Page 1

© Electrolux

Muggenhofer Straße 135

D-90429 Nürnberg

Germany

Fax +49 (0)911 323 1022

Spares Operation

Publ.-Nr.:

599 518 355 EN

10.2003

DGS-TDS-N - R.Kurzke

Ausgabe:

SERVICE MANUAL

Compact front loaded

Washing Machines

(Timer controlled)

Compact front loaded

Washing Mashines

from Torsvik

Timer controlled

Page 2

- 2 -

10.2003 R.K. 599 518 355

Table of Contents

General features 3

Programs 4

Timer function 5

Operation principle 6

Types of Spin 7

Construction

Enclosure 9

Upperframe 9

Lowerframe 9

Rear of machine 10

Front panel 11

Detergent dispenser 11

Front hatch 12

Hatch locking switch 12

Washing unit with outer drum 13

Function

Monitoring of spin phase for imbalance 14

Water supply valve 15

Level regulator 15

Heating element 16

NTC-Thermistor 16

Drainage pump 17

Service/Accessibility

Top plate 18

Panel 19

Hatch 20

Hatch hinge 21

Rear ot machine 22

Drum unit 23

Shockabsorbers 23

Outer drum with drum bearing 24

Troubleshootings 25

Motor check 27

Diagrams 28

Washing programs table 30

Timer diagram 31

Timer connectors 32

Page 3

- 3 -

10.2003 R.K. 599 518 355

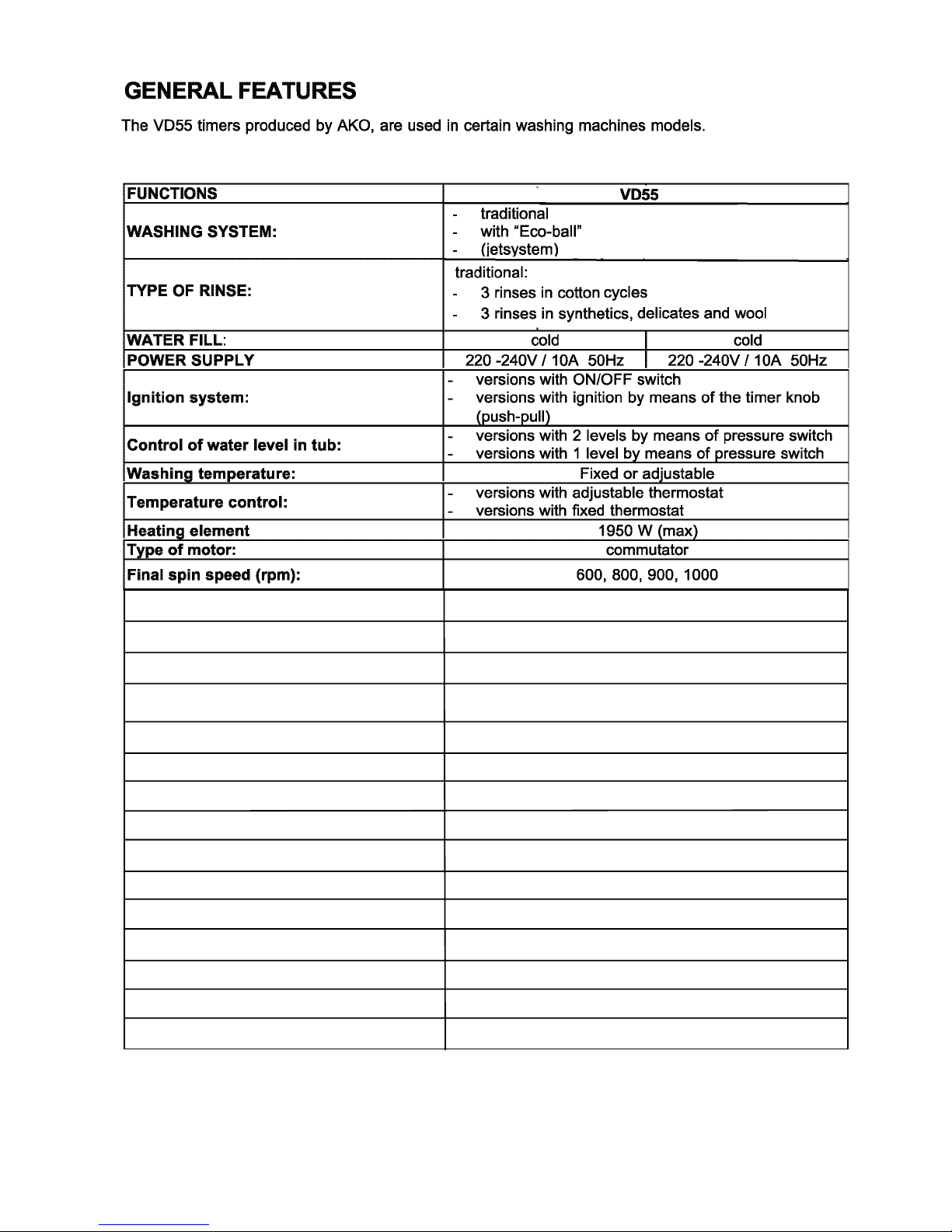

Controls

Timer type VD55

Push button functions On/off, Rinse hold

Knob/Command func. Program, Temperature

Dimensions

Height 670 mm

Width 495 mm

Depth 515 mm

Tub material Carboran

Drum volume 27 l

Washing capacity 3.00 kg

Inlet hose length 130 cm

Outlet hose length 160 cm

Det. dispenser type of Two chambers

Cord length 170 cm

Page 4

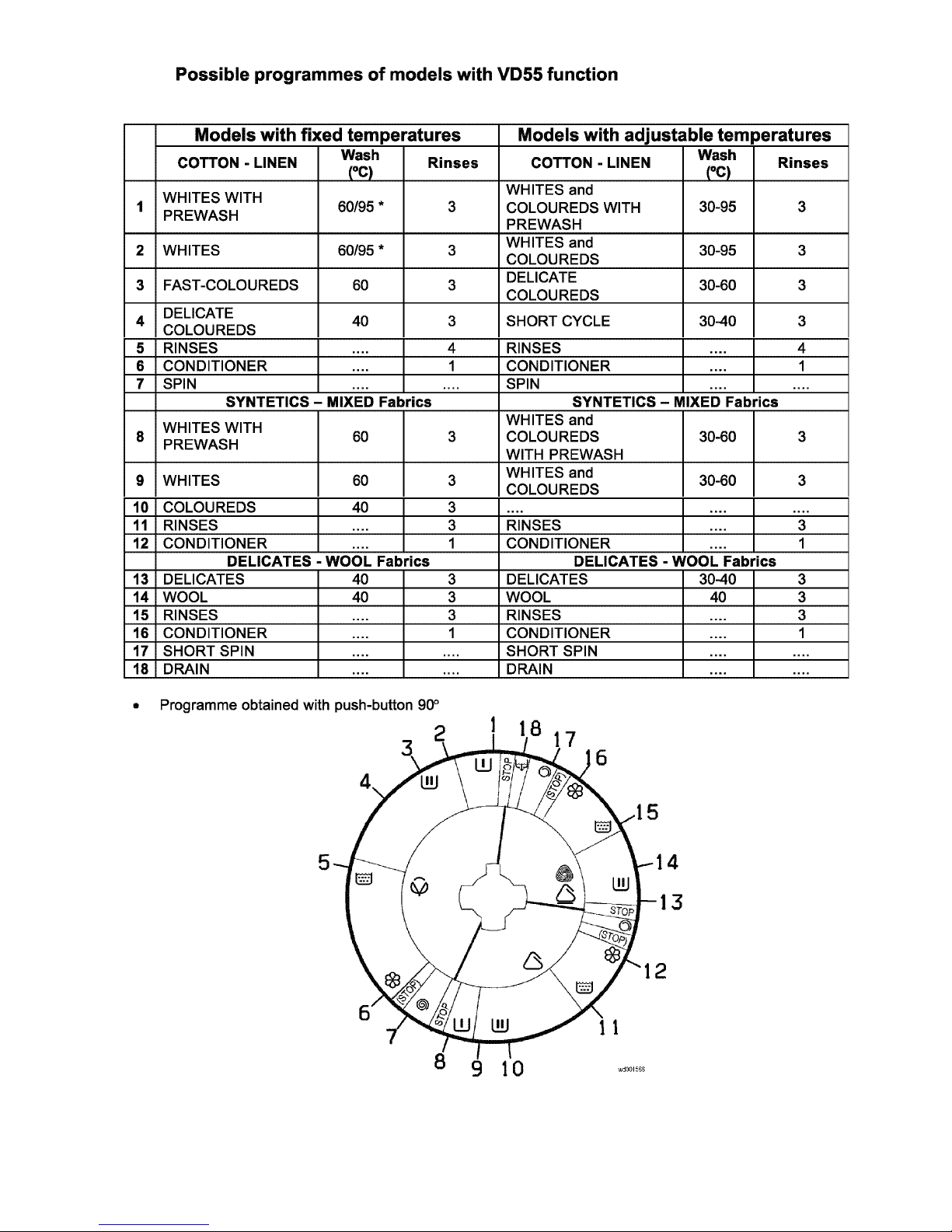

- 4 -

10.2003 R.K. 599 518 355

Page 5

- 5 -

10.2003 R.K. 599 518 355

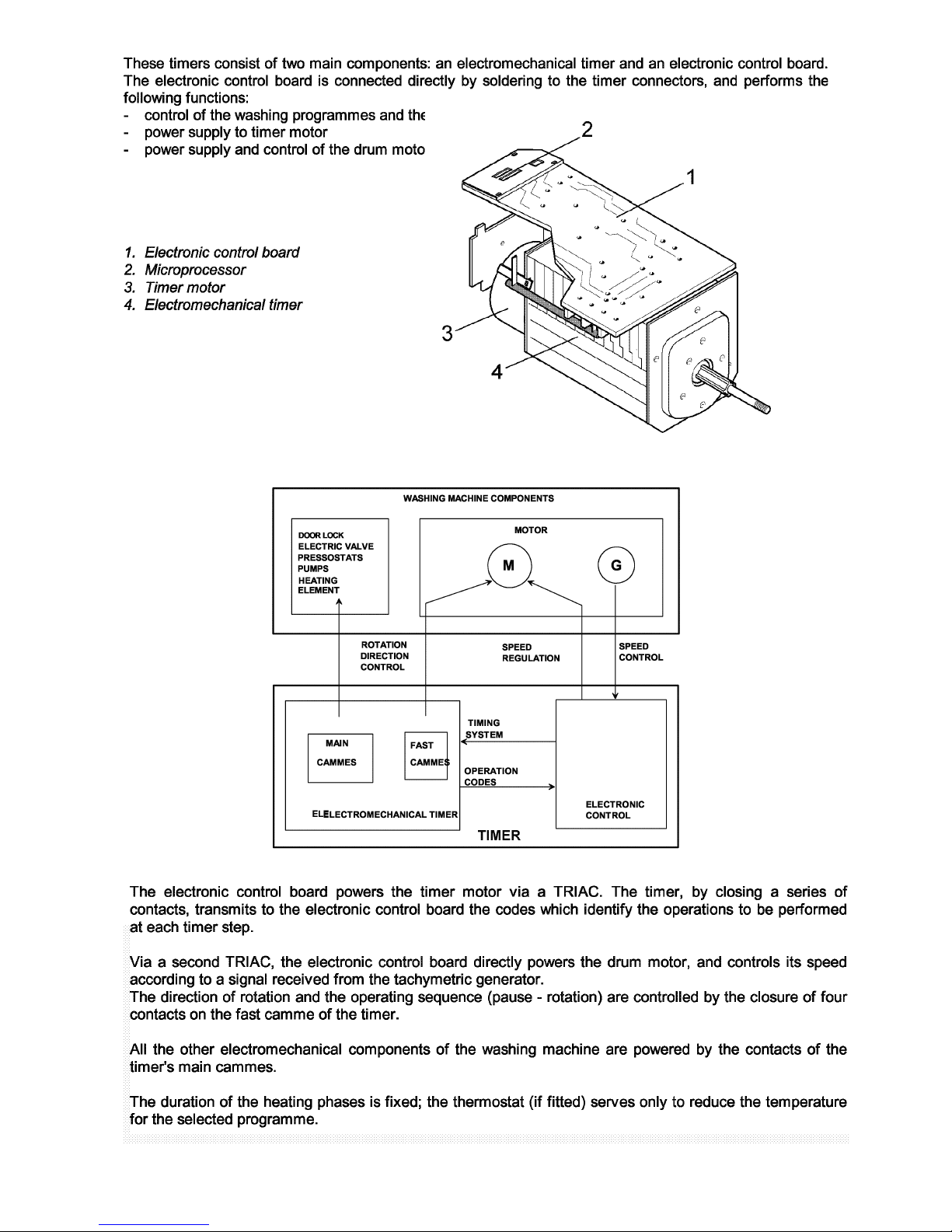

Page 6

- 6 -

10.2003 R.K. 599 518 355

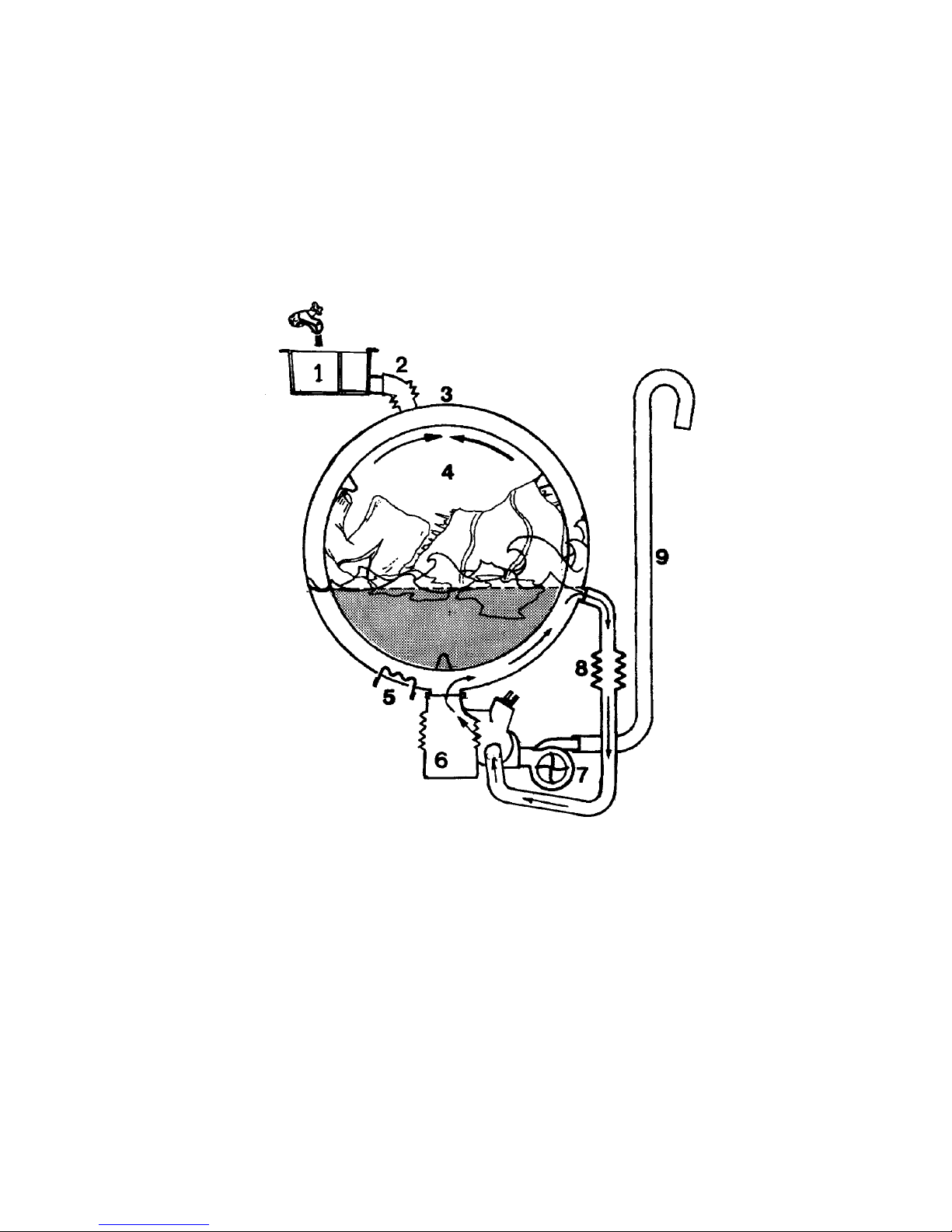

5 Heating element

6 Rubber bottom, fixed to outer drum

7 Drainage pump

8 Circulation hose

9 Drainage hose

OPERATION PRINCIPLE

Traditional washing Operation

1 Detergent hatch

2 Hose between detergent dispenser and outer drum

3 Outer drum

4 Inner drum

- The partides of soiling substances which are freed from the textile fibres by the chemical action of the detergent

at the temperature of the washing water are re-moved by the flow of water through the fibres.

- The reversing rotation ofthe drum causes mechamcal interaction between the parts ofthe load and the

detergent solution which separates the partides from the textlies.

- The water level is at such a height that the load is successively lifted from the solution by the ridges formed

in the inner drum and then falls back into the solution.

- The Circulation ofthe solution during the rotation ofthe drum prevents the accumulation of detergent in the

rubber bottom.

