Page 1

USA

- ELECTRICS HEATED MICROWAVE STEAM CONVECTION OVENS

INSTALLATION, OPERATION AND MAINTENANCE Page 11

IT

- FORNI CONVEZIONE/VAPORE MICROONDE ELETTRICI

INSTALLAZIONE, USO E MANUTENZIONE Pagina 35

- FOURS À CONVECTION/VAPEUR MICRO-ONDES ÉLECTRIQUES

CDN

INSTALLATION, UTILISATION ET ENTRETIEN Page 59

- HORNOS MICROONDAS DE CONVECCIÓN Y VAPOR ELECTRICOS

ES

INSTALACIÓN, USO Y MANTENIMIENTO Pág. 83

DOC. NO. 5958 992 00

EDITION 1 E 0410 LA

From the Electrolux Group

Page 2

USA

When using electrical appliances basic safety precautions should be followed, including the following:

WARNING - To reduce the risk of burns, electric shock, fire, injury to persons, or exposure to excessive microwave energy:

1) Read all instructions before installing and using the appliance.

2) Read and follow the specific "PRECAUTIONS TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY"

found on (see section III.).

3) This appliance must be grounded. Connect only to properly grounded outlet. See "GROUNDING INSTRUCTIONS" found

on (see paragraph 7. - section II.).

4) Install or locate this appliance only in accordance with the provided installation instructions.

5) Some products such as whole eggs and sealed containers - for example, closed glass jars - are able to explode and

should not be heated in this oven.

6) Use this appliance only for its intended use as described in the manual. Do not use corrosive chemicals or vapors in

this appliance. This type of oven is specifically designed to heat, cook, or dry food. It is not designed for industrial or

laboratory use.

7) As with any appliance, close supervision is necessary when used by children.

8) Do not operate this appliance if it has a damaged cord or plug, if it is not working properly, or if it has been damaged or

dropped.

9) This appliance should be serviced only by qualified service personnel. Contact nearest authorized service facility for

examination, repair, or adjustment.

10) Do not cover or block any openings on the appliance.

IMPORTANT SAFETY INSTRUCTIONS

11) Do not store this appliance outdoors. Do not use this product near water - for example, near a kitchen sink, in a wet

basement, near a swimming pool, or similar locations.

12) Do not immerse cord or plug in water.

13) Keep cord away from heated surfaces.

14) Do not let cord hang over edge of table or counter.

15) See door surface cleaning instructions on (see paragraph 7. - section III.).

16) To reduce the risk of fire in the oven cavity:

i) Do not overcook food. Carefully attend appliance when paper, plastic, or other combustible materials are placed inside

the oven to facilitate cooking.

ii) Remove wire twist-ties from paper or plastic bags before placing bag in oven.

iii) If materials inside the oven ignite, keep oven door closed, turn oven off, and disconnect the power cord, or shut off

power at the fuse or circuit breaker panel.

iv) Do not use the cavity for storage purposes. Do not leave paper products, cooking utensils, or food in the cavity when

not in use.

17) Liquids, such as water, coffee, or tea are able to be overheated beyond the boiling point without appearing to be boiling.

Visible bubbling or boiling when the container is removed from the microwave oven is not always present. THIS COULD

RESULT IN VERY HOT LIQUIDS SUDDENLY BOILING OVER WHEN THE CONTAINER IS DISTURBED OR A UTENSIL

IS INSERTED INTO THE LIQUID.

18) Don't install the oven on the free-standing support (for CANADA only).

SAVE THESE INSTRUCTION

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

2

5958 992 00

Page 3

IT

Durante l'uso di apparecchiature elettriche, si raccomanda di seguire le misure generali di sicurezza, incluse le seguenti:

AVVERTENZA - Per ridurre il rischio di ustioni, scosse elettriche, incendi, lesioni alle persone o eccessiva esposizione

all'energia delle microonde:

1) Leggere tutte le istruzioni prima di installare e utilizzare l'apparecchio.

2) Leggere e seguire le "PRECAUZIONI PER EVITARE L'ESPOSIZIONE ALLA ENERGIA ECCESSIVA DELLE MICROONDE",

riportata alla sezione III).

3) Questa apparecchiatura deve essere collegata alla messa a terra. Collegare l'apparecchio solo ad una presa

adeguatamente collegata alla messa a terra. Vedere le "ISTRUZIONI PER IL COLLEGAMENTO DI MESSA A TERRA"

al paragrafo 7 - sezione II).

4) Installare o posizionare l'apparecchio solo in conformità alle istruzioni di installazione fornite.

5) Alcuni prodotti, come uova intere e contenitori sigillati, (ad esempio, barattoli di vetro chiusi) potrebbero esplodere e

non devono essere riscaldati nel forno.

6) Utilizzare questo apparecchio solo per l'uso a cui è destinato, come descritto in questo manuale. Non utilizzare sostanze

chimiche o vapori corrosivi all'interno dell'apparecchio. Questo tipo di forno è progettato specificatamente per

riscaldare, cuocere o essicare alimenti. Non è designato per usi industriali o di laboratorio.

7) Come per ogni altro apparecchio, l'uso di questo prodotto da parte dei bambini è soggetto a rigido controllo degli adulti.

8) Non mettere in funzione l'apparecchio in presenza di una spina o un cavo danneggiati, o dopo malfunzionamenti

dell'apparecchio o in seguito a caduta o danni di qualsiasi tipo.

9) Le operazioni di assistenza per questo prodotto devono essere eseguite esclusivamente da personale professionalmente qualificato. Contattare la società autorizzata per l'assistenza per le operazioni di ispezione, riparazione e

regolazione.

ISTRUZIONI IMPORTANTI PER LA SICUREZZA

10) Non coprire o ostruire le aperture dell'apparecchiatura.

11) Non conservare questo apparecchio all'esterno. Non usare l'apparecchio in prossimità di acqua, ad esempio, vicino

ad un lavello, in un seminterrato, in una piscina o ambiente simile.

12) Non immergere il cavo o la spina di alimentazione in acqua.

13) Tenere il cavo lontano da superfici riscaldate.

14) Non lasciar pendere il cavo oltre il bordo del tavolo o del piano.

15) Vedere le istruzioni relative alla pulizia della superficie (paragrafo 7, sezione III).

16) Per ridurre il rischio di incendio nella cavità del forno:

i) Non cuocere troppo a lungo gli alimenti. Sorvegliare l'apparecchio con attenzione se si introduce carta, plastica o

altro materiale combustibile all'interno del forno per facilitare la cottura.

ii) Rimuovere i legacci metallici per la chiusura dei sacchetti di carta o plastica, prima di introdurre i sacchetti nel forno.

iii) Se il materiale all'interno del forno si incendia, lasciare chiusa la porta, spegnere il forno e scollegare la spina di

alimentazione oppure togliere l'elettricità al fusibile o all'interruttore di circuito.

iv) Non utilizzare la cavità del forno per conservare alimenti. Non lasciare prodotti di carta, utensili o cibi nella cavità

del forno quando questo non è in uso.

17) Alcuni liquidi come acqua, caffè o tè potrebbero surriscaldarsi senza che siano visibili i segni di ebollizione. I segni tipici

dell'ebollizione, come le bollicine, non sono sempre evidenti quando si rimuove il contenitore dal forno a microonde.

QUESTO POTREBBE COMPORTARE LA FUORIUSCITA DI LIQUIDI MOLTO CALDI QUANDO IL CONTENITORE VIENE

MOSSO OPPURE UN UTENSILE VIENE INTRODOTTO NEL LIQUIDO.

18) Non installare il forno sul supporto autoportante (Solo per il CANADA).

CONSERVARE QUESTE ISTRUZIONI

Non immagazzinare o usare benzina o altri materiali infiammabili o liquidi nelle vicinanze di questa o qualsiasi

altra apparecchiatura.

AVVERTENZA: Installazione impropria, adattamenti, modifiche o manutenzione possono causare danni alla

proprieta` o morte. Leggere attentamente le istruzioni per l'installazione, il funzionamento e la manutenzione prima di

installare questa apparecchatura.

5958 992 00

3

Page 4

CDN

CDN

Lors de l'utilisation d'appareils électriques, il est recommandé d'observer les consignes de sécurité fondamentales suivantes:

AVERTISSEMENT - Pour réduire les risques de brûlures, de décharge électrique, d'incendie, de blessures corporelles ou

d'exposition à une énergie de micro-ondes excessive :

1) Lire toutes les instructions avant d'installer et d'utiliser l'appareil.

2) Lire et observer les "PRÉCAUTIONS À PRENDRE POUR ÉVITER L'EXPOSITION À UNE ÉNERGIE DE MICRO-ONDES

EXCESSIVE" (voir section III.).

3) Cet appareil doit être mis à la terre. Branché seulement sur une prise correctement mise à la terre. Voir "Instructions

pour la mise à la terre" (voir paragraphe 7. - section II.).

4) Installer cet appareil en respectant les instructions d'installation fournies.

5) Certains produits comme, par exemple, des œufs entiers et des récipients hermétiquement fermés - pots de verre

fermés - risquent d'exploser et ne doivent donc pas être réchauffés dans le four.

6) Utiliser cet appareil seulement pour l'utilisation prévue tel que décrit dans le présent manuel. Ne pas utiliser de vapeurs

ou de produits chimiques corrosifs dans cet appareil. Ce type de four est spécialement conçu pour chauffer, cuire ou

sécher les aliments. Il n'est pas conçu pour un usage industriel ou de laboratoire.

