Built-in Side by Side Refrigerator

May 2005

1

5995432258

SAFE SERVICING PRACTICES - ALL APPLIANCES

To avoid personal injury and/or property damage, it is important that Safe

Servicing Practices be observed. The following are some limited examples of safe

practices:

1. DO NOT attempt a product repair if you have any doubts as to your ability to

complete it in a safe and satisfactory manner.

2. Before servicing or moving an appliance:

• Remove the power cord from the electrical outlet, trip the circuit breaker to

the OFF position, or remove the fuse.

• Turn off the gas supply.

• Turn off the water supply.

3. Never interfere with the proper operation of any safety device.

4. USE ONLY REPLACEMENT PARTS CATALOGED FOR THIS APPLIANCE.

SUBSTITUTIONS MAY DEFEAT COMPLIANCE WITH SAFETY

STANDARDS SET FOR HOME APPLIANCES.

5. GROUNDING: The standard color coding for safety ground wires is GREEN,

or GREEN with YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is EXTREMELY important that the service technician

reestablish all safety grounds prior to completion of service. Failure to do so

will create a hazard.

6. Prior to returning the product to service, ensure that:

• All electrical connections are correct and secure

• All electrical leads are properly dressed and secured away from sharp

edges, high-temperature components, and moving parts

• All non-insulated electrical terminals, connectors, heaters, etc. are

adequately spaced away from all metal parts and panels

• All safety grounds (both internal and external) are correctly and securely

connected

• All panels are properly and securely reassembled

ATTENTION!!!

This service manual is intended for use by persons having electrical and mechnical

training and a level of knowledge of these subjects generally considered acceptable in the

appliance repair trade. Electrolux Home Products cannot be responsible, nor assume any

liability, for injury or damage of any kind arising from the use of this manual.

© 2001 White Consolidated Industries

25995432258

Table of Contents

3-Way Valve .................................................................................................................................40

Auger Motor .................................................................................................................................32

Casters and Leveling ....................................................................................................................26

Components ................................................................................................................................. 23

Component Locator Views ...........................................................................................................12

Component Resistance Values ...................................................................................................... 8

Compressor .................................................................................................................................. 39 - 61to 65

Control Features ............................................................................................................................10

Cube Motor and Cube Reed Switch ..............................................................................................32

Defrost Cycles ...............................................................................................................................43

Diagnostic Mode ...........................................................................................................................54

Dispenser Control Panel ................................................................................................................34

Dispenser Heater ...........................................................................................................................37

Dispenser Switch ...........................................................................................................................37

Doors ............................................................................................................................................ 23

Door Closer Assembly ...................................................................................................................25

Door Switches ............................................................................................................................... 41

Door Water Line Replacement .......................................................................................................38

Drain Pan ...................................................................................................................................... 26

Drier .............................................................................................................................................. 40

Duct Door Assembly ......................................................................................................................36

Evacuation and Charging Procedure ............................................................................................. 16

Fans .............................................................................................................................................. 44

Freezer Evaporator Assembly ....................................................................................................... 46

Freezer Evaporator Components .................................................................................................. 49

Freezer Heater Testing .................................................................................................................. 46

Fresh Food Evaporator Assembly ................................................................................................. 50

Fresh Food Evaporator Components ............................................................................................ 52

Fresh Food Heater Testing ............................................................................................................ 50

Heat Exchanger ............................................................................................................................. 39

Icemaker Controls ..........................................................................................................................11

Icemaker Fill Tube and Heater .......................................................................................................31

Ice Bin and Icemaker .....................................................................................................................31

Ice Dispenser ................................................................................................................................ 35

Installation Example 42" Model ......................................................................................................5

Interior Airfl ow .............................................................................................................................17

Interior Lights ................................................................................................................................42

Introduction ................................................................................................................................... 4

Machine Compartment Access Door .............................................................................................23

Main Switch ..................................................................................................................................34

Mufflers .........................................................................................................................................39

Nomenclature ............................................................................................................................... 9

Power Control Board (PCB) ..........................................................................................................27

Refrigerant Flow ............................................................................................................................14

Refrigeration Components .............................................................................................................13

Refrigeration System .....................................................................................................................13

Replacing the Freezer or Fresh Food Evaporator ........................................................................ 52

Schematics ................................................................................................................................... 58

Service Diagnostics ...................................................................................................................... 54 to 65

Technical Data ............................................................................................................................... 8

Terminal Block Panel .....................................................................................................................29

Thermistors ................................................................................................................................... 42

Troubleshooting Notes .........................................................................................................

Water Valve and Water T ank ......................................................................................................... 35

......... 57

IntroductionINTRODUCTION

3

5995432258

INTRODUCTION

The new Profi le Built-In Side by Side refrigerator has the following features:

•

•

•

•

•

•

•

•

•

Separate freezer and fresh food evaporators are recessed into the machine compartment for

increased effi ciency and interior space savings.

3-Way valve directs refrigerant fl ow where needed.

High-and low-side sealed system muffl ers quiet the operation.

Inverter is built into the power control board (PCB).

Combined dispenser and temperature control board provides customer control and test mode

operations.

Dispenser cube motor and cam replaces solenoid-operated cube mechanism.

Room ambient thermistor aids power control board (PCB) operation.

Component electrical testing is performed at the machine compartment-mounted terminal block.

Rear leveling mechanism is front-adjustable.