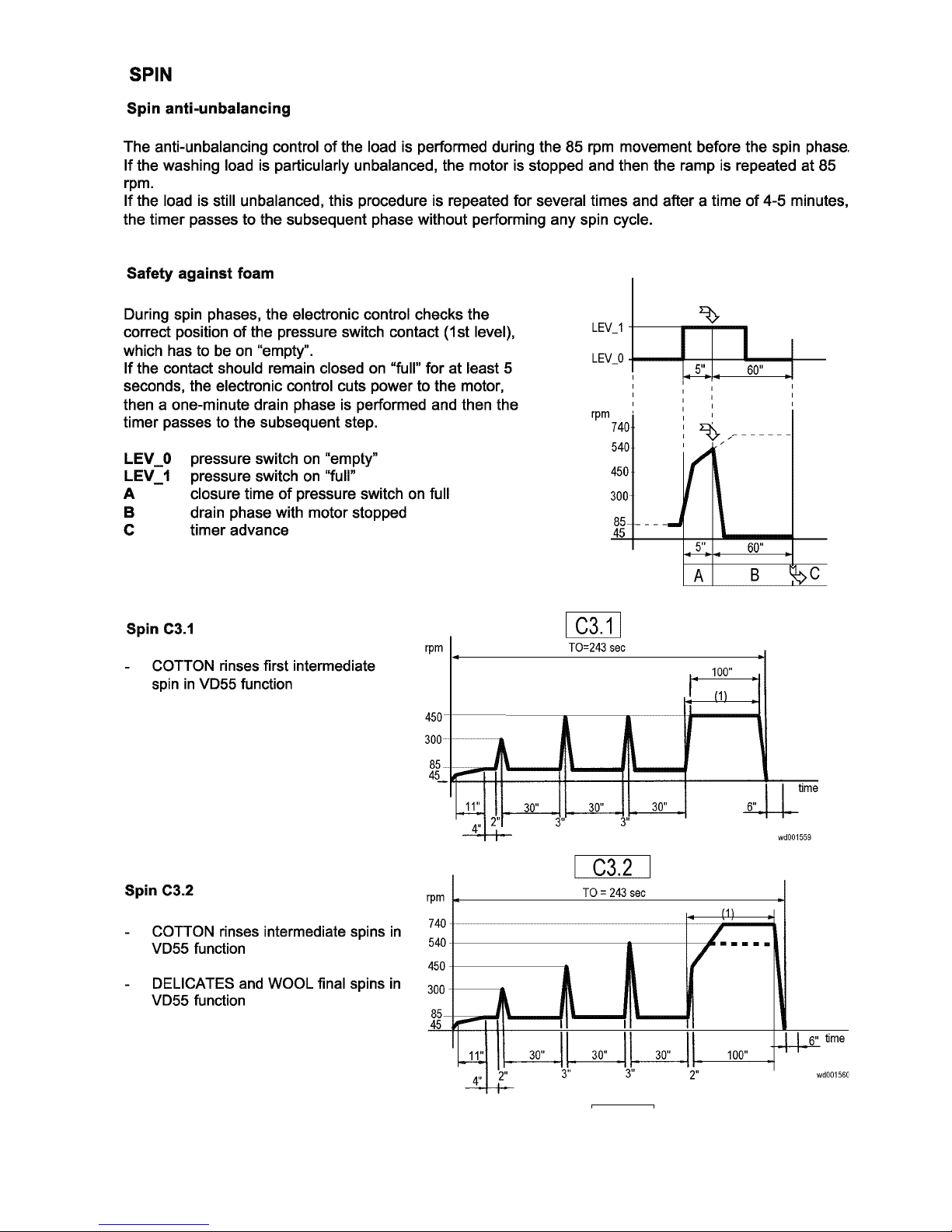

Page 7

- 7 -

10.2003 R.K. 599 518 355

Page 8

- 8 -

10.2003 R.K. 599 518 355

Page 9

- 9 -

10.2003 R.K. 599 518 355

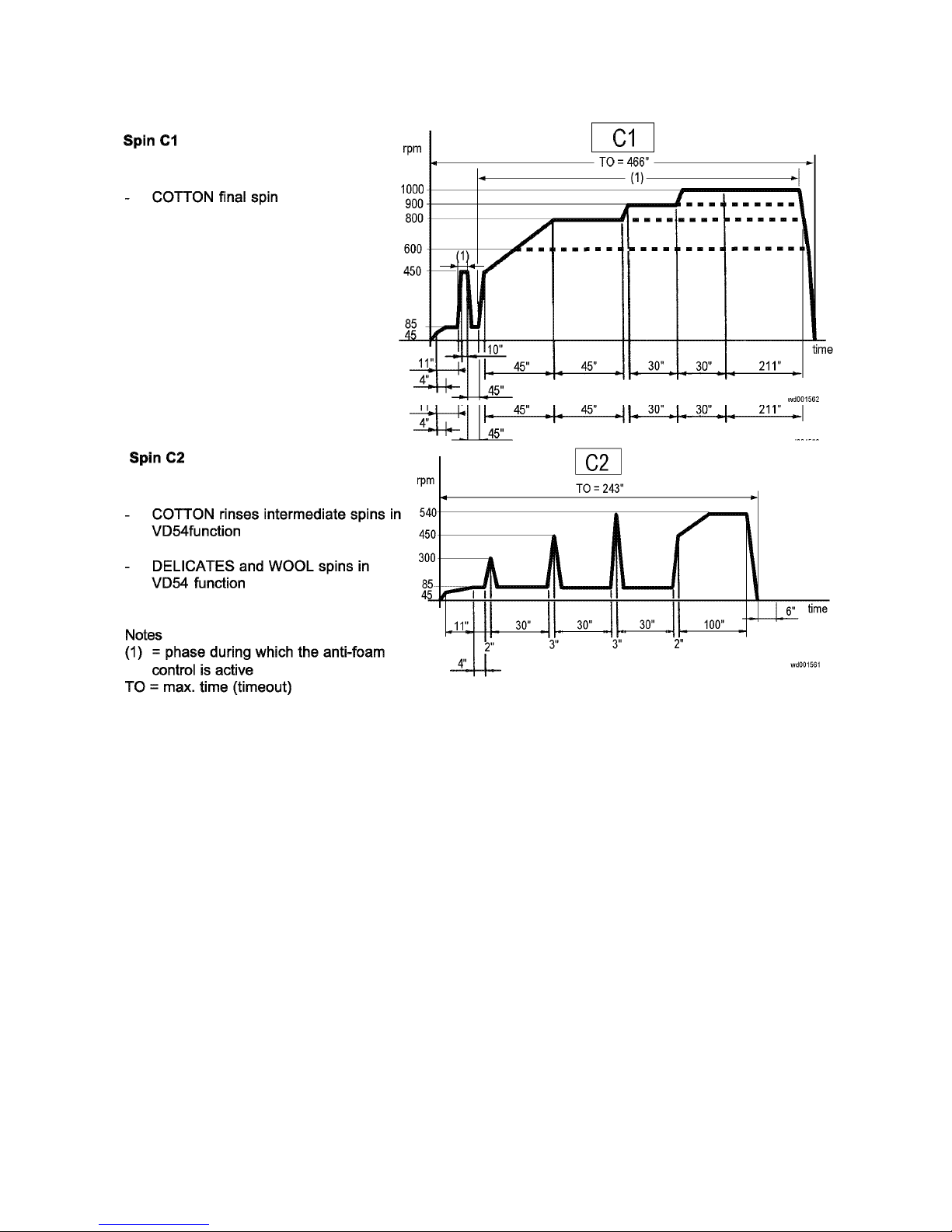

CONSTRUCTION

Enclosure

The enclosure consists of: - a lacquered steel sheet

pressing forming the front and both sides, fixed

between upper and lower CARBORAN frames

- a removabie galvanized sheet steel back plate

- a top of lacquered steel sheet, fixed to the rear of

the upper GARBORAhOframe.

