Page 1

PS-6000 Series

Programmable Limit Switches

PL

µ

S

Controls Div.

Available with Modbus™ ASCII Communications

16 DC Logic Level

*Slimline Modules

have built-in

Fuses & LED's

*9 Plug-In

Output Modules for

Real World Control of

Electro-Mechanical

Devices

PS-6144-24-P16M09

DIN Rail

Mountable

* Modules sold separately.

Available in AC, DC, Analog &

Reed Relay

Outputs for Direct

Interfacing to PLC's

Controller

2-Line Backlit

Supertwist

LCD Display

Controllers

can be used

with or without

Keypad/Display

PS-6400-24-001

Keypad/Display

*17 Plug-In

Output Modules for

Real World Control of

Electro-Mechanical

Devices

Plug-In

Terminal Blocks

Simplify Wiring

Dual Resolver

Inputs

Compact 1/4 DIN Keypad/Display mounts remotely.

Multiple keypads may be used with one controller.

PS-6344-24-M17

Controller

Description

The PLµS PS-6144 Series Programmable Limit Switches

are microprocessor based units designed to control machine

functions on automated equipment. They can be used as

stand-alone controllers, or interfaced to PLC’s in larger automation systems.

Benefits

Improved Machine Control

Features such as automatic speed compensation, combined

with fast scan times, enable a PLµS Controller to quickly respond to changes in line speed and product movement, minimizing machine errors and reducing scrap and downtime.

The PLµS PS-6344 Programmable Dual Axis Limit Switch

is designed to control machine functions on two independent

axes. It can also be used as a stand-alone controller, or interfaced to PLC's in larger automation systems.

Easier Operator Control

By handling complex automation functions under rapidly

changing line conditions, PLµS Controllers allow an operator

to concentrate on product flow into and out of the line, instead

of constantly monitoring the line for malfunctions and manu-

Typical applications include:

■ Polybag Machines ■ Cartoners

■ Labelling Machines ■ Case Packers

■ Can Making Machines ■ Palletizers

■ Form-Fill-Seal Machines ■ De-Palletizers

■ Paper Converting Machines ■ Vision Systems

■ Pick & Place Machines ■ Filling Machines

■ Metal Processing/Stamping ■ Beverage Fillers

■ Adhesive Application Systems ■ High Speed Presses

■ Automatic Assembly Machines

ally adjusting setpoints. PLµS Controllers increase operator

interface capabilities and contribute to smooth, efficient production.

Faster Changeovers, Greater Flexibility

PLµS Controllers can store multiple programs of timing

setpoints for solenoids, cylinders, motors, glue guns, and other

mechanisms. This allows quick changes in product size or

configuration, reducing downtime and improving productivity.

13647 Metric Rd • Roscoe, IL 61073 USA • 815-389-2620 • FAX 815-389-3304 • 800-228-5487 (USA & Canada)

Page 2

PLµS Controllers Enhance PLC Systems

PLµS Controllers are Fast!

As the system in

duction line every 300 to 500 µsec, approximately 100 times

faster than an average PLC with its more extensive programming. Although the PLC does interface directly with the production line, the functions it controls are lower speed, and deals

more with the logic functions necessary for machine control.

For high speed, critical functions such as label-to-product registration, the PLµS provides faster control and improved precision, reducing scrap and rejects.

Figure 1

shows, the PLµS monitors the pro-

PLµS Controllers have Built-In DC Inputs & Outputs!

Using transistor outputs, the PLµS can signal changes to the

PLC within 300 to 500 µsec (as fast as 40 µsec on special models); much faster than the serial communications speed of approximately 50 msec. When product sensors send a signal to

the DC input of the PLµS, the PLµS responds to that signal

quickly.

PLµS Controllers have Serial Communications!

For product changeovers, the PLC can send commands and

operating parameters to the PLµS controller to change setpoint

programs. This eliminates the need for an operator to manually

change programs through the PLµS keyboard.

PLµS Controllers Save PLC Memory!

The PLµS controller can store many programs containing various setpoints for the production line. The PLC need only select

the correct program, and the PLµS will do the rest.