Installation Example 42" Mo

45995432258

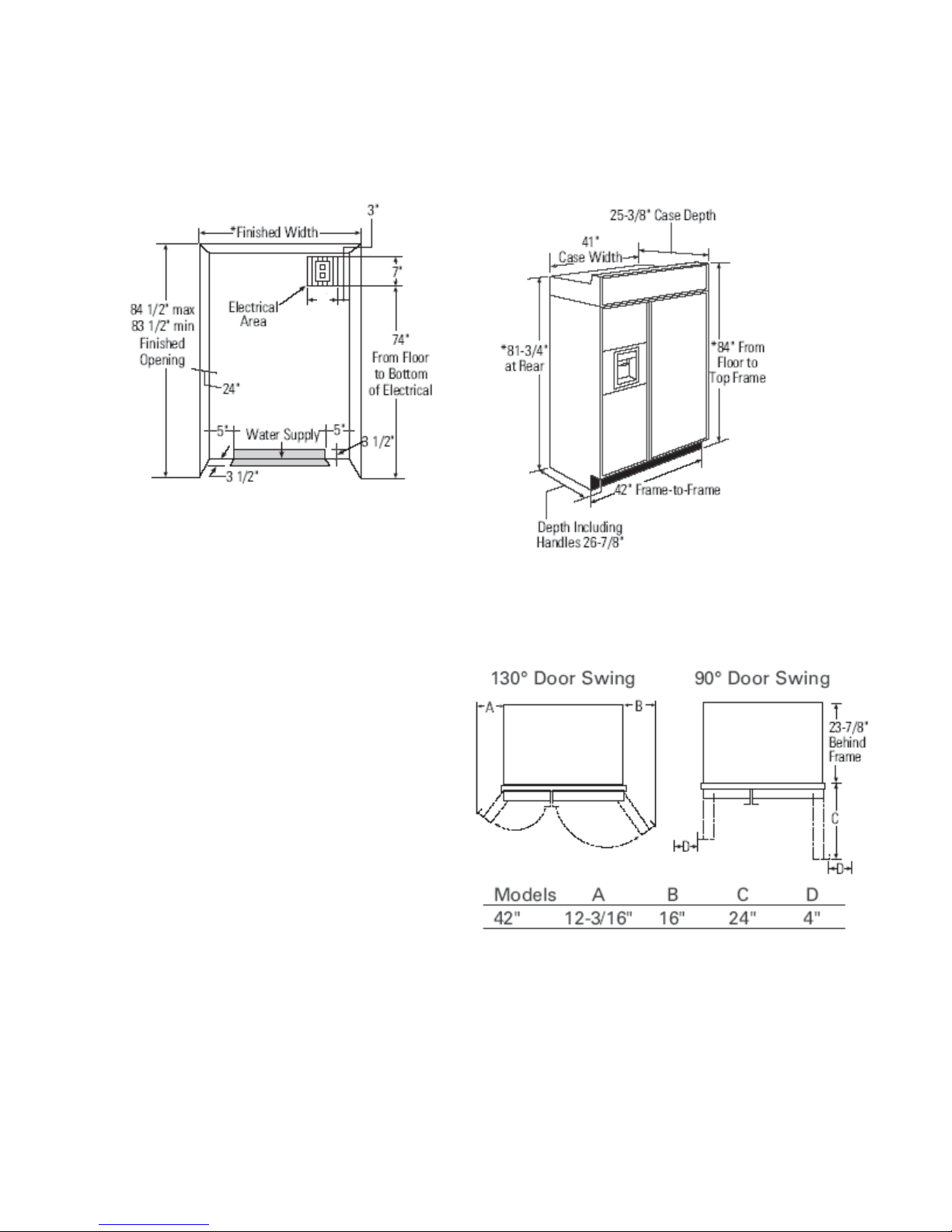

INSTALLATION EXAMPLE 42” MODEL

THE INSTALLATION SPACE

7”

* The finished cutout width must be:

41-1/2” for 42” models

Water and Electrical Locations

The opening must be prepared with the

electrical and water supply located as shown.

The cutout depth must be 24"

The refrigerator will project forward, slightly

beyond adjacent cabinets, depending on

your installation.

Additional Specifications

• A 120 volt, 60Hz, 15 or 20 amp power

supply is required. An individual properly

grounded branch circuit or circuit breaker

is recommended. Install a properly

grounded 3-prong electrical receptacle

recessed into the back wall. Electrical must

be located on rear wall as shown.

Note: GFI (ground fault interrupter) is not

recommended.

• Water line can enter the opening through

the floor or rear wall. The water line installed

should be 1/4" O.D. copper tubing between the

cold water line and water connection location.

The line should be long enough to extend to

the front of the refrigerator. Installation of an

easily accessible shutoff valve in the water line

is required.

Wood Panel 70 LB food door 30 LB freezer door

DIMENSIONS AND CLEARANCES

*Shipping height

The front height

may be adjusted

from 83-1/2" to 84-1/2"

by adjusting front and

rear leveling legs a

maximum of 1".

Product Clearances

These refrigerators are equipped with a 2

position door stop. The factory set 130° door

swing can be adjusted to 90° if clearance to

adjacent cabinets or walls is restricted

May Change with

our handle

Allow minimum clearances for Freezer

door (Dimension A) and Fresh Food door

(Dimension B) for a full 130° door swing

and to allow for drawer removal.

Four inch (4") minimum clearance is required

when door swing is adjusted to 90°. If the 90°

door stop position is used, drawer access is

maintained, but drawer removal is restricted.

5

5995432258

65995432258

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNECT ALL GROUNDING

DEVICES

7

5995432258

TECHNICAL DATA

All parts of this appliance capable of conducting

electrical current are grounded. If grounding

wires, screws, straps, clips, nuts or washers

used to complete a path to ground are removed

for service, they must be returned to their

original position and properly fastened.

CAUTION

To avoid personal injury when servicing the

condensing unit, stand on a ladder which will

give enough support to allow removal of the top

panel and safely allow access to service the unit.

REFRIGERA TION DIAGNOSIS

ELECTRICAL SPECIFICA TIONS

Max Defrost Control

w/No Door Openings........................16 hrs

Evap Defrost Thermistor........68°F (FZ)..63°F (FF)

Electrical Rating: 115V AC 60 HZ.............5.4 amp

Maximum Current Leakage......................0.75 mA

Maximum Ground Path Resistance...............0.1 W

Energy Consumption Model 42........50.5 KWh/mo

Energy Consumption Model 48......53.75 KWh/mo

COMPOENENT RESISTANCE VALUES

FF fan motor ……………………..............1600 &! ± 20%

FZ fan motor ………………………….......1600 &! ± 20%

Condenser fan motor ………………........1600 &! ± 20%

Auger motor ………………………..............3.7 &! ± 15%

Cube motor …………………………….....2091 &! ± 10%

Cover motor ……………………………....2091 &! ± 10%

Defrost heater FZ ……..................................44 &! ± 7%

Drain heater FZ ..........................................377 &! ± 7%

Sub-heater FZ ………...............................1322 &! ± 7%

Defrost heater FF .......................................120 &! ± 7%

Drain heater FF …......................................440 &! ± 7%

Fill-tube heater .……….............................2645 &! ± 7%

Dispenser heater (Recess)………………..1889 &! ± 7%

Compressor (between the different

phase) …………….....................11. 7 &! ± 7% / 1 phase

3- way valve …………………………..40 ± 4 &!/ 1 phase

Water valve (Ice maker) …………...............180 &! ± 7%

Water valve (Dispenser) ..………................325 &! ± 7%

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic and mechanical experience. Any

attempt to repair a major appliance may result

in personal injury and property damage. The

manufacturer or seller cannot be responsible for

the interpretation of this information, nor can it

assume any liability in connection with its use.

NO LOAD PERFORMANCE

Control Position 37-0°F and

Ambient T emperature of: 70°F 90°F

Fresh Food °F 37-42 36-43

Frozen Food °F (-2)-2 (-2)-5

Percent Running Time, %..........35-45 65-75

REFRIGERATION DIAGNOSIS

To access the low pressure side of the system,

install a line tap valve on the process tube

extending from the compressor case.

REFRIGERATION SYSTEM

Refrigerant Charge (R134a)......................8.11 ounces

Compressor......................................738-1270 BTU/hr

Minimum Compressor Capacity

Vacuum..........................................................26 inches

Minimum Equalized Pressure

@70°F.............................................................66 PSIG

@90°F.............................................................74 PSIG

To change the

Technical Data

Nomenclature

Icemaker Controls

85995432258

MODEL AND SERIAL NUMBER INFORMATION

E42BS85EPS THE PS IS FOR STAINLESS STEEL

E42BS75ETT THE TT IS FOR MODEL WITH TRIM ON DOORS

Serial Plate

Location

The Serial

plate is located

at the top of

the fresh food

section on the

right-side wall.