1 Top, lacquered steel sheet

2 Upper frame, CARBORAN

3 Back plate,

4 Front and sides, lacquered steel sheet

5 Lower frame, CARBORAN

Upper frame

1. Upper frame of CARBORAN®

2. Interference suppressor

4. Spring, drum suspension

5. Level regulator, level 1

level 2, and

anti-foam function

6. Level regulator, overflow protection

7. Water supply valve

Lower Frame

1. Lower frame, of CARBORANO

2. Shock absorber, fixed to frame with plastic pin

3. Electronics unit

4. Drainage pump, inserted in track and locked to

lower frame with plastic snap fixing

5. Plastic protection for drainage pump

6. Drainage hose, fixed with two plastic clamps

7. Adjustable rear foot with lock nut

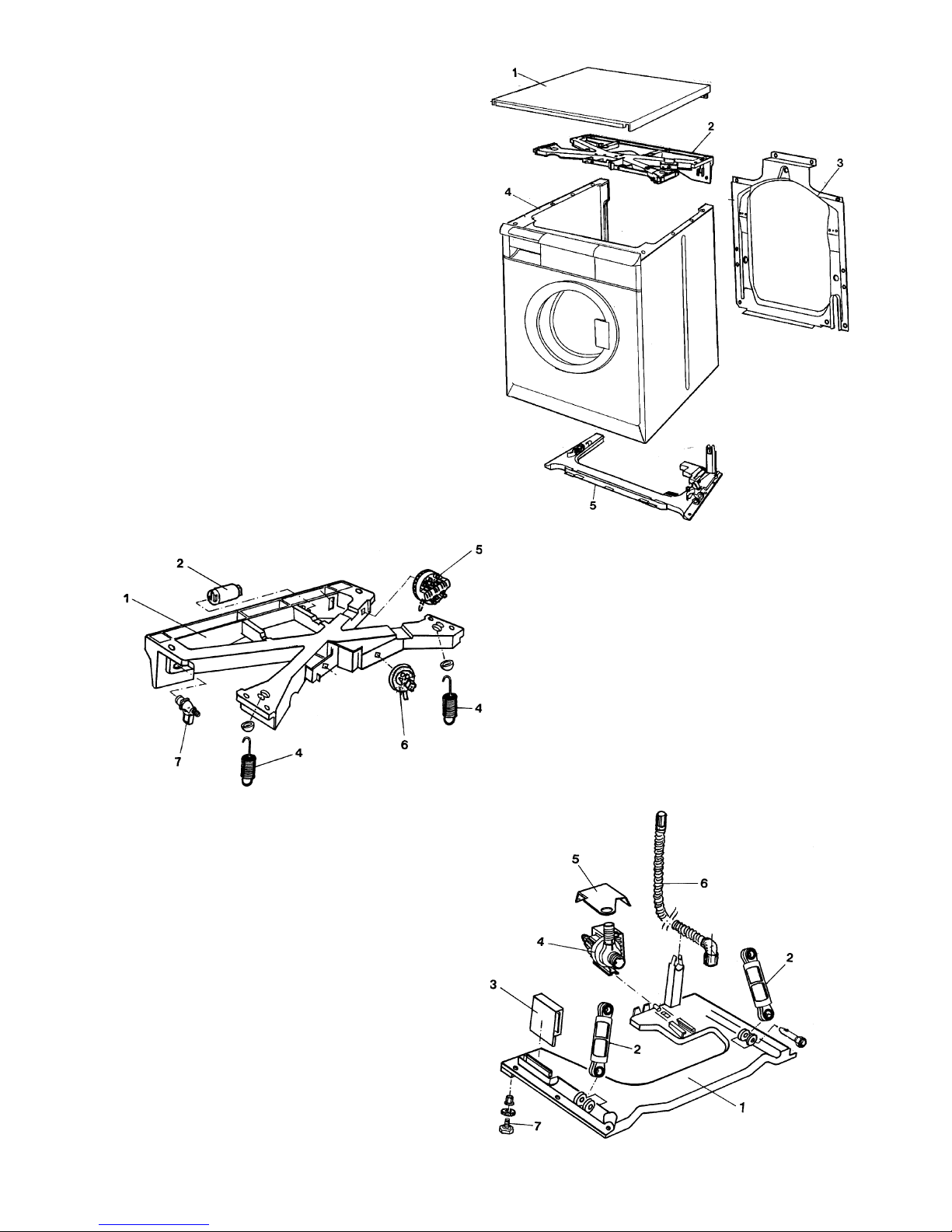

Page 10

- 10 -

10.2003 R.K. 599 518 355

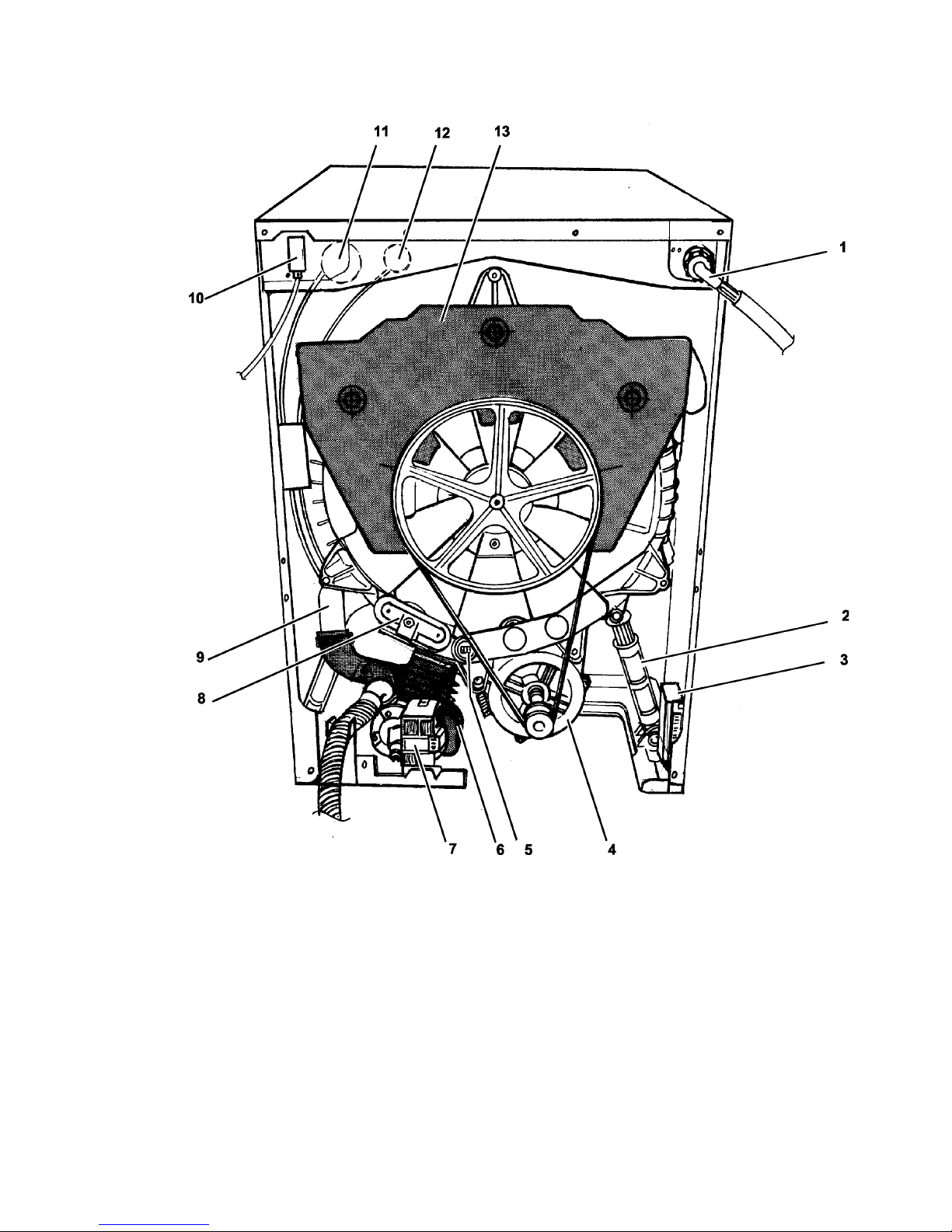

1 Water supply hose

2 Shock absorber

3 Electronics unit 4 Motor

5 Temperature sensor, NTC thermistor

6 Rubber bottom with "pin trap" (filter not provided)

7 Drainage pump

8 Heating element, 1600 W.

9 Pressure chamber

10 Connection terminal block

11 Level regulator, level and anti-foam function

12 Level regulator, overflow protection

13 Rear counterweight

Rear of machine

Page 11

- 11 -

10.2003 R.K. 599 518 355

Front panel

1 Front panel

2 Program scale

3 Temperature scale

4 Knob

5 Detergent hatch/dispenser

6 Fixing screw, (behind detergent hatch)

7 Lamp lens

8 Pilot lamp

9 Fixing screw, (Under top plate)

11 Fixing screw for panel

Detergent dispenser

Water enters through the rear nozzle (6) and then through the water distributor to the detergent dispenser. Water is

directed to the detergent dispenser section in accord-ance with the position ofthe program-controlled cam-guided finger,

washing the detergent/rinsing agent it contams down into the drum.

1 Detergent hatch

2 Detergent dispenser with internal water distributor

3 Linkage arm

4 Water distributor cam, program-controlled

5 Programmed Controller

6 Nozzle, water supply

7 Link System pivot

8 Cam-guided finger

Page 12

- 12 -

10.2003 R.K. 599 518 355

Front hatch

The hatch is locked during washing by a bimetallic

electric hatch lock and is opened by depressmg the

hatch lock pad. When the hatch is closed and the

