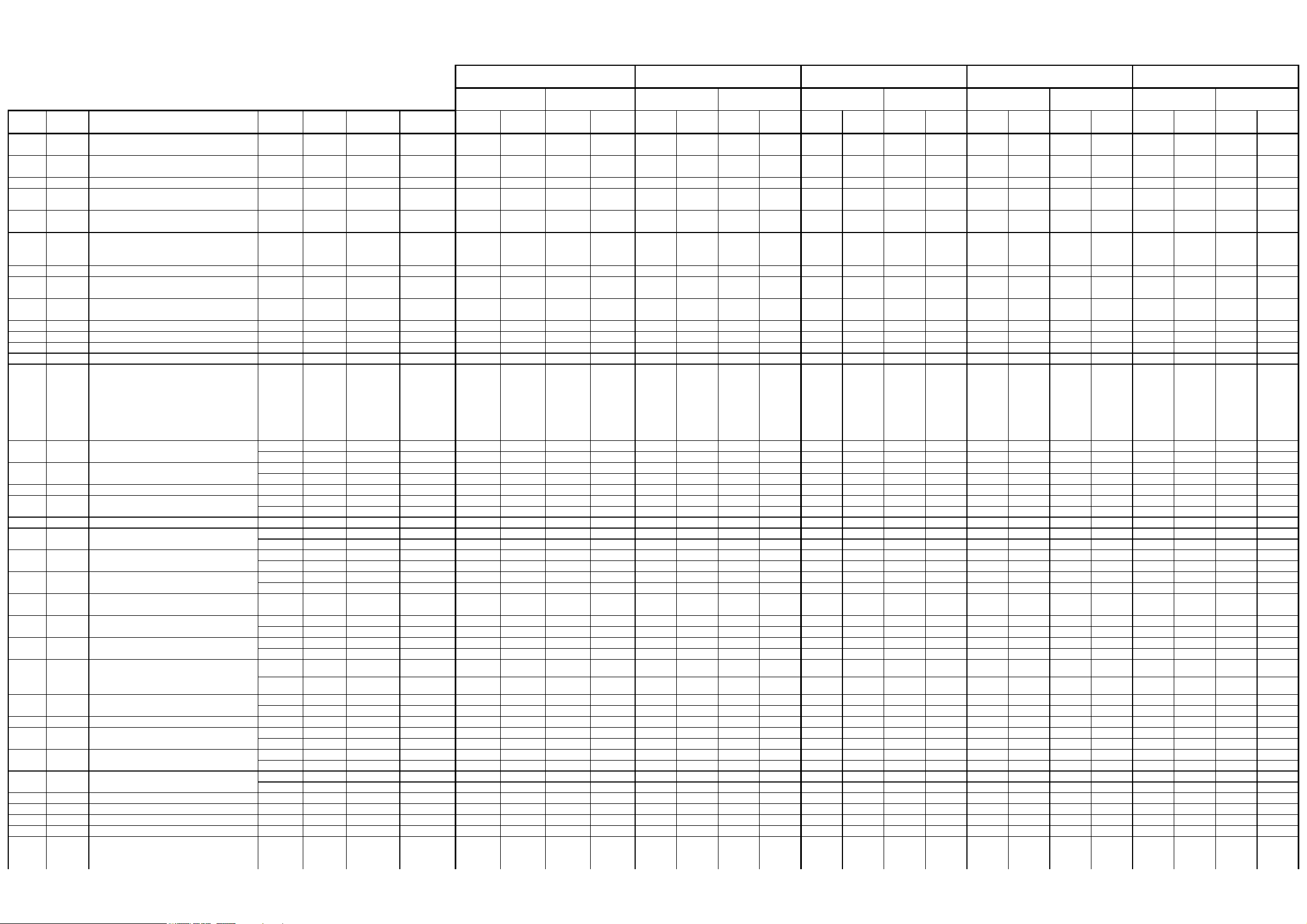

Electrolux AOS061, AOS101, AOS201, AOS202, AOS102 Part Manual

(0)

