Page 1

PLµS™ PS-6244 Series

Programmable Limit Switch

PGM:1 RPM:1500

MENU< POS: 180

Programming &

Installation Manual

4/99

13647 Metric Rd • Roscoe, IL 61073 U.S.A. • 815-389-2620 • FAX 815-389-3304 • 800-228-5487 (USA & Canada)

Page 2

Copyright © 1999

All Rights Reserved

Neither this document nor any part may be reproduced or transmitted in

any form or by any means without permission in writing from the publisher.

, PLµS, SLIMLINE, and PLµSNET are all registered trademarks of

1-2 Introduction

Page 3

Table of Contents

Section 1—Introduction

Mechanical Cam Switches .............1-5

Programmable Limit Switches........1-5

PS-6244 Description ......................1-6

Basic Terminology..........................1-7

PS-6244 Features ..........................1-8

Section 2—Installation & Wiring

General Mounting & Wiring ............2-1

Mounting Dimensions.....................2-2

Terminals & Components

PS-6244-17 ...............................2-3

PS-6244-25 ...............................2-4

Controller Input Wiring....................2-5

Output Wiring .................................2-8

Keypad Wiring ................................2-12

DIP Switch Configurations..............2-13

Communications Wiring..................2-15

Encoder Wiring...............................2-16

Fuse Tester & Fuse Replacement..2-17

Output Transistor Replacement......2-18

Section 3—Programming

Keypad Overview ...........................3-1

Menu Tree .....................................3-2

Initial Programming.........................3-3

Functions (Alphabetically)

Analog Output............................3-4

Analog Quantity .........................3-5

Communications........................3-6

Default Program ........................3-7

Enable Codes ............................3-8

Enable Options ..........................3-10

Increasing Direction...................3-10

Input ANDing .............................3-11

Input Status ...............................3-11

Keyboard Quantity.....................3-12

Main Screen ..............................3-12

Memory Tests............................3-13

Motion ANDing ..........................3-14

Motion Detection .......................3-15

Section 3—Programming Continued

Offset.........................................3-15

Output Status ............................3-16

Password...................................3-16

Per Channel Enable ..................3-17

Program Copy ...........................3-18

Program Select Mode................3-18

Pulse Copy ................................3-19

Rate Setup ................................3-20

RPM Update Rate .....................3-21

Scale Factor ..............................3-21

Setpoint Use..............................3-22

Setpoints ...................................3-22

Shift Position .............................3-23

Shift Register ANDing ...............3-24

Software Version .......................3-26

Speed Compensation................3-27

Toggle RPM ..............................3-28

Section 4—Troubleshooting

Controller Diagnostics ....................4-1

Keypad Diagnostics .......................4-2

Encoder Troubleshooting ...............4-3

General Troubleshooting................4-4

Fuse Part Numbers ........................4-6

Section 5—Speed Compensation

Introduction to Speed Comp ..........5-1

Standard Speed Comp...................5-2

Leading/Trailing Speed Comp........5-4

Negative Speed Comp ...................5-5

Speed Comp Guidelines ................5-6

Section 6—PluSNET II™ Communications

Appendix

Controller Specs.............................A-1

Module Specs ................................A-2

Factory Defaults .............................A-3

Index ..................................................I-1

Form to Record Setpoints

1-3 Introduction

Page 4

WARRANTY

1. Electro Cam Corp. warrants that for a period of twelve (12) months from the date of shipment to

the original purchaser, its ne w product to be free from defects in material and workmanship and

that the product conforms to applicable drawings and specifications approved by the Manufacturer. This warranty period will be extended on Distributor or OEM orders to a maximum of

eighteen months to take into consideration Distributor or OEM shelf time.

2. The remedy obligations of Electro Cam Corp. under this w arranty are e xclusive and are limited to

the repair, or at its option, the replacement or refund of the original purchase price of any new

apparatus which proves def ective or not in conf ormity with the drawings and specifications. Shipment of the claimed defectiv e product to Electro Cam Corp. shall be at the cost of the consumer.

Shipment of the repaired or replacement product to the consumer shall be at the cost of Electro

Cam Corp. All claims must be made in writing to Electro Cam Corp., 13647 Metric Road, Roscoe,

IL 61073 USA.

3. In no event, and under no circumstances, shall Electro Cam Corp. be liable for:

a. Any product damaged or lost in shipment. Inspection for damage should be made before

acceptance or signing any delivery documents releasing responsibility of the delivering carrier.

b. Product failure or damages due to misuse abuse, improper installation or abnormal condi-

tions of temperature, dirt or other contaminants as determined at the sole discretion of Electro

Cam Corp.

c. Product failures due to operation, intentional or otherwise, above rated capacities as deter-

mined at the sole discretion of Electro Cam Corp.

d. Non-authorized expenses for removal, inspection, transportation, repair or rework. Nor shall

the manufacturer ever be liable for consequential and incidental damages, or in any amount

greater than the purchase price of the equipment.

4. There are no warranties which extend be yond the description on the f ace hereof. This warranty is

in LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED INCLUDING (BUT NOT

LIMITED T O) ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ALL OF WHICH ARE EXPRESSLY DISCLAIMED. Any legal proceeding

arising out of the sale or use of this apparatus must be commenced within (18) months of the date

of shipment from the manufacturer.

1-4 Introduction

Page 5

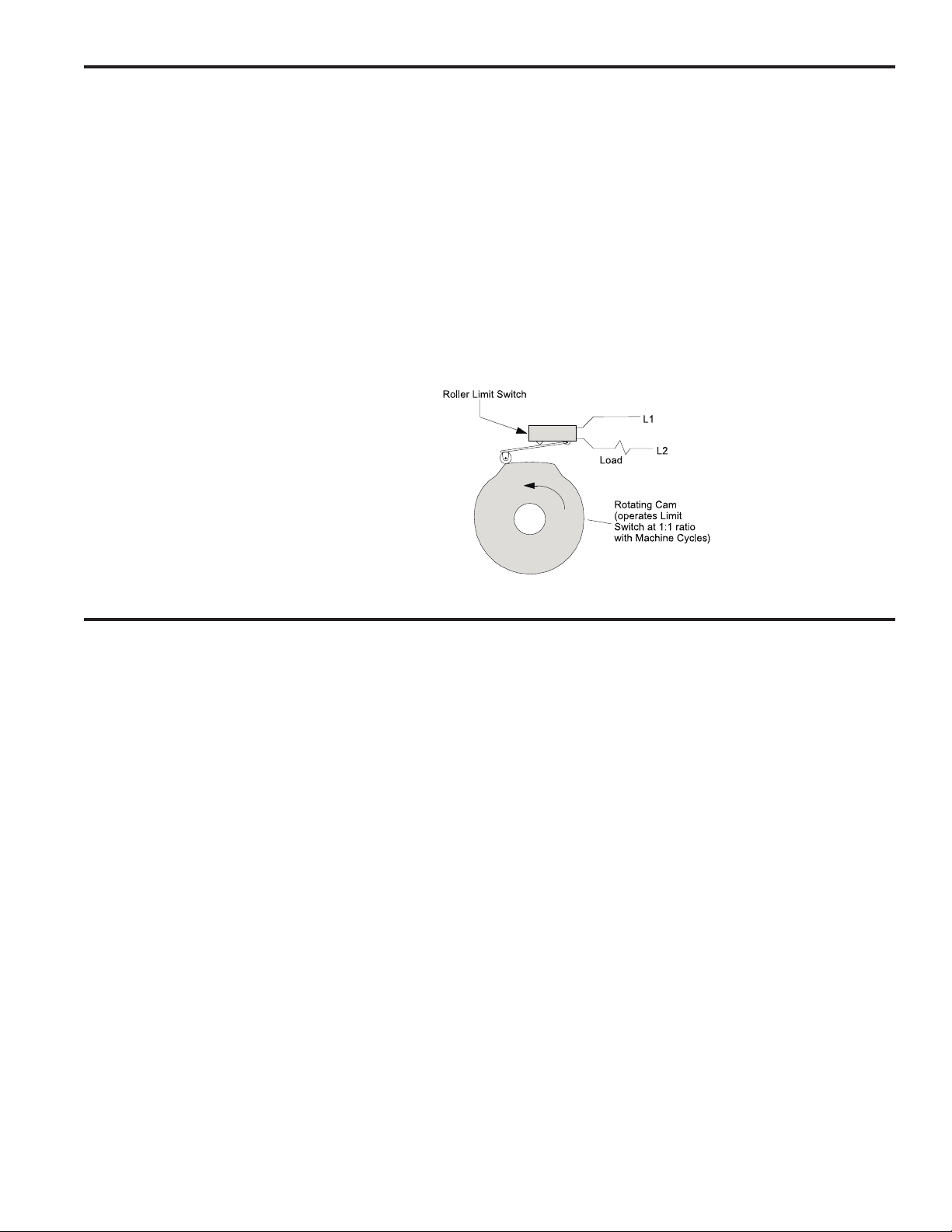

Mechanical Cam Switches

Mechanical Cams The PS-6244 Programmable Limit Switch electronically simulates mechanical cam

switches. A cam switch consists of a roller limit switch whose arm rides on a cam as

shown in Figure 1. The cam shaft is driven by a machine at a 1:1 ratio, so that the cam

switch turns on and off at specific positions in the machine cycle. Cam limit switches

have the following disadvantages:

• The roller, the cam, and the limit switch wear out.

• The machine must be stopped during adjustment.

• On/off patterns are limited, and changing the pattern may require replacement of one

cam with another. For example, a cam that switches on and off twice in one revolution would need to be replaced with a different cam if three on/off pulses per revolution were required.

• They cannot run at high speeds because of contact bounce and excessive mechanical wear.

Figure 1—Basic Cam Switch

Programmable Limit Switches

PS-6244’s & Encoders The PS-6244 Programmable Limit Switch uses a quadrature encoder (Figure 2) in-

stead of a cam to indicate machine position. A quadrature encoder uses optical discs to

generate streams of pulses that can be processed by the PS-6244. From the encoder

signals, the PS-6244 can determine shaft position, direction, and speed. The encoder

is usually coupled to a machine shaft at a 1:1 ratio so that one encoder shaft rotation

corresponds to one machine cycle. Encoders have no brushes, contacts, or any frictional moving parts to wear out.

Based on the encoder signal, the PS-6244 Programmable Limit Switch turns electrical

circuits, or “Outputs,” on and off, simulating the mechanical roller limit switch. Because

the combination PS-6244/encoder system is completely electronic and has no frictional

parts, it offers several advantages over mechanical cam switches:

• Long service life with no parts to wear out.

• “On” and “off” points can be adjusted instantly from the keypad; there are no cams to

rotate or replace.

• Adjustment is possible with the machine running or stopped.

• Programmable logic allows complex switching functions that are impossible with

mechanical cams.

• Operation at speeds up to 1500 RPM.

1-5 Introduction

Page 6

Programmable Limit Switches

Figure 2—PS-6244-24-N16M09 Programmable Limit Switch and Quadrature Encoder

Typical

Quadrature Encoder

(BEI H25D shown)

Controller

PS-6400

Keypad/Display

PS-6244 Description

Controller & Keypad PS-6244 Series Programmable Limit Switches consist of two main components: the

controller and the keypad/display. The controller houses the microprocessor, associated circuitry, and all of the I/O circuits. This eliminates the need for external I/O racks.

Figure 3—PS-6244 Models

A separate 1/4 DIN keypad/display provides a complete user interface from which every aspect of the controller’s operation can be monitored and programmed. Multiple

keypads can be connected to a single controller. In addition, when interfaced to a PLC

or other computer, the controller can be used without a keypad/display. When properly

mounted with the gasket provided, the keypad/display meets NEMA 4X standards. A

clear silicon rubber boot assembly is available to provide protection for installations

where harsh washdown chemicals are used.

The PS-6244 Series is available in two models: the PS-6244-24-M17 and the PS-624424-X16M09 Both are described in Figure 3.

