Electrolux 267505, AOS202GAD1, 267515, AOS202GAG1 User Manual

Electrolux air-o-steam - level A

Combi LW 20 GN 2/1-gas

Electrolux air-o-steam blends tradition with the latest technological research in order to satisfy the creativity

and working requirements of today's professional kitchen. The air-o-steam range offers a choice of different

models available in two levels of operation, providing a high degree of automation and an extensive range of

accessories. The air-o-steam combis are designed to form complete cook&chill systems together with

air-o-chill blast chillers/freezers, therefore, any installation can be tailored to meet the needs of the caterer.

The air-o-steam combis detailed are level A, 20 GN 2/1 gas models.

OPERATING MODES

• Convection cycle (max. 300 ºC):

ideal for meat to be cooked

without humidity and "au gratin".

In conjunction with the half-power

function for all kinds of pastry

cooking. The humidity generated

by the food itself can be controlled

by air-o-clima with Lambda sensor

for a natural cooking.

• Steam cycle (max. 130 ºC): for

products that can be cooked in

water. Steam cooking respects the

original properties of food and

reduces weight loss.

• Combi cycle (max. 250ºC): ideal

for most kinds of cooking.

Impressive reduction of cooking

times and food shrinkage. The

humidity generated by the food

and the steam generator can be

controlled by air-o-clima with

Lambda sensor for consistent

results regardless of the food load.

• air-o-steam ovens can cook by

controlling either the cooking time

or the product's core temperature

through a 6-sensor probe.

• Regeneration cycle: it produces

the best humidity conditions for

quickly heating the products to be

regenerated (max. 250ºC) on the

plate.

• Fan speeds: full, half speed (for

delicate cooking such as for

baking cakes) and HOLD (pulse

ventilation for baking and low

temperature cooking). The "HOLD

utility" is also perfect for keeping

food warm at the end of the

cooking cycle.

• Low power cycle: for delicate

cooking such as for baking cakes.

• Eco-delta: the temperature

267505

inside the cooking cell is higher

than the temperature of the food

and rises accordingly.

• Low Temperature Cooking (LTC,

automatic cycle): indicated for

large pieces of meat, automatically

selects the cooking parameters to

achieve the lowest weight loss. It

features ARTE (Algorithm for

Remaining Time Estimation).

• Exhaust valve electronically

controlled to extract the humidity

excess.

• Break phase: set a time to delay

the start of cooking programs or

to program a break between two

cooking cycles (for example to

allow rising).

• 20 pre-set programs and 100

7-step free cooking programs.

Electrolux air-o-steam - level A

Combi LW 20 GN 2/1-gas

• air-o-clean: 4 different pre-set

cycles to clean the cooking cell,

according to the actual

requirements. The cleaning

system is built-in (no need for

add-ons).

• Quick cooling: useful when

passing to a type of cooking that

requires a lower temperature than

the previous one. It works

automatically and manually.

• Manual injection of water in the

cell.

• Automatic steam generator

water draining with an automatic

scale diagnosis system.

• HACCP management as

standard: it allows the recording of

the cooking programme according

to H.A.C.C.P. standard (Hazard

Analysis and Critical Control

Points).

PERFORMANCE

• air-o-clima: controls and

displays the exact (single degree

of accuracy) humidity degree of

the oven atmosphere in hot air,

combi and regeneration cycles.

Air-o-clima measures physically

the real humidity level inside the

cooking cell and acts

consequently according to the set

value. With hot air cycles,

air-o-clima also manages to

exhaust the excess humidity

generated by the food.

• air-o-flow: blows fresh air from

outside through the bi-functional

fan, which pulls the air in from the

backside of the oven after it is

pre-heated, thus guaranteeing an

even cooking process.

• Multi-sensor food probe: 6

sensors, ½ ºC accuracy.

• NXT cell and steam generator

gas burners: GASTEC certification

on high efficiency and low

emissions. High efficiency cell and

steam generator heat exchangers.

CONSTRUCTION

• Stainless steel 304 throughout,

with seamless joints in the cooking

cell.

• Height adjustable legs.

• Double thermo-glazed door

equipped with drip pans to catch

condensate and prevent slippery

floor for maximum security and

four holding positions allowing

easier loading and unloading.

• Halogen lighting in the cooking

cell.

• Access to main components

from the front panel.

• Automatic scale diagnosis

system in the steam generator to

detect the presence of scale

build-up.

• IPX5 water protection.

• air-o-steam ovens meet

GASTEC safety requirements.

