Page 1

PL

µ

PS — 4256 / 4456

ABSOLUTE GRAY CODE ENCODER

S

Controls Div.

PS-4456/4457 (NEMA 4X)

Easily Interfaced to PLCs Using Standard Digital DC Inputs

Or Directly to Gray Code Modules*

Features

■ Absolute 8 Bit Output

■ Rugged Construction

■ 3/4" Shaft with Ball Bearings

■ NEMA 12 or NEMA 4X

Applications

■ Packaging Machines

■ Pick and Place Operations

■ Assembly Machines

■ Food Processing Equipment

■ Indexing Equipment

PS-4256/4257 (NEMA 12)

General Information

Sinking† or Sourcing† Output — The encoders are available with Sinking† or Sourcing† outputs. Be sure to order

the type that is compatible with the control's input circuits. The use of fast response DC inputs is recommended

to minimize missed fast pulsing encoder outputs.

NEMA 4X Option — The NEMA 4X version of the encoder includes a stainless steel enclosure and shaft,

double sealed ball bearings, and conformal coating on

both sides of the internal circuit board. This version should

be ordered for applications which involve washdowns,

high humidity or corrosive atmospheres.

*

A-B 1771-DL or Similar type modules

13647 Metric Rd • Roscoe, IL 61073 USA • 815-389-2620 • FAX 815-389-3304 • 800-228-5487 (USA & Canada)

†

See page 7 for sinking/sourcing definitions

Page 2

Why 8 Bit Gray Code?

When wiring an encoder to the PLC, the most important thing to

remember is which output is the MSB (Most Significant Bit) and

which is the LSB (Least Significant Bit). If the order is reversed,

or the output wiring is out of order (transposed wires), the value

that you create in the PLC register will not sequence properly.

MSB and LSB are digits of the binary number. An understanding of the different number systems used by logic controllers

(binary, hex, decimal, etc.) is essential to know what these codes

signify.

■ Gray Code is a cyclic or reflected binary code, specifi-

cally designed for positioning information. In a Gray Code

number only one-digit changes at a time. In a binary number, going from one number to the next may have many

of its digits change.

The cyclic change is created by the relationship of the 8

pulse disks that turn the encoder OFF and ON. (See

Figure 6, page 6.)

■ Most Significant Bit refers to the binary code (Gray

Code) digit that is on the far left when written out. This

digit changes the least as the binary number goes from

0 to 255.

■ Least Significant Bit refers to the binary code (Gray

Code) digit that is on the far right when written out. This

digit changes the most as the binary number goes from

0 to 255.

Absolute Position Decoding — The 8 Bit Gray Code

signal always represents the current position of the encoder shaft. The PLC cannot get out of sync with the

present encoder position — not even when the encoder

shaft is turned while power is off to the controller.

8 Bit Resolution (256 increments) — The revolution of

the encoder shaft is divided into 256 uniform increments.

Each increment is 1.4 degrees wide, which allows any

machine position to be known within ±0.7 degrees. This

is appropriate resolution for many applications, especially

when PLC scan times are taken into account (@ 60 RPM,

a 10 mSec scan time equates to 3.6 degrees of motion

between scans).

Error Free Decoding — Only one of the bits changes

state when the encoder shaft rotates, eliminating the need

for sophisticated latching and/or handshaking circuitry between the encoder and the PLC. Standard DC input cards

are used to interface with the encoder. The only special

programming needed is 8 exclusive-ORed (XOR) ladder

rungs.

RPM / Response Considerations

The operating speed and resolution required of the application

must be considered when interfacing the Gray Code encoder

directly to a PLC or other control device. The scan speed and/or

hardware response will cause delays that can reduce the overall

system response and resolution. Where full 8 bit resolution is

required at higher speeds, the use of an Electro Cam PL

µS

(Programmable Limit Switch) is recommended.

Values might not be true for certain fast response PLC inputs.

Faster response times are dependent on hardware.