7) Comme avec tout appareil, l'étroite supervision d'un adulte est nécessaire si le four est utilisé par des enfants.

8) Ne pas faire fonctionner cet appareil si sa prise ou son cordon électrique est endommagé, s'il ne fonctionne pas bien

ou s'il est tombé ou endommagé.

9) Cet appareil ne doit être réparé que par un personnel qualifié. Pour tout réglage, révision ou réparation, contacter le

réparateur agréé le plus proche.

CONSIGNES DE SÉCURITÉ IMPORTANTES

10) Ne pas couvrir ou bloquer les orifices d'évacuation de l'appareil.

11) Ne pas ranger cet appareil à l'extérieur. Ne pas utiliser ce produit près d'un point d'eau - par exemple, à proximité d'un

évier, dans une cave humide, à proximité d'une piscine ou d'autres installations de ce type.

12) Ne pas plonger le cordon ou la prise électrique dans de l'eau.

13) Tenir le cordon d'alimentation loin des surfaces chaudes.

14) Ne pas laisser le cordon pendre sur le bord de la table ou du comptoir.

15) Se reporter aux instructions de nettoyage de la surface de la porte (voir paragraphe 7. - section III.).

16) Pour réduire les risques d'incendie dans la cavité du four :

i) Ne pas trop faire cuire les aliments. Surveillez l'appareil si vous utilisez du papier, du plastique ou toute autre matière

combustible à l'intérieur du four pour faciliter la cuisson.

ii) Retirer les liens torsadés des sachets en papier ou en plastique avant de placer ceux-ci dans le four.

iii) Si des matériaux prennent feu à l'intérieur du four, laisser la porte fermée, éteindre le four et débrancher le cordon

électrique ou couper le courant à partir du tableau des fusibles ou disjoncteurs.

iv) Ne pas utiliser la cavité du four pour ranger des objets. Ne pas laisser de produits de papier, d'ustensiles de cuisson

ou d'aliments dans la cavité du four lorsqu'il n'est pas utilisé.

17) Ne pas faire trop réchauffer les liquides, comme l'eau, le café ou le thé pour éviter l'effet d'ébullition à retardement.

L'ébullition n'est pas toujours visible au moment où le récipient est sorti du four micro-ondes. L'ÉBULLITION PEUT ÊTRE

À RETARDEMENT ET SOUDAINE AU MOMENT OÙ LE RÉCIPIENT EST BOUGÉ OU LORSQU'UN USTENSILE EST

INTRODUIT DANS LE LIQUIDE.

18) Ne pas installer le four sur le pied autoportant (pour le CANADA seulement).

CONSERVER CES INSTRUCTIONS

Il ne faut pas emmagasiner ou utiliser l’essence ou d’autres matériaux inflammables ou liquides à côté de cet

appareil ou d’autres appareils.

AVERTISSEMENT: L’installation, l’adaptation, la modification et l’entretien inadéquats peuvent causer des

dommages aux structures ou aux personnes et la mort. Lire attentivement les instructions d’installation, de fonctionnement

et d’entretien avant d’installer cet appareil.

4

5958 992 00

Page 5

ES

Se deben seguir las precauciones básicas de seguridad al usar aparatos eléctricos, incluyendo las siguientes:

ADVERTENCIA: Para reducir el riesgo de quemaduras, choque eléctrico, incendio, lesiones a personas o exposición a la

energía excesiva de microondas:

1) Lea todas las instrucciones antes de instalar y usar el aparato.

2) Lea y siga las "PRECAUCIONES PARA EVITAR UNA POSIBLE EXPOSICIÓN A LA ENERGÍA EXCESIVA DE MICROONDAS"

3) Este aparato debe tener conexión a tierra. Conéctelo únicamente a un tomacorriente con adecuada conexión a tierra.

4) Instale o ubique este aparato solamente de acuerdo con las instrucciones de instalación provistas.

5) Algunos productos, tales como huevos enteros y recipientes sellados – por ej., frascos de vidrio cerrados – pueden

6) Use este aparato únicamente para el uso previsto descrito en el manual. No use agentes químicos ni vapores corrosivos

7) Como con cualquier aparato, es necesaria una rigurosa supervisión si este está en manos de niños.

8) No opere este aparato si tiene un cable o un enchufe dañado, si no está funcionando adecuadamente o si está dañado

9) Las tareas de servicio de este aparato deben ser realizadas únicamente por personal de servicio calificado. Póngase

IMPORTANTES INSTRUCCIONES DE SEGURIDAD

específicas detalladas (ver sección III.).

Consulte las "INSTRUCCIONES PARA CONEXIÓN A TIERRA" detalladas (ver párrafo 7. - sección II.).

explotar y no deben ser calentados en este horno.

en este aparato. Este tipo de horno está especialmente diseñado para calentar, cocinar o secar comida. No está

diseñado para uso industrial o de laboratorio.

o se ha caído.

en contacto con el centro de servicios autorizado más cercano para inspección, reparación o ajustes.

10) No cubra ni bloquee las aberturas de este aparato.

11) No almacene este aparato al aire libre. No use este producto cerca del agua – por ej., cerca del vertedero de la cocina,

en un sótano húmedo, cerca de una alberca o lugares similares.

12) No sumerja el cable ni el enchufe en agua.

13) Mantenga el cable alejado de superficies calientes.

14) No permita que el cable cuelgue sobre el borde de la mesa o de la superficie de trabajo.

15) Consulte las instrucciones de limpieza para la superficie de la puerta (ver párrafo 7. - sección III.).

16) Para reducir el riesgo de incendio en la cavidad del horno:

i) No cocine comida por demás. Esté cuidadosamente atento al colocar papel, plástico u otros materiales combustibles

dentro del horno para facilitar la cocción.

ii) Retire los alambres de sujeción de bolsas de papel o plástico antes de colocar la bolsa en el horno.

iii) Si los materiales que están dentro del horno se incendian, mantenga la puerta cerrada, apague el horno y desconecte

el cable de alimentación o interrumpa la alimentación en el panel de fusibles o interruptor de circuito.

iv) No use la cavidad como lugar de almacenamiento. No deje productos de papel, utensilios de cocina ni comida en la

cavidad cuando no la esté usando.

17) Los líquidos, tales como agua, café o té se pueden sobrecalentar más allá del punto de ebullición sin que parezca que

han hervido. No siempre se presenta un burbujeo o ebullición visible al retirar un recipiente del horno microondas. ESTO

PUEDE CAUSAR EL DESBORDE DE LÍQUIDOS MUY CALIENTES AL MOVER EL RECIPIENTE O AL INSERTAR UN

UTENSILIO EN EL LÍQUIDO.

18) No instale el horno sobre el soporte independiente (únicamente para CANADÁ).

CONSERVE ESTAS INSTRUCCIONES

No almacenar o utilizar gasolina u otros materiales inflamables o líquidos cerca de este u otros aparatos.

ADVERTENCIA: Una instalación indacuada, lo mismo que modificaciones y operaciones de mantenimiento

incorrectas pueden causar daños a la estructura y a las personas y provocar la muerte. Antes de instalar el aparato leer con

mucha atención las instrucciones de la instalación, del funcionamiento y del mantenimiento.