Figure 1

PLµS Controllers Simplify PLC Programming!

By handling complex functions like speed compensation, timed

outputs, and sensor gating, the PLµS controller relieves a programmer of having to write complicated PLC control programming from scratch. The PLC software can simply exchange

process variables and control data with the PLµS controller,

which handles direct high speed machine control through its

own dedicated software.

PLµS Controllers Simplify Operator Interface Design!

Many production lines require an operator to select product

sizes or configurations through a keyboard. The 1/4 DIN keypad/display of the PS-6000 can be mounted near the production machinery, giving an operator easy access to critical control functions. The keypad transmits these changes back

through the PLµS controller to the PLC, eliminating the need

for a PLC system designer to supply custom operator interface

software and hardware for PLS functions.

Electro Cam Corp. has Systems Experience!

Our standard PLµS controllers feature extensive capabilities

for integration into larger control systems, PLC based or otherwise. We can supply IBM-PC compatible PLuSNet software to

facilitate communications between our controllers and a host

computer. In addition, we can supply controllers with custom

features such as shift-register capability, or the ability to function in non-rotary environments. For information on our systems capabilities, please call our toll free number.

800-228-5487

2

Page 3

Standard PS-6000 Series Features

Analog Output

PS-6000 controllers can drive two analog output modules whose

output signals will be linearly proportional to RPM. The analog

signal level at zero RPM can be programmed, as well as the

RPM that corresponds to maximum signal. No measuring equipment is required for initial setup, and calibration is not needed.

Typical uses for the analog output are to control adhesive pressure as machine speeds change, or to match speeds of other

equipment to the machine being controlled by the PS-6000.

Multiple Programs

Up to 48 programs can be stored in the control’s memory, each

containing different setpoints. To change product size or configuration, simply switch program numbers and all of the output settings will change accordingly. Program numbers can be

selected by the keypad/display, mechanical switches, PLC DC

outputs, or serial communication messages.

Output Speed Compensation

Speed compensation allows outputs to compensate for lagging response times of the controlled devices by turning on

earlier as machine speeds increase. This eliminates the need

to manually adjust output settings whenever machine speeds

are changed, allowing high production speeds.

Internal High Speed Logic

Outputs can be divided into Groups, and each Group can be

associated with an input device to perform discrete logic. There

are six different modes of operation, or logic functions, that

can be selected for each Group. For example, some modes

activate the Group only when the input has signaled that product is present. Adhesive control is a typical application where

outputs are disabled until product is sensed. Output grouping

is a powerful tool in many applications because each Group

can be in any of the six modes and operate independently of

the other Groups.

Timed Outputs

Timed outputs are programmed like standard outputs to turn

“ON” and “OFF” at specific points of resolver rotation. However, once a timed output turns ON, it will remain ON for a

specified time period. Timed outputs are used to drive devices

such as heat seal bars, spot welders, etc., that require a fixed

time to perform a task, regardless of machine speed.

Selectable Scale Factor

The Scale Factor, or number of increments per revolution, can

be programmed by the user. Standard controls have a maximum of 1024 increments per revolution, while controls available with an “-H” option have a maximum of 4096 increments

per revolution. Scale Factor can be defined to correlate to Real

World increments. For example, a controller could be programmed so that one increment of rotation corresponds to 0.1"

of travel.

Serial Communication

Using Electro Cam Corp.’s PLuSNet software for IBM-PC compatible computers, the controller’s entire program can be saved

to a disk file or loaded from a disk file to the control. The program can be printed or edited using the computer. Using MMI

software, it is also possible to send individual communication

commands to the control, while running, to change settings in

the program.

Motion Detection

Two speed ranges can be programmed into the controller, and

specified outputs can then be enabled or disabled, based on

the machine speed being within the designated range. This feature can turn off outputs if the machine stops; disable outputs

until the machine reaches a minimum speed; or disable outputs if the machine exceeds a specified speed. In adhesive

applications, speed range logic is often used to turn off the flow

of adhesive if the conveyor carrying products stops.

Certifications are standard.