On/Off button is pressed, a Signal lamp Illuminates

after approximately 5 seconds, the hatch 1s locked

electrically and the selected washing cycle Starts.

When the program has been exe-cuted, the lamp

extinguishes after 45-120 seconds and the hatch

can be reopened.

1 External hatch frame

2 Hatch lock pad

3 Hatch glass

4 Internal hatch frame

5 Hatch hinge

6 Electrical hatch lock

7 Locklever

8 Splash protection

9 Supporting beam

Hatch locking switch

The security of the hatch is ensured by an electromagnetlc lock

with function äs described below.

when the lock is activated, the voltage-sensing unit closes

the switch which con-nects voltage to the electrical

components of the machine.

During operations, the slide (A) remains mechanically

locked and thereby prevents opening of the hatch by fixing

the hatch lock lever

When the hatch lock has been deactivated, It remains

locked for approximately 45-120 seconds to ensure that

the drum is statlonary before the hatch is opened.

ELECTRICAL DIAGRAM

1 Lock lever (in hatch)

2 Slide

3 PTC resistor

4 Switch activated by the PTC resistor

Page 13

- 13 -

10.2003 R.K. 599 518 355

Washing unit with outer drum of CARBORAN®

1 Ring for fixing bellows to enclosure

2 Bellows

3 Screw, front counterweight

4 Front counterweight

5 Screw, front/rear outer drum

6 Ring for fixing bellows

7 Front section of outer drum, CARBORAN®

8 Packing

9 Inner drum, stamless steel

10 Rear section of outer drum, CARBORAN®

11 Drum shaft sealing ring

12 Inner ball bearing

13 Outer ball beanng

14 Rear counterweight

15 Pulley wheel

The outer drum consists of two sections of

CARBORAN® fixed together with a number

ofthread-cutting screws. The two counterweights

are screwed to the sections.

Page 14

- 14 -

10.2003 R.K. 599 518 355

Programmed control unit

Imbalance control, function

A check for imbalance of the load 1s performed during 15 seconds at 85 rev/min. before the spin phase.

- If imbalance is detected, the tachometer generator and the motor current give an irregulär Signal

to the micro-processor on the electronics board which then Interrupts the spin phase. The

machine then returns to 55 rev/mm.. rotation and re-distributes the load to achieve balance

before performing a new check at 85 rev/min..