It contains

the model and

serial numbers

and specifi es

the minimum

installation clearances, electrical voltage,

frequency, maximum amperage rating, and

refrigerant charge.

Mini-Manual

The mini-manual is located behind the

grille panel at the top of the refrigerator.

When service is completed, return the

mini-manual to its original location for

future use.

Serial Number

The first letter tells us where the product was made, the

second letter tells us what type product it is. The first

number is the year the product was made. The next two

numbers are the week the product was made.

Example BA51400000,

B - Is the Anderson refrigerator factory.

A - Is a refrigerator

5 - Is 2005

14 - Is week 14

The rest of the numbers are the sequence number for week

14 of 2005.

9

5995432258

Control Features

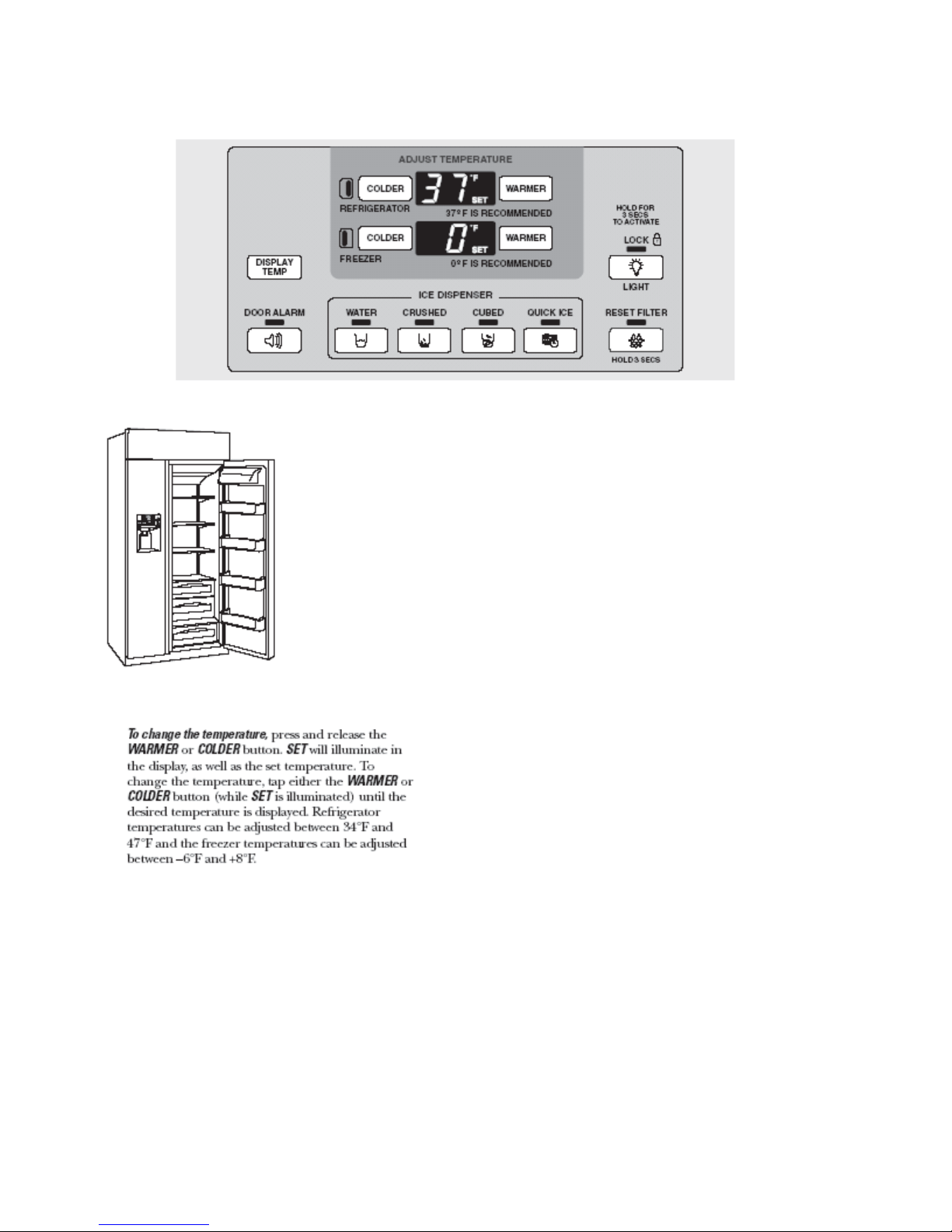

The temperature controls are preset in the factory at 37°F for the

refrigerator compartment and 0°F for the freezer compartment. Allow

24 hours for the temperature to stabilize to the preset recommended

settings.

The temperature controls can display both the SET temperature

as well as the actual temperature in the refrigerator and freezer.

The actual temperature may vary slightly from the SET temperature

based on usage and operating environment.

NOTE: The refrigerator is shipped with protective film covering the

temperature controls. If this film was not removed during installation,

remove it now.

Icemaker Controls

Once the desired temperature has been set,

the temperature display will clear after 10 seconds.

To display the temperature, the DISPLAY TEMP

button may be tapped.

Several adjustments may be required. Each time

you

adjust controls, allow 24 hours for the refrigerator

to

reach the temperature you have set.