AOS202GAG1

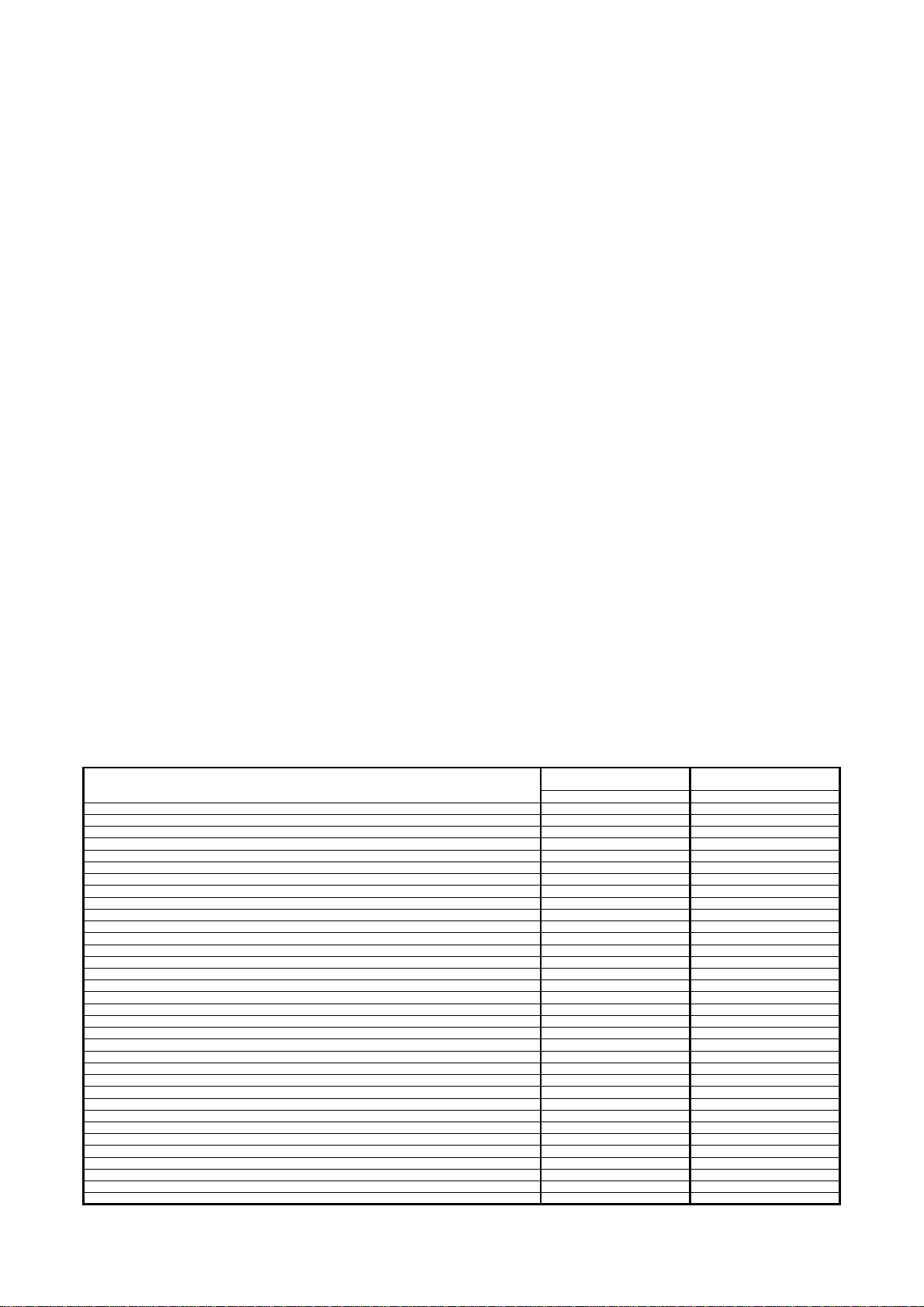

TECHNICAL DATA

Power supply Gas Gas

Gas Natural Gas LPG

Number of grids 20 20

Runners pitch - mm 63 63

Cooking cycles - °C

air-convection 300 300

steam 130 130

combi 250 250

Convection ● ●

Steaming ● ●

Convection/steaming ● ●

Humidity control ● ●

Cook&hold ● ●

Regeneration ● ●

Low temp steaming ● ●

Two-speed fan ● ●

Multi Point Probe ● ●

Automatic cleaning system ● ●

N° of programs 100 100

External dimensions - mm

width 1243 1243

depth 1107 1107

height 1795 1795

Internal dimensions - mm

width 933 933

depth 830 830

height 1450 1450

Power - kW

boiler 55 55

auxiliary 2 2

cooking chamber 55 55

gas 95 95

Net weight - kg. 414 414

Supply voltage 230 V, 1N, 50/60 230 V, 1N, 50/60

267505

AOS202GAD1

267515

ECBA0502009-09-21Subject to change without notice

Internet: http://www.electrolux.com/foodservice

Loading...

Loading...