Page 1

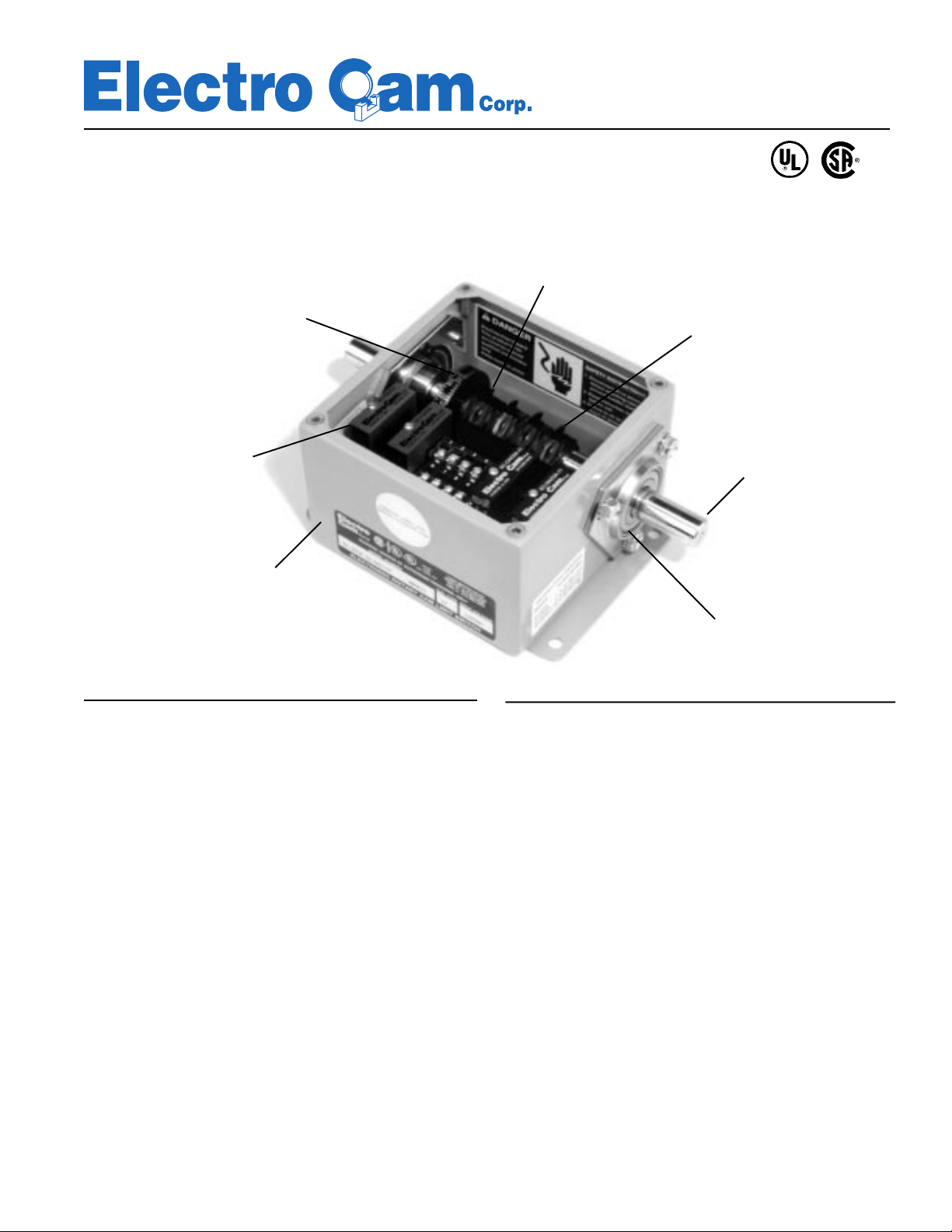

EC-3000/3400 Series

Solid State Rotary Cam Limit Switches

Interrupter Discs and

Photocouplers

Internal

Degree Wheel

and Pointer

Eliminate Contact

Wear and Bounce

Interrupter Discs

Seat Tightly on O-Rings.

Easy-to-Adjust with Wrench.