5958 992 00

5

Page 6

USA

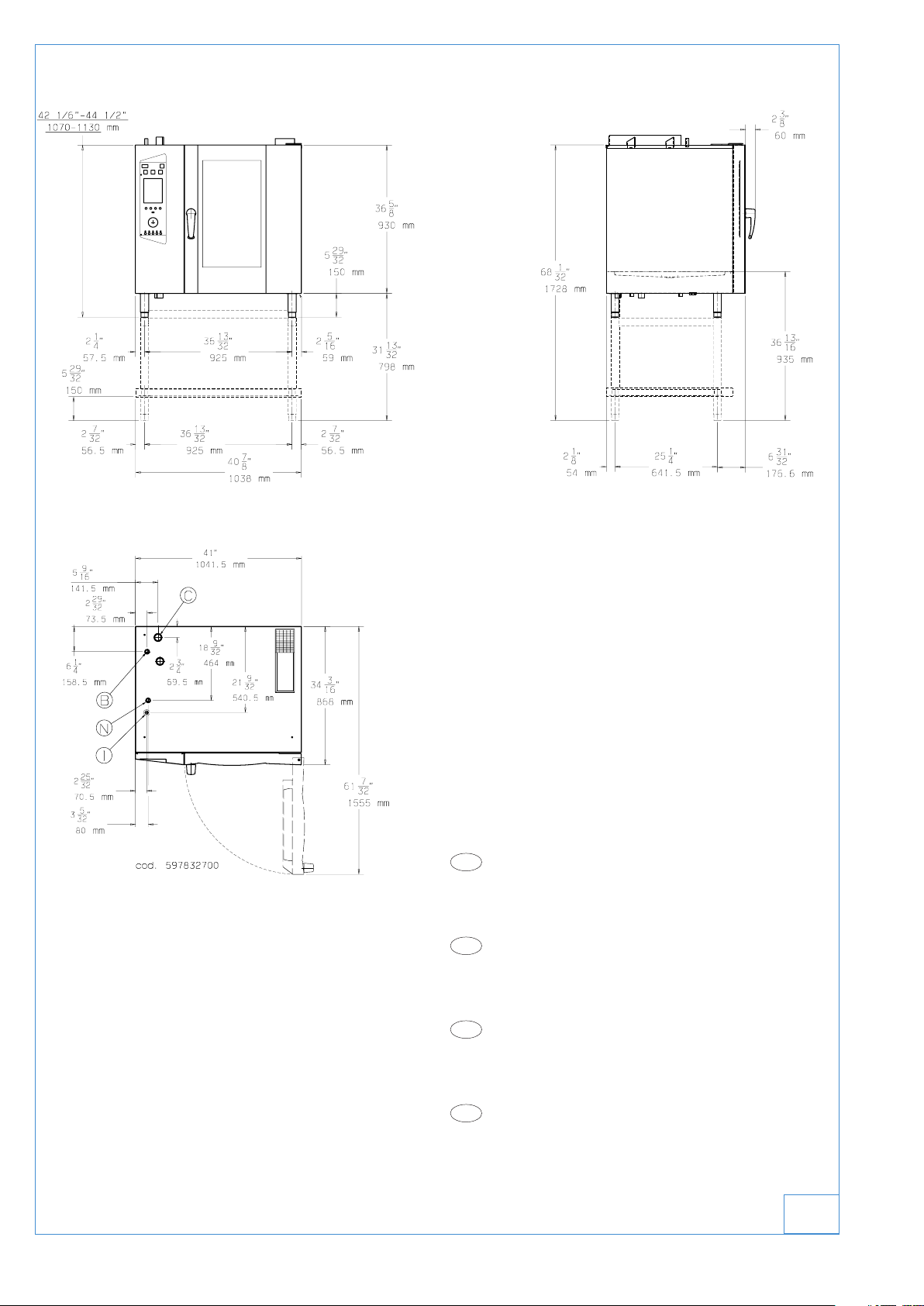

INSTALLATION DIAGRAM

IT

SCHEMI DI INSTALLAZIONE

CDN

SCHEMAS D'INSTALLATION

ES

ESQUEMA PARA LA INSTALACIÓN

5958 992 00

6

Page 7

IN THE NEXT PICTURE

USA

I - Power supply cable inlet

B - Water supply connection (0.5- 5 °F) ø3/4" water conn.

C - Water drain connection ø1"1/4 NPT gasline

N - Steam condens. water connection ø3/4" water conn.

IT

I - Entrata cavo elettrico

B - Attacco alim. acqua (0,5 - 5 °F) ø3/4" water conn.

C - Collettore scarico acqua ø1"1/4 NPT gasline

N - Attacco acqua Conden. fumane ø3/4" water conn.

CDN

I - Entrée câble électrique

B - Entrée eau (0,5 - 5 °F) ø3/4" water conn.

C - Collecteur évacuation eau ø1"1/4 NPT gasline

N - Entrée eau Conden.vapeurs ø3/4" water conn.

ES

I - Ingreso cable eléctrico

B - Conexión de agua (0,5 - 5 °F) ø3/4" water conn.

C - Colector del desagüe ø1"1/4 NPT gasline

N - Entrada del agua de condensación ø3/4" water conn.

5958 992 00

1a

7

Page 8

Mod.: 10 GN 1/1

USA

I - Power supply cable inlet

B - Water supply connection (0.5- 5 °F) ø3/4" water conn.

C - Water drain connection ø1"1/4 NPT gasline

N - Steam condens. water connection ø3/4" water conn.

IT

I - Entrata cavo elettrico

B - Attacco alim. acqua (0,5 - 5 °F) ø3/4" water conn.

C - Collettore scarico acqua ø1"1/4 NPT gasline

N - Attacco acqua Conden. fumane ø3/4" water conn.

CDN

I - Entrée câble électrique

B - Entrée eau (0,5 - 5 °F) ø3/4" water conn.

C - Collecteur évacuation eau ø1"1/4 NPT gasline

N - Entrée eau Conden.vapeurs ø3/4" water conn.

ES

I - Ingreso cable eléctrico

B - Conexión de agua (0,5 - 5 °F) ø3/4" water conn.

C - Colector del desagüe ø1"1/4 NPT gasline

N - Entrada del agua de condensación ø3/4" water conn.

1b

5958 992 00

8

Page 9

IN THE NEXT PICTURE

USA

I - Power supply cable inlet

B - Water supply connection (0.5- 5 °F) ø3/4" water conn.

C - Water drain connection ø1"1/4 NPT gasline

N - Steam condens. water connection ø3/4" water conn.

IT

I - Entrata cavo elettrico

B - Attacco alim. acqua (0,5 - 5 °F) ø3/4" water conn.

C - Collettore scarico acqua ø1"1/4 NPT gasline

N - Attacco acqua Conden. fumane ø3/4" water conn.

CDN

I - Entrée câble électrique

B - Entrée eau (0,5 - 5 °F) ø3/4" water conn.

C - Collecteur évacuation eau ø1"1/4 NPT gasline

N - Entrée eau Conden.vapeurs ø3/4" water conn.

ES

I - Ingreso cable eléctrico

B - Conexión de agua (0,5 - 5 °F) ø3/4" water conn.

C - Colector del desagüe ø1"1/4 NPT gasline

N - Entrada del agua de condensación ø3/4" water conn.

5958 992 00

1c

9

Page 10

NO TEXT ON THIS PAGE

10

5958 992 00

Page 11

STEAM/CONVECTION OVENS MICROWAVE ELECTRIC

6 GN 1/1

260450 260462 260456

260451 260463 260457

°

**

°

**

°

**

400 230 200

2. TABLE 1: TECHNICAL DATA

INSTALLATION AND OPERATING INSTRUCTIONS(valid for Italy)

Summary Page

- Installation diagrams ........................................................ 8