105995432258

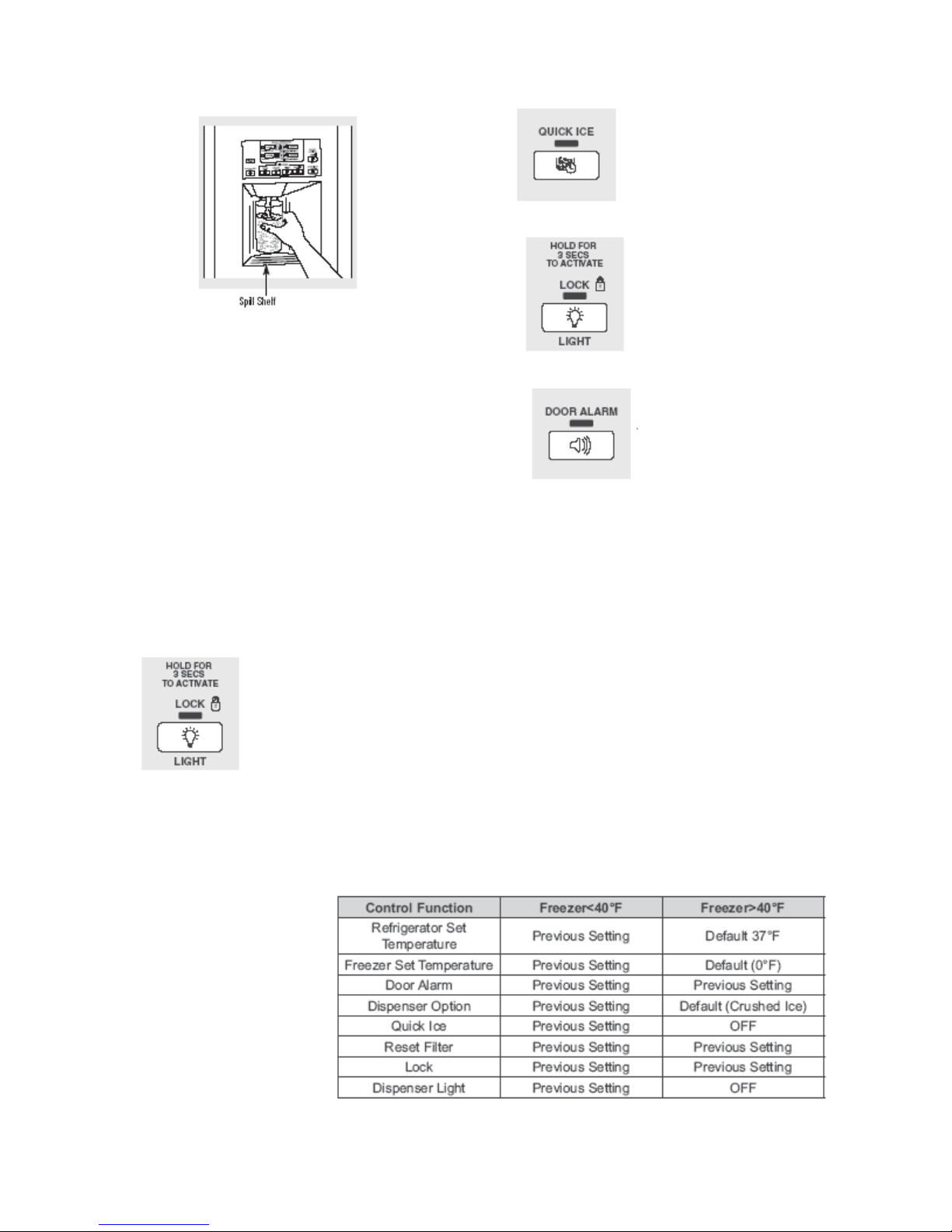

To Use the Dispenser

Select CUBED , CRUSHED or WATER . Press the glass

gently against the middle of the dispenser pad. The spill shelf

is not self-draining.To reduce water spotting, the shelf and

its grille should be cleaned regularly.

If no water is dispensed when the refrigerator is first

installed, there may be air in the water line system. Press

the dispenser arm for at least two minutes to

remove trapped air from the water line and to fill the water

system. To flush out impurities in the water line, throw

away the first six glassfuls of water.

CAUTION:

Never put fingers or any other objects into the ice crusher

discharge opening.

Locking the Dispenser

Press the LOCK/LIGHT

button for 3 seconds to lock the

dispenser and control panel. To

unlock, press and hold the button

again for 3 seconds.

Quick Ice

When you need ice in a hurry,

press this button to speed up ice

production. This will increase ice

production for the following

48 hours or until you press the

button again.

Dispenser Light

This button turns the night light

on the dispenser on and off.

The light also comes on when

the dispenser pad is pressed. If

this light burns out, it should be

replaced with a 6 watt 12V

maximum bulb.

Door Alarm

To turn the Door Alarm on, press

the DOOR ALARM button once.

The ACTIVE light will come on.

To turn it off, press it again.

When the DOOR ALARM is

active, the ACTIVE light will

flash if you open the door and

beep if you keep the door open

for more than 2 minutes. The

light goes out and the beeping

stops when you close the door.

Spill Shelf

Note: When QUICK ICE is selected, the freezer

temperature operates at -9°F for 48 hours or until QUICK

is pressed again. There is no change of temperature on

ICE

the display panel. In the event of a power loss, if the

freezer temperature is above 40°F, Quick Ice will not

restart. Below 40°F, the refrigerator will return to

the Quick Ice mode.

Display after power failure:

After a power failure, the

display will reset based

on freezer temperature.

If the freezer temperature

is below 40°F, the display

will retain the settings

prior to power loss. The

chart at the right describes

the possible settings.