No Cumbersome Lock Screws

Plug-In

AC, DC, or

Reed Relay

Output Modules

Gasketed NEMA 12

Enclosure on EC-3000;

NEMA 4X Stainless Steel

Enclosure on EC-3400

Description

EC-3000 Series and EC-3400 Series Rotary Cam Limit Switches

use interrupter discs and photocouplers instead of traditional

cams and mechanical limit switches, eliminating contact wear

and bounce. They provide on/off control of devices such as glue

guns, solenoids, air cylinders, or relays on shaft-driven machinery. Electronic Cam Limit Switches can be used as stand-alone

switches, or they can be interfaced to programmable logic controllers (PLC’s) or other logic circuitry.

Although generally used for applications which do not require

setpoint adjustment for speed changes or product changeover,

EC-3000 Series and EC-3400 Series switches can accommodate multiple setpoint schemes by assigning groups of interrupters to different product configurations. For product changeover,

simply activate the appropriate group of interrupters.

Typical applications for EC-3000 Series and EC-3400 Series

switches include cartoners and case packers, palletizers, gluing

machines, high-speed presses, automatic assembly, pick and

place equipment, and similar machinery.

Right, Left, or

Double-Ended Shaft

Configurations

Available

Heavy-Duty

Sealed

Ball Bearings

Features

• Available with 4, 8, or 12 fused, optically-isolated outputs.

• Heavy-duty construction for industrial environments.

• Plug-in modules for AC or DC outputs; replaceable input/

output fuses, easily removed and installed with a needle

nose pliers.

• LED’s indicate output status.

• EC-3000 units housed in NEMA 12 enclosures; EC-3400

units housed in NEMA 4X stainless steel enclosures.

• Sealed ball bearings.

• Internal degree wheel and pointer located on shaft for easy

and accurate adjustment.

• Right, left, or double-ended shaft extensions with a #606

Woodruff key provision; double-ended stainless steel shaft

standard with NEMA 4X models.

• Available options include multi-pulse discs, external degree

wheel and pointer, sprocket disengagement clutch, highvibration models, and special shafts.

• Standard EC-3000 and EC-3400 UL listed, CSA certified;

