de manière à ce qu’ils se

prolongent dans la conduite du système

d’évacuation. De la charpie pourrait

s’accumuler sur le grillage, les vis ou les

rivets, et obstruer l’écoulement d’air dans

le système, entraînant un risque d’incendie

et l’augmentation des temps de séchage.

Utilisez une bouche d’évacuation approuvée

pour terminer la conduite à l’extérieur,

et scellez tous les joints avec du ruban

métallique. Toutes les extrémités mâles des

conduites doivent être installées en aval

relativement au sens de l’écoulement d’air.

RISQUE D’INCENDIE

AVERTISSEMENT

Le fait de dépasser la longueur de conduites ou

le nombre de coudes indiqués dans les tableaux

de « LONGUEUR MAXIMALE » peut entraîner

l’accumulation de charpie dans le système.

Toute obstruction au système d’évacuation peut

entraîner un risque d’incendie, en plus d’accroître

le temps de séchage.

RISQUE D’INCENDIE

Nombre de tours à 90°

0 125 ft. (38 m) 110 ft. (33.5 m)

1 115 ft. (35 m) 100 ft. (30.5 m)

2 105 ft. (32 m) 90 ft. (27.5 m)

3 95 ft. (29 m) 80 ft. (24.5 m)

4 85 ft. (26 m) 70 ft. (21.5 m)

LONGUEUR MAXIMALE

pour le conduit en métal rigide de 102 mm (4 po)

TYPE DE BOUCHE D’ÉVACUATION

(De préférence)

4”

(10.2 cm) À volets

2.5”

(6.35 cm)

AVERTISSEMENT

● N’installez pas de matériel de ventilation en

plastique ou en aluminium flexible.

● Si vous installez du matériel de ventilation

semi-rigide, il est nécessaire que la longueur

du conduit soit égale ou inférieure à 2,4 m

(8 pi).

DIRECTION D’ÉVACUATION

Il est possible de diriger l’évacuation en

posant un coude de 90° à courbe immédiate

directement à la sortie d’évacuation de la

sécheuse. Les coudes pour évacuation de

sécheuse sont disponibles auprès du distributeur

de pièces de votre région ou à la quincaillerie.

Consultez également la section

EXIGENCES DE DÉGAGEMENT

à la page suivante.

RISQUE D’INCENDIE

REMARQUE

L’utilisation d’un

coude

à 90° à courbe

immédiate est nécessaire pour répondre

aux exigences de

profondeur minimale.

Page 27

Exigences d’Installation

CORRECT

INCORRECT

Exigences du système d’évacuation (suite)

7

AVERTISSEMENT

N’installez pas la sécheuse là où de l’essence

ou autres matières inflammables sont

entreposées. Si la sécheuse est installée dans

un garage, elle doit être placée au moins à

45,7 cm (18 po) du sol. Le non-respect de

cette recommandation peut entraîner un choc

électrique, une explosion, un incendie ou

même la mort.

Pour une installation où le système d’évacuation

n’est pas décrit dans les tableaux, la méthode

suivante doit être utilisée pour vérifier la

conformité du système :

1. Branchez un manomètre à tube incliné ou un

2. Réglez la minuterie de la sécheuse, la

3. Relevez le résultat du manomètre.

4. La contre-pression du système NE DOIT PAS

RISQUE D’EXPLOSION

manomètre numérique entre la sécheuse et

le point où l’évacuation est raccordée à la

sécheuse.

température à duvetage (refroidissement), et

mettez l’appareil en fonction.

être supérieure à 25 mm (1 po) de colonne

d’eau. Si la contre-pression du système

est inférieure à 25 mm (1 po) de colonne

d’eau, le système est conforme. Si la lecture

du manomètre indique une colonne d’eau

supérieure à 25 mm (1 po), le système est trop

restreignant et n’est pas conforme.

Installez les raccords mâles dans le bon sens :

Bien que l’orientation verticale du système

d’évacuation soit acceptable, certaines

circonstances pourraient influer sur le rendement

de l’appareil.

● Seule une conduite métallique rigide doit être

utilisée.

● L’évacuation verticale par le toit peut

entraîner le phénomène de contre-tirage,

ce qui accroît la restriction du système

d’évacuation.

● L’acheminement de la conduite d’évacuation

dans un endroit non isolé peut entraîner de

la condensation et l’accumulation plus rapide

de charpie.

● Le fait de comprimer ou de pincer le système

d’évacuation entraînera l’augmentation de la

restriction dans le système.

● Le système d’évacuation doit être inspecté

et vérifié au moins tous les 18 mois avec un

usage normal. Plus l’appareil est utilisé, plus

la période de vérification du système et de la

bouche d’évacuation doit être raccourcie.

