Page 1

Electrolux air-o-convect Bakery

Gas Convection 5x(400x600)

Electrolux air-o-convect Bakery blends tradition with the latest technological research in order to satisfy the

creativity and working requirements of today's professional kitchen. The air-o-convect Bakery range offers a

choice of different models, providing a high degree of automation and an extensive range of accessories. The

air-o-convect Bakery convection ovens with direct steam are designed to form complete cook&chill systems

together with air-o-chill blast chillers/freezers, therefore, any installation can be tailored to meet the needs of

the caterer.

The air-o-convect Bakery oven detailed in this sheet is a gas 5x(400x600) tray-capacity model, specifically

designed to suit the needs of the bakery and pastry-making working environment.

OPERATING MODES

• Convection cycle (max. 300 ºC)

with automatic moistener (11

settings): 0 no additional moisture

(browning and gratinating); 1-2 low

moisture (stewed vegetables); 3-4

medium-low moisture (au gratin

vegetables, roasted meat and

fish); 5-6 medium moisture (all

small portions of meat and fish);

7-8 medium-high moisture (large

pieces of red meat); 9-10 high

moisture (large pieces of white

meat, baking and pre-cooked food

regeneration).

• air-o-convect Bakery ovens can

cook by controlling either the

cooking time or the product's core

temperature through a

single-sensor probe.

• Fan speeds: full, half speed and

pulse (pulse ventilation for baking

and low temperature cooking). The

pulse function is also perfect for

keeping food warm at the end of

the cooking cycle and for low

temperature cooking of large

pieces of meat.

• Exhaust valve electronically

controlled to extract excess

humidity.

• air-o-clean: 4 different pre-set

cycles to clean the cooking cell,

according to the actual

requirements. The cleaning

system is built-in (no need for

add-ons). Semi-automatic

cleaning cycle also available.

• Quick cooling: useful when

passing to a type of cooking that

requires a lower temperature than

the previous one. It works

automatically and manually.

• Manual injection of water in the

cell.

PERFORMANCE

• air-o-flow: blows fresh air from

outside through the bi-functional

fan, which pulls the air in from the

backside of the oven after it is

pre-heated, thus guaranteeing an

even cooking process.

• Single-sensor food probe.

• NXT cell gas burner: GASTEC

certification on high efficiency and

low emissions. High efficiency cell

heat exchanger.

Page 2

Electrolux air-o-convect Bakery

Gas Convection 5x(400x600)

CONSTRUCTION

• Stainless steel 304 throughout,

with seamless joints in the cooking

cell.

• Fixed internal structure designed

to accommodate 400x600 mm

trays.

• Double thermo-glazed door

equipped with drip pans to catch

condensate and prevent slippery

floor for maximum security and

four holding positions allowing

easier loading and unloading.

• Halogen lighting in the cooking

cell.

• Access to main components

from the front panel.

• IPX5 water protection.

• air-o-convect Bakery ovens

meet GASTEC safety

requirements.