11

5995432258

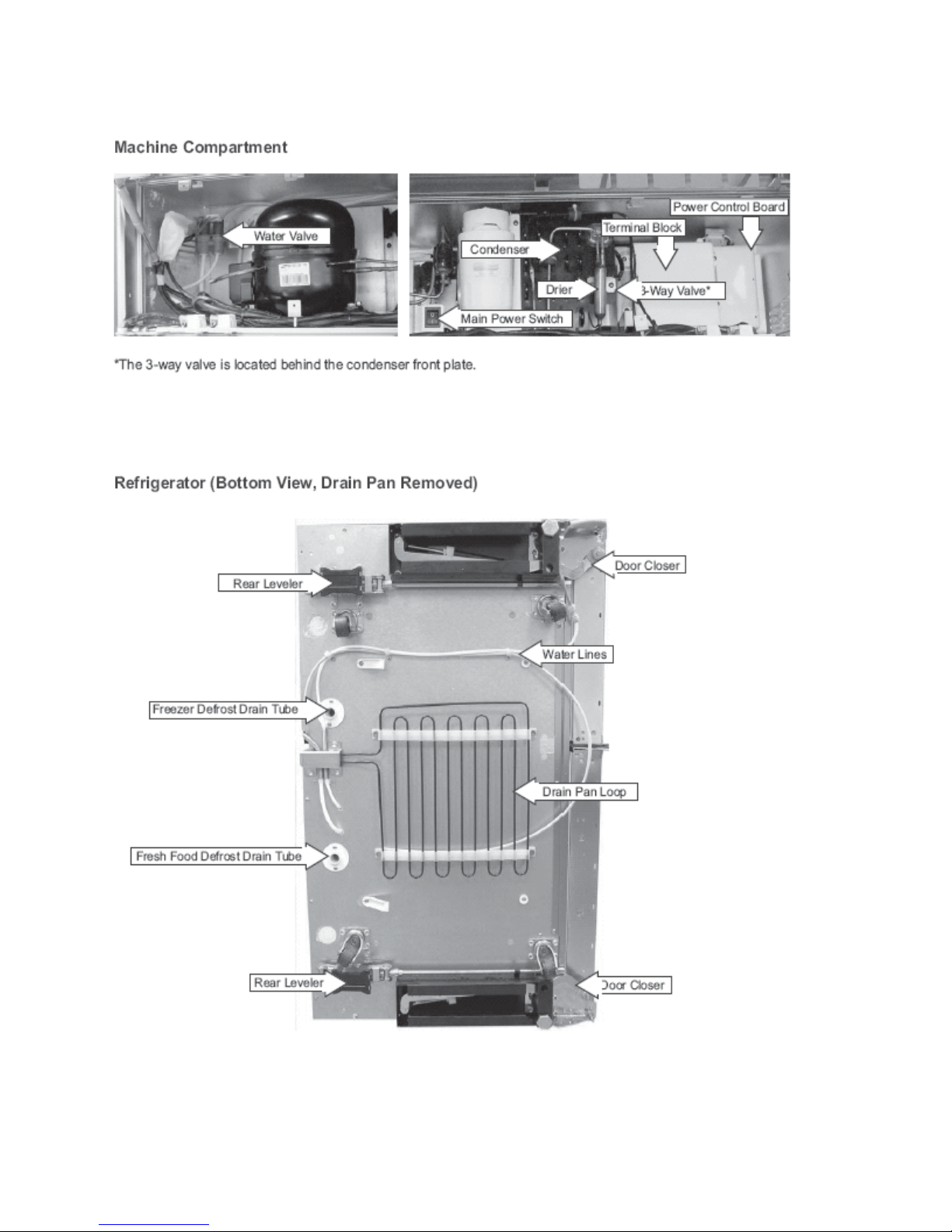

Component Locator Views

Component Locator Views

125995432258

Refrigeration Components

Refrigeration System

13

5995432258

Refrigerant Flow

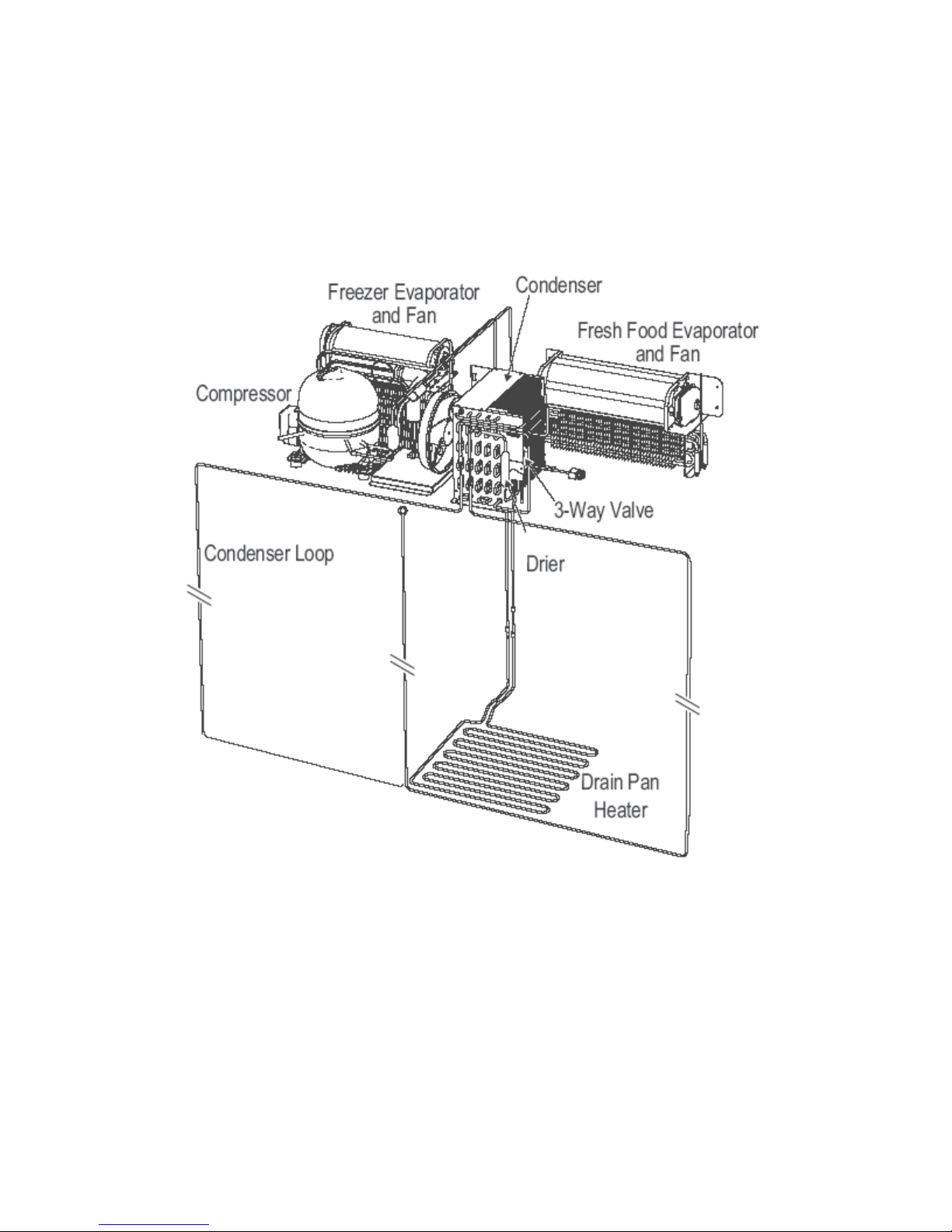

The compressor compresses R134a refrigerant,

raising its pressure and temperature. Refrigerant

vapor is pumped out the compressor discharge,

down through the drain pan loop, up through

the condenser coil, around the condenser loop,

through the drier, and into the 3-way valve. By

the time the refrigerant has reached the 3-way

valve, it has completely condensed into a liquid.

Depending upon whether the main control board

opens the 3-way valve to the freezer evaporator

or the fresh food and freezer evaporators,

refrigerant fl ows through the appropriate capillary

tube and into the evaporator. As the high pressure

liquid passes through the capillary and enters the

low pressure evaporator, it quickly expands and

evaporates. During evaporation, the refrigerant

absorbs heat, becoming cold. At the outlet of the

freezer evaporator, an accumulator captures any

remaining liquid, allowing only low pressure vapor

to return to the compressor through the suction

line.

145995432258

Note: The refrigerator will operate with the 3-way valve set for freezer only or set for fresh food and

freezer. There is no 3-way valve setting for fresh food only. If the fresh food thermistor is not satisfi ed,

but the freezer thermistor is satisfi ed, the refrigerator will still operate with the 3-way valve set in the

fresh food and freezer mode.