PS-6244-24-N16M09 Controller—Up to 25 OutputsPS-6244-24-M17 Controller—Up to 17 Outputs

The PS-6244-24-M17 has 17 total outputs:

• Outputs 1 through 15 can accept AC or DC output

modules for driving “real world” devices such as

solenoids, valves, or glue guns.

• Output 16 will accept an AC or DC module, or an

analog module that generates a control signal

proportional to RPM.

• Output 17 is dedicated to analog output.

1-6 Introduction

The PS-6244-24-N16M09 has 25 total outputs:

• 16 transistor outputs are built into the controller.

• Outputs 17 through 23 can accept AC or DC output

modules for driving “real world” devices such as

solenoids, valves, or glue guns.

• Output 24 will accept an AC or DC module, or an

analog module that generates a control signal

proportional to RPM.

• Output 25 is dedicated to analog output.

Page 7

Basic T erminology

The following terms will be used throughout this manual to explain PS-6244 installation,

programming and operation:

Outputs (channels) An “output,” or “output channel,” refers to an external circuit that the PS-6244 controls

based on encoder position or speed. Outputs can be one of two types:

Switching outputs turn circuits on or off.

Analog outputs generate a control signal that is proportional to RPM.

Setpoints “Setpoints” are the points within one rotation of the encoder at which an output channel

turns on or off. Setpoints can be programmed into an output channel through the keypad/display, or they can be downloaded from a computer or PLC through serial communications. The PS-6244 can turn any given output on and off multiple times within

one rotation.

Pulses A “pulse” is the “on” period between the time an output is turned on and off. The “on”

point is the leading edge of the pulse, and the “off” point is the trailing edge. When

multiple “on” and “off” points are programmed into one output channel, the output is

said to have multiple pulses.

Programs Suppose that 15 output channels on a cartoner are programmed with setpoints to fold

and glue a certain size carton. These settings could be stored as a “program.” Then, the

15 output channels could be re-programmed with different setpoints for a different size

carton. This second set of setpoints could also be stored as a program. To change

carton sizes, an operator could simply activate the correct program, and the corresponding setpoints would take effect.

The use of programs can provide tremendous advantages over mechanical cam switches. Standard PS-6244’s can store up to 48 programs. The active program can be selected through the keypad/display, mechanical switches, direct PLC interface, or serial

communication messages.

Inputs (hardware inputs) In addition to accepting a signal from the encoder, the PS-6244 can accept up to 16

input signals from mechanical switches, relay contacts, DC two- or three-wire sensors,

solid state DC output modules, or PLC DC outputs. The PS-6244 hardware inputs are

dedicated to specific functions involving program selection and controlling output channels based on sensor signals.

1-7 Introduction

Page 8

PS-6244 Features

Programming Access Three levels of programming access are provided: Operator, Setup, and Master. Each

level can be assigned a password that must be entered to allow programming at that

level. In addition, the Operator and Master levels can be activated on an individual

keypad through hardware terminals on the back. Careful use of programming access

levels can provide key personnel the flexibility they need in programming the controller,

while protecting settings against accidental or unauthorized changes.

Speed Compensation Speed compensation advances the setpoints for an output channel as machine speed

increases. This eliminates the need to manually adjust the settings for fixed-response

devices whenever machine speeds are changed. Speed compensation provides greater

accuracy, higher production speeds, and reduced downtime for machine adjustment.

Motion ANDing Two speed ranges can be programmed into the controller, and output channels can be

ANDed with either speed range so that they will be disabled unless the machine speed

is within the specified range. A common use for this feature is disabling outputs to glue

valves to turn off the glue flow if the machine stops.

Input ANDing An output channel may be ANDed with one of eight input signals so that the output is

disabled unless the input signal is present.

Shift Register ANDing The PS-6244 includes a shift register that can turn output channels on or off up to 255

revolutions after a signal is applied to Input Terminal 16, Figure 7. The terminal is usually connected to a product sensor.

Analog Outputs PS-6244 controllers can drive up to two analog output modules whose output signal will

be linearly proportional to RPM. The analog signal level at zero RPM can be programmed,

as well as the RPM that corresponds to maximum signal. No measuring equipment is

required for initial setup, and calibration is not needed. Typical uses for the analog

output are to control glue pressure as machine speeds change, or to match speeds of

other equipment to the machine being controlled by the PS-6244.

Serial Communication Using Electro Cam Corp.’s PLuSNET software for IBM-PC compatible computers, the

PS-6244’s programs can be saved to a disk file or loaded from a disk file to the PS-

6244. The programs can be printed or edited using the computer. Individual commands

may also be sent to the PS-6244 to change settings while running.

Washdown Boot A clear silicon rubber boot can be supplied that fits over and around the keypad face.

The back of this boot provides sealing between the back of the keypad and the panel.

The boot is transparent and pliable, allowing the keypad to be viewed and operated

through it. In addition to preventing contamination from harsh chemicals, the boot also

protects the keypad from grease, oil, dirt and normal wear that could otherwise shorten

its life.

1-8 Introduction

Page 9

General Mounting & Wiring

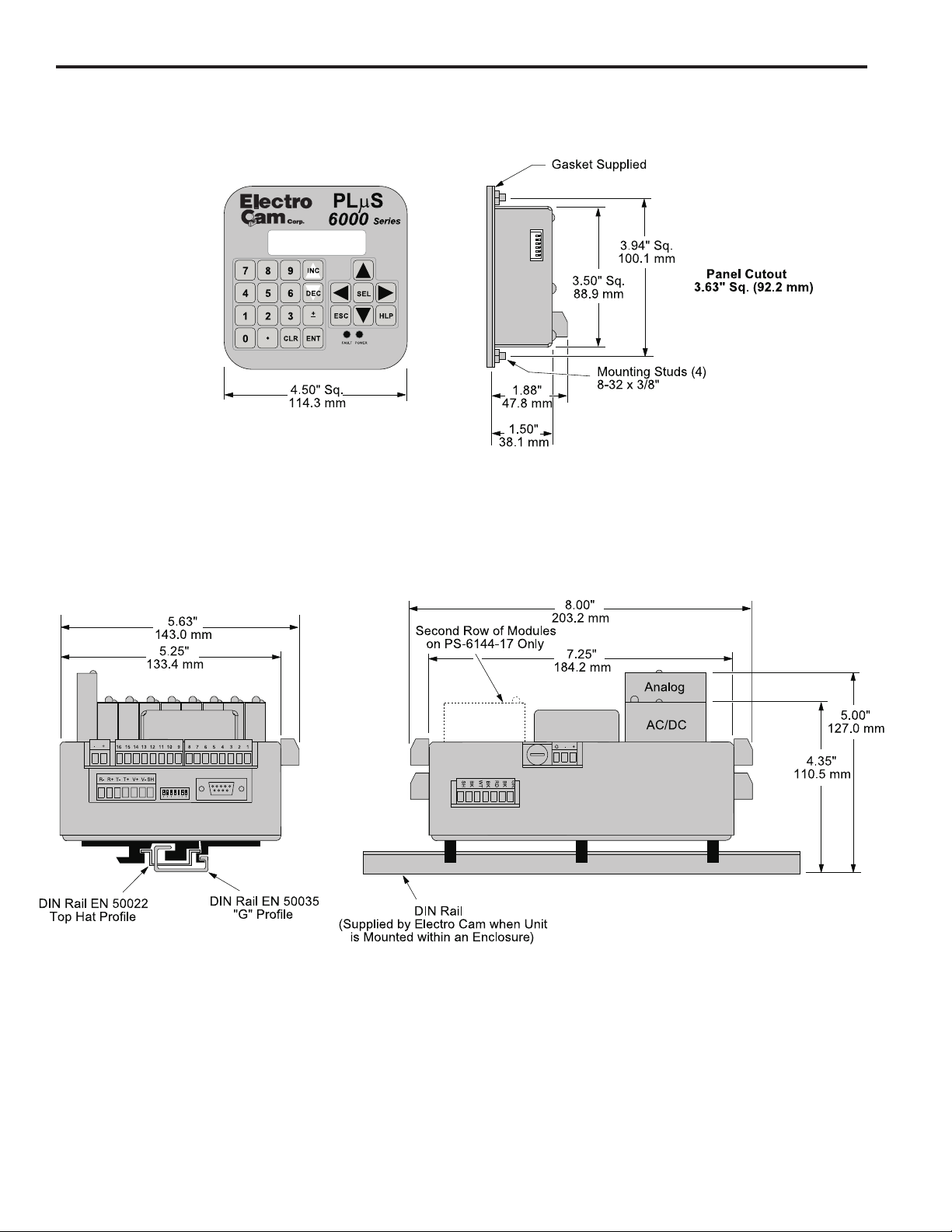

Controller The controller body mounts on a DIN rail as shown in Figure 4.

Keypad/Display Mount the keypad/display to a panel using the four studs on the back of the keyboard.

Enclosures are available from Electro Cam if an appropriate mounting location does

not exist.

DIP Switches For convenience, set the DIP switches on the side of the controller and keypad to

their proper positions before mounting the units in a panel. See page 2-13 for DIP

switch information.

Environment 1. Allow space at both sides and the top of controller for terminal blocks to be un-

plugged.

2. Ambient temperature range is +32° to +130° F (0° to +55°C)

3. Locate the controller and keypad away from devices that generate electrical noise,

such as contactors and drives.

4. Use the keypad/display gasket provided to prevent contaminants from getting into

the cabinet.

Terminal Blocks All terminal blocks can be unplugged from the controller. Each block is keyed so it

cannot be plugged into the wrong socket. All terminals are labelled on each block.

Wiring Guidelines Follow normal wiring practices associated with the installation of electronic controls.

Some guidelines are:

CAUTION

1. Route input and output wiring away from high voltage, motor drive, and other high

level control signals.

2. Use shielded cables for encoder, input, transistor output, and communication circuits. Also shield module output circuits that are driving low current electronic input

circuits.

3. Ground shielded cables at the PS-6244 end only (except for encoder cable). Use

any of the screws on the controller back for grounding.

4. Use appropriate suppression devices where module outputs are directly driving inductive loads.

Power Supply Wiring Connect a 20 to 30 VDC power supply to TB8 (Fig. 5 or 6). Reversing the polarity will

blow the 1-1/4 amp power fuse. The controller will not be damaged, but you must correct the polarity and replace the fuse before the controller will operate.

To insure electrical noise immunity, connect a good electrical ground to the ground

terminal on the power supply terminal block.

Module Mounting A phillips head screw holds each module in place. Individual modules can be removed

and installed without affecting the other modules on the unit

However, disconnect power to the controller before changing modules.