Installation dans une maison usinée ou mobile

1. L’installation DOIT être conforme à la norme

Manufactured Home Construction and Safety

Standard, titre 24 CFR, article 32-80 (anciennement désignée comme la Federal Standard

for Mobile Home Construction and Safety,

titre 24, HUD, article 280) ou à la norme

CAN/CSAZ240 MH.

2. La sécheuse DOIT être évacuée vers l’extérieur

(à l’air libre et non sous la maison mobile)

avec une gaine métallique ininflammable.

La conduite métallique doit posséder un

diamètre de 10,16 cm (4 po) et ne contenir

aucune obstruction. De préférence, utilisez une

conduite métallique rigide.

3. Si la sécheuse est évacuée par le plancher

et que l’espace sous la maison mobile est

4. Reportez-vous aux sections précédentes de

5. Lors de l’installation d’une sécheuse à gaz

6. L’installateur DOIT ancrer (1) cette sécheuse

cloisonné, le système d’évacuation DOIT se

terminer à l’extérieur de la cloison et être fixé

solidement à la structure de la maison.

ce guide relativement aux autres exigences

d’évacuation importantes.

dans une maison mobile, des dispositions

doivent être prises pour permettre l’entrée

d’air d’appoint de l’extérieur. Cette installation

ne doit pas mesurer moins de deux fois la

surface de la bouche d’évacuation.

ou (2) la monter sur un socle au sol avec une

trousse d’installation de maison mobile, nº de

pièce 137067200.

Page 28

(0

1”

(2.5

0”

8

60 sq. in.

(387.1cm²)

3”

(7.6cm)

60 sq. in.

(387.1cm²)

3”

(7.6cm)

Exigences d’Installation

Exigences de dégagement

IMPORTANT

N’INSTALLEZ PAS VOTRE SÉCHEUSE :

1. À un endroit exposé aux écoulements d’eau

ou aux aléas des conditions météorologiques

extérieures.

2. À un endroit où elle entrera en contact avec

des rideaux ou tout autre objet qui nuirait à

l’écoulement de l’air de combustion ou de

ventilation.

3. Sur un tapis. Le plancher DOIT être solide et

présenter une pente inférieure à 2,5 cm (1 po).

INSTALLATION DANS UN ENDROIT EN RETRAIT

OU UNE ARMOIRE

1. Une sécheuse installée dans une chambre à

coucher, une salle de bains, un renfoncement

ou un placard DOIT être évacuée vers

l’extérieur.

2. Aucun autre appareil à combustion ne doit

être installé dans le même placard que la

sécheuse.

3. Votre sécheuse a besoin d’espace pour

assurer une ventilation adéquate.

N’INSTALLEZ PAS votre sécheuse dans un

placard muni d’une porte pleine.

4. Porte de placard assurant une ventilation

requise : Une ouverture d’au moins 774,2 cm2

(120 po2), divisée également au-dessus et

au-dessous de la porte, est requise. Les

ouvertures doivent être situées à 7,6 cm

(3 po) du haut et du bas de la porte. Les

ouvertures ne doivent pas être obstruées

lorsqu’une porte est installée. Une porte

à persiennes dont les ouvertures sur

l’ensemble de la porte sont équivalentes aux

recommandations peut être utilisée.

DÉGAGEMENTS MINIMAUX - Centimètres (pouces)

Alcôve 0” (0 cm) 0” (0 cm)* 0” (0 cm) n/a

Sous le

comptoir

Placard 0” (0 cm) 0” (0 cm)* 0” (0 cm) 1” (2.5 cm)

* Pour toute installation autre qu’une évacuation

CÔTÉS ARRIÈRE DESSUS AVANT

0” (0 cm) 0” (0 cm)* 0” (0 cm) n /a

directe, un coude de 90° à courbe immédiate doit

être utilisé pour respecter l’exigence de 0 cm (0 po).

0”

cm)

0”

(0

cm)

cm)

(0 cm)

REMARQUE

Pour obtenir une installation avec un

dégagement de 0 cm (0 po) à l’arrière de la

sécheuse (pour une installation autre qu’avec

une sortie directe), un coude de 90° à courbe

immédiate doit être installé, comme il est décrit

précédemment dans ce guide.