- If imbalance persists, redlstribution of the load is repeated for a period of 10 minutes (16

attempts) or until balance is achleved.

- If no balance is obtained after 10 minutes, the program continues forward with-outspln.

- When balance is obtained, the program continues with spin atthe speed speci-fied.

Monrtoring of spin phase for imbalance

This sequence is repeated while the

load remains unbalanced...

...a total of 16 times (10 minutes) or until

balance is achieved. if balance is not obtained,

the spin is omitted from the program.

Page 15

- 15 -

10.2003 R.K. 599 518 355

Water supply valve

General characteristics

This electro-magnetic controlled valve regulates the supply of water

to the machine via the water distributor in the detergent distributor.

It 1s actuated by a solenold which is controlled electrically bythe

programmed Controller via the level regulator.

When the valve Is inactive, (without voltage) the spring holds the

splndle down and the rubber cone seals a small hole at the centre

of the membrane. A head of water bullds up which holds the

membrane against Its seating and closes the valve.

When voltage 1s applled to the solenold, the splndle with the rubber

cone is drawn up-ward against the spring and the hole in the

membrane 1s exposed, permitting the passage of water. The

pressure differential 1s lost and water can flow freely through the

valve.

1 Water entry

2 Valve housing

3 Filter

4 Flow regulator

5 Coil

6 Spring

7 Spindle

8 Rubber cone

9 Membrane 10 Water delivery

Level regulator

General characteristics

The level regulator momtors the level of the water in the

machlne and

adapts the water level to that required at different stages

ofthe washing sequence selected.

acts äs a low-water safety device äs It is connected in

series with the heating ele-ment. It disconnects the

voltage to the element when the water falls below a

certaln level.

acts äs an anti-foam protection by sending a Signal to

the electromcs which Interrupts the spln phase and

restarts this when the foam has subsided. (VE 60 and

V 60 program med Controllers).

Page 16

- 16 -

10.2003 R.K. 599 518 355

Heating Element

General characteristics

The element for heating the water is of the

encapsulated type, i.e. the spiral resistor is

hermetically sealed in a stainless steel enclosure.

Power 1600 W

Resistance 230 V 31.2 - 34.3 Ohm

240 V 33.9 - 37.4 Ohm

1 Element

2 Rubber packing

3 Fixed f lange

4 Electrical connection pin

5 Locking nut

6 Adjustable f lange

7 Fuse

The seal between the element and the outer drum is

obtained with a rubber packing which expands when

the locking nut is tightened.

NTC-Thermistor (Temperature control)

Temperature control by means of NTC thermistors is incorporated in models

controlled by Programmed control units VA 60, VB 60 and VE 60.

NTC temperature sensors

1 Plastic housing

2 Metal capsule

3 NTC resistance

4 Electrical contacts

Table with resistance at different temperatures (3%)

Temperature °C Resistance kOhm

30 17.3

40 11.5

50 7.84

60 5.46

70 3.90

78 2.97

85 2.32

The temperature of the washing water is controlled by the microprocessor via an NTC sensor.

The internal resistance ofthe sensor decreases äs the temperature increases. This decrease is registered by the

microprocessor which disconnects the heating element when the required temperature has been reached.

With a short-circult or other failure in the NTC thermistor, the control unit cancels the heating stage and completes the

program without heating.

Page 17

- 17 -

10.2003 R.K. 599 518 355

Drainage pump

1 Impeller

2 Rotor

3 Stator

4 Pump housing

5 0-ring

The rotor consists of a permanent magnet which can rotate clockwise or anti clock-wise. The rotor can

rotate one quarter revolution without movement ofthe impeller.

Ifthe impeller seizes, the rotor can therefore make small movements in both directions until the impeller

is freed. An unusual sound may be heard at Start which is quite normal.

Function check

1 Check that the impeller can move freely.

2 Check the resistance of the Stator winding. This should be 170 Ohm.

Max. capacity = 20 l/mm.

Power consumptlon = 30 W

Page 18

- 18 -

10.2003 R.K. 599 518 355

SERVICE/ACCESSIBILITY

Top plate

1 Remove the 4 screws (A) at the rear edge of the

plate.

2 Draw the top plate backward

Accessibility:

A Supply valve

B Level regulator, level and anti-foam C Level

regulator, overflow protection D Capacitor/

Interference suppressor

Page 19

- 19 -

10.2003 R.K. 599 518 355

Panel

1 Remove the top plate

2 Remove the 2 screws (9).

3 Remove the knob (4).

Unlock the holding catch

by msertmg a fine screwdriver

(or equivalent) straight through

the hole, rotating the knob

anti clockwise at the same

time until the knob can

be removed.

4 Remove the temperature

scale (3) by llfting the lock

on the plastlc shaft and

with-drawing the scale.

5 Remove the program scale after

removmg the nut.

Remove the screw behlnd the

program scale.

6 Remove the detergent hatch (5) by jerking iIt past a stop.

Remove the screw (6) inside the hatch.

7 Remove the screw (10) to free the detergent dispenser and llft the panel away

from the front edge of the detergent hatch.

Accessibility:

A Programmed control unit

B Press-operated switch

C Potentiometer, temperature setting

(Not provided on all modeis)

Page 20

- 20 -

10.2003 R.K. 599 518 355

Hatch

Removal:

1 Remove the two screws (A) holding the hatch to Its hinge.

2 The outer hatch frame is snapped over the outer edge ofthe

inner hatch frame. Carefully lever the frames apart and

remove the outer frame.

3 The opening pad with springs, fixed to the inner frame

with 2 screws Is now accessible.

4 The hatch glass Is fixed in the inner frame with 4 plastic projections.

Bend these open to permit removal ofthe glass.

Re-assembly:

1 Place the glass agalnst the inner hatch frame. Check that the 2 projections (B) on the edge of the glass are in

llne with the corresponding spaces In the Inner frame and press Into positlon past the plastic projections.

2 Place the outer hatch frame agalnst the inner frame and press together.

Hatch lock fixed to the Inner hatch

Page 21

- 21 -

10.2003 R.K. 599 518 355

Hatch hinge

1 Remove the hatch from the hinge. (Screws A)

2 Remove the locking ring around the outer part of

the bellows and remove the bellows.

3 Press the bellows Inward toward the drum

to permit passage ofthe hinge.