2-1 Installation & Wiring

Page 10

Mounting Dimensions

Figure 4—Mounting Dimensions

PGM:1 RPM:1500

MENU< POS: 180

2-2 Installation & Wiring

Page 11

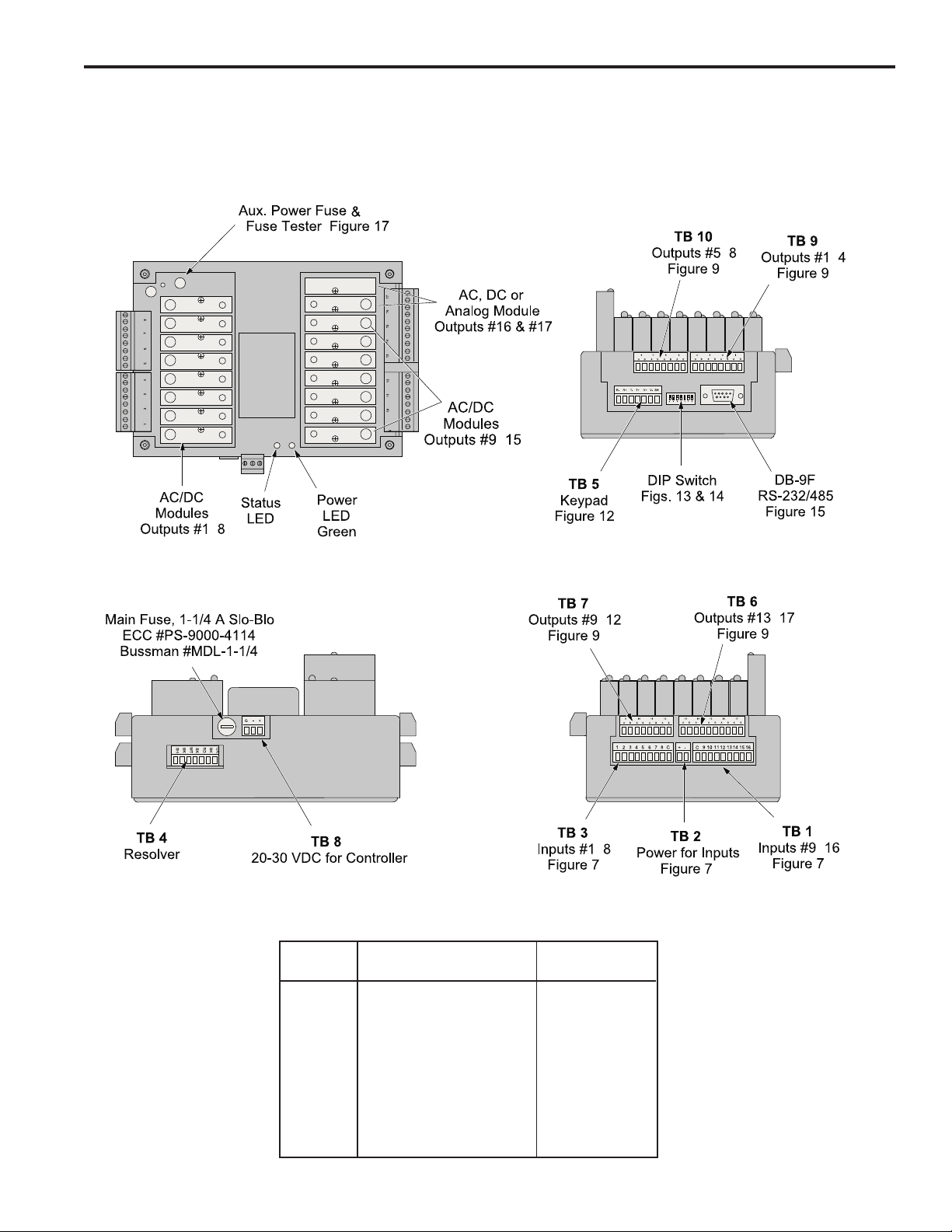

Terminals & Components—PS-6244-24-M17

Figure 5—PS-6244-24-M17 Terminals & Components

Top View

-

Yellow

Front View

Left Side View

-

-

-

Right Side View

-

-

-

Terminal Block Details

Terminal

Block Function ECC Part #

TB 1 Inputs #9–16 PS-9006-0024

TB 2 Auxiliary power output PS-9006-0018

TB 3 Inputs #1–8 PS-9006-0023

TB 4 Encoder connector PS-9006-0032

TB 5 Keypad connector PS-9006-0029

TB 6 Module outputs #13-17 PS-9006-0031

TB 7 Module outputs #9-12 PS-9006-0030

TB 8 Power for controller PS-9006-0026

TB 9 Module outputs #1-4 PS-9006-0033

TB 10 Module outputs #5-8 PS-9006-0034

1

Keyed to prevent accidental insertion into wrong sockets.

-

1

2-3 Installation & Wiring

Page 12

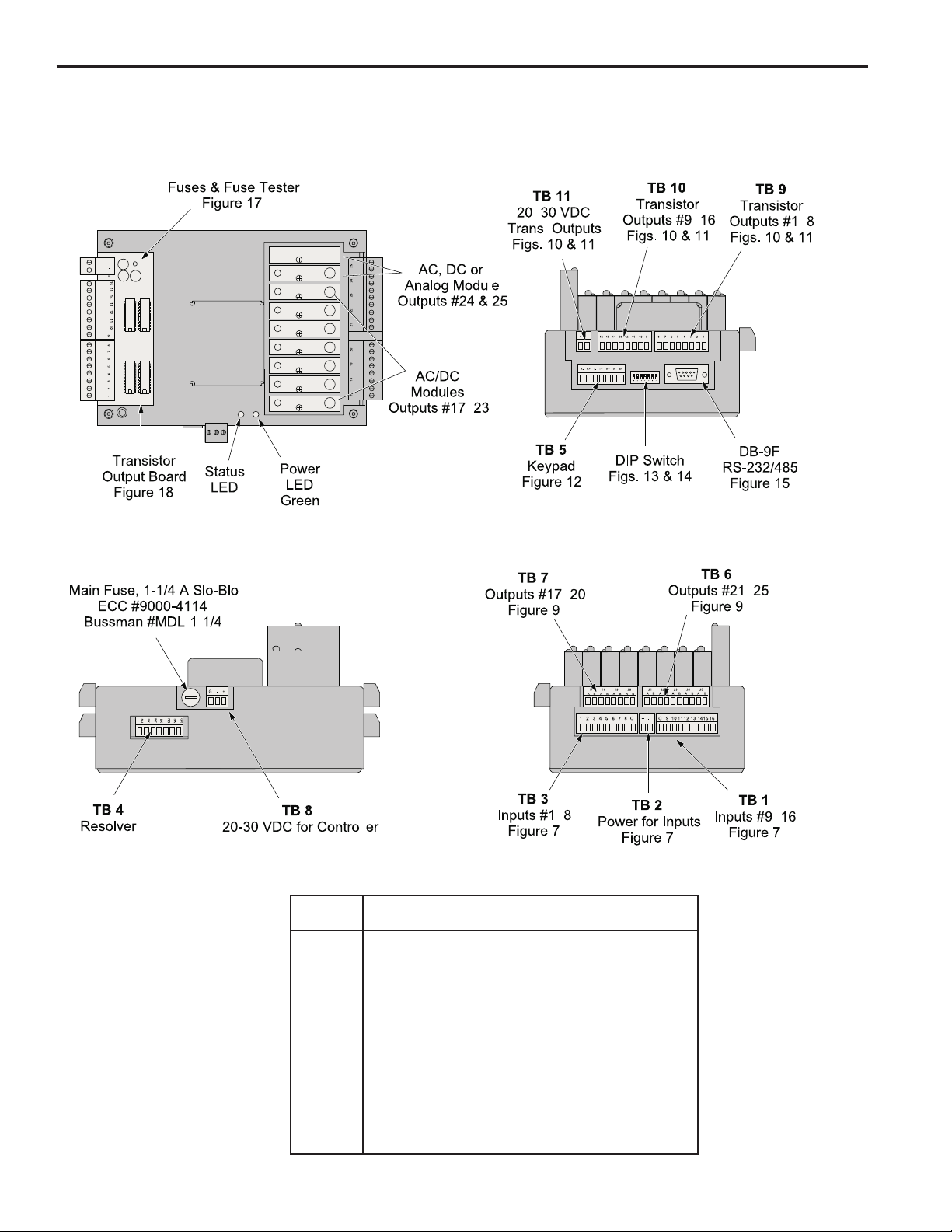

Terminals & Components—PS-6244-24-X16M09

Figure 6—PS-6244-24-X16M09 Terminals & Components

Top View

Yellow

Front View

Left Side View

-

-

-

-

Right Side View

-

-

2-4 Installation & Wiring

-

Terminal Block Details

Terminal

Block Function ECC Part #

TB 1 Inputs #9–16 PS-9006-0024

TB 2 Auxiliary power output PS-9006-0018

TB 3 Inputs #1–8 PS-9006-0023

TB 4 Encoder connector PS-9006-0032

TB 5 Keypad connector PS-9006-0029

TB 6 Module outputs #21–25 PS-9006-0028

TB 7 Module outputs #17–20 PS-9006-0027

TB 8 Power for controller PS-9006-0026

TB 9 Transistor outputs #1–8, sinking PS-9006-0019

TB 10 Transistor outputs #9–16, sinking PS-9006-0020

TB 11 Power for transistor outputs PS-9006-0017

1

Keyed to prevent accidental insertion into wrong sockets.

Transistor outputs #1–8, sourcing PS-9006-0021

Transistor outputs #9–16, sourcing PS-9006-0022

-

1

Page 13

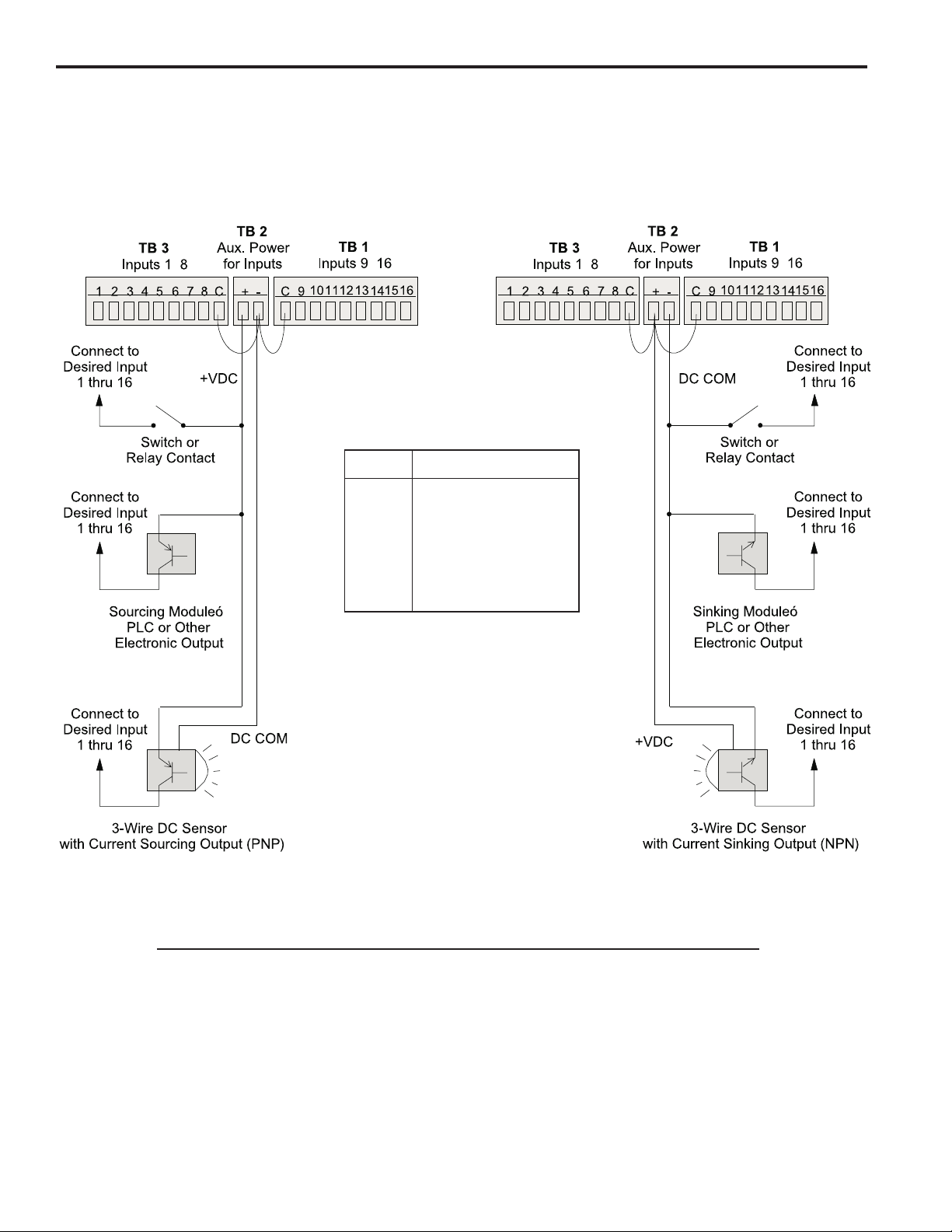

Controller Input Wiring

Input Terminals Hardware inputs can be used to select a program of setpoints, disable keypads, accept

sensor signals, or clear the shift register. The 16 inputs on the PS-6244 are arranged

on two terminal strips, TB 1 and TB 3, as shown in Figure 7. Each input is optically

isolated and can be powered from an external DC power source or the Auxiliary Power

terminals located on TB 2.