Porte de placard

Page 29

Dimensions de sécheuse

53.2” (135 cm)*

avec la porte grande ouverte

31.6” (80 cm)*

à partir de l’avant de la

porte lorsqu’elle est fermée

Exigences d’Installation

27.0”

(68.5 cm)

alimentation

38.0”

(96.5 cm)

électrique à

l’arrière de la

sécheuse

1

9

sécheuse autonome

sur le plancher

plancher

sécheuse montée sur

le socle optionnel

plancher

53.5” (136 cm)*

avec la porte grande ouverte

kit d’empilage

approuvé (STACKIT7X)

requis pour l’installation

empilée

32.0” (81.25 cm)*

à partir de l’avant de la

porte lorsqu’elle est fermée

53.25”

(135.5 cm)

raccord de

l’alimentation en

eau à l’arrière de

la laveuse

alimentation en

gaz à l’arrière de

l’appareil à gaz

75.75 ”

(192.5 cm)

alimentation

en gaz à

l’arrière de

l’appareil à gaz

17. 0”

(43 cm)

39.0”

(99 cm)

(9.5 cm)

1.5”

(4 cm)

3.75”

du côté jusqu’au

centre de l’évent arrière

Tuyau de vidange

à l’arrière de la

2

laveuse

13.5”

(34.5 cm)

3.7”

(9.5 cm)

19. 0”

(48 cm)

hauteur de la ligne

centrale de l’évent

arrière

alimentation

électrique à

l’arrière de la

1

sécheuse

hauteur de la

ligne centrale

de l’évent arrière

hauteur de la

ligne centrale

de l’évent

3

arrière

41.0”

(105 cm)

plancher

*Le raccordement du tuyau d’arrivée d’eau sur les modèles à la vapeur ajoute 2 cm (3/4 po) à la profondeur d’installation.

1

Longueur du cordon d’alimentation de la sécheuse à gaz ou la sécheuse électrique (Canada), environ 152,5 cm (60 po).

2

Longueur du tuyau de vidange de la laveuse, environ 150 cm (59 po).

3

Longueur du cordon d’alimentation de la laveuse, environ 152,5 cm (60 po).

Page 30

10

Instructions d’Installation

Installation électrique

Vous trouverez ci-dessous les exigences pour

l’installation électrique adéquate et sécuritaire

de votre appareil. Le non-respect de ces

instructions pourrait entraîner le risque de choc

ou d’incendie.

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

● Cet appareil DOIT être adéquatement mis à

la terre. La mise à la terre inadéquate de la

sécheuse pourrait entraîner des risques de

choc électrique. Suivez les instructions de ce

guide pour une mise à la terre adéquate.

● N’utilisez pas de rallonge avec cet appareil.

Certains cordons prolongateurs ne sont

pas conçus pour la quantité de courant

électrique utilisé par cette sécheuse

et pourraient fondre, entraînant des

risques de choc électrique ou d’incendie.

Placez la sécheuse à une distance de

la prise convenant à la longueur de la

rallonge, permettant d’installer la rallonge

lâchement. Reportez-vous aux exigences de

préinstallation de ce guide pour savoir quel

cordon d’alimentation acheter.

AVERTISSEMENT

RISQUE DE CHOC ÉLECTRIQUE

● Un réducteur de tension certifié UL doit

être installé sur le cordon d’alimentation. Si

le réducteur de tension n’est pas installé,

le cordon peut être arraché de l’appareil

ou coupé par tout mouvement, ce qui

entraînerait un risque de choc électrique.

● N’utilisez pas une prise avec câblage en

aluminium avec un cordon d’alimentation

et une fiche avec fils en cuivre (ou l’inverse).

Une réaction chimique se produit entre

l’aluminium et le cuivre, ce qui pourrait

entraîner un court-circuit. Il faut utiliser un

cordon, une fiche et une prise avec des fils

en cuivre.

REMARQUE

Les sécheuses alimentées par une tension de

208 V posséderont des temps de séchage

plus longs qu’une sécheuse alimentée par une

tension de 240 V.

Exigences de mise à la terre - Sécheuse électrique (É.-U.)

AVERTISSEMENT

Un raccordement inadéquat du conducteur

de mise à la terre de l’équipement peut

accroître les risques de choc électrique. En

cas de doute quant à la mise à la terre de

l’appareil, consultez un électricien qualifié.

Pour une sécheuse avec cordon, mise à la terre :

1. Cet appareil DOIT être mis à la terre. En cas

de mauvais fonctionnement ou de panne,

la mise à la terre diminue les risques de

choc électrique en fournissant au courant

électrique une trajectoire de moindre

résistance.

2. Après l’achat et l’installation d’un cordon

d’alimentation à 3 ou 4 fils doté d’un fil de

mise à la terre et d’une fiche de mise à la

terre qui correspond à votre système de

câblage, la fiche DOIT être branchée dans

un réceptacle cuivré installé et mis à la terre

conformément aux codes et règlements

locaux. En cas de doute, faites appel à un