240 VAC models not UL listed.

13647 Metric Rd • Roscoe, IL 61073 USA • 815-389-2620 • FAX 815-389-3304 • 800-228-5487 (USA and Canada)

Page 2

Theory of Operation

Degree Wheel

Pointer

Degree Wheel

Adjustable to

Correspond to

Machine Zero

Photocoupler

0 to 180 Degree Mode

-Light Energized181 to 360 Degree Mode

-Dark Energized-

SWITCH

MODE

0° - 180°

Light

Energized

DIP Switch

Figure 1

ENERGIZED

BY

Photocoupler

Light Beam

-PASSING-

Wrench

for Cam Adjustment

LED Indicator

ON

TIME

Fully

Adjustable

1° to 180°

Interrupter Disc

Halves

From

0° to 170°

ON for 170°

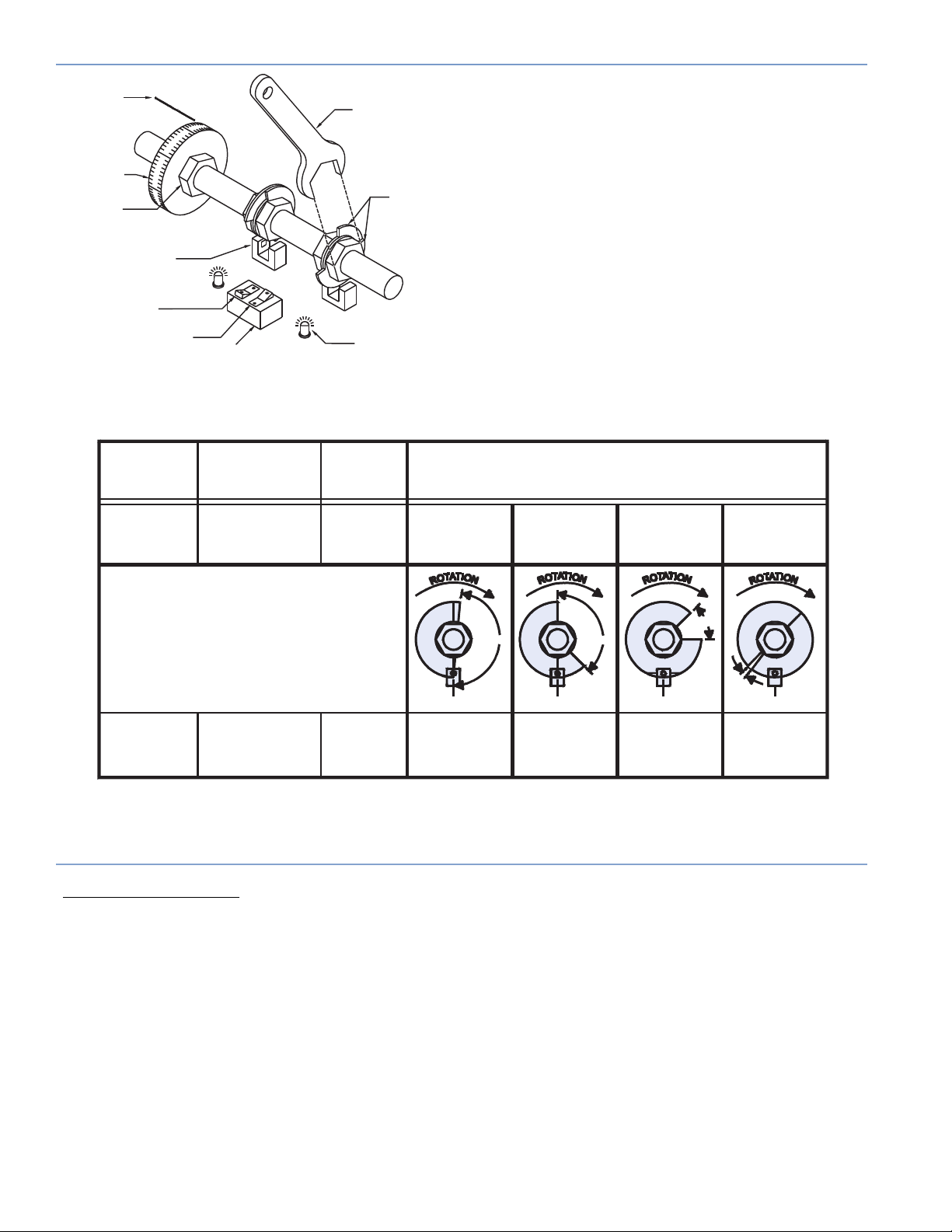

As shown in Figure 1, each output switch is controlled by

two-part interrupter discs which break the beam of light in

a photocoupler. If the DIP switch associated with a

photocoupler is in the “0° to 180°,” or Light Energized mode,

the output will be switched on when the beam is unbroken.

If the DIP switch is in the “181° to 360°,” or Dark Energized

mode, the output will be switched on when the interrupter

breaks the beam.

The gap, or open window in the interrupter is adjusted by

using a wrench to turn the disc halves. Shown below in

Figure 2 is a chart showing a few examples of setting “on”

times, by adjusting the gap and the DIP switch positions.

Disc halves seat tightly to the shaft with O-rings. The discs

are easy to adjust with a wrench, requiring no cumbersome locking screws or other devices.

EXAMPLE

CAM SETTINGS

From

45° to 180°

ON for 135°

From

90° to 135°

ON for 45°

From

312° to 322°

ON for 7°

45°

181° - 360°

Dark

Energized

Photocoupler

Light Beam

-BLOCKED-

Fully

Adjustable

181° to 359°

"0"

From

170° to 0°

ON for 190°

170°

From

180° to 45°

ON for 225°

135°

7°

"0"

"0"

From

135° to 90°

ON for 315°

"0"

From

322° to 315°

ON for 353°

Figure 2

†

SINKING or SOURCING ( as pertaining to Electro Cam Corp. products )

Sinking

common or ground to the connected device.

Sourcing

voltage to the connected device.

This information is important when interfacing an Electro Cam Corp. product with another electronic device. The terms

SOURCING

Bradley 1746-IN16 “sinking” input card* or similar A-B device, you have to supply a +DC voltage to this card, NOT a DC common o r

ground. In these cases,

means that when the logic is true and the output (or input device) is ON, the output (or input device) is providing a DC

means that when the logic is true and the output (or input device) is ON, the output (or input device) is providing a +DC

SINKING /

are not used in the same context by all manufacturers. If you are using an Electro Cam Corp. product input to an Allen-

Sinking

is what the card does with the input voltage; sinks it to common or ground.

* Other manufacturers include, but not limited to: Koyo (formerly GE Series 1, Texas Instruments, or Siemens SIMATIC PLS’s) that use descriptions

similar to Allen-Bradley.

page 2

Page 3

Standard Models

All EC-3000 Series units are housed in NEMA 12 enclosures. All EC-3400 Series units are housed in NEMA 4X

stainless steel enclosures. All units have either right, left,

or double-ended shaft extensions with a #606 Woodruff

Key provision; Nema 4X models have a double-ended

stainless steel shaft. The cover plate on the EC-3400 Series units is secured with clamps to avoid contamination.

