Electrolux EFLS527UIW1, EFLS527UTT1, EFLS627UIW1, EFLS627UTT1, EFLW317TIW2 Installation Guide

...Page 1

EN FRONT LOAD WASHER

FR LAVEUSE Á CHARGEMENT FRONTAL

ES LAVADORA DE CARGA FRONTAL

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACIÓN

A11200201 January 2018

Page 2

2

Important Safety Instructions

WARNING

For your safety the information in this manual must be followed to minimize the risk of

fire or explosion or to prevent property damage, personal injury or loss of life. Do not

store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

Safety Precautions

Do not attempt to install or operate

your unit until you have read the safety

precautions in this manual. Safety items

throughout this manual are labeled with a

Danger, Warning, or Caution based on the

risk type.

Definitions

This is the safety alert symbol. It is

used to alert you to potential personal injury

hazards. Obey all safety messages that

follow this symbol to avoid possible injury

or death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Table of Contents

Important Safety Instructions ................ 2

Installation Requirements ...................... 4

Unpacking Washer ...............................8

Installation Instructions .......................10

Reversing Door ................................... 12

Options ..............................................15

IMPORTANT

Indicates installation, operation, or maintenance information which is important

but not hazard-related.

©2017 Electrolux Major Appliances All rights reserved.

Page 3

Important Safety Instructions

WARNING

RISK OF FIRE

Read all the following instructions before installing and using this appliance.

• Dispose of the carton and plastic bags after the washer is unpacked. Children

might use them for play. Cartons covered with rugs, bedspreads, or plastic sheets

can become airtight chambers causing suffocation. Place all materials in a garbage

container or make these materials inaccessible to children.

• For your safety the information in this manual must be followed to minimize the risk

of fire or explosion or to prevent property damage, personal injury or loss of life. Do

not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

• Install the washer according to the manufacturer’s instructions and local codes.

• The electrical service to the washer must conform with local codes and ordinances

and the latest edition of the National Electrical Code, ANSI/NFPA 70, or in Canada,

the Canadian Electrical Code CSA C22.1 part 1.

• To avoid back or other injury, have more than one person move or lift the washer.

• Do not stack a dryer on top of washer already installed on pedestal. Do not stack

washer on top of dryer. Do not stack washer on top of another washer.

• The instructions in this manual and all other literature included with this washer are

not meant to cover every possible condition and situation that may occur. Good safe

practice and caution MUST be applied when installing, operating and maintaining

any appliance.

3

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Page 4

4

box wrench

wrench

Installation Requirements

Please read and save

this guide

Thank you for choosing Electrolux, the

premium brand in home appliances. These

Installation Instructions are part of our

commitment to customer satisfaction and

product quality throughout the life of your

new appliance.

Installation Checklist

Shipping Hardware

Foam shipping support (under wash

tub) removed and stored

Shipping bolts and spacers removed

from rear of appliance and stored

Hole plugs (shipped in bag in drum)

installed in holes in backsheet

Leveling

Washer is level, side-to-side and

front-to-back

Cabinet is sitting solid on all corners

Water Supply

Use only new hoses and verify

rubber sealing washers are installed

HOT supply is connected to HOT

inlet and COLD supply is connected

to COLD inlet

HOT and COLD water supply

turned on

No leaks present at water supply

connections or appliance inlet

connections - recheck in 24 hours

Questions?

Toll-free telephone and online support:

U.S.

1-877-4ELECTROLUX (1-877-435-3287)

www.electroluxappliances.com

Canada

1-800-265-8352

www.electroluxappliances.ca

Drain

Stand pipe or wall drain height

minimum 24”

Verify anti-siphon disc is attached

toward end of drain hose

Drain hose secured in place with

cable tie (shipped in drum)

Door Reversal

Follow detailed instructions in

this guide

Test hinge and latch for function

Electrical Power

House power turned on

Washer plugged in

Final Checks

Installation Instructions and Use

and Care Guide read thoroughly

Door locks and water enters drum

when cycle starts

Registration card sent in

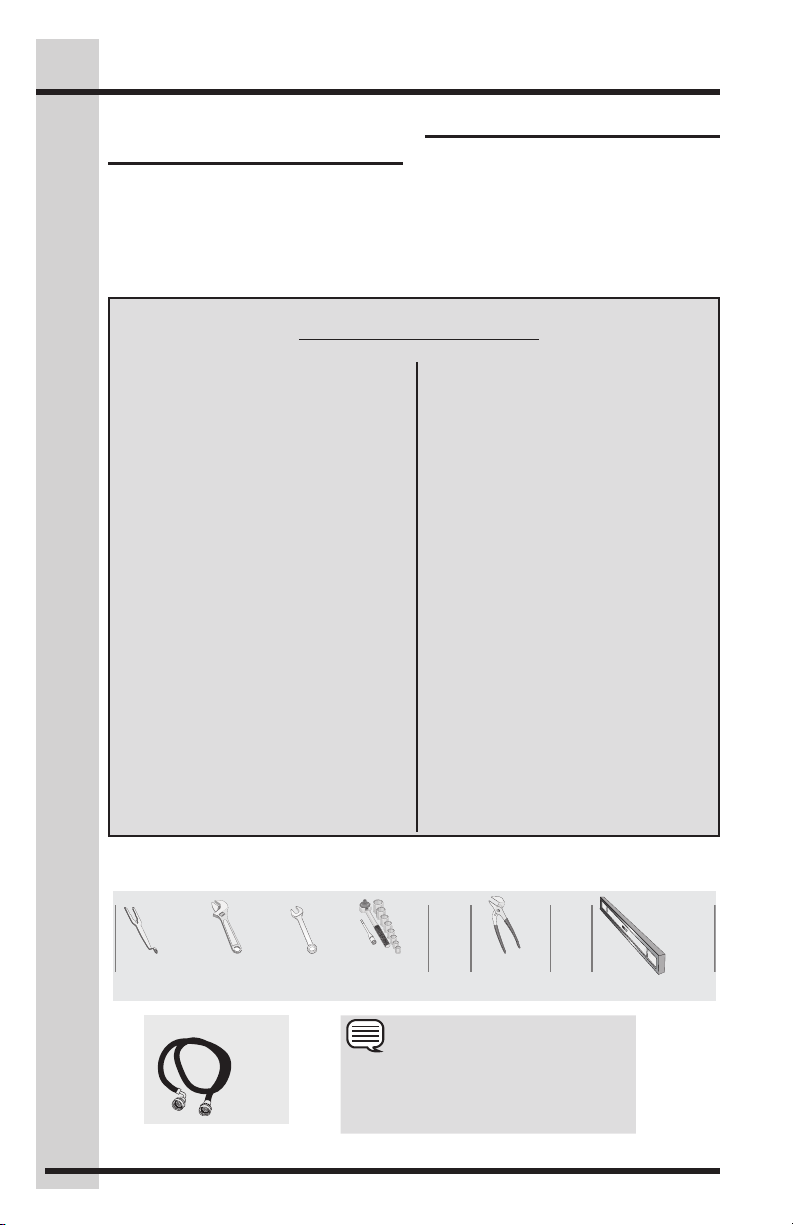

Tools and materials needed for installation:

OR OR OR AND AND

Optional

universal

Adjustable

wrench

3/8" or

10 mm

Ratchet and

socket set

NOTE

Inlet

Hose

(x2)

Hoses are not included with washer

purchase. See “Accessories” section for

various inlet hose kits to fit your specific

installation.

Adjustable

pliers

Carpenter’s level

Page 5

Installation Requirements

5

Electrical system

requirements

CIRCUIT - Individual, properly polarized

and grounded 15 amp. branch circuit

fused with 15 amp. time delay fuse or

circuit breaker.

POWER SUPPLY - 2 wire, with ground,

120 volt single phase, 60 Hz, Alternating

Current.

NOTE

Because of potentially inconsistent voltage

capabilities, the use of this washer with

power created by gas powered generators,

solar powered generators, wind powered

generators or any other generator other

than the local utility company is not recommended.

OUTLET RECEPTACLE - Properly

grounded 3-prong receptacle to be

located so the power supply cord is

accessible when the washer is in an

installed position.

WARNING

Improper grounding of the washer may

cause serious injury or death. Check with a

licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

WARNING

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment

grounding conductor can result in a risk

of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is properly grounded.

2. Since your washer is equipped with

a power supply cord having an

equipment-grounding conductor and

a grounding plug, the plug MUST be

plugged into an appropriate, copper wired receptacle that is properly

installed and grounded in accordance

with all local codes and ordinances or

in the absence of local codes, with the

National Electrical Codes, ANSI/NFPA

70 (latest edition), or in Canada, the

Canadian electrical code C22.1 part 1.

If in doubt, call a licensed electrician.

DO NOT cut off or alter the grounding

prong on the power supply cord. In

situations where a two-slot receptacle

is present, it is the owner’s responsibility to have a licensed electrician replace

it with a properly grounded three prong

grounding type receptacle.

Water supply

requirements

Hot and cold water faucets MUST be installed within hose length of your washer’s

water inlet. The faucets MUST be 3/4 inch

(1.9 cm) with threading for laundry hose

connection. Water pressure MUST be between 20 and 120 psi. Pressure difference

between hot and cold cannot be more

than 10 psi. Your water department can

advise you of your water pressure.

Power cord with

3-prong grounded plug

Grounding requirements

1. The washer MUST be grounded. In

the event of malfunction or breakdown, grounding will reduce the risk

of electrical shock by a path of least

resistance for electrical current.

Drain system

requirements

1. Drain capable of eliminating 17 gals

(64.3 L) per minute.

2. A standpipe diameter of 1-1/4 in. (3.18

cm) minimum.

3. The standpipe height above the floor :

Minimum height: 24 in. (61 cm)

Maximum height: 96 in. (244 cm).