- Appliance identification ................................................. 11

I. GENERAL CHARACTERISTICS ..................................... 12

1. Appliance description ................................................... 12

2. Table 1: Technical data .................................................. 12

3. General instructions ..................................................... 13

4. The environment ............................................................ 14

4.1 Packing..................................................................... 14

4.2 Use ........................................................................... 14

4.3 Cleaning ................................................................... 14

4.4 Disposal ................................................................... 14

II. INSTALLATION INSTRUCTIONS.................................... 15

1. Place of installation....................................................... 15

1.1 Reference standards ................................................ 15

2. Positioning ..................................................................... 15

3. Electrical connection .................................................... 15

3.1 Power cable installation ............................................ 16

4. Connection to water system ........................................ 16

4.1 Supply water characteristics .................................... 16

4.2 Water drain system .................................................. 16

5. Safety device ................................................................. 17

6. Operation check ............................................................ 17

7. Maintenance................................................................... 17

8. Brief troubleshooting guide ......................................... 18

9. Position of main components ...................................... 18

III. OPERATING INSTRUCTIONS ....................................... 19

1. Oven door opening ....................................................... 20

1.1 6- and 10-rack models ............................................. 20

2. Oven door closing ......................................................... 20

2.1 6- and 10-rack models ............................................. 20

3. Description of control panel......................................... 20

3.1 Foreword .................................................................. 20

3.2 Basic controls ........................................................... 20

3.3 Main cooking modes ................................................ 21

3.4 Special cooking modes ............................................ 21

3.5 Additional functions .................................................. 22

OVEN USE............................................................................. 23

4. Operating level A ........................................................... 23

4.1 Switching oven on .................................................... 23

4.2 Selecting controls ..................................................... 23

4.3 AUTOMATIC (Automatic control).............................. 23

4.4 MANUAL (Manual control) ....................................... 25

4.5 Support function settings ......................................... 28

4.6 PROGRAM (Program control).................................. 29

5. Basic data settings........................................................ 31

6 Modifying set parameters .............................................. 31

7. Information and errors .................................................. 32

8. Switching off in case of fault........................................ 32

9. Cleaning and maintenance ........................................... 32

9.1 Steam generator periodical maintenance ................ 33

9.2 Replacing consumable components ........................ 33

9.3 Particular cleaning.................................................... 34

EN

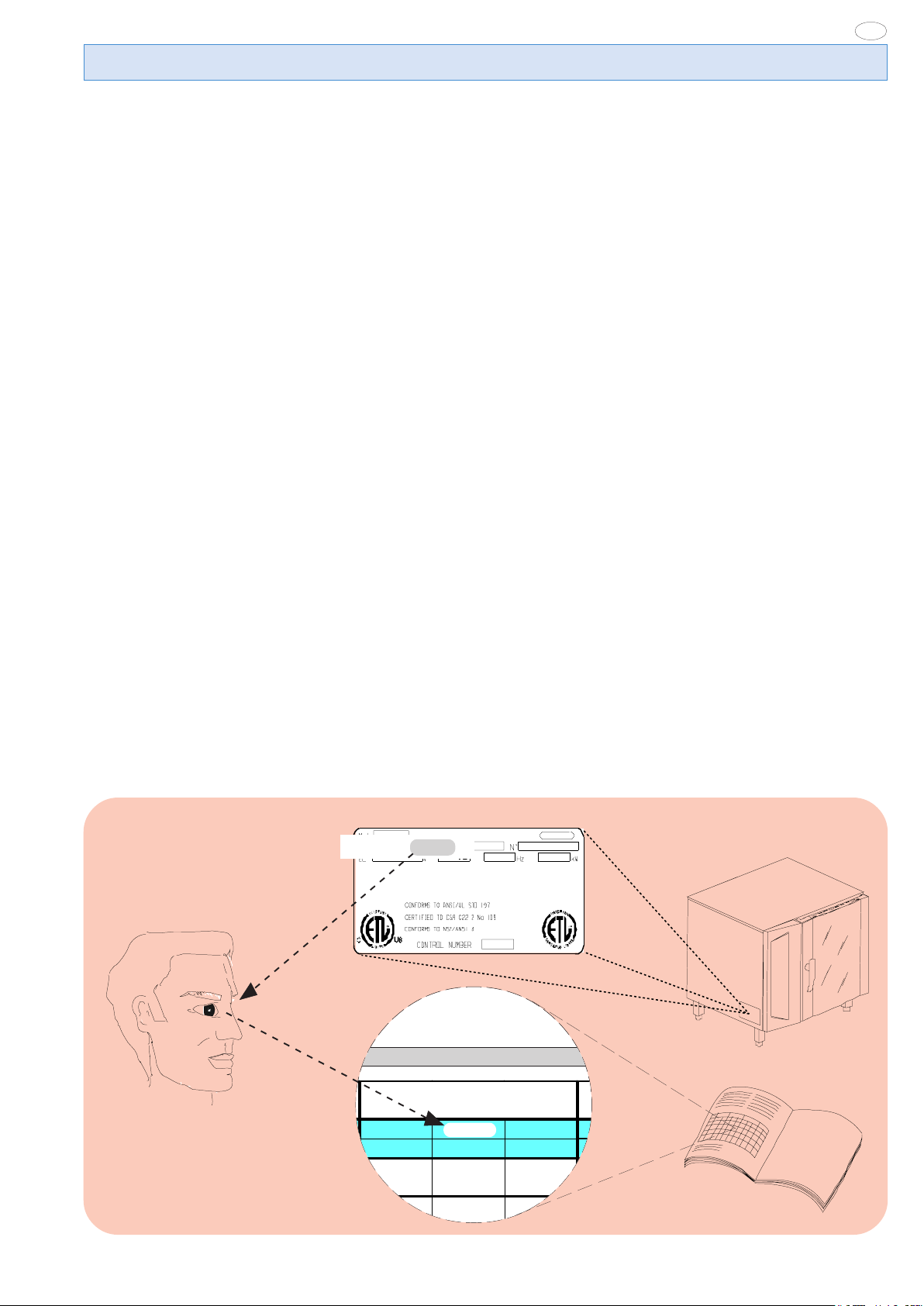

- APPLIANCE IDENTIFICATION

- CONTROL PANEL FIGURES ......................................... 107

Rating plate

PNC 9PDX 260462 05

260462

5958 992 00

11

Page 12

EN

I. GENERAL CHARACTERISTICS

1. APPLIANCE DESCRIPTION

This handbook concerns various appliance models.

For further information regarding your model, refer to Table

1"Technical Data”.

The appliance has the following features:

• Digital indication of temperature.

• Thermostatic probe for measuring the product’s “core” temperature (core probe).

• Constant monitoring of cooking parameters during the entire

cycle.

• Periodical emptying and subsequent automatic washing of the

steam generator to prevent excess scaling.

• Signalling the need for periodical boiler maintenance, see relevant section.

2. TABLE 1: TECHNICAL DATA

• Compartment rapid fume extraction device for gratinating, with

automatic activation.

• AIR-BREAK anti-backflow device for preventing backflow from

the drainage system entering the oven.

• Compartment lighting lamps.

• Door opening double-action safety mechanism to prevent burns.

• Door with double glass: better comfort in the kitchen and low

surface temperatures.

• Cycle for daily cleaning of cooking compartment (CLEANING

SYSTEM) (according to model).

• Self-diagnosis for possible malfunctions by means of signalling

with identification codes (refer to par. “Information and error

codes”.

GRI DS

PNC *

CONVECTO R °

BOILER * *

SUPPLY VOLTAGE

Total W atts

Maximum load capacities

(food)

Net we ight

Shipping we ight

Shipping width

Shipping height

Shipping depth

10GN1/1

(AOW101E)

260573

°

**

208V 3ph

60Hz

64amps

23 kW

110 lbs.

(50 kg)

386 lbs

(175 kg)

430 lbs.

(195 kg)

42 15/16"inch

(1090 mm )

49 5/8"inc h

(1260 mm )

39 9/16"inc h

(1005 mm)

Information on sound emissions: The functional components

of the appliances in question have a noise level not exceeding 70

dB (A).

The model of your oven is indicated at the PNC field on the

*

“Technical Data” plate located at the bottom of the left side.

^ OPERATING LEVEL.

5958 992 00

12

Page 13

EN

3. GENERAL INSTRUCTIONS

• The following terms alert you to potentially dangerous conditions

to the operator, service personnel or to the equipment.

• Danger! This term warns of immediate hazards which will result in

severe injury or death.

• Warning! This term refers to a potential hazard or unsafe

practice which could result in injury or death.

• Notice. This term refers to information that needs special

attention or must be fully understood, even though not dangerous.

• Keep the appliance area free and clear from combustibles.

Warning Fire hazard.

For your safety, do not store or use gasoline or other flammable,

vapors and liquids in the vicinity of this or any other appliance.

Keep area around appliances free and clear of combustibles

Warning!

Failure to properly vent the oven can be hazardous to the health

of the operator; and will result in operational problems,

unsatisfactory baking, and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will

not be covered by the Manufacturer’s warranty.

WARNING: The equipment warranty is not valid unless the

appliance is installed, started and demonstrated under the supervision

of a factory trained installer.

WARNING: The unit must be installed by Personnel who are

qualified to work with electricity and plumbing. Improper installation

can cause injury to personnel and/or damage to the equipment. The

unit must be installed in accordance with applicable codes.

Important: The installation instructions contained

herein are for the use of qualified installation and

service personnel only. Installation or service by

other than qualified personnel may result in

damage to the appliance and/or injury to the

operator. FAILURE TO COMPLY WITH

INSTALLATION INSTRUCTION OR

IMPROPER INSTALLATION WILL VOID

WARRANTY AND RESPONSIBLITIES OF THE

MANUFACTURE.

NOTICE: INTENDED FOR COMMERCIAL USE ONLY. NOT

FOR HOUSEHOLD USE.

CAUTION HOT SURFACES

CAUTION RISK ELECTRIC SHOCK

CAUTION: Do not locate unit adjacent to any high heat or

grease producing piece of equipment, such as a range top,

griddle, fryer, etc., that could allow radiant heat to raise the

exterior temperature of the Air-O-Steam Oven.

• Before installing and starting the appliance carefully read this

handbook as it provides important information and instructions

on safety, installation, use and maintenance.

• Our appliances have been studied and optimized to give the

highest performance. This appliance is intended for industrial use

only and is specifically designed to cook food. Any other use will be

considered “improper use” and will void the warranty and

manufacturer liability.

WARNING: ANY POTENTIAL USER OF THE EQUIPMENT

SHOULD BE TRAINED IN SAFE AND CORRECT OPERATIONG

PROCEDURES.

WARNING: BEFORE SERVICING, DISCONNET THE

ELECTRICAL SERVICE AND PLACE A RED TAG AT THE

DISCONNECT SWITCH TO INDICATED WORK IS BEING DONE

ON THAT CIRCUIT.

NOTICE: Using any parts other than OEM original spare parts

relieves the manufacturer of all warranty and liability.

• Carefully keep this handbook for further consultation by the

various operators, or in case the appliance is resold.

• The installation of this unit must conform to local codes or, in the

absence of local codes, to all National Codes governing plumbing,

sanitation, safety and good trade practices.

5958 992 00

NOTICE: Manufacturer reserves the right to change specifications

at any time without notice.

Failure to comply with the above requirement may jeopardise

the safety of the appliance and invalidate the guarantee.

13

Page 14

EN

WARNING: DO NOT SPRAY THE OUTSIDE OF THE

APPLIANCE WITH WATER OR CLEAN WITH A WATER JET.

CLEANING WITH A WATER JET CAN IMPREGNAT

CHLORIDES INTO THE STAINLESS STEEL, CAUSING THE

ONSET OF CORROSION.

WARNING: DO NOT USE PRODUCTS CONTAINING

CHLORINE (BLEACH, HYDROCHLORIC ACID ETC.) EVEN

DILUTED, TO CLEAN STEEL SURFACES.

WARNING: DO NOT USE CORROSIVE SUBSTANCES (E.G.

MURIATIC ACID) TO CLEAN THE FLOOR UNDER THE

APPLIANCE.

4. THE ENVIRONMENT

4.1 PACKING

• All packing materials are environmentally friendly. They can be

stored without risk or burned in a special waste incineration plant.

Recyclable plastic components are marked as follows:

polyethylene : outer wrapping, instruction handbook

PE bag, gas nozzle bag.

polypropylene: roof packing panels, straps

pp

polystyrene foam: corner protectors

PS

4.2 USE

• Our appliances are designed and optimized with laboratory testing in order to offer high performance and efficiency. In any case,

to reduce energy consumption (electricity, gas and water), avoid

using the equipment empty for long periods or in conditions that

compromise optimum efficiency (e.g. door open). Also, if possible, pre-heat the appliance immediately before use.

4.3 CLEANING

• In order to reduce the emission of pollutants into the environment, it is advisable to clean the appliance (externally and when

necessary internally) with products that are more than 90% bio-

degradable %.

4.4 DISPOSAL

• At the end of the appliance’s working life, make sure it is not

dispersed in the environment.