15

5995432258

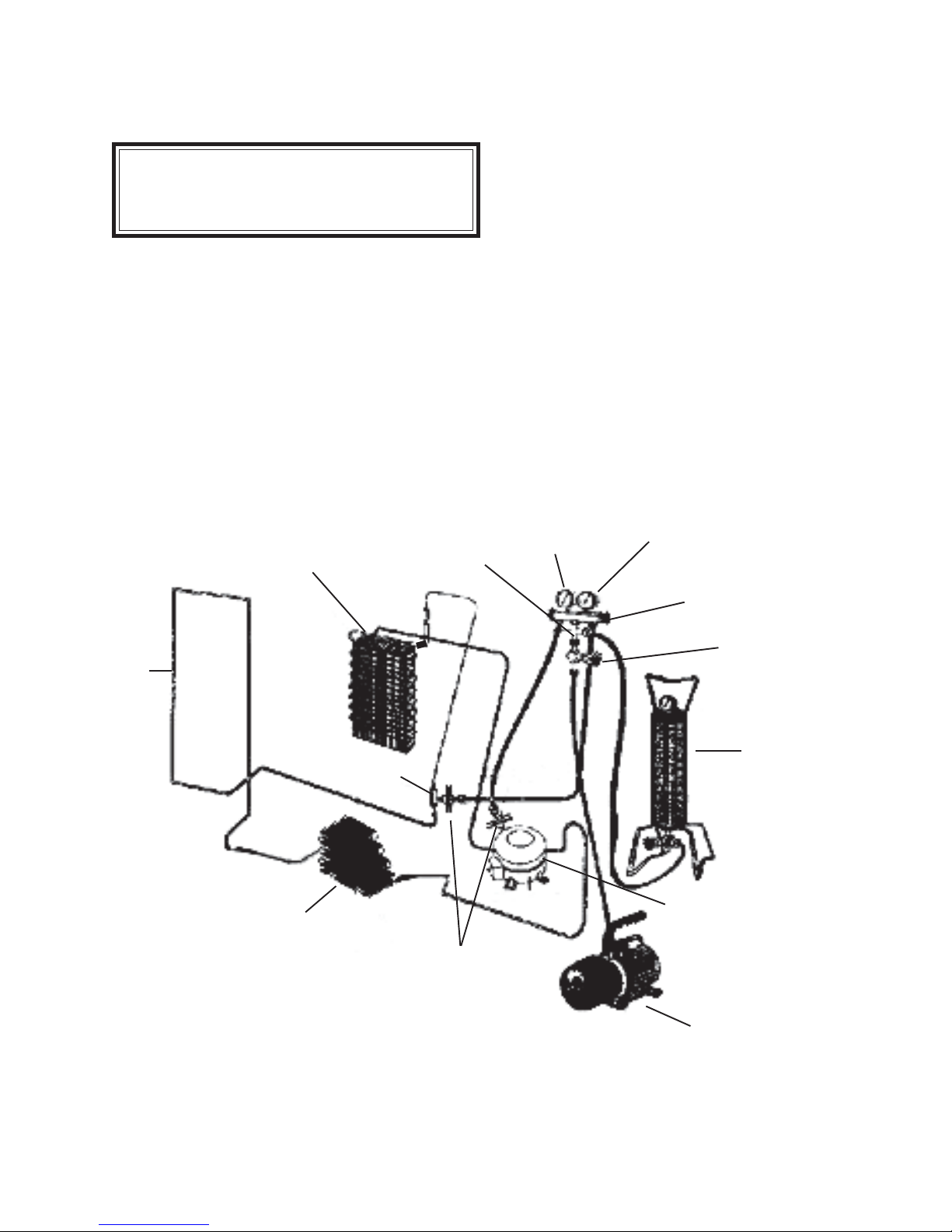

Evacuation and Charging Procedure

Equipment Needed for Evacuation & Recharging:

• Heated charging cylinder

• Standard 3-port manifold gauge set:

4 charging hoses

Tee fitting with valve core stem removed

(Robinair No. 40396)

Hand shut-off valve (Robinair No.40380)

• Two stage vacuum pump

• Process tube adapter kit (Robinair No. 12458)

• Tubing cutter

• Pinch-off tool capable of making leak proof seal

• Complete brazing torch set

• Small 3-corner file

• Grit cloth or Scotch-Brite

• 45% silver solder and flux

Installing Evacuation and Recharging Equipment

1. Disconnect refrigerator from electrical supply.

2. If compressor was replaced, install correct sized

process tube adaptor on process tube. If compressor

was not replaced, cut process tube with tubing cutter

leaving as much tube as possible and install correct

size process tube adaptor.

3. Install correct sized process tube adaptor on

high-side process tube.

4. Attach refrigeration service gauge manifold to

system in following order:

• Low-side (compound gauge) hose to

suction side process tube adaptor.

• High-side (pressure gauge) hose to high-

side process tube adaptor.

• Center port manifold hose before hand

shut-off valve to charging cylinder.

• Center port manifold hose after hand

shut-off valve to vacuum pump.

Evacuating System

WARNING: R-134A SYSTEMS ARE

PARTICULARLY SUSCEPTIBLE TO

MOISTURE CONTAMINATION WHICH CAN

ONLY BE PREVENTED BY EVACUATING THE

SYSTEM FOR A MINIMUM OF 30 MINUTES

TO ATTAIN A MINIMUM 29.9 INCH (500

MICRON OR LOWER) VACUUM.

To achieve the required levels of evacuation, a

properly maintained two stage vacuum pump in good

condition is required. It is absolutely essential to maintain

your vacuum pump according to the manufacturer’s

instructions including required oil changes at the recommended intervals. Vacuum pump oil should always be

changed after evacuating a contaminated system.

Vacuum pump performance should be checked

periodically with a micron gauge.

1. Make certain that charging cylinder valve, hand

shut-off valve, and manifold gauge valves are

closed.

2. Start vacuum pump.

3. Open hand shut-off valve and slowly open both

manifold valves, turning counterclockwise, for

two full rotations.

CAUTION: If high vacuum equipment is

used, just crack both manifold valves for a

few minutes and then open slowly for the

two full turns counterclockwise. This will

prevent the compressor oil from foaming

and being drawn into the vacuum pump.

4. Operate the vacuum pump for a minimum of 30

minutes to a minimum of 29.9” (500 micron)

vacuum.

5. Close hand shut-off valve to vacuum pump.

Watch compound gauge for several minutes. If

reading rises, there is a leak in the system, go to

step 6. If no leak is indicated, stop vacuum pump.

System is now ready for charging.

6. If a leak is indicated, stop vacuum pump and

introduce a small charge of refrigerant into

system by cracking valve on bottom of charging

cylinder until system is pressurized to 40 or 50 l

bs psig.

7. Leak test low-side. Close compound gauge.

Run compressor for a few minutes and leak test

high-side. When leak is found, recapture refrig

erant using EPA approved recovery system

Repair and go back to step 1.

Charging The System

CAUTION: Check the serial plate for the correct refrigerant type. It is extremely important

to verify the type of refrigerant in the system

before starting any sealed system repairs.

CAUTION: After charging the system with

liquid be certain to wait at least 5 minutes

before starting the compressor to give the

refrigerant a chance to disperse throughout

the system. Otherwise the compressor could

be damaged by attempting to pump excessive quantities of liquid.

Preparing The Charging Cylinder:

1. Make certain that hand shut-off valve to vacuum

pump is closed.

2. Close high-side manifold gauge valve.

3. Set charging cylinder scale to pressure indicated

on cylinder pressure gauge.

4. Observe refrigerant level in sight glass. Subtract

amount to be charged into system and note shut

off point.

5. Open charging cylinder valve slowly and allow

proper charge to enter system.

165995432258

6. As soon as refrigerant in sight glass has gone

down to predetermined level, close charging

cylinder valve.

WARNING: DISCONNECT THE CHARGING

CYLINDER HEATER AT THIS TIME TO

PREVENT THE CYLINDER PRESSURE

FROM EXCEEDING ITS MAXIMUM LIMITS.

7. Allow system to sit for five minutes.

8. Turn on refrigerator compressor. Run compres

sor for a few minutes and monitor system

pressures.