Sinking or Sourcing Each terminal strip TB 1 and TB 3 can be wired to accept sinking or sourcing input

signals, but all eight inputs on that strip will require the same type of signal. Many types

of hardware can drive these inputs, including mechanical switches, relay contacts, DC

3-wire sensors, solid state DC output modules, and PLC DC outputs. 2-wire DC sensors can also be used, but may require a load resistor in parallel with the input. Typical

wiring diagrams are shown in Figure 7.

Input Functions Following are the input terminals and their corresponding functions:

Channel Enable (1-8)

These terminals accept signals from sensors or from PLC’s. Each output channel on

the 6244 can be ANDed with any one of these inputs so that the output is enabled only

when a signal is present on the input terminal.

Program Select (9-13)

The on/off status of these terminals selects which program of setpoints is controlling

the outputs. Binary, BCD, or Gray Code formats can drive these terminals as shown in

Figure 8. Although standard controllers can store up to 48 programs, not all of these

programs can be selected through the Program Select terminals.

When all program select inputs are off, the “Default” program will become active as

programmed through DEFAULT PROGRAM function.

Shift Register Clear (14)

A signal on this terminal will completely clear the shift register for all output channels.

Keypad Disable (15)

When energized, this terminal disables any keypads connected to the controller. If the

controller will be used without any keypads, jumper this terminal so that it is always

energized.

Shift Register Input (16)

The leading edge of a signal on this terminal sets a bit in the shift register. See SHIFT

REGISTER ANDING for details.

2-5 Installation & Wiring

Page 14

Controller Input Wiring (cont’d)

Figure 7—Controller Input Wiring (See Figures 5 & 6 for Terminal Block Locations)

Sourcing Devices

(+VDC is being switched)

-

-

Term. Function

1-8 Channel Enable

9-13 Program Select

14 Shift Register Clear

15 Keypad Disable

16 Shift Register Input

Sinking Devices

(DC common is being switched)

-

-

Input Wiring Guidelines

• Voltage from TB 2 will be the same as the voltage supplied to the controller.

• Each input powered from TB 2 will draw 11 mA at 24 VDC. TB 2 is fused at 1/4 amp.

• Inputs will operate with voltages from 10 to 30 VDC.

• An external power supply can be used instead of TB 2 to power inputs.

• A combination of mechanical and solid state devices can be used.

• TB 1 can be wired for sourcing while TB 3 is wired for sinking, and vice versa.

2-6 Installation & Wiring

Page 15

Controller Input Wiring (cont’d)

Figure 8—Program Select Terminals for Various Formats

BCD Program Select Table

The BCD format allows standard 1- or 2-digit BCD switches

to operate the program select inputs. PLC’s can also

output values in BCD. The program number selected can

be calculated by adding up the values associated with

each of the input terminals that are on. For example, if

Input Terminals 9, 11 and 13 are on, Program 15 would be

active (10 + 4 + 1).

Please Note:

• Although the PS-6244 can store up to 48 programs, only

Programs 1 through 19 can be selected using BCD input.

A value larger than 19 will select Program 19.

• Only one of the normal four BCD digits for 10’s is used.

• 9 is the largest valid value for the units digit. A units

digit combination larger than 9 will set the units digit to 9.

Binary Program Select Table

The binary format is convenient for PLC program select

output signals. The program number selected can be

calculated by adding up the values associated with each

of the input terminals that are on. For example, if input

terminals 9, 11 and 13 are on, program number 21 would

be active (16 + 4 + 1).

Please Note:

• Although the PS-6244 can store up to 48 programs, only

Programs 1 through 31 can be selected using binary

input. A value larger than 31 will select Program 31.

Gray Code Select Table

Input

Term: 13 12 11 10 9

Value: 10 8 4 2 1

PGM

Default 0 0 0 0 0

100001

200010

300011

400100

500101

600110

700111

801000

901001

Input

Term: 13 12 11 10 9

Value: 16 8 4 2 1

PGM

Default 0 0 0 0 0

1 00001

2 00010

3 00011

4 00100

5 00101

6 00110

7 00111

8 01000

9 01001

10 01010

11 01011

12 01100

13 0 1 1 0 1

14 01110

15 01111

UNITS10's 10'sUNITS

Input

Term: 13 12 11 10 9

Value: 10 8 4 2 1

PGM

10 10000

11 10001

12 10010

13 1 0 0 1 1

14 10100

15 10101

16 10110

17 10111

18 11000

19 11001

Input

Term: 13 12 11 10 9

Value: 16 8 4 2 1

PGM

16 1 0 0 0 0

17 10001

18 10010

19 10011

20 10100

21 10101

22 10110

23 10111

24 11000

25 11001

26 11010

27 11011

28 11100

29 1 1 1 0 1

30 11110

31 11111

Electro Cam 8-position Gray Code selector switches are

available as accessories for PLuS controls.

Please Note:

• Although the PS-6244 can store up to 48 programs, only

Programs 1 through 31 can be selected using gray code

input. A value larger than 31 will select Program 31.

Input MSB LSB

Term: 13 12 11 10 9

PGM

Default 0 0 0 0 0

100001

200011

300010

400110

500111

600101

700100

801100

901101

10 0 1 1 1 1

11 0 1 1 1 0

12 0 1 0 1 0

13 0 1 0 1 1

14 0 1 0 0 1

15 0 1 0 0 0

Input

Term: 13 12 11 10 9

PGM

16 11000

17 11001

18 11011

19 11010

20 11110

21 11111

22 11101

23 11100

24 10100

25 10101

26 10111

27 10110

28 10010

29 10011

30 10001

31 10000

MSB LSB

2-7 Installation & Wiring

Page 16

Output Wiring

Output Types The outputs available depend on the PS-6244 Model:

Output Model Model

Type 6244-24-M17 6244-24-X16M09

Transistor None Outputs 1-16

AC/DC/RR Modules Only Outputs 1-15 Outputs 17-23

AC/DC/RR or Analog Modules Output 16 Output 24

Analog Modules Only Output 17 Output 25

The load device to be driven must match the output type.

Power Output Modules Output modules can directly switch inductive loads and resistive loads that require more

current or voltage than the transistor outputs can supply. The modules do not supply

the power for the load; they simply switch it. Each output module has two dedicated

terminals and therefore does not share any common signal with the other modules.

This allows AC and DC modules to be mixed on the same control. DC modules can be

wired to sink or source as shown in Figure 9.

Analog Output Modules Analog output modules generate signals that are proportional to the encoder RPM.

They can be used only in the output positions shown above. Either a 0-10 Vdc or 4-20

mA analog module can be used in either module position. ANALOG QTY must be

programmed for the number of analog modules installed. An external power supply is

not needed because the analog modules get the power they source from the controller.

The analog output signal is completely isolated.

Transistor Outputs PS-6244-25 models include 16 transistor outputs to drive the electronic input circuits of

other control devices. The outputs are limited to 30 Vdc, 50 mA each and should not be

used to control inductive devices such as solenoids, solenoid valves or relays.

The control can be ordered with either sinking or sourcing transistor outputs. Both types

require a 10-30 VDC power supply connected to TB 11 to drive the transistor output

circuitry. The transistor output fuse will blow if the power supply polarity is incorrect, but

the circuitry will not be damaged. See Figs. 17 & 18 for fuse and transistor chip replacement.

Sinking transistor outputs (N16 controls, Figure 10) conduct to the negative terminal of TB 11. Therefore the common for TB 11 and the load must be electrically the

same. This may require connecting commons together if the power supplied to TB 11 is

not also the load power supply. Electronic counters/ratemeters often fall into this category. The power supply that powers the load does not have to be the same voltage as

the transistor power supplied to TB 11.

Sourcing transistor outputs (P16 controls, Figure 11) conduct to the positive power

terminal of TB 11. The load is therefore powered from the same supply that is providing

the transistor power.

2-8 Installation & Wiring

Page 17

Output Wiring (cont’ d)

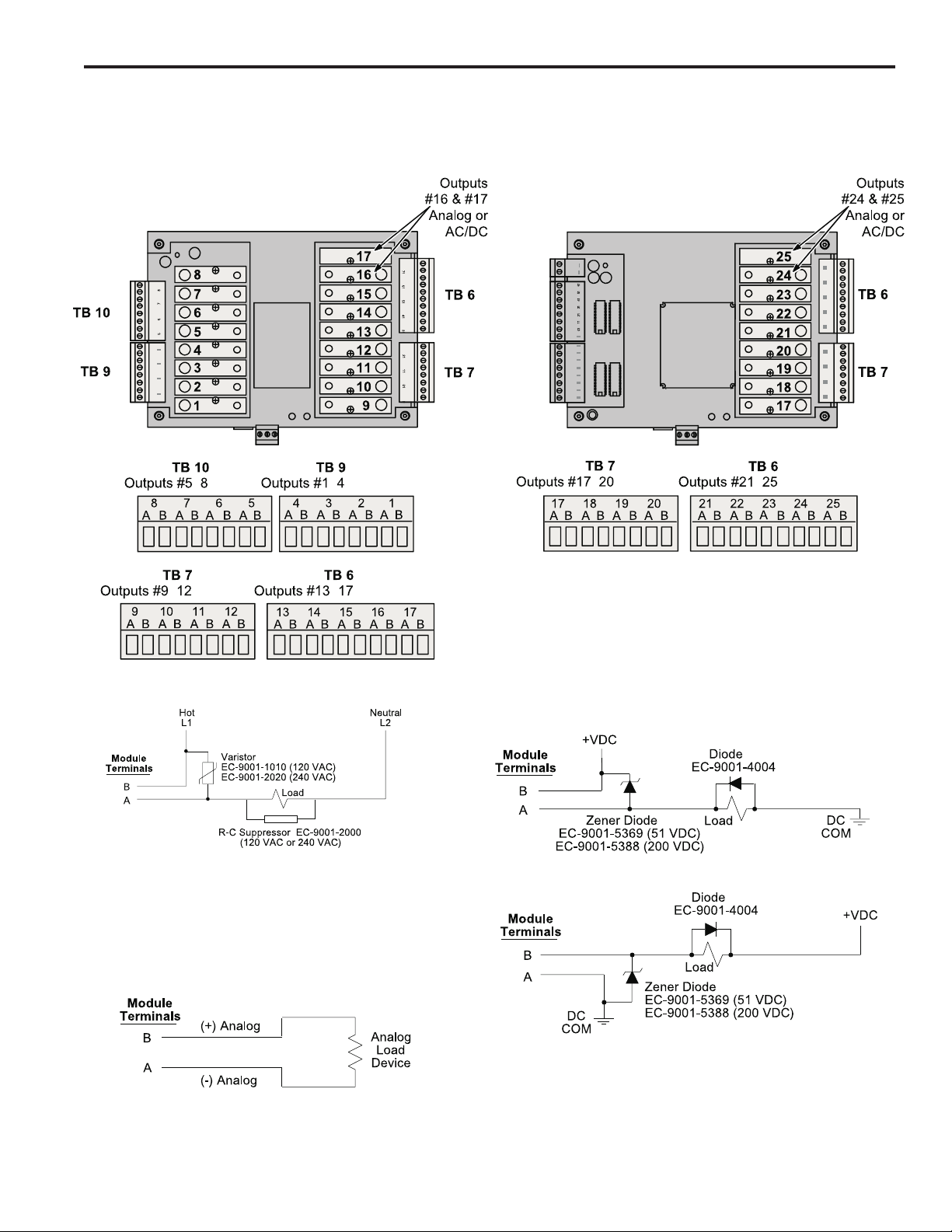

Figure 9—Wiring for Output Modules

PS-6244-24-M17

-

-

PS-6244-24-X16M09

-

-

--

-

-

AC Output

• When other switching devices are in series or parallel with the AC output

module, connect a varistor (MOV) across the terminals to prevent

module damage from inductive voltage spikes.