AOS061GCY2

269790

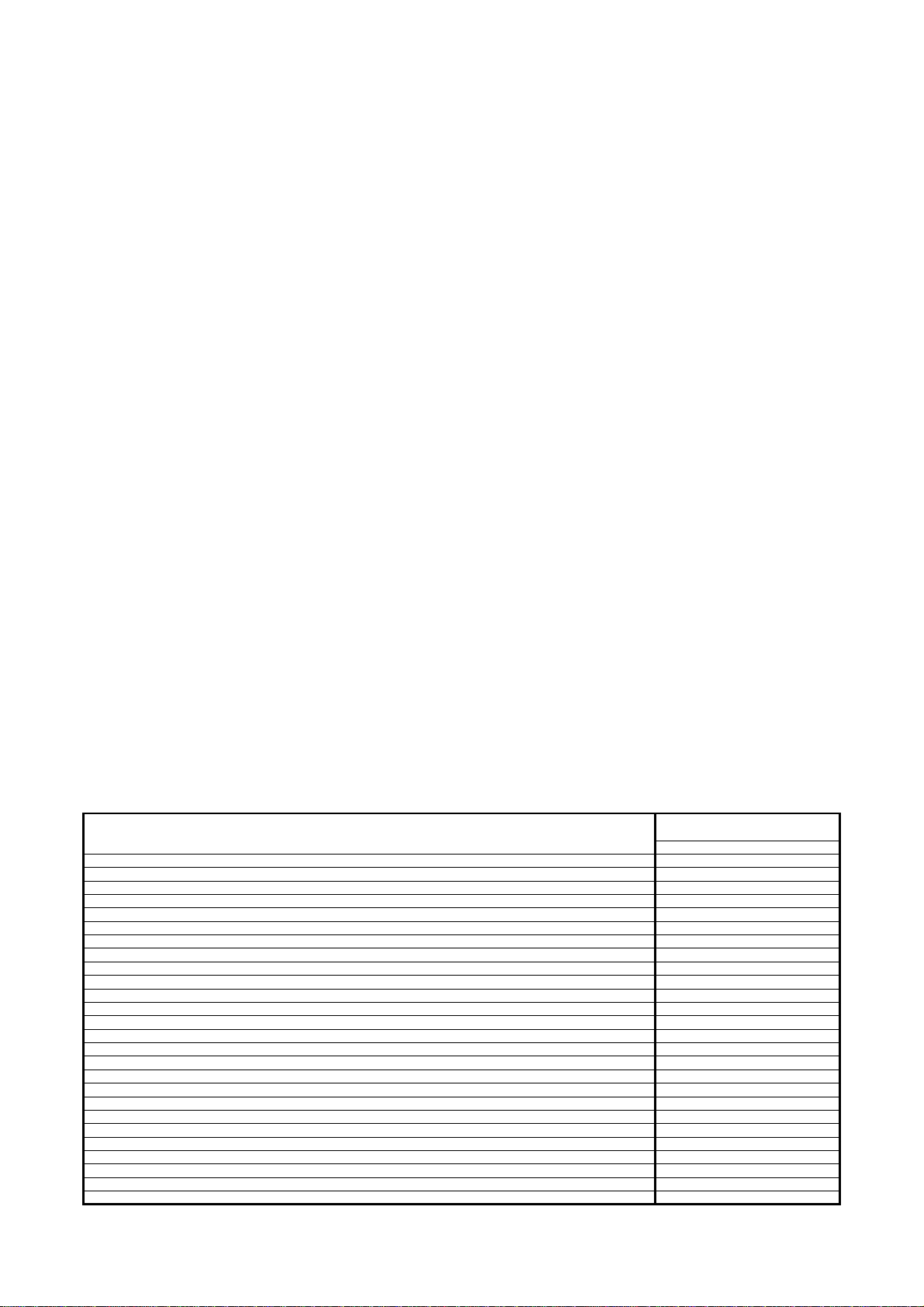

TECHNICAL DATA

Power supply Gas

Gas Natural Gas

Type A - 6 GRIDS

Number of grids 5

Runners pitch - mm 80

Cooking cycles - °C

air-convection 300

Convection ●

Meat probe ●

Automatic cleaning system ●

External dimensions - mm

width 898

depth 915

height 808

Internal dimensions - mm

width 460

depth 715

height 486

Power - kW

auxiliary 0.25

electric 0.25

cooking chamber 10

gas 10

auxiliary 0.25

Net weight - kg. 123

Supply voltage 230 V, 1N, 50/60

EBB00602011-05-16Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Page 3

Electrolux air-o-convect Bakery

Gas Convection 5x(400x600)