Page 6

6

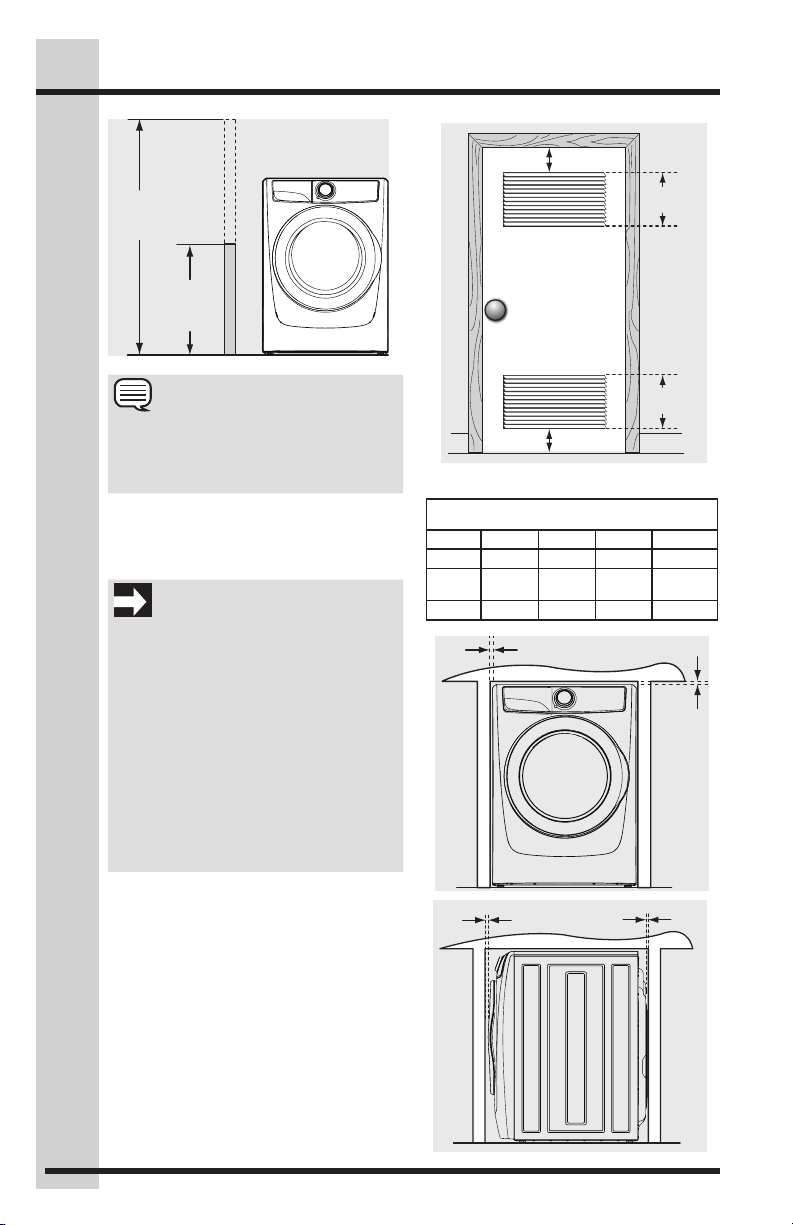

1"

(2.5 cm)

0"

(244 cm)

Installation Requirements

96"

max.

24"

(61 cm)

min.

3"

(7.6cm)

60 sq. in.

(387.1cm²)

NOTE

Drain hose length is 59 in. (150 cm). For

installations requiring a longer drain hose,

use hose P/N 137098000, available from

an authorized parts distributor.

Clearance requirements

IMPORTANT

DO NOT INSTALL YOUR WASHER:

1. In an area exposed to dripping water

or outside weather conditions.

2. In an area where gasoline or other

flammables are kept or stored. If

the washer is installed in a garage,

it must be a minimum of 18 inches

(45.7 cm) above the floor.

3. On carpet. Floor MUST be solid with

a maximum slope of 1 inch (2.5 cm).

To minimize vibration or movement,

reinforcement of the floor may be

necessary.

Installation in a recess or closet

If washer and dryer are installed in the

same closet, door ventilation is required:

A minimum of 120 square inches (774.2

cm²) of opening, equally divided at the

top and bottom of the door, is required.

Louvered openings should be located

3 inches (7.6 cm) from bottom and top

of door. Air openings are required to be

unobstructed when a door is installed. A

louvered door with equivalent air openings

for the full length of the door is acceptable.

60 sq. in.

(387.1cm²)

3"

(7.6cm)

closet door

MINIMUM INSTALLATION CLEARANCES -

Alcove 0” (0 cm) 0” (0 cm) 0” (0 cm) n/a

Under-

Counter

Closet 0” (0 cm) 0” (0 cm) 0” (0 cm) 1” (2.5 cm)

0"

(0 cm)

Inches (cm)

SIDES REAR TOP FRONT

0” (0 cm) 0” (0 cm) 0” (0 cm) n/a

0"

(0 cm)

(0 cm)

Page 7

Installation Requirements

(135.5 cm)

Washer dimensions

(136 cm)*

53.5"

to clear open door

freestand washer

on floor

floor line

washer mounted on

optional pedestal

floor line

53.5" (136 cm)*

to clear open door

approved

stacking kit

(STACKIT7X)

required for

stacked

installation

32" (81.25 cm)*

to front of closed door

32" (81.25 cm)*

to front of closed door

water supply

connection on

rear of unit

drain hose on

rear of unit

75.75"

(192.5 cm)

water supply

connection

on rear

of unit

gas supply

pipe on rear

of gas unit

7

27.0"

(68.5 cm)

38.0"

1

(96.5 cm)

53.25"

electrical

supply on

rear of unit

centerline

height for

rear vent

3

power

3

cord

on rear

of unit

39.0"

(99 cm)

drain

hose on

rear of

unit

2

power

cord on

rear of

unit

(105 cm)

1

41.0"

floor line

*

Connection of water inlet hose on steam dryer adds 3/4 in. (2 cm) to installation depth.

1

Power supply cord length on washer approximately 60 inches (152.5 cm).

2

Drain hose length on washer approximately 59 inches (150 cm).

3

Power supply cord length on gas dryer or electric Canadian dryer approximately 60

inches (152.5 cm).

Page 8

8

Unpacking Washer

Removing foam

packaging

WARNING

SUFFOCATION HAZARD

Dispose of the carton and plastic bags after

the washer is unpacked. Children might use

them for play. Cartons covered with rugs,

bedspreads, or plastic sheets can become

airtight chambers causing suffocation.

Place all materials in a garbage container

or make materials inaccessible to children.

1. Temporarily remove door tape.

2. Open washer

door and remove

everything from

the drum.

3. Close door and

reapply door

tape.

4. Using a rug,

blanket or piece

of cardboard to

protect the floor,

carefully lay the

washer on its

back.

6. Carefully

return the

washer to

an upright

position.

7. Carefully move the washer to within 4

feet (1 m) of its final location.

WARNING

ELECTRIC SHOCK HAZARD

Certain internal parts are intentionally

not grounded and may present a risk of

electrical shock if contacted during installation.

Do not contact the following parts while

the appliance is energized

• Pump

• Drive motor

• Electrical control boards

• Water valves

IMPORTANT

Save styrofoam base and shipping plug

for use to help prevent washer damage

during any future moves.

IMPORTANT

DO NOT place the washer onto its back

without the shipping bolts.

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have more

than one person move or lift the washer.

5. Remove styrofoam base and shipping

plug and set them aside.

IMPORTANT

DO NOT tip washer upside down onto its

top or onto its right side for any reason.

Page 9

Unpacking Washer

Removing shipping hardware

IMPORTANT

Failure to remove shipping hardware completely could result in damage to the appliance, damage to your home, or unexpected washing results.

Save all shipping bolts and spacers for future use. If the washer is to be transported at a

later date, the shipping hardware must be reinstalled to help prevent shipping damage

COLD Water Hose

HOT Water Hose

FRIA

CALIENTE

FROIDE

CHAUDE

P Clamps

Shipping Fork

(on select models)

Black Spacers

White Spacer

(on select models)

Shims

Bolts

9

For 300 Series:

Remove all of the following:

4 BOLTS

4 SHIMS

4 BLACK SPACERS

3 P CLAMPS

For 400, 500, and 600 Series:

Remove all of the following:

5 BOLTS

5 SHIMS

4 BLACK SPACERS

4 P CLAMPS

1 WHITE SPACER

1 SHIPPING FORK

NOTE

Rubber expansion material on spacers may need time to relax before they can be easily

pulled through shipping hole.

COLD Water Hose

HOT Water Hose

FRIA

CALIENTE

FROIDE

CHAUDE

x7

Installing hole plugs

Locate hole plugs in the small bag supplied with washer instruction guides. Insert

them in the holes in the washer back panel

where the shipping hardware has been

removed.

Page 10

10

Installation Instructions

Leveling your washer

Excessive noise and vibration can be prevented by properly leveling the washer.

1. For free

standing

installation

and with the

washer within

4 feet (1 m) of

its final location, place a level on top of the washer.

2. Use the universal wrench to adjust the

leveling legs so

the washer is

level front-torear and sideto-side, and

stable cornerto-corner.

3. Press down

on alternate

corners and

sides and feel for the slightest movement. Adjust the appropriate leg(s) so

the washer sits

solidly on the floor

on ALL four legs.

Keep the leveling

leg extension at a

minimum for best

performance of

the washer.

raise

lower

NOTE

For pedestal installations, see additional

installation instructions included with the

pedestal.

Connecting inlet water

1. Run some water

from the hot and cold

faucets to flush the

water lines and remove

particles that might

clog the water valve

screens and to determine which faucet is

hot and which is cold

supply.

2. Check to ensure

that the inlet

hoses have the

rubber washer

firmly in place.

Rubber Washers

Must Be Present

Hoses are not included with washer

purchase. See “Accessories” section for

various inlet hose kits to fit your specific

installation.

3. Connect the HOT

inlet hose to the

HOT inlet connection on the

washer and the

COLD inlet hose

to the COLD

inlet connection

on the washer.

The cold water inlet will have a blue cap

cover on the inlet connection and the

hot water inlet will have a red cap cover

on the inlet connection. Additionally,

depending on the model, the hot and

cold inlet connections will be marked

with either an adhesive label or markings

directly on the unit to indicate which side

is cold and which side is hot.

Tighten by hand

until snug. Then

tighten each supply connection

another 2/3 turn

with pliers.

Do not cross thread or overtighten these connections.

4. Connect the HOT

inlet hose to the

HOT water supply

and the COLD inlet

hose to the COLD

water supply.

USE ONLY

NEW HOSES

NOTE

Cold Hot

Cold inlet shown

on left side (select

models only)

IMPORTANT

Page 11

Installation Instructions

11

5. Tighten by hand

until snug. Then

tighten each

supply connection another 2/3

turn with pliers.

Do not bend, kink or pinch water

inlet hoses.

6. Turn on the water

and check for

leaks.

Connecting drain and

electrical

1. Verify the

anti-siphon

disc is

in place.

2. Form a “U”

shape on

the end of

the drain

hose with

the hose pointed toward the drain.

Place the formed end in a laundry tub

or a standpipe and secure the drain

hose with the cable tie (provided in the

enclosure package) to the standpipe,

inlet hose, laundry tub, etc. so the hose

does not pull out from the force of the

water.