(1=yes)

p

)

playing

t

prog

(

)

p

)

)

y

)

r

p

pp

r

r

p

r

y

r

p

r

r

r

guag

g

Electrolux AOS_Q LW Combi Oven: firmware 3.0x parameter list

y

)

r

j

(

)

(

)

AOS061

ELT GAS

Par. Nº Name Description Unit Default Minimum Maximum A B A B A B A B A B A B A B A B A B A B

Define if the oven is GAS heated (1) or

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

1

2

3

4

5

6

7

8

9

GAS

ELECTRIC heated

Presence of motorised cavity flap

EnFL

FAHr

cort

nMod

dSod

LAMb

6Prb

dCLn

APPL

APPM

Ston

StoF

ALFn

SPHb

SInC

SEAL

SbYP

HbYP

thMA

trMA

trMn

dutM

cot

bot

HAbP

StbP

dbon

tcdb

OCA1

Sbc

hboL

hAir

hStM

hcMb

erature unit (°F = 1, °C = 0

Tem

Flag to enable cavity temperature

dis

Define if the modification of store

Flag to disable the oven stops when

door is open in convection, steam and

combi mode:

Presence of lambda

Presence of 6-point meat probe (1=yes

for lev. A, 0 for lev. B

Flag to disable automatic cleaning

c

Level of the oven 6 3 6 3

Type of oven 0 0 4 1 1 1

Minimum time for "switch on" of boile

Minimum time for "switch off" of boiler sec 20 1 250

Activation of cavity motor thermal

rotection

0: No alarm

1: U

2: Lower moto

3: All motors

4: water level

Preheating temperature of the boiler

Boiler temperature that detect presence

of scale

Altitude above sea level metres 0 0 4000 Note 3

Bypass temperature with max. cooking

cavit

Max humidit

Define the max. temperature limit for

the manual injection of wate

Define the max. temperature for water

injection during cooling phase

Define the min. temperature for water

in

Maximum length of a phase with cavity

tem

Max. cooking chamber overheating

ETUC alarm

Max. steam generator overheating

ETUB alarm

Steam condenser engagement in "hot

air" mode (lev. B ovens) and all cycles

(lev. A ovens)