PS-6000 Series Options

Gray Code Position Output, “-G” & “-G10”

The “-G” option provides eight bits of position information to a

PLC or other electronic control device, eliminating the need for

expensive PLC accessory cards. The "-G10" option provides

ten bits of position information. This allows the PLC to control

non-critical machine functions, while the PLµS directly handles

high-speed machine control.

High Resolution, “-H”

Controls with this option can divide the resolver revolution into

as many as 4096 increments, while standard controls have a

maximum of 1024 increments. The control program allows resolver resolution to be set for any value in the range of 2-4096.

Large Program Memory, “-F”

Controls with the “-F” option can store up to 256 programs consisting of not more than 4589 output pulses total; standard controls can store up to 48 programs. This additional program storage capability is useful for applications requiring multiple complex programs, or those requiring the storage of more than 48

programs.

Leading/Trailing Edge Speed Comp, “-L”

Controls with this option allow the "ON" and "OFF" edges of

output pulses to be speed compensated by different amounts.

If a device has “ON” and “OFF” response times that are different, it may be necessary to compensate the “ON” edge by a

different amount than the “OFF” edge. This will ensure that the

device stays properly synchronized to the machine over a wide

range of speeds. High-speed adhesive application is an example that can benefit from this feature.

NEMA 4X Keyboard Boot, “-W”

Controls with the “-W” option are shipped with a clear silicon

rubber boot fitted over and around the keyboard area. The boot

provides a good seal between the back of the keyboard and the

control panel. The boot is transparent and pliable, allowing the

keyboard to be viewed and operated. In addition to preventing

contamination from harsh chemicals, the boot protects the keyboard from washdown damage.

Modbus™ ASCII Communication, “-MB”

See page 4.

Multiple Controllers Used with One Resolver, “-MSV”

See page 5.