Cable Tie

Anti-Siphon Disc

Insert Less

Than 8.5"

(21.5 cm)

NOTE

The standpipe inside diameter must be

1-1/4” (3.2 cm) minimum. There must be

an air gap around the drain hose in the

standpipe. A snug hose fit can cause a

siphoning action.

IMPORTANT

Check to ensure the power is off at a

circuit breaker/fuse box before plugging

the power cord into an outlet.

3. Plug the power cord into a grounded

outlet.

WARNING

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment

grounding conductor can cause an electrical shock that may result in serious injury or death. Check with a licensed electrician if you are in doubt as to whether the

appliance is properly grounded.

See

Electrical System Requirements

Grounding Requirements

instruction for additional information.

4. Turn on the power at a circuit breaker/

fuse box.

5. Carefully slide the washer to its final

position. Recheck for level and rock

corners for stability. See “Leveling

your washer” section. Remove and

discard door tape.

6. Read the Use & Care Guide provided

with the washer. It contains valuable

and helpful information that will save

you time and money.

7. Run the washer through a complete

cycle, checking for water leaks and

proper operation.

8. If you have any questions during initial

operation, please review the “Service

Prevention Checklist” in your Use &

Care Guide before calling for service.

9. Place these instructions in a location

near the washer for future reference.

sections of this

and

NOTE

A wiring diagram and technical data

sheet are located under the washer top

panel, on top of the detergent dispenser

housing.

Page 12

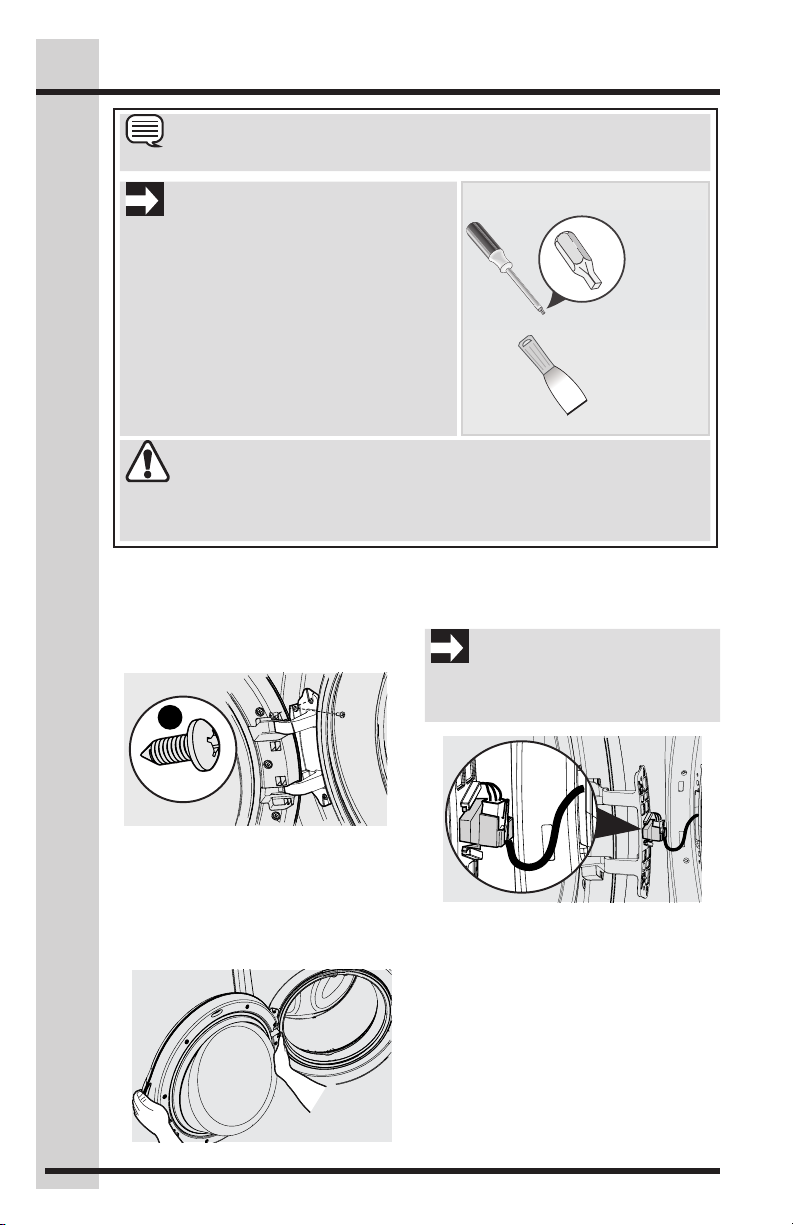

12

Reversing Door

NOTE

Door reversibility is available only on 500, or 600 series models.

IMPORTANT

BEFORE YOU REVERSE WASHER DOOR:

1. Be sure you have adequate swing area

before reversing door.

2. Gather your tools - including a screw driver

with a #2 square bit and plastic knife (or small,

flat prying tool that won’t damage paint).

3. Protect flat work surface, such as top of

washer or floor near washer, with a soft

cloth or towel.

4. Be sure washer is unplugged from power

source!

Tools needed for reversal:

Plastic knife

Screwdriver

with #2

square bit

WARNING

Failure to disconnect power source before servicing could result in personal injury or

even death.

Removing Door Assembly

1. Completely open the door to expose all

four hinge screws.

2. Remove all four hinge screws with #2

square bit driver. Save for reinstalling later.

x4

ELECTRICAL SHOCK HAZARD

4. While supporting the door with one

hand, pinch the tabs to release the plastic terminal cap from the hinge plate.

IMPORTANT

Take care not to pull the door away from

the washer until you remove the wiring

harness terminal cap.

Fine Thread

3. Hold the door with one hand supporting the handle area and one hand

supporting the hinge. While supporting

the door at the hinge, press firmly with

the other hand until the locating pins

on the back of the hinge plate dislocate

from the front panel.

5. Set the door face down on a flat surface protected by soft cloth or towel.

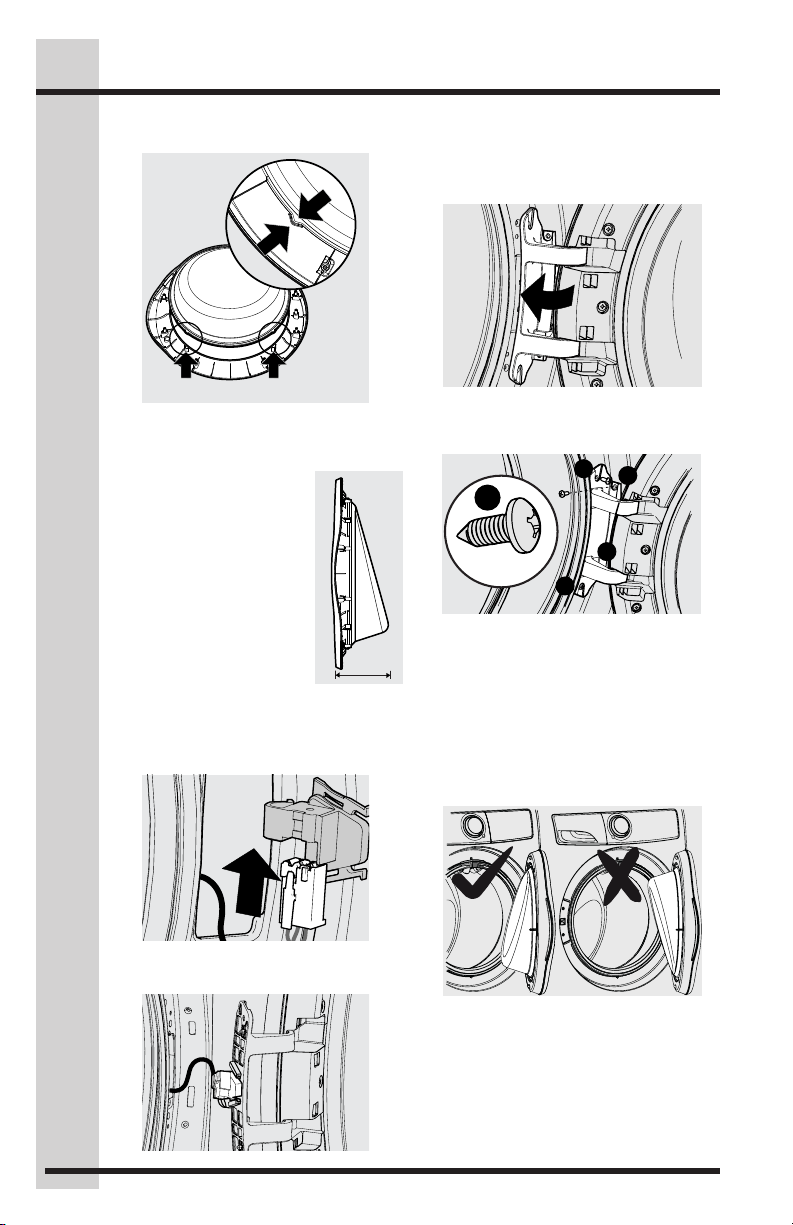

Page 13

Reversing Door

2

2

1

1

13

Removing Door Assembly, continued

6. Release wiring harness from retainer

on plastic terminal cap. Then release

terminal from terminal cap. Save the

cap to reinstall later.

Removing Door Lock and Plastic Hole Cover

1. Locate and remove both screws from

door lock. Save screws for later.

2. Rotate the lock as you pull it out

through the front panel. Take care not

to pull too hard or too far as the lock is

still attached to the wiring harness.

Front

x2

Coarse

Thread

3. Disconnect the wiring harness terminal

from the door lock. Set the door lock

aside for reinstallation later.

4. Pry the bottom of the plastic hole cover

upward to release it from the front

panel. You may have to use a nonscratching plastic knife if you are unable to release it manually. Then, slide

the cover down slightly and remove it

from the front panel.

Panel

Reinstalling Door Lock and Hole

Cover

1. Move the plastic cover to the other side

of the front panel. Position the cover so

the “hook” is at the bottom. Insert hook

into lower slot, slide the cover down,

and press upper retention tabs into

opening until they snap into place.

2. Insert wiring harness into door lock.

3. Insert door lock into front panel and

reinstall door lock screws.

1

2

Coarse

Thread

2

Reversing Door Assembly

1. Locate nine screws on inner door ring.

Remove each and save for reinstallation later. Remove inner door (with

hinge) and carefully set aside.

2. Lift door glass slightly and rotate 180

degrees, setting it back onto outer door.