Scan Time / Maximum RPM / Degrees Per Scan

Scan Time Max RPM @ 30 RPM @ 100 RPM Scan Time Max RPM @ 30 RPM @ 100 RPM

1 mSec 234 0.18 0.60 20 mSec 11 3 6 12.0

5 mSec 46 0.9 3.0 25 mSec 9 4.5 15.0

10 mSec 23 1.8 6.0 30 mSec 7 5.4 18.0

15 mSec 15 2.7 9.0 40 mSec 5 7.2 24.0

The table above indicates the maximum RPM that the encoder can be turning for all 256 positions to be decoded each revolution for the corresponding scan time.

Exceeding the indicated RPM will result in encoder shaft positions being skipped by the control. It is acceptable to skip encoder positions when 8 bit resolution is not

required. Worst case output response = 2 Scans + Hardware response.

Refer to the above chart to compare machine RPM to the values

listed on the chart. If speed exceeds the value, the PLC will not

"see" certain Gray Code values. Miscalculation of the output value

will occur.

If a bit is on for 30 µSec, and the scan time is 10 mSec, the

Deg / Scan Deg / Scan Deg / Scan Deg / Scan

Figure 1

When machine speed rises above a certain level, several factors need to be considered:

■ What is the scan time of the PLC program?

■ What is the response time of the input module?

■ What is the integer value that is being used, and is it de-

pendent on several of the least significant bits?

processor will not see that bit (or combination of bits). If the input

module's response time is longer than the bit, or bits on time, the

module will not react to the input. All of these factors show up as

non-sequencing position values, or outputs that are not performing properly.

2

Page 3

Decoding Gray Code?

The Ladder Programming examples shown below apply

for all Gray Code Encoder models. The examples show

how to convert the 8 Bit Gray Code output signal (G0-G7)

of the encoder to a binary number (B0-B7) during each

scan of the PLC. The value of the Binary result will always be in the range of 0 - 255 because the 8 bit encoder

divides each revolution into 256 uniform increments. Ladder rungs which follow the conversion can compare the

rotary position value to known positions for control of

machine devices that must operate at specific positions

within the overall machine cycle. The rotary position of

Models DDN & DDP

CLOCKWISE ROTATION

G7

B7 G6

G6B7

B6 G5

G5B6

B5 G4

G4B5

B4 G3

G3B4

B3 G2

G2B3

B2 G1

G1B2

B1 G0

G0B1

DRAWING L-1

B7

B6

B5

B4

B3

B2

B1

B0

COUNTER-CLOCKWISE ROTATION

G7

B7 G6

G6B7

B6 G5

G5B6

B5 G4

G4B5

B4 G3

G3B4

B3 G2

G2B3

B2 G1

G1B2

B1 G0

G0B1

DRAWING L-2

B7

B6

B5

B4

B3

B2

B1

B0

the machine cycle can also be used to gate input sensors

and shift register functions.

Converting Gray Code to Binary involves a sequence of

"Exclusive OR" operations. It is simple to program this

same conversion logic in other programming languages

besides ladder logic. In addition to decoding the rotary

position of the encoder, controls with arithmetic capability

can be programmed to perform direction reversal, position offset and re-zero functions, as well as convert the

position value to degrees for ease of monitoring and setup.

Model DDH

COUNTER-CLOCKWISE ROTATION

G7

B7 G6

G6B7

B6 G5

G5B6

B5 G4

G4B5

B4 G3

G3B4

B3 G2

G2B3

B2 G1

G1B2

B1 G0

G0B1

DRAWING L-3

B7

B6

B5

B4

B3

B2

B1

B0

CLOCKWISE ROTATION

G7

B7 G6

G6B7

B6 G5

G5B6

B5 G4

G4B5

B4 G3

G3B4

B3 G2

G2B3

B2 G1

G1B2

B1 G0

G0B1

DRAWING L-4

B7

B6

B5

B4

B3

B2

B1

B0

Use a limit test function to program a pulse in the PLC. The limit test uses a test reference (in this case the integer

register that the Gray Code is going into), and compares it to see if it is between a lower limit and an upper limit. If the

integer value is between the lower limit (ON setpoint), and the upper limit (OFF setpoint), the rung is true and an output

is turned on. If the integer value does not fall between the upper and lower limits, the rung is false, and nothing happens.

For every output pulse to occur, a different limit test must be programmed with the appropriate limits. Reminder: The

limit values are position values, not degrees.