• Output modules act like switches; they do not supply power to loads.

Analog Output

• Analog output modules source the analog signal.

• No external supply is required.

• Analog output signals are isolated.

DC Output

Sourcing

Sinking

• Suppress spikes in inductive DC loads with one of the following

methods:

Connect a zener diode across the terminals. Turn off time will not be

significantly affected. Voltage rating of diode must be greater than the

normal circuit voltage. 50 VDC Zener, #EC-9001-5369; 200 VDC

Zener, #EC-9001-5388.

Connect a reverse-biased diode across the load. This will increase the

turn off time of the load. #EC-9001-4004.

2-9 Installation & Wiring

Page 18

Output Wiring (cont’ d)

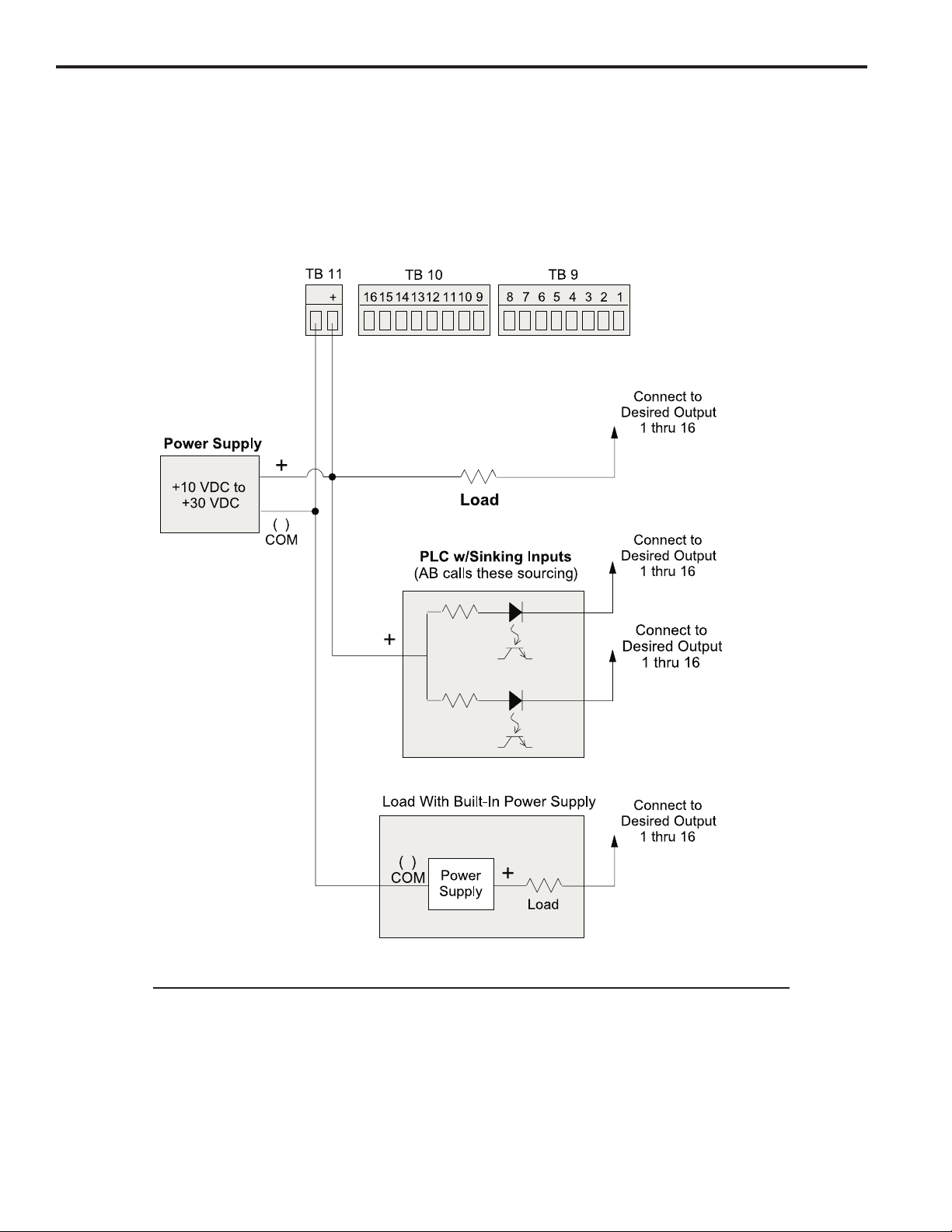

Figure 10—Wiring for Sinking Transistor Outputs (See Figure 6 for Terminal Block Locations)

Model PS-6244-24-N16M09

-

Please Note:

-

-

• Outputs are rated at 30 VDC, 50 mA.

• Transistor outputs should not be used to switch inductive devices such as solenoids or

relays.

• Sinking outputs conduct to the negative terminal of TB 11 when “on.”

• The power supply shown in “Load with Built-In Power Supply” does not have to be the same

voltage as the power supply connected to TB 11.

2-10 Installation & Wiring

Page 19

Output Wiring (cont’ d)

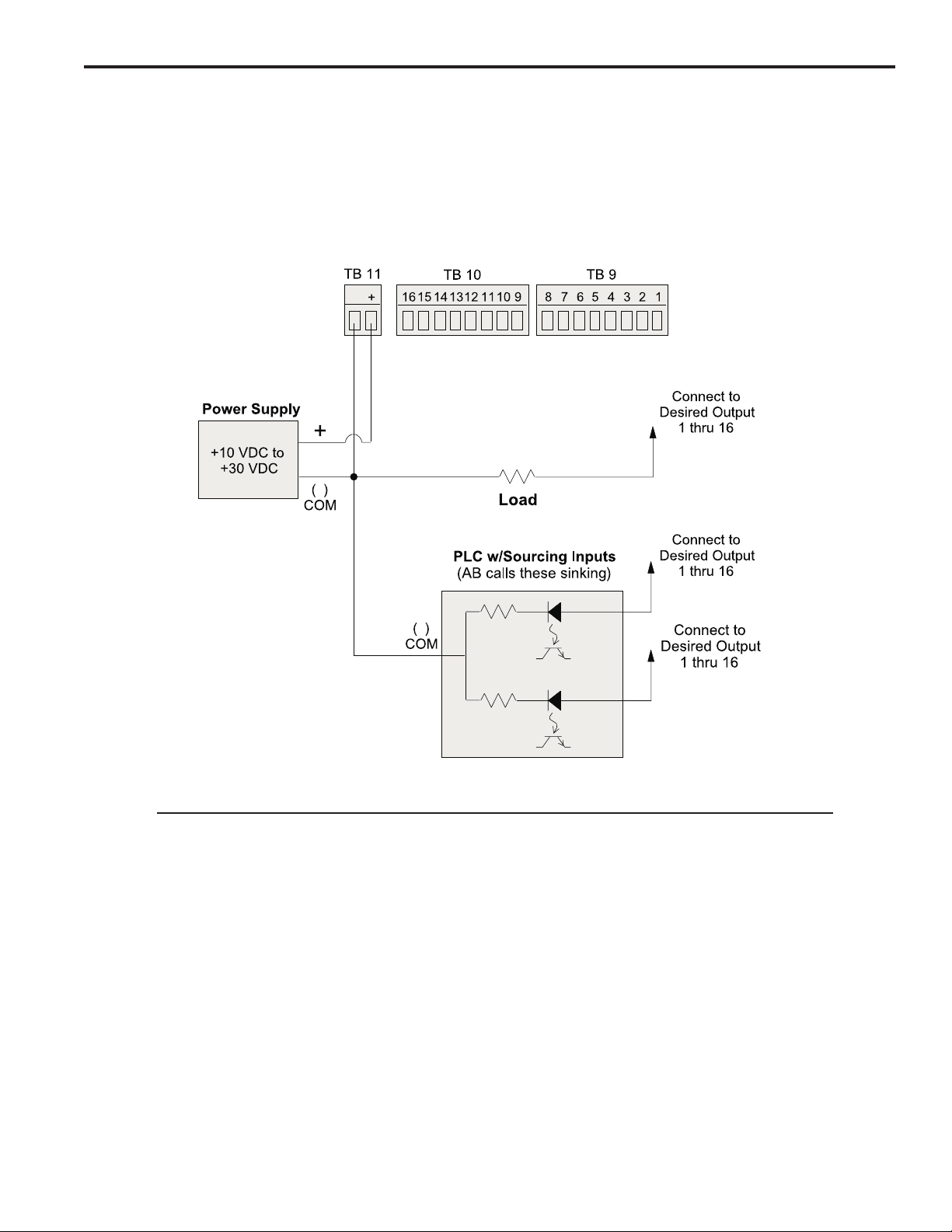

Figure 11—Wiring for Sourcing Transistor Outputs (See Figure 6 for Terminal Block Locations)

Model PS-6244-24-P16M09

-

-

-

Please Note:

• Outputs are rated at 30 VDC, 50 mA.

• Transistor outputs should not be used to switch inductive devices such as solenoids or relays.

• Sourcing outputs conduct to the positive terminal of TB 11 when “on.”

2-11 Installation & Wiring

Page 20

Keypad Wiring

Number of Keypads One or two keypads may be connected to a PS-6244 controller as shown in Figure 12.

See Figure 14 for possible system configurations.

Programming Enable The wiring connector on the back of each keypad includes terminals to select Operator

or Master level programming for that keypad. These terminals can be temporarily

jumpered during set-up to allow entry of programming access codes, or they can be

switched with a variety of devices including mechanical switches, relay contacts, and

PLC DC outputs. See ENABLE CODES in the programming section for details on programming access.

If a solid state device will be activating the Programming Enable terminals, that device

will determine whether sourcing or sinking wiring should be used. For mechanical devices such as jumpers or key switches, either sourcing or sinking wiring may be used.

Figure 12—Keypad Wiring

Keypad Connector

on Controller

-

Wh Bk Gn

Bk

Rd Bk

Programming Enable, Sourcing

Keypad

Terminal Block

Keypad

Terminal Block

--

Bk Wh Bk Gn

Rd Bk

Programming Enable, Sinking

-

-

Bk

Wh Bk

Rd Bk

Gn

2-12 Installation & Wiring

Page 21

DIP Switch Configurations

DIP Switches Each keypad and controller has a DIP switch as shown in Figure 13. For convenience,

set the DIP switches correctly before mounting the units in a panel.

Keypad Settings The address and termination settings on the keypad DIP switch apply to the RS-485

network that connects it to the controller. See Figure 14 for guidelines and sample

settings.

Controller Settings The address settings on the controller DIP switch apply to a network connecting the

controller to a PLC or other system host. When the DIP switch is set to zero, the default

address programmed through the COMMUNICATIONS function takes affect. Whereas

the DIP switches can set a maximum address of “7”, the COMMUNICATIONS function

can establish much higher address numbers. These settings are not related to com-

munications with the keypads.

Two sets of termination switches are included on the controller. One set establishes the

termination value for an RS-485 network connecting the controller to a PLC or other

system host. It does not apply to an RS-232 network. The other termination switches

apply to the keypad network. See Figure 14 for guidelines and sample settings.

Figure 13—DIP Switches and Related Communications Networks

NOTE: Both termination switches in a pair must be in the same position.

2-13 Installation & Wiring

Page 22

DIP Switch Configurations (cont’d)

Figure 14—DIP Switch Settings for Typical Systems

One Keypad

Two Keypads, Controller on End

Two Keypads, Controller in Middle

DIP Switch Guidelines

Termination: • Termination must be “on” for devices on each end of the chain.

• Termination must be “off” for devices in the middle of the chain.

• Both termination switches in a pair must be in the same position.

Address: • Keypad addresses must be assigned starting with “0” and increasing sequentially.

• The physical location of a keypad in the chain has no relationship to its address.