1

180

Page 14

14

Reversing Door

Reversing Door Assembly, continued

3. Make sure the alignment tabs reengage.

Connect to Notches

4. Reattach the inner door to the outer

door using the nine screws removed

earlier. See illustration, Step 1.

5. Check to verify that the

scoop (wider section) of

the door glass is situated

at the BOTTOM of the

door.

Reinstalling Door Assembly

1. Insert the wiring harness terminal into

the terminal cap and wrap the harness

into the harness retainer.

3. Insert hinge locating pins into the hole

that were previously covered by the

plastic hole cover. Press on the face

of the hinge to snap the other locating

pins into place.

4. Reinstall all four screws removed

earlier - two front screws first, then two

side screws.

1

3

x4

Fine Thread

4

2

Verify Reversed Door Operation

1. Test door for free, smooth swinging

operation and secure latching when

closed.

2. Verify inner door glass is in the correct

orientation with the “scoop” at the

bottom.

2. Slide terminal cap onto back of hinge

plate until tabs snap into place.

3. Plug in washer and close the door.

Test correct door lock operation by

starting a test cycle: lock should

engage, and door should not be able

to be opened until cycle is paused or

canceled.

Page 15

Options

(67 cm)

15

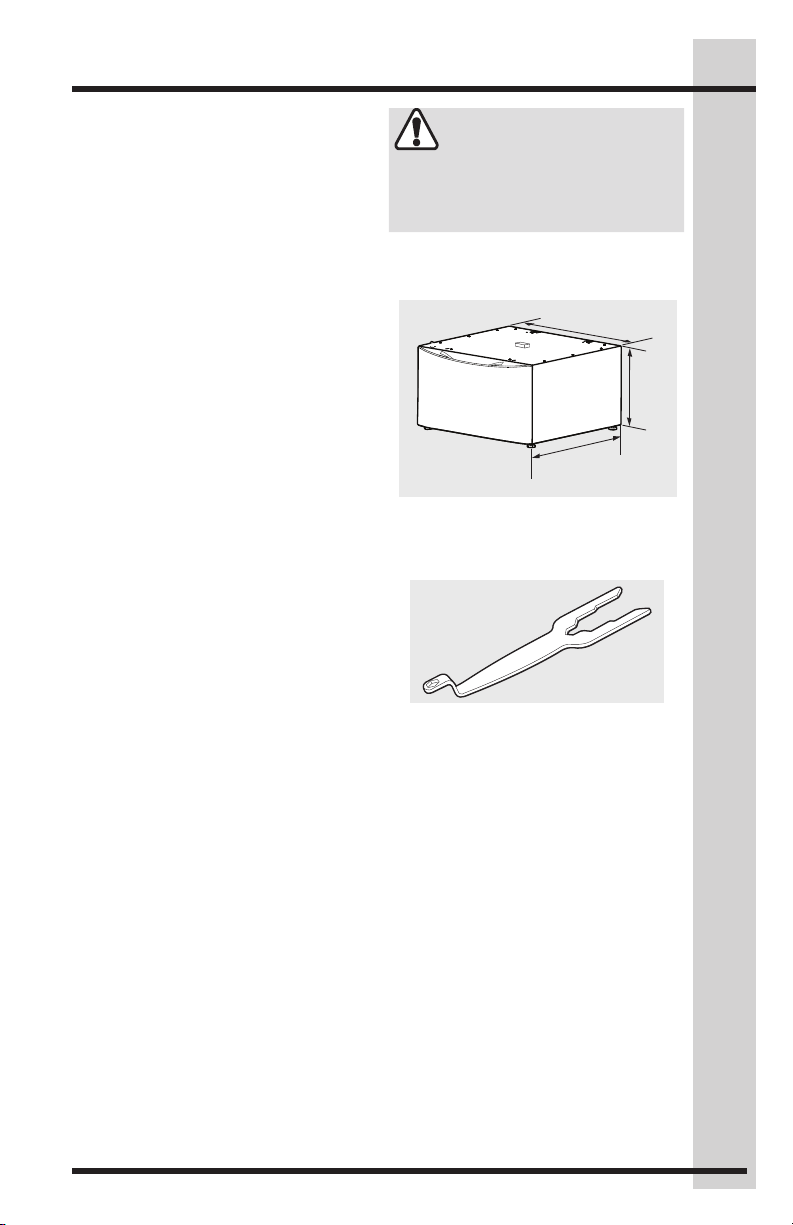

Accessories

MATCHING STORAGE PEDESTAL*

White Pedestal - P/N EPWD257UIW

Titanium Pedestal - P/N EPWD257UTT

A storage pedestal accessory, specifi-

cally designed for this washer may be

used to elevate the washer for ease of

use. This pedestal will add about 15”

(38 cm) to the height of your unit.

*Other colors may be available. Contact the

source where you purchased your washer.

DRYER STACKING KIT

P/N STACKIT7X

Depending on the model purchased, a

kit for stacking a matching dryer on top

of this washer may have been included

in the initial purchase of your dryer. If

your model did not include a stacking

kit or you desire another stacking kit,

you may order one.

INLET HOSE KITS

Please call 866-233-8353 (in Canada,

800-265-8352) to explore hose kit options that will meet your specific installation needs.

DRAIN HOSE EXTENSION KIT

P/N 137098000

In order to reach standpipe heights

or distances beyond the reach of the

drain hose supplied, order the Drain

Hose Extension Kit.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A Universal Appliance Wrench is avail-

able to aid in dryer/washer/pedestal

feet adjustment.

TOUCH UP PAINT PENS*

White - P/N 5304468812

Titanium - P/N 5304475700

*Other colors may be available. Contact the

source where you purchased your washer.

CAUTION

Failure to use accessories manufactured

by (or approved by) the manufacturer

could result in personal injury, property

damage or damage to the washer.

27”

(68.5 cm)

15”

(38 cm)

26.5”

Storage Pedestal

Universal Appliance Wrench

Replacement parts in

U.S. and Canada:

If replacements parts are needed for

your dryer, you can contact the source

where you purchased your dryer, call

1-877-4ELECTROLUX (1-877-435-

3287) in the U.S. or 1-800-265-8352

in Canada, or visit our website,

www.electroluxappliances.com in the U.S.

or www.electroluxappliances.ca in Canada

for the Electrolux Authorized Parts Distributor nearest you.

Page 16

electrolux.com/shop

Page 17

EN FRONT LOAD WASHER

FR LAVEUSE À CHARGEMENT FRONTAL

ES LAVADORA DE CARGA FRONTAL

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACIÓN

A11200201 Janvier 2018

Page 18

2

Consignes de sécurité importantes

AVERTISSEMENT

Pour votre sécurité, les informations contenues dans le présent Guide doivent être suivies

afin de minimiser les risques d'incendie ou d'explosion ou pour prévenir tout dommage,

dégât, blessure ou perte de vie. Ne pas entreposer ni utiliser de la gasoline ou tout autre

liquide ou vapeur inflammable à proximité de tout appareil y compris celui-ci.

Précautions de sécurité

Ne pas tenter d'installer ou d'utiliser

l'appareil avant d'avoir lu toutes les mesures

de sécurité dans le présent manuel. Les

mesures de sécurité présentées dans ce

guide sont identifiées par les mots DANGER,

AVERTISSEMENT ou MISE EN GARDE

selon le type de risque.

Définitions

Voici le symbole d'alerte de sécurité.

Il vous avertit lorsqu'il y a des risques

potentiels. Observer tous les messages

desécurité qui accompagnent ce symbole

pour éviter toute possibilité de blessures

graves ou la mort.

DANGER

DANGER indique une situation de

danger imminent qui, si elle n'est pas

évitée, entraînera des blessures graves,

voirelamort.

AVERTISSEMENT

AVERTISSEMENT indique une situation

qui, si elle n'est pas évitée, pourrait

entraîner des blessures graves,

voirelamort.

Table des matières

Consignes de sécurité importantes ....... 2

Conditions d'installation ........................ 4

Déballage de l'appareil .........................8

Instructions d'installation.....................10

Porte réversible ................................... 12

Options ..............................................15

ATTENTION

MISE EN GARDE indique une situation

potentiellement dangereuse qui, si elle

n'est pas évitée, pourrait causer des

blessures mineures ou modérées.

IMPORTANT

Indique des informations concernant

l'installation, l'emploi ou l'entretien qui sont

importantes, sans être reliées au danger.

©2017 Electrolux Électroménagers Tous droits réservés.

Page 19

Consignes de sécurité importantes

AVERTISSEMENT

RISQUE D'INCENDIE

Lire toutes les instructions avant d'installer et d'utiliser cet appareil.

• Détruire le carton d’emballage et les sacs en plastique après avoir déballé l’appareil.

Les enfants pourraient les utiliser pour jouer. Les cartons recouverts de tapis,

couvertes ou draps de plastique peuvent se transformer en chambres étanches

à l'air. Placer tous les matériaux dans une poubelle ou rendre les matériaux

inaccessibles aux enfants.

• Pour votre sécurité, les informations contenues dans le présent Guide doivent être

suivies afin de minimiser les risques d'incendie ou d'explosion ou pour prévenir

tout dommage, dégât, blessure ou perte de vie. Ne pas entreposer ni utiliser de la

gasoline ou tout autre liquide ou vapeur inflammable à proximité de tout appareil

ycompris celui-ci.

• Installer la laveuse selon les instructions du fabricant et les règlements locaux.

• L’alimentation électrique à la laveuse doit être conforme aux règlements locaux

ainsiqu’à la dernière édition du Code canadien de l’électricité ANSI/NFPA 70.

• Afin d'éviter toute blessure de dos ou autre, s'assurer d'avoir au moins deux

personnes pour déplacer ou soulever la laveuse.

• Ne pas superposer une sécheuse sur une laveuse qui possède déjà son socle.

Nepas superposer la laveuse sur la sécheuse. Ne pas superposer la laveuse

suruneautre laveuse.

• Les instructions dans le présent manuel et tous les autres documents inclus avec

cetappareil ne sont conçues pour couvrir toutes les conditions ou situations

possibles qui pourraient se produire. Le bon sens et la prudence DOIVENT être

exercés lorsde l'installation, de l'emploi et de l'entretien de tout électroménager.

3

CONSERVER CES INSTRUCTIONS

POUR RÉFÉRENCE FUTURE.

Page 20

4

charpentier

Conditions d'installation

Veuillez lire et conserver

ce guide

Merci d'avoir choisi Electrolux, la marque de

qualité en matière d’électroménagers. Ces

instructions d'installation font partie de notre

engagement à vous satisfaire et à vous

fournir un produit de qualité pendant toute

la durée de vie de votre nouvel appareil.