AOS061GCY2

269790

INCLUDED ACCESSORIES

PASTRY 5X(400X600)RACK+WHEELS-80MM,6X1/1 1

ACCESSORIES

1 GRID GN1/1 FOR 8 WHOLE CHICKENS(1.2KG) 922266

1 GRID GN1/2 FOR 4 WHOLE CHICKENS(1.2KG) 922086

2 FRYING BASKETS FOR OVENS 922239

2 GRIDS GN 1/1 FOR CHICKENS (8 PER GRID) 922036

AUTOMATIC WATER SOFTENER FOR OVENS 921305

BAKING TRAY(400X600X20)4 EDGES-ALUMINIUM 922191

BAKING TRAY(400X600X20)4 EDGES-PERF.ALUM 922190

BASE SUPPORT FOR 6 GN 1/1 LW WITH HOOD 922087

BASKET FOR DETERGENT TANK-WALL MOUNTED 922209

CONTROL PANEL FILTER-6&10 GN1/1 OVENS-LW 922246

CUPB. BASE+TRAY SUPP-6&10 GN1/1 OVENS LW 922096

CUPB. BASE+TRAY SUPP-6&10 GN1/1 OVENS LW 922223

DOUBLE-CLICK CLOSING CATCH FOR OVEN DOOR 922265

DRAIN KIT (D=50MM) OVENS 6&10 GN 1/1-2/1 922283

EXHAUST HOOD WITH FAN FOR 6&10 GN1/1-LW 640792

EXHAUST HOOD WITHOUT FAN F. 6&10GN1/1-LW 640791

EXTERNAL CONN. KIT FOR DETERG./RINSE AID 922169

EXTERNAL SIDE SPRAY UNIT 922171

FAT FILTER FOR OVEN 6 GN 922177

FLUE CONDENSER FOR GAS OVENS-LW 922235

FRYING GRIDDLE GN 1/1 FOR OVENS 922215

FRYING GRIDDLE GN 2/3 FOR OVENS 922284

GREASE COLLECTION KIT (TRAY+TROLLEY) 922287

HEAT SHIELD FOR 6 GN 1/1 OVENS 922250

HEAT SHIELD FOR STACKED OVEN 6GN ON 10GN 922245

HEAT SHIELD FOR STACKED OVENS 6GN ON 6GN 922244

HOLDER FOR DETERGENT TANK ON OPEN BASE 922212

HOT CUPB.+TRAY SUPP-6&10 GN1/1+(400X600) 922224

HOT CUPB.+TRAY SUPP-6&10 GN1/1+(400X600) 922227

KIT 4 ADJUSTABLE FEET 922012

KIT HACCP EKIS 922166

KIT INTEGRATED HACCP FOR OVENS 922275

KIT TO CONVERT FROM NATURAL GAS TO LPG 922277

NON-STICK U-PAN GN 1/1 H=20 MM 922090

NON-STICK U-PAN GN 1/1 H=40 MM 922091

NON-STICK U-PAN GN 1/1 H=65 MM 922092

NON-STICK U-PAN GN 2/3 H=20 MM 922285

OPEN BASE+TRAY SUPPORT 6&10X1/1GN LW 922195

OVEN GRILL (ALUMINIUM) GN 1/1 922289

PAIR OF 1/1GN AISI 304 S/S GRIDS 922017

PASTRY 5X(400X600)RACK+WHEELS-80MM,6X1/1 922065

PASTRY RUNNERS (400X600) 6&10GN1/1 BASES 922286

RESIN SANITIZER FOR WATER SOFTENER 921306

SLIDE-IN RACK+HANDLE FOR 6&10 GN1/1-LW 922074

STACKING KIT-GAS 6X1/1 ON GAS 6&10X1/1 922216

TRAY RACK+WHEELS 5X1/1 GN, 80MM PITCH 922008

TRAY RACK+WHEELS 6X1/1GN, 65MM PITCH 922005

TRAY SUPPORT FOR 6&10 GN1/1 OVEN BASES 922021

TRAY(400X600X38)5 ROWS-PERF.ALUM/SILICON 922189

TROLLEY FOR SLIDE-IN RACK 6&10X1/1GN 922004

WATER FILTER FOR OVENS 0.8 L/MIN. 922186

WHEEL KIT FOR BASE OF 6&10X1/1 LW 922003

EBB00602011-05-16Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Page 4

269790

Electrolux air-o-convect Bakery

Gas Convection 5x(400x600)

AOS061GCY2

269790

LEGEND

CWI - Cold water inlet 3/4"

D - Water drain 1"1/4

EI - Electrical connection 230 V, 1N, 50/60

G - Gas connection 1/2"

WIC - Cooling water inlet 3/4"

EBB00602011-05-16Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Loading...

Loading...