• Our appliances are manufactured using more than 90% metal

materials (stainless steel, iron, aluminum, galvanized sheet, etc.)

which can therefore be recycled by means of the conventional

recovery facilities, in conformity with the current regulations in

the country of use.

• Make the appliance unusable by removing the power cable and

any compartment or cavity closing mechanisms (when present)

in order to avoid the risk of someone becoming closed inside.

14

5958 992 00

Page 15

II. INSTALLATION INSTRUCTIONS

Important: The external panels of the oven must be

removed for the operations described in this section. As the

unit must be operating in order to carry out some

adjustments, pay maximum attention to the live parts.

1.3 UNPACKAGING

• Remove the appliance from the packaging and take away the

protective film that covers the appliance's external panels carefully to avoid leaving any trace of glue. If necessary remove the glue

using an a non-corrosive solvent, rinsing it off and drying carefully.

• Dispose of packaging material in compliance with the regulations

in force in the country where the product is to be used.

EN

1. PLACE OF INSTALLATION

1.1 VENTILATION

The necessity for a properly designed and installed ventilation

system cannot be over emphasized. The ventilation system will

allow the unit to function properly while removing unwanted vapors

and products of combustion from the operating area.

The appliance must be vented with a properly designed mechanically

driven exhaust hood. The hood should be sized to completely cover

the equipment plus an overhang of a least 6"/15.3cm on all sides not

adjacent to a wall. The capacity of the should be sized appropriately

and provisions for adequate makeup air.

Refer to your local ventilation codes. In the absence of local codes,

refer to the National ventilation code titled, “Standard for the

Installation of Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96Latest Edition.

It is recommended that the ventilation system and duct work be

checked at prevailing intervals as specified by the hood manufactured

• The appliance must only be installed in adequately ventilated

premises.

NOTICE: Proper ventilation is the owner's is responsibility. Any

problem due to improper ventilation will not be covered by the

warranty.

1.2 REFERENCE STANDARDS

Note: The electric supply installation must satisfy the requirements

of the appropriate statutory authority, such as the National Electrical

Code (NEC) ANSI/NFPA70, (U.S.A..): the Canadian Electrical

Code, CSA C22.2; or other applicable regulations.

Note: The electric supply connection must meet all national and

local electrical code requirements.

Note: The installation of this unit must conform to local codes or,

in the absence of local codes, to all National Codes governing

plumbing, sanitation, safety and good trade practices, and to the

National Gas Code ANSI Z223.1.

• Local codes regarding installation vary greatle from one area to

another. This equipment is to be installed to comply with the

applicable federal, state or local codes.

The installation instructions contained herein are for the use of

qualified installation and service personnel only. Installation or

service by other than qualified personnel may result in damage to

the appliance and/or injury to the operator.

FAILURE TO COMPLY WITH INSTALLATION INSTRUCTION

OR IMPROPER INSTALLATION WILL VOID WARRANTY AND

RESPONSIBLITIES OF THE MANUFACTURE.

The National Fire Protection Association, Inc states in its NFPA 96

latest edition that local codes are the "authority having jurisdiction"

when it comes to installation requirements for equipment.

Therefore, installations should comply with all local codes.

5958 992 00

1.4 IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

The container should be examined for damage before and during

unloading. The freight carrier has assumed responsibility for its

safe transit and delivery. If damaged equipment is received,

either apparent or concealed, a claim must be made with the

delivering carrier. Apparent damage or loss must be noted on the

freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not

signed, the carrier may refuse the claim. The supply can supply

the necessary forms. A request for inspection must be made to

the carrier within 15 days if there is concealed damage or loss that

is not apparent until after the equipment is uncrated. The carrier

should arrange an inspection. Be certain to hold all contents plus

all packing material. Under no circumstances should a damaged

appliance be returned to the manufacturer without prior notice and

written authorization.

2. POSITIONING

• For the overall space required and connection dimensions, refer to the installation diagrams given on the first pages of this

instruction handbook.

• The left, right and top surface of the appliance must remain

at least 23.62" (50cm) from other surfaces to enable maintenance

interventions (if not possible, minimum 1.97" -5cm- is request for

left and right), whereas the back must be at least

1.97" (5cm) from any surface.

• Position the appliance and if necessary adjust the height of the

worktop by means of the adjustable feet.

• The appliance is not suitable for built-in installation.

Important:

Make sure the steam coming from the oven discharge or

adjacent appliances does not reach the special vents for

the cooling of internal components, located at the

bottom of the appliance.

3. ELECTRICAL CONNECTION

• A fused disconnect switch or main circuit breaker (customer

furnished) MUST be installed in the electric supply line for the

appliance. It is recommended that this switch/circuit breaker

have lockout/tagout capability. Before making any electrical

connections to this appliance, check that the power supply is

adequate for the voltage, amperage, and phase requirements

on the rating plate.

• A safety cutout switch of suitable capacity with a contact

breaking distance of at least 3 mm must be fitted upstream of the

appliance.

The cutout switch must be installed near the appliance in the

permanent electrical system of the premises.

15

Page 16

EN

• The appliance must be electrically grounded in accordance with

local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.2, as applicable.

The grounding conductor must therefore be connected to the

terminal marked Gon the connection terminal board. The

appliance must also be connected to an earth grounding

system.

This connection is made using the stop screw marked E

located on the outside of the appliance near the power cable

inlet.

The grounding wire must have a minimum cross-section of

8 AWG (10 mm

GROUNDING INSTRUCTIONS

This appliance must be connected to a grounded, metallic,

permanent wiring system, or an equipment grounding

conductor should be run with the circuit conductors and

connected to the equipment grounding terminal or lead on

the appliance.

2

).

RATING PLATE

::

:

::

3.1 POWER CABLE INSTALLATION

To connect the power cable to the appliance, proceed as follows:

Model 6 - 10 - 20 GN

• Remove the left side panel.

• Connect the cable to the terminal block as shown in the wiring

diagram attached to the appliance, and secure it with the special

cable gland.

The manufacturer declines any liability if the safety regulations are not respected.

The manufacturer requires when stacking units each appliance

have its own branch circuit protection. An air-o-speed® unit stacked

with an air-o-chill® unit should have a separate circuit breaker for the

upper and lower units.

4.1 SUPPLY WATER CHARACTERISTICS

4.1.1 WATER INLET “N”.

Important (LEVEL A ONLY)

The water supply pipe must have an inside diameter of at

least 20 mm and be free of elbow unions.

The discharge steam condensation system can be fed with cold

water suitable for human consumption, having the following

characteristics:

- total hardness not exceeding 400ppm (40°fH); in LEVEL

A ovens equipped with CLEANING SYSTEM it is advisable to use

water of hardness not exceeding 5° French; for that purpose, a

water softener with automatic regeneration for installing on inlet

line “N” is supplied as an accessory by request.

- pressure between 22 to 36 psi (150-250 kPa); higher

pressures involve waste of water.

Note:

To check correct water installation, make sure the rotating wash

arm (CLEANING SYSTEM) does not turn below 100 rpm (120

max).

4.1.2 WATER INLET “B”.

(With feed pipe supplied)

The inlet for steam production must be fed with water suitable

for human consumption, having specific characteristics:

- total hardness between 5 - 50ppm (0.5 - 5 °fH) French

for reducing scaling inside the steam generator.

For that purpose, a water softener with automatic regeneration

for installing on inlet line “B” is supplied as an accessory by request;

it has a kit for sterilizing the resins (by further request).

- pressure between 22 to 36 psi (150-250 kPa); higher

pressures involve waste of water.

- chlorine concentration (Cl -) not high (acceptable refer-

ence value ~10 ppm), so as not to damage the steel structures

inside the oven.

- pH higher than 7.

For that purpose, a special filtering unit for installing on inlet line

“B” is supplied as an accessory by request. The purpose of this

unit is to reduce the water hardness to optimum values (below

50ppm "5 °fH") (optimum value), and therefore also serving as a

water softener.

- electric conductivity between 50 and 2000 µS/cm (68°F)

(20°C).

4. WATER CONNECTION

(See the installation diagrams at the beginning of this handbook)

This equipment is to be installed to comply with the applicable

Federal, State, Local plumbing codes, or the Basic Plumbing

Code of the Building Officials and Code Administrators

International Inc. (BOCA) and Food Service Sanitation Manual

of the Food and Drug Administration (FDA).

The oven has two separate inlets (“B” and “N”) for the supply

water.

The supply pipes of both inlets must be equipped with a mechanical filter and shutoff cock. Before installing the filters, it is

advisable to let a certain amount of water flow in order to clean

the pipe of any solid particles.

Important: The use of water treatment systems utilizing

methods different from those indicated by the manufacturer of

the equipment is not allowed and will completely invalidate the

warranty.

Likewise, dispensers of substances for preventing scale in

the pipes (e.g. polyphosphate dispensers) must not be

used because they can compromise correct machine

operation.

4.2 WATER DRAINING SYSTEM

The oven has an AIR-BREAK anti-backflow device inside to prevent possible backflow from the drainage system entering the

internal pipes and the oven compartment. This allows the drain

pipe to be connected directly to the mains system or discharging

into a floor grate.