Liste de vérification de l'installation

Quincaillerie de transport

Support de transport en styromousse

(sous la cuve de lavage) retiré et

entreposé

Boulons et entretoises de transport

retirés de l'arrière de l'appareil et

entreposés

Bouchons (dans le sac dans le

tambour) posés dans les trous

àl'arrière

Mise à niveau

La laveuse est à niveau

horizontalement et verticalement

Le cabinet est bien assis sur tous

les coins

Alimentation en eau

Utiliser uniquement de nouveaux

flexibles et vérifier que les rondelles

en caoutchouc sont mises en place

L'alimentation en eau CHAUDE est

raccordée à l'entrée d'eau CHAUDE

et l'alimentation en eau FROIDE et

raccordée à l'entrée en eau FROIDE

L'alimentation d’eau CHAUDE

etFROIDE est ouverte

Aucune fuite aux raccords d'alimen-

tation en eau ni aux raccords d'entrée

del'appareil - revérifier dans 24 heures

Des questions ?

Pour l'assistance aux États-Unis et au

Canada:

États-Unis

1-877-4ELECTROLUX (1-877-435-3287)

www.electroluxappliances.com

Canada

1-800-265-8352

www.electroluxappliances.ca

Vidange

Hauteur minimale de la colonne

montante ou du drain de mur 61 cm

(24 po)

Vérifier que le disque anti-siphonnage

est en place à l'extrémité du tuyau

de vidange

Tuyau de vidange fixé en place

àl'aide d'une attache de câble

(expédié dans letambour)

Inversion de la porte

Suivre les instructions détaillées

dansce guide

Vérifier le fonctionnement

de la charnière et du loquet

Alimentation électrique

L'alimentation électrique

domestiqueest sous tension

La laveuse est branchée

Vérifications finales

Instructions d'installation et d'utilisation

et d'entretien lire attentivement

La porte se verrouille et l'eau entre dans

la cuve lorsque le cycle commence

Carte d'enregistrement envoyée

Outils et matériaux requis pour l'installation :

OU OU OU ET ET

Clé

universelle

optionnelle

Clé à

molette

Clé polygonale

de 3/8 po

ou de 10 mm

Cliquet

et jeu de

douilles

REMARQUE

Le flexible

d'entrée

(x2)

Les tuyaux ne sont pas compris avec l'achat

de la laveuse. Voir la section «Accessoires»

pour trousses de flexibles pour correspondre

à vos besoins d'installation particuliers.

Pince à joint

coulissant

Niveau de

Page 21

Conditions d'installation

5

Exigences électriques

CIRCUIT - Circuit de dérivation de

15ampères individuel, correctement

polarisé et mis à la terre, fusionné avecc

un disjoncteur ou un fusible temporisé

de 15 ampères.

ALIMENTATION ÉLECTRIQUE – 2 fils plus

la mise à la terre, 120 volts, monophasé,

60 Hz, courant alternatif.

REMARQUE

Étant donné les variations de tension possibles, l’utilisation de cette laveuse avec

une source d’alimentation produite par une

génératrice à essence, solaire ou éolienne

ou par toute autre source d’alimentation

différente de celle fournie par les services

publics n’est pas recommandée.

PRISE ÉLECTRIQUE – Prise à 3 voies

correctement mise à la terre située de

façon à ce que le cordon soit accessible

lorsque la laveuse est installée dans sa

position définitive.

AVERTISSEMENT

De graves blessures, voire la moirt, pourraient se produire si la laveuse n'est pas

mise à la terre correctement. Consulter un

électricien agréé en cas de doute concernant la mise à la terre de l'appareil.

Prise murale avec mise à la terre

Il ne faut en aucun

cas couper, enlever

ou contourner la

broche de mise à

la terre.

Cordon d’alimentation

avec fiche à trois broches

avec mise à la terre

Exigences de mise

à la terre

1. La laveuse DOIT IMPÉRATIVEMENT

être mise à la terre. En cas de panne

ou de défaillance, la mise à la terre

offre un passage de résistance moindre

aucourant électrique, réduisant ainsi

lerisque d'électrocution.

AVERTISSEMENT

RISQUE DE CHOCS ÉLECTRIQUES

Un raccordement inadéquat du conducteur

de terre de l’équipement peut accroître les

risques de choc électrique. Consulter un

électricien agréé en cas de doute concernant la mise à la terre de l'appareil.

2. Étant donné que votre laveuse est

équipée d’un cordon d’alimentation

pourvu d’un conducteur de mise à la

terre et d’une fiche de mise à la terre,

la fiche DOIT IMPÉRATIVEMENT être

raccordée à une prise appropriée

avec conducteurs en cuivre

correctement installée et mise àlaterre

conformément aux codes etrèglements

locaux ou, si aucun code local ne régit

ce type d’installation, à la plus récente

édition du Code canadien de l'électricité

C22.1 partie 1. En cas de doute, faire

appel à un électricien qualifié. NE PAS

COUPER et NE PAS MODIFIER la

broche de mise à la terre du cordon

d’alimentation. Sivotre prise murale

n’est pourvue que de deux fentes,

il incombe au propriétaire de faire

appel àun électricien qualifié pour la

remplacer par une prise à trois alvéoles

et mise à la terre de façon adéquate.

Exigences d’alimentation

en eau

Les robinets d’eau chaude et d’eau froide

DOIVENT IMPÉRATIVEMENT être installés

à une distance de longueur de tuyau ou

moins de l’arrivée d’eau de votre laveuse.

Les robinets DOIVENT IMPÉRATIVEMENT

être de 1,9 cm (3/4 po) et filetés en fonction

d’un raccordement de tuyau de laveuse.

La pression d'eau DOIT se situer entre 20

et 120 psi. La différence de pression entre

l'eau chaude et froide ne peut pas dépasser

10 psi. Votre service d'aqueduc pourra

vous informer de votre pression d'eau.

Exigences du système

dedrain

1. Drain pouvant éliminer 64,3 l (17 gal)

par minute.

2. Diamètre de colonne montante

de3,18 cm (1-1/4 po) minimum.

3. Hauteur de la colonne montante depuis

lesol : Hauteur minimum : 61 cm (24po)

Hauteur maximum : 244 cm (96po).

Page 22

6

2.5 cm

0cm

Conditions d'installation

244 cm

(96")

max.

61 cm

(24")

min.

7.6 cm

(3")

387.1 cm²

(60 sq. in.)

REMARQUE

La longueur du tuyau est de 150 cm

(59po). Pour des installations nécessitant

un tuyau plus long, utiliser le tuyau portant

le numéro de pièce 137098000 disponible

auprès d’un distributeur de pièces autorisé.

Débattement requis

IMPORTANT

NE PAS INSTALLER LA LAVEUSE :

1. Dans un endroit exposé aux écoulements d’eau ou aux aléas des conditions météorologiques extérieures.

2. Dans un endroit où de l’essence

oud’autres substances inflammables

sont entreposées. Si la laveuse est

installée dans un garage, elle doit

l'être à au moins 45,7 cm (18 po)

au-dessus du sol.

3. Sur un tapis. Le plancher DOIT être

solide et présenter une pente inférieure à 2,54 cm (1 po). Il peut être

nécessaire de renforcer le plancher

pour prévenir la vibration ou le

mouvement de l’appareil.

Intallation dans une niche

ou un placard

Si la laveuse et la sécheuse sont installées

dans le même placard, une ventilation de

porte est requise : Une ouverture d'un

minimum de 774,2 cm² (120 po carrés)

est requise également au haut et au bas

de la porte. Les évents à lames doivent

sesituer à 7,6 cm (3 po) du bas et du

haut de la porte. Les évents doivent

être sans obstruction lorsqu'une porte

est installée. Une porte persienne avec

des évents équivalents toute la longueur

delaporte est acceptable.

7.6 cm

(3")

porte de placard

DÉGAGEMENTS MINIMUM POUR

L'INSTALLATION - cm (po)

CÔTÉS ARRIÈRE DESSUS AVANT

0 cm

(0po)

0 cm

(0po)

0 cm

(0po)

0 cm

(0po)

0 cm

(0po)

0 cm

(0po)

Alcôve

Sous le

comptoir

Armoire

0 cm

(0”)

(1”)

0 cm

(0po)

0 cm

(0po)

0 cm

(0po)

387.1 cm²

(60 sq. in.)

s/o

s/o

2,5 cm

(1po)

0 cm

(0”)

(0")

Page 23

Conditions d'installation

Dimensions de la laveuse

53.5" (136 cm)*

avec la porte grande ouverte

laveuse autonome

sur le plancher

plancher

laveuse montée

sur le socle

optionnel

plancher

53.5" (136 cm)*

avec la porte grande ouverte

kit d’empilage

approuvé

(STACKIT7X)

requis pour

l’installation

empilée

plancher

32" (81.25 cm)*

à partir de l’avant de la

porte lorsqu’elle est fermée

32" (81.25 cm)*

à partir de l’avant de la

porte lorsqu’elle est fermée

l’alimentation

l’arrière de la

75.75"

(192.5 cm)

raccord de

en eau à

l’arrière de

la laveuse

tuyau de

vidange à

laveuse

raccord de

l’alimentation

en eau à

l’arrière de

la laveuse

alimentation

en gaz à

l’arrière de

l’appareil

à gaz

39.0"

(99 cm)

7

27.0"

(68.5 cm)

38.0"

1

2

(96.5 cm)

53.25"

(135.5 cm)

alimentation

électrique à

l’arrière de la

3

sécheuse

hauteur de la

ligne centrale

de l’évent

arrière

cordon

d’alimentation

à l’arrière

de la

1

laveuse

41.0"

(105 cm)

cordon

d’alimentation

3

à l’arrière

de la

laveuse

Tuyau de

vidange à

l’arrière

de la

laveuse

*

Le raccord du flexible d'admission d'eau sur la sécheuse à vapeur ajoute 2 cm (3/4 po).

àla profondeur de l'installation.

1

Longueur du cordon d’alimentation de la laveuse d'environ 152,5 cm (60 pouces).

2

Longueur du tuyau d'évacuation de la laveuse d'environ 150 cm (59 pouces).

3

Longueur du cordon d’alimentation de la sécheuse à gaz ou de la sécheuse électrique

canadienne d'environ 152,5 cm (60 pouces).