3

Page 4

PS-6000 Series with -MB Option

— with Modbus ™ ASCII Communications

Description

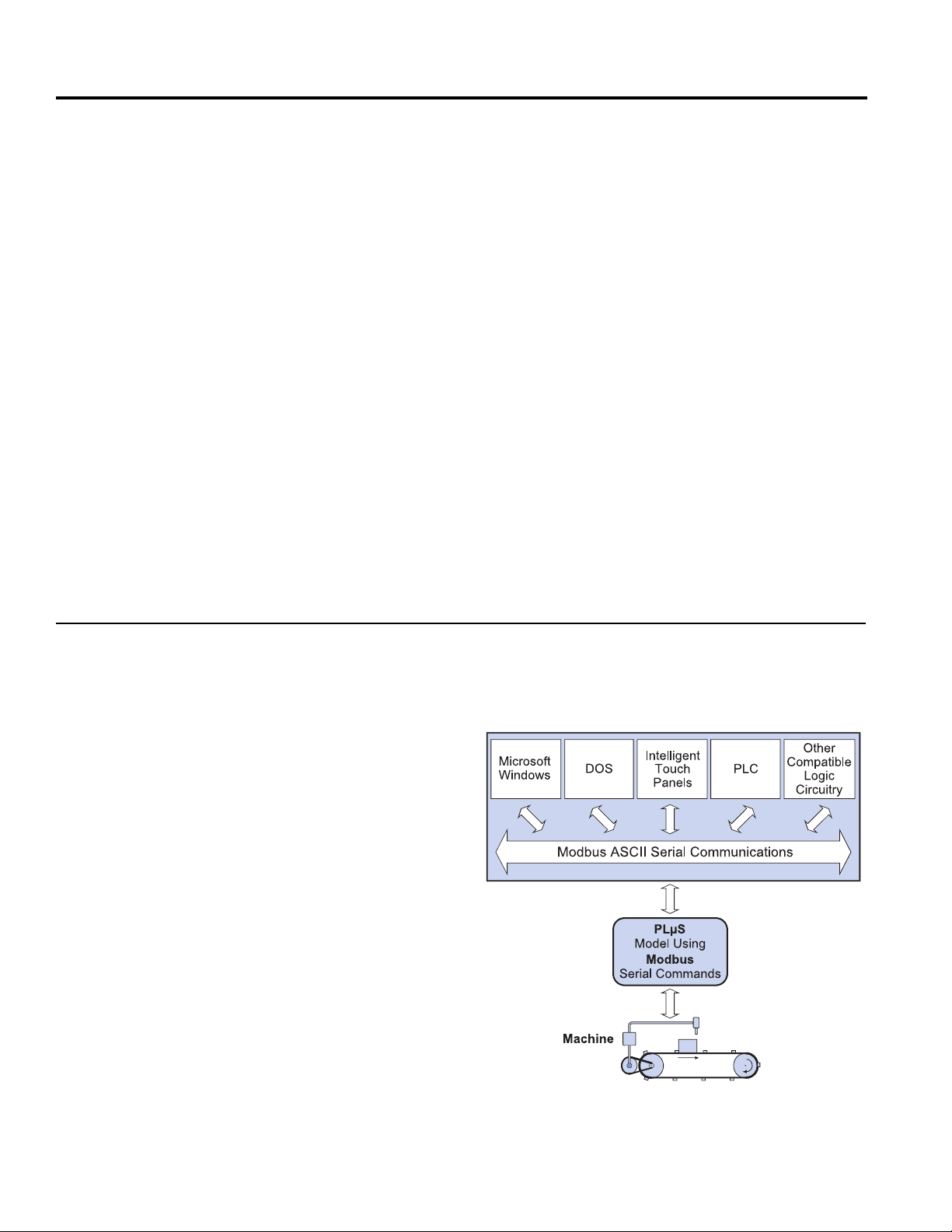

Standard Modbus™ ASCII protocol allows a host computer,

Programmable Logic Controller (PLC), intelligent touch panel,

or other compatible logic circuitry to easily monitor or modify

data within the PS-6000-MB while the machine is in motion.

The control data in the PS-6000-MB is organized as registers

and coils, compatible with PLC programming techniques. Registers are used to store control parameters at specific addresses.

Coils represent channel outputs and logic inputs. Through serial communications, coils allow outputs to be forced ON or OFF,

and allow inputs to be monitored.

The data can be changed by writing to registers, and monitored

by reading from registers. All controller data, including position,

pulses, RPM, speed compensation, and timed output values,

are available through registers.

NOTE: All other features of the -MB version of 6000 series

controllers are the same as those for standard PS-6000

series controllers.

PS-6000-MB System Configuration

Benefits

Improved Machine Control

The controller quickly responds to changes in line speed and

product movement by combining automatic speed compensation with fast scan times. Modbus serial communications makes

it easy to integrate the PLµS controller's high-speed control

characteristics into larger control systems.

Messaging Capability

The PLµS keypad/display can display stored messages or messages received from a host computer. Each message, containing up to 32 characters, is stored in non-volatile EEPROM

memory.

Mapping

Mapping allows the programmer to arrange data into blocks of

registers for optimal communication efficiency, giving direct

access to specific indexed data items. For example, setpoint

values may be mapped into a series of direct access registers

in order to display more than one value at once on the host

computer.

The Modbus™ ASCII protocol allows the PS-6000-MB Series

controller to communicate with various control hardware and

software, including:

■ PC's using Microsoft

FactoryLink®, Intellution™, Lookout™, and Wonderware

■ PC's using DOS software such as Interact™

■ Intelligent Touch Panels

■ PLC's

As the diagram in

municates to the PLµS using Modbus™ ASCII serial communications. The PLµS controller handles high-speed machine

functions through direct wiring of inputs and outputs to the machine.

The Modbus serial commands in the PS-6000-MB Series controller allow you to monitor the program, adjust the current program, or change the program through a host computer system.

This allows the flexibility to change product size or configuration quickly and automatically, reducing downtime and improving productivity.

Figure 2

®

Windows™ software such as

illustrates, the host computer com-

®

Figure 2

4

Page 5

PS-6000 Series with -MSV Option

Description

The -MSV (Master-Slave) option allows up to four controllers

to be daisy-chained to one resolver. Controllers with the -MSV

option are equipped with a jumper that the user can plug/unplug to configure the unit to be either a master or a slave. The

controller comes from the factory jumpered as a master, but

can be set to slave status by removing the jumper.

shows jumper location:

Figure 3

Figure 3

The wiring of the resolver is daisy-chained to all of the controllers as shown below in

supplies the reference signal to the resolver and slave units.