PLC

Output

LIM

Limit Test

Low Lim 107

107<

Test N7:0

0<

High Lim 128

128<

3

O:2.0

( )

0

Page 4

Gray Code — Error Free Decoding

The Gray Code chart below

(Figure 2)

shows the bit patterns that are used to represent all 256 encoder positions.

It can be seen on this chart that from any position to any

adjacent position, only 1 bit changes state. This ensures

that the encoder inputs can be read by the control at any

point in time (even during a transition) without error.

Consider the following comparison to Binary Code:

INC DEG GRAY CODE BINARY

127 178.6 01000000 01111111

128 180.0 11000000 10000000

When Gray Code advances from increment 127 to 128,

only 1 of the 8 bits changes state — bit 8. When Binary

Code advances from increment 127 to 128, all 8 bits

change states. Sampling the Binary bits during this transition could result in a very large decoding error. Sampling

the Gray Code bits during this transition would yield either

127 or 128, depending only on bit 8.

Refer to the table below to understand the relationship

between the

numbers

increment

(integer),

degrees

and

binary

. Use this table as a guide for setup and trouble-

shooting your Gray Code system.

■ INC (increment) column represents the integer value

to which the Gray Code is equal. The increments

are 0 to 255 (256 total) that repeat or cycle. (At 255,

the next number change is 0, increment to 255, then

repeat the cycle over again).

■ DEG (degree) column represents the actual degree

position that the Gray Code is indicating.

■ Gray Code column shows the Gray Code value

for that particular position. This Gray Code binary

number is the same as the Gray Code inputs status,

1 = ON and 0 = OFF.

Because the Gray Code value is also a graphic representation of the input status, it is an invaluable tool in

checking the position or troubleshooting.