Page 24

8

Déballage de l'appareil

Retirer l'emballage

enmousse

AVERTISSEMENT

RISQUE D'ÉTOUFFEMENT

Détruire le carton d’emballage et les sacs en

plastique après avoir déballé l’appareil. Les

enfants pourraient les utiliser pour jouer. Les

cartons recouverts de tapis, couvertes ou

draps de plastique peuvent se transformer

en chambres étanches à l'air. Placer tous les

matériaux dans une poubelle ou rendre les

matériaux inaccessibles aux enfants.

1. Retirer temporairement le ruban

de la porte.

2. Ouvrir la porte de

la laveuse et retirer

tout ce qu'il y a

dans le tambour.

3. Fermer la porte

et remettre le

ruban de porte.

4. Pour protéger

le plancher, utiliser un tapis, une

couvertureou une

pièce de carton et

coucher délicatement la laveuse

sur son dos.

6. Remettre

soigneuse

ment la

laveuse

en position

verticale.

7. Déplacer soigneusement la laveuse

àmoins de 1 m (4 pi) de son emplacement définitif.

AVERTISSEMENT

RISQUE DE CHOCS ÉLECTRIQUES

Certaines pièces internes ne sont pas

mises à la terre et peuvent présenter

unrisque de choc électrique si elles

sonttouchées durant l'installation.

Ne pas toucher les pièces suivantes une

fois que l'appareil est mis sous tension.

• Pompe

• Moteur d'entraînement

• Panneaux de commande électrique

• Valves d'eau

IMPORTANT

Conserver la base en styromousse et

le bouchon d’expédition afin d’éviter

d’endommager l’appareil dans le cas

d’un déplacement éventuel.

IMPORTANT

NE PAS placer la laveuse sur son dos

sans les boulons d'expédition.

ATTENTION

DANGER DE MASSE EXCESSIVE

Afin d'éviter toute blessure de dos ou autre,

s'assurer d'avoir au moins deux personnes

pour déplacer ou soulever la laveuse.

5. Retirer la base en styromousse

et lebouchon d’expédition et les

mettrede côté.

IMPORTANT

NE PAS basculer ni renverser la laveuse

pour quelque raison qui soit.

Page 25

Déballage de l'appareil

Retirer la boulonnerie de transport

IMPORTANT

Le non retrait de toute la quincaillerie d'expédition pourrait entraîner des dommages

àl'appareil, des dommages à la maison, ou des résultats de lavage inattendus.

Conserver tous les boulons et les cales d’espacement d’expédition pour un usage ultérieur.

Si la laveuse doit être transportée plus tard, ces pièces d’expédition doivent être réinstallées

pour éviter des dommages causés par le transport.

COLD Water Hose

HOT Water Hose

FRIA

CALIENTE

FROIDE

CHAUDE

Fourche de transport

(certains modèles)

Colliers en P

Entretoises

noires

White Spacer

(certains modèles)

Cales

de réglage

Boulons

9

Pour la série 300 :

Retirer tout ce qui suit :

4 BOULONS

4 CALES DE RÉGLAGE

4 ENTRETOISES NOIRES

3 COLLIERS EN P

Pour les séries 400, 500 et 600 :

Retirer tout ce qui suit :

5 BOULONS

5 CALES DE RÉGLAGE

4 ENTRETOISES NOIRES

4 COLLIERS EN P

1 ENTRETOISE BLANCHE

1 FOURCHE DE TRANSPORT

REMARQUE

Le matériel d'expansion en caoutchouc sur les cales d'espacement peuvent nécessiter

uncertain temps avant de pouvoir passer à travers le trou de transport.

COLD Water Hose

HOT Water Hose

FRIA

CALIENTE

FROIDE

CHAUDE

x7

Installation des

bouchons de trou

Situer les bouchons dans le petit sac

fourni avec les guides d'instructions

delalaveuse. Les insérer dans les trous

dansle panneau arrière de la laveuse

où laquincaillerie de transport avait

étéretirée.

Page 26

10

Instructions d'installation

Mise à niveau de votre

laveuse

Les bruits excessifs et les vibrations peuvent être évités en mettant correctement

la laveuse à niveau.

1. Pour une

installation

autonome où

la laveuse est

àmoins de 1

m (4pi) de son

emplacement

définitif, placer

un niveau sur le dessus de l’appareil.

2. Utiliser la clé universelle pour ajuster les

pieds de mise

à niveau de façon à ce que la

laveuse soit de

niveau d’avant

en arrière et

latéralement,

et qu’elle soit

stable aux

quatre coins.

3. Appuyer sur chaque coin et chaque côté

pour déterminer les endroits qui nécessitent un réglage. Ajuster les pieds de mise

à niveau appropriés de manière à

ce que la laveuse

repose solidement

sur ses QUATRE

pieds. Garder les

pieds demise à

niveau le plus près

possible de la laveuse afin d’optimiser

lerendement de la laveuse.

soulever

abaisser

REMARQUE

Pour une installation sur socle,

voir les instructions d’installation

complémentaires incluses avec le socle.

Raccordement à la

canalisation d'eau

1. Faire couler de l’eau

chaude et froide des

robinets pour purger

les tuyaux d’eau,

pour éliminer toute

particule qui pourrait

obstruer les grillages

des robinets, et pour

déterminer quels robinets fournissent l’eau

chaude et l’eau froide.

2. Vérifier que

la rondelle en

caouthcouc des

flexibles d'entrée

est solidement in

place.

Les rondelles en

caoutchouc doivent

être présentes

UTILISER

SEULEMENT

DES TUYAUX

NEUFS

REMARQUE

Les tuyaux ne sont pas compris avec

l'achat de la laveuse. Voir la section

«Accessoires» pour trousses de

flexibles pour correspondre à vos

besoins d'installation particuliers.

3. Brancher le flexible

d’eau CHAUDE au

robinet d'admission

d’eau CHAUDE

de la laveuse et

le flexible d’eau

FROIDE au robinet

d'admission d’eau

FROIDE de la

laveuse.

Entrée d'eau froide

sur le côté gauche

(certains modèles

Chaude

Froide

seulement)

IMPORTANT

L'entrée d'eau froide aura un bouchon

bleu sur son raccord et l'entrée d'eau

chaude aura un bouchon rouge sur son

raccord. En outre, selon le modèle, les

raccords chaud et froid seront marqués

soit d'une étiquette ou de repères directement sur l'appareil pour indiquer de quel

côté sont les raccords chaud et froid.

Serrer fermement

à la main. Ensuite,

serrer d'un autre

2/3 de tour au

moyen de la pince.

Ne pas fausser ni

trop serrer ces raccords.

4. Brancher le flexible

d’eau CHAUDE

au raccord

d'alimentation d’eau

CHAUDE domestique et le flexible

d’eau FROIDE au raccord d'alimentation

d’eau FROIDE domestique.

Page 27

Instructions d'installation

11

5. Serrer fermement

à la main.

Ensuite, serrer

d'un autre 2/3

detour au moyen

de la pince.

Attention de ne pas plier, déformer

ou pincer les flexibles d'entrée d'eau.

6. Ouvrir l'eau et

vérifier pour toute

présence de fuite.

Branchement de

l’alimentation électrique

et de l'évacuation

1. Vérifier que

le disque

antisiphonnage

est bien en

place.

2. Placer le

côté du

tuyau de

vidange en

forme de «U» dans l’ouverture dutuyau

d’évacuation. Placer l'extrémité ainsi

formée dans une cuve à lessive ou

un tuyau d'évacuation et fixer le tuyau

de vidange au moyen d’une attache

(incluse dans la trousse d’installation

fournie) au tuyau d’évacuation, au

tuyau d’entrée, à la cuve à lessive, etc.

defaçon à ce que le tuyau ne puisse

être arraché sous la force de l’eau.

Attache-câble

disque

anti-siphonnage

Introduire

moins de

21,5 cm (8,5”)

REMARQUE

Tuyau d’évacuation d’au moins 3,2 cm

(1-1/4 po) de diamètre. Il doit y avoir un

débattement autour du tuyau d'évacuation

dans la colonne montante. Un tuyau trop

serré cause un effet desiphonnement.

IMPORTANT

Vérifier que l’alimentation électrique est

coupée au disjoncteur ou au boîtier

defusibles avant de brancher le cordon

d’alimentation dans une prise électrique.

3. Brancher le cordon électrique dans

une prise électrique mise à la terre.

AVERTISSEMENT

RISQUE DE CHOCS ÉLECTRIQUES

Un raccordement inadéquat du conducteur

de terre de l’équipement peut accroître

les risques de choc électrique. Consulter

un électricien agréé en cas de doute

concernant la mise à la terre de l'appareil.

Voir

Exigences électriques

de mise à la terre

pour d'autres suggestions pratiques.

4. Ouvrir l’alimentation électrique au

disjoncteur ou au boîtier de fusibles.

5. Faire glisser soigneusement la laveuse

à son emplacement définitif. Vérifier à

nouveau la mise à niveau et la stabilité de

l’appareil. Voir la section «Mise àniveau

de votre laveuse». Retirer etjeter le

ruban de la porte.

6. Lire le Guide d'emploi et d'entretien

fourni avec la laveuse. Celui-ci contient

des informations pertinentes qui vous

économiseront temps et argent.

7. Faire marcher la laveuse pendant un

cycle complet pour vérifier la présence

de fuites et le bon fonctionnement de

la machine.

8. Si vous avez des questions concernant

le fonctionnement initial, veuillez consulter

la «Liste de prévention de service» dans

votre Guide d'emploi et d'entretien avant

de faire appel à un technicien.

9. Ranger ces instructions dans un endroit

proche de la laveuse pour référence

future.

dans ces instructions

et

Exigences

REMARQUE

Un schéma électrique et une fiche

technique sont situés sous le panneau

supérieur de la laveuse, au-dessus du

logement de distributeur de détergent.

Page 28

12

Porte réversible

REMARQUE

La porte réversible est disponible seulement sur les modèles de série 500 et 600.

IMPORTANT

AVANT D'INVERSER LA PORTE

DE LA LAVEUSE :

1. Vérifier qu'il y a de la place pour ouvrir

laporte avant de l'inverser.

2. Recueillir les outils nécessaires, incluant un

tournevis avec un embout carré #2 et un couteau en plastique (ou un petit outil de grattage

qui n'égratignera pas la peinture).

3. À l'aide d'une serviette ou d'un linge doux,

protéger une surface plane, comme le dessus

de la laveuse ou le plancher près de la laveuse.

4. S'assurer que la laveuse est débranchée

del'alimentation électrique !

Outils nécessaires :

Couteau

en plastique

AVERTISSEMENT

Si l'alimentation électrique n'est pas déconnectée avant l'entretien, cela pourrait

entraîner des blessures graves, voire la mort.