• During initial programming, the KEYBOARD QTY function must be used to enter the

number of keypads in the chain. KEYBOARD QTY can be accessed only through the

keypad whose address is “0.”

2-14 Installation & Wiring

Page 23

Communications Wiring

DB-9F Port Serial communication to a PLC or other system host is provided through a DB-9 female

connector as shown in Figures 5 & 6. This connector can be wired for RS-232 or RS485 communications.

RS-485 RS-485 can be used for “multi-drop” networks where more than one controller could be

connected to the system host.

RS-232 RS-232 can connect only a single PS-6244 to a system host.

RS-232/485 Selection Use the COMMUNICATIONS function to select RS-232 or RS-485 communications.

Figure 15—Communications Wiring

DB-9 Female Connector on Controller

(See Figures 5 & 6 for Location)

RS-232 Cable Wiring

DB-25 (Host) to DB-9F (PS-6244)

RS-232 Cable Wiring

DB-9 (Host) to DB-9F (PS-6244)

2-15 Installation & Wiring

Page 24

Encoder Wiring

General Information Choose a mounting location for the encoder that allows convenient mechanical con-

nection of the encoder shaft to the machine. The encoder is normally driven at a 1:1

ratio to machine cycles, but this is not true in all applications. Commonly used methods

for driving the encoder shaft include flexible couplings, timing belts and pulleys, chains,

and sprockets. Insure that the coupling method used is tight enough to minimize backlash without placing excessive side load on the encoder shaft.

If possible, select a location that shelters the encoder from accidental mechanical abuse,

lubricants, wash down chemicals or any other liquids.

Encoder Wiring Use shielded cable for wiring the encoder to the PS-6244 controller.

Figure 16—Encoder Connector Wiring

10-Pin Weidmiller TB4

654321

7

Pin Connection

1 +ENC

2 VREF

3A

4–A

5B

6–B

7Z

8–Z

9 COM

10 Shield

G-+

WX

ñ+Y

Z

S

98

10

2-16 Installation & Wiring

TB4 is EC part# PS-9006-0032.

It is keyed to prevent accidental

insertion into the wrong sockets.

Page 25

Fuse Tester & Fuse Replacement

Fuse Tester Figure 17 shows the location of a fuse test socket and LED which can be used to test

TR5 style fuses. PS-6244 controllers are shipped with a spare 4A fuse mounted in the

test socket.

Figure 17—TR5 Fuse Tester and Fuse Locations

PS-6244-24-M17 PS-6244-24-X16M09

Replacement TR5 Fuse Part Numbers

Rating Function ECC Part # Wickmann Part #

250 mA Power for Inputs (TB 2) PS-9005-0250 1937-035

1 A Power for Transistor Outputs (TB 11) PS-9005-0001 19370

4 A Fuse for Output Modules PS-9005-0004 19370-K

2-17 Installation & Wiring

Page 26

Output T ransistor Replacement

Check Fuse First If all of the transistor outputs fail to work, check the 1A fuse shown in Figures 17 & 18.

Also check to be sure that a 10–30 VDC power supply is connected to TB 11, Figure 6.

Correct Problems Chips will most likely be damaged by one of two events:

• A short circuit connected to one of the transistor outputs.

• A load exceeding 50 mA connected to one of the transistor outputs.

Before replacing a transistor output chip, fix the problem that damaged it.

Proper Placement When replacing a chip, be sure that all of the pins are properly seated in the socket.

Position the notch on the end of the chip as shown below.

Figure 18—Transistor Chip Replacement

TB 11

TB 10

TB 9

PS-6244-24-N16M09

Sinking Outputs

-

16 15 14 13 12 11 10 9

8 7 6 5 4 3 2 1

1A Fuse for

Transistor Outputs—

If blown, no transistor

outputs will work.

See Figure 17

for testing.

Empty

Socket Holes (2)

Position Notches

Like This

Jumper Block & Chip

For Outputs 9–16

• Jumper block

does not normally

need replacement.

Jumper Block & Chip

For Outputs 1–8

• Jumper block

does not normally

need replacement.

TB 11

TB 10

TB 9

PS-6244-24-P16M09

Sourcing Outputs

-

16 15 14 13 12 11 10 9

8 7 6 5 4 3 2 1

1A Fuse for

Transistor Outputs—

If blown, no transistor

outputs will work.

See Figure 17

for testing.

Chips for

Outputs 9–16

• Replace 2580 first.

• Replace 2803A if

that doesn’t work.

Position Notches

Like This

Chips for

Outputs 1–8

• Replace 2580 first.

• Replace 2803A if

that doesn’t work.

2-18 Installation & Wiring

Replacement Part Numbers

Description ECC Part #

UDN 2580 PS-9011-2580

ULN 2803A PS-9011-2803

DIP Jumper Block PS-9006-0015

Page 27

Motion Detection

l

t

Menu Path MAIN SCREEN to SETUP MENU to MOTION DETECT

Background Motion Detection establishes one or two “Motion Levels,” or speed ranges, with low

and high RPM values. These two ranges are independent of each other.

Using the MOTION ANDING screen, each output channel can be ANDed with either

Motion Level. ANDed outputs will be enabled only when the encoder speed is within the

specified speed range. Output channels that are not ANDed will be “on” whenever the

machine position is within their programmed setpoints, regardless of machine speed.

One use of Motion Levels and Motion ANDing is to turn off devices such as glue guns if

the machine stops or jams.

Screen The Motion Detection screen displays the Motion Level, the Low RPM, and the High

RPM.

MOTION LEVEL: 1

LO: 30 HI: 1500

Low RPM setpoint

Programming Use the numeric keys and ENT to change values for Motion Level, Low RPM, and High

RPM.

Motion Detector An output channel can be used as a motion detector by programming it to be on at “1”

and off at “1,” and then ANDing it with the desired Motion Level. This will turn the output

on constantly as long as the machine speed is within the specified Motion Level range.

See Also MOTION ANDING

Motion detection leve

High RPM setpoint

Offset

Menu Path MAIN SCREEN to SETUP MENU to OFFSET

Purpose This screen allows the encoder position to be set to zero at the desired machine posi-

tion, eliminating the need to mechanically adjust the encoder shaft coupling to the machine.

Output Group

GRP:1< POS: 0

ABS: 132

Group Position = Shaft Position + ABS Offse

Absolute Offset Value for this Group

Position Setup In order to set the Position to match the machine position, simply stop the machine at a

known position and enter the desired Position value. For example, jog the machine to a

position at the start of a new cycle, then set the Position to “0.”

Absolute Offset When you modify the Position, the Absolute Offset will change to the following number:

(Previous Absolute Offset) + (Change in Position)

• The Change in Position will be negative if the new position is less than the original

position, and will thus be subtracted from the Previous Absolute Offset.

Example: Absolute Offset is zero, and the machine is jogged to the start of a new cycle,

where the Position is 150. Using the keypad, the Position is reset to zero, for a change

in Position of (–150). The new Absolute Offset is thus zero minus 150. Since the model

of encoder used in this example shows positions from zero to 1000, the 150 is subtracted from 1000, resulting in an Absolute Position of 850.

Absolute Offset is intended to be used for "archival purposes", in case you lose correct

machine position and need to set the machine back up. Absolute Offset can be modified using the numeric keypad.

3-15 Programming

Page 28

Output Status

)

s

Menu Path MAIN SCREEN to SETUP MENU to I/O STATUS to OUTPUT

STATUS

Purpose This screen shows the On/Off state of the output channels.

Both Models, Outputs 1-8

12345678 OUTPUT

01001001 1-8<

Output On/Off Status (O=Off, 1=On)

PS-6344-17, Outputs 9-17

901234567 OUTPUT

0100100AA 9-17<

Analog Modules shown with "A"

PS-6344-25, Outputs 9-25

90123456 OUTPUT

01001000 9-16<

789012345 OUTPUT

0100100AA 17-25<

Output Numbers (1-8)

Output Numbers (9-17)

Output Numbers (9-16)

Output Numbers (17-25

Analog Modules shown with "A"

If any output positions have been programmed as analog outputs, the On/Off status will

show “A” instead of “0” or “1.”

Selecting Outputs To change the set of outputs displayed, press the SEL key.

Password

Menu Path MAIN SCREEN PASSWORD

This screen provides an area to enter a password. It also shows the current programming access level and the status of the Programming Enable terminals on the back of

the keypad, Figure 12.

PASSWORD:****<

LEV:NONE INP:OFF

Current programming level (hardware or software)

Enable Levels There are three programming access levels; OPERATOR, SETUP, and MASTER. See

Figure 21 for a summary of the programming functions available to the different levels.

The codes that correspond to each level are established in the ENABLE CODES screen.

Entering a Password Enter a password through the numeric keypad followed by ENT. As you press the

number keys, the asterisks will be replaced by dashes. If you make a mistake, press

CLR to erase the last key you pushed.

Password entry area

Keypad programming terminal input statu

3-16 Programming

Page 29

e

Password (Cont'd)

F

If you enter a password that has been programmed through ENABLE CODES, the

keypad will function at the corresponding programming level.

If either of the programming enable terminals on the back of the keypad is active when

a password is entered, the programming level will be whichever is greater.

PASSWORD:--**<

LEV:NONE INP:OFF

PASSWORD:****<

LEV:MAS INP:OFF

Enable level shown if number matches programmed password valu

Clearing a Password When programming operations are completed, enter a password value of “0,” then ENT

to clear the enable level.

If a keypad is left unattended with an active password, the access code will clear after

five minutes of keypad inactivity and the keypad will revert to the “Normal Display”

mode shown in Figure 21.

See Also ENABLE CODE

Dashes replace asterisks as numbers are entered

Dashes change back to asterisks with ENT

Per Channel Enable

Menu Path MAIN SCREEN to CONFIG MENU to PGM ENABLES to PER

CHN ENABLE

Purpose This screen is used to enable Operator Level access to individual output channels.

CHN ENABLE is used in conjunction with the ENABLE OPTIONS screen to assign

Operator Level access to selected programming functions.

CHN: 12<

CHN ENABLE: ON

Channel Select Press the INC/DEC keys, or use the numeric keys and ENT.

Enable Toggle Press the SEL key to toggle the enable ON or OFF.

See Also ENABLE OPTIONS

Channel number

Per channel enable: ON/OF

(Toggle with SEL key)

3-17 Programming

Page 30

Program Copy

L

Menu Path MAIN SCREEN to SETUP MENU to PGM COPY

Purpose Program Copy allows you to copy all of the channels and setpoints from one program to

another. It is often easier to copy an existing program and modify it, than to enter a new

program from scratch.

Screens The Program Copy function consists of four screens:

SRC PROGRAM:---<

DST PROGRAM:---<

DST PROGRAM: 6<

EXECUTE<

DST PROGRAM: 6

COMPLETE<

Programming Use the numeric keys and SEL to enter program numbers.

During programming, the cursor keys allow you to move between the Source and Destination screens to allow you to change values before selecting EXECUTE.

Program to be copied from

Destination to be copied to

Move cursor to EXECUTE, then press SE

to copy program

COMPLETE indicates program

successfully copied

Program Select Mode

Menu Path MAIN SCREEN to CONFIG MENU HARDWARE to PGM SEL

MODE

Purpose This screen allows you to specify the format for the hardware Program Select inputs on

terminals 9 through 13 of Terminal Block 11, Figure 7.

PROGRAM SELECT

MODE: BIN<

The Program Select inputs can operate in Binary, BCD, or Gray Code formats as shown

in Figure 8.

Use the SEL key to toggle the input format.

If the input signals controlling program selection are lost due to a malfunction,

the Default Program will activate. To prevent sudden changes in machinery operation that may damage equipment or injure personnel, program the Default

Program with settings that will not cause harm in the event of sudden activation.