INC DEG GRAYCODE

0 0.0 00000000

1 1.4 00000001

2 2.8 00000011

3 4.2 00000010

4 5.6 00000110

5 7.0 00000111

6 8.4 00000101

7 9.8 00000100

8 11.3 00001100

9 12.7 00001101

10 14.1 00001111

11 15.5 00001110

12 16.9 00001010

13 18.3 00001011

14 19.7 00001001

15 21.1 00001000

16 22.5 00011000

17 23.9 00011001

18 25.3 00011011

19 26.7 00011010

20 28.1 00011110

21 29.5 00011111

22 30.9 00011101

23 32.3 00011100

24 33.8 00010100

25 35.2 00010101

26 36.6 00010111

27 38.0 00010110

28 39.4 00010010

29 40.8 00010011

30 42.2 00010001

31 43.6 00010000

32 45.0 00110000

33 46.4 00110001

34 47.8 00110011

35 49.2 00110010

36 50.6 00110110

37 52.0 00110111

38 53.4 00110101

39 54.8 00110100

40 56.3 00111100

41 57.7 00111101

42 59.1 00111111

43 60.5 00111110

44 61.9 00111010

INC DEG GRAYCODE

45 63.3 00111011

46 64.7 00111001

47 66.1 00111000

48 67.5 00101000

49 68.9 00101001

50 70.3 00101011

51 71.7 00101010

52 73.1 00101110

53 74.5 00101111

54 75.9 00101101

55 77.3 00101100

56 78.8 00100100

57 80.2 00100101

58 81.6 00100111

59 83.0 00100110

60 84.4 00100010

61 85.8 00100011

62 87.2 00100001

63 88 6 00100000

64 90.0 01100000

65 91.4 01100001

66 92.8 01100011

67 94.2 01100010

68 95.6 01100110

69 97.0 01100111

70 98.4 01100101

71 99.8 01100100

72 101.3 01101100

73 102.7 01101101

74 104.1 01101111

75 105.5 01101110

76 106.9 01101010

77 108.3 01101011

78 109.7 01101001

79 111.1 01101000

80 112.5 01111000

81 113.9 01111001

82 115.3 01111011

83 116.7 01111010

84 118.1 01111110

85 119.5 01111111

86 120.9 01111101

87 122.3 01111100

88 123.8 01110100

89 125.2 01110101

8 Bit Gray Code Table

INC DEG GRAYCODE

90 126.6 01110111

91 128.0 01110110

92 129.4 01110010

93 130.8 01110011

94 132.2 01110001

95 133.6 01110000

96 135.0 01010000

97 136.4 01010001

98 137.8 01010011

99 139.2 01010010

100 140.6 01010110

101 142.0 01010111

102 143.4 01010101

103 144.8 01010100

104 146.3 01011100

105 147.7 01011101

106 149.1 01011111

107 150.5 01011110

108 151.9 01011010

109 153.3 01011011

110 154.7 01011001

111 156.1 01011000

112 157.5 01001000

113 158.9 01001001

114 160.3 01001011

115 161.7 01001010

116 163.1 01001110

117 164.5 01001111

118 165.9 01001101

119 167.3 01001100

120 168.8 01000100

121 170.2 01000101

122 171.6 01000111

123 173.0 01000110

124 174.4 01000010

125 175.8 01000011

126 177.2 01000001

127 178.6 01000000

128 180.0 11000000

129 181.4 11000001

130 182.8 11000011

131 184.2 11000010

132 185.6 11000110

133 187.0 11000111

134 188.4 11000101

INC DEG GRAYCODE

135 189.8 11000100

136 191.3 11001100

137 192.7 11001101

138 194.1 11001111

139 195.5 11001110

140 196.9 11001010

141 198.3 11001011

142 199.7 11001001

143 201.1 11001000

144 202.5 11011000

145 203.9 11011001

146 205.3 11011011

147 206.7 11011010

148 208.1 11011110

149 209.5 11011111

150 210.9 11011101

151 212.3 11011100

152 213.8 11010100

153 215.2 11010101

154 216.6 11010111

155 218.0 11010110

156 219.4 11010010

157 220.8 11010011