Dépose de la porte

1. Ouvrir complètement la porte pour

exposer les quatre vis de charnière.

2. Retirer les quatre vis de charnière

àl'aide d'un tournevis avec embout

carré #2. Les conserver pour la repose.

x4

RISQUE DE CHOCS ÉLECTRIQUES

4. Tout en supportant la porte d'une

main, pincer les onglets pour libérer

lecapuchon terminal de plastique

delaplaque de charnière.

IMPORTANT

Prendre soin de ne pas retirer la porte dela

laveuse avant d'avoir enlever le capuchon

terminal du faisceau de câblage.

Destornillador

con broca

cuadrada del 2

Filetage

Fin

3. Tenir la porte avec une main supportant la poignée et une main supportant

la charnière. Tout en supportant la

porte au niveau de la charnière, appuyer fermement avec l'autre main jusqu'à

ce que les goupilles de référence sur

le dos de la plaque de charnière se

délogent du panneau avant.

5. Placer la porte sur sa face sur une

surface plane protégée par une

serviette ou un linge doux.

Page 29

Porte réversible

2

1

13

Dépose de la porte, suite

6. Libérer le faisceau de câblage de

la retenue sur le capuchon terminal

de plastique. Puis libérer le terminal

du capuchon terminal. Conserver

lecapuchon pour la repose plus tard.

Dépose du verrou de porte

etdu bouchon en plastique

1. Situer et retirer les deux vis de verrouil-

lage de porte. Conserver les vis pour

plus tard.

2. Tourner le verrou en le tirant à travers

le panneau avant. Prendre soin de ne

pas tirer trop fort ni trop loin puisque

leverrou est toujours attaché au

faisceau de câblage.

x2

Repose du verrou de porte

etdu bouchon en plastique

1. Déplacer le bouchon en plastique vers

l'autre côté du panneau avant. Placer le

bouchon de façon à ce que le «crochet»

soit au fond. Introduire le crochet dans

la fente du bas, faire glisser le bouchon,

puis enfoncer les onglets de retenue supérieurs dans l'ouverture jusqu'à cequ'ils

s'enclenchent.

2. Intoduire le faisceau de câblage dans

leverrouillage de porte.

3. Introduire le verrou de porte dans

lepanneau avant et réinstaller les

visde verrou de porte.

1

1

2

Fil

Grossier

2

Porte réversible

Fil

Grossier

3. Débrancher le faisceau de câblage

terminal du verrou de la porte. Mettre

le verrou de la porte de côté pour

larepose plus tard.

4. Détacher le fond du bouchon en plastique du panneau avant en le tirant vers le

haut. Il sera peut-être nécessaire d'utiliser

un couteau en plastique non abrasif s'il

est impossible de le détacher àla main.

Ensuire, faire glisser le bouchon légèrement puis le retirer dupanneau avant.

2

1

1. Situer les neuf vis dans la bague intérieure

de la porte. Les retirer une à la fois et les

conserver pour la repose plus tard. Retirer

la porte intérieure (avec la charnière) et les

mettre soigneusement de côté.

2. Soulever légèrement le verre de la

porte et la tourner 180 degrés et ensuite le replacer sur la porte extérieure.

180

Page 30

14

Porte réversible

Porte réversible, suite

3. S'assurer que les onglets d'alignement

se réenclenchent.

connecter sur les coches

4. Remonter la porte intérieure sur la porte

extérieure à l'aide des neuf vis déposés

plus tôt. Voir l'illustration Étape 1.

5. Vérifier que la partie

bombée (la section plus

large) du verre de porte

est situé au BAS de la

porte.

Repose de la porte

1. Introduire le terminal du faisceau de

câblage dans le capuchon terminal

etmettre le faisceau dans son dispositif

de retenue.

3. Introduire les goupilles de référence

de la charnière dans le trou qui avait

précédemment été caché par le

bouchon de plastique. Appuyez sur

laface de la charnière pour enclencher

les autres goupilles en place.

4. Réinstaller les quatre vis retirées

précédemment - les deux vis avant

enpremier, puis les deux vis latérales.

1

3

x4

filetage fin

4

2

Vérifier le fonctionnement

de la porte inversée

1. Assurer une ouverture sans problème

et le verrouillage à la fermeture.

2. Vérifier que le verre de la porte

intérieure est bien orienté avec

la partie bombée vers le bas.

2. Faire glisser le capuchon terminl sur la

plaque de charnière jusqu'à ce que les

onglets s'enclenchent.

3. Brancher la laveuse puis fermer la

porte. Valider le verrouillage de la porte

en lançant un cycle d’essai : laserrure

doit s’engager et il doit êtreimpossible

d’ouvrir la porte avant la fin ou

l’annulation du cycle.

Page 31

Options

15

Accessoires

SOCLE DE RANGEMENT ASSORTI*

Socle blanc - PIÈCE N° EPWD257UIW

Socle argenté -PIÈCE N° EPWD257UTT

Un socle de rangement conçu expres-

sément pour cette laveuse qui peut être

utilisé pour soulever l'appareil, facilitant

ainsi son utilisation. Le socle ajoute

environ 38 cm (15 po) à la hauteur

del'appareil.

*Il se peut que d’autres couleurs soient

disponibles. Communiquez avec le détaillant

qui vous a vendu votre laveuse.

NÉCESSAIRE DE SUPERPOSITION

DESÉCHEUSE PIÈCE N° STACKIT7X

Selon le modèle que vous avez acheté,

il se peut qu’un nécessaire pour superposer cette sécheuse sur une laveuse

assortie ait été inclus dans l’achat initial

de votre sécheuse. Si votre modèle

ne comprenait pas de nécessaire de

superposition ou que vous en désirez

un autre, il vous est possible d’en

commander un.

TUYAUX D‘ALIMENTATION

Veuilles téléphoner 866-233-8353

au 800-265-8352 pour connaître les

options de tuyaux qui répondront à

vosbesoins d'installation particuliers.

NÉCESSAIRE DE RALLONGE DE TUYAU

DE VIDANGE PIÈCE N° 137098000

Pour atteindre un tuyau d’évacuation

qui est trop haut ou trop loin pour la

longueur de tuyau fournie, commandez

le nécessaire de rallonge de tuyau

devidange.

CLÉ D’APPAREIL UNIVERSELLE

PIÈCEN° 137019200

Une clé d’appareil universelle est

offerte pour faciliter le réglage des

pieds de sécheuse/laveuse/socle.

CRAYONS DE PEINTURE DE RETOUCHE*

Crayon de retouche blanc -

PIÈCE N° 5304468812

Crayon de retouche argenté-

PIÈCE N° 5304475700

*Il se peut que d’autres couleurs soient

disponibles. Communiquez avec le détaillant

qui vous a vendu votre laveuse.

ATTENTION

L'utilisation d'accessoires non fabriquées

(ni autorisées) par le fabricant pourrait

entraîner des blessures, des dommages

matériels ou des dommages à la

laveuse.

68.5 cm

(27”)

38 cm

(15”)

67 cm

(26.5”)

Socle de rangement

Clé universelle

Pièces de rechange aux

États-Unis et au Canada

Si vous avez besoin de pièces de rechange

pour votre sécheuse, contactez le détaillant

où vous avez acheté votre sécheuse, faites

le 18774ELECTROLUX (1877435-3287)

aux États-Unis ou le 1800265-8352

au Canada, ou visitez notre site Internet

http://www.electroluxappliances.ca/fr-CA

pour trouver le distributeur de pièces agréé

Electrolux le plus près de chez vous.

Page 32

electrolux.com/shop

Page 33

EN FRONT LOAD WASHER

FR LAVEUSE Á CHARGEMENT FRONTAL

ES LAVADORA DE CARGA FRONTAL

INSTALLATION INSTRUCTIONS

INSTRUCTIONS D’INSTALLATION

INSTRUCCIONES DE INSTALACIÓN

A11200201 Enero 2018

Page 34

2

Instrucciones de seguridad importantes

ADVERTENCIA

Por su seguridad siga la información contenida en este manual para minimizar el riesgo

de incendio o explosión y evitar daños materiales, lesiones o incluso pérdida de vidas.

No guarde ni use gasolina u otros líquidos o productos inflamables cerca de este o de

cualquier otro electrodoméstico.

Precauciones de seguridad

No intente instalar u operar su unidad

hasta que haya leído las precauciones

deseguridad en este manual. Los elementos de seguridad en este manualestán

etiquetados con Peligro, Advertencia

o Atención, según el tipo de riesgo.

Definiciones

Este es el símbolo de alerta de seguridad. Se utiliza para alertarle de potenciales

peligros de sufrir lesiones. Obedezca todos

los mensajes de seguridad que aparezcan después de este símbolo para evitar

posibles lesiones o incluso la muerte.

PELIGRO

PELIGRO indica una situación inminente

y peligrosa que, de no evitarse, producirá

la muerte o lesiones graves.

ADVERTENCIA

Una indicación de ADVERTENCIA

representa una situación potencialmente

peligrosa que, si no se evita, podría tener

como resultado la muerte o una lesión

grave.

PRECAUCIÓN

Una indicación de PRECAUCIÓN

representa una situación potencialmente

peligrosa que, si no se evita, puede

tener como resultado una lesión leve

o moderada.

Índice

Instrucciones de seguridad

importantes .......................................... 2

Requisitos para la instalación ................ 4

Desembalaje de la lavadora .................. 8

Instrucciones de instalación ................ 10

Puerta reversible ................................. 12

Opciones ............................................ 15

IMPORTANTE

Indica información de instalación,

funcionamiento o mantenimiento que

es importante pero no se relaciona con

ningún peligro.

©2017 Electrolux Major Appliances Todos los derechos reservados.

Page 35

Instrucciones de seguridad importantes

ADVERTENCIA

PELIGRO DE INCENDIO

Lea todas las instrucciones antes de instalar y utilizar este aparato.

• Deseche el cartón y las bolsas de plástico después de desembalar la lavadora.

Los niños podrían utilizarlas para jugar. Las cajas de cartón cubiertas con esterillas,

colchas o láminas de plástico pueden convertirse en cámaras herméticas y provocar

asfixia. Coloque todos estos materiales en un contenedor de basuras o fuera del

alcance de los niños.

• Por su seguridad siga la información contenida en este manual para minimizar

elriesgo de incendio o explosión y evitar daños en las propiedades, lesiones

personales o incluso pérdida de vidas. No guarde ni use gasolina u otros líquidos

oproductos inflamables cerca de este o de cualquier otro electrodoméstico.