The drain pipe (rigid or flexible type) can be run to the side or

16

5958 992 00

Page 17

back if the oven is not placed against a wall, excluding the front

part with rack support structure. It must not be more than 3 feet

(1 metre) long, with inside diameter not less than that of the

oven discharge pipe (1" 1/4), and must withstand temperatures

of at least 212°F (100°C). Make sure there are no constrictions in

hoses or elbows in metal pipes, along the entire drain path. Avoid

horizontal sections where water can collect and stagnate (min.

slope 5%).

WARING: BLOCKING THE DRAIN IS HAZARDOUS.

C - Oven drain

C1 - Safety outlet

Important:

- Do not obstruct the safety outlet C1.

- Do not connect the safety outlet C1 to the drainage system.

Note:

If water comes out of the AIR-BREAK (safety outlet C1) this means

the drain C is blocked. Any elimination of the obstruction must

be carried out by specialized technical personnel.

5. SAFETY DEVICE

The appliance is equipped with the following safety devices:

- Fuses, see the wiring diagram, located behind the control panel.

For replacement, unscrew the holding cap and replace the damaged component with another one of equal capacity; this value is

indicated on the rating plate located in the same place.

- Compartment manual-reset safety thermostat located behind the control panel; it intervenes, cutting off the convection

heating supply.

RESETTING OPERATIONS MUST BE CARRIED OUT BY

SPECIALIZED TECHNICAL PERSONNEL AFTER ELIMINATING

THE CAUSES OF INTERRUPTION.

- Automatic-reset thermal device inside the fan motor, which

intervenes in case the motor overheats, protecting equipment

operation; it intervenes, cutting off the electric power to the appliance.

- MAGNETRON manual-reset safety thermostat located behind the left side panel; it intervenes, cutting off the power supply

to the MAGNETRON.

Resetting operations must be carried out by specialized technical personnel after eliminating the causes of interruption.

5958 992 00

EN

6. OPERATION CHECK

- Switch the appliance on, following the instructions in the section “Operating instructions”;

- Explain appliance operation, routine maintenance and cleaning

operations to the user, with the help of the instruction handbook.

Important:

- During operation, pay attention

to the hot zones of the exterior surface.

- Do not place objects on the outlets located at the top

of the appliance.

- With oven hot, check the correct working of the door closing

mechanism. If necessary, adjust closing by adjusting the position

of the catch.

7. MAINTENANCE

PRECAUTION TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

(a) Do not operate or allow the oven to be operated with

the door open.

(b) Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

(1) interlock operation,

(2) proper door closing,

(3) seal and sealing surfaces (arcing, wear, and other

damage),

(4) damage to or loosening of hinges and latches,

(5) evidence of dropping or abuse.

(c) Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, wave guide or

transmission line, and cavity for proper alignment,

integrity, and connection.

(d) Any defective or misadjusted components in the

interlock, monitor, door seal, and microwave generation

and transmission systems shall be repaired, replaced, or

adjusted by procedures described in this manual before

the oven is released to the owner.

(e) A microwave leakage check to verify compliance with

the Federal Performance Standard should be performed

on each oven prior to release to the owner.

The components requiring routine maintenance are accessible

by opening the control panel, and the left, right and rear panels.

Danger: Live voltage is present with panels removed and unit

switch on. Exercise extreme caution when work with live voltage.

NOTICE: Using any parts other than OEM original spare parts

relieves the manufacturer of all warranty and liability.

::

:

::

17

Page 18

EN

8. BRIEF TROUBLESHOOTING GUIDE

Even with correct use, malfunctions can occur.

Oven compartment heating does not switch on or is inefficient. Possible causes:

- Oven compartment temperature limiter activated

- Heating elements damaged

- Element contactor coil damaged

- Oven compartment temperature probe damaged (error EPt1 con-

figuration).

- Controller damaged

- Fuse F2 blown, see wiring diagram.

- MAGNETRON limiters activated.

The steam generator heating does not switch on or is inefficient in steam production. Possible causes:

- Heating elements damaged

- Element contactor coil damaged

- Controller damaged

- Fuse F2 blown

- No water in system

- Boiler drain closing device faulty

- Water inlet solenoid valves damaged (they do not open)

Incorrect oven compartment temperature thermostatting.

Possible causes:

- Electronic controller faulty.

- Oven compartment temperature probe dirty, faulty or discon-

nected, see error EPt1 configuration.

The oven goes off. Possible causes:

- Fuse F2 blown due to damaged auxiliary circuit components.

Oven compartment lamps damaged

Important: Switch the appliance off before changing oven com-

partment lamps.

9. POSITIONING OF MAIN COMPONENTS

(Any operation inside the appliance must only be carried out

by an installer authorized by the Manufacturer)

Open the control panel to access the following components:

Danger: Live voltage is present with panels removed and unit

switch on. Exercise extreme caution when work with live voltage.

- Electronic boards.

- Compartment temperature limiter thermostat.

- Fuses.

- Door safety microswitch.

- Transformer for compartment lamps

- Compartment vent shutter control gear motor

WARNING: Before servicing unit switch off power at the main

circuit breaker and place a red tag on the breaker to indicate work

is being done on the circuit.

Remove the appliance left, right and rear panels to access to all

the other components.

18

5958 992 00

Page 19

III. OPERATING INSTRUCTIONS

EN

Before starting the appliance, carefully read this handbook. The

instructions and information given in it are important for correct

and optimum oven use. If required, further details regarding its

characteristics and cooking performance can be obtained from

the dealer.

ANY POTENTIAL USER OF THE EQUIPMENT SHOULD BE

TRAINED IN SAFE AND CORRECT OPERATING PROCEDURES.

• This appliance is intended for industrial use only and is specifically

designed to cook food. Any other use will be considered "improper

use" and will void the warranty and manufacturer liability.

• To avoid obstructing the fume and steam discharge pipes, do

not place pans or utensils of any kind on the oven.

• Have the appliance fully checked periodically (at least once a

year). For that purpose, it is advisable to stipulate a maintenance

contract.

• The core probe is a precision component. Absolutely avoid

impacts, forcing when inserting, and pulling of the flexible cable (in

particular when using the trolley-mounted structures). The

warranty does not cover the replacement of core probes

damaged by improper use.

• In the combi cooking cycle it is advisable not to exceed

temperatures of 392-410°F (200-210°C). Higher values can reduce the efficiency of the compartment seals.

• When arranging food inside the oven compartment, keep a

space of at least 1.5" (40 mm) between trays, to ensure better

circulation of hot air.

• Do not salt food inside the oven compartment, in particular

with humid cycles.

MICROWAVE INSTRUCTIONS

- make sure the utensils are those suitable for microwave

ovens;

- when warming food in paper or plastic containers, check the

oven frequently, due to the risk of fires;

- if any smoke is noticed, switch off and unplug the appliance

and keep the door closed in order to extinguish possible

flames;

- eggs with shells and hard boiled eggs must not be warmed

in microwave ovens because they may explode.

- periodically clean the oven, removing all traces of food;

failure to keep the oven clean will lead to deterioration of the

surfaces, and thus affect appliance life and give rise to

hazardous situations.

- IMPORTANT - IF THE DOOR OR THE DOOR SEALS ARE

DAMAGED, THE OVEN MUST NOT BE USED UNTIL IT HAS

BEEN REPAIRED BY AUTHORIZED PERSONNEL;

- WARNING - IT IS DANGEROUS FOR ANYONE EXCEPT

AUTHORIZED PERSONNEL TO CARRY OUT MAINTENANCE

OR REPAIR OPERATIONS INVOLVING THE REMOVAL OF

ANY COVER PROTECTING AGAINST EXPOSURE TO MICROWAVE ENERGY;

Only use the HEAT PROBE (probe) recommended for this

microwave oven.

• Do not place flammable liquids (e.g. spirits) inside the oven

compartment during operation.

Important!

The maximum height at which the trays are placed in the oven

does not exceed 5.25 ft (tm. 1,6). This applies if it is installed

according to the instructions and with the use of original

accessories.

Whenever using supports different from ours, make sure not to

exceed the above-mentioned height when installing the oven.

Otherwise there could be the risk of spilling hot cooking liquids

(sauces, oil, melted fat, etc.) contained in the high trays and

not visible during handling.

PLACE THE LABEL SUPPLIED AND CONTAINING THE FOLLOWING INSTRUCTIONS, IN A VISIBLE POSITION NEXT TO

THE OVEN:

- CAUTION - MICROWAVE WARMING OF BEVERAGES

MAY RESULT IN DELAYED BOILING OVER, THEREFORE

TAKE CARE WHEN HANDLING THE CONTAINER;

- CAUTION - FEEDING-BOTTLES AND HOMOGENIZED

FOODS IN JARS MUST BE OPEN DURING WARMING, THE

CONTENTS MUST BE AGITATED OR SHAKEN AND THE

TEMPERATURE MUST BE CHECKED BEFORE CONSUMPTION, IN ORDER TO AVOID SCALDING;

- CAUTION - LIQUIDS OR OTHER FOODS MUST NOT BE

WARMED IN SEALED CONTAINERS BECAUSE THEY

COULD EXPLODE.

PRECAUTIONS TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY :

(a) Do not attempt to operate this oven with the door open

since open-door operation can result in harmful exposure

to microwave energy. It is important not to defeat or

tamper with the safety interlocks.

(b) Do not place any object between the oven front face

and the door or allow soil or cleaner residue to

accumulate on sealing surfaces.

(c) Do not operate the oven if it is damaged. It is

particularly important that the oven door close properly

and that there is no damage to the:

(1) door (bent),

(2) hinges and latches (broken or loosened),

(3) door seals and sealing surfaces.