158 222.2 11010001

159 223.6 11010000

160 225.0 11110000

161 226.4 11110001

162 227.8 11110011

163 229.2 11110010

164 230.6 11110110

165 232.0 11110111

166 233.4 11110101

167 234.8 11110100

168 236.3 11111100

169 237.7 11111101

170 239.1 11111111

171 240.5 11111110

172 241.9 11111010

173 243.3 11111011

174 244.7 11111001

175 246.1 11111000

176 247.5 11101000

177 248.9 11101001

178 250.3 11101011

179 251.7 11101010

INC DEG GRAYCODE

180 253.1 11101110

181 254.5 11101111

182 255.9 11101101

183 257.3 11101100

184 258.8 11100100

185 260.2 11100101

186 261.6 11100111

187 263.0 11100110

188 264.4 11100010

189 265.8 11100011

190 267.2 11100001

191 268.6 11100000

192 270.0 10100000

193 271.4 10100001

194 272.8 10100011

195 274.2 10100010

196 275.6 10100110

197 277.0 10100111

198 278.4 10100101

199 279.8 10100100

200 281.3 10101100

201 282.7 10101101

202 284.1 10101111

203 285.5 10101110

204 286.9 10101010

205 288.3 10101011

206 289.7 10101001

207 291.1 10101000

208 292.5 10111000

209 293.9 10111001

210 295.3 10111011

211 296.7 10111010

212 298.1 10111110

213 299.5 10111111

214 300.9 10111101

215 302.3 10111100

216 303.8 10110100

217 305.2 10110101

218 306.6 10110111

219 308.0 10110110

220 309.4 10110010

221 310.8 10110011

222 312.2 10110001

223 313.6 10110000

224 315.0 10010000

INC DEG GRAYCODE

225 316.4 10010001

226 317.8 10010011

227 319.2 10010010

228 320.6 10010110

229 322.0 10010111

230 323.4 10010101

231 324.8 10010100

232 326.3 10011100

233 327.7 10011101

234 329.1 10011111

235 330.5 10011110

236 331.9 10011010

237 333.3 10011011

238 334.7 10011001

239 336.1 10011000

240 337.5 10001000

241 338.9 10001001

242 340.3 10001011

243 341.7 10001010

244 343.1 10001110

245 344.5 10001111

246 345.9 10001101

247 347.3 10001100

248 348.8 10000100

249 350.2 10000101

250 351.6 10000111

251 353.0 10000110

252 354.4 10000010

253 355.8 10000011

254 357.2 10000001

255 358.6 10000000

Figure 2

4

Page 5

Wiring

Figure 3

NEMA 12

Dimensions

NEMA 4X

Figure 4

5

Figure 5

Page 6

Specifications

General NEMA 12 NEMA 4X

Ambient Temp. 0 - 60 Degrees C 0 - 60 Degrees C

Enclosure JIC - 16 Ga Steel JIC - 16 GA Stainless

Shaft Dia. / Material 3/4" Stainless Steel 3/4" Stainless Steel

Bearings 3/4" Sealed Ball Bearing 3/4" Double Sealed Ball

Conformal Coating Component Side of PCB Both Sides of PCB

Electrical Sourcing

Input Voltage 12 - 30 VDC 12 - 30 VDC

Output Voltage 12 - 30 VDC 3 - 30 VDC

Output Current (each bit) 50 mA 50 mA

Output Logic Type High True Low True or High True

†

See page 7 for sinking/sourcing definitions

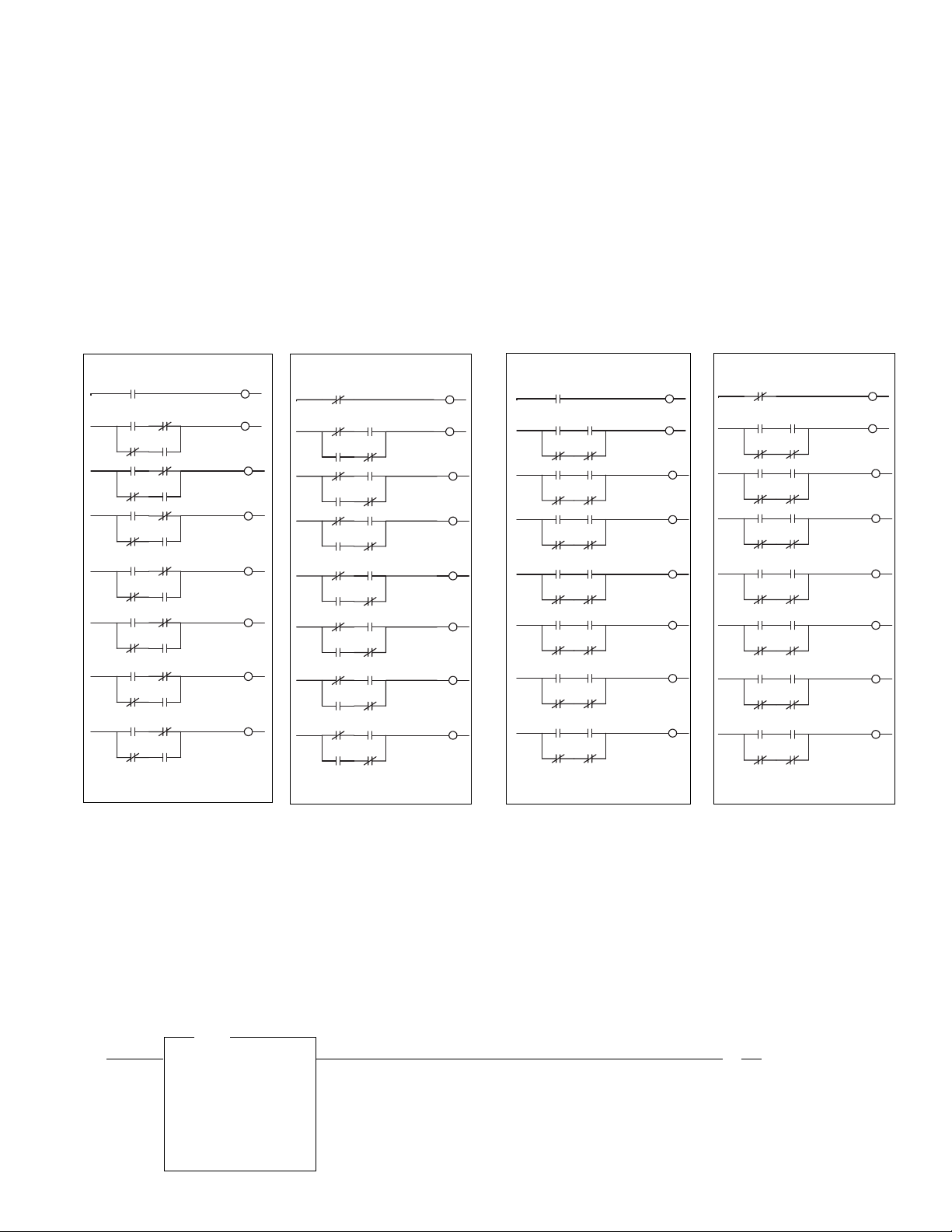

The 8 Bit Gray Code Encoder Output Chart (

Figure 6

†

Sinking

) shows the transitions of each of the 8 bits as the encoder rotates

†

from 0 to 360 degrees. The output bits are phased so that only one bit changes state at each of the 256 increments.

The pulse disc which operates bit 0 (least significant) has 64 uniformly spaced slots, bit 1 has 32 uniformly spaced