The resolver supplies the position information to all units. Only

a single unit can be the master. Daisy-chain the power from

controller to controller in the same way as the resolver signals.

Connect one of the controllers directly to the power supply.

Power for the other devices in the system should come directly

from the power supply. DO NOT power other devices from the

wires powering the controllers. This will help reduce the risk of

problems associated with EMI and ground loops. Use the standard resolver cable from master to resolver. Use a PS-530005-XXX resolver cable from the master to slave controllers, and

from slave to slave.

NOTE: PS-6344 Series Controllers include Master-Slave

feature as standard.

All other features of the -MSV version of 6000 series controllers are the same as those for standard PS-6000 series

controllers.

Figures 4 & 5

. The master controller

Figure 4

Figure 5

5

Page 6

PS-6X44 Specifications

Controller PS-6144-24-P16M09 (Sourcing

Part Numbers PS-6144-24-N16M09 (Sinking

PS-6344-24-P16M09 (Sourcing

PS-6344-24-N16M09 (Sinking

Electrical

Input Voltage

Input Current

Permanent Memory

20-30 VDC

System: 850 mA max. @ 20 VDC. Includes controller,

2 keypads, resolver, 16 transistor outputs, 7 power modules, 2 analog modules, and 16 inputs, all ON. Current

will be less at higher voltage.

Controller only: 150 mA max. @ 20 VDC

Controller, Resolver, 1 Keypad: 275 mA max @ 20 VDC

EEPROM (no battery required) EEPROM (no battery required)

Environment

Operating Temp.

Storage Temp.

Humidity

NEMA Rating

0° to 55°C (32° to 131°F)

-40° to 70°C (-40° to 160°F)

95% maximum relative non-condensing

For use on type 1, 4, 4X or 12 enclosure

Physical

Overall Dimensions

Weight

See Dimensions (Figures 4 & 5) on page 8.

Controller: 3.5 lbs. (1.6 kg). Keypad/Display: 0.5 lbs.

(0.2 kg)

†

Transistor Outputs)

†

Transistor Outputs) PS-6144-24-M17

†

Transistor Outputs)

†

Transistor Outputs) PS-6344-24-M17

20-30 VDC

System: 850 mA max. @ 20 VDC. Includes controller,

2 keypads, resolver, 15 power modules, 2 analog modules and 16 inputs, all ON. Current will be less at higher

voltage.

Controller only: 150 mA max. @20 VDC

Controller, Resolver, 1 Keypad: 275 mA max @ 20 VDC

0° to 55°C (32° to 131°F)

-40° to 70°C (-40° to 160°F)

95% maximum relative non-condensing

For use on type 1, 4, 4X or 12 enclosure

See Dimensions (Figures 4 & 5) on page 8.

Controller: 3.5 lbs. (1.6 kg). Keypad/Display: 0.5 lbs.

(0.2 kg)

Mounting

Controller

Keypad/Display

Inputs

DC Inputs

Input On State Voltage

Input Current

Input Response Times

Outputs

PS-6144 Series

Real World Outputs

Analog Outputs

DC (transistor) Outputs

Brackets accept EN-50035 ("G" profile) or EN-50022

("Top Hat" profile) DIN rail.

Mounts up to 1000' from controller. Up to 2 keypads

may be connected to one controller.

16 DC inputs; can be configured as sinking† or sourcing

in groups of 8. Optically isolated in groups of 8.

10-30 VDC

11 mA @ 24 VDC

1 - 2 scans

Up to 9 SLIMLINE modules may be plugged into controller. Modules may be any mix of AC, DC, reed relay, & up

to 2 analog. All modules optically isolated.

Up to two 4-20 mA or 0-10 VDC SLIMLINE analog modules may be plugged into controller. Output proportional

to RPM. 12 bit resolution. Update frequency 10 times/

sec (100 msec). Linearity is ±0.3% @ 77°F (25° C). Offset & full scale RPM are programmable.