Five standard EC-3000 Series and four standard EC-3400

Series models are available:

Model Outputs Standard Shafts*

EC-3004/EC-3404 4 Right, left, or double

EC-3008/EC-3408 8 Right, left, or double

EC-3012/EC-3412 12 Right, left, or double

*See dimensional drawings for shaft illustrations.

Special shafts can be supplied. Please enclose shaft

drawing and specs with your order. All NEMA 4X

units are ONLY available in double-ended shafts.

Model EC-3004-10-ARO

Options

Pulse Generating Discs

Multi-output pulse generating discs are an option offered

for applications requiring multiple outputs per revolution.

These discs are most often used to generate timing pulses

for tachometers, motion detection, glue stitching, or wherever multi-pulse signals are required. Glue stitching patterns on carton and case sealing equipment is an example

of an application that benefits from pulse generating discs.

Standard pulse discs are available with 1, 2, 3, 4, 6, 7, 10,

16, 20, 32, 60, and 64 slots per revolution, allowing for

quick changeover. Pulse generating discs must be ordered

with the unit. The discs are factory mounted on the cam

shaft, and each disc replaces one set of adjustable cams.

See Publication 107B for more detailed information.

Sprocket Disengagement Clutch

The sprocket disengagement clutch is essential in situations where the shaft needs to be easily disconnected from

the sprocket without removing the chain. The clutch not

only allows for disengagement of one station of the machine to check operation without jogging the entire machine, but it simplifies the adjustment of the rotary cam

limit switch. The clutch automatically locks back in the home

position after one revolution. The clutch has a 3/4 inch

bore with the provision for a #606 Woodruff key. There are

five standard and numerous special sprockets

available. See Publication 108B for more detailed information.

External Degree Wheel and Pointer

An internal degree wheel and pointer is included with each

EC-3000 and EC-3400 unit for reference during cam

adjustment. To visually determine shaft position without removing the cover, an optional external degree wheel and

pointer is available. This option must be ordered with the

unit, and requires a double-ended shaft for mounting.

Specify mounting on left- or right-hand shaft (see mounting dimensions), and clockwise or counterclockwise rotation as viewed from end of shaft.

CFX for High Shock / Vibration

For extremely high shock or vibration, such as punch press

applications, a CFX option may be needed on the EC-3000

or EC-3400 units. The CFX option adds clear conformal

coating on both sides of the printed circuit board and removable jumpers replace the DIP switch. The jumpers

eliminate the possibility of intermittent connection to the

DIP switch or the accidental changing of the DIP switch

setting through shock or vibration.

CF for Highly Contaminating Environments

For highly contaminating environments, the CF option may

be ordered with the EC-3000 units. The CF option adds

clear conformal coating to both sides of the printed circuit

board. This option is standard on all EC-3400 units.

page 3

Page 4

Mounting and Shaft Connection

The shaft can be coupled to the machine using a chain and sprocket, timing pulley and

belt, or a direct in-line shaft-to-shaft coupling.

If a shaft-to-shaft coupling is used, Electro Cam Corp. recommends the use of a flexible

coupling. Flexible couplings available through Electro Cam Corp. are listed on the Rotary

Cam Switch Price List, Lit. #111.

Using a solid coupling with shaft misalignment greater than 0.005" (T.I.R.) may

damage the unit. Because of tolerance stackups, this will require shimming of the

individual unit to its mounting surface.

Specifications

Max Speed: 3000 RPM, clockwise or counterclockwise rotation

Max Phase Shift: 1°/1000 RPM

Ambient Temp: 0° to 60°C (32° to 140°F)

Input V oltage: 120 VAC (108 to 132 VAC), 50 or 60 Hz.

12 VDC, 24 VDC or 240 VAC units available

Input Power: EC-3004/EC-3404 3 VA Max

EC-3008/EC-3408 6 VA Max

EC-3012/EC-3412 6 VA Max

Shaft: 3/4" diameter shaft extensions. The shaft is rated at 32,000 PSI yield and necked down to 0.500"

internally. Power transmission through shaft should be based on these figures.

Max Side Load: 100 lbs. at speeds up to 1800 RPM / 200 lbs. at speeds up to 500 RPM

Bearing Life: 10 years (87,660 hours) continuous running with 75 lbs. side load at 1000 RPM

Note: Consult factory if higher speeds or larger loads are required.