slots, bit 2 has 16 uniformly spaced slots, and so on. The 8 bit output of the encoder is always one of the 256 bit

patterns shown in the table on page 4

(Figure 2)

and always represents the current position of the encoder shaft. For

this reason, the control cannot get out of sync with the encoder. High speed count cards that use incremental encoders are NOT absolute and require marker pulses, or other reference signals, for position synchronization.

Figure 6

6

Page 7

Encoder Part Numbers

NEMA

1000 RPM MAX 2000 RPM MAX Output Type Rating

PS - 4256 - 12 - DDP PS - 4257 - 12 - DDP Sourcing

†

12

PS - 4256 - 12 - DDN PS - 4257 - 12 - DDN Sinking† (Low True)* 12

PS - 4256 - 12 - DDH PS - 4257 - 12 - DDH Sinking† (High True)* 12

PS - 4456 - 12 - DDP PS - 4457 - 12 - DDP Sourcing

†

4X

PS - 4456 - 12 - DDN PS - 4457 - 12 - DDN Sinking† (Low True)* 4X

PS - 4456 - 12 - DDH PS - 4457 - 12 - DDH Sinking† (High True)* 4X

*High True = Current Flow

Low True = No Current Flow

Accessories

PS - 4300 - 03 - XXX (XXX = Length in Feet): 10 Conductor #22 gauge shielded (foil and braid) cable for use with encoders. Cut to

specified length, stripped, tinned, connectors attached to shield.

EC - 8001 - XXX - XXX (X's for pitch and # of teeth): Sprocket disengagement clutch allows encoder to be rotated without turning the

chain which drives the encoder. Call for more information.

†

SINKING or SOURCING (as pertaining to Electro Cam Corp. products)

Sinking

means that when the logic is true and the output (or input device) is ON, the output (or input device) is providing a DC

common or ground to the connected device.

Sourcing

means that when the logic is true and the output (or input device) is ON, the output (or input device) is providing a +DC

voltage to the connected device.

This information is important when interfacing an Electro Cam Corp. product with another electronic device. If you are using an

Electro Cam Corp. product input to an Allen-Br adley 1746-IN16 “sinking” input card* or similar A-B de vice, y ou hav e to supply a +DC

voltage (Electro Cam Corp.

Sourcing

output) to this card, NOT a DC common or ground. In these cases,

Sinking

is what the card

does with the input voltage; sinks it to common or ground.

* Other manufacturers include, b ut not limited to: Koyo (formerly GE Series 1, Texas Instruments, or Siemens SIMATIC PLS’s) that use descriptions

similar to Allen-Bradley.

7

Page 8

Electro Cam Corp. is highly experienced in supplying

automation solutions to a variety of industrial machinery.

For assistance with your application, please call us.

800-228-5487

Copyright © 2000

All Rights Reserved

Neither this document nor any part may be reproduced or transmitted in

any form or by any means without permission in writing from the publisher.

, PLµS, SLIMLINE, and PLµSNET are all registered trademarks of

201 07/00

13647 Metric Rd • Roscoe, IL 61073 USA • Web Site: http://www.electrocam.com • email: ecam@electrocam.com

Loading...

Loading...