4 Remove the two screws (B) fixing the hinge.

Note the locking nuts on the inside.

5 To simplify Installation of a new hinge, the Internal

beam supporting the hinge Is also to be be removed.

Lean the machlne backward and remove the

screw (C) fixing the beam to the bottom edge

of the front (under the machlne).

6 Then remove both hinge and beam.

Re-assembly:

7 To Install a new hinge, It Is simplest to fix the hinge

first agalnst the supporting beam by means of a pop-rivet

through the upper triangulär hole In the hinge and the hole

in the correspondmg place In the beam (D).

If no such hole Is avallable, mark the beam through the

triangulär hole and drill a hole f3.5 mm. Mountthe pop-rivet

with its head toward the hinge.

Note that the plastlc splash protection Is to be located

between the hinge and the supporting beam when

mounting the pop-rivet.

8 Then insert the hinge with supporting beam through the

hatch opening.

Fix with screws and locking nuts.

Refitthe beam in position against the bottom

edge of the front.

Pop-rivet 0 3,2 mm

Supporting.

beam

Plastic splash

protection

Hinge

Page 22

- 22 -

10.2003 R.K. 599 518 355

Rear of machine

1 Remove the 4 screws fixing the back plate to the top plate (1).

2 Remove the 11 screws around the edges of the back plate (2).

3 Remove the back plate.

Accessibility:

A Belt and pulley

The pulley is fixed to the drum axie with

a 5 mm hex.socket head screw.

B Electronic circuit board for speed control of motor

Disconnect the electrical contacts and press the

plastic snap fixing (under the machine ) to the

side and then lift out the electronics unit.

C Motor

This is fixed with 4 hex. socket head screws to

the outer drum. Use an 8 mm Allen key to remove

these screws.

D Removal of heating element

Disconnect the electrical contacts.

Remove the nut at the middle of the element

(that which expanded the pack-ing).

Then press the threaded section inward.

Withdraw the element from the outer drum.

E Temperature sensor, NTC thermistor

Disconnect the electrical contacts.

Carefully lever, using a screwdriver, the rubber bushing from the outer drum.

Remove the NTC thermistor from the rubber bushing.

F Removal of drainage pump

Slacken the hose clamps and remove the hoses from the pump.

Disconnect the electrical contacts and remove the plastic protection over the pump.

Push down the plastic projection (H) and withdraw the pump backward.

G Rubber bottom, (pin trap)

Slacken the clamps holding the hoses fixed to the rubber bottom.

H Rear counterweight

Remove the belt and pulley.

Remove the 3 screws fixing the counterweight to the outer drum.

Lift the counterweight away from the expander bolt fixmgs.

J Pressure chamber

Remove the hose clamp at the rubber bottom.

Remove the screw (8 mm socket) holding the pressure chamber to the outer drum.

Draw the Container backward and remove the hoses to the pressure (water level) switch.

Page 23

- 23 -

10.2003 R.K. 599 518 355

Drurn unit

(to be lifted out when replaeing inner drum, bearing or front counterweight).

1 Remove top plate and rear plate.

2 Remove the clamping ring around the hatch opening and then separate the bellows from the front.

3 Disconnect all of the electrical contacts from the drum unit (heating element, motor and temperature sensor).

4 Disconnect the drainage hose and the drainage pump from the rubber bottom (see page 33).

5 Disconnect the hoses between the detergent dispenser and the outer drum (at the drum).

6 Disconnect the air hoses at the level regulators.

7 The rear counterweight and the motor can be removed from the drum unit to simplify the lifting of the drum unit

out of the enclosure.

8 Remove the pressure chamber and the electronics unit to obtain access to the shock absorbers.

9 Disconnect the shock absorbers from the drum unit by removing the pin at the upper fixing.

10 Lay the machine on the floor, front downwards, making suitable arrangements to protect knobs, buttons etc.

against damage.

11 Disconnect the suspension springs from the upper part. This can be simplified by placing a wire loop under

the end of the spring and pulling on the loop with a "handle" - a screwdriver or similar.

12 Grip the pulley and lift the drum unit, (with back so straight as possible), off the chassis. lt is recommended

that two persons perform this operation.

Shock absorbers

The shock absorbers are installed between the lower frame and the drum unit and are held in positlon in the fixmgs with

pms.

Removal of shock absorbers:

Depress the lockmg catch by pushmg a pipe socket (A) over the end ofthe pin and the catch, (internal diameter of

socket (0 = 14 mm.).

Withdraw the pin from its fixmg with pliers.

The shock absorber can be removed when the upper and lower pins are removed.

Replacement:

As the original pms may be damaged during withdrawal,

new pms should be used.

Lubricate the pm with some type of alcohol.

The lubricant must evaporate after insertion of the

pins and grease may not be used.

Rotate and fully insert the pm from elther slde.

Check that the locking catches project and lock

the pins correctiy.

Page 24

- 24 -

10.2003 R.K. 599 518 355

Outer drum with drum bearing

The outer drum consists of two sections of CARBORAN with a sealing ring between, fixed together with a number

of thread-cutting screws (A).

When installing the sealing ring, the splice, marked with red, is to be located upward so that the red marking is

visible at the recess on the upper sides of the drum sections.

The bearing which carries the drum axle is installed

inside a cylindrical steel support embedded in the rear section

D Outer rear drum section

E Rear ball bearing (0 40 mm. type 6203-2Z).

F Front ball bearing (0 53 mm. type 6205-2Z).

G Drum axle seal

H Earth connection pin.

Front outer drum B lnner drum Rear outer drum

A

Page 25

- 25 -

10.2003 R.K. 599 518 355

Page 26

- 26 -

10.2003 R.K. 599 518 355

Page 27

- 27 -

10.2003 R.K. 599 518 355

Page 28

- 28 -

10.2003 R.K. 599 518 355

Page 29

- 29 -

10.2003 R.K. 599 518 355

Page 30

- 30 -

10.2003 R.K. 599 518 355

Programmes tables legend

* In models with one-level pressure switch, all

water fills are performed at the same level

P 1st level water fill time

´ Minutes

´´ Seconds

RA Rapid advance

TO Spin max. time (timeout)

Page 31

- 31 -

10.2003 R.K. 599 518 355

Page 32

- 32 -

10.2003 R.K. 599 518 355

Loading...

Loading...