• Instale la lavadora de conformidad con las instrucciones del fabricante y los códigos

locales.

• El suministro eléctrico a la lavadora debe cumplir los códigos y ordenanzas locales

yla última edición del Código Eléctrico Nacional, ANSI/NFPA 70, o en Canadá,

elcódigo eléctrico canadiense CSA C22.1 parte 1.

• Para evitar lesiones en la espalda o de otro tipo, la lavadora debe ser levantada

otrasladada por más de una persona.

• No apile una secadora encima de una lavadora instalada sobre pedestal. No apile

lalavadora encima de una secadora. No apile la lavadora encima de otra lavadora.

• Las instrucciones de este manual y cualquier otra publicación incluida con esta lavadora no están previstas para cubrir todas las posibles condiciones y situaciones que

puedan darse. TIENE QUE utilizar el sentido común y tener precaución al instalar,

poner en funcionamiento y realizar el mantenimiento de cualquier electrodoméstico.

3

GUARDE ESTAS INSTRUCCIONES

PARA CONSULTAS FUTURAS.

Page 36

4

o 10 mm

Requisitos para la instalación

Lea y guarde esta guía

Gracias por elegir Electrolux, la marca

premium de electrodomésticos. Estas

Instrucciones de Instalación forman parte

de nuestro compromiso con la satisfacción del cliente y la calidad del producto

durante la vida útil de su nuevo aparato.

¿Preguntas?

Para llamadas gratuitas en EE.UU. yen

Canadá:

EE.UU.

1-877-4ELECTROLUX (1-877-435-3287)

www.electroluxappliances.com

Canadá

1-800-265-8352

www.electroluxappliances.ca

Lista de comprobación para la instalación

Materiales de embalaje y envío

Sujeción de espuma para envío (debajo

del tambor) retirada yguardada

Separadores y pernos de transporte

retirados de la parte trasera del

electrodoméstico y almacenados

Tapones (entregados en bolsa en

eltambor) instalados en los orificios

de la placa posterior.

Nivelación

La lavadora está nivelada, de

ladoalado y de frontal a trasera

El mueble se apoya bien

entodaslasesquinas

Suministro de agua

Utilice solo mangueras nuevas

ycompruebe que estén colocadas

las arandelas de goma de sellado

El suministro de agua CALIENTE

está conectado a la entrada de

aguaCALIENTE y la de agua FRÍA,

ala entrada de agua FRÍA

Suministros de agua CALIENTE

yFRÍA conectados

Las conexiones del suministro de

agua y las conexiones de entrada

del aparato no presentan pérdidas;

volver a comprobar en 24 horas

Herramientas y materiales necesarios para la instalación:

Desagüe

Tubería vertical o desagüe de pared,

altura mínima 24”

Compruebe que el disco antisifón

está instalado hacia el extremo de

lamanguera de desagüe.

Manguera de desagüe fijada con brida

para cables (se entrega en el tambor)

Reversibilidad de la puerta

Siga las instrucciones detalladas

deesta guía

Prueba de bisagra y de

funcionamiento del pestillo

Alimentación eléctrica

Corriente eléctrica de la vivienda

encendida

Lavadora enchufada

Comprobaciones finales

Instrucciones de instalación

yGuíade uso y mantenimiento:

leídas atentamente

La puerta se bloquea y entra

aguaenel tambor cuando se

iniciaelciclo

Tarjeta de registro enviada

(O bien)

Llave

universal

opciona

Llave

Inglesa

La manguera

de entrada

(x2)

(O bien)

Llave

combinada

de 3/8"

Conjunto

de trinquete

y tubos

Y Y

Alicates

Nivel de carpintero

NOTA

El precio de la lavadora no incluye mangueras. Consulte la sección “Accesorios” para ver los distintos kits de mangueras de

entrada adecuados a su instalación concreta.

Page 37

Requisitos para la instalación

5

Requisitos del sistema

eléctrico

CIRCUITO - Circuito de derivación individual

de 15 amperios adecuadamente polarizado y conectado a tierra con fusible

odisyuntor de 15 amperios con retardo.

FUENTE DE ALIMENTACIÓN - 2 cables,

con conexión a tierra 120 voltios,

monofase, 60 Hz, corriente alterna.

NOTA

Debido a la posible falta de voltaje constante, no se recomienda el uso de esta

lavadora con alimentación mediante generadores de gas, solares, eólicos u otro tipo

de generador distinto del suministrado por

su empresa de electricidad local.

TOMA DE CORRIENTE - Toma de corri-

ente de pared de 3 clavijas con conexión

a tierra situada de modo que el cable de

alimentación quede accesible cuando la

lavadora quede instalada en su posición.

ADVERTENCIA

Una inadecuada conexión a tierra de la

lavadora puede provocar lesiones graves

o la muerte. Consulte a un electricista cualificado en caso de duda sobre si el aparato

está adecuadamente conectado a tierra.

Tomacorriente de pared con

conexión a tierra

Bajo ninguna

circunstancia corte,

extraiga o desvíe

las patas de

conexión a tierra.

Cable de alimentación

con enchufe de tres patas

con conexión a tierra

Requisitos de conexión

a tierra

1. La lavadora TIENE QUE estar

conectada a tierra. En caso de fallo

oavería, la conexión a tierra reducirá

elriesgo de descarga eléctrica

mediante una vía de menor resistenciaparala corriente eléctrica.

ADVERTENCIA

PELIGRO DE DESCARGA ELÉCTRICA

Una incorrecta conexión del conductor

de puesta a tierra del equipo puede crear

un riesgo de descarga eléctrica. Consulte

a un electricista cualificado en caso de

duda sobre si el aparato está adecuadamente conectado a tierra.

2. Como su lavadora está provista de

uncable de alimentación eléctrica que

tiene un conductor de puesta a tierra del

equipo y un enchufe con toma de tierra,

el enchufe SE TIENE QUE enchufar en

un receptáculo apropiado con cable de

cobre que esté correctamente instalado

y conectado a tierra de conformidad con

todos los códigos y ordenanzas locales

o en ausencia de estos, de acuerdo con

los Códigos Eléctricos Nacionales ANSI/

NFPA 70 (última edición), o en Canadá,

según el código eléctrico canadiense

C22.1 parte 1. En caso de duda, llame

a un electricista cualificado. NO corte

ni modifique la clavija de conexión a

tierra del cable de alimentación eléctrica.

Cuando se disponga de un receptáculo

de dos ranuras, el propietario tiene la

responsabilidad de pedir a un electricista cualificado que lo sustituya por

uno de tres clavijas con toma de tierra

debidamente conectada.

Requisitos del suministro

de agua

Las llaves de agua fría y caliente TIENEN

QUE instalarse dentro de la longitud

de manguera de entrada de agua de

lalavadora. Las llaves TIENEN QUE ser

de1,9 cm (3/4 de pulgada) con roscado

para conexión a manguera de lavado.

La presión de agua TIENE QUE estar

entre 20 y 120 psi. La diferencia de presión entre caliente y fría no puede ser de

más de 10psi. El servicio de aguas podrá

asesorarle sobre su presión de agua.

Requisitos del sistema

de desagüe

1. Desagüe capaz de eliminar 17 galones

(64,3 l) por minuto.

2. Tubería vertical (general) con un

diámetro mínimo de 3,18 cm(1-1/4”).

3. Altura de la tubería vertical por encima

del suelo : Altura mínima: 61 cm (24”)

Altura máxima: 244 cm (96”).

Page 38

6

0 cm

2.5 cm

0cm

Requisitos para la instalación

7,6 cm

244 cm

(96”)

max.

61 cm

(24”)

min.

NOTA

La longitud de la manguera de desagüe

es 150 cm (59”). Para instalaciones que

requieran una manguera de desagüe

más larga, utilice la manguera pieza nº

137098000, disponible en un distribuidor

autorizado de piezas.

Requisitos de holgura

IMPORTANTE

NO INSTALE SU LAVADORA:

1. En un área expuesta a goteo de agua

o a las condiciones atmosféricas del

exterior.

2. En un lugar donde se almacene

oguarde gasolina u otros productos

inflamables. Si la lavadora se instala en

un garaje, debe estar a un mínimo de

45,7 cm (18 pulgadas) sobre el suelo.

3. Sobre moquetas o alfombras.

Elsuelo TIENE QUE ser sólido con

unapendiente máxima de 2,5cm

(1pulgada). Para minimizar la

vibración o movimiento puede

sernecesario reforzar el suelo.

HOLGURAS MÍNIMAS PARA LA

INSTALACIÓN- Pulgadas (cm)

LADOS

Hueco 0 cm (0”) 0 cm (0”) 0 cm (0”) n/d

Debajo

deen-

0 cm (0”) 0 cm (0”) 0 cm (0”) n/d

cimera

Armario 0 cm (0”) 0 cm (0”) 0 cm (0”) 2,5 cm (1”)

(0”)

7,6 cm

puerta de armario

POSTE-

RIOR

(3”)

(3”)

SUPE-

RIOR

387,1 cm²

(60 sq. in.)

387,1 cm²

(60 sq. in.)

FRONTAL

0 cm

(0”)

Instalación en nicho o armario

Si en el mismo armario se instala la

lavadora y una secadora es necesario

que la puerta disponga de ventilación. Se

precisa una abertura mínima de 774,2 cm²

(120 pulgadas cuadradas), dividida por igual

en la parte superior e inferior de la puerta.

Las aberturas de listones estarán situadas

a 7,6 cm (3pulgadas) de las partes inferior

y superior de la puerta. Si se instala una

puerta, deberá tener aberturas de aire sin

obstrucciones. Es aceptable una puerta de

listones con aberturas de aire equivalentes

para toda la longitud de la puerta.

(1”)

(0")

Page 39

Requisitos para la instalación

la parte trasera

centro de

línea del

conducto

de ventilación

Dimensiones de la lavadora

136 cm (53,5”)*

para puerta abierta

freestand washer

on floor

línea de suelo

lavadora

montada sobre el

pedestal opcional

línea de suelo

136 cm (53,5”)*

para puerta abierta

kit de apilado

homologado

(STACKIT7X)

requerido para

la instalación

apilada

81,25 cm (32”)*

para puerta cerrada

81,25 cm (32”)*

para puerta cerrada

Suministro de

agua conexión

en la parte

trasera

de la unidad

tubo de desagüe

en la parte trasera

de la unidad

Suministro

de agua

conexión en la

parte trasera

de la unidad

suministro

de gas tubería

en la parte

trasera de la

unidad de gas

192,5 cm

(75,75”)

3

68.5 cm

(27,0”)

cable de