Steam condenser engagement in

"steam/boiler" mode in lev. B ovens

Delay for boiler drain h/4 1 0 999

Max water temperature for boiler drain

OFFSET of cavity probe

Cooling temperature set for board

ventilation

Boiler hour counte

Hot air hour counte

Steam hour counte

Combi hour counter h 0 0 9999

Lan

0: En

1: Italian

adjustmen

ram is disable

0=the oven stops

robe (1=yes

cles (1=disable

er moto

robe erro

steam temperature (calibration

value to stop the boile

ection during cooling phase

erature over "tCMS" ºC

e for the menu

lish

sec 5 1 250

ºC 85 0 100 50

ºF 185 32 212 122

ºC 115 1 150

ºF 239 33 302

ºC 100 80 110 Note 4

ºF 212 176 230 Note 4

% 98 80 100

°C 250 0 300

°F 482 32 572

ºC 180 0 300

ºF 356 32 572

ºC 40 0 300

ºF 104 32 572

min 10 1 900 111111111111

ºC 320 250 340

ºF 608 482 644

ºC 125 90 200

ºF 257 194 392

ºC 90 50 300

ºF 194 122 572

ºC 80 50 100

ºF 176 122 212

ºC 50 0 100

ºF 122 32 212

ºC 0 -10 10 Note 5 Note 5 Note 5

ºF 0 -10 10 Note 5 Note 5 Note 5

ºC 25 0 55 0

ºF 77 32 131 32

h/4 0 0 9999

h 0 0 9999

h 0 0 9999

001 11 11111111

10 1

00 1

0 0 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1 Note 1

00 1

00 1

10 1 0

101 0 0 00000000

001 1 1 11111111

00 4

0

3

Note 3

Note 4

Note 4

Note 5

Note 5

0

32

Note 5 Note 5 Note 5

Note 5 Note 5 Note 5

AOS101

ELT GAS

0

3

Note 3

Note 4

Note 4

0

32

0

3

1

Note 3

Note 4

Note 4

Note 5

Note 5

0

32

333

Note 5 Note 5 Note 5

Note 5 Note 5 Note 5

AOS102

ELT GAS

0

3

Note 3

Note 4

Note 4

0

32

0

3

3

Note 3

Note 4

Note 4

Note 5

Note 5

0

32

AOS201

ELT GAS

0

3

222

Note 3

Note 4

Note 4

Note 5 Note 5 Note 5

Note 5 Note 5 Note 5

0

32

0

3

2

Note 3

Note 4

Note 4

Note 5

Note 5

0

32

AOS202

ELT GAS

0

3

444

Note 3

Note 4

Note 4

Note 5 Note 5 Note 5

Note 5 Note 5 Note 5

0

32

122

Note 3

Note 4

Note 4

Note 5

Note 5

0

3

4

50

0

32

ELX261.xls Page 1/3

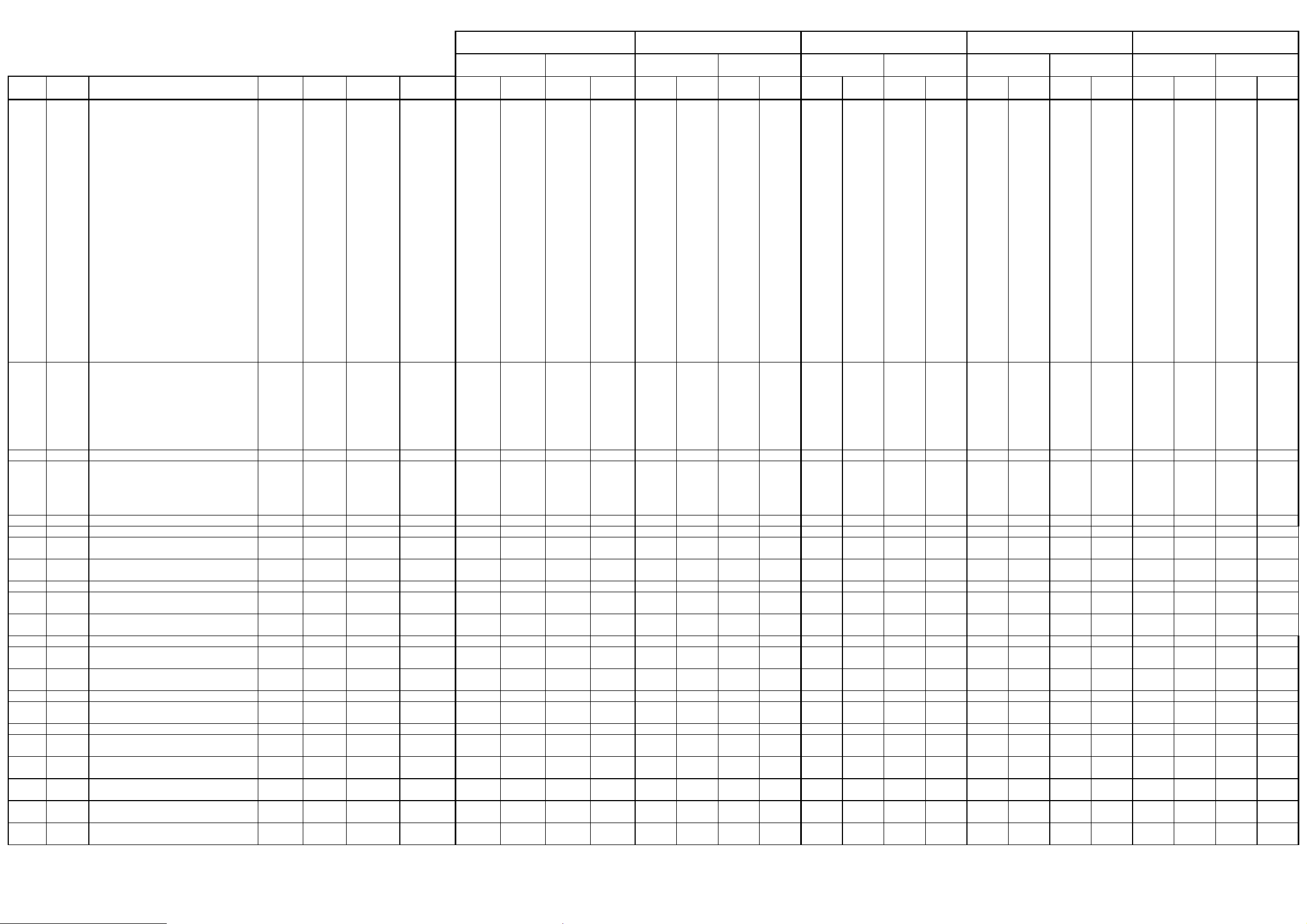

AOS061

p

g

k

g

g

g

r

)

y

g

(p

)

)

g

)

y

s

p

V

g

)

)

(

)

g

)

AOS101

AOS102

AOS201

AOS202

ELT GAS

Par. Nº Name Description Unit Default Minimum Maximum A B A B A B A B A B A B A B A B A B A B

2: German

3: French

4: S

anish

5: Dutch

6: Swedish

7: Danish