See Also DEFAULT PROGRAM

Hardware Program Select Format: BIN = Binary,

GRAY = Gray Code, BCD = Binary Coded Decimal

3-18 Programming

Page 31

Pulse Copy

Menu Path MAIN SCREEN to SETUP MENU to PULSE COPY

Purpose Pulse Copy allows you to program a series, or “train” of pulses into a channel without

having to enter the On and Off setpoints for each pulse. The Pulse Copy function prompts

you for the beginning and ending setpoints for the pulse train; the number of pulses in

the train; and the duration of a pulse. Pulse Copy then divides the designated portion of

the encoder cycle into the specified number of pulses, evenly dividing the unused portion of the segment between the pulses.

Screens The Pulse Copy function consists of eight screens:

PROGRAM:---<

CHANNEL:---<

ON:---<

OFF:---<

COUNT---<

DURATION:---<

DURATION: 35

EXECUTE<

Program to add pulses to;

Enter number, then SEL to go to next screen

Channel to add pulses to;

Enter number, then SEL to go to next screen

"On" time of leading edge of first pulse;

Enter number, then ENT & SEL to go to next screen

"Off" time of trailing edge of last pulse;

Enter number, then ENT & SEL to go to next screen

Total number of pulses to be added;

Enter number, then ENT & SEL to go to next screen

Duration of each pulse added;

Enter number, then ENT & SEL to go to next screen

Move cursor to EXECUTE, then press SEL to

generate pulses. To review values before executing,

move cursor to top row and press SEL as needed

DURATION: 35

COMPLETE<

Example Generate a train of pulses for a Krones Label Check Unit as follows:

Pulse On Off

1050

2 100 150

3 200 250

4 300 350

5 400 450

6 500 550

7 600 650

8 700 750

9 800 850

10 900 950

COMPLETE indicates pulses have been generated

3-19 Programming

Page 32

Pulse Copy (cont’d)

3

Each pulse is 50 increments wide, separated from the next pulse by 50 increments.

Program PULSE COPY as follows:

PROGRAM:---<

CHANNEL:---<

ON: 0<

OFF:950<

COUNT 10<

DURATION: 50<

DURATION: 50

EXECUTE<

Program to add pulses to;

Enter number, then SEL to go to next screen

Channel to add pulses to;

Enter number, then SEL to go to next screen

"On" time of leading edge of first pulse;

Enter 0, then ENT & SEL to go to next screen

"Off" time of trailing edge of last pulse;

Enter 950, then ENT & SEL to go to next screen

Total number of pulses to be added;

Enter 10, then ENT & SEL to go to next screen

Duration of each pulse added;

Enter 50, then ENT & SEL to go to next screen

Move cursor to EXECUTE, then press SEL to

generate pulses.

DURATION: 35

COMPLETE<

Go to SETPOINTS to confirm the pulse train:

<-P-> CH: 1 <EDG

ON: 0 OF: 50

COMPLETE indicates pulses have been generated

Move cursor to OF and use arrow keys to

review pulse setpoints

Rate Setup

Menu Path MAIN SCREEN to CONFIG MENU to DISPLAY

RATE SETUP

Purpose The Rate Setup function allows you to configure the RPM display on the Main Screen.

The Main Screen can display the encoder speed in units of Revolutions Per Minute

(RPM), Bags Per Minute (BPM), or Cartons Per Minute (CPM). The encoder speed can

also be displayed as .5X, 1X, 2X, or 3X actual RPM.

Screen

MPY: 1< DP: 0

DIV: 1 RPM

Multiplier: 0 through 1091

Number of decimal points displayed: 0, 1, 2, or

Units: RPM, BPM, CPM, IPM

Divider: 1 through 63

3-20 Programming

Page 33

Rate Setup (Cont'd)

SCALE

FACTOR: 360<

Number of increments each revolution is broken into

RPM UPDATE

RATE: 1/S<

RPM Update Rate: How often RPM display on main

screen is updated; 1/Sec, 2/Sec, or 10/Sec.

Press the SEL key to toggle display mode or rate. Following is a chart summarizing the

relationships between encoder speed, units, and rate multiplier:

If And Then an Is

Units Rate Encoder Displayed

Are… Is… Speed Of… As…

RPM .5X 100 RPM 50 RPM

1X 100 RPM 100 RPM

2X 100 RPM 200 RPM

3X 100 RPM 300 RPM

BPM .5X 100 RPM 50 BPM

1X 100 RPM 100 BPM

2X 100 RPM 200 BPM

3X 100 RPM 300 BPM

CPM .5X 100 RPM 50 CPM

1X 100 RPM 100 CPM

2X 100 RPM 200 CPM

3X 100 RPM 300 CPM

RPM Update Rate

Menu Path MAIN SCREEN to CONFIG MENU to DISPLAY

RPM UPD RATE

Purpose The RPM Update Rate is how often the RPM display on the Main Screen is updated.

This rate can be programmed to be 1/Sec, 2/Sec, or 10/Sec.

Screen

Press the SEL key to toggle the selection.

Scale Factor

Menu Path MAIN SCREEN to CONFIG MENU to HARDWARE MENU SCALE

FACTOR

Purpose The Scale Factor screen displays the number of increments into which one encoder

revolution is divided. For the PS-6244 special unit, Scale Factor is fixed at 1000.

3-21 Programming

Page 34

Setpoint Use

g

y

l

s

Menu Path MAIN SCREEN to SETUP MENU to SYSTEM INFO SETPOINT

USE

Purpose This function displays the total number of setpoint On/Off pairs, or “pulses” available for

programming, and the number of pulses that have been programmed.

Screen

TOTAL: 1200

USED: 64

The number of setpoints shown as "Used" is the sum of all pulses that are programmed

into all channels of all programs. The "Total" value is the number of pulses that can be

stored in non-volatile EEPROM memory. The difference between the two numbers is

the number of pulses available for programming.

The number of pulses programmed into all channels of all programs cannot exceed the

value displayed as Total.

There are no values that can be changed in this screen.

Total number of pulses available for programmin

Number of pulses programmed into all channels

of all programs

Setpoints

Menu Path MAIN SCREEN to SETPOINTS

Screens When SETPOINTS is selected, a preliminary screen specifies the program whose

setpoints will be programmed.

PGM NUMBER: <

The active program is displayed, but any other program can be specified by using the

numeric keys or INC and DEC to choose a program, then pressing SEL to move to

setpoint programming.

Blank if only 1 pulse in channe

Channel

CH: 1 <EDG

ON: 90 OF: 270

ON setpoint

<-P-> indicates multiple pulses in channel

<-P-> CH:1<EDG

ON: 90 OF: 270

Channel to Edit Use the numeric keypad and ENT to select the channel to program.

• CHN 91 is a special channel used for shift register functions. See “Shift Register

ANDing” for details.

Program to view or modif

Pulse mode

OFF setpoint

Setpoint Values Use the left and right arrow keys to move between the On and Off setpoints.

• If a channel has more than one pulse, you may view the other pulses by pressing the

right cursor key when viewing the Off setpoint, or by pressing the left cursor key when

viewing the On setpoint.

• If a channel contains no pulses, the On and Off setpoints will be “0.”

• If a channel is always on, both the On and Off setpoints will be “1.”

CH:1 EDG

ON: 0< OF: 0

3-22 Programming

ON and OFF setpoints both 0 if no pulse

in channel. Both 1 if channel always ON

Page 35

Setpoints (cont’d)

Adding a Pulse You may add a new pulse to a channel by pressing the SEL key when the cursor points

to either the On or the Off setpoint.

CH:1 EDG

ON:---< OF:---

The display will change to show blank On and Off setpoints; the cursor will point to the

On setpoint. Enter the On setpoint through the numeric keypad, and then press the

ENT key or the right cursor to move to the Off setpoint. Enter the Off setpoint through

the numeric keypad and then press the ENT key.

Adding Multiple Pulses If On and Off setpoints for a pulse are visible on the screen and you press SEL to

program a new pulse, the original pulse will remain in the output channel. If the On or

Off setpoints you enter overlap an existing pulse in the channel, you will see an “Error:

Pulse Overlap” message.

To abort entering a pulse at any time, press ESC.

Changing Setpoints Change a setpoint value with the numeric keys followed by ENT, or with the INC and

DEC keys.

Pulse Modes The Pulse Mode controls how the INC and DEC keys modify setpoints. There are three

modes; EDG (edge), PUL (pulse), and CHN (channel.) You change the Pulse Mode by

pressing the SEL key when the cursor points to the Pulse Mode.

Enter ON setpoint, then ENT or right cursor to OF.

Enter OFF setpoint, then press ENT.

In EDG mode, the INC and DEC keys will affect the selected On or Off setpoint only.

In PUL mode, both On and Off setpoints will be incremented or decremented simulta-

neously.

In CHN mode, all On and Off setpoints for all pulses in the channel will be incremented

or decremented simultaneously.

Deleting a Pulse A pulse may be deleted by making On equal to Off, or vice versa. If there is more than

one pulse in the channel, the next pulse will appear in the On/Off setpoint area. If the

channel has no more pulses, the On and Off setpoint will both be zero.

Clearing a Channel To clear a channel of all pulses, enter a new pulse with On and Off setpoints of “0.”

Channel Always ON A channel may be programmed to be On for a full revolution (always On) by entering a

new pulse with both On and Off values equal to “1.”

Record Setpoints Photocopy the form inside of the back cover and use it to write down setpoints for each

program.

Shift Position

Menu Path MAIN SCREEN to SETUP MENU to SHIFT POSITION

Purpose The Shift Position is the point in the encoder revolution at which the shift register data

shifts. See Shift Register ANDing for details.

SHIFT POS: 850

Programming Use INC and DEC, or the numeric keys and ENT.

Position at which Shift Register will shift.

3-23 Programming

Page 36

Shift Register ANDing

Menu Path MAIN SCREEN to CONFIG MENU to CHN ANDING MENU SHFT

REG ANDING

Background The shift register is a form of electronic memory that sets a “bit” in the zero count of the

register when a signal is applied to Terminal 16, Fig. 7. Afterwards, each time the encoder passes the point programmed through SHIFT POSITION, the register “shifts” the

bit to the next higher count. The bit passes along the shift register until, on the 256th

shift, the bit is erased.

An output channel can be ANDed with any count in the shift register, so that the channel is enabled only when a bit appears in that count. In this way, output channels can be

enabled up to 255 revolutions after Terminal 16 is energized.

Zero Bit is Set

If Terminal 16 is

Energized Within

Channel 91 Window

Count:

1 2 3 4 253 254 255

0

Bit Shifts Up Once

Each Time Encoder

Passes Shift Position

Bit is Erased

On Last Shift

Output Channels

Can Be ANDed with Any

Shift Register Count

Programming This screen allows you to enter the output channel to ANDed with the shift register, and

the shift register count that will enable it.

CHN: 1

SHIFT COUNT: 0

Output Channel to be ANDed

Shift Count That Will Enable Output Channel

To select the output channel and the shift register count, use the numeric keys and

ENT, or use the INC and DEC keys.

• ANDing an output channel with Count “0” is the same as turning Shift Register

ANDing off. The shift register will have no affect on channel operation.

• Any number of output channels can be ANDed to a single shift register count.

• Shift Register ANDing, Input ANDing, and Motion ANDing can be combined for any

given output channel.

Input Window A bit is set in Position “0” of the shift register when Terminal 16 of TB 1, Figure 7, is

energized. A special channel, Channel 91, is provided to limit the portion of an encoder

revolution during which the signal will be accepted from Terminal 16. A “window” can

be programmed into Channel 91 so that a bit is set in the register only if Terminal 16

becomes energized within that window.

3-24 Programming

Page 37

Shift Register ANDing (cont’d)

Shift Position The point in the encoder revolution at which the register shifts data is programmed

through SHIFT POSITION. When programming Shift Position and the On/Off setpoints

for a channel, remember the following:

Don’t Place the Shift Position at the Start of a Pulse

When a pulse starts at the Shift Position, as

0

500

Shift

Position

220

Output

Channel

On at 220

Off at 290

Don’t Let Speed Comp Move a Pulse Onto the Shift Position

shown here, the pulse will be enabled as soon as

a bit is shifted into the programmed shift count.