16 sinking† or sourcing†, optically isolated. 30 VDC,

50 mA max. each. Note: Sinking† or sourcing† must be

specified on order.

Brackets accept EN-50035 ("G" profile) or EN-50022

("Top Hat" profile) DIN rail.

Mounts up to 1000' from controller. Up to 2 keypads

may be connected to one controller.

†

16 DC inputs; can be configured as sinking† or sourcing

in groups of 8. Optically isolated in groups of 8.

10-30 VDC

11 mA @ 24 VDC

1 - 2 scans

Up to 17 SLIMLINE modules may be plugged into controller. Modules may be any mix of AC, DC, reed relay, &

up to 2 analog. All modules optically isolated.

Up to two 4-20 mA or 0-10 VDC SLIMLINE analog modules may be plugged into controller. Output proportional

to RPM. 12 bit resolution. Update frequency 10 times/

sec (100 msec). Linearity is ±0.3% @ 77°F (25° C). Offset & full scale RPM are programmable.

†

Outputs

PS-6344 Series

†

See page 12 for sinking/sourcing definitions.

Outputs are assignable to each resolver.

Outputs are assignable to each resolver.

Specifications continued...

6

Page 7

PS-6X44 Specifications (continued)

Controller PS-6144-24-P16M09 (Sourcing

Part Numbers PS-6144-24-N16M09 (Sinking

PS-6344-24-P16M09 (Sourcing

PS-6344-24-N16M09 (Sinking

Operation

Scan Time

Position Resolution

Speed Compensation

Output Timeout

Number of Timed

Outputs

Multiple Programs

Total Pulse Memory

Pulses per Program

Pulses per Output

Maximum Speed

300 to 500 µsec typical (exact time determined by programming). For higher speeds, interrupt driven versions

are available — consult factory.

10 bits (1024 increments). 12 bits (4096 increments)

available with "-H" option.

Programmed in 0.1 msec steps. 16 individually compensated outputs maximum. Calculations every 10

msec. Special algorithm prevents false firing under rapid

acceleration and deceleration. Separate leading/trailing edge compensation available with "-L" option.

1.0 msec time base (accuracy +1, -0 msec)

Four maximum

48 programs standard (256 available with "-F" option).

1258 pulses standard (4589 available with "-F" option).

512 maximum standard (512 available with "-F" option).

512 maximum standard (512 available with "-F" option).

3000 RPM

†

Transistor Outputs)

†

Transistor Outputs) PS-6144-24-M17

†

Transistor Outputs)

†

Transistor Outputs) PS-6344-24-M17

300 to 500 µsec typical (exact time determined by programming). For higher speeds, interrupt driven versions

are available — consult factory.

10 bits (1024 increments). 12 bits (4096 increments)

available with "-H" option.

Programmed in 0.1 msec steps. 16 individually compensated outputs maximum. Calculations every 10

msec. Special algorithm prevents false firing under rapid

acceleration and deceleration. Separate leading/trailing edge compensation available with "-L" option.

1.0 msec time base (accuracy +1, -0 msec)

Four maximum

48 programs standard (256 available with "-F" option).

1258 pulses standard (4589 available with "-F" option).

512 maximum standard (512 available with "-F" option).

512 maximum standard (512 available with "-F" option).

3000 RPM

RS-232/485 Serial

Communication

Port Types

Baud Rates

Slimline Output

Modules

0-60 VDC, 0-3 amps

0-200 VDC, 0-1 amp

24-280 VAC rms,

50/60 Hz. 0.02-3 amps

Reed Relay

Analog, 0-10 VDC

Analog, 4-20 mA DC

Keypad/Display

(Up to 2 keypad/displays can be

used with one controller)

Keypad/Display w/Gasket

Cable, Keypad-to-Controller

Resolvers & Cables

1 RS-232 or 1 RS-422/485 — RS-485 can be configured as a "Multi-Drop" network.

4800, 9600, 19.2K, 38.4K

Part Numbers

EC-ODC060-3

EC-ODC200-1

EC-OAC240-3

EC-ORR000-0

EC-SANL-010V

EC-SANL-420M

PS-6400-24-001

PS-6300-01-XXX (XXX = length in feet)

Electro Cam Corp. offers a wide variety of resolver

models, shaft sizes, & mounting configurations, including a stainless steel resolver. The cable required

depends on the resolver. Contact Electro Cam for

details.