Enclosures: EC-3000—NEMA 12 steel housing

EC-3400—NEMA 4X stainless steel housing

Printed Circuit

Board: EC-3000—conformal coating on top only

EC-3400—conformal coating on top and bottom

Net Weight: EC-3004/EC-3404: 9.0 lbs. 4.0 kg

EC-3008/EC-3408: 13.5 lbs. 6.1 kg

EC-3012/EC-3412: 15.0 lbs. 6.8 kg

Output Module Specifications

The EC-3000 Series and the EC-3400 Series units offer plug-in modules for DC, AC, and Reed Relay outputs. One output

module must be purchased for each output desired. For further information, please consult the factory.

DC Output: EC-ODC5, Red

AC Outputs: EC-OAC5A-11, Black/Gray

Output Voltage: 0 to 60 VDC

Output Current: 1.0 Amp @ 35°C (95°F)

Derate 35.7 mA/°C above 35°C (95°F)

DC Output: EC-ODC5A, Red

Output Voltage: 0 to 200 VDC

Output Current: 0.5 Amp

Derate .018 amp/°C above 45°C (113°F)

page 4

Output Voltage: 24 to 132 VAC

Output Current: 0.8 Amp @ 35°C (95°F)

Derate 50 mA/°C above 35°C (95°F)

Reed Relay: EC-ORR5, White

Output Type: Reed Relay Contacts

DC Rating: 0 to 24 VDC

0 to 100 mA DC (resistive loads only)

AC Rating: 0 to 120 VAC

0 to 30 mA AC (resistive loads only)

Page 5

Terminal and Component Identification

The following three drawings are component layouts.

EC-3400 Series Units

All EC-3400 Series units have the same component layout as the EC-3000 Series units except a stainless steel doubleended shaft extension and stainless steel enclosure with clamps to secure the cover are standard.

Figure 3

EC-3004 Unit

1 1/16" Dia. Hole

(For 3/4" Conduit)

Figure 4

EC-3008 Unit

Figure 5

EC-3012 Unit

Degree Wheel

and Pointer

Left-Hand Shaft

Extension Shown

0° to 180°

181° to 360° 181° to 360°

151

5

1 1/16" Dia. Hole

(For 3/4" Conduit)

0° to 180°

6

Interrupter Discs

DIP Switches

Indicator Lights

1/4 Amp Input Fuse

EC-9000-0250

Output Terminals

1

Wireway

234L

Output Modules

1213

11

14

18

1617

15

L6789

19

202122

26252423

1 1/16" Dia. Hole

EC-OAC5A-11 for AC

EC-ODC5 for DC

EC-ODC5A for DC

EC-ORR5 Reed Relay

3 Amp Output Fuses

EC-9000-0003

120 VAC

Input Terminals

(For 3/4" Conduit)

page 5

Page 6

Mounting Dimensions - EC-3004, EC-3008 & EC-3012

Right-Hand or DoubleEnded Shaft Extension

.75"

0

19.1 mm

0.750/0.748"

19.05/19.00 mm

Left-Hand

Shaft Slotted

for Woodruff Key #606

(Customer Supplied)

G

HJ

1 1/16" Dia. Hole

4) Holes

F

E

D

(

0.31" Dia.

7.9 mm

.07"

2

52.6 mm

69.9 mm

(For 3/4" Conduit)

2.75"

4.38"

111.3 mm

L

K

C

B

A

Figure 6

EC-3004, EC-3008 & EC-3012

EC-3004 EC-3008 EC-3012

A 7.50" (190.5 mm) 9.50" (241.3 mm) 11.50" (292.1 mm)

B 6.00" (152.4 mm) 8.00" (203.2 mm) 10.00" (254.0 mm)

C 3.00" (76.2 mm) 3.38" (85.9 mm) 5.00" (127.0 mm)

D 1.94" (49.3 mm) 2.50" (63.5 mm) 2.50" (63.5 mm)

E 6.75" (171.5 mm) 8.75" (222.3 mm) 10.75" (273.1 mm)

F 6.25" (158.8 mm) 8.25" (209.6 mm) 10.25" (260.4 mm)

G 0.88" (22.4 mm) 1.25" (31.8 mm) 1.25" (31.8 mm)

H 4.00" (101.6 mm) 6.00" (152.4 mm) 6.00" (152.4 mm)