(d) The oven should not be adjusted or repaired by

anyone except properly qualified service personnel.

5958 992 00

19

Page 20

EN

1. OVEN DOOR OPENING

The oven is equipped with a safety system to prevent you being

exposed to steam when opening the door completely, therefore

carry out the following operations, according to the model:

1.1 6- AND 10-RACK MODELS

Caution! Risk of burns.

Always open the door with caution when the oven is hot.

a) Turn the oven door handle counter-clockwise as far as it will go.

The door opens slightly and is stopped by the door safety device.

If there is a cooking program in progress it will be interrupted but

will continue when door is closed.

3. DESCRIPTION OF CONTROL PANEL

3.1 FOREWORD

For easy understanding of oven operation, when reading keep

the flap relating to the control panel of your model open, identifying it from those given on the last pages of this manual.

All the functions available in the various models of the range are

described below.

Certain functions are shared by all models, whereas others

are available only on some versions.

3.2 BASIC CONTROLS

Main switch

Cooking cycle/program Start/stop.

b) Turn the door handle to the vertical position and then pull

outwards, the door will offer light resistance and then open

completely.

2. OVEN DOOR CLOSING

2.1 6- AND 10-RACK MODELS

a) Turn the door handle counter-clockwise as far as it will go and

press the door closed against the oven.

b) Keeping the door pressed closed, lock it by turning the handle

to the vertical position.

GRAPHIC DISPLAY management controls : buttons for selecting oven control mode.

GRAPHIC DISPLAY

Graphic display for showing all available oven functions.

P1-P2-P3-P4 Button for selecting the functions shown on the

GRAPHIC DISPLAY.

Press this button once to select the function shown above the

arrow.

K Knob for selecting and setting the values of each function.

20

5958 992 00

Page 21

EN

3.3 MAIN COOKING MODES

Convection cycle: for roasting and gratinating at maximum tem-

perature 572°F(300°C).

Combi cycle: superheated steam. The steam generator and compartment heaters are used at the same time to keep foods soft

(max. temperature 482°F)(250°C).

Steam cycle: Ideal for boiling (operating temperature automatically fixed at 212°F)(100°C).

Low temperature steam can be set for gentle cooking, vacuum

packed foods and for thawing (temperature from 77°F a

210°F)(25° to 99°C); superheated steam 214° a 266)(101° a

130°C).

Microwave cycle: fast heating by microwaves that act directly

inside the food.

1:00

Timer for control of cooking time.

Digital thermometer/thermostat for control of product core tem-

perature.

- Microwave adjustment: for adjusting microwave power in all

cooking cycles.

1:00

3.4 SPECIAL COOKING MODES

Utilities

Functions useful for the type of cooking required.

Low power cycle (heating): for gentle baking, such as light patisserie. Combinable with all cycles.

Regeneration cycle: produces the optimum humidity for fast

heating of products to be regenerated (max. temperature

482°F)(250°C).

The regeneration program is a single phase function characterized by:

- a special cycle with controlled humidity;

- a preset temperature of 356°F(140°C) (adjustable if required);

- use of full power;

- operation in continuous Cont mode; once activated it remains

on with the door open or closed.

Caution

Always

Alternatively to continuous mode it can also accept a set cooking

time or the core probe.

Pause phase: by setting a time in this mode, it is possible to

delay the start of cooking programs or include pauses between

two cycles (e.g. proving).

- Electronic humidity adjustment: enables adjustment of the

required humidity level in convection, combi and regeneration

cycles.

! Risk of burns.

open the door with caution when the oven is hot.

300

Digital thermometer/thermostat for control of compartment tem-

5958 992 00

perature.

Low speed cycle (fan): for gentle baking, such as light patisserie. Combinable with all cycles.

Convection and microwave cycle with compartment vent

open: for very dry cooking, allowing the removal of humidity when

necessary (max. temperature 572°F (300°C).

Maintaining cycle (149°F) (65°C): for slow and prolonged

cooking, typically for meat (large cuts). Activated at the end of

cooking.

It can be used in combination with convection and steam modes.

Cooking with ECO-DELTA: for cooking large pieces of food (5kg

and over, e.g. whole turkey, leg of pork, etc.).

A temperature setting of between 34°F(1°C) and 248°F(120°C)

is used in this cooking mode.

In this case, cooking is moderate and long, because the COMPARTMENT temperature is automatically adjusted according to

that inside the food (CORE PROBE), maintaining a constant difference (ECO-DELTA) between them, throughout cooking.

E.g.

COOKING: START ...... END

ECO-DELTA = 176°... 176... 176... 176... 176°F (set)

CORE PROBE = 50°... 51... 52... 104... 140°F (set)

COMPARTMENT = 194°... 195... 196... 248... 284°F (result)

21

Page 22

EN

3.5 ADDITIONAL FUNCTIONS

Preheat or cooking: indicates (in AUTOMATIC) that the oven is

preheating the compartment (please wait) or cooking.

Warning light signalling oven door open.

Scale light: when this light comes on, the steam generator must

be descaled. Follow the instructions given in par. 7.

Introduce food (and insert core probe): indicates (in AUTOMATIC) that the oven is ready for loading food and possibly for

inserting the core probe in the product to be cooked.

Higher core temperature?: enables the core probe temperature to be increased at end of cycle (in AUTOMATIC).

More time?: enables the cooking time to be increased at end of

cycle (in AUTOMATIC).

Cooking with phases in sequence: for setting cooking programs

with several phases in automatic sequence (max. 6 phases).

- MANUAL -

Skip PHASE: for going from the phase in progress to the next.

- AUTOMATIC -

Display from AUTOMATIC to MANUAL: enables (in Manual

mode) control of the corresponding cooking parameters set in

Automatic mode.

D

DELAY START - (delayed cycle start): enables the cooking

cycle to be started later, by setting the required time.

A B C

Steam generator status light:

A - generator in filling phase or no water. Make sure water

reaches the oven!

B - generator in preheating phase.

C - generator ready (light off).

Information: press this button for important help regarding the

functions, and instructions on how to proceed.

Manual injection of water in compartment: for instantly increasing the moisture level during a cooking cycle.

Manual draining of steam generator water: press the button to

drain water from the steam generator.

Important

generator, make sure to:

respect the parameters regarding the water supply – see

always drain the generator at the end of each day.

! In order to reduce excessive scaling in the steam

installation;

Maintenance (Service)

A number of functions necessary for oven maintenance.

Display of current cooking parameters: press the corresponding

button to check the compartment temperature and humidity

values, the core probe temperature and cycle duration at any time

during cooking.

Cleaning System: automatic oven cleaning cycle (refer to par. 7.

CLEANING AND MAINTENANCE).

Fast compartment cooling: useful for going from one type of

cooking to another at lower temperature; it enables fan rotation

and automatic injection of water (TS < 180°C) even with the door

open.

Caution

Always

Before using the oven, make sure:

- the external electric safety switch is on;

- the water shutoff cocks are open;

- the oven outlets are not blocked.

22

! Risk of burns.

open the door with caution when the oven is hot.

5958 992 00

Page 23

OVEN USE

4. OPERATING LEVEL A

Foreword:

The initial condition is restored if no key is pressed or the knob is

not turned within 15 seconds (approx.) when selecting some functions.

4.1 SWITCHING THE OVEN ON

To switch the oven on, press the button I(O - I) of the following

switch:

EN

4.3 AUTOMATIC (Automatic control)

The AUTOMATIC control mode is used for automatic cooking, by

setting several simplified functions. This saves the operator from

having to know the cooking parameter values (temperature, time,

humidity and microwave) and makes the same type of cooking

more equal.

The functions to be set are as follows:

1) FOOD category

- 2) FOOD type

- 3) FOOD load

- 4) FOOD status

- 5) FOOD cooking level

4.3.1 FOOD CATEGORY

1) Press the button P2 (

turning knob K.

) and select the food CATEGORY by

The following occurs:

- the corresponding button lights up;

- the control panel lights up and the page in manual is shown;

- the display indicates the parameters (convection cycle, tem-

perature, and time) already set on the oven;

- the compartment lights up;

- the steam generator is

in filling phase

or no water

Make sure water reaches the oven!

- the steam generator is

in preheating phase ;

- the steam generator is

ready

(light off);

4.1.1 SWITCHING THE OVEN OFF

The oven is switched off by pressing the button O (O - I) of the

following switch:

PORK

FILLET

MED

12PCS 25oz 3GRID

FRESH

PORKPORK

PORK

PORKPORK

PORK is selected in the figure

2) Press the button P2 ( ) and select the food type with knob K.

4.2 SELECTING CONTROLS

(AUTOMATIC, MANUAL OR PROGRAMMED)

After SWITCHING THE OVEN ON select one of the following 3

modes to control the oven by pressing the relative button:

AUTOMATIC = automatic (

MANUAL = manual (

PROGRAM = programmed (

)

)

)

5958 992 00

FILLET

MED 12PCS 25oz 3GRID

FRESH

P2

3) Press the button P2 (

) and select the food load (MIN - MED -

MAX) with knob K (e.g. 3 grids with 12 pieces 25 oz "700 g" to one)

.

FILLET

MED 12PC 700G 3RACKS

FRESH

23

Page 24

EN

4) Press the button P2 ( ) and select the food status (FRESH -

FROZEN) with knob K.