1 RS-232 or 1 RS-422/485 — RS-485 can be configured as a "Multi-Drop" network.

4800, 9600, 19.2K, 38.4K

Part Numbers

EC-ODC060-3

EC-ODC200-1

EC-OAC240-3

EC-ORR000-0

EC-SANL-010V

EC-SANL-420M

PS-6400-24-001

PS-6300-01-XXX (XXX = length in feet)

Electro Cam Corp. offers a wide variety of resolver

models, shaft sizes, & mounting configurations, including a stainless steel resolver. The cable required

depends on the resolver. Contact Electro Cam for

details.

Note: Controllers may be used with or without keypad/display.

†

See page 12 for sinking/sourcing definitions.

7

Page 8

PS-6X44 Controllers & PS-6400 Keypad/Display Dimensions

Figure 3

PS-6400-24-001 Keypad/Display

†

See page 12 for sinking/sourcing definitions.

Figure 4

PS-6144-24-M17

PS-6144-24-P16M09 (Sourcing†)

PS-6144-24-N16M09 (Sinking†)

Figure 5

PS-6344-24-M17

PS-6344-24-P16M09 (Sourcing†)

PS-6344-24-N16M09 (Sinking†)

8

Page 9

Resolvers

The 7-pin resolver connector is supplied as part of the PLµS Programmable Limit Switch Controllers effective with date

code 9723. Prior to that date code, connectors were supplied on the resolver cables. Spare 7-pin resolver connectors

that plug into controllers may be purchased under part number PS-5300-01-TER. Some resolver configurations are

shown below. See Price List (Literature #202) for complete listing.

PS-5275-11-ADS

Foot Mount

• 3/4" Shaft

• Top side, Right side, Left side or Rear connection

PS-5238-11-SDR

Servo Mount

• 3/8" Shaft

• Top side, Right side, Left side or Rear connection

PS-5238-11-ADR

Flange Mount

• 3/8" or 5/8" Shaft

• Top side, Right side, Left side or Rear connection

PS-5262-11-CTG

Stainless Steel

• 5/8" Shaft

• Left side or Right side connection

PS-5275-051-ADL*

Foot Mount Geared

• 3/4" Shaft

• 5:1 Gear Ratio

• Top side, Right side or Left side connection

*Also available in 10:1 and 36:1 Ratio

PS-5212-11-SVW

Unhoused Servo Mount

• .120" Shaft

• Standard Size 11

9

Page 10

Resolver Dimensions

Foot Mount

With Rear Connector (shown):

PS-5275-11-ADR

With Side Connector:

PS-5275-11-ADS

Cable:

PS-5300-01-XXX where "XXX" is length in feet.

Flange Mount

With Rear Connector (shown):

PS-5238-11-ADR

With Side Connector:

PS-5238-11-ADS

Cable:

PS-5300-01-XXX where "XXX" is length in feet.

Stainless Steel

With Right Connector (shown):

PS-5262-11-CTG

With Left Connector:

PS-5262-11-CTL

Cable:

PS-5300-02-XXX where "XXX" is length in feet.

Unhoused Servo Mount

Size 11, .120" Shaft:

PS-5212-11-SVW

Contact the Factory for detailed specifications on other available resolvers.

10

Page 11

Controller Part Number Breakdown

P S - X X X X - X X - X X X(XXX) - X

PLuS Part Number

MODEL/DISPLAY SELECTION

6 - 1/4 DIN LCD Display

TRANSDUCER SELECTION

1 - Resolver Input

3 - 2 Resolver Input

INPUT/OUTPUT CONFIGURATION

4 - DC Transistor Outputs and/or SLIMLINE

Modules on Keyboard/Controller back

with input capability

FUNCTIONS

4 - Output Enable Modes & Standard Features

TYPE & NUMBER OF OUTPUTS

M17 - 17 SLIMLINE AC and/or DC Module Outputs, 2 of which may be analog

N16M09 -16 DC Sinking† Transistor Outputs & 9 SLIMLINE AC and/or DC Module Outputs, 2 of which may be analog