8: Portu

9: Gree

10: Finnish

11: Norwe

36

37 3 0

38

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

LAnG

12: Russian

13: Estonian

14: Hun

15: Turkish

16: Polish

17: Slovenian

18: Croatian

19: Romanian

20: Czech

21: Slovakian

22: Latvian

23: Lithuanian

24: Bul

25: Serbian

RS485 bit rate

0: 1200 baud

1: 2400 baud

2: 4800 baud

bAud

3: 9600 baud

4: 19200 baud

5: 38400 baud

6: 57600 baud

Addr

RS485 address 1 1 250

HACCP Mode

0=No HACCP

HCCP

1=Basic

2=Advanced

3=Monito

tPrn

Print frequency (0=no print

StcA

PWM value at start of cavit

PWM value at middle power of cavity

hAcA

burners

PWM value at full power of cavity

FucA

burners

Stbo

PWM value at start of boiler burners % 40 0 100 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6

PWM value at middle power of boiler

hAbo

burners

PWM value at full power of boiler

Fubo

burners

CLt1

Len

Length of detergent+water injection

CLt2

Length of rinser+water injection (phase

CLt3

C

CLt4

Len

ON phase of the humidifier with combi

HUon

c

OLbd

Calibration of the lambda

Flag to enable Peak Power

PPM

Mana

Flag to enable DEMO (0=disable;

dEMO

1=enable

Timeout for water level probe alarm

tbon

0=disabled control

Delay for fast filling during opening of

dtSb

boiler drain valve

Flag to enable starting of cooking

AbSP

closin

uese

ian

arian

arian

burners % 40 0 100 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6

th of detergent injection (phase A)100ms 30 1 250 50 50 60 60 80 80

hase A

th of water injection (phase C

cle beetween 50 and 100 degree

robe

ement (0=disable; 1=enable

the door (0=disable; 1=enable

s 30 0 250

% 40 0 100 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6

% 80 0 100 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6

% 40 0 100 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6

% 80 0 100 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6 Note 6

100ms 20 1 250 30 30 30 30 40 40

100ms 50 1 250 80 80 100 100 150 150

100ms 10 1 250 30 30 20 20 40 40

100ms 5 0 250

76,29 μ

s 0 0 2400

s 255 0 255

0

00

0 -999 999 Note 7 Note 7 Note 7 Note 7 Note 7 Note 7 Note 7 Note 7 Note 7 Note 7

00 1

00 1

00 1

400

6

339

ELT GAS

ELT GAS

ELT GAS

ELT GAS

ELX261.xls Page 2/3

Loading...

Loading...