MED 12PCS 25oz 3GRID

FRESH

This field is not selectable for some food types because there is only

one food condition, only FRESH or only FROZEN.

5) Press the button P2 (

) and select the food cooking level with

knob K .

FRESHFRESH

FRESH

FRESHFRESH

level 3 of 5

__

___________

FRESH

The GRAPHIC DISPLAY shows the COOKING IN PROGRESS

screen, giving the following information:

condition* __________________

PREHEATING

Time elapsed_______________

0:08

_____

Food CATEGORY

Food TYPE

Food LOAD

Food STATUS

_____________________

_________________

_________________

COOKING LEVEL

_______

PORK

FILLET

MED 12PC 700g 3RACKS

FRESH

_________________

P2 P4

P1 P2

6) If necessary, press the button P1 ( ) to go to the previous

functions.

Note:

In MANUAL mode, to check the corresponding parameters set in

AUTOMATIC MODE, press the following button

from AUTOMATIC to the corresponding MANUAL

After entering MANUAL mode it is not possible to go back to the

AUTOMATIC mode settings, therefore a new setting must be made,

whereas it is possible to modify the corresponding set parameters

and start cooking.

* The operating condition during cooking can be one of the following:

PREHEATING (please wait)

INTRODUCE FOOD or

INTRODUCE FOOD and CORE PROBE

- Open the door and introduce the product to be cooked

Caution! Risk of burns.

Always open the door with caution when the oven is hot.

- Close the door and press the button P4 ( )to confirm that

the food and the core probe have been introduced.

COOKING

HIGHER TEMPERATURE AT CORE ?

Turn the knob K to increase the cooking temperature at the

core of the food.

Press the button P2 (

EXTRA TEMPERATURE AT CORE?

) to confirm or P3 ( ) to cancel.

65

4.3.2 STARTING COOKING CYCLE - AUTOMATIC

- make sure the oven door is closed;

- Press the START/STOP button (the message PREHEAT appears)

Preheating is automatic for any set cooking cycle and cannot be

skipped in the AUTOMATIC control.

PORK

MORE TIME ?

Turn the knob K to increase the cooking time.

Press the button P2 ( ) to confirm or P3 ( ) to cancel.

EXTRA TIME?

0:10

PORK

5958 992 00

24

Page 25

EN

Note:

- The cooking cycles (steam, combi, convection and regenera-

tion) cannot be started until the steam generator is ready, as indicated by the corresponding light off (see par. 4.1).

During this period the time count does not start and the Start

cooking button flashes; this occurs also when the oven door is

opened.

Caution! Risk of burns.

Always open the door with caution when the oven is hot.

4.3.3 STOPPING THE COOKING CYCLE - AUTOMATIC

At the end of the set time, the cooking cycle automatically stops

and the oven bell sounds continuously.

Open the door and remove the product.

Caution! Risk of burns.

Always open the door with caution when the oven is hot.

Notes:

- The bell can be stopped in advance by carrying out any opera-

tion on the control panel or by opening the door.

The cooking cycle can be stopped manually by keeping the cycle

Start/Stop button pressed for 2 seconds.

Shorter presses will be ignored by the oven.

A cycle identical to that just completed can be repeated by pressing the Start/Stop button again.

1:00'

4.4 MANUAL (Manual control)

SETTING COOKING CYCLE

The MANUAL control mode is used to carry out food cooking

manually by setting the various parameters of a cycle.

The food is cooked by heating it and can occur in a certain MODE,

with a givenTEMPERATURE, TIME and also HUMIDITY. Therefore these factors must be set in order to perform a COOKING

CYCLE.

The oven works mainly by carrying out the operations given in

the following sections:

— SETTING COOKING CYCLE —-

- SELECTING COOKING MODE

- SETTING COOKING TEMPERATURE

- SETTING COOKING TIME

- SETTING AND USE OF CORE PROBE

- SETTING COOKING HUMIDITY

- MICROWAVE SETTING

- STARTING THE COOKING CYCLE

There are also other sections containing instructions on support

functions, such as:

- MANUAL CYCLE (CONTINUOUS COOKING)

- PREHEAT

- UTILITY

- COOKING PHASES IN AUTOMATIC SEQUENCE

Note:

In certain cooking cycles some cooking parameters (humidity,

temperature, etc.) cannot be selected.

4.4.1 SELECTING COOKING MODE

1) Press the button P2 (

following cooking modes by turning knob K.

CONVECTION

COMBI

STEAM

MICROWAVE

REGENERATION

PAUSE

) several times and select one of the

100

300

100

5958 992 00

COMBI is selected in the figure.

For a description of the various cooking modes, refer to par. 3.3

MAIN COOKING MODES.

25

Page 26

EN

4.4.2 SETTING COOKING TEMPERATURE

1) Press the button P2 (

ment cooking TEMPERATURE field

knob K.

E.g.

COMPARTMENT

TEMPERATURE 300°F

Note

The steam cycle has an operating temperature automatically

set to212°F (100°C). Low temperature steam can be set from

77°F (25°C) to 211°F (99°C) by turning the corresponding knob.;

superheated steam (temperature from 213°to 266°F) (from101°

to 130°C).

) several times to select the compart-

and set it as required with

0

300

P1 P2

0

3) First, press the button P2 ( ) several times to select the time

field

then press the button P3 (

The starting value is 50°F "10°C"( max 210°F "99°C").

.

and set the required temperature with knob K.

(display without TIMED PHASES)

P2 P3

) to display the CORE PROBE field

65

E.g.

SET CORE PROBE

TEMPERATURE 65°C

(display with TIMED PHASES)

E.g.

TOTAL TIME _____

FOR PHASES 1 hour and 30 minutes

4) Starting the cycle.

- make sure the oven door is closed;

- Press the START/STOP button (the message PREHEAT appears)

______

:

1 30

65

4.4.3 SETTING COOKING TIME

1) Press the button P2 ( ) several times to select the cooking

TIME

4.4.4 SETTING AND USE OF CORE PROBE (PRODUCT CORE

TEMPERATURE CONTROL)

The core probe allows accurate control of the core temperature

of the product being cooked. This allows setting of the required

value and automatic stopping of cooking when that value is

reached.

Important: The core probe is a precision component.

field of the phase and set that required with the knob K.

(display with one TIMED PHASE)

:

1 00

Eg.: (TIMED PHASE)

(display with several TIMED PHASES)

Eg.:

TOTAL REMAINING_________

TOTAL PHASES

2 hours and 30 minutes

Absolutely avoid impacts, forcing when inserting and

pulling of the flexible cable (in particular when using the

trolley-mounted structures). The warranty does not cover

the replacement of core probes damaged due to improper

use.

2 30

TIME 1 hour

:

:

1 00

Preheating is automatic for any cooking cycle set; to skip it, press

the button P3 (

- Wait until the compartment temperature field indicates the reaching of preheating temperature (the message LOAD appears).

- Open the door and introduce the product to be cooked.

Caution! Risk of burns.

Always open the door with caution when the oven is hot.

Remove the core probe “C” from its seat “D” and insert it in the

product without forcing excessively, making sure the tip (the sensitive part) is positioned near the center of the product.

) or go to the next point.

1) Switch the oven on.

2) Select the required cooking mode (4.4.1SELECTING COOKING MODE) and set the cooking temperature in the field .

MULTIPOINT 6-sensor core probe

5958 992 00

26

Page 27

EN

The oven is equipped with a MULTIPOINT core probe with 6 sensors along the entire stem, for correctly measuring the product

core temperature even if the tip is not completely in the center.

- Close the door and press the button P3 (

5) Stopping the cycle. When the required product core tem-

perature is reached the oven stops automatically with the

previously described procedure (refer to par. 4.3.7 STOPPING

OF COOKING CYCLE) and the elapsed cooking cycle time is

shown in a special window (POP-UP).

6) Core probe mode deactivation.(Operationis only possible

with cooking cycle stopped). Set a cooking time on the Timer

This action automatically cuts out the core probe, whereas the opposite occurs when the time is set.

Core probe mode is also deactivated when the oven is switched

off.

4.4.5 SETTING COOKING HUMIDITY

(Only in CONVECTION, COMBI and REGENERATION

cooking modes)

Important

When the oven is switched on after several hours of inactivity,

wait 20 seconds (the time necessary for stabilization of the

LAMBDA probe) for a correct HUMIDITY reading.

After selecting CONVECTION, COMBI or REGENERATION cooking mode, press the button P2 to select the % HUMIDITY field and

set it as required with knob K.

E.g.

SET COMPARTMENT________________

HUMIDITY 75%

CURRENT HUMIDITY___________

is displayed by the colored zone of the % field (blue 50%)

4.4.6 MICROWAVE SETTING

1) Press the button P2 (

WAVE field

level square) with knob K.

E.g.

SET MICROWAVE__________________

POWER 1500W

and set the required microwave power (500W every

) several times to select the MICRO-

I

I

I

);

ing of preheating temperature (the message LOAD appears)

- Open the door and introduce the product to be cooked.

Caution! Risk of burns.

Always open the door with caution when the oven is hot.

- Close the door and press the button P3 ( );

The GRAPHIC DISPLAY shows the COOKING IN PROGRESS

screen, giving the following information:

DISPLAY OF SET PARAMETERS

recipe or program ________________________

.

phase___________________________

cooking mode____________________

set humidity (100%)____________________

________

set temperature (300°F)

_ _________________

300

100

I

I

I

1:00