Although the output will function normally on this

revolution, a small output spike may occur on the

following revolution as the bit is shifted to the

next shift count.

Machine at

“Zero” Speed

0

500

At “Zero” Speed in this example, the output turns on 100 increments after the Shift

Position. However, as the machine accelerates, speed compensation advances the

setpoints until they overlap the Shift Position. This may split the pulse between two

machine cycles. The portion of the pulse following the Shift Position may activate

during one cycle, while the portion ahead of the Shift Position may activate during

the following cycle.

Shift

Position

100

Output

Channel

On at 200

Off at 270

Machine at High RPM

Setpoints Advanced

By Speed Comp

0

500

Shift

Position

100

The Channel 91 Window is “edge sensitive” to the signal from Terminal 16. The leading

edge of the signal must appear in the window for a bit to be set in the register.

Shift Register Clear Energizing Terminal 14 on TB 1, Figure 7, clears all bits from the shift register immedi-

ately.

(continued)

3-25 Programming

Page 38

Shift Register ANDing (cont’d)

Edge Sensitivity of Channel 91 Window

(Channel 91 programmed “on” at 650, “off” at 750 in this example; Shift Position = 0)

Shift

Position

CHN 91

0

500

Terminal 16

Leading Edge

On Within Channel 91;

Bit Set at 0 In Register

Leading & Trailing Edges

Bit Set at 0 In Register

Shift

Position

0

500

Terminal 16

Within Channel 91;

Channel 91 Overlaps Shift Position—Not Recommended!

When Channel 91 overlaps the shift position as

shown here, two problems may occur.

One Product, Two Bits: Due to variations in conditions,

sensors sometimes generate more than one pulse for a

product. If the product sensor sends a pulse early in the

window, that pulse will shift when the encoder reaches

the shift position. If the sensor sends a second pulse for

the same product after the shift position, a second bit will

be set for the same product.

Inconsistent Timing: Some products may appear early

in the Channel 91 window, while others appear late. For

early products, a bit will be set, then immediately shifted

at the shift position. For late products, a bit will be set

after the shift position, and a full revolution will occur

before the bit shifts to 1.

In most applications, programming Channel 91 to

overlap the Shift Position will cause problems.

Shift

Position

CHN 91CHN 91

0

500

Terminal 16

Leading Edge

On Before Channel 91;

Bit Not Set

Channel 91

On at 900

Off at 100

Shift

Position

CHN 91

0

500

Terminal 16

Leading & Trailing Edges

Outside Channel 91;

Bit Not Set

First Bit Set

Shift Position

Second Bit Set

0

500

Software V ersion

Menu Path MAIN SCREEN to SETUP MENU to SYSTEM INFO to

SOFTWARE VERSION

Purpose The Software Version screen displays the revision number of the firmware contained

within the controller. This information may be useful if the unit needs to be returned for

service.

MAJOR REV:1.75

BASE REV:1.17

There are no values that can be changed in this screen.

3-26 Programming

Page 39

Speed Compensation

)

Menu Path MAIN SCREEN to SETUP MENU to SPEED COMP

Background Some devices such as hydraulic cylinders and glue guns require a fixed amount of time

to perform their function. As a machine speeds up, these devices need to be actuated

earlier in the cycle in order to complete their action at the required time. Speed compensation automatically advances the On/Off setpoints of specified output channel(s) as

the machine speeds up, maintaining proper synchronization at all speeds.

Speed Comp Units Speed compensation is programmed by entering the response time of the output de-

vice in milliseconds (.001 Sec). The output will always turn on this number of mSec

before the programmed On position is reached, and turn off this number of mSec before the programmed Off position is reached. As speed increases, the number of degrees of advance will automatically increase to maintain the number of mSec of advance.

Screen The speed compensation screen shows the Output Channel and the speed compensa-

tion value for that channel.

Output Channel

CH: 1<LE: 10.0

TE: 20.0

To change speed comp values, use the numeric keys or INC and DEC. You can enter

values of speed comp in milliseconds without using the decimal point: “12 ENT” will

result in a value of 12.0.

To change output channels, move the cursor to the channel number and enter a new

one. You may also INC or DEC the channel number.

Negative Speed Comp Negative values of speed compensation cause the output channel to lag its programmed

machine position by the specified number of mSec.

It is used when an input sensor is being gated, by the corresponding output channel,

into another control system (PLC, registration control, etc.) Sensor lag can cause an

object that is present at the correct position in the cycle to appear late. Negative speed

comp can retard the gate signal so the sensor and gate signals are in sync when the

object is in the correct position.

Since most sensors have very fast response times, negative speed comp is needed

only where the sensor is slow to respond or the machine speeds are high and sensor

timing is critical.

It may also be used if there is mechanical "wrap up" present in the machine being

controlled. Wrap up will cause machine elements to shift relative to each other as speed

increases. This situation may cause an event to happen later in the cycle as the machine goes faster.

Setting Negative Comp Press the +/- key after entering a number but before pressing ENT, or by decrement a

value below zero.

Leading edge compensation (10 msec shown

Trailing edge compensation (20 msec shown)

3-27 Programming

Page 40

Toggle RPM

Menu Path MAIN SCREEN to CONFIG MENU to DISPLAY MENU to

TOGGLE RPM

Purpose Toggle RPM is the encoder speed at which the Position display on the Main Screen will

disappear. At speeds below the Toggle RPM the Position display will be visible; at

speeds above the Toggle RPM the Position will not be shown.

TOGGLE

RPM: 50

This screen displays the Toggle RPM.

Toggle RPM: Position display on main screen

is not shown at speeds above Toggle RPM

3-28 Programming

Page 41

Controller Diagnostics

CAUTION

Status LED The red Status LED on the controller, Figures 5 & 6, blinks in various patterns to indi-

The controller cannot be repaired in the field. If a unit fails, do not disassemble it.

Return it to the factory for replacement.

cate the controller status.

Normal Operation

The Status LED blinks on and off rapidly.

Keypad Not Connected

If the controller is powered without a keypad connected, the LED blinking pattern will be

“off” for one second, followed by four quick “on” blinks.

Internal Errors

If the LED blinking pattern is “on” for a second, followed by one or more quick blinks

“off,” the controller is experiencing internal errors. The specific error is indicated by the

number of “off” blinks:

One “Off” Blink—Corrupt RAM

Two “Off” Blinks—Checksum error indicating EPROM corruption.

Three “Off” Blinks—System error.

Four “Off” Blinks—System error.

If any of the above four patterns occur, power cycle the control. If the pattern occurs

again, remove the controller from service and return it to the factory.

Five “Off” Blinks—Internal error; possibly noise problems.

Six “Off” Blinks—Internal error; possibly noise problems.

If either of these two patterns occur, check for loose connections and fix any obvious

noise problems. If the problem persists, remove the controller from service and return it

to the factory.

4-1 Troubleshooting

Page 42

Keypad Diagnostics

CAUTION

Keypad Fault LED If the Fault LED on the keypad lights, turn the controller off and back on. If the keypad

Keypad Diagnostics The 6400 Keypad includes a series of diagnostics that show the status of various key-

The keypad cannot be repaired in the field. If a unit fails, do not disassemble it.

Return it to the factory for replacement.

Fault LED does not go off, the keypad microprocessor has malfunctioned. Return the

keypad to the factory.

pad functions. To start the diagnostics, turn the controller off, then restart the controller

while pressing any key on the keypad.

Unique key ID# appears here when any key is pressed.

15 REV 1.00

CS:024B 07APR94

Keypad software revision #.

Keypad software revision date.

Keypad checksum.

FAULT LED

Fault LED blinks ON one second, OFF one second.

Press up or down arrow to return to menu.

PROGRAM ENABLE

1 = E1 jumpered; 2 = E2 jumpered.

Press up or down arrow to return to menu.

ADDRESS SWITCHES

COMM PORT

DISPLAY

KEYBOARD

Figure 22—Keypad Communications Port Test Setup

_

When the COMM PORT diagnostic is run with keypad terminals W,

X, Y, and Z jumpered as shown, a string of “plus” signs will scroll

across the display. When either jumper is removed, the scrolling will

stop.

Shows keypad DIP switch address setting.

Press up or down arrow to return to menu.

Tests communication.

Press up or down arrow to return to menu.

Complete character set scrolls across both lines.

Press up or down arrow to return to menu.

Displays unique key# for each key pressed.

Press hidden key on face below HLP key to exit.

4-2 Troubleshooting

Page 43

Encoder T roubleshooting

Encoder Type The encoder used with the PS-6244 controller is an incremental quadrature encoder.

The encoder sends three signals to the controller: A, B, and Z, as shown below in

Figure 23.

Failure Symptoms Most encoder failures or wiring problems will affect the POS (position) display. Some of

the possible symptoms are listed below:

Pins 1, 2, 3, 5, 9: Failure Before Startup

Position display remains at zero.

Failure During Operation

The display will freeze on the position at the time of circuit break. If the circuit is reconnected before power is turned off, the display will resume incrementing until the

zero pulse (Signal “Z”) is received, at which time the display will return to its programmed offset value.

Pin 7: Failure Before Startup

Position display remains at zero.

Failure During Operation

Operation will appear to be unaffected. However, errors in count values may accumulate, and on subsequent startup, the display will remain at zero.

Depending on the type and timing of encoder failure, the machine may continue

operating normally until it is turned off. On subsequent startup, the POS (position) display may be “frozen” at zero.

Figure 23—Quadrature Encoder Signals & Controller Pin Connections

10-Pin Weidmiller TB4

Pin Connection

1 +ENC

2 VREF

3A

4–A

5B

6–B

7Z

8–Z

9 COM

10 Shield

Signal

A

B

Z

Pulses

Function

Increments position; relationship with "B"

indicates direction.

Increments position; relationship with "A"

indicates direction.

Resets position to "0" once per revolution.

4-3 Troubleshooting

Page 44

General T roubleshooting

The controller and keypad cannot be repaired in the field. If a unit fails, do not

disassemble it. Return it to the factory for replacement.

Problem Possible Solution

Controller & keypad dead. 1. Check main fuse shown in Figs. 5 & 6.

2. Check power supply to controller.

Keypad dead, but controller 1. Check wiring between keypad and controller, Figure 12.

LED’s are on.

Keypad Fault LED “On” 1. Keypad microprocessor has malfunctioned. Turn the controller off and back on. If the

keypad Fault LED does not go off, return the keypad to the factory.

Menu operation Slow on 1. Check KEYBOARD QTY programming. If it is set for two keypads, but only one is

keypad display connected, menu operation will be very slow.

COMM FAILURE—HOST TO 1. This message may flash briefly on power-up under normal conditions.

KEYBOARD message 2. If the message persists, check keypad wiring connections at keypad and controller,

Figure 12.

3. Check DIP switch settings, Figures 13 & 14.

4. Be sure Input Terminal #15, Figure 7, is not energized.

Programming functions not 1. Programming not enabled. See Figure 12, and also ENABLE CODES for details.

accessible.

POS (position) frozen at “0” 1. Encoder or encoder wiring may have failed. Unplug cable at encoder and plug a

spare encoder into the cable. If this solves the problem replace the encoder on the

machine. If not, prepare a short encoder cable (Fig. 16), unplug the cable at the

controller, and plug the short cable with spare encoder into the controller. If this solves

the problem, replace the cable on the machine. See page 4-3 for more.

POS (position) moves opposite 1. Check INCREASING DIR for the correct direction of rotation.

to machine direction. 2. Check encoder wiring, Figure 16.

POS (position) does not 1. Verify that OFFSET is correct. Once set, the offset value should not change. If it

match machine position. does, check the encoder coupling to be sure it is not loose. Also see “Encoder Trouble-

shooting,” page 4-3. An intermittent encoder connection on controller pins 1, 2, 3, 5,

or 9 might cause POS to lag the actual encoder position until the next “zero” pulse

(“Z” signal) is received from the encoder.

Serial communications 1. Check COMMUNICATIONS programming to be sure type, baud rate, and address

not working are correctly set.