J 6.25" (158.8 mm) 8.25" (209.6 mm) 8.25" (209.6 mm)

K 6.00" (152.4 mm) 8.00 (203.2 mm) 8.00" (203.2 mm)

L 1.88" (47.8 mm) 2.25" (57.2 mm) 2.25" (57.2 mm)

Table 1

EC-3004, EC-3008 and EC-3012 Dimensions

Page 7

Figure 7

EC-3404

Mounting Dimensions - NEMA 4X Units

1-1/16" Dia. Hole

(For 3/4" Conduit)

Figure 8

EC-3408 & EC-3412

J

H

G

F

E

2.07"

52.6 mm

D

1-1/16" Dia. Hole

(For 3/4" Conduit)

Table 2

EC-3408 & EC-3412 Dimensions

B

A

C

EC-3408 EC-3412

A 9.50" (241.3 mm) 11.50" (292.1 mm)

B 8.00" (203.2 mm) 10.00" (254.0 mm)

C 3.38" (85.9 mm) 5.00" (127.00 mm)

D 2.56" (65.0 mm) 2.75" (69.9 mm)

E 1.00" (25.4 mm) 1.50" (38.1 mm)

F 5.25" (133.4 mm) 7.25" (184.2 mm)

G 8.75" (222.3 mm) 10.75" (273.1 mm)

H 8.25" (209.6 mm) 10.25" (260.4 mm)

J 8.00" (203.2 mm) 10.00" (254.0 mm)

Page 8

Input Wiring

1

Lower Terminals

L2

9

8

7

6

120 VA C

(108 to 132 VAC)

Upper Terminals

4

L1

3

2

The terminal block shown is for an EC-3004 unit or

EC-3404 unit. Other models will contain more blocks.

Figure 9

Output Module Wiring

Output modules act like switches; they do not supply power to loads.

Output modules available f or the EC-3000 and EC-3400 Series units include DC , AC, and Reed Relay . An output module is required

for each output being used. Refer to page 4 f or further module information. Module signals are isolated from one another, allo wing AC

and DC modules to be mixed on the same control.

DC Output Module Wiring

DC output modules can be wired to sink

Upper

Terminal

Lower

Terminal

C COM

D

Diode--EC-9001-4004

ener Diode--

Z

EC-9001-5369 (51 VDC)

EC-9001-5388 (200 VDC)

Figure 10 - Sinking† Output

†

or source† load circuit.

VDC

+

oad

L

AC Output Module Wiring

AC output modules are wired with the load connected to the lower

terminal of the output module, while the external power supply is

connected to the upper terminal.

Upper

Terminal

Lower

Terminal

aristor

V

EC-9001-1010 (120 VAC)

EC-9001-2020 (240 VAC)

oad

L

R-C Suppressor EC-9001-2000

(120 VAC or 240 VAC)

Load

Power

Supply

Figure 12

Figure 11 - Sourcing† Output

Most applications will function properly without the diodes shown

in the wiring diagrams above. Howe ver , highly inductive DC loads

may damage modules by generating voltage spikes when

switched off. This type of inductive load may need to be suppressed by a diode. If necessar y, use one of the following two

methods to incorporate a diode into your circuit.

• Connect a Zener diode across the terminals. This will not significantly increase the load turn-off time. The v oltage r ating of

the diode must be greater than the normal circuit voltage.

• Connect a reverse-biased diode across the load. This may

increase the load turn-off time.

†

See page 2 for sinking/sourcing definitions.

Most applications will function properly without the varistor or

R-C suppressor shown in the wiring diagram above. However,

when other switching devices are in series or parallel with the

AC output module, voltage spikes may damage the module. If

necessary, use one of the following two methods to suppress

voltage spikes.

• For infrequent switching, connect a varistor (MOV) across the

terminals.

• For continuous switching, connect an R-C suppressor in parallel with the load.

Upper

Terminal

Lower

Terminal

PLC

Input

Resistor EC-9001-5010

(5 Watt, 10K Ohm)

Load

Power

Supply

Figure 13

Most applications will function properly without the resistor shown

in the wiring diagram above. However, it may be necessary to

add the resistor if the load is affected by the module's off-state

leakage of 2 mA maximum. Keep in mind that a resistor across

a PLC input card may speed up the response time of that PLC

input.

103 6/98

13647 Metric Rd • Roscoe, IL 61073 USA • Web Site: www.electrocam.com • email: ecam@electrocam.com

Loading...

Loading...