P16M09 -16 DC Sourcing† Transistor Outputs & 9 SLIMLINE AC and/or DC Module Outputs, 2 of which may be analog

INPUT VOLTAGE

24 - (20 - 30 VDC Input)

OPTIONS

F - Additional setpoint/program

storage

G - Gray Code Output (8 bit)

G10

- Gray Code Output (10 bit)

H - High Resolution (12 bit-4096)

L - Leading & Trailing Edge

Speed Compensation

W - Washdown boot

MB - Modbus™ communication

protocol available for

PS-6X44 Models

MSV

- Multiple Controllers used

with one resolver

Resolver Part Number Breakdown

P S - 5 2 X X - X X X - X X X

PLuS Part Number

Resolver

SHAFT SIZE

12 - 1/8 DIA.

15 - 15 mm DIA.

20 - 20 mm DIA.

38 - 3/8” DIA., 2.06” Bolt Flange

62 - 5/8” DIA., 2.25” Bolt Flange

75 - 3/4” DIA.

RATIO

11 - Standard 1:1 (Note: 3rd digit not used on Standard 1:1)

051 - Geared 5:1 - Ext. shaft to internal resolver shaft

101 - Geared 10:1 - Ext. shaft to internal resolver shaft

361 - Geared 36:1 - Ext. shaft to internal resolver shaft

†

See page 12 for sinking/sourcing definitions.

HOUSING

A - Can housing w/flange or foot endbells

C - Stainless steel square housing

E - 74 mm bolt spacing, flange mount

S - Servo mount ( .12 = size 11; .38 - size 25 )

TYPE OF CABLE CONNECTION

D - Military bayonet style connector

T - Terminal strip with NO conduit entrance

V - No connector, just stripped & tinned wires

S - Sealed connector — screw type

Note: Part # PS-5903-01-001 conduit entrance for

terminal strip models sold separately

LOCATION OF CABLE CONNECTION

W- With stripped & tinned leads

G - Right (120° from top on “A” housings)

R - Rear (not available on Geared Resolver)

L - Left (120° from top on “A” housings)

S - Side (Top)

11

Page 12

Typical System(s)

Component(s) Qty. Part Number

PS-6X44 Controller(s) (1) PS-6144-24-P16M09-L

PS-6400 Keypad/Display(s) (1) PS-6400-24-001

Keypad-to-Controller Cable(s) (1) PS-6300 -01-005

Resolver(s) (1) PS-5275-11-ADR

Resolver Cable(s) (1) PS-5300-01-010

SLIMLINE Output Modules (7) EC-ODC060-3

SLIMLINE Analog Modules (2) EC-SANL-010V

†

SINKING or SOURCING ( as pertaining to Electro Cam Corp. products )

Sinking

DC common or ground to the connected device.

Sourcing

a +DC voltage to the connected device.

This information is important when interfacing an Electro Cam Corp. product with another electronic device. The terms

SINKING / SOURCING

product input to an Allen-Bradley 1746-IN16 “sinking” input card* or similar A-B de vice, y ou hav e to supply a +DC v oltage to

this card, NOT a DC common or ground. In these cases,

common or ground.

* Other manufacturers include, but not limited to: Koyo (formerly GE Series 1, Texas Instruments, or Siemens SIMATIC PLS’s) that use

descriptions similar to Allen-Bradley.

means that when the logic is true and the output (or input device) is ON, the output (or input device) is providing a

means that when the logic is true and the output (or input device) is ON, the output (or input device) is pro viding

are not used in the same context by all manufacturers. If you are using an Electro Cam Corp.

Sinking

is what the card does with the input voltage; sinks it to

Electro Cam Corp. is highly experienced in supplying

automation solutions to a variety of industrial machinery.

For assistance with your application, please call us.

800-228-5487

221 04/98

13647 Metric Rd • Roscoe, IL 61073 USA • Web Site: http://www.electrocam.com • email: ecam@electrocam.com

Loading...

Loading...