9. When satisfied that the unit is operating cor

rectly, clamp the high-side process tube with the

pinch-off tool while the unit is still running.

10.Slowly open the high-side manifold gauge valve

to allow the compressor to remove any refriger

ant trapped in the high-side hose and the process

fitting.

11.Close both of the manifold gauge valves. If the

high-side gauge reading rises, the pinch-off

must be corrected before proceeding.

12.Remove the high-side process tube adaptor

and solder the process tube closed.

13.Clamp the low-side process tube with the pinchoff tool while the unit is running. Remove the

low-side process tube adaptor and solder the

process tube closed.

14.Check the process tubes for refrigerant leaks.

Final leak test

1. With the refrigerator turned OFF leak test all

low-side system components.

2. Turn the unit ON and run until the condenser is

warm. Leak test the high-side system components.

HOT

TUBE

EVAPORATOR

CONDENSER

FILTER

DRIER

TEE

FITTING

PROCESS TUBE

ADAPTERS

COMPOUND

GAUGE

PRESSURE

GAUGE

GAGE

MANIFOLD

HAND SHUTOFF

VALVE

HEATED

CHARGING

CYLINDER

COMPRESSOR

Figure E2

17

2 STAGE VACUUM

PUMP

5995432258

R-134a service information

NOTICE: Instructions given here are furnished as a guide. Persons attempting to use these instructions to make

repairs to the sealed refrigeration system should have a working knowledge of refrigeration and previous training on

sealed system repair.

Verify refrigerant type in the system

CAUTION: R-134a and R-12 are completely

incompatible. Before starting any sealed

system repair, it is extremely important to

check serial plate of product to verify the

type of refrigerant in the system.

Dedicated Equipment

R-134a must not be mixed with other types of

refrigerants. R-134a must be recovered in dedicated and

properly identified recovery bags and tanks.

It will be necessary to check with the manufacturer

of your recovery equipment to determine R-134a

compatibility. Some recovery equipment manufacturers

have changeover instructions for switching between

refrigerant types. Protect yourself and your equipment by

following all manufacturer guidelines.

Also, ensure that your refrigeration hoses are

specified for use with R-134a refrigerant. Research has

shown that compounds in standard refrigeration hoses may

enter sealed systems and ultimately restrict the cap tube

in an R-134a system.

R-134a refrigeration systems

The sealed refrigeration system will consist of the

same basic components being utilized in the R-12 systems.

There is a 10% to 15% discharge pressure increase

using R-134a, with a 5% to 10% decrease in suction

pressure when compared to the same product with an R12 system operating at 90°F (32°C) ambient temperature conditions. Lower suction pressures result from the

lower density of R-134a refrigerant which effects refrigerant flow rate. R-134a systems commonly operate in a 1”2” vacuum on the suction side.

Products using R-134a refrigerant will generally

have a longer capillary tube to maintain a similar flow rate

and some models will have a larger condenser to reduce

the discharge pressures and lower start-up sound transmission.

Miscibility of r-134a and ester oil

A special synthetic oil known as Ester oil is used as

a lubricant in refrigeration systems operating on R-134a.

Ester oils are produced from alcohols and fatty acids

and are available in several different variants. Ester

oils have a pleasant aroma reminiscent of fruit.

Ester oils generally include various types of

additives for improving certain properties such as

viscosity, temperature sensitivity, etc. These additives are

often aggressive, and skin contact with Ester oils should

therefore be avoided.

One of the most important requirements made on a

refrigerant system is that the oil mix with the refrigerant.

Since mineral oil and ordinary synthetic oil DO NOT mix

with R-134a, Ester oil is used for lubrication. Ester oil

dissolves in R-134a.

Ester oil is broken down by chlorine and cannot be

used with R-12 (R-12 contains chlorine) or any other

compound containing chlorine. Therefore, R-134a

refrigeration systems have virtually no tolerance for

chlorine molecules from CFC refrigerants (R-134a is an

HFC and contains no chlorine).

CAUTION: During R-134a service, it is

extremely important to avoid using

equipment that may contain residual amounts

of mineral oil, CFC’s or HCFC’s which could

enter and contaminate the sealed system.

For example, hoses that were used for a refrigeration

system operating on R-12 may contain small quantities of

mineral oil which can block the capillary tube in a system

operating on R-134a. As little as one milligram may be

sufficient to cause a blockage. In addition, sealed system

components that have been used with CFC systems must

not be used with R-134a systems. These components may

contain residual amounts of refrigerant and oil which

could damage an R-134a system.

At the earliest stage of development work on R134a, tests were carried out on a different type of synthetic

oil known as Poly-Alkaline Glycol (PAG). This oil is also

used in certain air conditioning systems for cars. PAG and

Ester oil DO NOT mix with one another. Service equipment used for R-134a / Ester oil must not come into

contact with PAG.

185995432258

Water in the refrigeration system

Even in very small quantities, water in any refrigera-

tion system can cause the following problems:

• Ice plugs in capillary tubes.

• Copper plating in compressor.

• Reactions with organic materials in systems.

• Corrosion of metals.

R-134a and Ester oil will aggravate the problem of

water in the refrigeration system. Ester oil may react with

water vapor and is hydroscopic (it will absorb water if it

comes in contact with humid air). Water is also more

soluble in R-134a than R-12.

2-Stage Vacuum Pump

To minimize the water content whenever service

work is performed, the refrigeration system should always

be thoroughly evacuated through process tube adaptors on

both the high and low sides of the system. Evacuation

must be for a minimum of 30 minutes to at least a 29.9

inch (500 micron) vacuum.

TRAHCMUUCAV

muucaV

.gHsehcnI

snorciM

tnioPgnilioB

F°retaWfo

049.82000529.77

035.92000010.25

238.9200640.23

288.9200010

.1

109.920052.11-

519.920518.23-

719.920012.83-

919.92050.94-

Figure

E3

Vacuum pump maintenance

It is absolutely essential to maintain your vacuum

pump according to the manufacturer’s instructions

including required oil changes at the recommended

intervals. Vacuum pump oil should always be changed

after evacuating a contaminated system. Vacuum pump

performance should be checked periodically with a micron

gauge.

Vacuum pump suppliers may or may not recommend

changing the vacuum pump oil to the same type that’s in

the system being evacuated. Some manufacturers may

recommend a vacuum pump that’s dedicated to R-134a

systems.

Robinair has stated that their current and

discontinued vacuum pump models, using mineral oil

currently specified for use in their vacuum pumps, can be

used to evacuate R-134a/Ester oil systems. Robinair also

states that it is acceptable to alternate between evacuating

R-12/mineral oil and R-134a/Ester oil systems without

adversely effecting the vacuum pump’s performance.

For other brands of vacuum pumps, check with the

manufacturer for restrictions and guidelines when using

with R-134a.

To achieve the required 29.9 inch (500 micron)

vacuum, a properly maintained two-stage vacuum pump in

good condition is required. A two stage pump can reach a

deeper vacuum than a single stage because the exhaust

from the first pumping stage is discharged into the second

pumping stage. This means the second stage begins

pumping at a lower pressure so a lower ultimate vacuum

can be achieved (See 2-Stage Vacuum Pump, Figure E3).

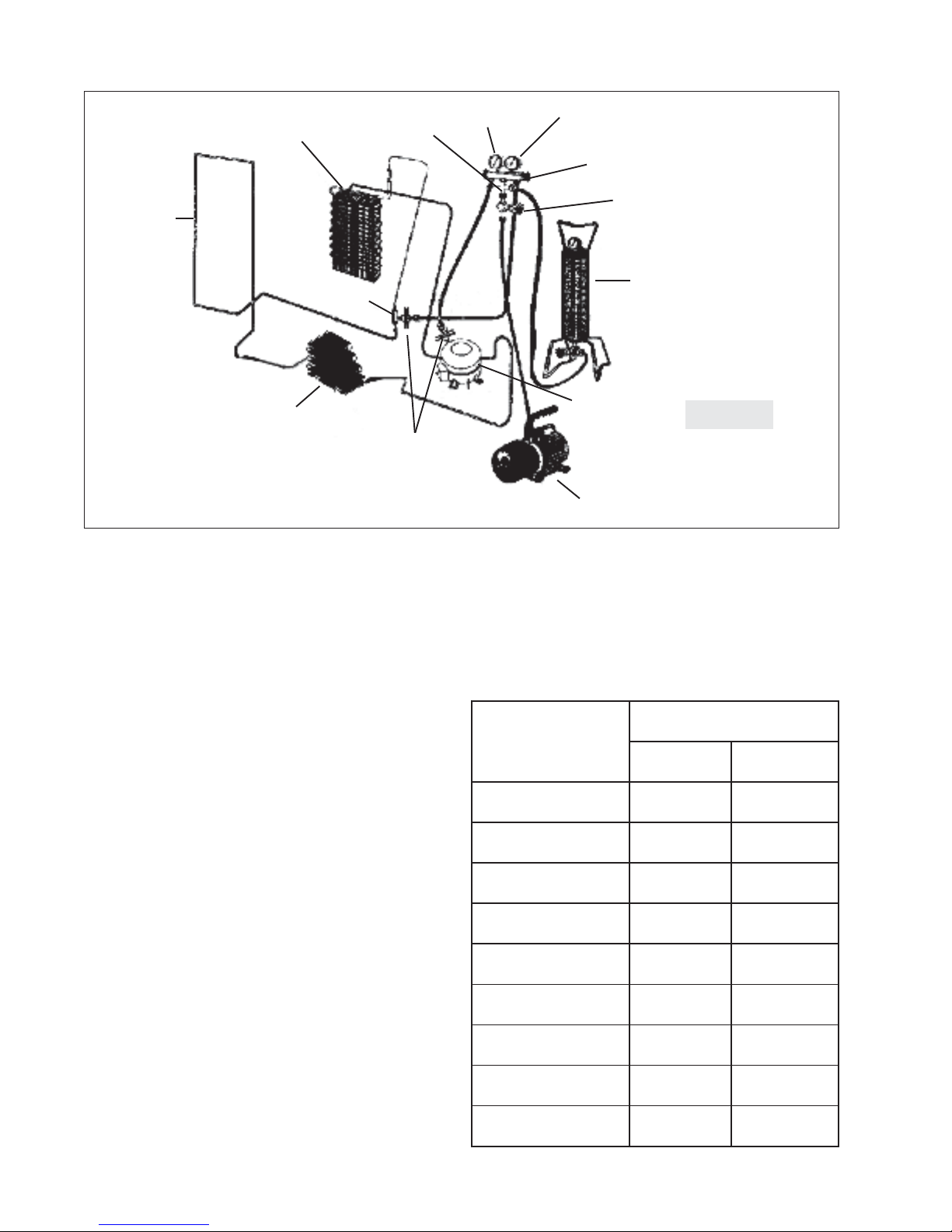

CAUTION: If you use a vacuum pump with

mineral oil to evacuate an R-134a system, it

is ABSOLUTELY ESSENTIAL to have a shutoff valve between pump and your manifold

gauge set as shown in Figure E4. The hand

valve must be closed during all times when

vacuum pump is not operating. This will

prevent migration of mineral oil vapor into

R134a/Ester oil system. If vacuum pump

should stop during evacuation for any reason,

the hand pump shut-off valve must be closed

immediately.

19

5995432258

HOT

TUBE

EVAPORATOR

FILTER

DRIER

TEE

FITTING

COMPOUND

GAUGE

PRESSURE

GAUGE

GAGE

MANIFOLD

HAND SHUTOFF

VALVE

HEATED

CHARGING

CYLINDER

CONDENSER

PROCESS TUBE

ADAPTERS

Evacuating and Recharging Connections

Refrigerant leaks

A system with R-134a and Ester oil will become

saturated with moisture much faster than a system with

R-12 and mineral oil. The compressor in an R-134a system

will have to be replaced if the product has had a low side

leak.

R-134a refrigerant molecules are smaller than R-12

molecules. This means that R-134a will pass more minor

leaks and the rate of flow will be greater than for R-12.

Therefore, it is now more important than ever to follow

good brazing practices. Use a good grade of silver solder.

45% silver solder is recommended.

leak detection

R-134a system leaks can be pinpointed by means of

an electronic leak detector or by bubble solution.

Electronic leak detectors for R-134a service are

currently available from several manufacturers. The least

expensive models are non-selective detectors that will

detect any type of emission or vapor present, regardless of

its chemical composition. Some non-selective detectors

designed for use with R-12 may have a much lower

sensitivity when used with R-134a. However, newly

designed detectors with good R-134a sensitivity are now

available. Be sure to consult with the manufacturer before

selecting or using a non-selective detector with R-134a.

Halogen-specific detectors use a specialized sensor

that allows detection of compounds containing chlorine,

fluorine, bromine, and iodine without being activiated by

other species. The major advantage of this type of detector

is a reduction in the number of “nuisance alarms”.

Halogen-specific detectors are generally more expensive

COMPRESSOR

Figure

E4

2 ST AGE VACUUM

PUMP

than non-selective detectors but feature higher

sensitivity.R-134a properties

R-134a properties

The properties of R-134a are very similar to those of

R12. The principal data for the two refrigerants are shown

in the chart below.

STNAREGIRFER

21-Ra431-R

EMAN

alumroF

)lom/g(thgieWraluceloM

laitnetoPnoitelpeDenozO

)PDO(

laitnetoPgnimraWlabolG

)PWG(

F°tnioPgnilioB

)F°77(erusserPropaV

ytilibammalF

niretaWfoytilibuloS

)F°77@%tw(tnaregirfeR

-oroulfidorolhciD

enahtem

ICC2F

2

39.0213.201

10

1.33.0

6.12-7.51-

gisp08gisp28

enoNenoN

900.011.0

HC

-arteT--2,1,1,1

enahtemoroulf

FC-F

2

3

205995432258

Loading...

Loading...